relay GREAT WALL FLORID 2008 User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 180 of 281

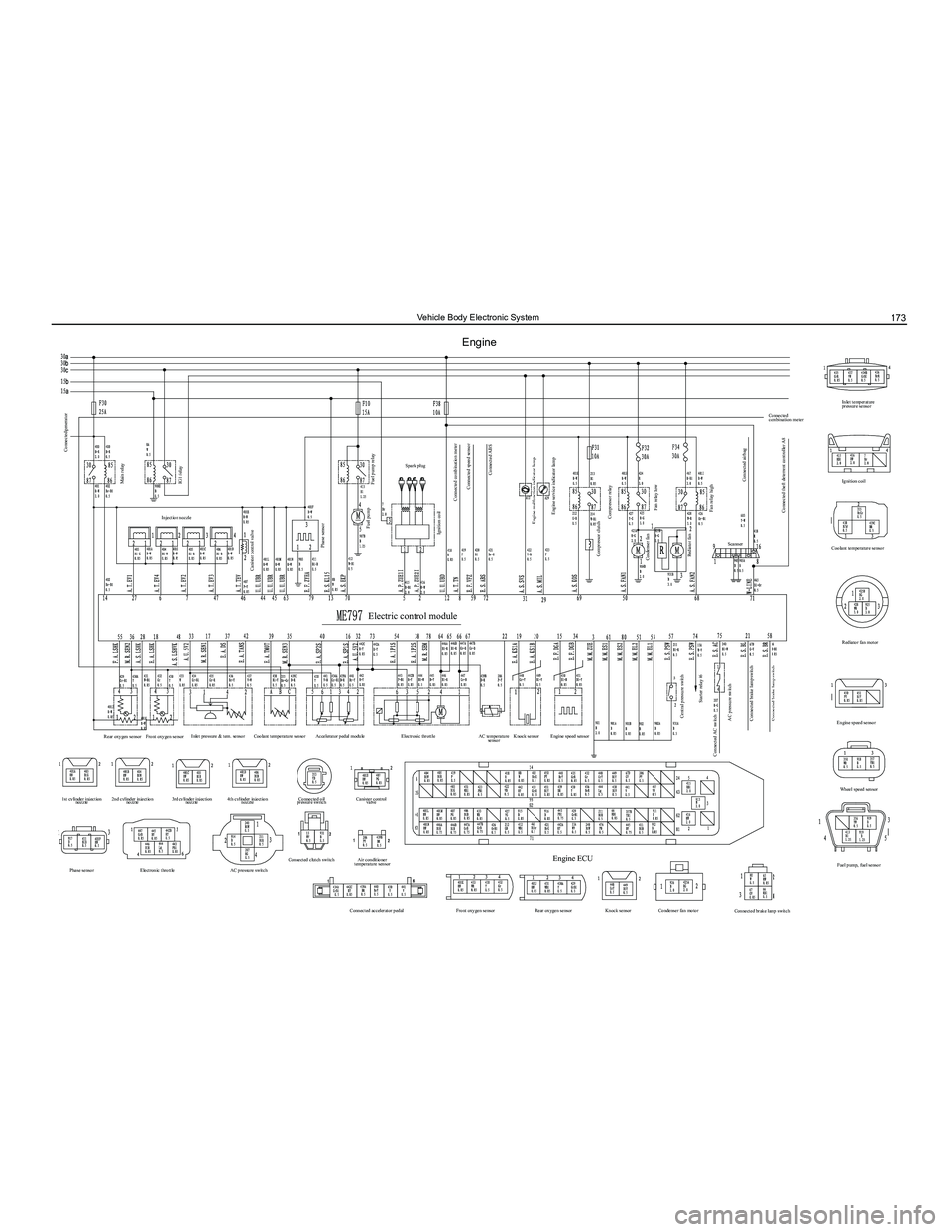

Downloaded from www.Manualslib.com manuals search engine 173Vehicle Body Electronic System

Engine

Connected generator

Canister control valve

Rear oxygen sensor

1st cylinder injection nozzle

Phase sensor Electronic throttle AC pressure switchConnected clutch switch

Air conditioner

temperature sensor

Connected accelerator pedal Front oxygen sensorRear oxygen sensorKnock sensorCondenser fan motor

Connected brake lamp switch

Engine ECU

2nd cylinder injection

nozzle 3rd cylinder injection

nozzle 4th cylinder injection

nozzle Connected oil

pressure switch Canister control

valve

Front oxygen sensor

Inlet pressure & tem. sensor

Coolant temperature sensor Accelerator pedal module Electronic throttle AC temperature

sensor Knock sensor

Engine speed sensor

Phase sensor

Fuel pump relay

Connected combination meter Connected speed sensor

Engine malfunction indicator lamp Engine service indicator lamp

Compressor relay

Compressor clutch

Central pressure switch Starter relay 86

Connected AC switch AC pressure switch

Connected brake lamp switch

Connected brake lamp switch Condenser fan

Rediator fan Fan relay lowScanner

Fan relay high

Connected airbag

Connected theft deterrent controller A8

Connected

combination meter

Ignition coil

Coolant temperature sensor

Rediator fan motor

Engine speed sensor Wheel speed sensor

Fuel pump, fuel sensor Inlet temperature

pressure sensor

Connected ABS

Spark plug

Fuel pump

Electric control module

Ignition coil

Main relay

Injection nozzle

IG1 relay

Page 181 of 281

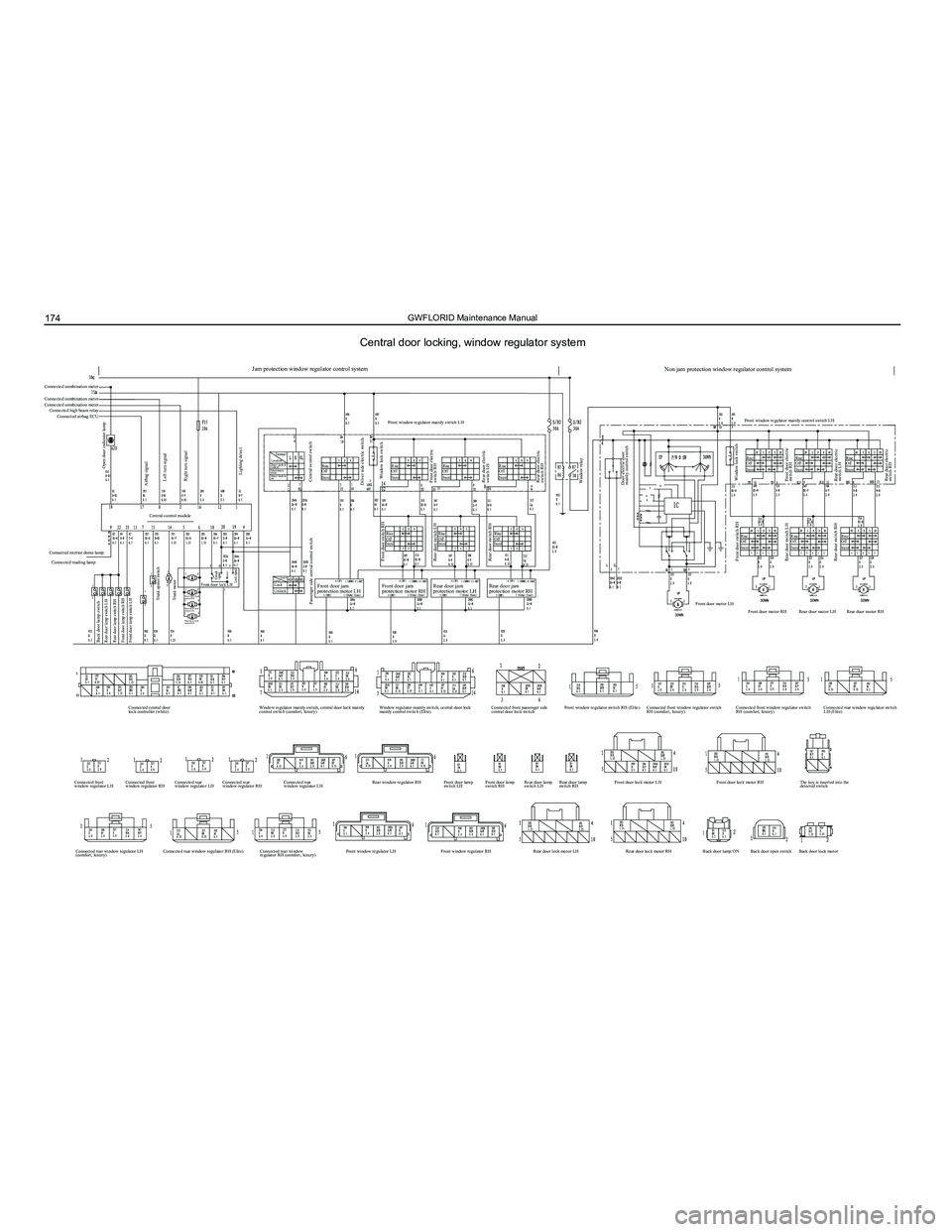

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual174

Central door locking, window regulator system

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Front door switch RH

Rear door switch LH

Rear door switch RH

Jam protection window regulator control system

Front window regulator mainly switch LH

Front door jam

protection motor LHFront door jam

protection motor RHRear door jam

protection motor LH Rear door jam

protection motor RH

Connected combination meter

Connected combination meter

Connected combination meter

Connected high beam relay

Connected airbag ECU

Central control module

Connected interior dome lamp Connected reading lamp

Open door indicator lamp

Airbag signal

Back door lamp switch

Rear door lamp switch LH

Rear door lamp switch RH

Front door lamp switch RH

Front door lamp switch LH

Trunk opener switch

Trunk motor

Unlock

signal

Lock signalFront door lock LH Lock

UnlockRise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

Descend

Rise

Off

DescendDoor lock is

locked

Stationary

state

Door lock is

on

Front door lock

motor RH

Rear door lock

motor LH

Rear door lock

motor RH

Left turn signal

Right turn signal

Lighting detect

Passenger side central ocntrol switch Central ocntrol switch

Driver side electric switch Window lock switch

Front door electric

switch RH

Rear door electric

switch LH

Rear door electric

switch RH

Window relay

Window lock switch

Front door switch RH

Rear door switch LH

Rear door switch RH Door electric door

mainly control switch

Front door electric

switch RH

Rear door electric

switch LH

Rear door electric

switch RH

Non jam protection window regulator control system

Front door motor LH

Connected central door

lock controller (white)

Connected front

window regulator LH Connected rear window regulator LH

(comfort, luxury) Connected rear window regulator RH (Elite)

Connected rear window

regulator RH (comfort, luxury)Front window regulator LH

Rear door lock motor LHRear door lock motor RHBack door lamp ONBack door open switch Back door lock motor

Front window regulator RH

Connected front

window regulator RH

Connected rear

window regulator LHConnected rear

window regulator RH Connected rear

window regulator LH Rear window regulator RH

Front door lamp

switch LHFront door lamp

switch RHRear door lamp

switch LHRear door lamp

switch RH Front door lock motor LH

Front door lock motor RHThe key is inserted into the

detected switch

Window regulator mainly switch, central door lock mainly

control switch (comfort, luxury) Window regulator mainly switch, central door lock

mainly control switch (Elite)Connected front passenger side

central door lock switchFront window regulator switch RH (Elite)

Connected front window regulator switch

RH (comfort, luxury) Connected front window regulator switch

RH (comfort, luxury)Connected rear window regulator switch

LH (Elite)

Front door motor RH

Rear door motor LHRear door motor RH

Front window regulator mainly control switch LH

Terminal

Location

Terminal

Location

Page 182 of 281

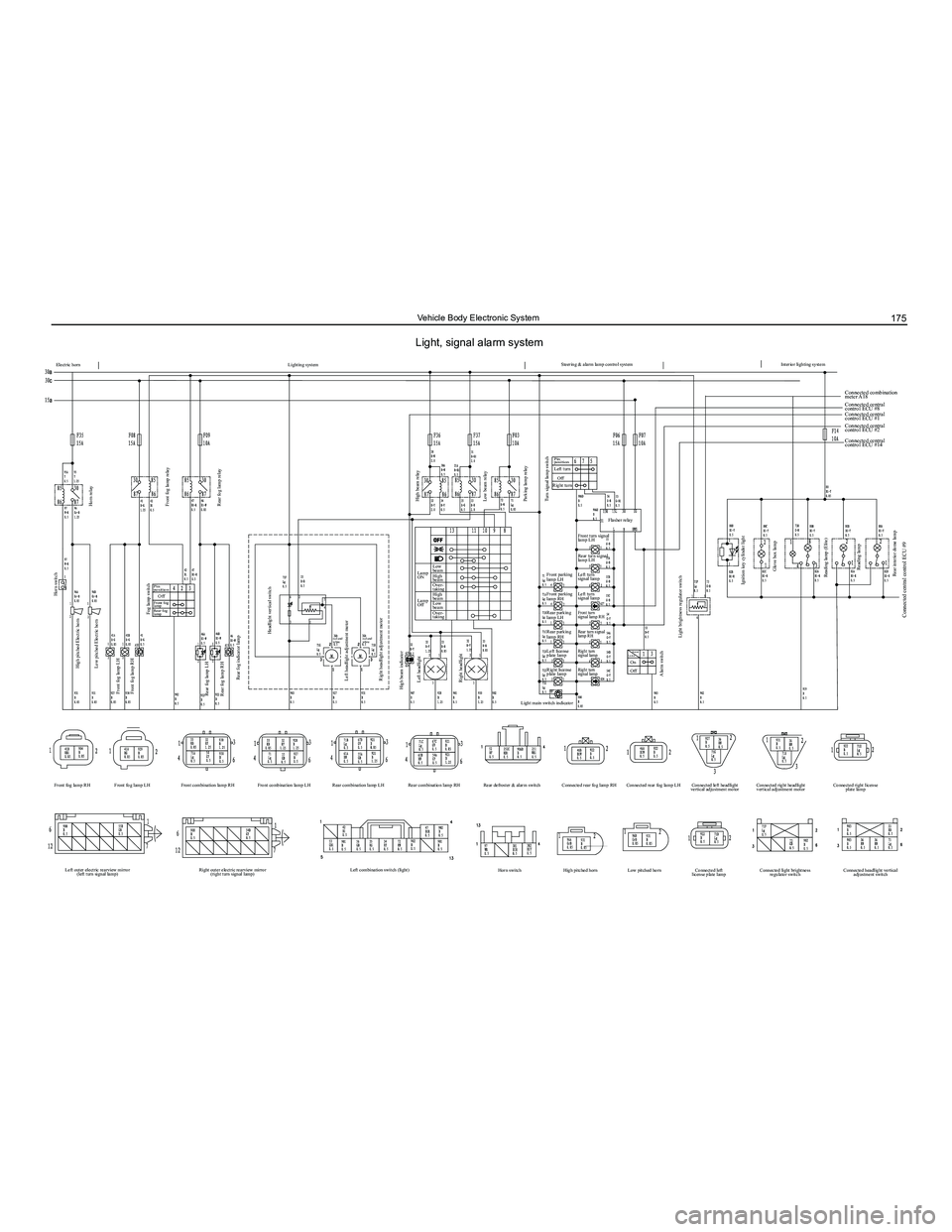

Downloaded from www.Manualslib.com manuals search engine 175Vehicle Body Electronic System

Electric horn

Horn switch

High pitched Electric horn

Low pitched Electric horn

Front fog lamp LH

Front fog lamp RH

Left outer electric rearview mirror (left turn signal lamp) Right outer electric rearview mirror

(right turn signal lamp) Left combination switch (light)

Horn switch High pitched horn Low pitched horn Connected left

license plate lamp Connected light brightness

regulator switch Connected headlight vertical

adjustment switch

Front fog lamp LH

Front combination lamp RH Front combination lamp LH Rear combination lamp LH Rear combination lamp RH Rear defroster & alarm switch Connected rear fog lamp RH Connected rear fog lamp LH Connected left headlight

vertical adjustment motor Connected right headlight

vertical adjustment motor Connected right license

plate lamp

Front fog lamp RH

Rear fog lamp LH

Rear fog lamp RH

Rear fog indicator lamp

Left headlight adjustment motor

Right headlight adjustment motor High beam relay

Lamp

ON Low

beam

Low

beam High

beam

High

beam Over-

taking

Over-

taking

Lamp

Off

Low beam relay

Parking lamp relay

Flasher relay

Connected combination

meter A18

Connected central

control ECU #8

Connected central

control ECU #1

Connected central

control ECU #2

Connected central

control ECU #14

Front parking

lamp LH Front turn signal

lamp LH

Rear turn signal

lamp LH

Left turn

signal lamp

Left turn

signal lamp

Front turn

signal lamp RH

Rear turn signal

lamp RH

Right turn

signal lamp

Right turn

signal lamp

Front parking

lamp RH

Rear parking

lamp LH

Rear parking

lamp RH

Left license

plate lamp

Right license

plate lamp

Light main switch indicator

Turn signal lamp switch

Alarm switch Light brightness regulator switch

Ignition key cylinder light Glove box lamp

Reading lamp (Elite) Reading lamp

Rear interior dome lamp

Connected central control ECU #9

High beam indicator Left headlight

Right headlight Headlight vertical switch

red and

white

red and

white

Fog lamp switch

Pin

position Pin

position

Left turn

Right turn Off

Front fog

lamp

Rear fog

lamp Off

Horn relay

Front fog lamp relay

Rear fog lamp relay

Lighting system Steering & alarm lamp control system

Interior lighting system

Terminal

Location

Off On

Light, signal alarm system

Page 189 of 281

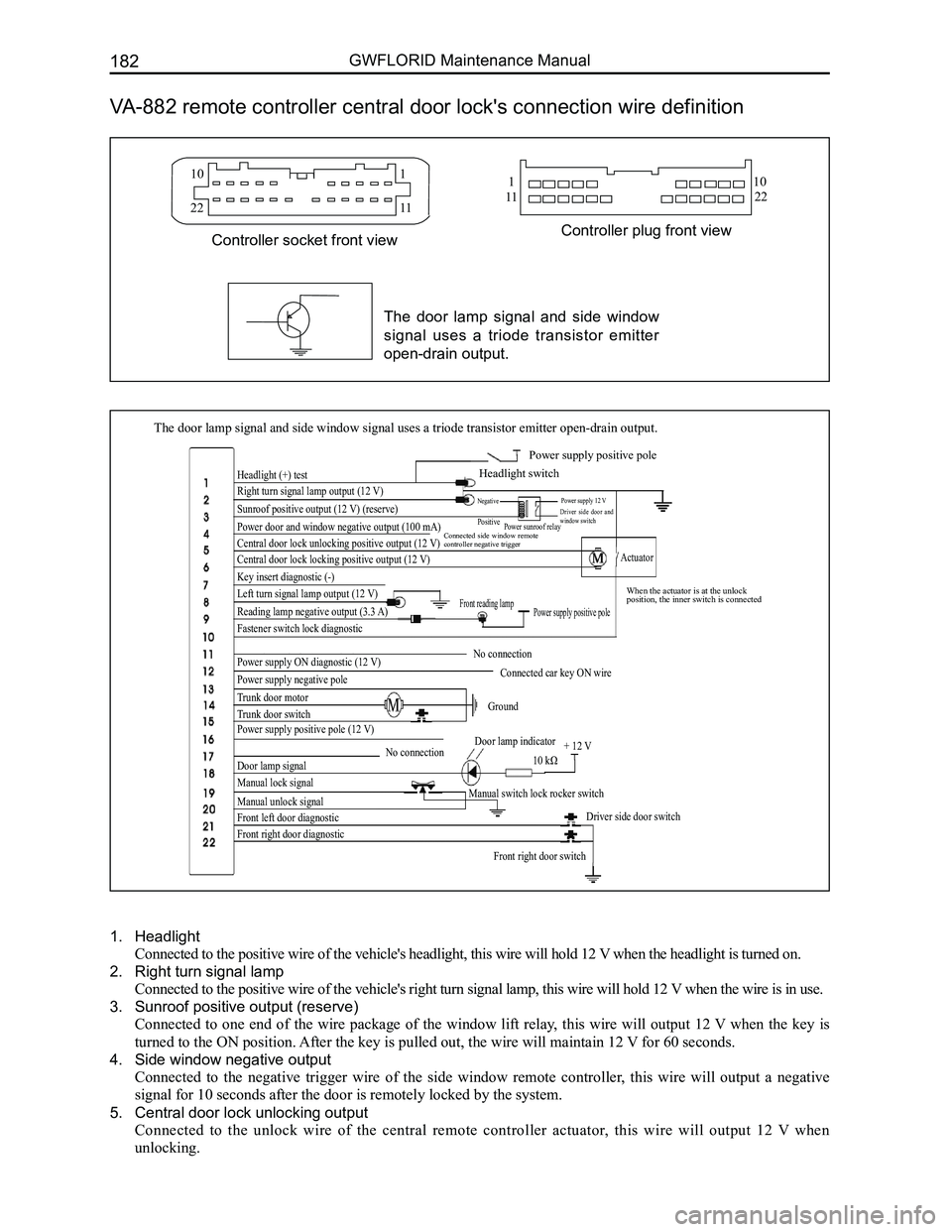

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual182

VA-882 remote controller central door lock's connection wire definition

The door lamp signal and side window signal uses a triode transistor emi\

tter open-drain output.

Headlight (+) test

Right turn signal lamp output (12 V)

Sunroof positive output (12 V) (reserve)

Power door and window negative output (100 mA)

Central door lock unlocking positive output (12 V)

Central door lock locking positive output (12 V)

Key insert diagnostic (-)

Left turn signal lamp output (12 V)

Reading lamp negative output (3.3 A)

Fastener switch lock diagnostic

Power supply ON diagnostic (12 V)

Power supply negative pole

Trunk door motor

Trunk door switch

Power supply positive pole (12 V)

Door lamp signal

Manual lock signal

Manual unlock signal

Front left door diagnostic

Front right door diagnostic

Front right door switch

Driver side door switch

Manual switch lock rocker switch

No connectionDoor lamp indicator

10 kΩ + 12 V

Ground

Connected car key ON wire

No connection

Power supply positive poleFront reading lamp

Actuator

When the actuator is at the unlock position, the inner switch is connected

Connected side window remote controller negative trigger

Power sunroof relay

Power supply 12 VDriver side door and window switch

Negative

Positive

Power supply positive pole

Headlight switch

10

22

110

1122

1

11

Controller plug front viewController socket front view

The door lamp signal and side window

signal uses a triode transistor emitter

open-drain output.

1. Headlight

Connected to the positive wire of the vehicle's headlight, this wire will hold 12 V when the headlight is turned on.

2. Right turn signal lamp

Connected to the positive wire of the vehicle's right turn signal lamp, this wire will hold 12 V when the wire is in use.

3. Sunroof positive output (reserve)

Connected to one end of the wire package of the window lift relay, this wire will output 12 V when the key is

turned to the ON position. After the key is pulled out, the wire will maintain 12 V for 60 seconds.

4. Side window negative output

Connected to the negative trigger wire of the side window remote controller, this wire will output a negative

signal for 10 seconds after the door is remotely locked by the system.

5. Central door lock unlocking output

Connected to the unlock wire of the central remote controller actuator, this wire will output 12 V when

unlocking.

Page 191 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual184

Power Windows

The GWFLORID electric power window actuator consist of a motor and module. Its functions include: jam

protection, centralized control rise, soft-stop, characterized by easy control, long life, etc.

The functions of electric power window actuator

1. Jam protection

Power windows have an jam protection function when manually or automatically rising after it has been

initialized. There is no limit on the amount of jam protections. When room temperature is 25±5oC, wire

resistance 150 mΩ and 14.5 V working voltage, the jam protection force risen glass is less than 100 N. When the

window is manually or electrically rising, once it encounters a force greater than the jam protection force, the glass

will immediately stop rising and make the motor rotate in reverse. Rever\

se rotation distance is about 125 mm.

2. Centralized control rise

The central door lock controller provides four lifters with a low level signal. The power windows will close until

they are completely closed. This enables the two power window actuators to start separately, which can avoid

hitting peak currents if they start up at the same time. As long as the centralized controller's rising pin receives

the low level signal, the motor will close the window until it is comple\

tely closed.

3. Soft-stop

If the motor suffers from an impacting block when the window is rolled all the way up or all the way down, it

would shorten the power window actuator's use life. In order to avoid this, the soft-stop function must be used,

in which both manual and automatic rolling up and down should have this \

function.

(a) Soft close function:

When the window is about to get to the top, that is to say, when it's rising to the soft-stop point, the engine's

power will cut off to make the motor stop working, meanwhile the rising inertia will continue to roll the

window up to the top. The soft-stop point is about 2 mm under the top limiting position.

(b) When the window is about to lower to the bottom, that is to say, when it's lowering to the soft-stop point,

the engine's power will cut off to make it stop working, meanwhile the lowering inertia will continue to roll

the window down to the bottom. The soft-stop point is about 12 mm above the bottom limiting position.

(c) Zero position calibration: This position takes the top limiting position as the zero position. In order to

guarantee reliable and safer system operation while in use, the zero pos\

ition will need constant calibration.

Manual calibration: When the window stops at the rising soft-stop position after rising for a period,

press the rise button so it will rise to the limiting position. Zero cal\

ibration is then complete.

Automatic calibration: After the motor runs forward and reverse more than 20 times, it will undergo

zero position calibration one time. That is to say, when it completely starts or stops operating, the motor will

be blocked one time. Currently, there is no soft close or start-up function. Zero position calibration is com-

pleted when the window is completely closed to the limiting position.

4. Motor locked protection

The control module will cut off the power supply to stop the motor from working within 250 ms of the l\

ocking.

5. Motor temperature protection

When the control module is powered on, the initial temperature of the motor is set at 40oC. There are two

temperature limits for the motor's thermal protection function. If the temperature of the coil exceeds the first

temperature limit (170oC), the motor will not respond to any new operation input, but it will still complete the present

operation. If the motor's temperature exceeds the first temperature limit during its operation, it will keep working until

the temperature of the motor coil reaches the second temperature limit (190oC), then the motor will not be limited by

the second temperature's threshold while reversing, so as to guarantee the safety of the users. Once the temperature of

the motor has lowered below the temperature limit, the motor will work normally.

6. Self-diagnostic protection function

So as to guarantee the system's reliability while improving the system's average non-failure time, self-diagnostic

protection measures are used: If the power supply voltage exceeds 16 V, the control module will close the auto-

rising function.

(a) Switch contact point adhesion:

If it is detected that the switch contact point adhesion has reached up to 10 m input instructions will no

longer be received. If later the switch contact is detected to be disconnected again, it's function will return

to normal.

(b) Relay contact point adhesion:

The power window actuator is controlled by two contact point relays.

After a shutoff command is sent to one of the relays, if the system detects that this relay is still on, then

the system will choose this relay contact point for adhesion. Thereupon, the system will send out another

command to make the other electric relay switch on as well, so as to guarantee the motor's power supply is

Page 192 of 281

Downloaded from www.Manualslib.com manuals search engine 185Electrical Accessories

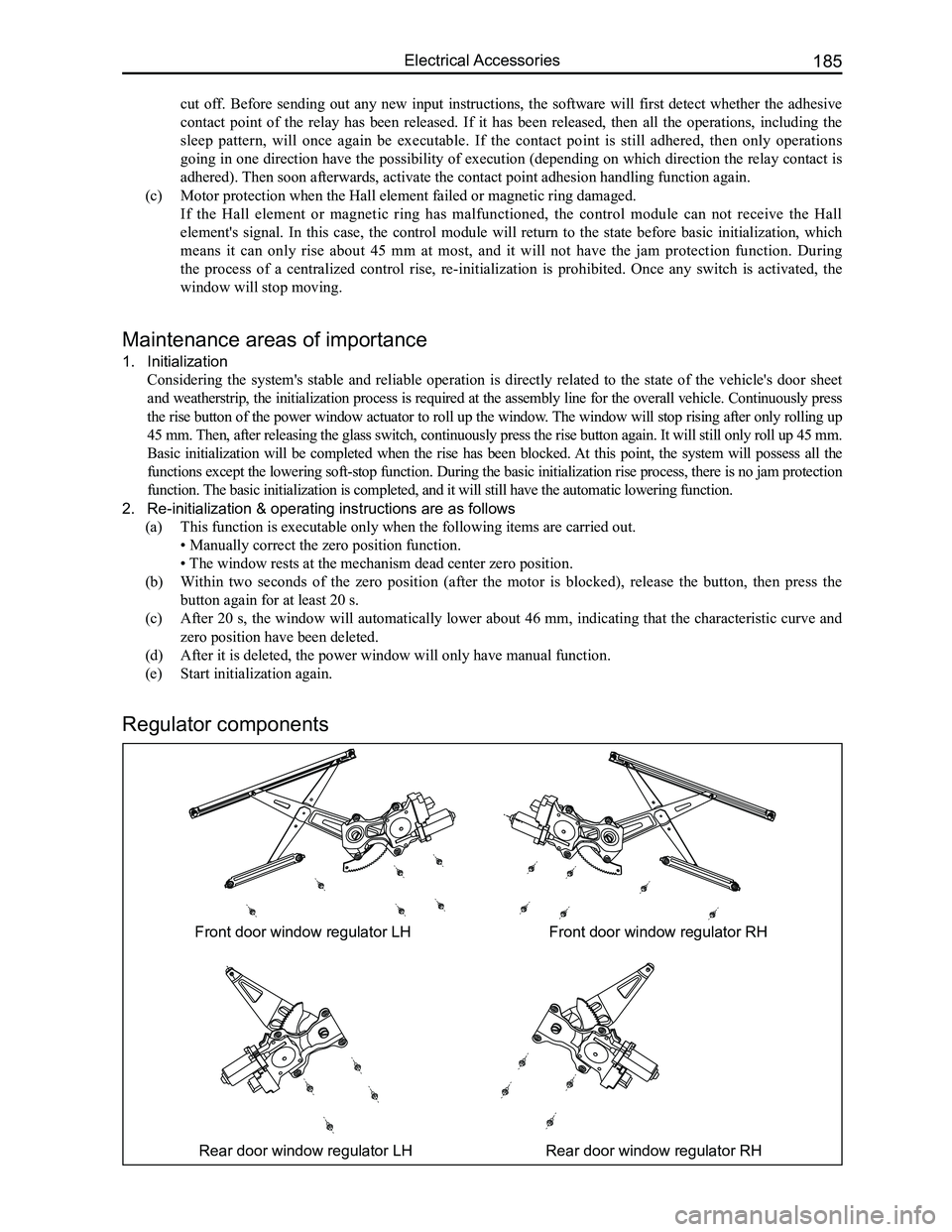

Front door window regulator LHFront door window regulator RH

Rear door window regulator LHRear door window regulator RH

Regulator components

Maintenance areas of importance

1. Initialization

Considering the system's stable and reliable operation is directly related to the state of the vehicle's door sheet

and weatherstrip, the initialization process is required at the assembly line for the overall vehicle. Continuously press

the rise button of the power window actuator to roll up the window. The window will stop rising after only rolling up

45 mm. Then, after releasing the glass switch, continuously press the rise button again. It will still only roll up 45 mm.

Basic initialization will be completed when the rise has been blocked. At this point, the system will possess all the

functions except the lowering soft-stop function. During the basic initialization rise process, there is no jam protection

function. The basic initialization is completed, and it will still have the automa\

tic lowering function.

2. Re-initialization & operating instructions are as follows

(a) This function is executable only when the following items are carried out.

• Manually correct the zero position function.

• The window rests at the mechanism dead center zero position.

(b) Within two seconds of the zero position (after the motor is blocked), release the button, then press the

button again for at least 20 s.

(c) After 20 s, the window will automatically lower about 46 mm, indicating that the characteristic curve and

zero position have been deleted.

(d) After it is deleted, the power window will only have manual function.

(e) Start initialization again.

cut off. Before sending out any new input instructions, the software will first detect whether the adhesive

contact point of the relay has been released. If it has been released, then all the operations, including the

sleep pattern, will once again be executable. If the contact point is still adhered, then only operations

going in one direction have the possibility of execution (depending on which direction the relay contact is

adhered). Then soon afterwards, activate the contact point adhesion handling funct\

ion again.

(c) Motor protection when the Hall element failed or magnetic ring damaged.

If the Hall element or magnetic ring has malfunctioned, the control module can not receive the Hall

element's signal. In this case, the control module will return to the state before basic initialization, which

means it can only rise about 45 mm at most, and it will not have the jam protection function. During

the process of a centralized control rise, re-initialization is prohibited. Once any switch is activated, the

window will stop moving.

Page 211 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual204

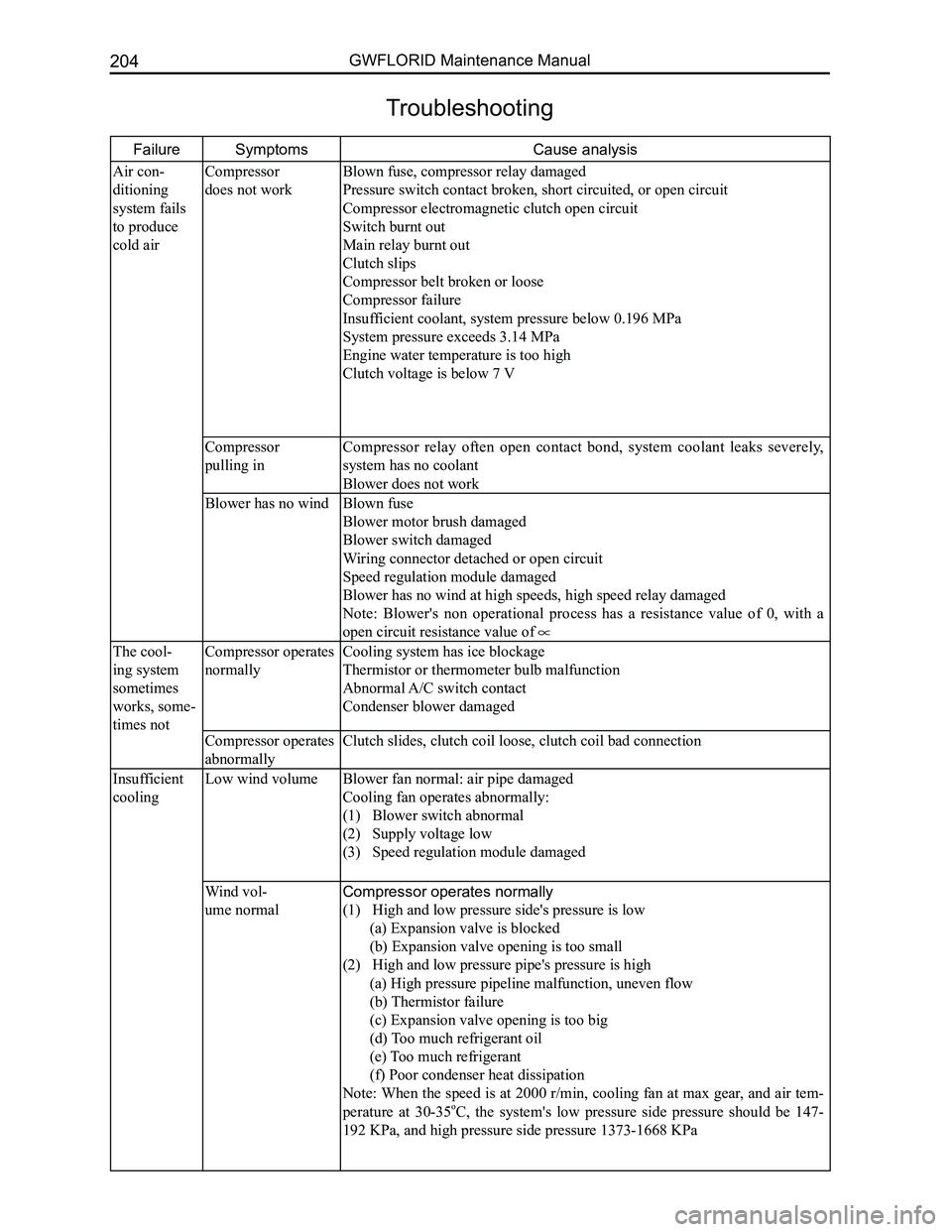

FailureSymptoms Cause analysis

Air con-

ditioning

system fails

to produce

cold air

Compressor

does not work

Blown fuse, compressor relay damaged

Pressure switch contact broken, short circuited, or open circuit

Compressor electromagnetic clutch open circuit

Switch burnt out

Main relay burnt out

Clutch slips

Compressor belt broken or loose

Compressor failure

Insufficient coolant, system pressure below 0.196 MPa

System pressure exceeds 3.14 MPa

Engine water temperature is too high

Clutch voltage is below 7 V

Compressor

pulling in

Compressor relay often open contact bond, system coolant leaks severely,

system has no coolant

Blower does not work

Blower has no windBlown fuse

Blower motor brush damaged

Blower switch damaged

Wiring connector detached or open circuit

Speed regulation module damaged

Blower has no wind at high speeds, high speed relay damaged

Note: Blower's non operational process has a resistance value of 0, with a

open circuit resistance value of

The cool-

ing system

sometimes

works, some-

times not

Compressor operates

normally

Cooling system has ice blockage

Thermistor or thermometer bulb malfunction

Abnormal A/C switch contact

Condenser blower damaged

Compressor operates

abnormally

Clutch slides, clutch coil loose, clutch coil bad connection

Insufficient

cooling

Low wind volume

Blower fan normal: air pipe damaged

Cooling fan operates abnormally:

(1) Blower switch abnormal

(2) Supply voltage low

(3) Speed regulation module damaged

Wind vol-

ume normal

Compressor operates normally

(1) High and low pressure side's pressure is low

(a) Expansion valve is blocked

(b) Expansion valve opening is too small

(2) High and low pressure pipe's pressure is high

(a) High pressure pipeline malfunction, uneven flow

(b) Thermistor failure

(c) Expansion valve opening is too big

(d) Too much refrigerant oil

(e) Too much refrigerant

(f) Poor condenser heat dissipation

Note: When the speed is at 2000 r/min, cooling fan at max gear, and air tem-

perature at 30-35oC, the system's low pressure side pressure should be 147-

192 KPa, and high pressure side pressure 1373-1668 KPa

Troubleshooting

Page 212 of 281

Downloaded from www.Manualslib.com manuals search engine 205Air Conditioning System

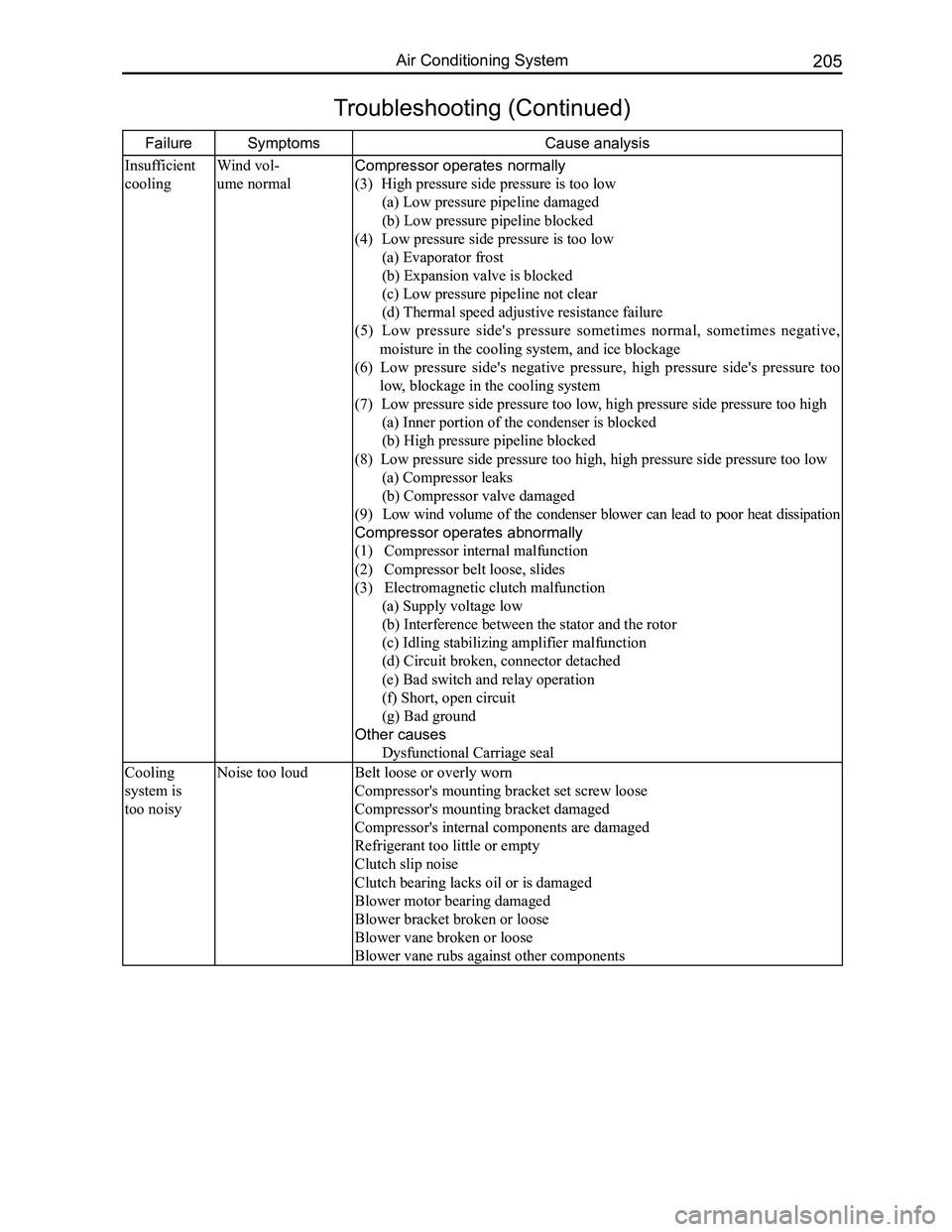

FailureSymptoms Cause analysis

Insufficient

cooling

Wind vol-

ume normal

Compressor operates normally

(3) High pressure side pressure is too low

(a) Low pressure pipeline damaged

(b) Low pressure pipeline blocked

(4) Low pressure side pressure is too low

(a) Evaporator frost

(b) Expansion valve is blocked

(c) Low pressure pipeline not clear

(d) Thermal speed adjustive resistance failure

(5) Low pressure side's pressure sometimes normal, sometimes negative,

moisture in the cooling system, and ice blockage

(6) Low pressure side's negative pressure, high pressure side's pressure too

low, blockage in the cooling system

(7) Low pressure side pressure too low, high pressure side pressure too high

(a) Inner portion of the condenser is blocked

(b) High pressure pipeline blocked

(8) Low pressure side pressure too high, high pressure side pressure \

too low

(a) Compressor leaks

(b) Compressor valve damaged

(9) Low wind volume of the condenser blower can lead to poor heat dissipation

Compressor operates abnormally

(1) Compressor internal malfunction

(2) Compressor belt loose, slides

(3) Electromagnetic clutch malfunction

(a) Supply voltage low

(b) Interference between the stator and the rotor

(c) Idling stabilizing amplifier malfunction

(d) Circuit broken, connector detached

(e) Bad switch and relay operation

(f) Short, open circuit

(g) Bad ground

Other causes

Dysfunctional Carriage seal

Cooling

system is

too noisy

Noise too loudBelt loose or overly worn

Compressor's mounting bracket set screw loose

Compressor's mounting bracket damaged

Compressor's internal components are damaged

Refrigerant too little or empty

Clutch slip noise

Clutch bearing lacks oil or is damaged

Blower motor bearing damaged

Blower bracket broken or loose

Blower vane broken or loose

Blower vane rubs against other components

Troubleshooting (Continued)

Page 213 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual206

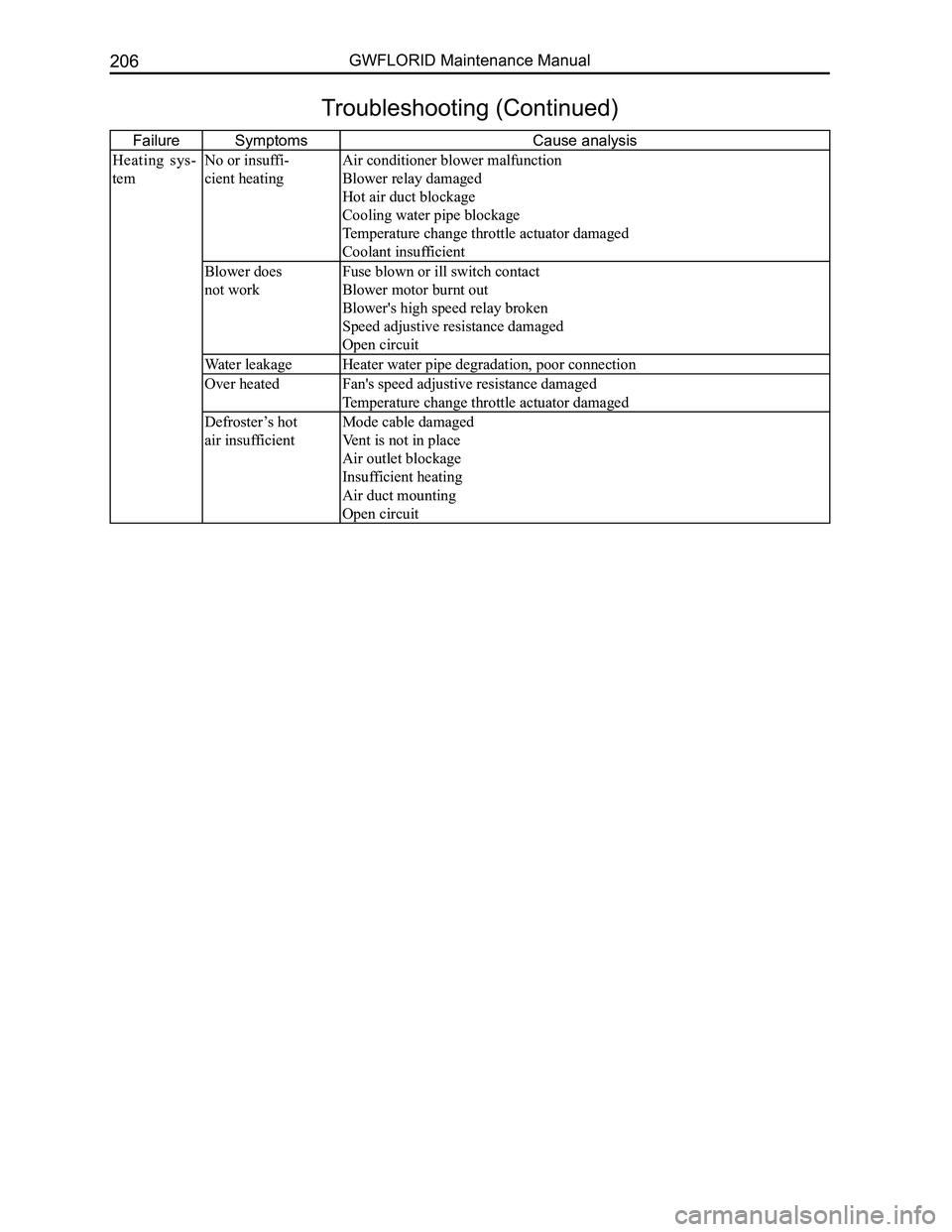

FailureSymptoms Cause analysis

Heating sys-

tem

No or insuffi-

cient heating

Air conditioner blower malfunction

Blower relay damaged

Hot air duct blockage

Cooling water pipe blockage

Temperature change throttle actuator damaged

Coolant insufficient

Blower does

not work

Fuse blown or ill switch contact

Blower motor burnt out

Blower's high speed relay broken

Speed adjustive resistance damaged

Open circuit

Water leakageHeater water pipe degradation, poor connection

Over heatedFan's speed adjustive resistance damaged

Temperature change throttle actuator damaged

Defroster’s hot

air insufficient

Mode cable damaged

Vent is not in place

Air outlet blockage

Insufficient heating

Air duct mounting

Open circuit

Troubleshooting (Continued)

Page 215 of 281

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual208

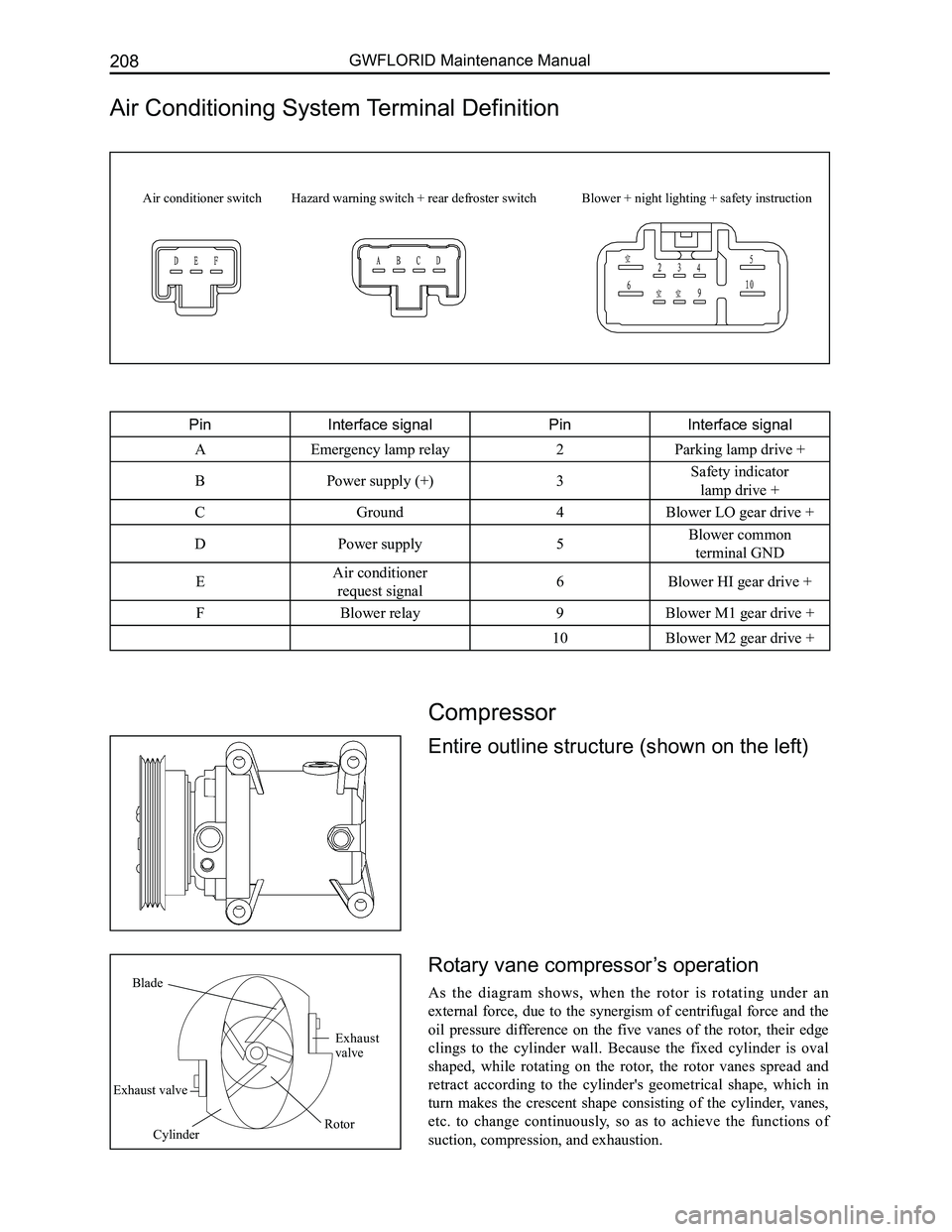

Air Conditioning System Terminal Definition

PinInterface signalPinInterface signal

AEmergency lamp relay2Parking lamp drive +

BPower supply (+)3Safety indicator

lamp drive +

CGround4Blower LO gear drive +

DPower supply5Blower common

terminal GND

EAir conditioner

request signal6Blower HI gear drive +

FBlower relay9Blower M1 gear drive +

10Blower M2 gear drive +

Air conditioner switchHazard warning switch + rear defroster switchBlower + night lighting + safety instruction

Cylinder

Blade

Exhaust valve

Rotor

Exhaust valve

Compressor

Entire outline structure (shown on the left)

Rotary vane compressor’s operation

As the diagram shows, when the rotor is rotating under an

external force, due to the synergism of centrifugal force and the

oil pressure difference on the five vanes of the rotor, their edge

clings to the cylinder wall. Because the fixed cylinder is oval

shaped, while rotating on the rotor, the rotor vanes spread and

retract according to the cylinder's geometrical shape, which in

turn makes the crescent shape consisting of the cylinder, vanes,

etc. to change continuously, so as to achieve the functions of

suction, compression, and exhaustion.