light GMC YUKON DENALI 2004 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: YUKON DENALI, Model: GMC YUKON DENALI 2004Pages: 468, PDF Size: 3.18 MB

Page 317 of 468

{CAUTION:

If a ®re starts while you are refueling, do not

remove the nozzle. Shut off the ¯ow of fuel by

shutting off the pump or by notifying the

station attendant. Leave the area immediately.

Notice:If you need a new fuel cap, be sure to get

the right type. Your dealer can get one for you.

If you get the wrong type, it may not ®t properly.

This may cause your malfunction indicator lamp to

light and may damage your fuel tank and emissions

system. See

Malfunction Indicator Lamp on

page 3-40.

Filling a Portable Fuel Container

{CAUTION:

Never ®ll a portable fuel container while it is in

your vehicle. Static electricity discharge from

the container can ignite the gasoline vapor.

You can be badly burned and your vehicle

damaged if this occurs. To help avoid injury to

you and others:

·Dispense gasoline only into approved

containers.

·Do not ®ll a container while it is inside a

vehicle, in a vehicle's trunk, pickup bed or

on any surface other than the ground.

·Bring the ®ll nozzle in contact with the

inside of the ®ll opening before operating

the nozzle. Contact should be maintained

until the ®lling is complete.

·Do not smoke while pumping gasoline.

5-9

Page 326 of 468

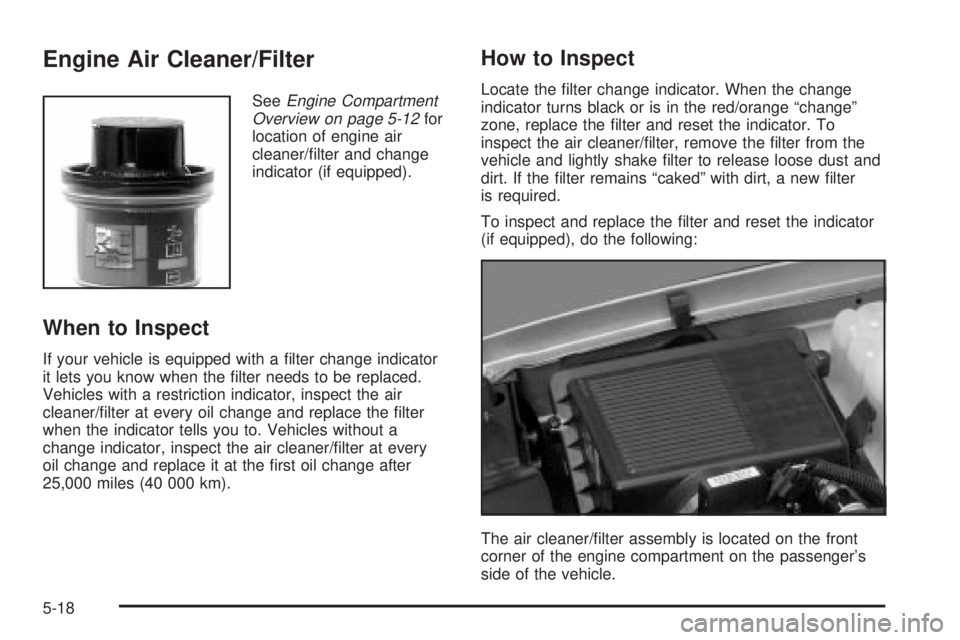

Engine Air Cleaner/Filter

SeeEngine Compartment

Overview on page 5-12for

location of engine air

cleaner/®lter and change

indicator (if equipped).

When to Inspect

If your vehicle is equipped with a ®lter change indicator

it lets you know when the ®lter needs to be replaced.

Vehicles with a restriction indicator, inspect the air

cleaner/®lter at every oil change and replace the ®lter

when the indicator tells you to. Vehicles without a

change indicator, inspect the air cleaner/®lter at every

oil change and replace it at the ®rst oil change after

25,000 miles (40 000 km).

How to Inspect

Locate the ®lter change indicator. When the change

indicator turns black or is in the red/orange ªchangeº

zone, replace the ®lter and reset the indicator. To

inspect the air cleaner/®lter, remove the ®lter from the

vehicle and lightly shake ®lter to release loose dust and

dirt. If the ®lter remains ªcakedº with dirt, a new ®lter

is required.

To inspect and replace the ®lter and reset the indicator

(if equipped), do the following:

The air cleaner/®lter assembly is located on the front

corner of the engine compartment on the passenger's

side of the vehicle.

5-18

Page 331 of 468

Engine Coolant

The cooling system in your vehicle is ®lled with

DEX-COOLžengine coolant. This coolant is designed

to remain in your vehicle for 5 years or 150,000 miles

(240 000 km), whichever occurs ®rst, if you add

only DEX-COOL

žextended life coolant.

The following explains your cooling system and how to

add coolant when it is low. If you have a problem

with engine overheating, see

Engine Overheating on

page 5-25.

A 50/50 mixture of clean, drinkable water and

DEX-COOL

žcoolant will:

·Give freezing protection down to-34ÉF (-37ÉC).

·Give boiling protection up to 265ÉF (129ÉC).

·Protect against rust and corrosion.

·Help keep the proper engine temperature.

·Let the warning lights and gages work as they

should.

Notice:Using coolant other than DEX-COOLžmay

cause premature engine, heater core or radiator

corrosion. In addition, the engine coolant may

require changing sooner, at 30,000 miles (50 000 km)

or 24 months, whichever occurs ®rst. Any repairs

would not be covered by your warranty. Always use

DEX-COOL

ž(silicate-free) coolant in your vehicle.

What to Use

Use a mixture of one-halfclean, drinkable waterand

one-half DEX-COOLžcoolant which won't damage

aluminum parts. If you use this coolant mixture,

you don't need to add anything else.

{CAUTION:

Adding only plain water to your cooling

system can be dangerous. Plain water, or

some other liquid such as alcohol, can boil

before the proper coolant mixture will. Your

vehicle's coolant warning system is set for the

proper coolant mixture. With plain water or the

wrong mixture, your engine could get too hot

but you would not get the overheat warning.

Your engine could catch ®re and you or others

could be burned. Use a 50/50 mixture of clean,

drinkable water and DEX-COOL

žcoolant.

Notice:If you use an improper coolant mixture,

your engine could overheat and be badly damaged.

The repair cost would not be covered by your

warranty. Too much water in the mixture can freeze

and crack the engine, radiator, heater core and

other parts.

5-23

Page 346 of 468

Notice:

·Using the wrong ¯uid can badly damage brake

system parts. For example, just a few drops of

mineral-based oil, such as engine oil, in your

brake system can damage brake system

parts so badly that they will have to be replaced.

Do not let someone put in the wrong kind of

¯uid.

·If you spill brake ¯uid on your vehicle's painted

surfaces, the paint ®nish can be damaged. Be

careful not to spill brake ¯uid on your vehicle. If

you do, wash it off immediately. See

Appearance

Care on page 5-92.

Brake Wear

Your vehicle has four-wheel disc brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound

may come and go or be heard all the time your vehicle

is moving (except when you are pushing on the

brake pedal ®rmly).

{CAUTION:

The brake wear warning sound means that

soon your brakes will not work well. That

could lead to an accident. When you hear the

brake wear warning sound, have your vehicle

serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.

Some driving conditions or climates may cause a brake

squeal when the brakes are ®rst applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque speci®cations.

Brake linings should always be replaced as complete

axle sets.

5-38

Page 349 of 468

Notice:If you leave your radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered

by your warranty. Always turn off your radio and

other accessories when jump starting your vehicle.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or accessory power outlets. Turn off the

radio and all lamps that aren't needed. This

will avoid sparks and help save both batteries. And

it could save your radio!

4. Open the hoods and locate the positive (+) and

negative (-) terminal locations of the other vehicle.

Your vehicle has a remote positive (+) jump

starting terminal and a remote negative (-) jump

starting terminal. You should always use these

remote terminals instead of the terminals on the

battery.

The remote positive (+) terminal is located under a

red plastic cover, if equipped, near the engine

accessory drive bracket. To access the remote

positive (+) terminal, open the red plastic cover, if

equipped.

The remote negative (-) terminal is located on the

engine accessory drive bracket and is marked GND.

See

Engine Compartment Overview on page 5-12for more information on location.

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

¯ashlight if you need more light.

Be sure the battery has enough water. You do

not need to add water to the ACDelco

žbattery

installed in your new vehicle. But if a battery

has ®ller caps, be sure the right amount of

¯uid is there. If it is low, add water to take care

of that ®rst. If you do not, explosive gas could

be present.

Battery ¯uid contains acid that can burn you.

Do not get it on you. If you accidentally get it

in your eyes or on your skin, ¯ush the place

with water and get medical help immediately.

5-41

Page 367 of 468

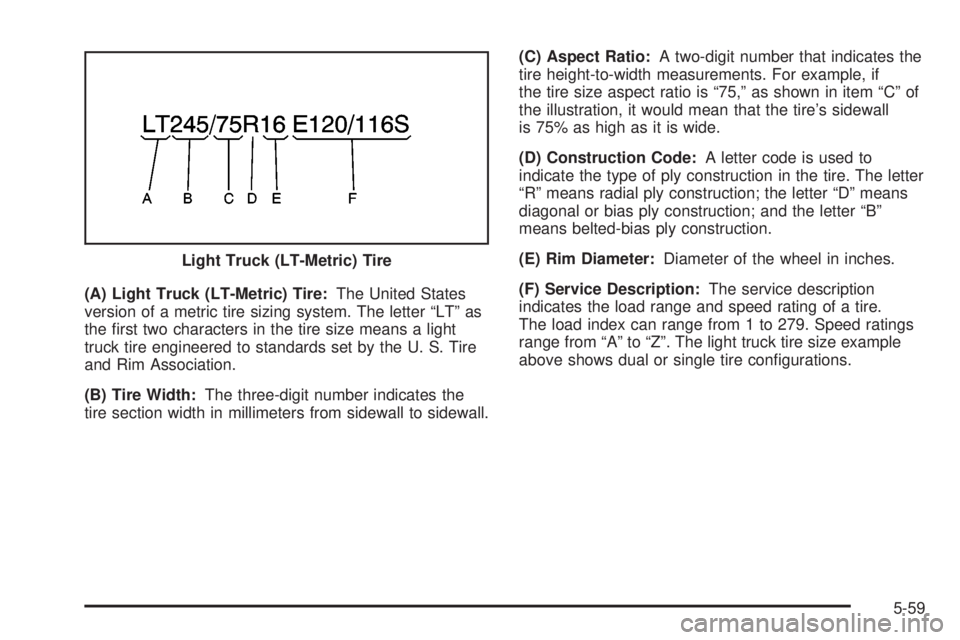

(A) Light Truck (LT-Metric) Tire:The United States

version of a metric tire sizing system. The letter ªLTº as

the ®rst two characters in the tire size means a light

truck tire engineered to standards set by the U. S. Tire

and Rim Association.

(B) Tire Width:The three-digit number indicates the

tire section width in millimeters from sidewall to sidewall.(C) Aspect Ratio:A two-digit number that indicates the

tire height-to-width measurements. For example, if

the tire size aspect ratio is ª75,º as shown in item ªCº of

the illustration, it would mean that the tire's sidewall

is 75% as high as it is wide.

(D) Construction Code:A letter code is used to

indicate the type of ply construction in the tire. The letter

ªRº means radial ply construction; the letter ªDº means

diagonal or bias ply construction; and the letter ªBº

means belted-bias ply construction.

(E) Rim Diameter:Diameter of the wheel in inches.

(F) Service Description:The service description

indicates the load range and speed rating of a tire.

The load index can range from 1 to 279. Speed ratings

range from ªAº to ªZº. The light truck tire size example

above shows dual or single tire con®gurations. Light Truck (LT-Metric) Tire

5-59

Page 369 of 468

Intended Outboard Sidewall:The side of an

asymmetrical tire, that must always face outward when

mounted on a vehicle.

Kilopascal (kPa):The metric unit for air pressure.

There are 6.9 kPa's to one psi.

Light Truck (LT-Metric) Tire:A tire used on light duty

trucks and some multipurpose passenger vehicles.

Load Index:An assigned number ranging from 1

to 279 that corresponds to the load carrying capacity

of a tire.

Maximum In¯ation Pressure:The maximum air

pressure to which a cold tire may be in¯ated. The

maximum air pressure is molded onto the sidewall.

Maximum Load Rating:The load rating for a tire at the

maximum permissible in¯ation pressure for that tire.

Maximum Loaded Vehicle Weight:The sum of curb

weight; accessory weight; vehicle capacity weight;

and production options weight.

Normal Occupant Weight:The number of occupants a

vehicle is designed to seat multiplied by 150 pounds

(68 kg). See

Loading Your Vehicle on page 4-44.Occupant Distribution:Designated seating positions.

Outward Facing Sidewall:The side of a asymmetrical

tire that has a particular side that faces outward

when mounted on a vehicle. The side of the tire that

contains a whitewall, bears white lettering or bears

manufacturer, brand and or model name molding that is

higher or deeper than the same moldings on the

other sidewall of the tire.

Passenger (P-Metric) Tire:A tire used on passenger

cars and some light duty trucks and multipurpose

vehicles.

Recommended In¯ation Pressure:Vehicle

manufacturer's recommended tire in¯ation pressure and

shown on the tire placard. See

In¯ation - Tire Pressure

on page 5-62andLoading Your Vehicle on page 4-44.

Radial Ply tire:A pneumatic tire in which the ply cords

that extend to the beads are laid at 90 degrees to the

centerline of the tread.

Rim:A metal support for a tire and upon which the tire

beads are seated.

Sidewall:The portion of a tire between the tread and

the bead.

5-61

Page 372 of 468

Tire Pressure Monitor System

The Tire Pressure Monitor (TPM) system uses radio

and sensor technology to check tire pressure levels.

If your vehicle has this feature, sensors are mounted on

each tire and wheel assembly, except the spare tire.

The TPM sensors transmit tire pressure readings

to a receiver located in the vehicle.

When a low tire pressure condition is detected, the TPM

system will display the CHECK TIRE PRESSURE

warning message on the Driver Information Center

(DIC); and at the same time illuminate the low tire

pressure warning symbol. For additional information and

details about the DIC operation and displays see DIC

Operation and Displays on page 3-46andDIC Warnings

and Messages on page 3-57.

When the tire pressure

monitoring system warning

light is lit, one or more

of your tires is signi®cantly

under-in¯ated.

You should stop and check your tires as soon as

possible, and in¯ate them to the proper pressure as

indicated on the vehicle's tire information placard.Driving on a signi®cantly under-in¯ated tire causes the

tire to overheat and can lead to tire failure.

Under-in¯ation also reduces fuel efficiency and tire tread

life, and may affect the vehicle's handling and stopping

ability. Each tire, including the spare, should be

checked monthly when cold and set to the

recommended in¯ation pressure as speci®ed in the

vehicle placard and owner's manual.

The Certi®cation/Tire label or the Tire and Loading

Information label (tire information placard) shows the

size of your vehicle's original tires and the correct

in¯ation pressure for your vehicle's tires when they are

cold. See

In¯ation - Tire Pressure on page 5-62. For

the location of the tire and loading information label, see

Loading Your Vehicle on page 4-44.

Your vehicle's TPM system can alert you about a low

tire pressure condition but it does not replace normal tire

maintenance. See

Tire Inspection and Rotation on

page 5-66andTires on page 5-54.

Notice:Do not use a tire sealant if your vehicle is

equipped with Tire Pressure Monitors. The liquid

sealant can damage the tire pressure monitor

sensors.

5-64

Page 373 of 468

TPM Sensor Identi®cation Codes

Each TPM sensor has a unique identi®cation code.

Any time you rotate your vehicle's tires or replace one

or more of the TPM sensors, the identi®cation codes will

need to be matched to the new tire/wheel position.

Each tire/wheel position is matched to a sensor,

by increasing or decreasing the tire's air pressure.

The sensors are matched to the tire/wheel positions in

the following order: left front (LF); right front (RF);

right rear (RR) and left rear (LR).

You will have one minute to match the ®rst tire/wheel

position, and ®ve minutes overall to match all four

tire/wheel positions. If it takes longer than one minute,

to match the ®rst tire and wheel, or more than ®ve

minutes to match all four tire and wheel positions the

matching process stops and you will need to start over.

The TPM sensor matching process is outlined below:

1. Set the Parking brake.

2. Turn the ignition switch to RUN with the engine off.

3. Turn the exterior lamp switch from ªOffº to ªOnº

four times within 3 seconds. A double horn chirp

will sound and the TPM low tire warning light

will begin to ¯ash. The double horn chirp and¯ashing TPM warning light indicate that the TPM

matching process has started. The TPM warning

light should continue ¯ashing throughout the

matching procedure. The SERVICE TIRE

MONITOR message will be displayed on the Driver

Information Center (DIC).

4. Start with the left (driver's side) front tire.

5. Remove the valve cap from the valve cap stem.

Activate the TPM sensor by increasing or

decreasing the tire's air pressure for 10 seconds,

then stop and listen for a single horn chirp.

The single horn chirp should sound within 15

seconds, con®rming that the sensor identi®cation

code has been matched to this tire and wheel

position. If you do not hear the con®rming single

horn chirp, you will need to start over with step

number one. To let air-pressure out of a tire you can

use the pointy end of the valve cap, a pencil-style

air pressure gage or a key.

6. Proceed to the right (passenger's side) front tire,

and repeat the procedure in step 5.

7. Proceed to the right (passenger's side) rear tire,

and repeat the procedure in step 5.

8. Proceed to the left (driver's side) rear tire, and

repeat the procedure in step 5.

5-65

Page 374 of 468

9. After hearing the con®rming horn chirp for the left

rear tire, check to see if the TPM warning light is

still ¯ashing. If yes, turn the ignition switch to OFF.

10. Set all four tires to the recommended air pressure

level as indicated on the Certi®cation/Tire label or

the Tire and Loading Information label.

11. Put the valve caps back on the valve stems

The spare tire does not have a TPM sensor. If you

replace one of the road tires with the spare, the CHECK

TIRE PRESSURE message will be displayed on the DIC

screen. This message should go off once you re-install

the road tire containing the TPM sensor. The SERVICE

TIRE MONITOR message is displayed when the TPM

system is malfunctioning. One or more missing or

inoperable TPM sensors will cause the service tire

monitor message to be displayed. See your dealer for

service.

Federal Communications Commission and

Industry and Science Canada

The TPM system operates on a radio frequency subject

to Federal Communications Commission (FCC) Rules

and with Industry and Science Canada.

This device complies with Part 15 of the FCC Rules and

with RSS-210 of Industry and Science Canada.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and(2) this device must accept any interference received

including interference that may cause undesired

operation of the device.

Changes or modi®cations to this system by other than

an authorized service facility could void authorization to

use this equipment.

Tire Inspection and Rotation

Tires should be rotated every 5,000 to 8,000 miles

(8 000 to 13 000 km).

Any time you notice unusual wear, rotate your tires as

soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-68andWheel Replacement

on page 5-71for more information.

Make sure the spare tire is stored securely. Push, pull,

and then try to rotate or turn the tire. If it moves,

use the ratchet/wheel wrench to tighten the cable.

See

Changing a Flat Tire on page 5-74.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See

Scheduled Maintenance

on page 6-4.

5-66