fuel GMC YUKON DENALI 2004 Service Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2004, Model line: YUKON DENALI, Model: GMC YUKON DENALI 2004Pages: 468, PDF Size: 3.18 MB

Page 417 of 468

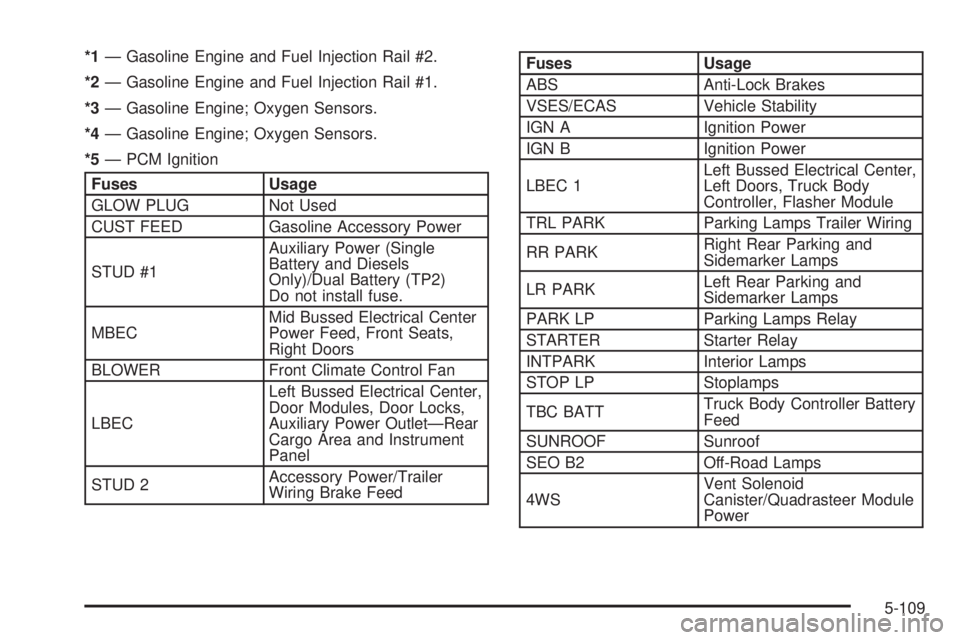

*1Ð Gasoline Engine and Fuel Injection Rail #2.

*2Ð Gasoline Engine and Fuel Injection Rail #1.

*3Ð Gasoline Engine; Oxygen Sensors.

*4Ð Gasoline Engine; Oxygen Sensors.

*5Ð PCM Ignition

Fuses Usage

GLOW PLUG Not Used

CUST FEED Gasoline Accessory Power

STUD #1Auxiliary Power (Single

Battery and Diesels

Only)/Dual Battery (TP2)

Do not install fuse.

MBECMid Bussed Electrical Center

Power Feed, Front Seats,

Right Doors

BLOWER Front Climate Control Fan

LBECLeft Bussed Electrical Center,

Door Modules, Door Locks,

Auxiliary Power OutletÐRear

Cargo Area and Instrument

Panel

STUD 2Accessory Power/Trailer

Wiring Brake Feed

Fuses Usage

ABS Anti-Lock Brakes

VSES/ECAS Vehicle Stability

IGN A Ignition Power

IGN B Ignition Power

LBEC 1Left Bussed Electrical Center,

Left Doors, Truck Body

Controller, Flasher Module

TRL PARK Parking Lamps Trailer Wiring

RR PARKRight Rear Parking and

Sidemarker Lamps

LR PARKLeft Rear Parking and

Sidemarker Lamps

PARK LP Parking Lamps Relay

STARTER Starter Relay

INTPARK Interior Lamps

STOP LP Stoplamps

TBC BATTTruck Body Controller Battery

Feed

SUNROOF Sunroof

SEO B2 Off-Road Lamps

4WSVent Solenoid

Canister/Quadrasteer Module

Power

5-109

Page 418 of 468

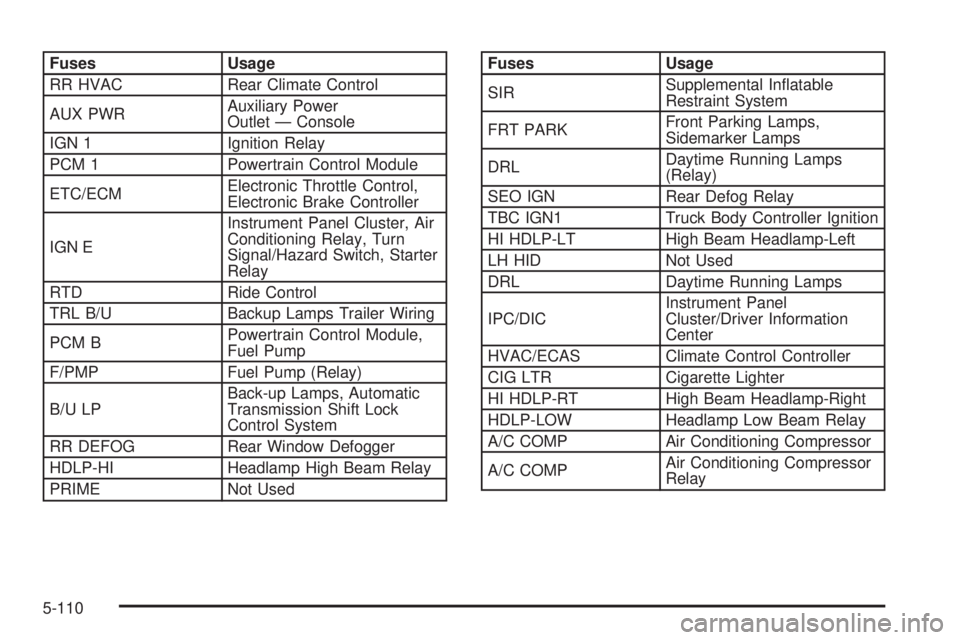

Fuses Usage

RR HVAC Rear Climate Control

AUX PWRAuxiliary Power

Outlet Ð Console

IGN 1 Ignition Relay

PCM 1 Powertrain Control Module

ETC/ECMElectronic Throttle Control,

Electronic Brake Controller

IGN EInstrument Panel Cluster, Air

Conditioning Relay, Turn

Signal/Hazard Switch, Starter

Relay

RTD Ride Control

TRL B/U Backup Lamps Trailer Wiring

PCM BPowertrain Control Module,

Fuel Pump

F/PMP Fuel Pump (Relay)

B/U LPBack-up Lamps, Automatic

Transmission Shift Lock

Control System

RR DEFOG Rear Window Defogger

HDLP-HI Headlamp High Beam Relay

PRIME Not UsedFuses Usage

SIRSupplemental In¯atable

Restraint System

FRT PARKFront Parking Lamps,

Sidemarker Lamps

DRLDaytime Running Lamps

(Relay)

SEO IGN Rear Defog Relay

TBC IGN1 Truck Body Controller Ignition

HI HDLP-LT High Beam Headlamp-Left

LH HID Not Used

DRL Daytime Running Lamps

IPC/DICInstrument Panel

Cluster/Driver Information

Center

HVAC/ECAS Climate Control Controller

CIG LTR Cigarette Lighter

HI HDLP-RT High Beam Headlamp-Right

HDLP-LOW Headlamp Low Beam Relay

A/C COMP Air Conditioning Compressor

A/C COMPAir Conditioning Compressor

Relay

5-110

Page 420 of 468

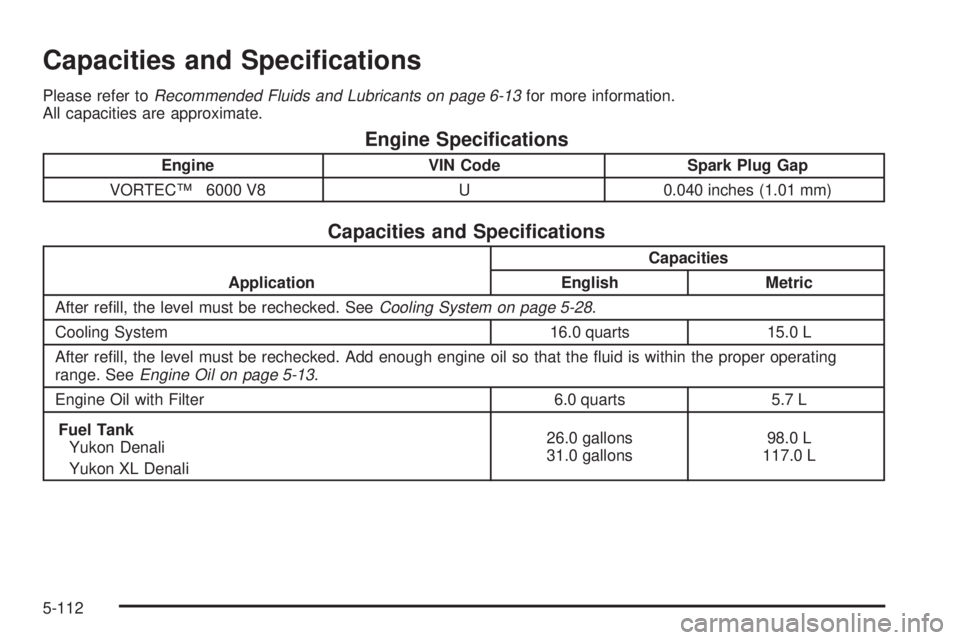

Capacities and Speci®cations

Please refer toRecommended Fluids and Lubricants on page 6-13for more information.

All capacities are approximate.

Engine Speci®cations

Engine VIN Code Spark Plug Gap

VORTECŸ 6000 V8 U 0.040 inches (1.01 mm)

Capacities and Speci®cations

ApplicationCapacities

English Metric

After re®ll, the level must be rechecked. See

Cooling System on page 5-28.

Cooling System 16.0 quarts 15.0 L

After re®ll, the level must be rechecked. Add enough engine oil so that the ¯uid is within the proper operating

range. See

Engine Oil on page 5-13.

Engine Oil with Filter 6.0 quarts 5.7 L

Fuel Tank

Yukon Denali

Yukon XL Denali26.0 gallons

31.0 gallons98.0 L

117.0 L

5-112

Page 423 of 468

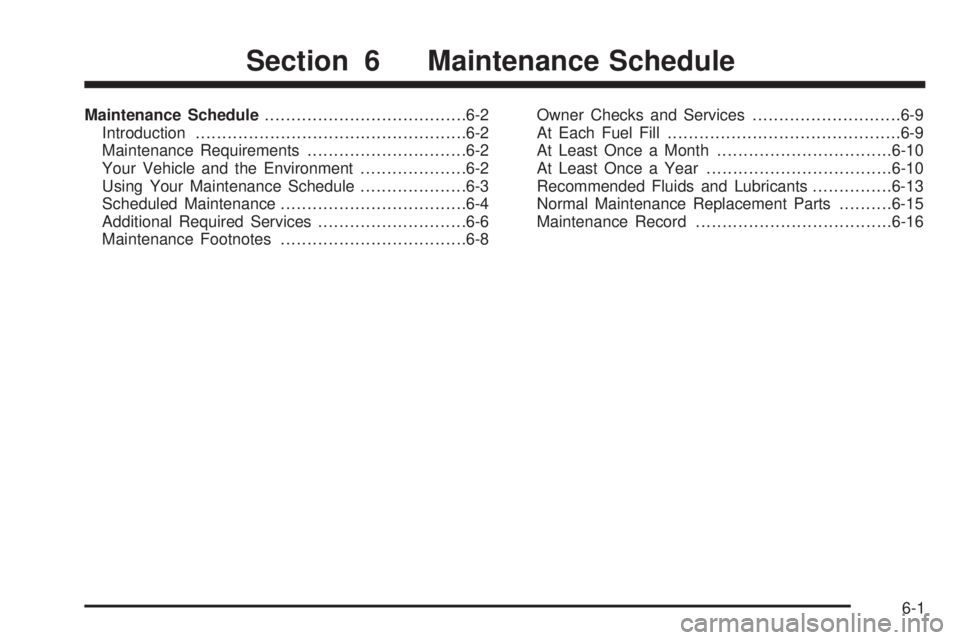

Maintenance Schedule......................................6-2

Introduction...................................................6-2

Maintenance Requirements..............................6-2

Your Vehicle and the Environment....................6-2

Using Your Maintenance Schedule....................6-3

Scheduled Maintenance...................................6-4

Additional Required Services............................6-6

Maintenance Footnotes...................................6-8Owner Checks and Services............................6-9

At Each Fuel Fill............................................6-9

At Least Once a Month.................................6-10

At Least Once a Year...................................6-10

Recommended Fluids and Lubricants...............6-13

Normal Maintenance Replacement Parts..........6-15

Maintenance Record.....................................6-16

Section 6 Maintenance Schedule

6-1

Page 425 of 468

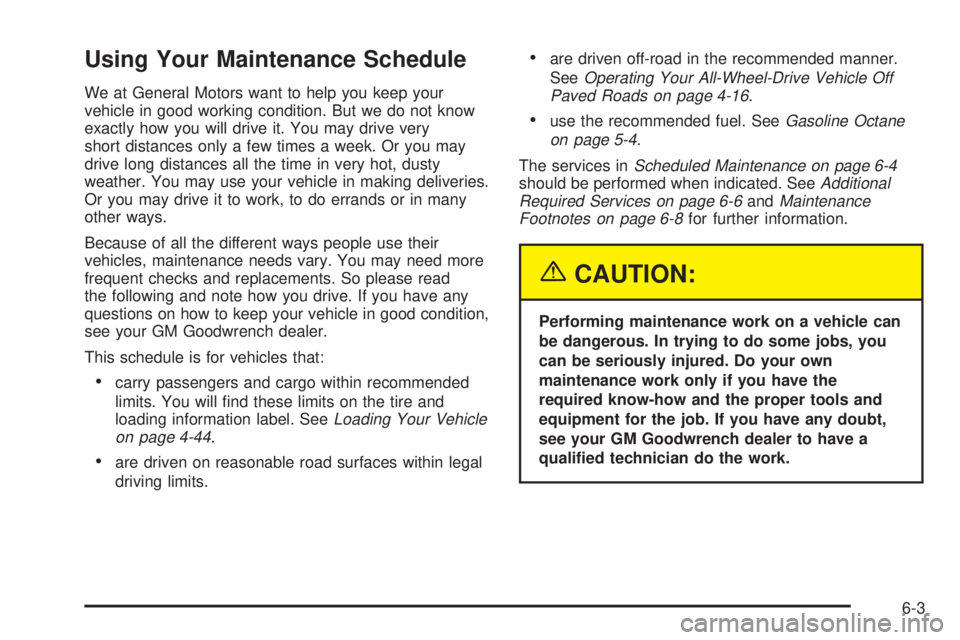

Using Your Maintenance Schedule

We at General Motors want to help you keep your

vehicle in good working condition. But we do not know

exactly how you will drive it. You may drive very

short distances only a few times a week. Or you may

drive long distances all the time in very hot, dusty

weather. You may use your vehicle in making deliveries.

Or you may drive it to work, to do errands or in many

other ways.

Because of all the different ways people use their

vehicles, maintenance needs vary. You may need more

frequent checks and replacements. So please read

the following and note how you drive. If you have any

questions on how to keep your vehicle in good condition,

see your GM Goodwrench dealer.

This schedule is for vehicles that:

·carry passengers and cargo within recommended

limits. You will ®nd these limits on the tire and

loading information label. See

Loading Your Vehicle

on page 4-44.

·are driven on reasonable road surfaces within legal

driving limits.

·are driven off-road in the recommended manner.

See

Operating Your All-Wheel-Drive Vehicle Off

Paved Roads on page 4-16.

·use the recommended fuel. SeeGasoline Octane

on page 5-4

.

The services in

Scheduled Maintenance on page 6-4should be performed when indicated. SeeAdditional

Required Services on page 6-6andMaintenance

Footnotes on page 6-8for further information.

{CAUTION:

Performing maintenance work on a vehicle can

be dangerous. In trying to do some jobs, you

can be seriously injured. Do your own

maintenance work only if you have the

required know-how and the proper tools and

equipment for the job. If you have any doubt,

see your GM Goodwrench dealer to have a

quali®ed technician do the work.

6-3

Page 428 of 468

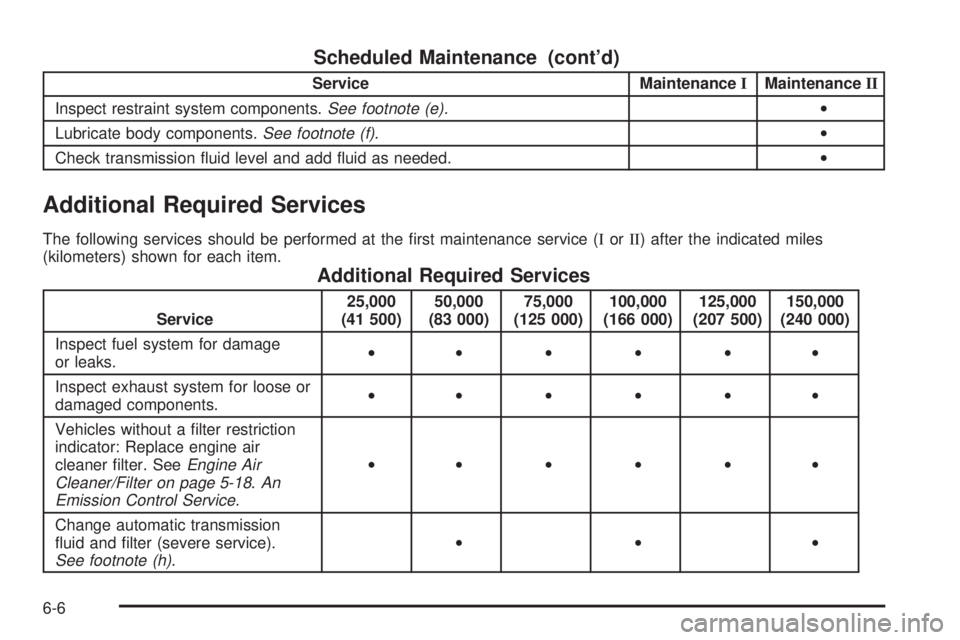

Scheduled Maintenance (cont'd)

Service MaintenanceIMaintenanceII

Inspect restraint system components.

See footnote (e).·

Lubricate body components.

See footnote (f).·

Check transmission ¯uid level and add ¯uid as needed.·

Additional Required Services

The following services should be performed at the ®rst maintenance service (IorII) after the indicated miles

(kilometers) shown for each item.

Additional Required Services

Service25,000

(41 500)50,000

(83 000)75,000

(125 000)100,000

(166 000)125,000

(207 500)150,000

(240 000)

Inspect fuel system for damage

or leaks.······

Inspect exhaust system for loose or

damaged components.······

Vehicles without a ®lter restriction

indicator: Replace engine air

cleaner ®lter. See

Engine Air

Cleaner/Filter on page 5-18.An

Emission Control Service.······

Change automatic transmission

¯uid and ®lter (severe service).

See footnote (h).···

6-6

Page 430 of 468

Maintenance Footnotes

²The U.S. Environmental Protection Agency or the

California Air Resources Board has determined that the

failure to perform this maintenance item will not nullify

the emission warranty or limit recall liability prior to

the completion of the vehicle's useful life. We, however,

urge that all recommended maintenance services be

performed at the indicated intervals and the

maintenance be recorded.

#Lubricate the front suspension, ball joints, steering

linkage, transmission shift linkage and parking

brake cable guides. Ball joints should not be lubricated

unless their temperature is 10ÉF (-12ÉC) or higher,

or they could be damaged.

(a)Visually inspect brake lines and hoses for proper

hook-up, binding, leaks, cracks, cha®ng, etc. Inspect

disc brake pads for wear and rotors for surface

condition. Inspect other brake parts, including calipers,

parking brake, etc.

(b)Visually inspect front and rear suspension and

steering system for damaged, loose or missing parts,

signs of wear or lack of lubrication. Inspect power

steering lines and hoses for proper hook-up, binding,

leaks, cracks, cha®ng, etc. Visually check constant

velocity joints, rubber boots and axle seals for leaks.

(c)Visually inspect hoses and have them replaced if they

are cracked, swollen or deteriorated. Inspect all pipes,

®ttings and clamps; replace with genuine GM parts as

needed. To help ensure proper operation, a pressure test

of the cooling system and pressure cap and cleaning the

outside of the radiator and air conditioning condenser is

recommended at least once a year.

(d)Visually inspect wiper blades for wear or cracking.

Replace blade inserts that appear worn or damaged

or that streak or miss areas of the windshield.

(e)Make sure the safety belt reminder light and all your

belts, buckles, latch plates, retractors and anchorages

are working properly. Look for any other loose or

damaged safety belt system parts. If you see anything

that might keep a safety belt system from doing its

job, have it repaired. Have any torn or frayed safety belts

replaced. Also look for any opened or broken air bag

coverings, and have them repaired or replaced. (The air

bag system does not need regular maintenance.)

(f)Lubricate all key lock cylinders, hood latch assembly,

secondary latch, pivots, spring anchor, release pawl, door

hinges, liftgate hinge, liftgate linkage, liftgate handle pivot

points, latch bolt, fuel door hinge, locks and folding seat

hardware. More frequent lubrication may be required

when exposed to a corrosive environment. Applying

silicone grease on weatherstrips with a clean cloth will

make them last longer, seal better and not stick or

squeak.

6-8

Page 431 of 468

(g)Inspect system. Check all fuel and vapor lines and

hoses for proper hook-up, routing and condition.

Check that the purge valve works properly (if equipped).

Replace as needed.

(h)Change automatic transmission ¯uid and ®lter if the

vehicle is mainly driven under one or more of these

conditions:

þIn heavy city traffic where the outside temperature

regularly reaches 90ÉF (32ÉC) or higher.

þIn hilly or mountainous terrain.

þWhen doing frequent trailer towing.

þUses such as found in taxi, police or delivery

service.

(i)Drain, ¯ush and re®ll cooling system. See Engine

Coolant on page 5-23for what to use. Inspect hoses.

Clean radiator, condenser, pressure cap and ®ller neck.

Pressure test the cooling system and pressure cap.

(j)

A ¯uid loss in any vehicle system could indicate a

problem. Have the system inspected and repaired and

the ¯uid level checked. Add ¯uid if needed.

Owner Checks and Services

These owner checks and services should be performed

at the intervals speci®ed to help ensure the safety,

dependability and emission control performance of your

vehicle. Your GM Goodwrench dealer can assist you

with these checks and services.

Be sure any necessary repairs are completed at once.

Whenever any ¯uids or lubricants are added to your

vehicle, make sure they are the proper ones, as shown

in

Recommended Fluids and Lubricants on page 6-13.

At Each Fuel Fill

It is important to perform these underhood checks at

each fuel ®ll.

Engine Oil Level Check

Check the engine oil level and add the proper oil if

necessary. SeeEngine Oil on page 5-13for further

details.

Notice:It is important to check your oil regularly

and keep it at the proper level. Failure to keep your

engine oil at the proper level can cause damage

to your engine not covered by your warranty.

6-9

Page 436 of 468

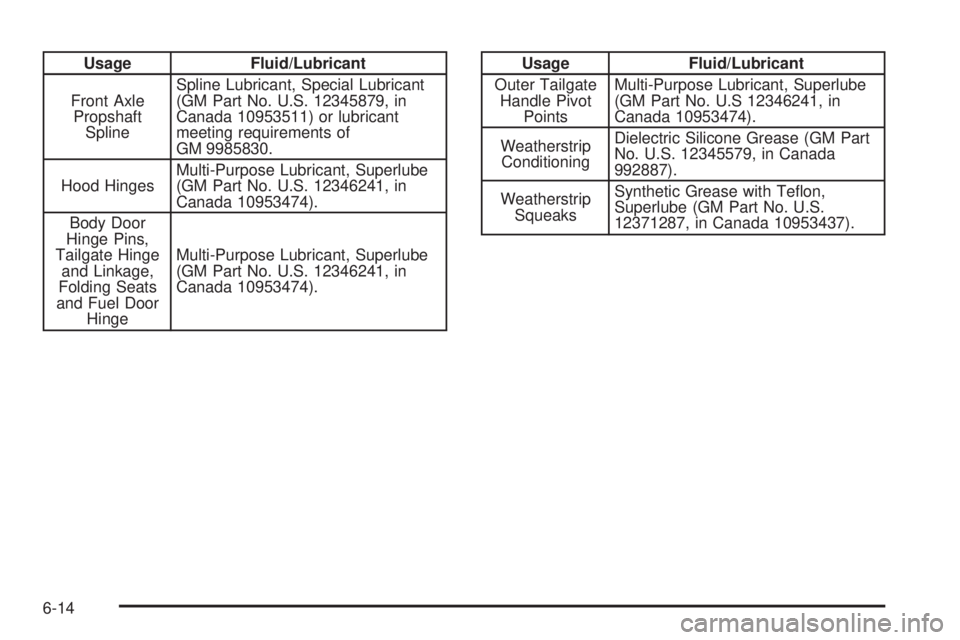

Usage Fluid/Lubricant

Front Axle

Propshaft

SplineSpline Lubricant, Special Lubricant

(GM Part No. U.S. 12345879, in

Canada 10953511) or lubricant

meeting requirements of

GM 9985830.

Hood HingesMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474).

Body Door

Hinge Pins,

Tailgate Hinge

and Linkage,

Folding Seats

and Fuel Door

HingeMulti-Purpose Lubricant, Superlube

(GM Part No. U.S. 12346241, in

Canada 10953474).Usage Fluid/Lubricant

Outer Tailgate

Handle Pivot

PointsMulti-Purpose Lubricant, Superlube

(GM Part No. U.S 12346241, in

Canada 10953474).

Weatherstrip

ConditioningDielectric Silicone Grease (GM Part

No. U.S. 12345579, in Canada

992887).

Weatherstrip

SqueaksSynthetic Grease with Te¯on,

Superlube (GM Part No. U.S.

12371287, in Canada 10953437).

6-14

Page 437 of 468

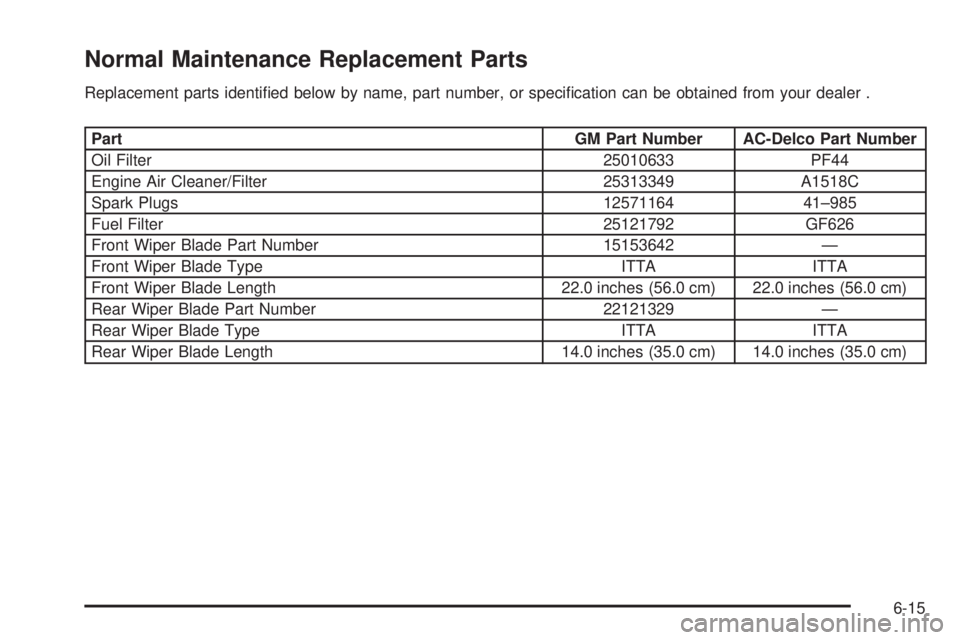

Normal Maintenance Replacement Parts

Replacement parts identi®ed below by name, part number, or speci®cation can be obtained from your dealer .

Part GM Part Number AC-Delco Part Number

Oil Filter 25010633 PF44

Engine Air Cleaner/Filter 25313349 A1518C

Spark Plugs 12571164 41±985

Fuel Filter 25121792 GF626

Front Wiper Blade Part Number 15153642 Ð

Front Wiper Blade Type ITTA ITTA

Front Wiper Blade Length 22.0 inches (56.0 cm) 22.0 inches (56.0 cm)

Rear Wiper Blade Part Number 22121329 Ð

Rear Wiper Blade Type ITTA ITTA

Rear Wiper Blade Length 14.0 inches (35.0 cm) 14.0 inches (35.0 cm)

6-15