tow GMC YUKON HYBRID 2010 Owner's Manual

[x] Cancel search | Manufacturer: GMC, Model Year: 2010, Model line: YUKON HYBRID, Model: GMC YUKON HYBRID 2010Pages: 120, PDF Size: 1.03 MB

Page 54 of 120

6. Use an adequate clamping device designed fortowing to ensure that the front wheels are locked

into the straight position.

{WARNING:

Shifting a four-wheel-drive vehicle's transfer case

into N (Neutral) can cause the vehicle to roll even

if the transmission is in P (Park). The driver or

others could be injured. Make sure the parking

brake is firmly set before the transfer case is

shifted to N (Neutral).

7. Shift the transfer case to N (Neutral). See “Shifting

into N (Neutral)” underFour-Wheel Drive

on

page 3‑10

8. Turn the ignition to LOCK/OFF.

After towing, see “Shifting Out of N (Neutral)” under

Four-Wheel Drive on page 3‑10.

Towing a Trailer

For more information, see “Towing a Trailer”in the

owner manual Index.

Weight of the Trailer

How heavy can a trailer safely be?

It depends on how the rig is used. For example, speed,

altitude, road grades, outside temperature and how

much the vehicle is used to pull a trailer are all

important. It can depend on any special equipment

on the vehicle, and the amount of tongue weight the

vehicle can carry.

Maximum trailer weight is calculated assuming only the

driver is in the tow vehicle and it has all the required

trailering equipment. The weight of additional optional

equipment, passengers and cargo in the tow vehicle

must be subtracted from the maximum trailer weight.

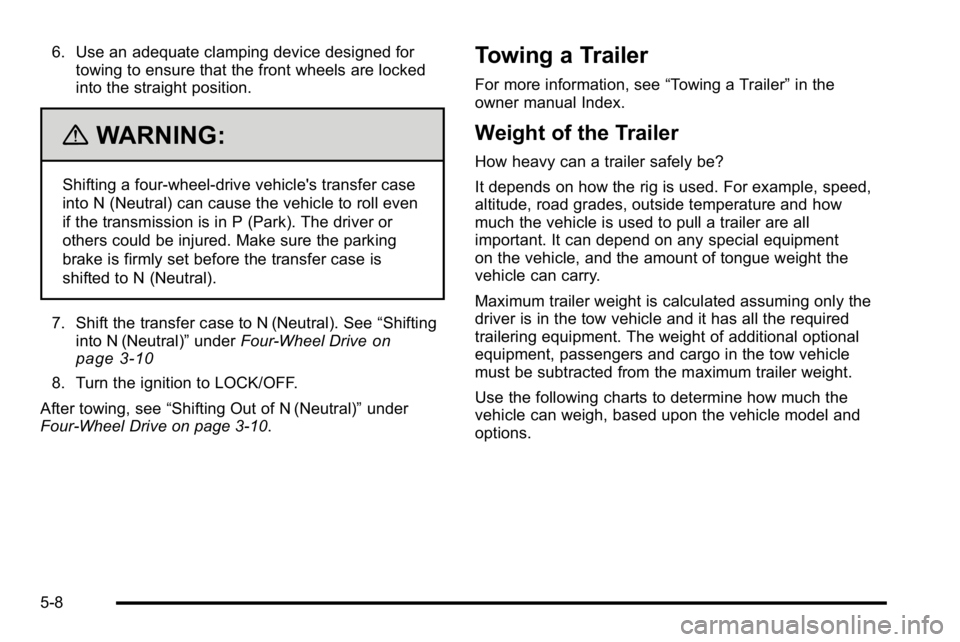

Use the following charts to determine how much the

vehicle can weigh, based upon the vehicle model and

options.

5-8

Page 55 of 120

VehicleAxle Ratio Maximum Trailer Weight GCWR*

2WD 6.0L V8—Tahoe/

Yukon 3.08 6,200 lbs (2 812 kg) 12,000 lbs (5 443 kg)

2WD 6.0L V8 —Yukon

Denali 3.08 6,000 lbs (2 722 kg) 12,000 lbs (5 443 kg)

4WD 6.0L V8 —Tahoe/

Yukon 3.08 6,000 lbs (2 722 kg) 12,000 lbs (5 443 kg)

4WD 6.0L V8 —Yukon

Denali 3.08 5,700 lbs (2 586 kg) 12,000 lbs (5 443 kg)

*The Gross Combination Weight Rating (GCWR) is the total allowable weight of the completely loaded vehicle and

trailer including any passengers, cargo, equipment and conversions. The GCWR for the vehicle should not be

exceeded.

Trailer Brakes

If a trailer is being towed that has trailer brakes and the

trailer brakes are manually applied while driving slower

than 25 mph (40 km/h), the vehicle may go into auto

stop mode even if the brakes are not being pressed.

Using the trailer brake system manually can make

the hybrid vehicle perform as if the brake pedal in the vehicle is being pressed. The trailer brake operation

check will still work. If the trailer brakes are manually

applied for an extended period of time, the SERVICE

BRAKE SYSTEM DIC message comes on. The

message goes off after the trailer brakes have been

released. No other action is necessary. For more

information, see

“Trailer Brakes”in the Index of the

vehicle's owner manual.

5-9

Page 61 of 120

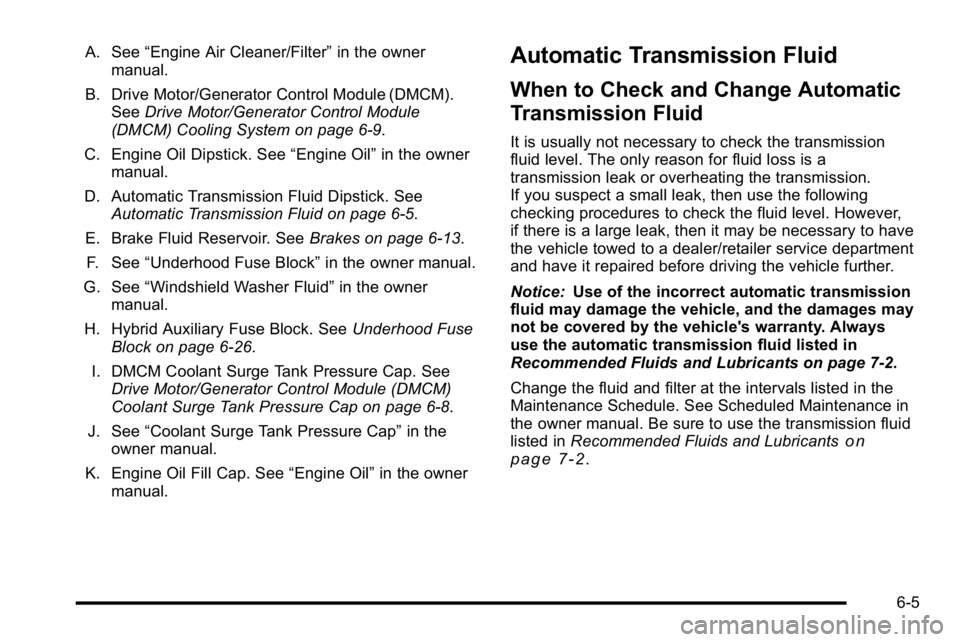

A. See“Engine Air Cleaner/Filter” in the owner

manual.

B. Drive Motor/Generator Control Module (DMCM). See Drive Motor/Generator Control Module

(DMCM) Cooling System on page 6‑9.

C. Engine Oil Dipstick. See “Engine Oil”in the owner

manual.

D. Automatic Transmission Fluid Dipstick. See Automatic Transmission Fluid on page 6‑5.

E. Brake Fluid Reservoir. See Brakes on page 6‑13.

F. See “Underhood Fuse Block” in the owner manual.

G. See “Windshield Washer Fluid” in the owner

manual.

H. Hybrid Auxiliary Fuse Block. See Underhood Fuse

Block on page 6‑26.

I. DMCM Coolant Surge Tank Pressure Cap. See Drive Motor/Generator Control Module (DMCM)

Coolant Surge Tank Pressure Cap on page 6‑8.

J. See “Coolant Surge Tank Pressure Cap” in the

owner manual.

K. Engine Oil Fill Cap. See “Engine Oil”in the owner

manual.Automatic Transmission Fluid

When to Check and Change Automatic

Transmission Fluid

It is usually not necessary to check the transmission

fluid level. The only reason for fluid loss is a

transmission leak or overheating the transmission.

If you suspect a small leak, then use the following

checking procedures to check the fluid level. However,

if there is a large leak, then it may be necessary to have

the vehicle towed to a dealer/retailer service department

and have it repaired before driving the vehicle further.

Notice: Use of the incorrect automatic transmission

fluid may damage the vehicle, and the damages may

not be covered by the vehicle's warranty. Always

use the automatic transmission fluid listed in

Recommended Fluids and Lubricants on page 7‑2.

Change the fluid and filter at the intervals listed in the

Maintenance Schedule. See Scheduled Maintenance in

the owner manual. Be sure to use the transmission fluid

listed in Recommended Fluids and Lubricants

on

page 7‑2.

6-5

Page 62 of 120

How to Check Automatic Transmission

Fluid

Notice:Too much or too little fluid can damage your

transmission. Too much can mean that some of the

fluid could come out and fall on hot engine parts or

exhaust system parts, starting a fire. Too little fluid

could cause the transmission to overheat. Be sure

to get an accurate reading if you check your

transmission fluid.

Before checking the fluid level, prepare the vehicle as

follows:

1. Start the engine and park the vehicle on a level surface. Keep the engine running.

2. Apply the parking brake and place the shift lever in P (Park).

3. With your foot on the brake pedal, move the shift lever through each gear range, pausing for about

three seconds in each range. Then, move the shift

lever back to P (Park).

4. Allow the engine to idle (500 –800 RPM) for at

least one minute. Slowly release the brake pedal.

5. Keep the engine running and press the Trip/Fuel button or trip odometer reset stem until TRANS

TEMP (Transmission Temperature) displays on the

Driver Information Center (DIC). 6. Using the TRANS TEMP reading, determine and

perform the appropriate check procedure. If the

TRANS TEMP reading is not within the required

temperature ranges, allow the vehicle to cool,

or operate the vehicle until the appropriate

transmission fluid temperature is reached.

Cold Check Procedure

Use this procedure only as a reference to determine if

the transmission has enough fluid to be operated safely

until a hot check procedure can be made. The hot

check procedure is the most accurate method to check

the fluid level. Perform the hot check procedure at the

first opportunity. Use this cold check procedure to check

fluid level when the transmission temperature is

between 24°C and 34°C (75°F and 93°F).

1. Locate the

transmission dipstick at

the rear of the engine

compartment, on the

passenger side of the

vehicle.

See Engine Compartment Overview

on page 6‑4for more information.

2. Pull out the dipstick and wipe it with a clean rag or paper towel.

6-6

Page 63 of 120

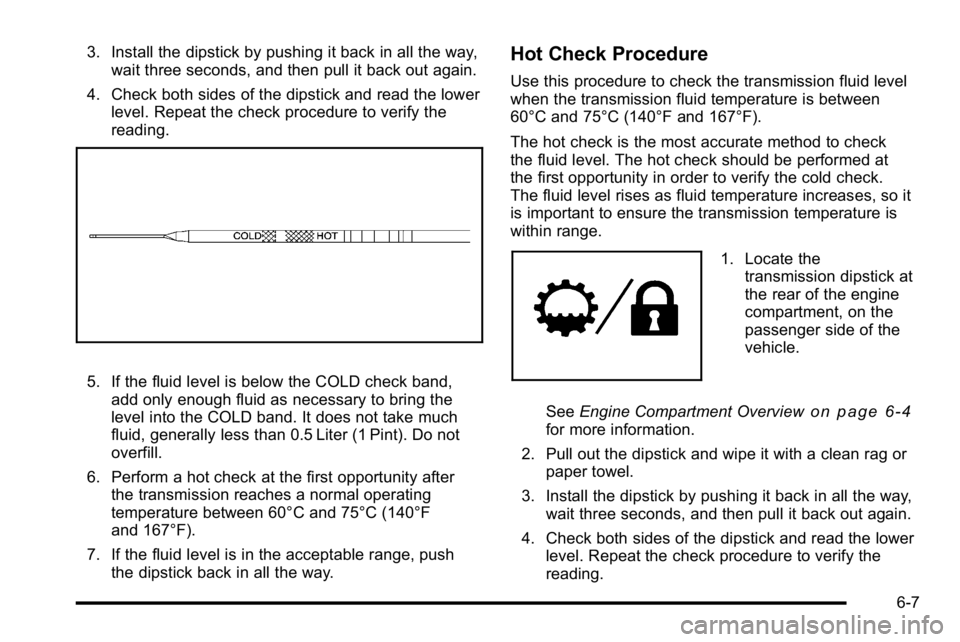

3. Install the dipstick by pushing it back in all the way,wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

5. If the fluid level is below the COLD check band,add only enough fluid as necessary to bring the

level into the COLD band. It does not take much

fluid, generally less than 0.5 Liter (1 Pint). Do not

overfill.

6. Perform a hot check at the first opportunity after the transmission reaches a normal operating

temperature between 60°C and 75°C (140°F

and 167°F).

7. If the fluid level is in the acceptable range, push the dipstick back in all the way.

Hot Check Procedure

Use this procedure to check the transmission fluid level

when the transmission fluid temperature is between

60°C and 75°C (140°F and 167°F).

The hot check is the most accurate method to check

the fluid level. The hot check should be performed at

the first opportunity in order to verify the cold check.

The fluid level rises as fluid temperature increases, so it

is important to ensure the transmission temperature is

within range.

1. Locate thetransmission dipstick at

the rear of the engine

compartment, on the

passenger side of the

vehicle.

See Engine Compartment Overview

on page 6‑4for more information.

2. Pull out the dipstick and wipe it with a clean rag or paper towel.

3. Install the dipstick by pushing it back in all the way, wait three seconds, and then pull it back out again.

4. Check both sides of the dipstick and read the lower level. Repeat the check procedure to verify the

reading.

6-7

Page 90 of 120

Tire Chains

{WARNING:

Do not use tire chains. There is not enough

clearance. Tire chains used on a vehicle without

the proper amount of clearance can cause

damage to the brakes, suspension, or other

vehicle parts. The area damaged by the tire

chains could cause you to lose control of the

vehicle and you or others may be injured in a

crash. Use another type of traction device

only if its manufacturer recommends it for use

on the vehicle and tire size combination and

road conditions. Follow that manufacturer's

instructions. To help avoid damage to the vehicle,

drive slowly, re‐adjust or remove the device if it

is contacting the vehicle, and do not spin the

wheels. If you do find traction devices that will fit,

install them on the rear tires.

If a Tire Goes Flat

Your vehicle has a tire inflator kit. There is no spare tire,

no tire changing equipment, and no place to store a tire.

It is unusual for a tire to blow out while you are driving,

especially if you maintain your tires properly. If air goes

out of a tire, it is much more likely to leak out slowly.

But, if you should ever have a blow out, here are a

few tips about what to expect and what to do:

If a front tire fails, the flat tire creates a drag that pulls

the vehicle toward that side. Take your foot off the

accelerator pedal and grip the steering wheel firmly.

Steer to maintain lane position, and then gently brake to

a stop well out of the traffic lane.

A rear blow out, particularly on a curve, acts much like a

skid and may require the same correction you would

use in a skid. In any rear blow out, remove your foot

from the accelerator pedal. Get the vehicle under

control by steering the way you want the vehicle to go.

It may be very bumpy and noisy, but you can still steer.

Gently brake to a stop, well off the road if possible.

6-34

Page 101 of 120

To install a new sealant canister:1. Align the sealant/air hose (F) with the slot in the air compressor.

2. Push the sealant canister (B) down and turn it clockwise.

3. Wrap the sealant/air hose (F) around the air compressor channel to stow it in its original

location.

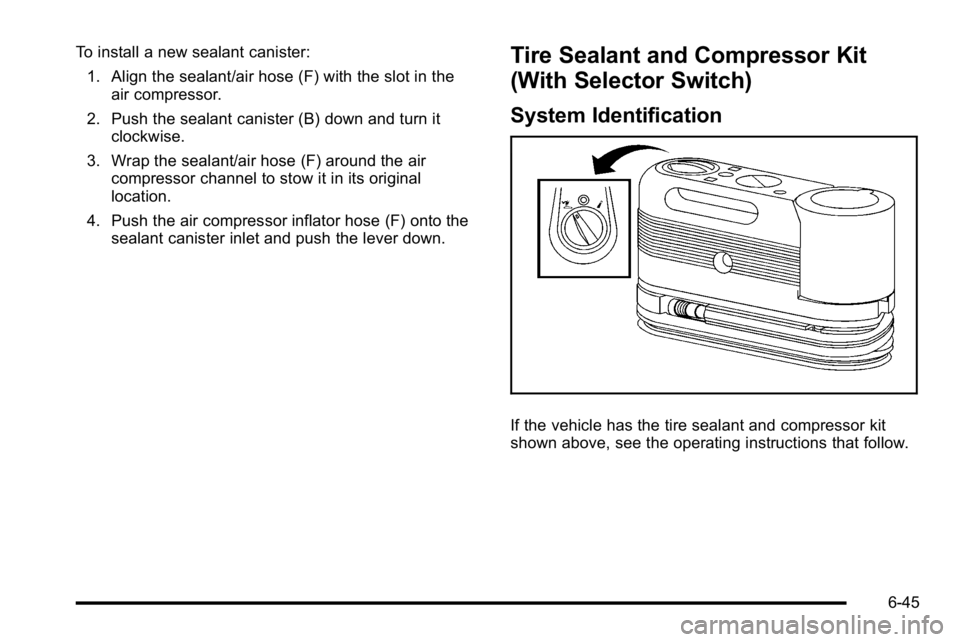

4. Push the air compressor inflator hose (F) onto the sealant canister inlet and push the lever down.Tire Sealant and Compressor Kit

(With Selector Switch)

System Identification

If the vehicle has the tire sealant and compressor kit

shown above, see the operating instructions that follow.

6-45

Page 120 of 120

T

Tachometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

TaillampsTurn Signal, Stoplamps and Back-up Lamps . . . . . . 6-24

Tires Chains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

If a Tire Goes Flat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-34

Inflation, Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-28

Inspection and Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . 6-33

Sealant and Compressor Kit . . . . . . . . . . 6-35, 6-45, 6-55

Towing

Towing Your Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Trailer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Transmission, Automatic Fluid . . . . . . . . . . . . . . . . . . . . . . .6-5

V

Vehicle Running While Parked . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Voltage Devices, and Wiring . . . . . . . . . . . . . . . . . . . . . . . . .6-3

W

Wiring, High Voltage Devices . . . . . . . . . . . . . . . . . . . . . . . .6-3

i - 4