ignition GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 376 of 425

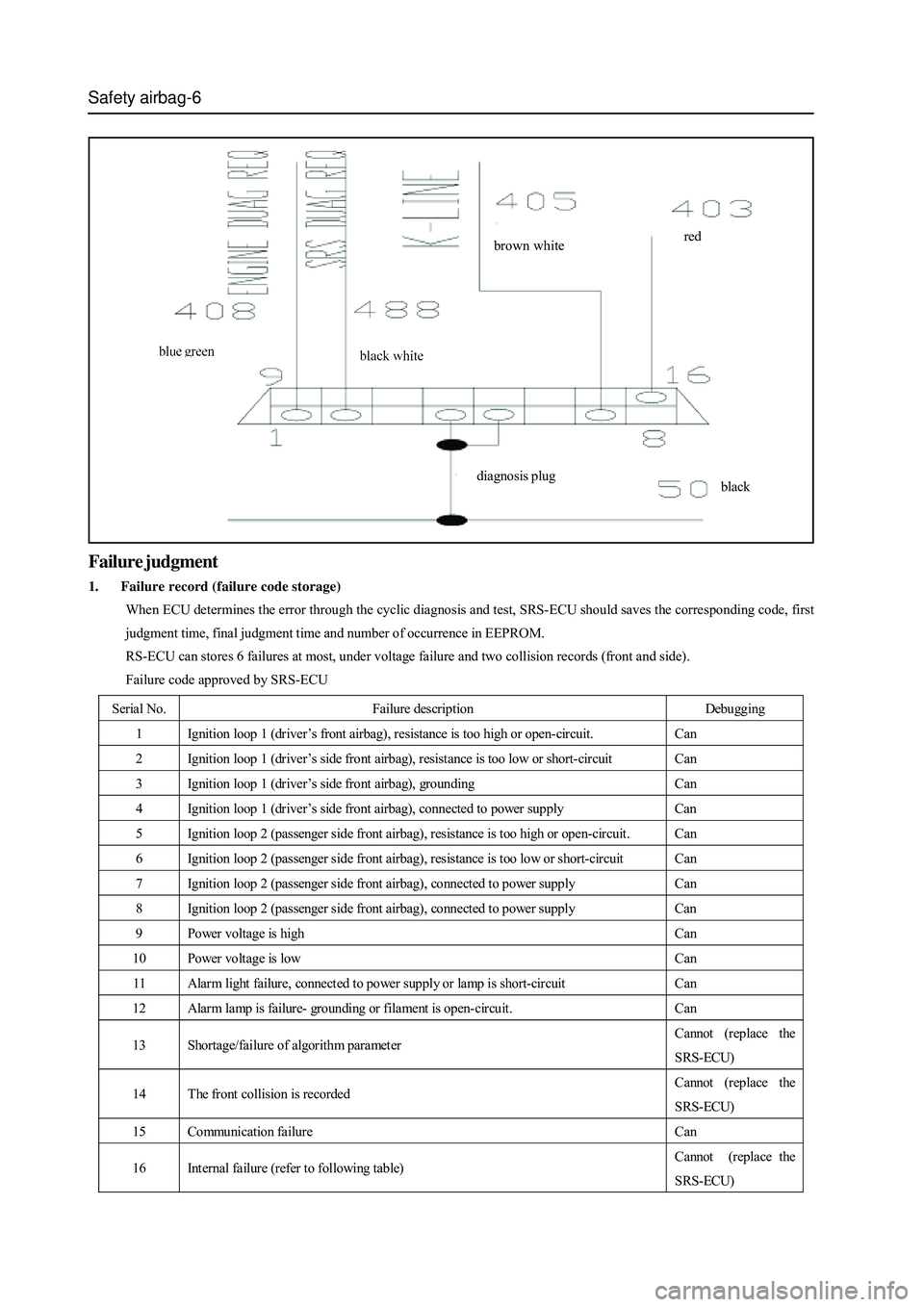

Safety airbag-6

brown whitered

diagnosis plug

black

Failure judgment

1. Failure record (failure code storage)

When ECU determines the error through the cyclic diagnosis and test, SRS-ECU should saves the corresponding code, first

judgment time, final judgment time and number of occurrence in EEPROM.

RS-ECU can stores 6 failures at most, under voltage failure and two collision records (front and side).

Failure code approved by SRS-ECU

Serial No. Failure description Debugging

1 Ignition loop 1 (driver ’s front airbag), resistance is too high or open-circuit. Can

2 Ignition loop 1 (driver ’s side front airbag), resistance is too low or short-circuit Can

3 Ignition loop 1 (driver ’s side front airbag), grounding Can

4 Ignition loop 1 (driver’s side front airbag), connected to power supply Can

5 Ignition loop 2 (passenger side front airbag), resistance is too high or open-circuit. Can

6 Ignition loop 2 (passenger side front airbag), resistance is too low or short-circuit Can

7 Ignition loop 2 (passenger side front airbag), connect ed t o power supply Can

8 Ignition loop 2 (passenger side front airbag), connect ed t o power supply Can

9 Power voltage is high Can

10 Power voltage is low Can

11 Alarm light failure, connect ed to power supply or lamp is short-circuit Can

12 Alarm lamp is failure- grounding or filament is open-circuit. Can

13 Shortage/failure of algorithm parameter Cannot (replace the

SRS-ECU)

14 The front collision is recorded Cannot (replace the

SRS-ECU)

15 Communication failure Can

16 Internal failure (refer to following table) Cannot (replace the

SRS-ECU)

Page 377 of 425

Safety airbag-7

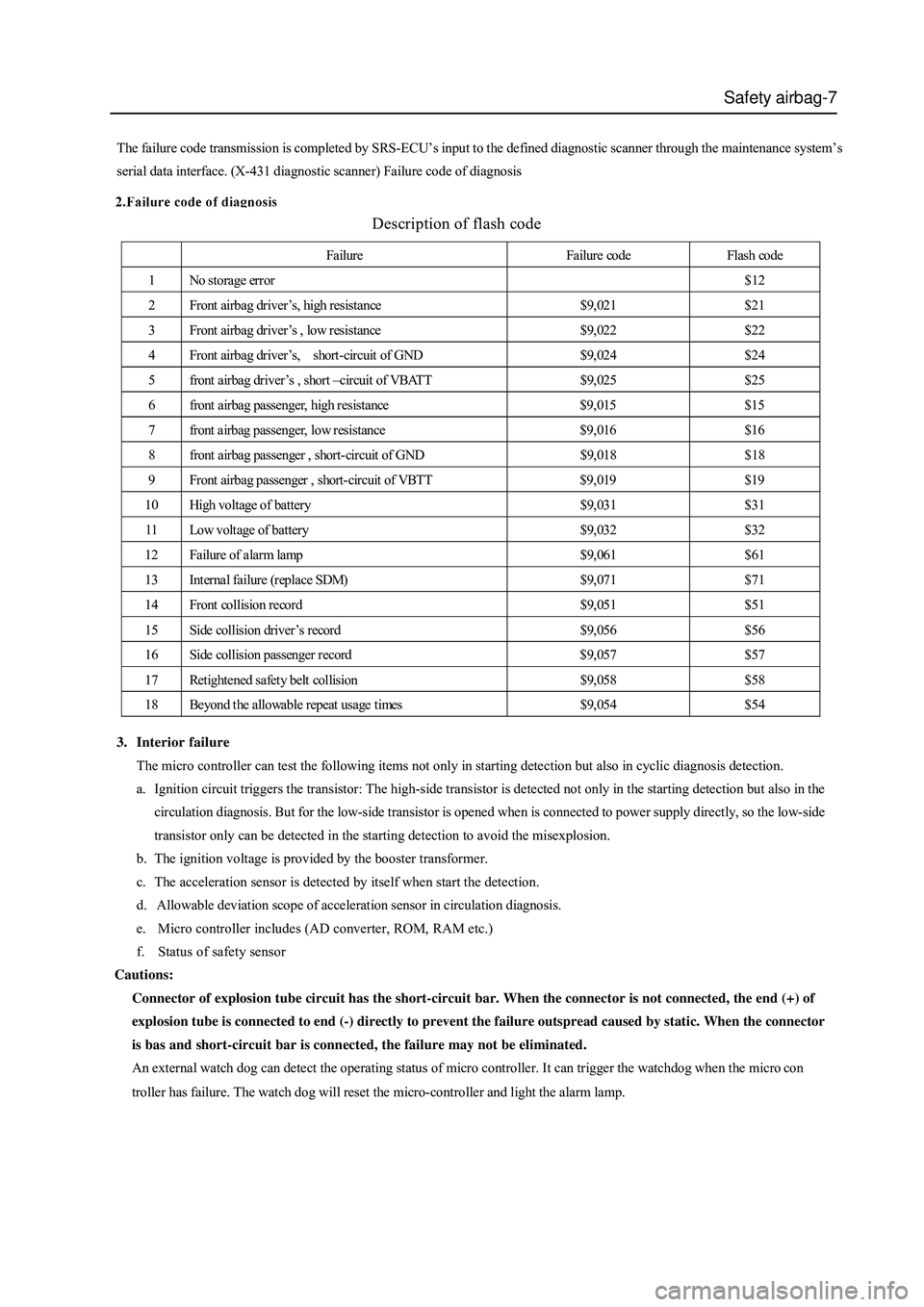

Description of flash code

The failure code transmission is completed by SRS-ECU’s input to the defined diagnostic scanner through the maintenance system’s

serial data interface. (X-431 diagnostic scanner) Failure code of diagnosis

Failure Failure code Flash code

1 No storage error $12

2 Front airbag driver’s, high resistance $9,021 $21

3 Front airbag driver’s , low resistance $9,022 $22

4 Front airbag driver ’s, short-circuit of GND $9,024 $24

5 front airbag driver ’s , short –circuit of VBATT $9,025 $25

6 front airbag passenger, high resistance $9,015 $15

7 front airbag passenger, low resistance $9,016 $16

8 front airbag passenger , short-circuit of GND $9,018 $18

9 Front airbag passenger , short-circuit of VBTT $9,019 $19

10 High voltage of battery $9,031 $31

11 Low voltage of battery $9,032 $32

12 Failure of alarm lamp $9,061 $61

13 Internal failure (replace SDM) $9,071 $71

14 Front collision record $9,051 $51

15 Side collision driver’s record $9,056 $56

16 Side collision passenger record $9,057 $57

17 Retightened safety belt collision $9,058 $58

18 Beyond the allowable repeat usage times $9,054 $54

3. Interior failure

The micro controller can test the following items not only in starting detection but also in cyclic diagnosis detection.

a. Ignition circuit triggers the transistor: The high-side transistor is detected not only in the starting detection but also in the

circulation diagnosis. But for the low-side transistor is opened when is connected to power supply directly, so the low-side

transistor only can be detected in the starting detection to avoid the misexplosion.

b. The ignition voltage is provided by the booster transformer.

c. The acceleration sensor is detected by itself when start the detection.

d. Allowable deviation scope of acceleration sensor in circulation diagnosis.

e. Micro controller includes (AD converter, ROM, RAM etc.)

f. Status of safety sensor

Cautions:

Connector of explosion tube circuit has the short-circuit bar. When the connector is not connected, the end (+) of

explosion tube is connected to end (-) directly to prevent the failure outspread caused by static. When the connector

is bas and short-circuit bar is connected, the failure may not be eliminated.

An external watch dog can detect the operating status of micro controller. It can trigger the watchdog when the micro con

troller has failure. The watch dog will reset the micro-controller and light the alarm lamp.

Page 378 of 425

Safety airbag-8

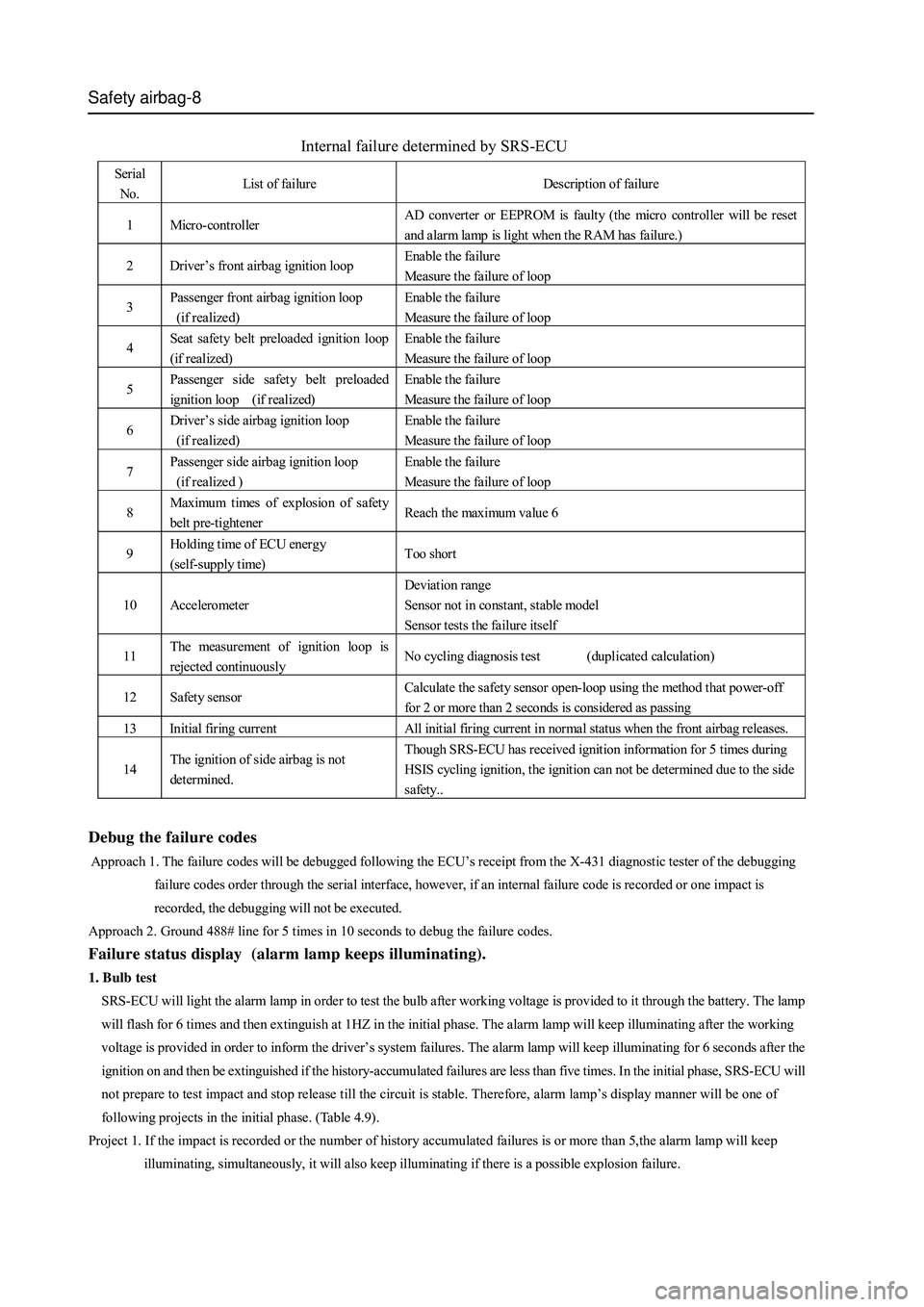

Internal failure determined by SRS-ECU

Serial

No. List of failure Description of failure

1 Micro-controller AD converter or EEPROM is faulty (the micro controller will be reset

and alarm lamp is light when the RAM has failure.)

2 Driver’s front airbag ignition loop Enable the failure

Measure the failure of loop

3 Passenger front airbag ignition loop

(if realized) Enable the failure

Measure the failure of loop

4 Seat safety belt preloaded ignition loop

(if realized) Enable the failure

Measure the failure of loop

5 Passenger side safety belt preloaded

ignition loop (if realized) Enable the failure

Measure the failure of loop

6 Driver’s side airbag ignition loop

(if realized) Enable the failure

Measure the failure of loop

7 Passenger side airbag ignition loop

(if realized ) Enable the failure

Measure the failure of loop

8 Maximum times of explosion of safet y

belt pre-tightener Reach the maximum value 6

9 Holding time of ECU ener gy

(self-supply time) Too short

10 Accelerometer Deviation range

Sensor not in constant, stable model

Sensor tests the failure itself

11 The measurement of ignition loop is

rejected continuously No cycling diagnosis test (duplicated calculation)

12 Safety sensor Calculate the safety sensor open-loop using the method that power-off

for 2 or more than 2 seconds is considered as passing

13 Initial firing current All initial firing current in normal status when the front airbag releases.

14 The ignition of side airbag is not

determined. Though SRS-ECU has received ignition information for 5 times during

HSIS cycling ignition, the ignition can not be determined due to the side

safety..

Debug the failure codes

Approach 1. The failure codes will be debugged following the ECU’s receipt from the X-431 diagnostic tester of the debugging

failure codes order through the serial interface, however, if an internal failure code is recorded or one impact is

recorded, the debugging will not be executed.

Approach 2. Ground 488# line for 5 times in 10 seconds to debug the failure codes.

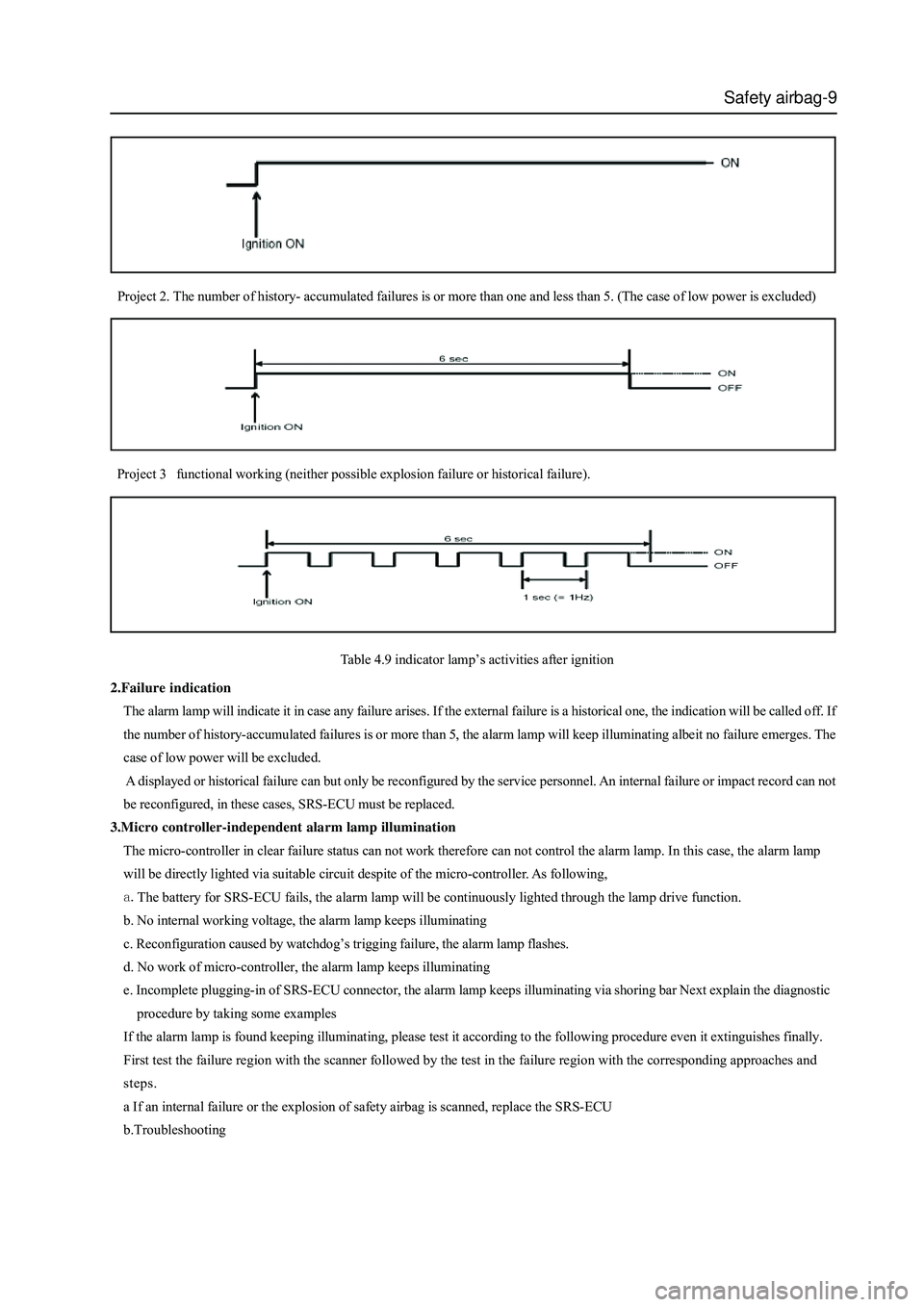

Failure status display (alarm lamp keeps illuminating).

1. Bulb test

SRS-ECU will light the alarm lamp in order to test the bulb after working voltage is provided to it through the battery. The lamp

will flash for 6 times and then extinguish at 1HZ in the initial phase. The alarm lamp will keep illuminating after the working

voltage is provided in order to inform the driver’s system failures. The alarm lamp will keep illuminating for 6 seconds after the

ignition on and then be extinguished if the history-accumulated failures are less than five times. In the initial phase, SRS-ECU will

not prepare to test impact and stop release till the circuit is stable. Therefore, alarm lamp’s display manner will be one of

following projects in the initial phase. (Table 4.9).

Project 1. If the impact is recorded or the number of history accumulated failures is or more than 5,the alarm lamp will keep

illuminating, simultaneously, it will also keep illuminating if there is a possible explosion failure.

Page 379 of 425

Safety airbag-9

Project 3 functional working (neither possible explosion failure or historical failure).

Table 4.9 indicator lamp’s activities after ignition

2.Failure indication

The alarm lamp will indicate it in case any failure arises. If the external failure is a historical one, the indication will be called off. If

the number of history-accumulated failures is or more than 5, the alarm lamp will keep illuminating albeit no failure emerges. The

case of low power will be excluded.

A displayed or historical failure can but only be reconfigured by the service personnel. An internal failure or impact record can not

be reconfigured, in these cases, SRS-ECU must be replaced.

3.Micro controller-independent alarm lamp illumination

The micro-controller in clear failure status can not work therefore can not control the alarm lamp. In this case, the alarm lamp

will be directly lighted via suitable circuit despite of the micro-controller. As following,

The battery for SRS-ECU fails, the alarm lamp will be continuously lighted through the lamp drive function.

b. No internal working voltage, the alarm lamp keeps illuminating

c. Reconfiguration caused by watchdog’s trigging failure, the alarm lamp flashes.

d. No work of micro-controller, the alarm lamp keeps illuminating

e. Incomplete plugging-in of SRS-ECU connector, the alarm lamp keeps illuminating via shoring bar Next explain the diagnostic

procedure by taking some examples

If the alarm lamp is found keeping illuminating, please test it according to the following procedure even it extinguishes finally.

First test the failure region with the scanner followed by the test in the failure region with the corresponding approaches and

steps.

a If an internal failure or the explosion of safety airbag is scanned, replace the SRS-ECU

b.Troubleshooting Project 2. The number of history- accumulated failures is or more than one and less than 5. (The case of low power is excluded)

Page 380 of 425

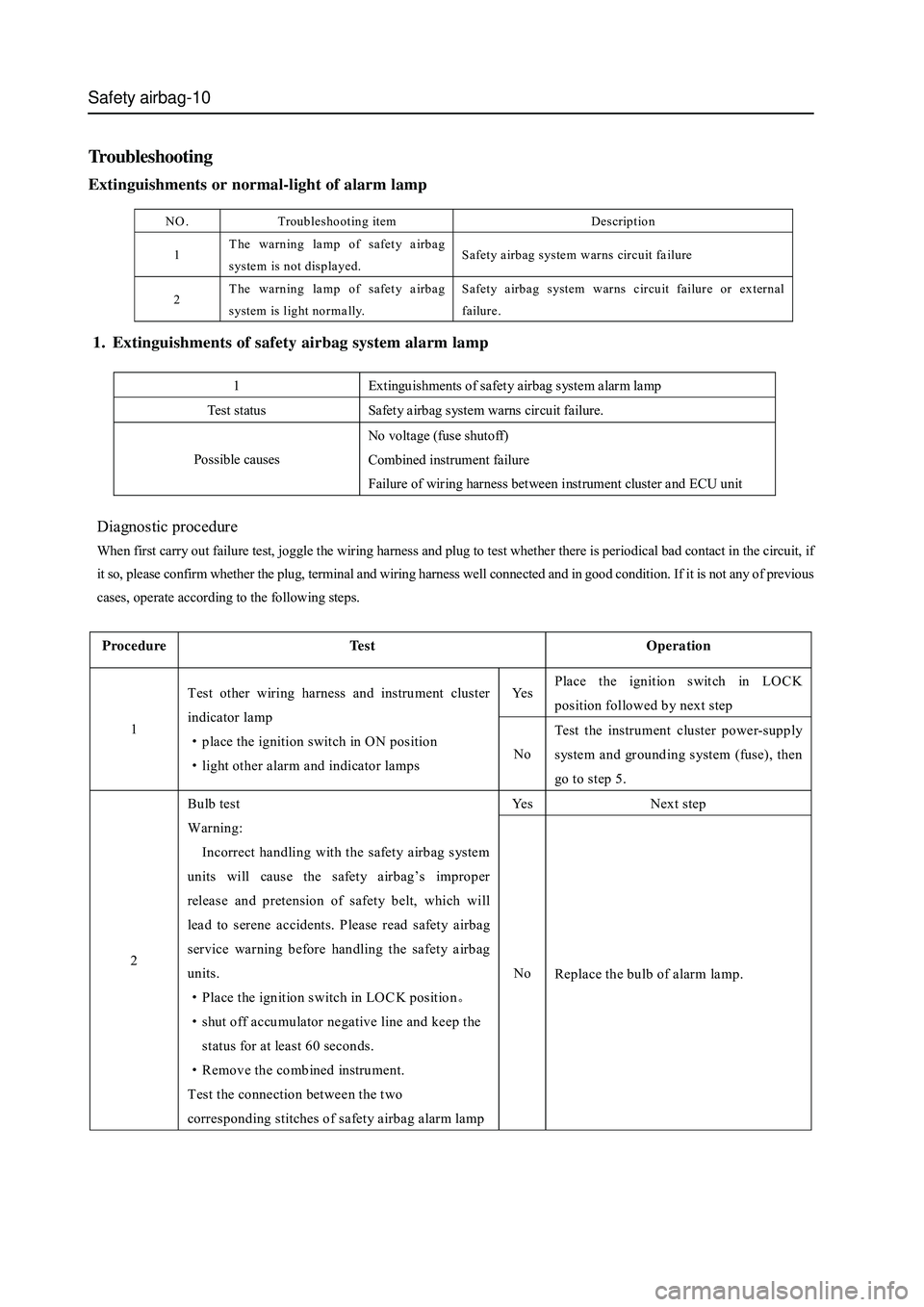

Safety airbag-10

1. Extinguishments of safety airbag system alarm lamp

Troubleshooting

Extinguishments or normal-light of alarm lamp

NO . Troubleshooting item Description

1 T he warning la mp of safety a irbag

system is not displayed. Safety airbag system warns circuit failure

2 T he warning la mp of safety a irbag

system is light normally. Safety airbag system warns circuit failure or external

failure.

1 Extinguishments of safety airbag system alarm lamp

Test status Safety airbag system warns circuit failure.

Possible causes No voltage (fuse shutoff)

Combined instrument failure

Failure of wiring harness between instrument cluster and ECU unit

Diagnostic procedure

When first carry out failure test, joggle the wiring harness and plug to test whether there is periodical bad contact in the circuit, if

it so, please confirm whether the plug, terminal and wiring harness well connected and in good condition. If it is not any of previous

cases, operate according to the following steps.

Procedure Te s t Operation

Ye s Place the ignition switch in LOCK

position followed by next step

1 Test other wiring harness and instrument cluster

indicator lamp

·place the ignition switch in ON position

·light other alarm and indicator lamps No Test the instrument cluster power-supply

system and grounding s ystem (fuse), then

go to step 5.

Yes Next step

2 Bulb test

Warning:

Incorrect handling with the safety airbag system

units will cause the safety airbag’s improper

release and pretension of safety belt, which will

lead to serene accidents. Please read safety airbag

service warning before handling the safety airbag

units.

·Place the ignition switch in LOCK position。

·shut off accumulator negative line and keep the

status for at least 60 seconds.

·Remove the combined instrument.

Test the connection between the two

corresponding stitches of safety airbag alarm lamp No

Rep la ce th e b ulb of a larm la mp.

Page 381 of 425

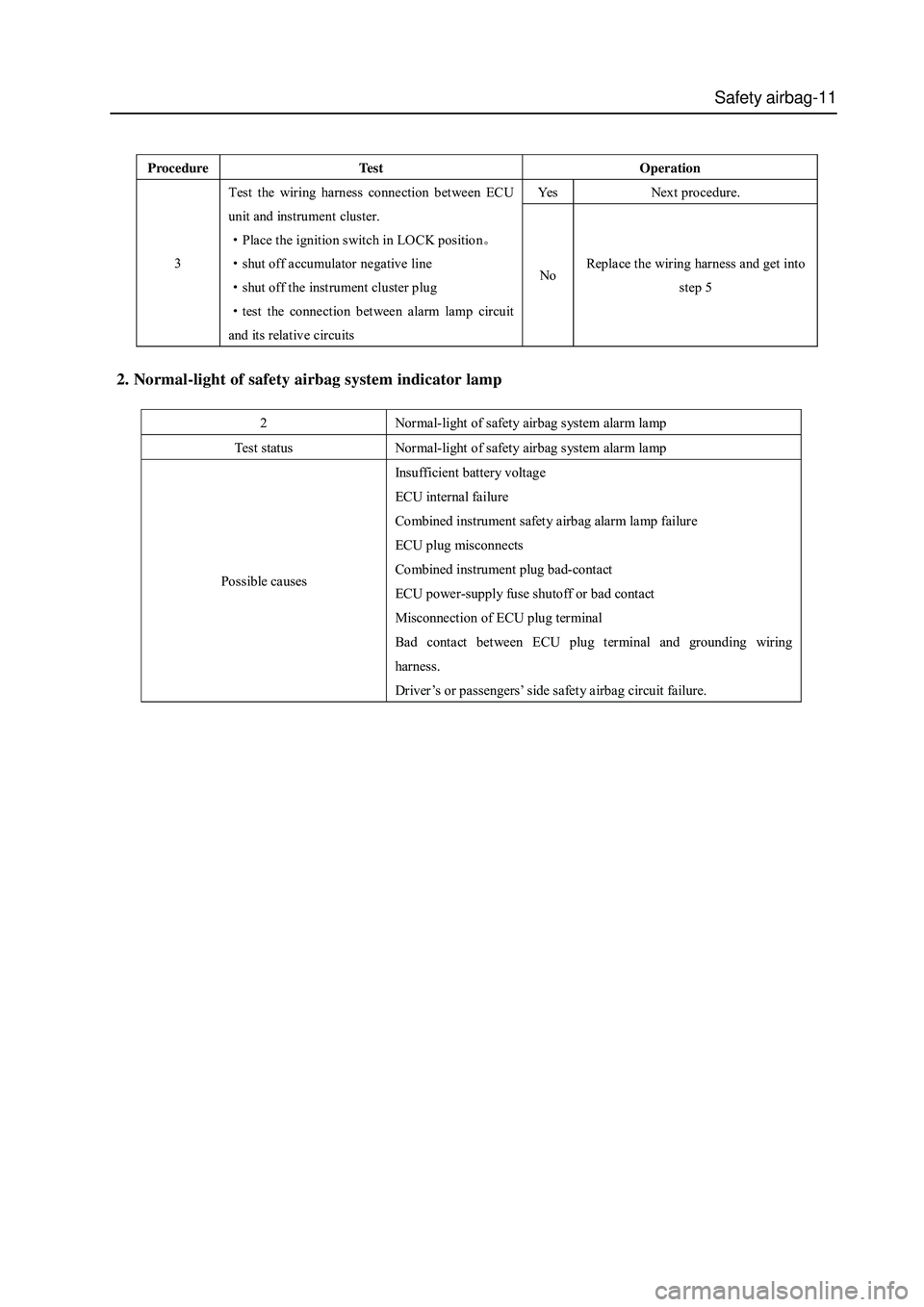

Safety airbag-11

2. Normal-light of safety airbag system indicator lamp

2 Normal-light of safety airbag system alarm lamp

Test status Normal-light of safety airbag system alarm lamp

Possible causes Insufficient battery voltage

ECU internal failure

Combined instrument safety airbag alarm lamp failure

ECU plug misconnects

Combined instrument plug bad-contact

ECU power-supply fuse shutoff or bad contact

Misconnection of ECU plug terminal

Bad contact between ECU plug terminal and grounding wiring

harness.

Driver ’s or passengers’ side safety airbag circuit failure.

Procedure Te s t Operation

Yes Next procedure.

3 Test the wiring harness connection between ECU

unit and instrument cluster.

·Place the ignition switch in LOCK position。

·shut off accumulator negative line

·shut off the instrument cluster plug

·test the connection b etween alarm lamp circuit

and its relative circuits No Replace the wiring harness and get into

step 5

Page 382 of 425

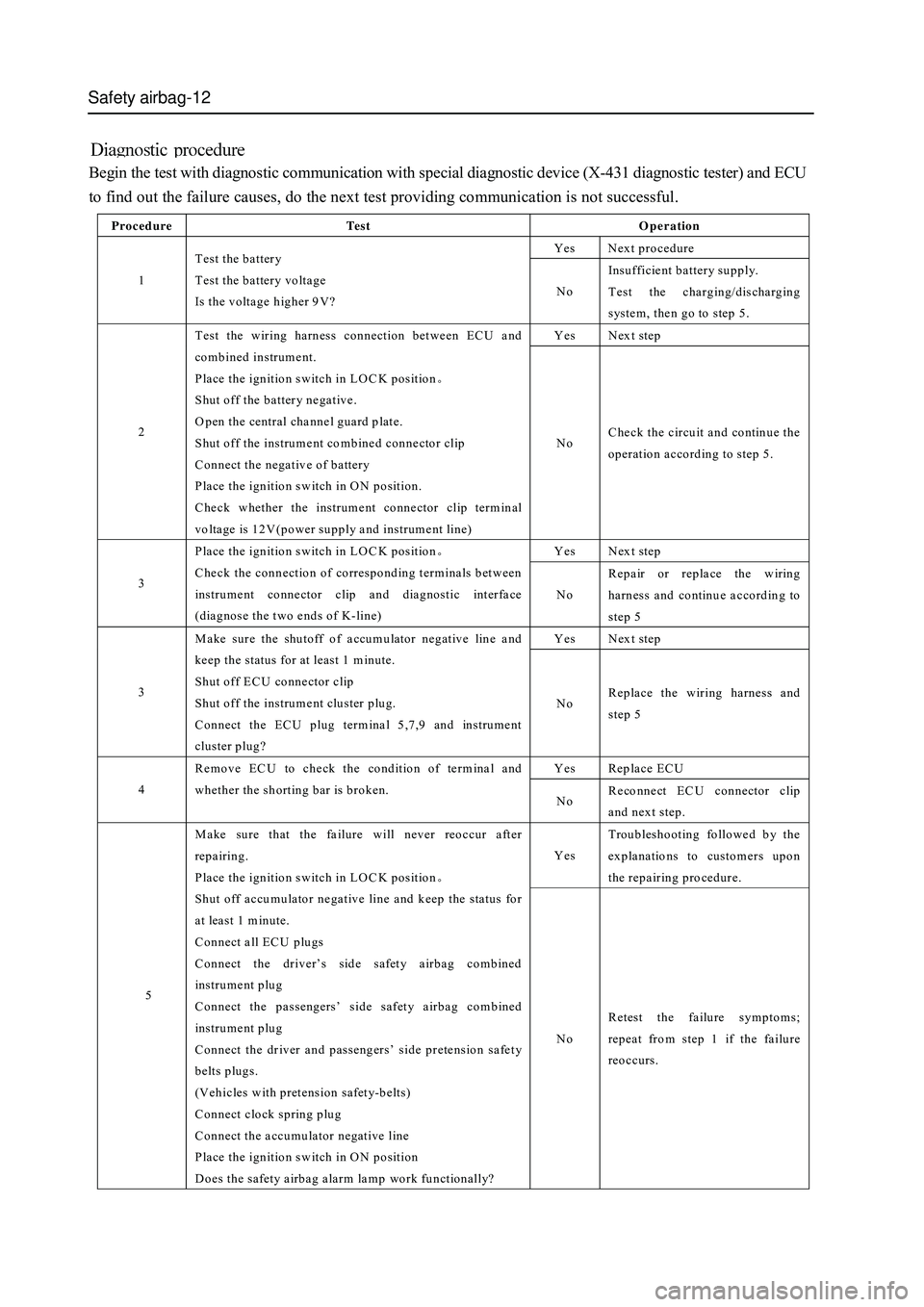

Safety airbag-12

Begin the test with diagnostic communication with special diagnostic device (X-431 diagnostic tester) and ECU

to find out the failure causes, do the next test providing communication is not successful.

Procedure Te s t Operation

Yes Next procedure

1 Test the battery

Test the battery voltage

Is the voltage higher 9V? No Insufficient battery supply.

Test the charging/discharging

system, then go to step 5.

Yes Next step

2 Test the wiring harness connection between ECU and

combined instrument.

Place the ignition switch in LO C K position。

Shut off the battery negative.

O pen the central channel guard plate.

Shut off the instrument combined connector clip

Connect the negative of battery

Place the ignition switch in ON position.

Check whether the instrument connector clip terminal

voltage is 12V(power supply and instrument line) No Check the circuit and continue the

operation according to step 5.

Yes Next step

3 Place the ignition switch in LO C K position。

Check the connection of corresponding terminals between

instrument connector clip and diagnostic interface

(diagnose the two ends of K-line) No Repair or replace the wiring

harness and continue according to

step 5

Yes Next step

3 Make sure the shutoff of accumulator negative line and

keep the status for at least 1 minute.

Shut off ECU connector clip

Shut off the instrument cluster plug.

Connect the ECU plug terminal 5,7,9 and instrument

cluster plug? No Replace the wiring harness and

step 5

Yes Replace ECU

4 Remove EC U to check the condition of term inal and

whether the shorting bar is broken.

No Reconnect EC U connector clip

and next step.

Yes Troubleshooting followed by the

explanations to customers upon

the repair ing pro ced ur e.

5

Make sure that the failure will never reoccur after

repairing.

Place the ignition switch in LO C K position。

Shut off accumulator negative line and keep the status for

at least 1 m in ute.

Connect all ECU plugs

Connect the driver’s side safety airbag combined

instrum ent p lug

Connect the passengers’ side safety airbag combined

instrum ent p lug

Connect the driver and passengers’ side pretension safety

belts plugs.

(Vehicles with pretension safety-b elts)

Connect clock spring plug

Connect the accumulator negative line

Place the ignition switch in ON position

Does the safety airbag alarm lamp work functionally? No Retest the failure symptoms;

repeat from step 1 if the failure

reoccurs.

Page 384 of 425

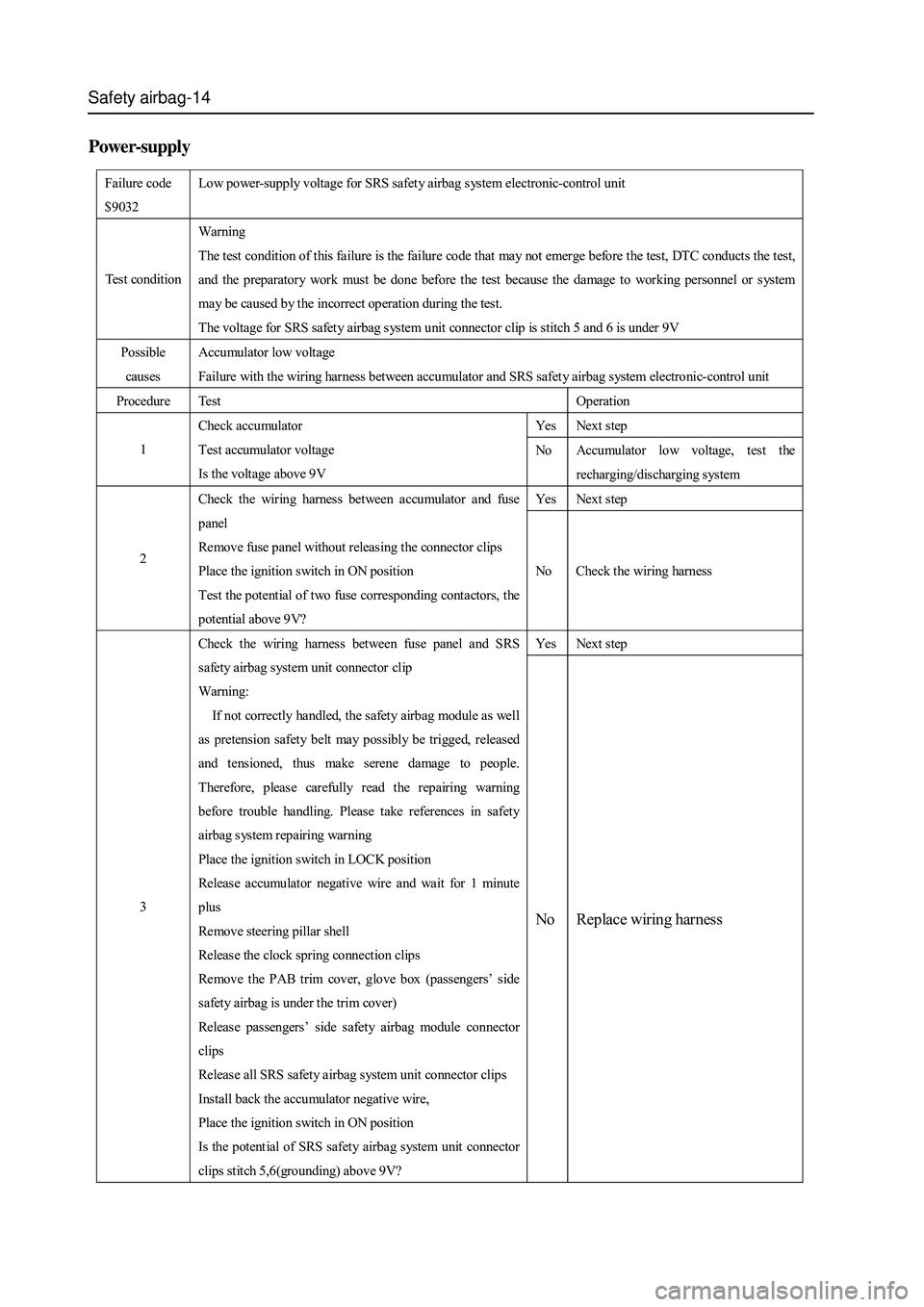

Safety airbag-14

Power-supply

Failure code

$9032 Low power-supply voltage for SRS safety airbag system electronic-control unit

Test condition Warning

The test condition of this failure is the failure code that may not emerge before the test, DTC conducts the test,

and the preparatory work must be done before the test because the damage to working personnel or system

may be caused by the incorrect op eration during the test.

The voltage for SRS safety airbag system unit connector clip is stitch 5 and 6 is under 9V

Possible

caus es Accumulator low voltage

Failure with the wiring harness between accumulator and SRS safety airbag system electronic-control unit

Procedure Test Operation

Yes Next step

1 Check accumulator

Test accumulator voltage

Is the voltage above 9V No Accumulator low voltage, test the

recharging/discharging system

Yes Next step

2 Check the wiring harness between accumulator and fuse

panel

Remove fuse panel without releasing the connector clips

Place the ignition switch in ON position

Test the potential of two fuse corresponding contactors, the

potential above 9V? No Check the wiring harness

Yes Next step

3 Check the wiring harness between fuse panel and SRS

safety airbag system unit connector clip

Warning:

If not correctly handled, the safety airbag module as well

as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people.

Ther efor e, pleas e carefully r ead the r epairing warning

before trouble handling. Please take references in safety

airbag system repairing warning

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove steering pillar shell

Release the clock spring connection clips

Remove the PAB trim cover, glove box (passengers’ side

safety airbag is under the trim cover)

Release passengers’ side safety airbag module connector

clips

Release all SRS safety airbag system unit connector clips

Install back the accumulator negative wire,

Place the ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

Page 385 of 425

Safety airbag-15

Yes Present failure codes

Replace SRS safety airbag system unit

See he removal/installation of SRS

safety airbag system unit

History accumulated failure codes

The end of failure diagnosis

4 Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute

plus

Remove the left trim cover

Shut off SRS safety airbag system unit translation

connector clips

Install back the accumulator negative wire, place the

ignition switch in ON position

Is the potential of SRS safety airbag system unit connector

clips stitch 5,6(grounding) above 9V? No Replace wiring harness

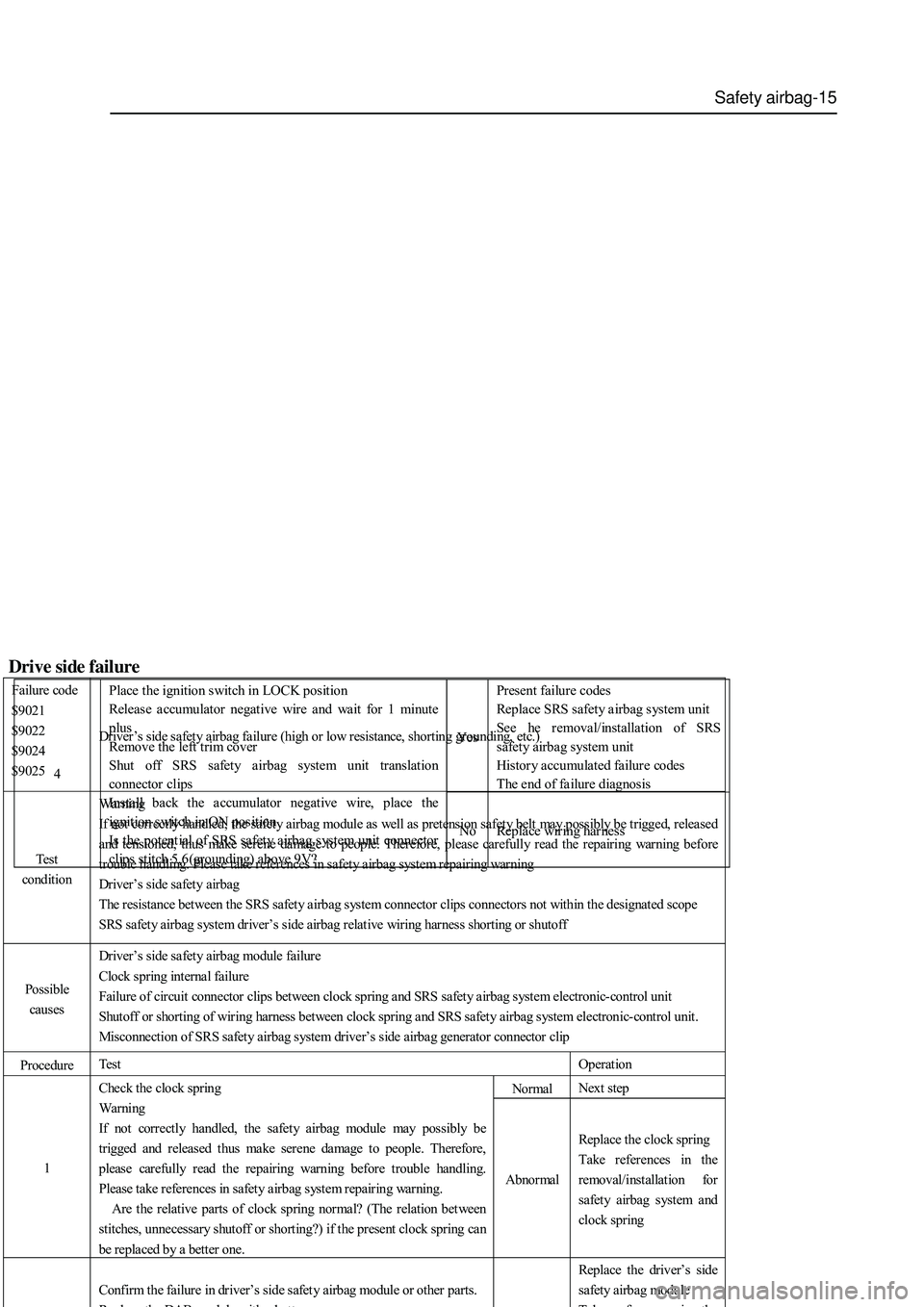

Drive side failure

Failure code

$9021

$9022

$9024

$9025 Driver ’s side safety airbag failure (high or low resistance, shorting grounding, etc.)

Tes t

condition Warni ng

If not correctly handled, the safety airbag module as well as pretension safety belt may possibly be trigged, released

and tensioned, thus make serene damage to people. Therefore, please carefully read the repairing warning before

trouble handling. Please take references in safety airbag system repairing warning

Driver’s side safety airbag

The resistance between the SRS safety airbag system connector clips connectors not within the designated scope

SRS safet y airbag system driver’s side airbag relative wiring harness shorting or shutoff

Possible

caus es Driver’s side safety airbag module failure

Clock spring internal failure

Failure of circuit connector clips between clock spring and SRS safety airbag system electronic-control unit

Shutoff or shorting of wiring harness between clock spring and SRS safety airbag system electronic-control unit.

Misconnection of SRS safety airbag system driver’s side airbag generator connector clip

Procedure Tes t Operation

Normal Next step

1 Check the clock spring

Warni ng

If not correctly handled, the safety airbag module may possibly be

trigged and released thus make serene damage to people. Therefore,

please carefully read the repairing warning before trouble handling.

Please take references in safety airbag system repairing warning.

Are the relative parts of clock spring normal? (The relation bet ween

stitches, unnecessary shutoff or shorting?) if the pr esent clock spring ca n

be replaced by a better one. Abnormal Replace the clock spring

Take references in the

removal/installation for

safety airbag system and

clock spring

Replace the driver’s side

safety airbag module

Tk f i th

Confirm the failure in driver’s side safety airbag module or other parts.

Rl thDAB dl ithbtt

Page 386 of 425

Safety airbag-16

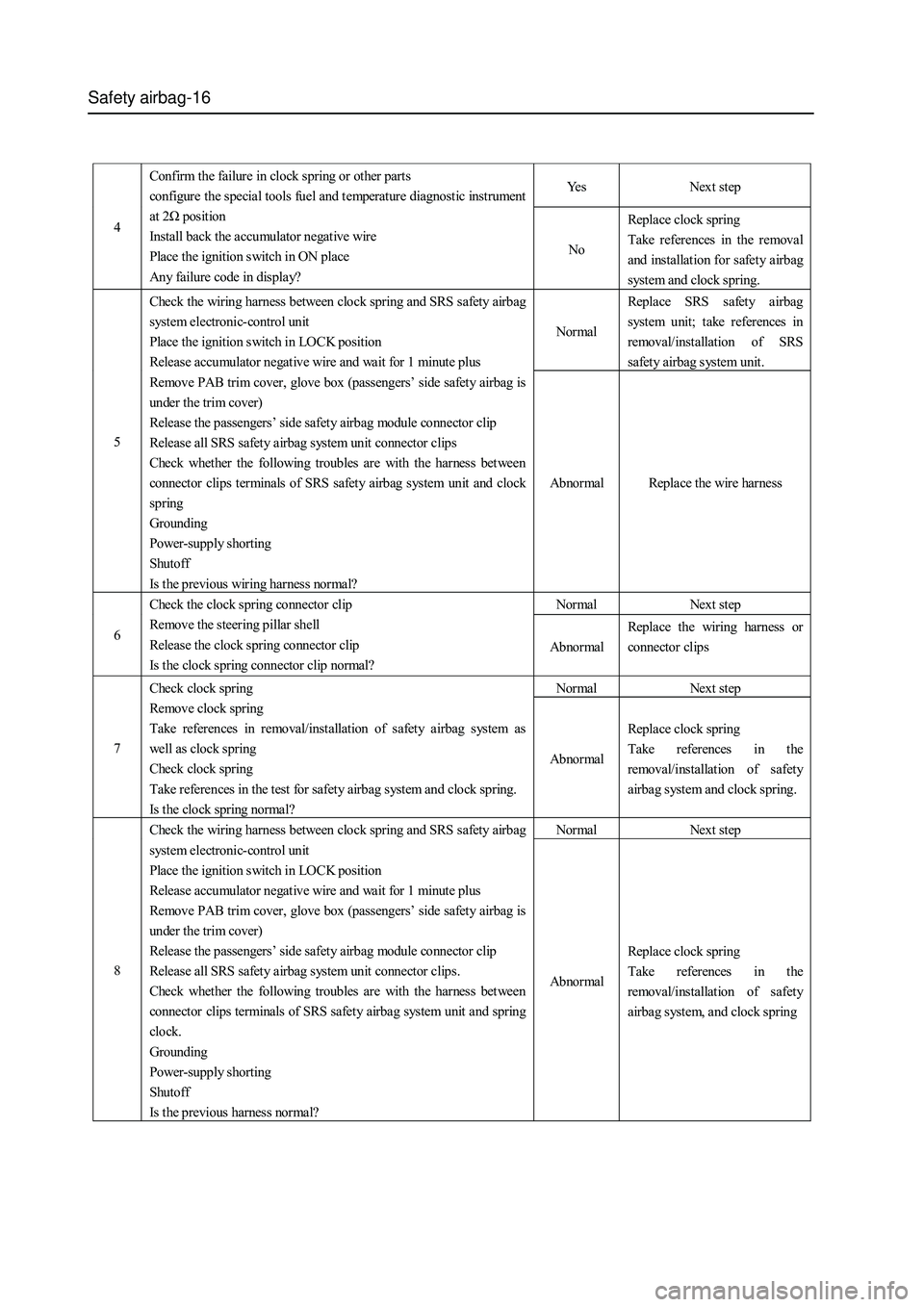

Yes Next step

4 Confirm the failure in clock spring or other parts

configure the special tools fuel and t emperature diagnostic instrument

at 2Ω position

Install back the accumulator negative wire

Place the ignition switch in ON place

Any failure code in display? No Replace clock spring

Take references in the removal

and installation for safety airbag

system and clock spring.

Nor mal Replace SRS safety airbag

system unit; take references in

removal/installation of SRS

safety airbag system unit.

5 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and clock

spring

Grounding

Power-supply shorting

Shutoff

Is the previous wiring harness normal? Abnormal Replace the wire harness

Nor mal Next step

6 Check the clock spring connector clip

Remove the steering pillar shell

Release the clock spring connector clip

Is the clock spring connector clip normal? Abnormal Replace the wiring harness or

connector clips

Nor mal Next step

7 Check clock spring

Remove clock spring

Take references in removal/installation of safet y airbag system as

well as clock spring

Check clock spring

Take references in the test for safety airbag system and clock spring.

Is the clock spring normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system and clock spring.

Nor mal Next step

8 Check the wiring harness between clock spring and SRS safety airbag

system electronic-control unit

Place the ignition switch in LOCK position

Release accumulator negative wire and wait for 1 minute plus

Remove PAB trim cover, glove box (passengers’ side safety airbag is

under the trim cover)

Release the passengers’ side safety airbag module connector clip

Release all SRS safety airbag system unit connector clips.

Check whether the following troubles are with the harness between

connector clips terminals of SRS safety airbag system unit and spring

clock.

Grounding

Power-supply shorting

Shutoff

Is the previous harness normal? Abnormal Replace clock spring

Take references in the

removal/installation of safety

airbag system, and clock spring