lock GMC YUKON DENALI 2004 Owners Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: YUKON DENALI, Model: GMC YUKON DENALI 2004Pages: 468, PDF Size: 3.18 MB

Page 398 of 468

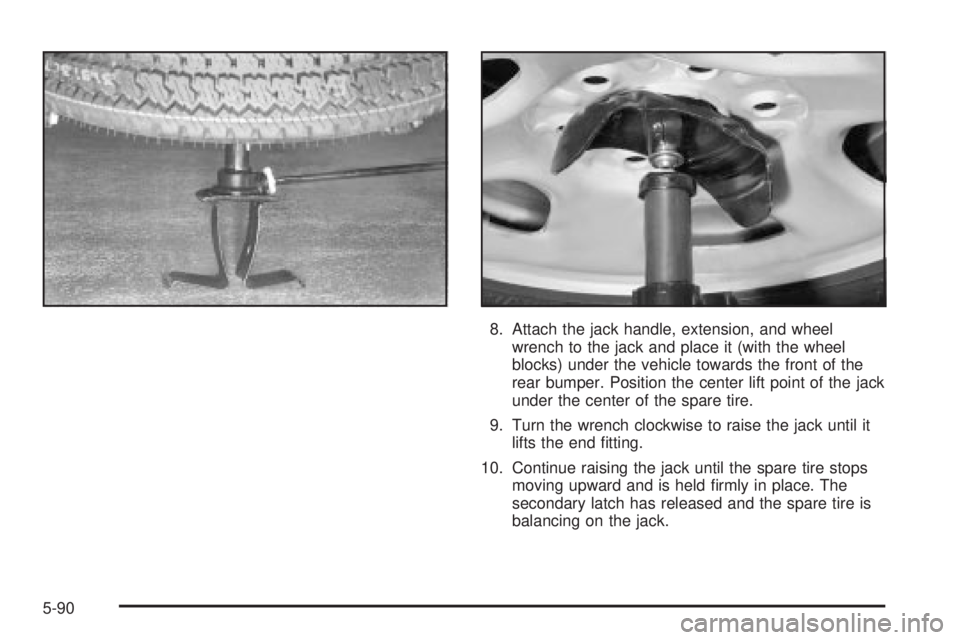

8. Attach the jack handle, extension, and wheel

wrench to the jack and place it (with the wheel

blocks) under the vehicle towards the front of the

rear bumper. Position the center lift point of the jack

under the center of the spare tire.

9. Turn the wrench clockwise to raise the jack until it

lifts the end ®tting.

10. Continue raising the jack until the spare tire stops

moving upward and is held ®rmly in place. The

secondary latch has released and the spare tire is

balancing on the jack.

5-90

Page 399 of 468

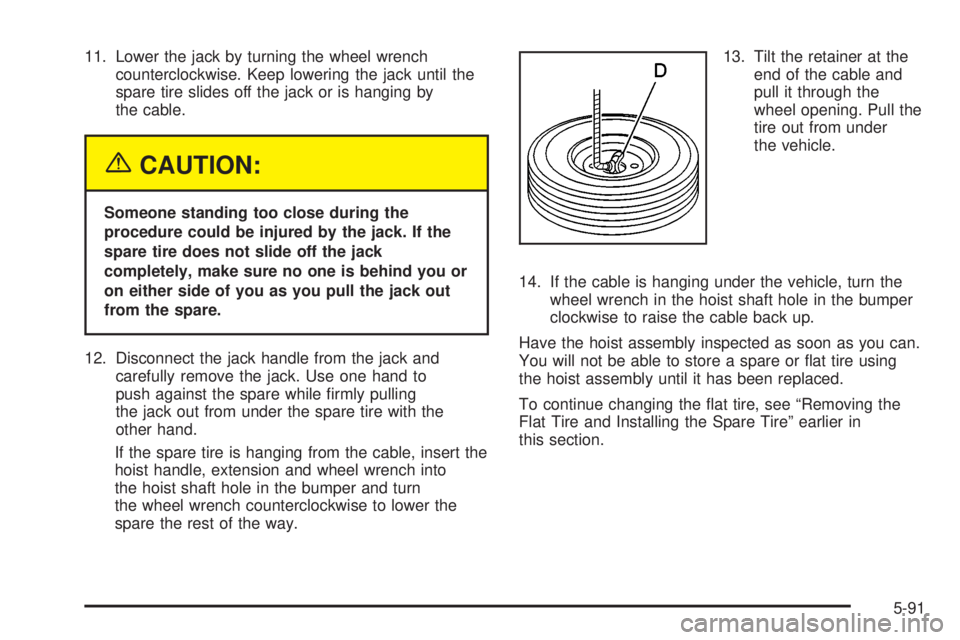

11. Lower the jack by turning the wheel wrench

counterclockwise. Keep lowering the jack until the

spare tire slides off the jack or is hanging by

the cable.

{CAUTION:

Someone standing too close during the

procedure could be injured by the jack. If the

spare tire does not slide off the jack

completely, make sure no one is behind you or

on either side of you as you pull the jack out

from the spare.

12. Disconnect the jack handle from the jack and

carefully remove the jack. Use one hand to

push against the spare while ®rmly pulling

the jack out from under the spare tire with the

other hand.

If the spare tire is hanging from the cable, insert the

hoist handle, extension and wheel wrench into

the hoist shaft hole in the bumper and turn

the wheel wrench counterclockwise to lower the

spare the rest of the way.13. Tilt the retainer at the

end of the cable and

pull it through the

wheel opening. Pull the

tire out from under

the vehicle.

14. If the cable is hanging under the vehicle, turn the

wheel wrench in the hoist shaft hole in the bumper

clockwise to raise the cable back up.

Have the hoist assembly inspected as soon as you can.

You will not be able to store a spare or ¯at tire using

the hoist assembly until it has been replaced.

To continue changing the ¯at tire, see ªRemoving the

Flat Tire and Installing the Spare Tireº earlier in

this section.

5-91

Page 412 of 468

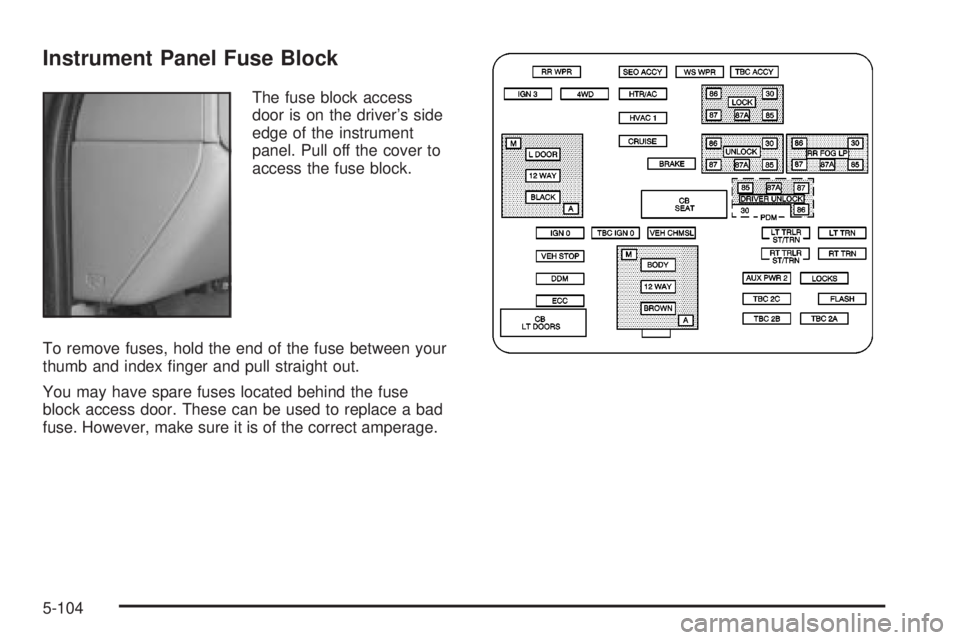

Instrument Panel Fuse Block

The fuse block access

door is on the driver's side

edge of the instrument

panel. Pull off the cover to

access the fuse block.

To remove fuses, hold the end of the fuse between your

thumb and index ®nger and pull straight out.

You may have spare fuses located behind the fuse

block access door. These can be used to replace a bad

fuse. However, make sure it is of the correct amperage.

5-104

Page 413 of 468

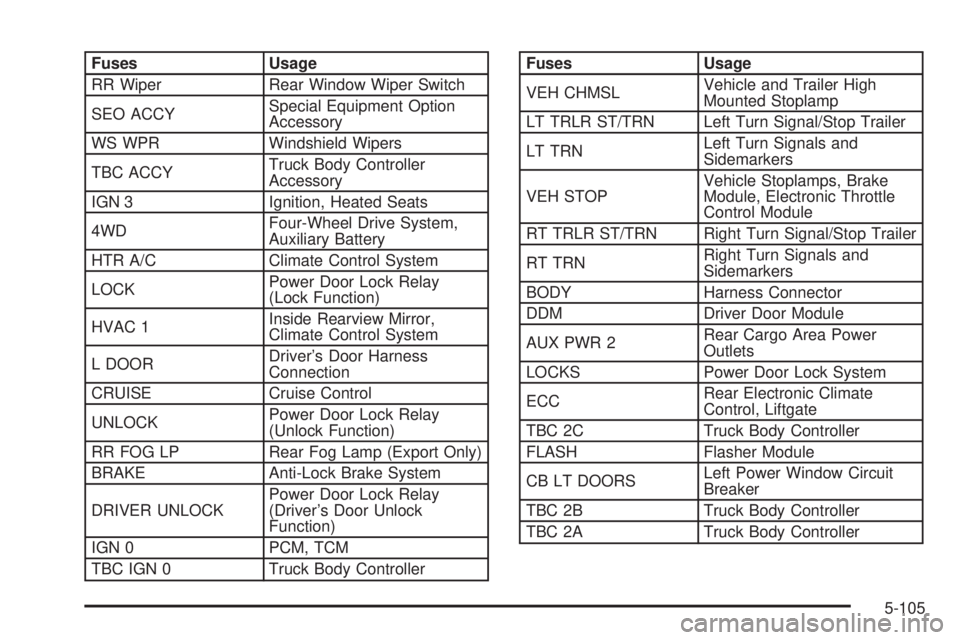

Fuses Usage

RR Wiper Rear Window Wiper Switch

SEO ACCYSpecial Equipment Option

Accessory

WS WPR Windshield Wipers

TBC ACCYTruck Body Controller

Accessory

IGN 3 Ignition, Heated Seats

4WDFour-Wheel Drive System,

Auxiliary Battery

HTR A/C Climate Control System

LOCKPower Door Lock Relay

(Lock Function)

HVAC 1Inside Rearview Mirror,

Climate Control System

L DOORDriver's Door Harness

Connection

CRUISE Cruise Control

UNLOCKPower Door Lock Relay

(Unlock Function)

RR FOG LP Rear Fog Lamp (Export Only)

BRAKE Anti-Lock Brake System

DRIVER UNLOCKPower Door Lock Relay

(Driver's Door Unlock

Function)

IGN 0 PCM, TCM

TBC IGN 0 Truck Body ControllerFuses Usage

VEH CHMSLVehicle and Trailer High

Mounted Stoplamp

LT TRLR ST/TRN Left Turn Signal/Stop Trailer

LT TRNLeft Turn Signals and

Sidemarkers

VEH STOPVehicle Stoplamps, Brake

Module, Electronic Throttle

Control Module

RT TRLR ST/TRN Right Turn Signal/Stop Trailer

RT TRNRight Turn Signals and

Sidemarkers

BODY Harness Connector

DDM Driver Door Module

AUX PWR 2Rear Cargo Area Power

Outlets

LOCKS Power Door Lock System

ECCRear Electronic Climate

Control, Liftgate

TBC 2C Truck Body Controller

FLASH Flasher Module

CB LT DOORSLeft Power Window Circuit

Breaker

TBC 2B Truck Body Controller

TBC 2A Truck Body Controller

5-105

Page 414 of 468

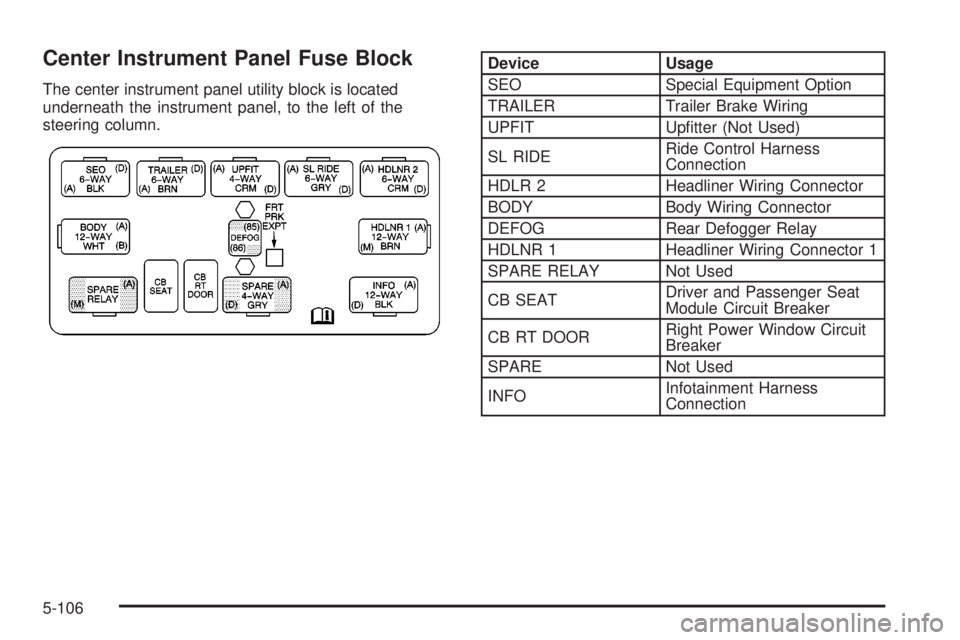

Center Instrument Panel Fuse Block

The center instrument panel utility block is located

underneath the instrument panel, to the left of the

steering column.

Device Usage

SEO Special Equipment Option

TRAILER Trailer Brake Wiring

UPFIT Up®tter (Not Used)

SL RIDERide Control Harness

Connection

HDLR 2 Headliner Wiring Connector

BODY Body Wiring Connector

DEFOG Rear Defogger Relay

HDLNR 1 Headliner Wiring Connector 1

SPARE RELAY Not Used

CB SEATDriver and Passenger Seat

Module Circuit Breaker

CB RT DOORRight Power Window Circuit

Breaker

SPARE Not Used

INFOInfotainment Harness

Connection

5-106

Page 415 of 468

Underhood Fuse BlockThe underhood fuse block in the engine compartment

on the driver's side of the vehicle near the battery.

Lift the cover for access to the fuse/relay block.

To remove fuses, hold the end of the fuse between your

thumb and index ®nger and pull straight out.

See

Engine Compartment Overview on page 5-12for

more information on its location.

5-107

Page 417 of 468

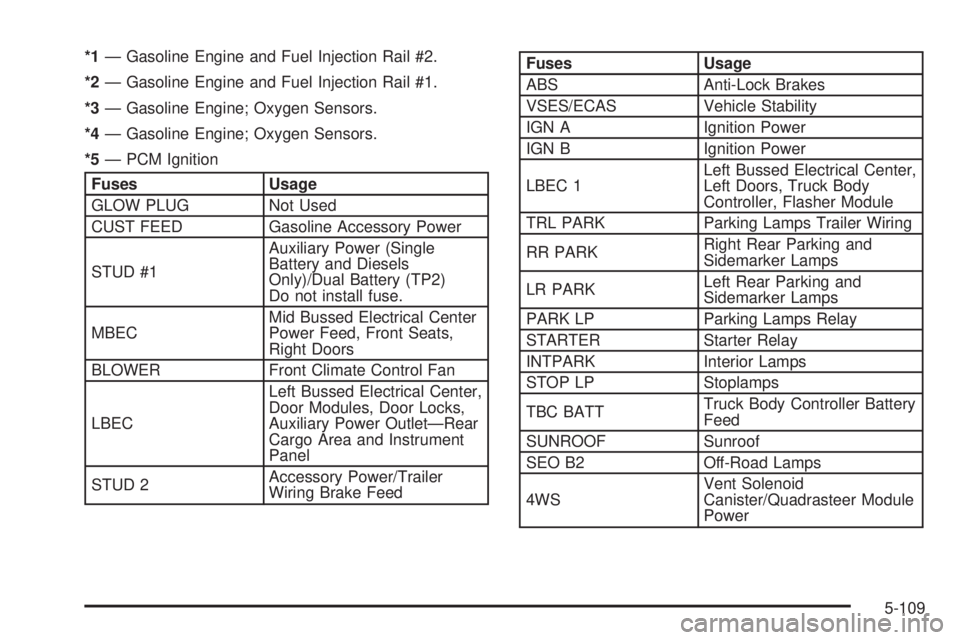

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Gasoline Accessory Power

STUD #1Auxiliary Power (Single

Battery and Diesels

Only)/Dual Battery (TP2)

Do not install fuse.

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical Center,

Door Modules, Door Locks,

Auxiliary Power OutletÐRear

Cargo Area and Instrument

Panel

STUD 2Accessory Power/Trailer

Wiring Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller Battery

Feed

SUNROOF Sunroof

SEO B2 Off-Road Lamps

4WSVent Solenoid

Canister/Quadrasteer Module

Power

5-109

Page 418 of 468

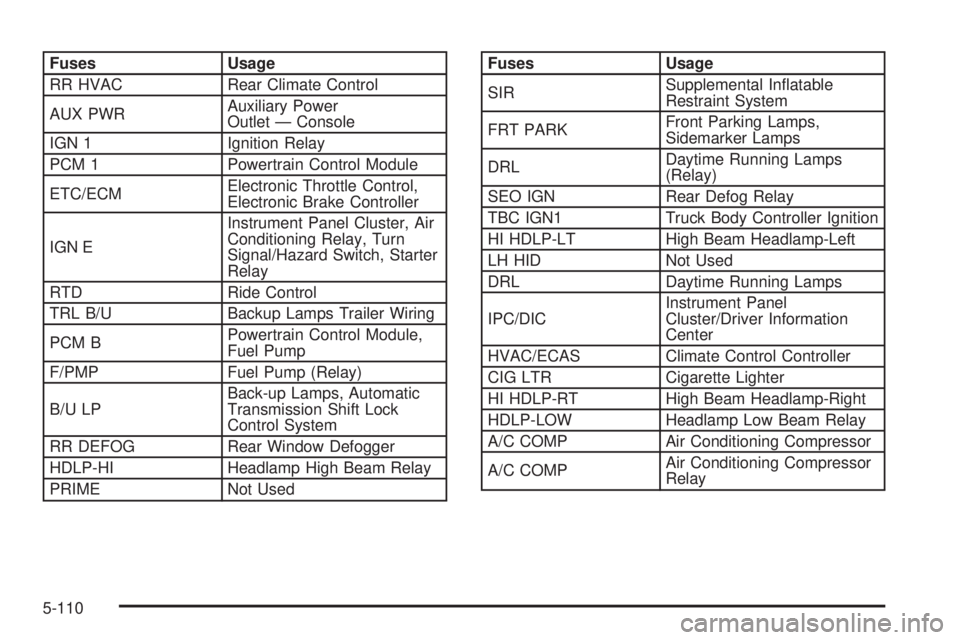

Fuses Usage

RR HVAC Rear Climate Control

AUX PWRAuxiliary Power

Outlet Ð Console

IGN 1 Ignition Relay

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

IGN EInstrument Panel Cluster, Air

Conditioning Relay, Turn

Signal/Hazard Switch, Starter

Relay

RTD Ride Control

TRL B/U Backup Lamps Trailer Wiring

PCM BPowertrain Control Module,

Fuel Pump

F/PMP Fuel Pump (Relay)

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock

Control System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not UsedFuses Usage

SIRSupplemental In¯atable

Restraint System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRLDaytime Running Lamps

(Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP-LT High Beam Headlamp-Left

LH HID Not Used

DRL Daytime Running Lamps

IPC/DICInstrument Panel

Cluster/Driver Information

Center

HVAC/ECAS Climate Control Controller

CIG LTR Cigarette Lighter

HI HDLP-RT High Beam Headlamp-Right

HDLP-LOW Headlamp Low Beam Relay

A/C COMP Air Conditioning Compressor

A/C COMPAir Conditioning Compressor

Relay

5-110

Page 419 of 468

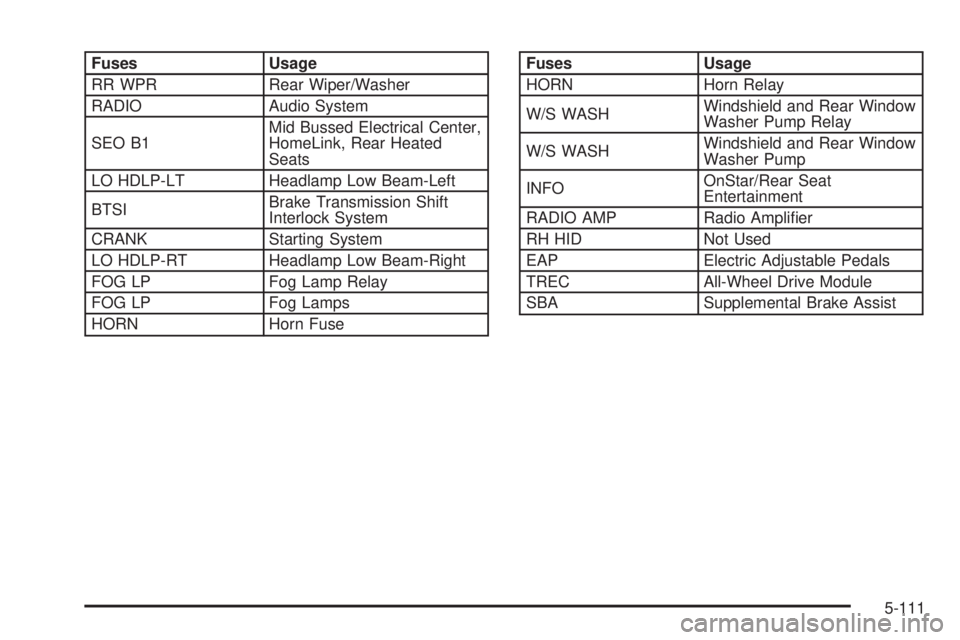

Fuses Usage

RR WPR Rear Wiper/Washer

RADIO Audio System

SEO B1Mid Bussed Electrical Center,

HomeLink, Rear Heated

Seats

LO HDLP-LT Headlamp Low Beam-Left

BTSIBrake Transmission Shift

Interlock System

CRANK Starting System

LO HDLP-RT Headlamp Low Beam-Right

FOG LP Fog Lamp Relay

FOG LP Fog Lamps

HORN Horn FuseFuses Usage

HORN Horn Relay

W/S WASHWindshield and Rear Window

Washer Pump Relay

W/S WASHWindshield and Rear Window

Washer Pump

INFOOnStar/Rear Seat

Entertainment

RADIO AMP Radio Ampli®er

RH HID Not Used

EAP Electric Adjustable Pedals

TREC All-Wheel Drive Module

SBA Supplemental Brake Assist

5-111

Page 430 of 468

Maintenance Footnotes

²The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle's useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, ball joints, steering

linkage, transmission shift linkage and parking

brake cable guides. Ball joints should not be lubricated

unless their temperature is 10ÉF (-12ÉC) or higher,

or they could be damaged.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha®ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts,

signs of wear or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, cha®ng, etc. Visually check constant

velocity joints, rubber boots and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace with genuine GM parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken air bag

coverings, and have them repaired or replaced. (The air

bag system does not need regular maintenance.)

(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl, door

hinges, liftgate hinge, liftgate linkage, liftgate handle pivot

points, latch bolt, fuel door hinge, locks and folding seat

hardware. More frequent lubrication may be required

when exposed to a corrosive environment. Applying

silicone grease on weatherstrips with a clean cloth will

make them last longer, seal better and not stick or

squeak.

6-8