ABS GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 201 of 425

N m: specified torque

Used component which can not be used any more.

precoated component

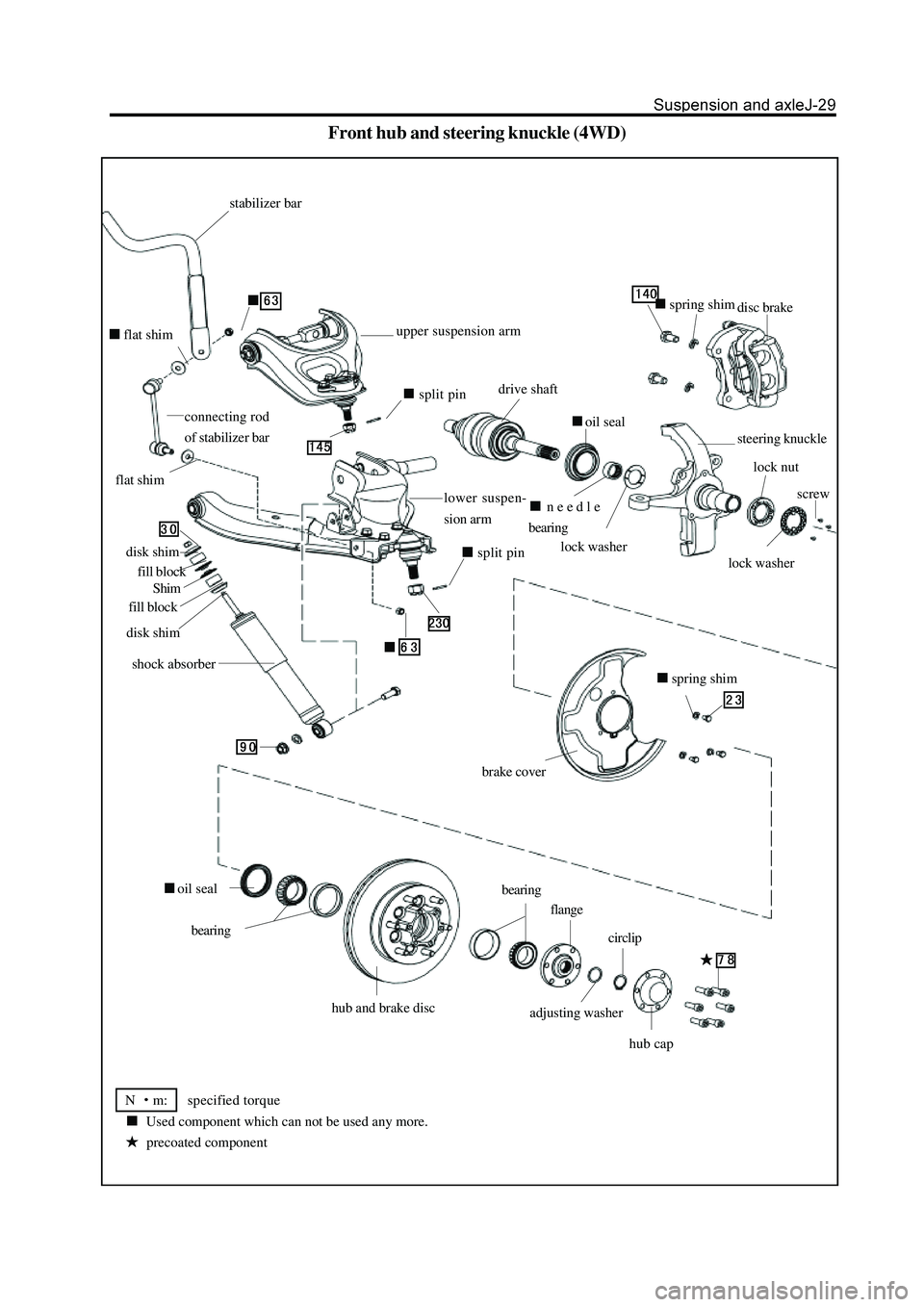

Front hub and steering knuckle (4WD)

stabilizer bar

flat shim

connecting rod

of stabilizer bar

hub and brake disc

flange

adjusting washer

circlip

hub cap

spring shimdisc brake

split pin

lower suspen-

sion arm

split pin

upper suspension arm

drive shaft

oil seal

needle

bearing

lock washer

steering knuckle

lock nut

lock washer

screw

brake cover

spring shim

flat shim

disk shimShim

fill blockfill block disk shim

oil seal

bearingbearing shock absorber

Page 210 of 425

clip

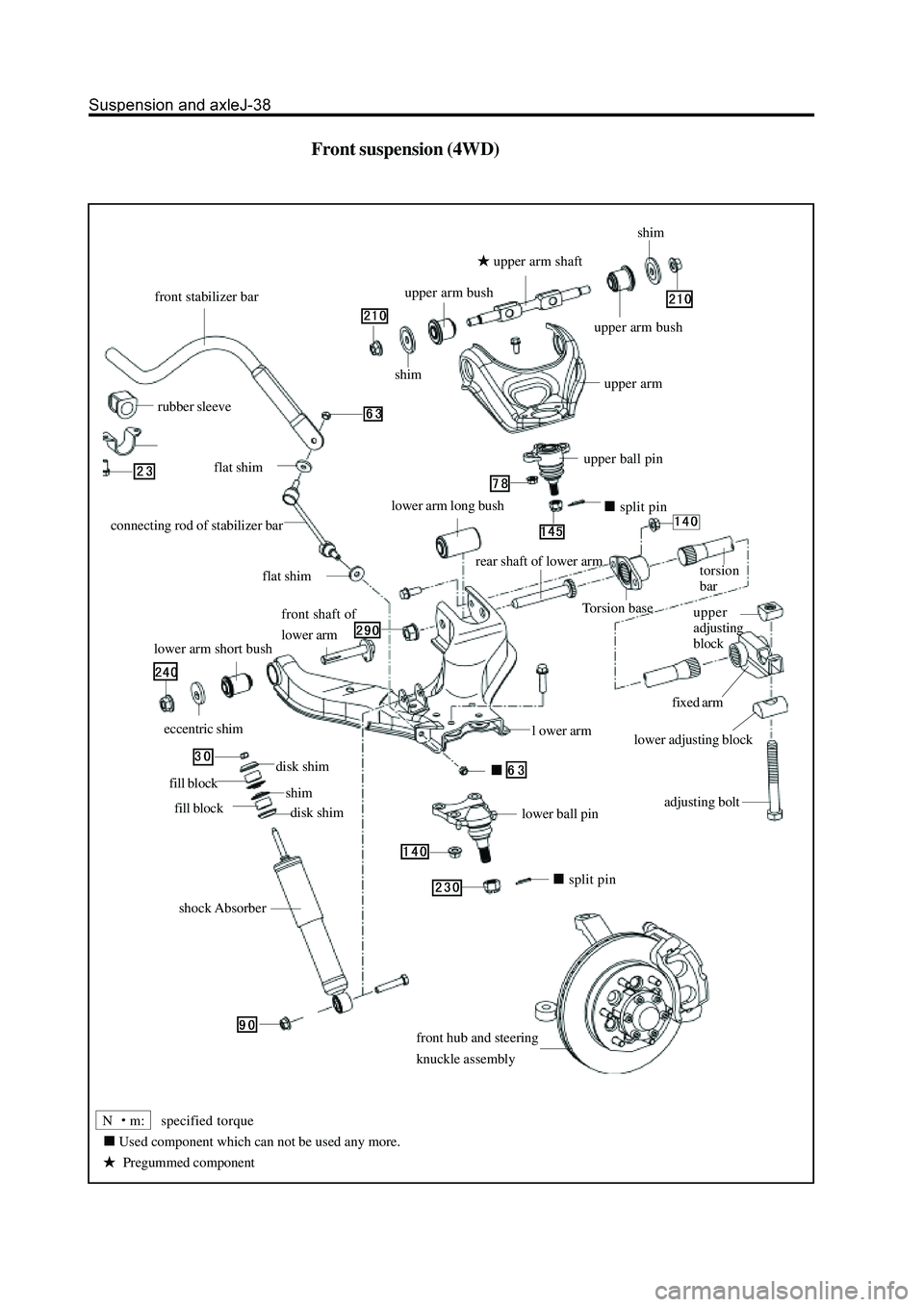

Front suspension (4WD)

N m: specified torque

Used component which can not be used any more.

Pregummed component

rubber sleeve

front shaft of

lower arm

disk shim

fill blockshimfill blockdisk shim

shock Absorber

front hub and steering

knuckle assembly

split pin

lower ball pinadjusting bolt

lower adjusting block

fixed arm

upper

adjusting

block

l ower arm

rear shaft of lower arm

Torsion base

torsion

bar

lower arm long bushsplit pin

upper ball pin

upper arm

shim

upper arm bush

upper arm shaft

upper arm bush

shim

front stabilizer bar

flat shim

connecting rod of stabilizer bar

flat shim

lower arm short bush

eccentric shim

Page 287 of 425

Brake-1

Chapter 8

Brake

Cautions...................................................................................... 2

Troubleshooting............................................................................2

Check and adjustment..................................................................5

Brake pedal..................................................................................7

Parking brake...............................................................................8

Front brake...................................................................................9

Rear brake...................................................................................16

Rear parking brake......................................................................22

Sensor load proportional valve.....................................................29

Antilock Braking System (ABS)..................................................31

Page 304 of 425

Brake-18

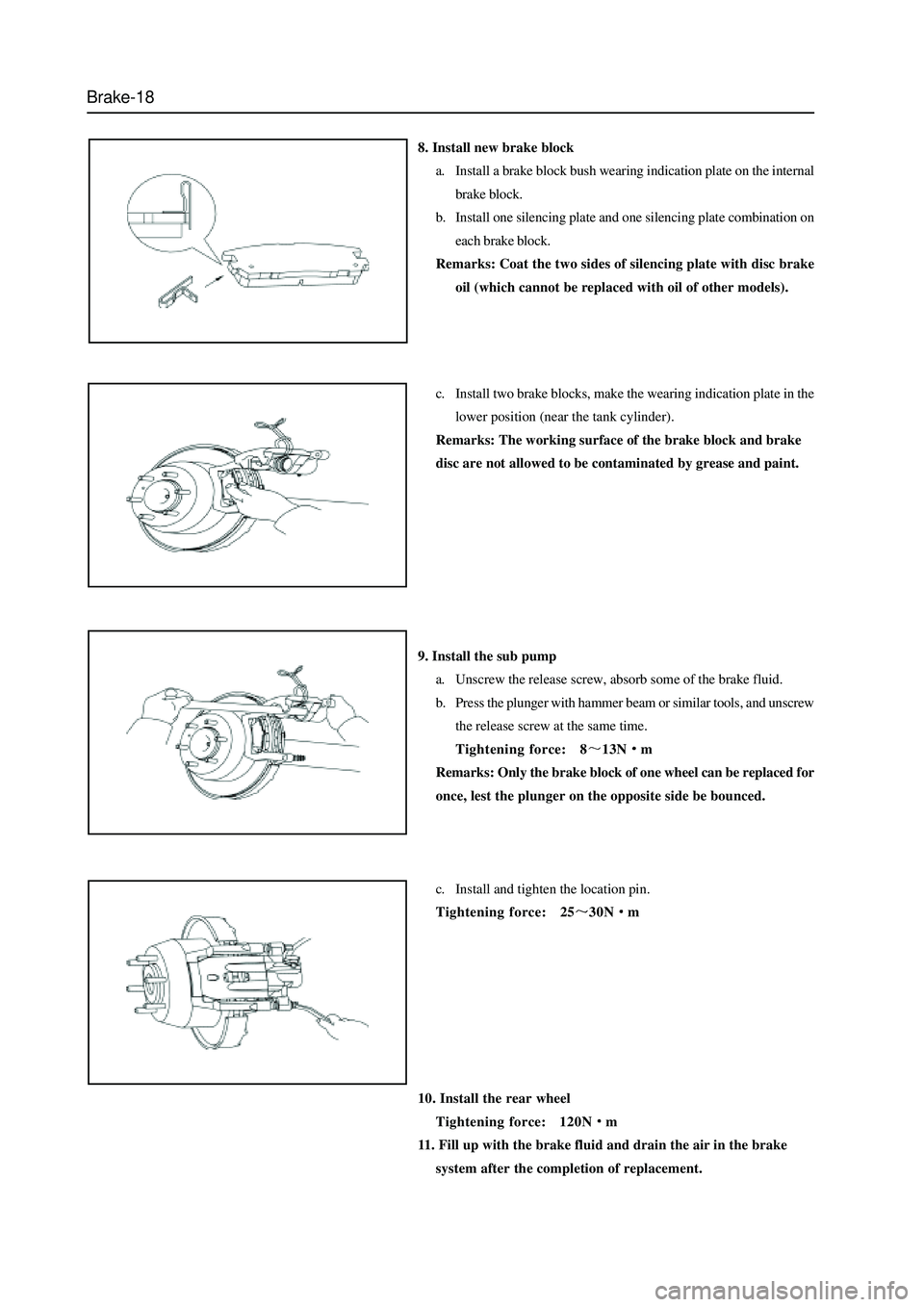

8. Install new brake block

a. Install a brake block bush wearing indication plate on the internal

brake block.

b. Install one silencing plate and one silencing plate combination on

each brake block.

Remarks: Coat the two sides of silencing plate with disc brake

oil (which cannot be replaced with oil of other models).

c. Install two brake blocks, make the wearing indication plate in the

lower position (near the tank cylinder).

Remarks: The working surface of the brake block and brake

disc are not allowed to be contaminated by grease and paint.

9. Install the sub pump

a. Unscrew the release screw, absorb some of the brake fluid.

b. Press the plunger with hammer beam or similar tools, and unscrew

the release screw at the same time.

Tightening force: 8

13Nm

Remarks: Only the brake block of one wheel can be replaced for

once, lest the plunger on the opposite side be bounced.

c. Install and tighten the location pin.

Tightening force: 25

30Nm

10. Install the rear wheel

Tightening force: 120N

m

11. Fill up with the brake fluid and drain the air in the brake

system after the completion of replacement.

Page 317 of 425

Brake-31

Antilock Braking System (ABS)

Cautions

1. It must not remove or install the electric elements and wire bunch plug when the ignition switch is in ON to avoid

the damage of ECU. It should turn off the ignition switch if needs disassembly.

2. Pay attention to do not knock or impact the ABS ECU during the maintenance and repair, for it will damage the

ABS ECU easily.

3. The wheel speed sensor and hydraulic unit (integrated with ECU) of BOSCH ABS8.0 can not be repaired, it should

be replaced in integral if damaged.

4. After the brake system is maintained, the brake pedal maybe soft. Discharge the air according to the normal brake

system.

5. It must use the brake fluid from original manufacturer; the brake fluid of different number cannot be used in mixed,

otherwise it will cause the failure of brake system. Select the tyre of original type as most as possible

Repair of Antilock Braking System (ABS)

1. It should process the failure diagnosis for the brake system before process the ABS failure diagnosis. It can

diagnose out the failure rapidly by using Table 1. In Table 1, the small number means the failure which occurs most

possibly. Check each element according to the sequence and maintain or replace it if necessary.

2. Check the following elements for normal operation before the diagnosis:

Brake fluid level and brake fluid quality

Pressure of tyre, size of tyre, shape and depth of tyre figure

Other brake component

These components will affect the brake effect of the ABS. Check the system sensor, connecting wire and connector for correct

installation, arrangement and connection. Ensure the completeness of fuse, repair or replace it if necessary.

3. Process the analysis and diagnosis according to the ABS advanced by owner. Use the diagnosis instrument (Annex

1) for final check and confirmation. It must process the run inspection after the competition of all ABS maintenance.

The test condition is shown as follows:

a. Confirm the tyre complies with the requirement, the tyre pressure is normal.

b. The brake system (including brake light ) is normal

c. The brake system is without leakage.

d. The position and installation of wheel speed sensor is correct.

e. All fuses are normal.

4. test method:

Run for 1 min at least when the vehicle speed is beyond 40Km/h, process a proper brake. Then read out the failure code to

ensure the ABS is without failure code.