height GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 214 of 425

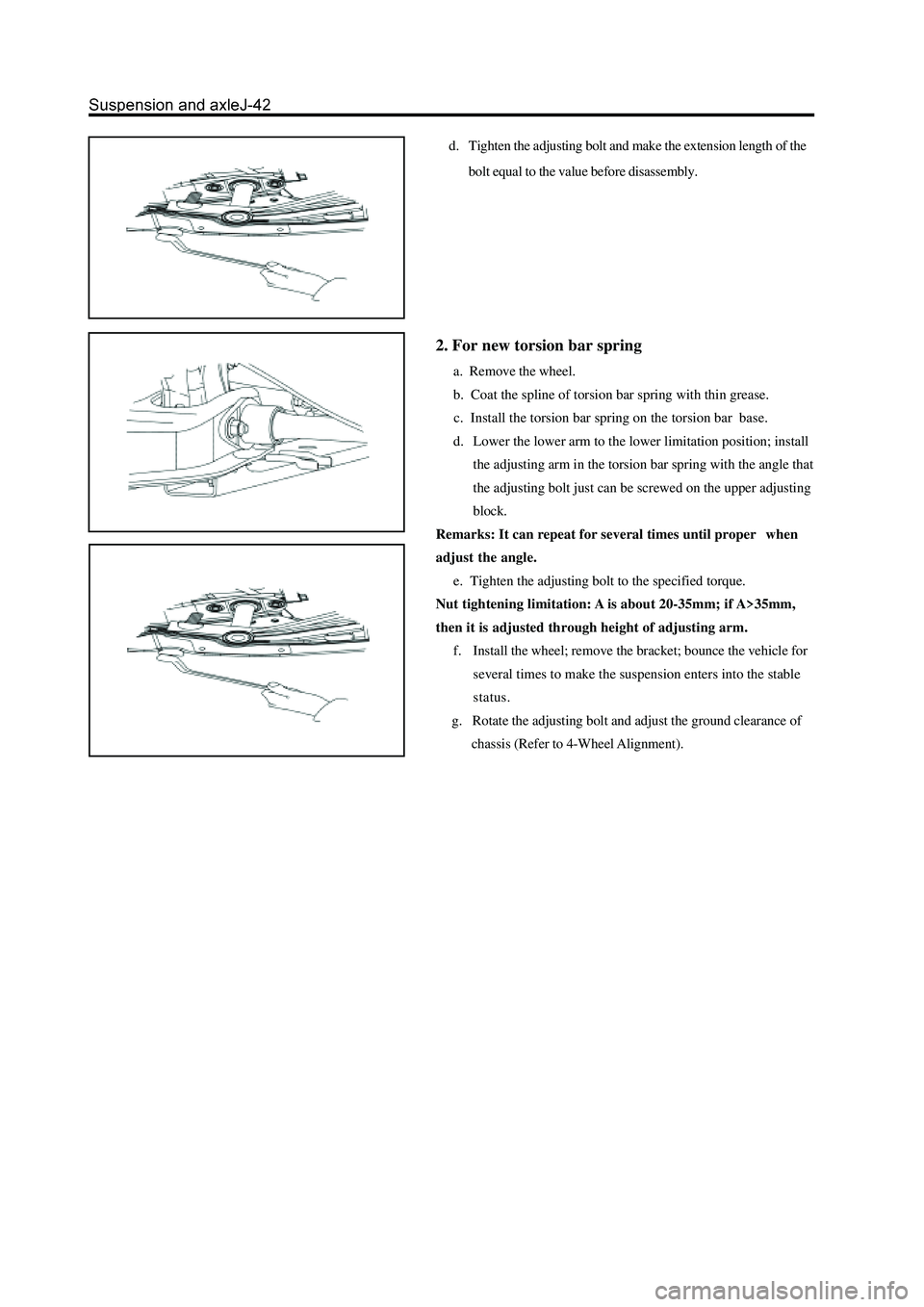

d. Tighten the adjusting bolt and make the extension length of the

bolt equal to the value before disassembly.

2. For new torsion bar spring

a. Remove the wheel.

b. Coat the spline of torsion bar spring with thin grease.

c. Install the torsion bar spring on the torsion bar base.

d. Lower the lower arm to the lower limitation position; install

the adjusting arm in the torsion bar spring with the angle that

the adjusting bolt just can be screwed on the upper adjusting

block.

Remarks: It can repeat for several times until proper when

adjust the angle.

e. Tighten the adjusting bolt to the specified torque.

Nut tightening limitation: A is about 20-35mm; if A>35mm,

then it is adjusted through height of adjusting arm.

f. Install the wheel; remove the bracket; bounce the vehicle for

several times to make the suspension enters into the stable

status.

g. Rotate the adjusting bolt and adjust the ground clearance of

chassis (Refer to 4-Wheel Alignment).

Page 285 of 425

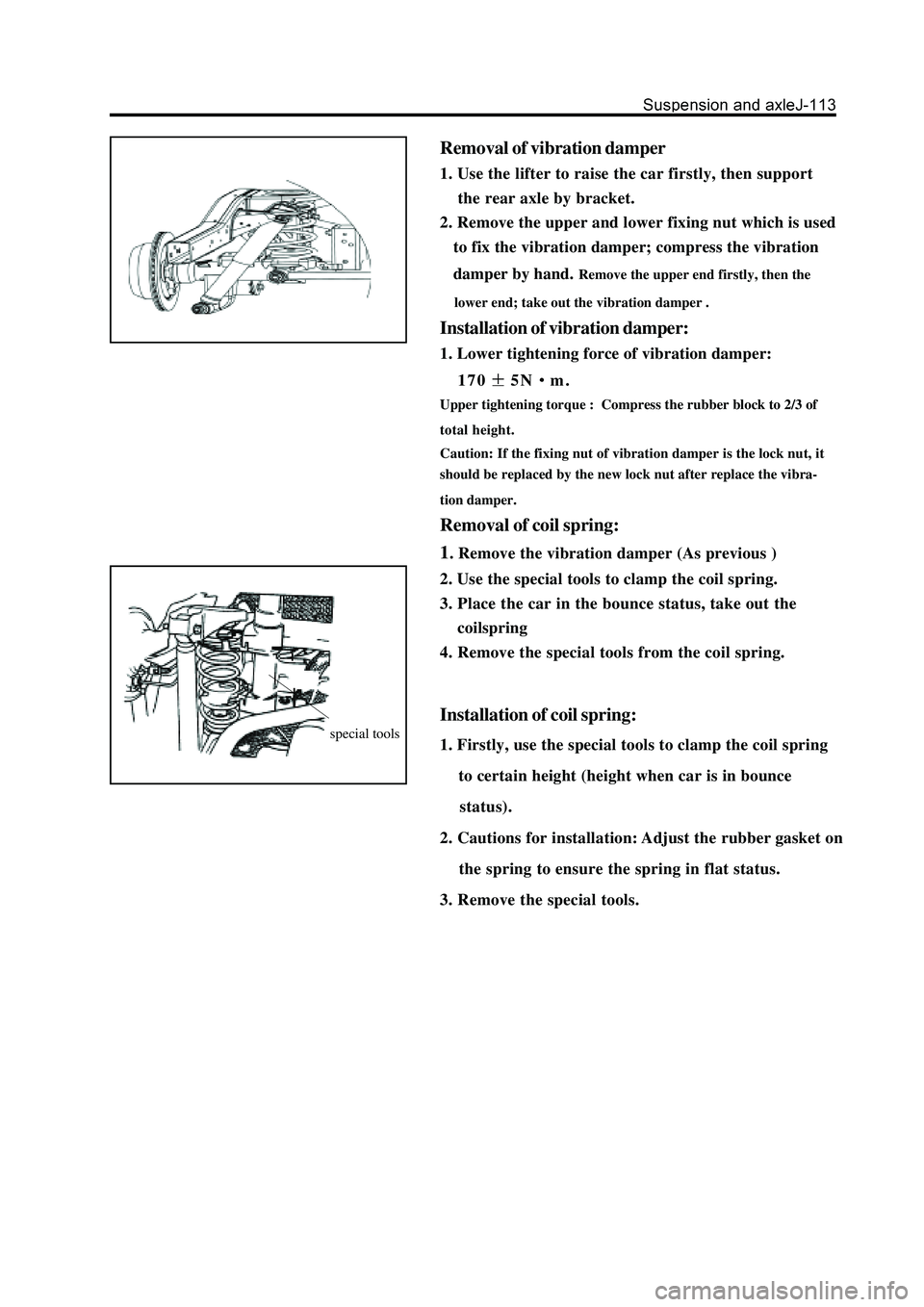

Removal of vibration damper

1. Use the lifter to raise the car firstly, then support

the rear axle by bracket.

2. Remove the upper and lower fixing nut which is used

to fix the vibration damper; compress the vibration

damper by hand.

Remove the upper end firstly, then the

lower end; take out the vibration damper .

Installation of vibration damper:

1. Lower tightening force of vibration damper:

170

5Nm.

Upper tightening torque : Compress the rubber block to 2/3 of

total height.

Caution: If the fixing nut of vibration damper is the lock nut, it

should be replaced by the new lock nut after replace the vibra-

tion damper.

Removal of coil spring:

1

. Remove the vibration damper (As previous )

2. Use the special tools to clamp the coil spring.

3. Place the car in the bounce status, take out the

coilspring

4. Remove the special tools from the coil spring.

Installation of coil spring:

1. Firstly, use the special tools to clamp the coil spring

to certain height (height when car is in bounce

status).

2. Cautions for installation: Adjust the rubber gasket on

the spring to ensure the spring in flat status.

3. Remove the special tools.special tools

Page 291 of 425

Brake-5

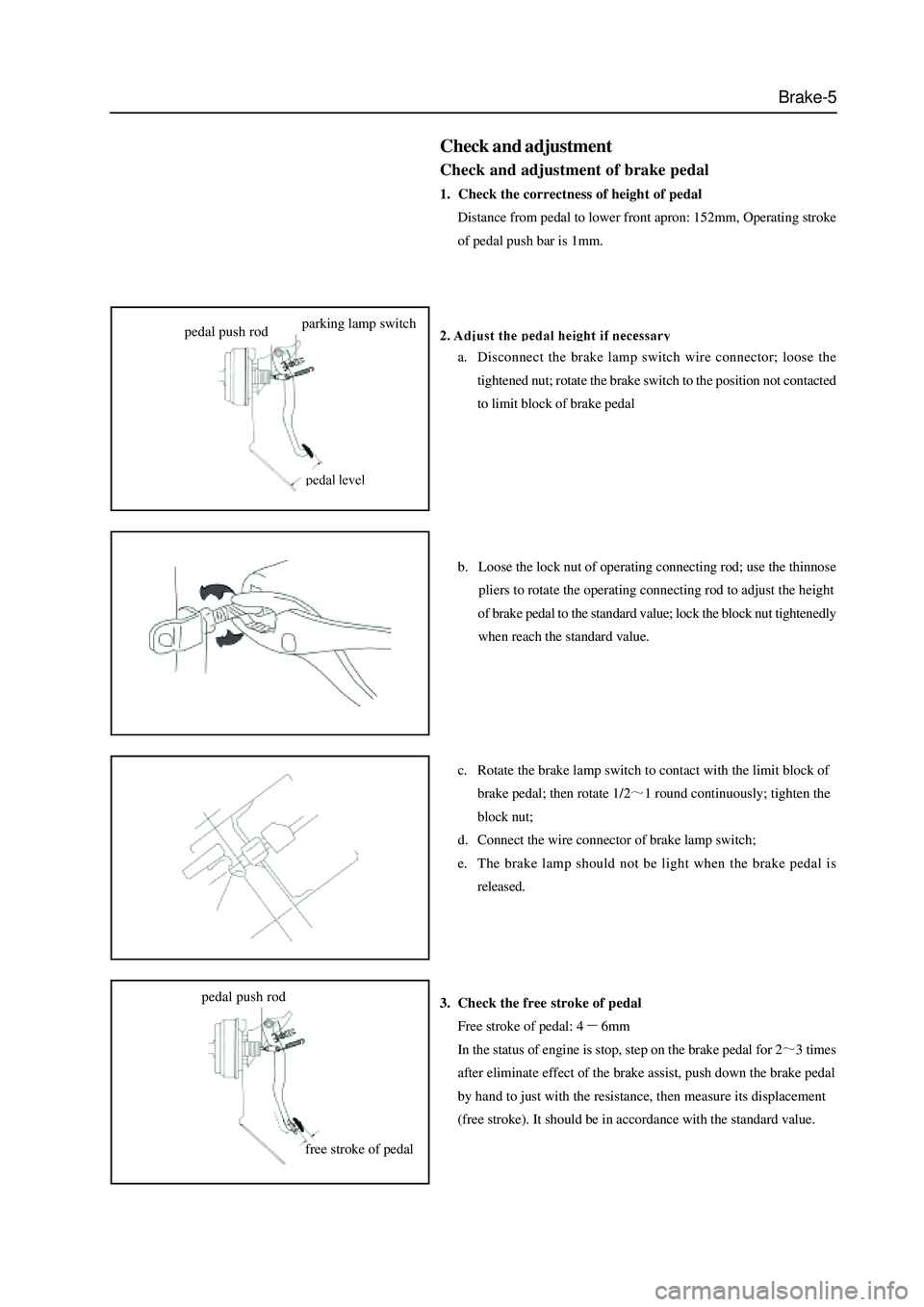

Check and adjustment

Check and adjustment of brake pedal

1. Check the correctness of height of pedal

Distance from pedal to lower front apron: 152mm, Operating stroke

of pedal push bar is 1mm.

a. Disconnect the brake lamp switch wire connector; loose the

tightened nut; rotate the brake switch to the position not contacted

to limit block of brake pedal

b. Loose the lock nut of operating connecting rod; use the thinnose

pliers to rotate the operating connecting rod to adjust the height

of brake pedal to the standard value; lock the block nut tightenedly

when reach the standard value.

c. Rotate the brake lamp switch to contact with the limit block of

brake pedal; then rotate 1/2

1 round continuously; tighten the

block nut;

d. Connect the wire connector of brake lamp switch;

e. The brake lamp should not be light when the brake pedal is

released.

3. Check the free stroke of pedal

Free stroke of pedal: 4

6mm

In the status of engine is stop, step on the brake pedal for 2

3 times

after eliminate effect of the brake assist, push down the brake pedal

by hand to just with the resistance, then measure its displacement

(free stroke). It should be in accordance with the standard value.

pedal push rodparking lamp switch

free stroke of pedal pedal push rod

Page 292 of 425

Brake-6

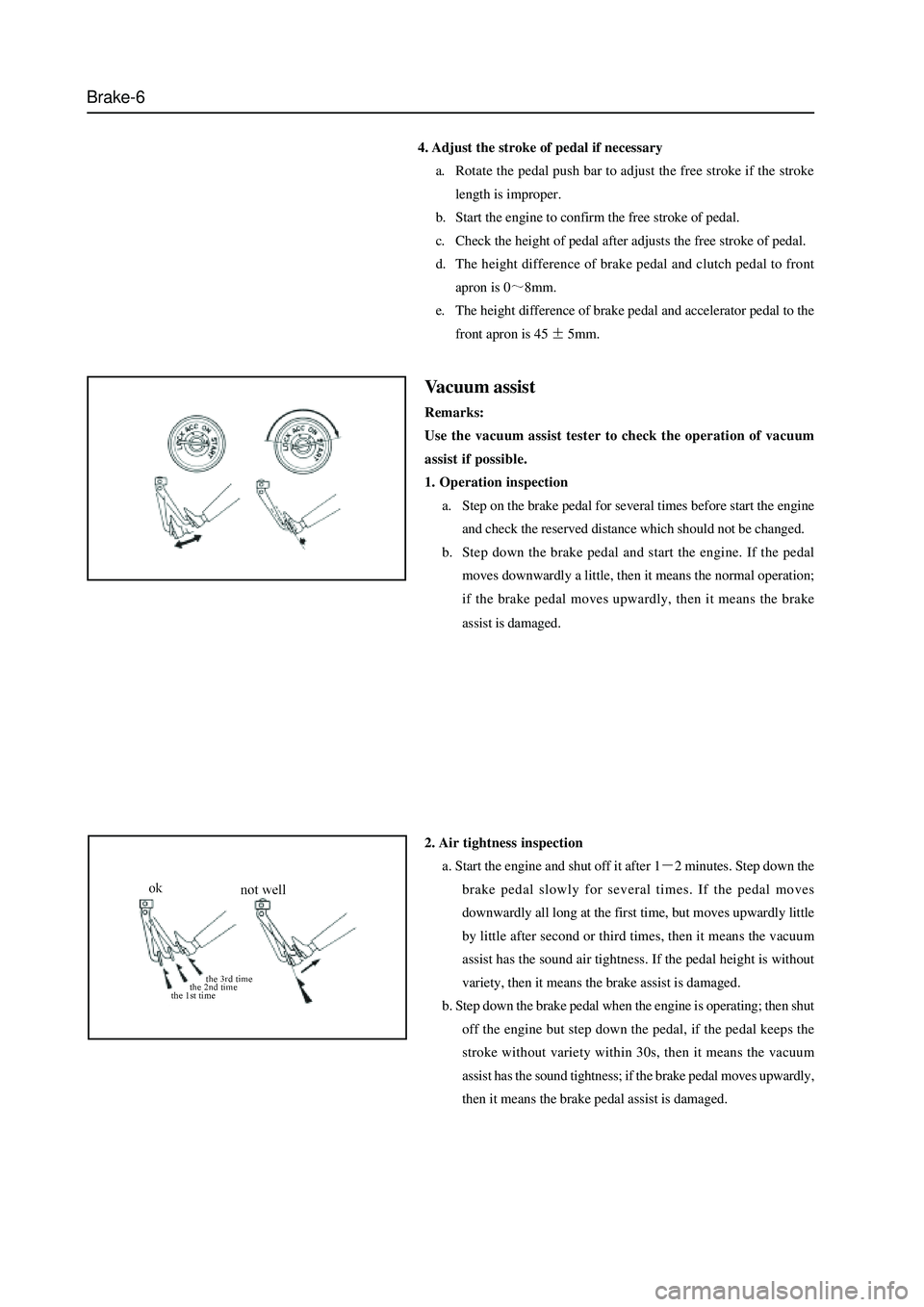

4. Adjust the stroke of pedal if necessary

a. Rotate the pedal push bar to adjust the free stroke if the stroke

length is improper.

b. Start the engine to confirm the free stroke of pedal.

c. Check the height of pedal after adjusts the free stroke of pedal.

d. The height difference of brake pedal and clutch pedal to front

apron is 0

8mm.

e. The height difference of brake pedal and accelerator pedal to the

front apron is 45

5mm.

Vacuum assist

Remarks:

Use the vacuum assist tester to check the operation of vacuum

assist if possible.

1. Operation inspection

a. Step on the brake pedal for several times before start the engine

and check the reserved distance which should not be changed.

b. Step down the brake pedal and start the engine. If the pedal

moves downwardly a little, then it means the normal operation;

if the brake pedal moves upwardly, then it means the brake

assist is damaged.

2. Air tightness inspection

a. Start the engine and shut off it after 1

2 minutes. Step down the

brake pedal slowly for several times. If the pedal moves

downwardly all long at the first time, but moves upwardly little

by little after second or third times, then it means the vacuum

assist has the sound air tightness. If the pedal height is without

variety, then it means the brake assist is damaged.

b. Step down the brake pedal when the engine is operating; then shut

off the engine but step down the pedal, if the pedal keeps the

stroke without variety within 30s, then it means the vacuum

assist has the sound tightness; if the brake pedal moves upwardly,

then it means the brake pedal assist is damaged.

Page 414 of 425

Appendix A-8

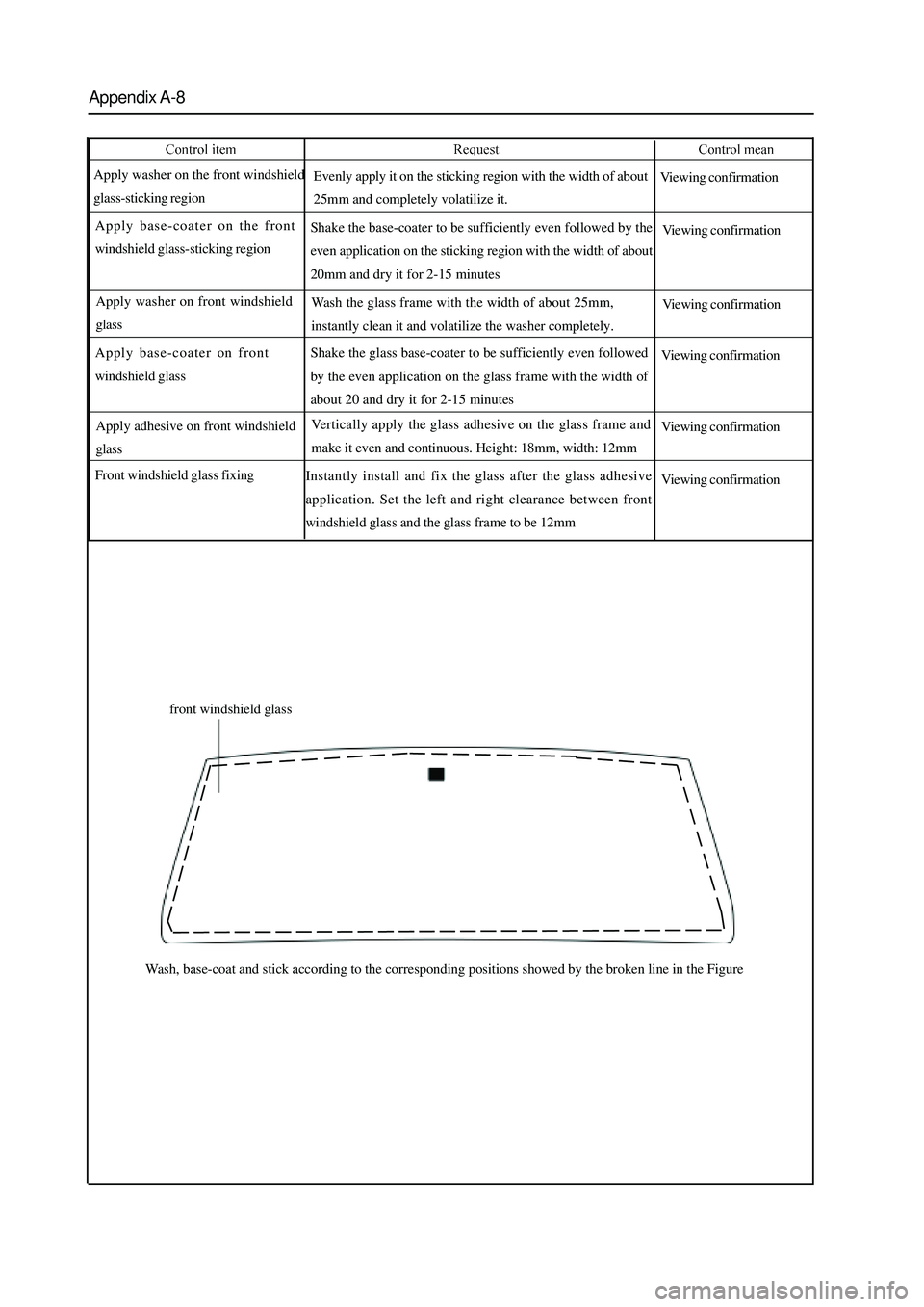

front windshield glass

Apply washer on the front windshield

glass-sticking regionEvenly apply it on the sticking region with the width of about

25mm and completely volatilize it.Viewing confirmation

Viewing confirmation Apply base-coater on the front

windshield glass-sticking regionShake the base-coater to be sufficiently even followed by the

even application on the sticking region with the width of about

20mm and dry it for 2-15 minutes

Apply washer on front windshield

glassWash the glass frame with the width of about 25mm,

instantly clean it and volatilize the washer completely.

Apply adhesive on front windshield

glassShake the glass base-coater to be sufficiently even followed

by the even application on the glass frame with the width of

about 20 and dry it for 2-15 minutes Apply base-coater on front

windshield glass

Vertically apply the glass adhesive on the glass frame and

make it even and continuous. Height: 18mm, width: 12mm

Front windshield glass fixing

Instantly install and fix the glass after the glass adhesive

application. Set the left and right clearance between front

windshield glass and the glass frame to be 12mmViewing confirmation

Viewing confirmation

Viewing confirmation

Viewing confirmation

Wash, base-coat and stick according to the corresponding positions showed by the broken line in the Figure

Page 415 of 425

Appendix A-9

Viewing confirmation

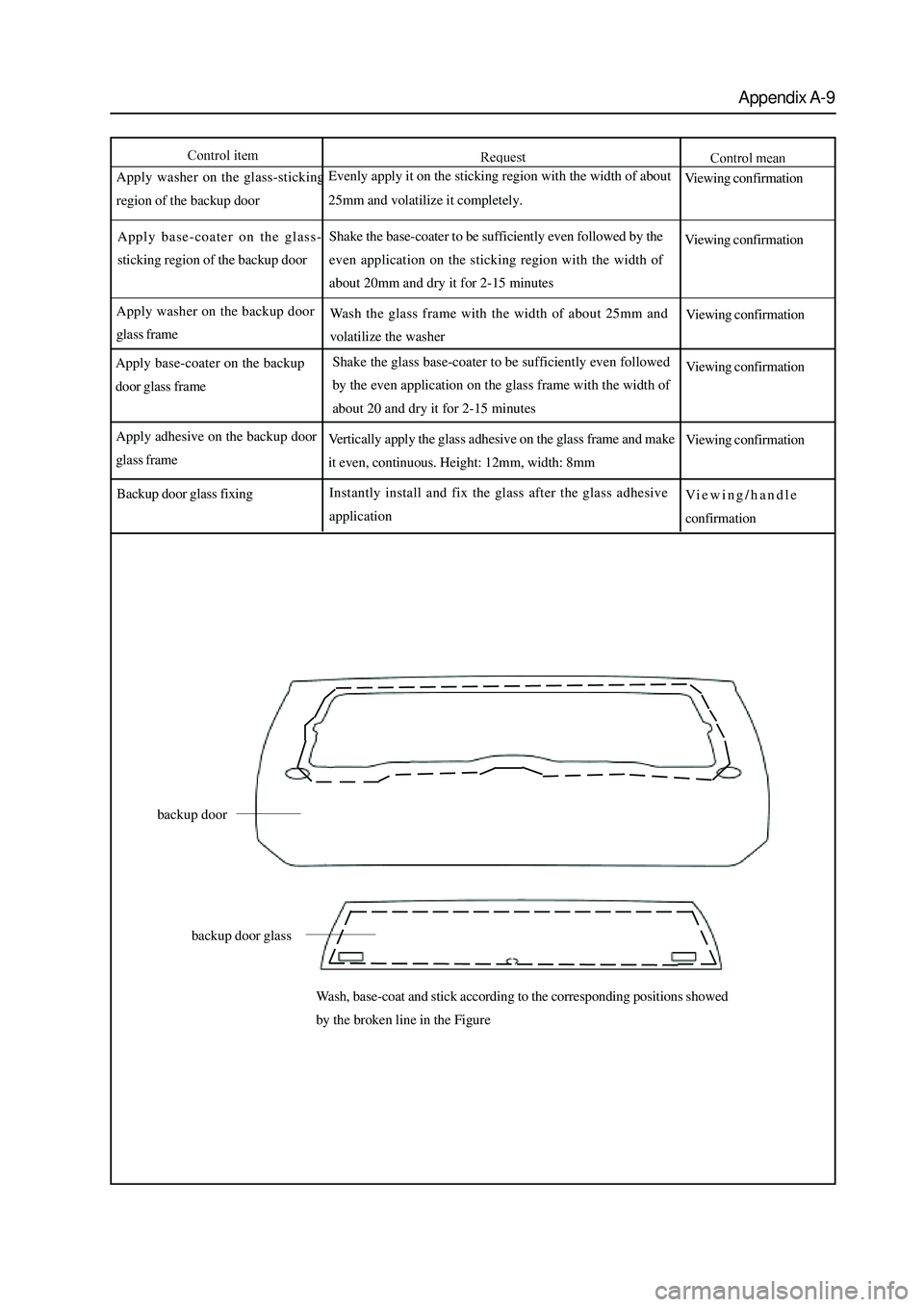

backup door

backup door glass

Wash, base-coat and stick according to the corresponding positions showed

by the broken line in the Figure

Apply washer on the glass-sticking

region of the backup doorViewing confirmation

Viewing confirmation

Shake the glass base-coater to be sufficiently even followed

by the even application on the glass frame with the width of

about 20 and dry it for 2-15 minutesViewing confirmation

Viewing confirmation

Evenly apply it on the sticking region with the width of about

25mm and volatilize it completely.

Shake the base-coater to be sufficiently even followed by the

even application on the sticking region with the width of

about 20mm and dry it for 2-15 minutes

Wash the glass frame with the width of about 25mm and

volatilize the washer Apply base-coater on the glass-

sticking region of the backup door

Apply washer on the backup door

glass frame

Apply base-coater on the backup

door glass frame

Apply adhesive on the backup door

glass frame

Backup door glass fixingInstantly install and fix the glass after the glass adhesive

application Vertically apply the glass adhesive on the glass frame and make

it even, continuous. Height: 12mm, width: 8mm

Viewing/handle

confirmation

Page 416 of 425

Appendix A-10

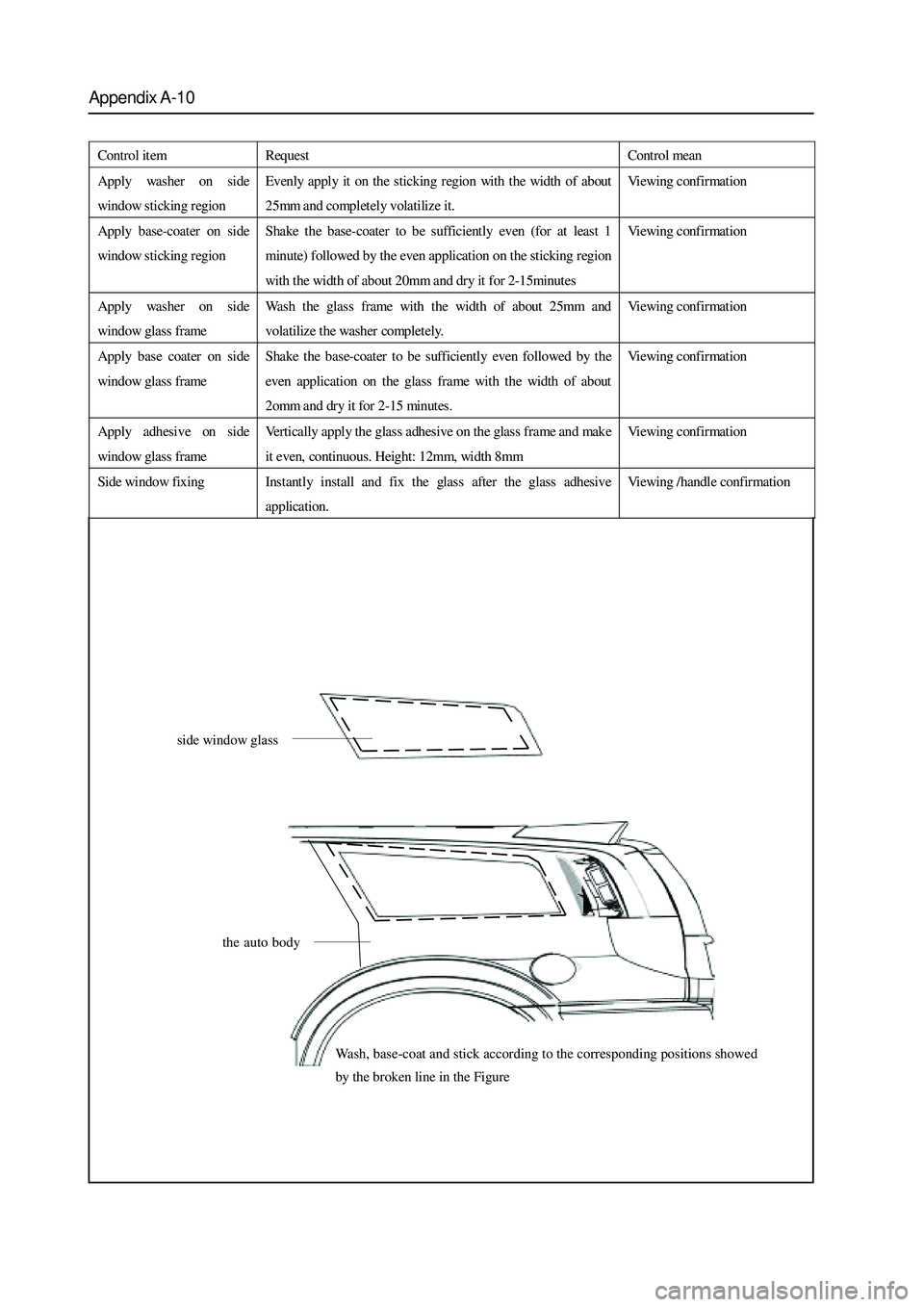

Wash, base-coat and stick according to the corresponding positions showed

by the broken line in the Figure

the auto body

side window glass

Control it em Request Control mean

Apply washer on side

window sticking region Evenly apply it on the sticking region with the width of about

25mm and completely volatilize it. Vi e w i n g c o n f i r ma t i o n

Apply base-coater on side

window sticking region Shake the base-coater to be sufficiently even (for at least 1

minute) followed by the even application on the sticking region

with the width of about 20mm and dry it for 2-15minutes Vi e w i n g c o n f i r ma t i o n

Apply washer on side

window glass frame Wash the glass frame with the width of about 25mm and

volatilize the washer completely. Vi e w i n g c o n f i r ma t i o n

Apply base coater on side

window glass frame Shake the base-coater to be sufficiently even followed by the

even application on the glass frame with the width of about

2omm and dry it for 2-15 minutes. Vi e w i n g c o n f i r ma t i o n

Apply adhesive on side

window glass frame Vertically apply the glass adhesive on the glass frame and make

it even, continuous. Height: 12mm, width 8mm Vi e w i n g c o n f i r ma t i o n

Side window fixing Instantly install and fix the glass after the glass adhesive

application. Viewing /handle confirmation