length GREAT WALL FLORID 2008 Service Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2008, Model line: FLORID, Model: GREAT WALL FLORID 2008Pages: 281, PDF Size: 43.97 MB

Page 18 of 281

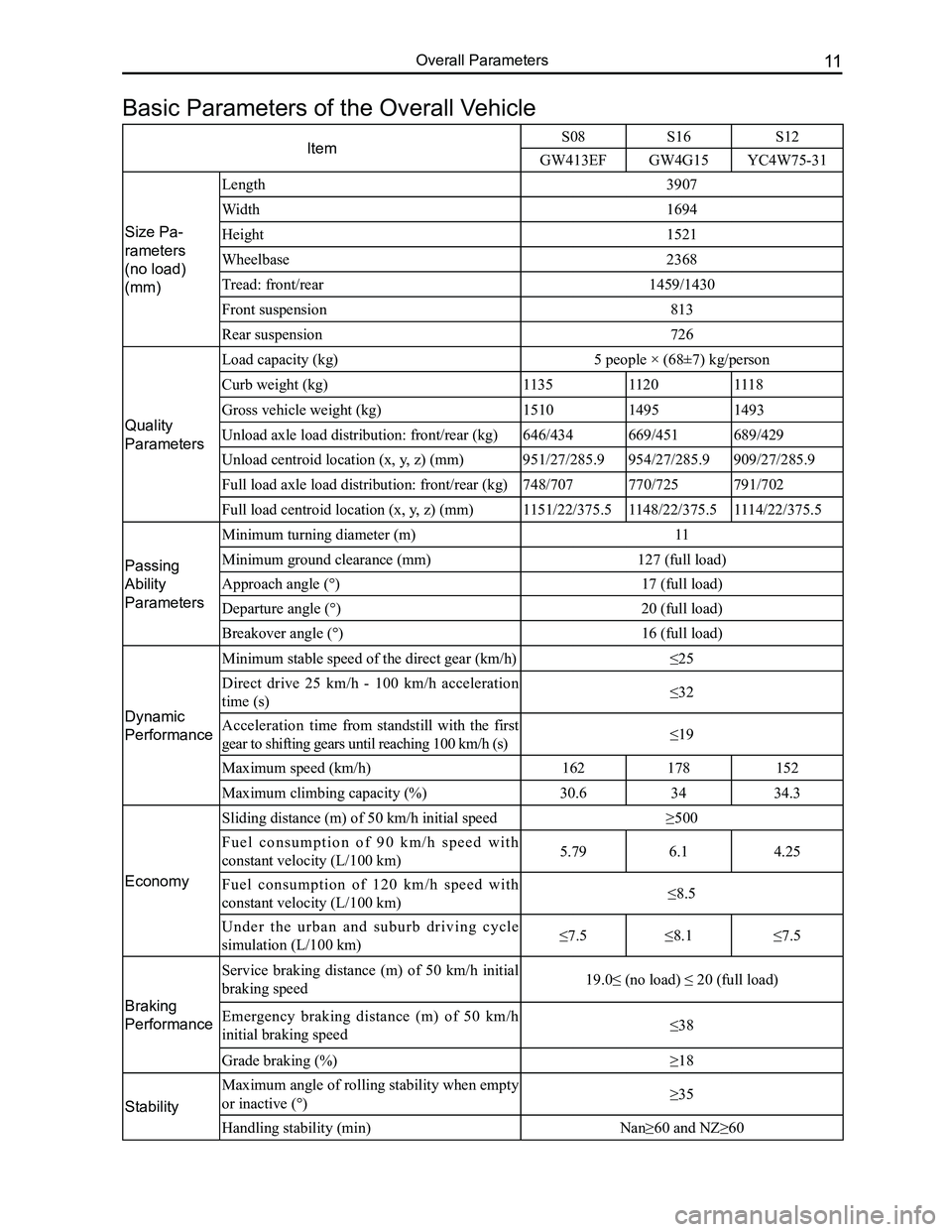

Downloaded from www.Manualslib.com manuals search engine 11Overall Parameters

ItemS08 S16S12

GW413EFGW4G15YC4W75-31

Size Pa-

rameters

(no load)

(mm)

Length3907

Width1694

Height1521

Wheelbase2368

Tread: front/rear1459/1430

Front suspension813

Rear suspension726

Quality

Parameters

Load capacity (kg)5 people × (68±7) kg/person

Curb weight (kg)113511201118

Gross vehicle weight (kg)151014951493

Unload axle load distribution: front/rear (kg)646/434669/451689/429

Unload centroid location (x, y, z) (mm)951/27/285.9954/27/285.9909/27/285.9

Full load axle load distribution: front/rear (kg)748/707770/725791/702

Full load centroid location (x, y, z) (mm)1151/22/375.51148/22/375.51114/22/375.5

Passing

Ability

Parameters

Minimum turning diameter (m)11

Minimum ground clearance (mm)127 (full load)

Approach angle (°)17 (full load)

Departure angle (°)20 (full load)

Breakover angle (°)16 (full load)

Dynamic

Performance

Minimum stable speed of the direct gear (km/h)≤25

Direct drive 25 km/h - 100 km/h acceleration

time (s)≤32

Acceleration time from standstill with the first

gear to shifting gears until reaching 100 km/h (s)≤19

Maximum speed (km/h)162178152

Maximum climbing capacity (%)30.63434.3

Economy

Sliding distance (m) of 50 km/h initial speed≥500

F u e l c o n s u m p t i o n o f 9 0 k m / h s p e e d w i t h

constant velocity (L/100 km)5.796.14.25

Fuel consumption of 120 km/h speed with

constant velocity (L/100 km)≤8.5

U n d e r t h e u r b a n a n d s u b u r b d r i v i n g c y c l e

simulation (L/100 km)≤7.5≤8.1≤7.5

Braking

Performance

Service braking distance (m) of 50 km/h initial

braking speed19.0≤ (no load) ≤ 20 (full load)

Emergency braking distance (m) of 50 km/h

initial braking speed ≤38

Grade braking (%)≥18

Stability

Maximum angle of rolling stability when empty

or inactive (°)≥35

Handling stability (min)Nan≥60 and NZ≥60

Basic Parameters of the Overall Vehicle

Page 29 of 281

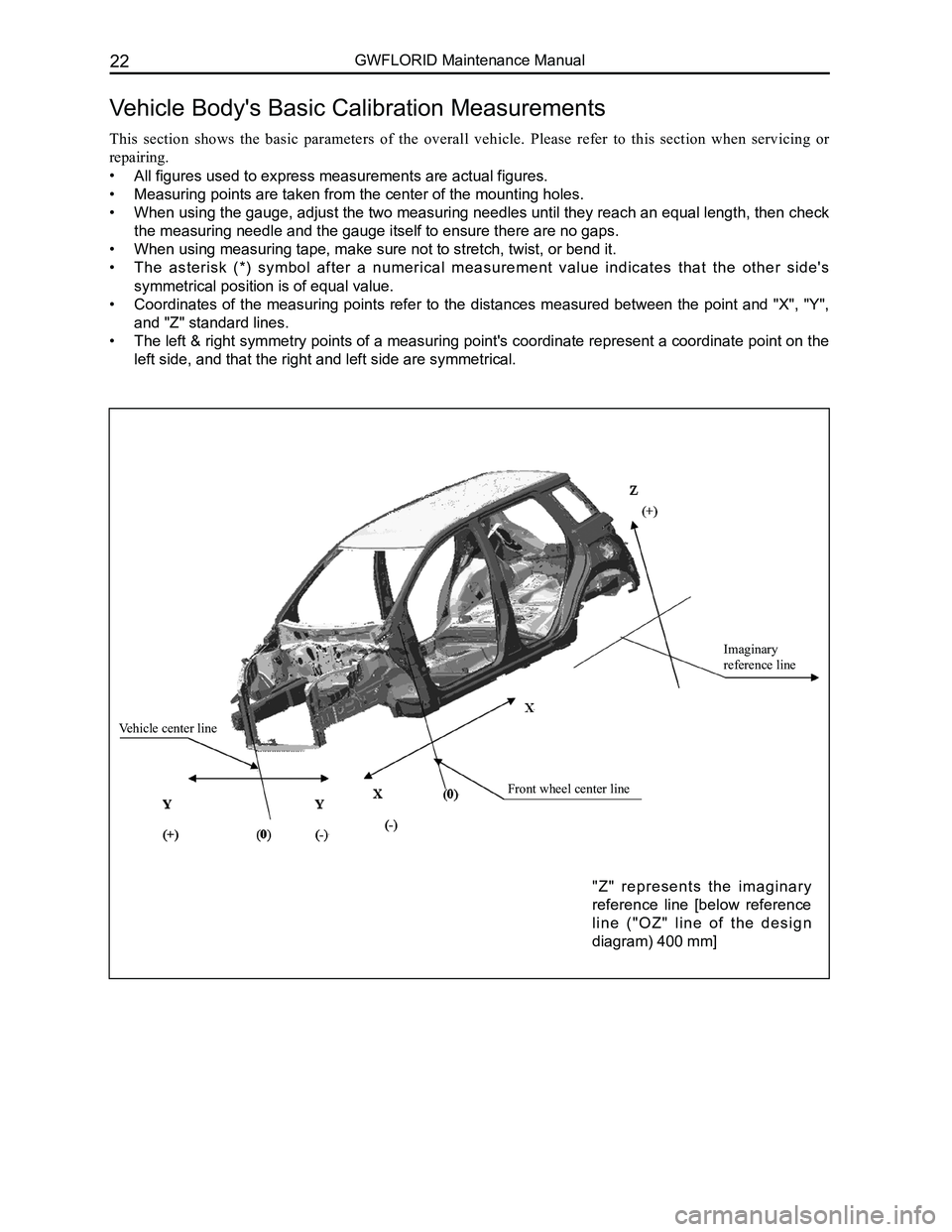

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual22

Imaginary

reference line

Front wheel center line

Vehicle center line

"Z" represents the imaginary

reference line [below reference

l i n e ( " O Z " l i n e o f t h e d e s i g n

diagram) 400 mm]

Vehicle Body's Basic Calibration Measurements

This section shows the basic parameters of the overall vehicle. Please refer to this section when servicing or

repairing.

• All figures used to express measurements are actual figures.

• Measuring points are taken from the center of the mounting holes.

• When using the gauge, adjust the two measuring needles until they reach an equal length, then check

the measuring needle and the gauge itself to ensure there are no gaps.

• When using measuring tape, make sure not to stretch, twist, or bend it. \

• The asterisk (*) symbol after a numerical measurement value indicates that the other side's

symmetrical position is of equal value.

• Coordinates of the measuring points refer to the distances measured between the point and "X", "Y",

and "Z" standard lines.

• The left & right symmetry points of a measuring point's coordinate represent a coordinate point on the

left side, and that the right and left side are symmetrical.

Page 137 of 281

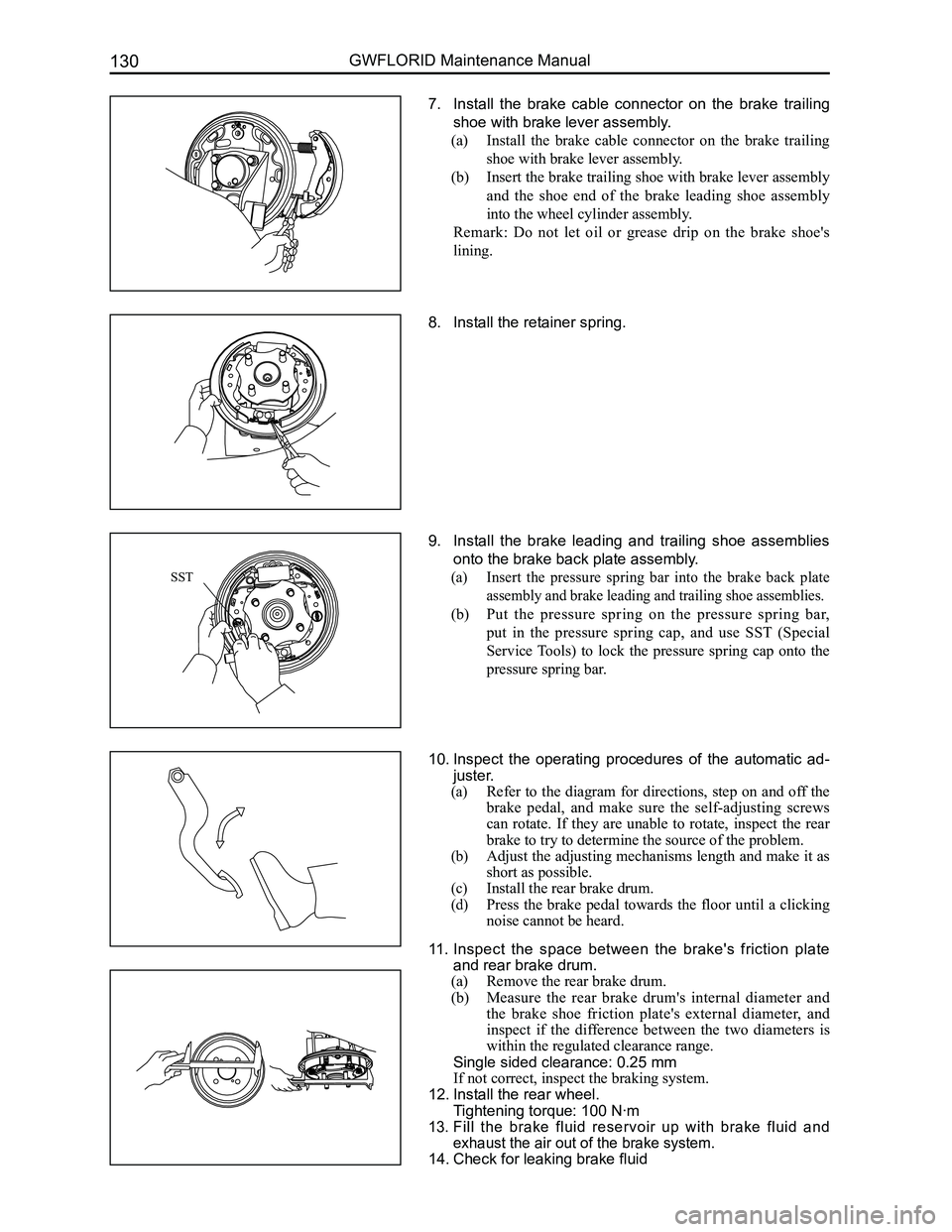

Downloaded from www.Manualslib.com manuals search engine GWFLORID Maintenance Manual130

7. Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(a) Install the brake cable connector on the brake trailing

shoe with brake lever assembly.

(b) Insert the brake trailing shoe with brake lever assembly

and the shoe end of the brake leading shoe assembly

into the wheel cylinder assembly.

Remark: Do not let oil or grease drip on the brake shoe's

lining.

8. Install the retainer spring.

9. Install the brake leading and trailing shoe assemblies

onto the brake back plate assembly.

(a) Insert the pressure spring bar into the brake back plate

assembly and brake leading and trailing shoe assemblies.

(b) Put the pressure spring on the pressure spring bar,

put in the pressure spring cap, and use SST (Special

Service Tools) to lock the pressure spring cap onto the

pressure spring bar.

10. Inspect the operating procedures of the automatic ad-

juster.

(a) Refer to the diagram for directions, step on and off the

brake pedal, and make sure the self-adjusting screws

can rotate. If they are unable to rotate, inspect the rear

brake to try to determine the source of the problem.

(b) Adjust the adjusting mechanisms length and make it as

short as possible.

(c) Install the rear brake drum.

(d) Press the brake pedal towards the floor until a clicking

noise cannot be heard.

11. Inspect the space between the brake's friction plate

and rear brake drum.

(a) Remove the rear brake drum.

(b) Measure the rear brake drum's internal diameter and

the brake shoe friction plate's external diameter, and

inspect if the difference between the two diameters is

within the regulated clearance range.

Single sided clearance: 0.25 mm

If not correct, inspect the braking system.

12. Install the rear wheel.

Tightening torque: 100 N·m

13. Fill the brake fluid reservoir up with brake fluid and

exhaust the air out of the brake system.

14. Check for leaking brake fluid

SST