maintenance GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 125 of 425

Automatic transmission-49

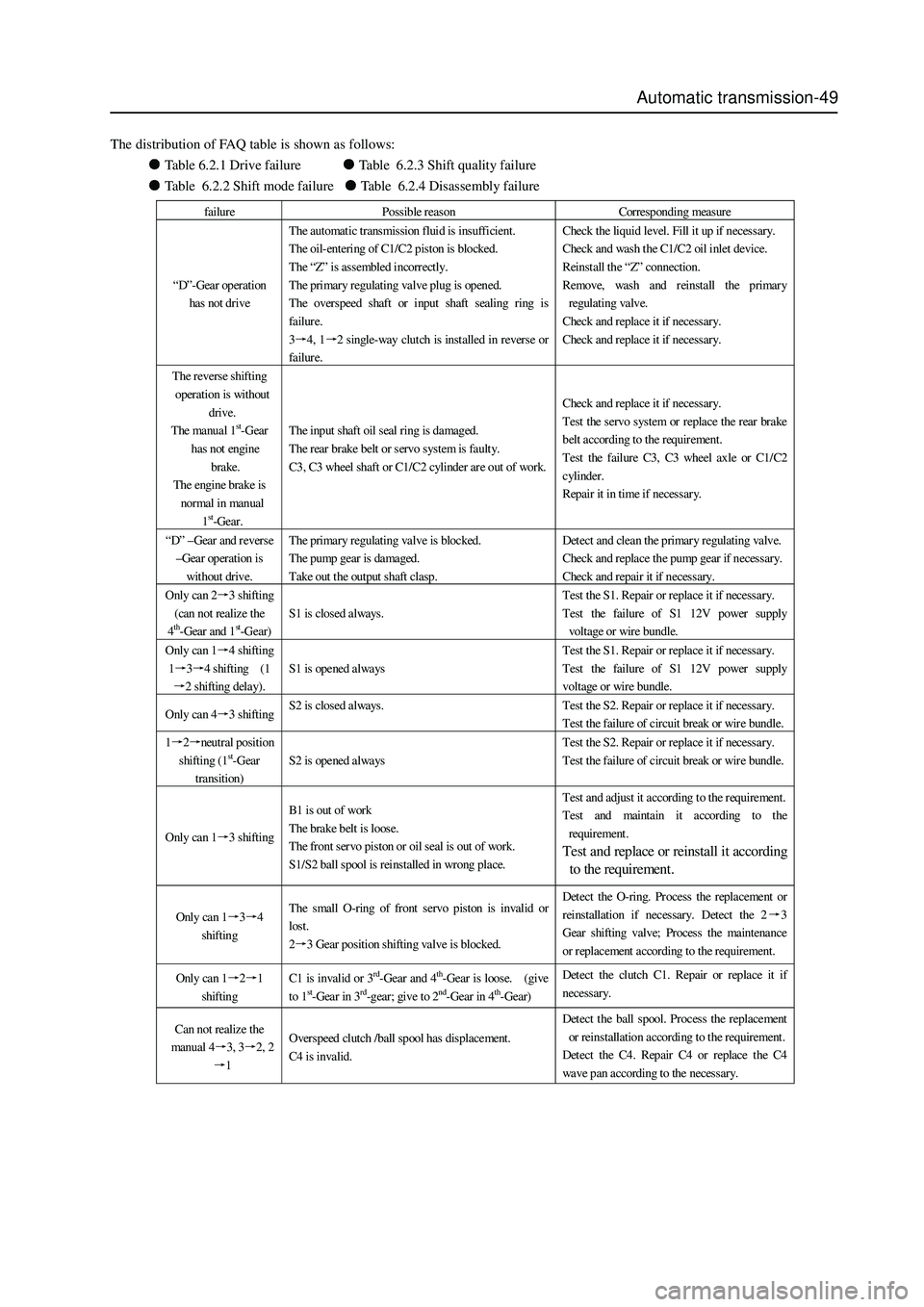

The distribution of FAQ table is shown as follows:

Table 6.2.1 Drive failure Table 6.2.3 Shift quality failure

Table 6.2.2 Shift mode failure Table 6.2.4 Disassembly failure

failure Possible reason Corresponding measure

“D”-Gear operation

has not drive The automatic transmission fluid is insufficient.

The oil-entering of C1/C2 piston is blocked.

The “Z” is assembled incorrectly.

The primary regulating valve plug is opened.

The overspeed shaft or input shaft sealing ring is

failure.

3→4, 1→2 single-way clut ch is installed in revers e or

failure. Check the liquid level. Fill it up if necessary.

Check and wash the C1/C2 oil inlet device.

Reinstall the “Z” connection.

Remove, wash and reinstall the primary

regulating valve.

Check and replace it if necessary.

Check and replace it if necessary.

The reverse shifting

operation is without

drive.

The manual 1

st-Gear

has not engine

brake.

The engine brake is

normal in manual

1

st-Gear. The input shaft oil seal ring is damaged.

The rear brake belt or servo system is faulty.

C3, C3 wheel shaft or C1/C2 cylinder are out of work. Check and replace it if necessary.

Test the servo system or replace the rear brake

belt according to the requirement.

Test the failure C3, C3 wheel axle or C1/C2

cylinder.

Repair it in time if necessary.

“D” –Gear and reverse

–Gear operation is

without drive. The primary regulating valve is blocked.

The pump gear is damaged.

Take out the output shaft clasp. Det ect and clean the primary regulating valve.

Check and replace the pump gear if necessary.

Check and repair it if necessary.

Only can 2→3 shifting

(can not realize the

4

th-Gear and 1st-Gear) S1 is closed always. Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 1→4 shifting

1→3→4 shifting (1

→2 shifting delay). S1 is opened always Test the S1. Repair or replace it if necessary.

Test the failure of S1 12V power supply

voltage or wire bundle.

Only can 4→3 shifting S2 is closed always.

Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

1→2→neutral position

shifting (1st-Gear

transition) S2 is opened always Test the S2. Repair or replace it if necessary.

Test the failure of circuit break or wire bundle.

Only can 1→3 shifting B1 is out of work

The brake belt is loose.

The front servo piston or oil s eal is out of work.

S1/S2 ball spool is reinstalled in wrong place. Test and adjust it according to the requirement.

Test and maintain it according to the

requirement. Test and replace or reinstall it according

to the requirement.

Only can 1→3→4

shifting The small O-ring of front s ervo piston is invalid or

lost.

2→3 Gear position shifting valve is blocked. Det ect the O-ring. Process the replacement or

reinstallation if necessary. Detect the 2→3

Gear shifting valve; Process the maintenance

or replacement according to the requirement.

Only can 1→2→1

shifting C1 is invalid or 3rd-Gear and 4th-Gear is loose. (give

to 1st-Gear in 3rd-gear; give to 2nd-Gear in 4th-Gear) Det ect the clutch C1. Repair or replace it if

necessary.

Can not realize the

man ual 4→3, 3→2, 2

→1 Overspeed clutch /ball spool has displacement.

C4 is invalid. Detect the ball spool. Process the replacement

or reinstallation according to the requirement.

Det ect the C4. Repair C4 or r eplace the C4

wave pan according to the necessary.

Page 126 of 425

Automatic transmission-50

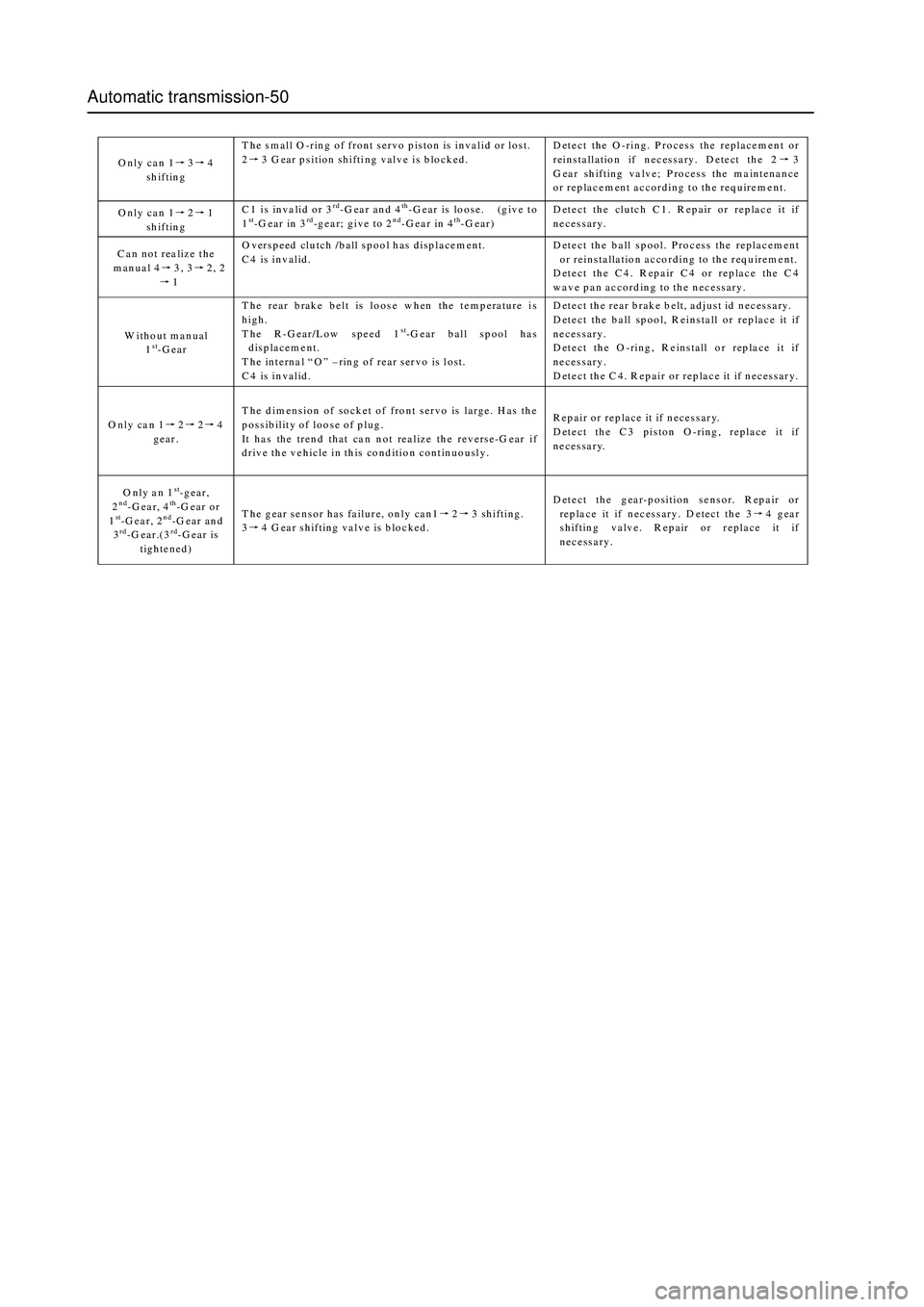

Only can 1→3→4

shifting The sm all O -ring of front servo piston is invalid or lost.

2→3 G ear psition shifting valve is blocked. D etect the O -ring. P rocess the replacem ent or

reinstallatio n if n ecessary. D etect th e 2→3

G ear shifting valve; Process the maintenance

or replacem ent according to the requirem ent.

Only can 1→2→1

shifting C1 is invalid or 3rd-G ear and 4th- G ea r is lo o s e . (g iv e t o

1st-G ear in 3rd-gear; give to 2nd-G ear in 4th-G ear) D etect th e clutch C 1 . R ep air or rep la ce it if

necessary.

Can not realize the

manual 4→3, 3→2, 2

→1 O verspeed clutch /ball spool has displacem ent.

C4 is invalid. D etect the ball spool. Process the replacem ent

or reinstallation according to the req uirem ent.

D etect the C4. R epair C4 or replace the C 4

wave pan according to the necessary.

W itho ut m an ual

1st-G ear The rear brake belt is loose when the tem perature is

high.

The R -G ear/Low speed 1

st-G ear ball spool has

displacem ent.

The internal “O ” –ring of rear servo is lost.

C4 is invalid. D etect the rear brake b elt, adjust id necessary.

D et e ct t h e b a ll sp o o l, R ein s ta ll o r r ep la c e it if

necessary.

D etect the O -ring, R einstall or replace it if

necessary.

D et e ct th e C 4 . R ep a ir o r r ep la c e it if n e c ess a r y.

Only can 1→2→2→4

gear. The dim ension of socket of front servo is large. H as the

possibility of loose of plug.

It has the trend that ca n n ot realize th e reverse-G ear if

drive the vehicle in this condition continuously. Repair or replace it if necessary.

Detect the C3 piston O -ring, replace it if

necessary.

Only an 1st-gear,

2nd-G ear, 4th-G ear or

1st-G ear, 2nd-G ear an d

3rd-G ear.(3rd-G ear is

tightened) The gear sensor has failure, only can1→2→3 shifting.

3→4 Gear shifting valve is blocked. D etect the gear-position sensor. R epair or

replace it if necessary. D etect the 3→4 gear

shiftin g va lv e. R ep air or r ep la ce it if

necessary.

Page 127 of 425

Automatic transmission-51

Table 6.2.3Shifting quality failure

Bad 1→2 Gear

shifting quality The throttle position sensor has failure.

T he brake b elt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

S1, S4 has the failure.

The brake belt combination regulating valve (BAR) has

the failur e.

The front servo release spring is installed incorrectly. Detect the resistance, replace the sensor if

necessary.

Detect and replace the rake belt if necessary.

Detect and r epla ce the O -ring if necessary.

Detect, repair or repla ce the S5 if necessary.

Detect, repair or repla ce the S1, S4 if

necessary.

Detect, repair or repla ce the B AR if

necessary.

Detect and repair it if necessary.

Bad 2→3 Gear

shifting quality B1brake belt release valve is blocked.

S3, S2 has the failure.

The clutch combination regulating valve has failure.

The clutch combination oil feed ball spool is lost or

damaged.

The input shaft oil seal is damaged.

C1 piston O-ring is damaged.

C1 piston oil feed ball spool is damaged. Detect the blow-off valve. Replace or

maintain it if necessary.

Detect the S3, S2.Replace or maintain it if

necessary.

Detect the r egulating valve. R eplace or

maintain it if necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Detect the sealing ring. Reinstall or replace it

if necessary.

Detect the O -ring .R einstall or replace it if

necessary.

Detect the ball spool .Reinstall or replace it if

necessary.

Bad 3→4 Gear

shifting quality S1, S4 has failure.

B1brake belt release valve is blocked.

T he brake b elt is adjusted incorrectly.

The front servo piston O-ring is damaged.

The variable pressure solenoid valve (S5) is damaged or

has failure.

The brake belt combination regulating valve has failure. Detect the S1, S4.R einstall or replace it if

necessary.

Detect the blow-off valve. Replace or repair

it if necessary.

Detect the brake belt. Adjust it if necessary.

Detect the O -ring .R eplace or maintain it if

necessary.

Detect the S5.R epla ce or maintain it if

necessary.

Detect the r egulating valve. R eplace or

maintain it if necessary.

The engine has

the

extinguishing

co nd itio n

when select

the automatic

gear or R-gear. The torque converter clutch control valve is blocked or

solenoid valve 7 has failure. Detect and clean the torque converter clutch

valve (CCCV)

Has unstable

vibration

co nd itio n. S7 has the failure. Process the necessary detection, maintenance

and replacement according to the

requirem ent.

Page 129 of 425

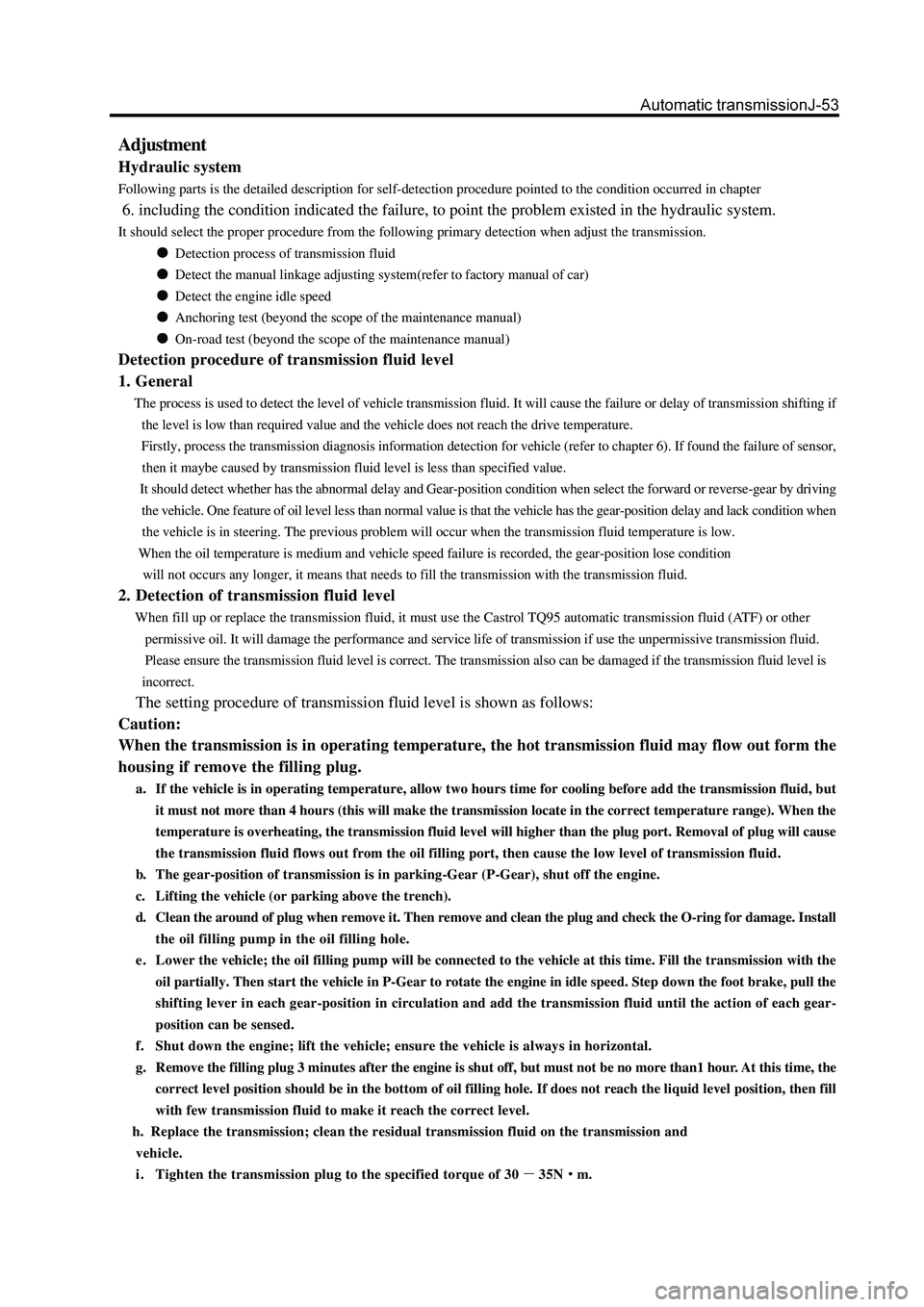

Adjustment

Hydraulic system

Following parts is the detailed description for self-detection procedure pointed to the condition occurred in chapter

6. including the condition indicated the failure, to point the problem existed in the hydraulic system.

It should select the proper procedure from the following primary detection when adjust the transmission.

Detection process of transmission fluid

Detect the manual linkage adjusting system(refer to factory manual of car)

Detect the engine idle speed

Anchoring test (beyond the scope of the maintenance manual)

On-road test (beyond the scope of the maintenance manual)

Detection procedure of transmission fluid level

1. General

The process is used to detect the level of vehicle transmission fluid. It will cause the failure or delay of transmission shifting if

the level is low than required value and the vehicle does not reach the drive temperature.

Firstly, process the transmission diagnosis information detection for vehicle (refer to chapter 6). If found the failure of sensor,

then it maybe caused by transmission fluid level is less than specified value.

It should detect whether has the abnormal delay and Gear-position condition when select the forward or reverse-gear by driving

the vehicle. One feature of oil level less than normal value is that the vehicle has the gear-position delay and lack condition when

the vehicle is in steering. The previous problem will occur when the transmission fluid temperature is low.

When the oil temperature is medium and vehicle speed failure is recorded, the gear-position lose condition

will not occurs any longer, it means that needs to fill the transmission with the transmission fluid.

2. Detection of transmission fluid level

When fill up or replace the transmission fluid, it must use the Castrol TQ95 automatic transmission fluid (ATF) or other

permissive oil. It will damage the performance and service life of transmission if use the unpermissive transmission fluid.

Please ensure the transmission fluid level is correct. The transmission also can be damaged if the transmission fluid level is

incorrect.

The setting procedure of transmission fluid level is shown as follows:

Caution:

When the transmission is in operating temperature, the hot transmission fluid may flow out form the

housing if remove the filling plug.

a. If the vehicle is in operating temperature, allow two hours time for cooling before add the transmission fluid, but

it must not more than 4 hours (this will make the transmission locate in the correct temperature range). When the

temperature is overheating, the transmission fluid level will higher than the plug port. Removal of plug will cause

the transmission fluid flows out from the oil filling port, then cause the low level of transmission fluid.

b. The gear-position of transmission is in parking-Gear (P-Gear), shut off the engine.

c. Lifting the vehicle (or parking above the trench).

d. Clean the around of plug when remove it. Then remove and clean the plug and check the O-ring for damage. Install

the oil filling pump in the oil filling hole.

e. Lower the vehicle; the oil filling pump will be connected to the vehicle at this time. Fill the transmission with the

oil partially. Then start the vehicle in P-Gear to rotate the engine in idle speed. Step down the foot brake, pull the

shifting lever in each gear-position in circulation and add the transmission fluid until the action of each gear-

position can be sensed.

f. Shut down the engine; lift the vehicle; ensure the vehicle is always in horizontal.

g. Remove the filling plug 3 minutes after the engine is shut off, but must not be no more than1 hour. At this time, the

correct level position should be in the bottom of oil filling hole. If does not reach the liquid level position, then fill

with few transmission fluid to make it reach the correct level.

h. Replace the transmission; clean the residual transmission fluid on the transmission and

vehicle.

i. Tighten the transmission plug to the specified torque of 30

35Nm.

Page 166 of 425

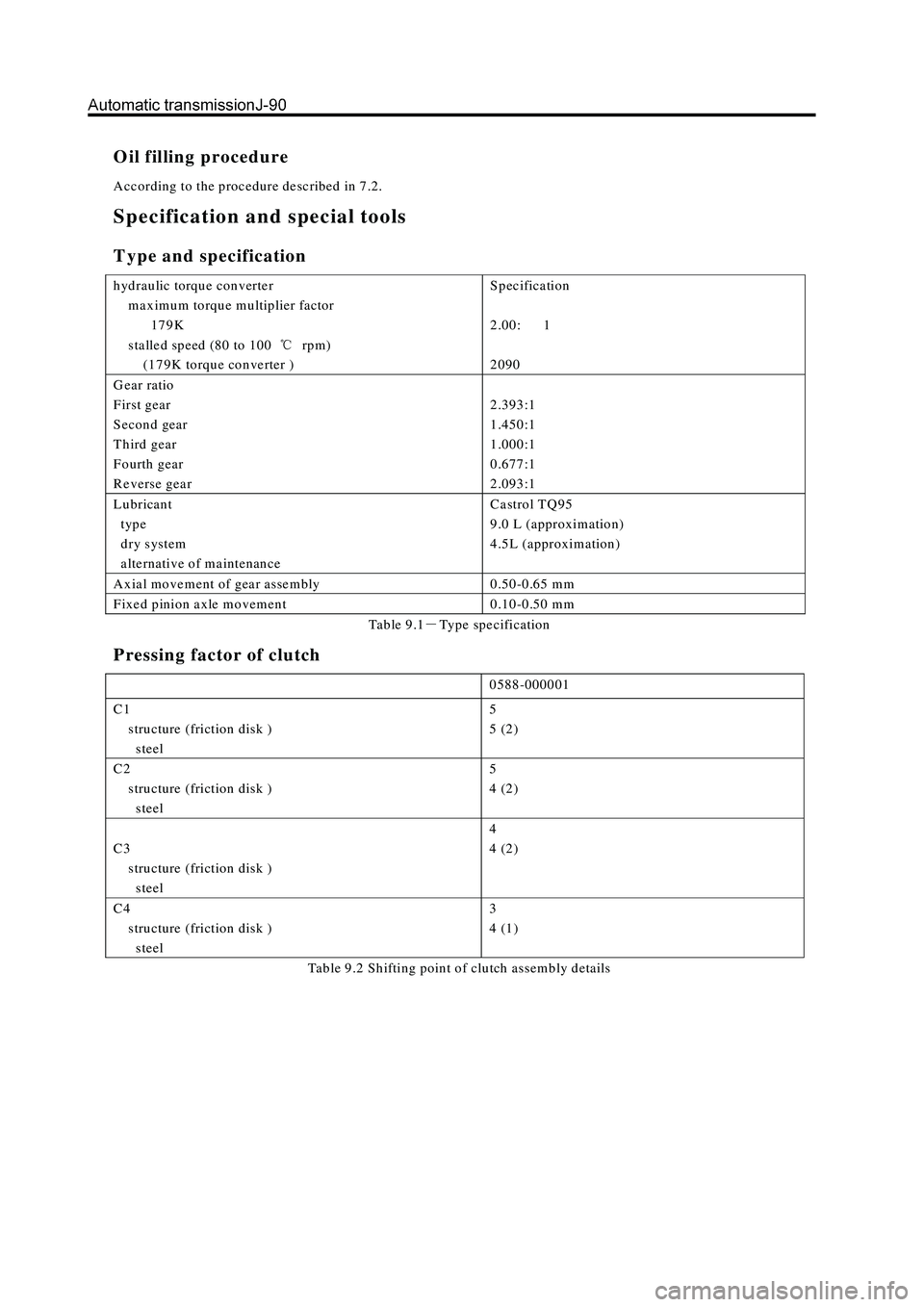

O il fillin g procedure

According to the procedure described in 7.2.

Specification and special tools

Type and specification

hydraulic torque converter

maximum torque multiplier factor

179K

stalled speed (80 to 100 ℃ rp m)

(179K torque converter ) Specification

2.00: 1

2090

Gear ratio

First gear

Second gear

Third gear

Fourth gear

Reverse gear

2.393:1

1.450:1

1.000:1

0.677:1

2.093:1

Lubricant

type

dry system

alternative of maintenance Castrol TQ95

9.0 L (approximation)

4.5L (approximation)

Axial movement of gear assembly 0.50-0.65 mm

Fixed pinion axle movement 0.10-0.50 mm

Tab le 9 .1-Type specification

Pressing factor of clutch

0588-000001

C1

structure (friction disk )

steel 5

5 (2)

C2

structure (friction disk )

steel 5

4 (2)

C3

structure (friction disk )

steel 4

4 (2)

C4

structure (friction disk )

steel 3

4 (1)

Table 9.2 Shifting point of clutch assembly details

Page 238 of 425

11Rivet the drive gear nut after meet the previ-

ous requirements.

12

Install the reducer assembly on the front drive

axle assembly and assemble the front drive shaft

assembly (refer to Assembly of Front Reducer Assembly

and Assembly of Front Drive Shaft Assembly)

13

Install the oil drain plug; screw off the oil

filling plug and filled with the hypoid gear oil.

Tightening force of oil drain plug: 30-35Nm

Model of lubrication oil: GL-5

Filling amount: Flush to the lower edge of oil filling open

14Insert the oil filling plug washer and tighten

the oil filling plug to the specified torque.

Specified torque : 140-150Nm

15Install the front drive axle assembly on the

carriage.

16

Connect the drive shaft to the flange

a. Align the assembly mark; use four bolts and nuts to connect

the flange of drive shaft and front drive axle.

b.Tighten the nut to the specified torque.

specified torque:

Remarks: Keep the clean of the field during the maintenance.

Page 317 of 425

Brake-31

Antilock Braking System (ABS)

Cautions

1. It must not remove or install the electric elements and wire bunch plug when the ignition switch is in ON to avoid

the damage of ECU. It should turn off the ignition switch if needs disassembly.

2. Pay attention to do not knock or impact the ABS ECU during the maintenance and repair, for it will damage the

ABS ECU easily.

3. The wheel speed sensor and hydraulic unit (integrated with ECU) of BOSCH ABS8.0 can not be repaired, it should

be replaced in integral if damaged.

4. After the brake system is maintained, the brake pedal maybe soft. Discharge the air according to the normal brake

system.

5. It must use the brake fluid from original manufacturer; the brake fluid of different number cannot be used in mixed,

otherwise it will cause the failure of brake system. Select the tyre of original type as most as possible

Repair of Antilock Braking System (ABS)

1. It should process the failure diagnosis for the brake system before process the ABS failure diagnosis. It can

diagnose out the failure rapidly by using Table 1. In Table 1, the small number means the failure which occurs most

possibly. Check each element according to the sequence and maintain or replace it if necessary.

2. Check the following elements for normal operation before the diagnosis:

Brake fluid level and brake fluid quality

Pressure of tyre, size of tyre, shape and depth of tyre figure

Other brake component

These components will affect the brake effect of the ABS. Check the system sensor, connecting wire and connector for correct

installation, arrangement and connection. Ensure the completeness of fuse, repair or replace it if necessary.

3. Process the analysis and diagnosis according to the ABS advanced by owner. Use the diagnosis instrument (Annex

1) for final check and confirmation. It must process the run inspection after the competition of all ABS maintenance.

The test condition is shown as follows:

a. Confirm the tyre complies with the requirement, the tyre pressure is normal.

b. The brake system (including brake light ) is normal

c. The brake system is without leakage.

d. The position and installation of wheel speed sensor is correct.

e. All fuses are normal.

4. test method:

Run for 1 min at least when the vehicle speed is beyond 40Km/h, process a proper brake. Then read out the failure code to

ensure the ABS is without failure code.

Page 366 of 425

CD Player and Air Conditioning System-13

1 .CC6460K air conditioning system is designed with SD7V16 compressor, whose refrigeration oil type as

specified is SP-10P AG; hence application of other type of refrigeration oil may damage the parts and compo

nents of the compressor. When the

air conditioning system goes through maintenance and replacement of

parts, it should be added with new refrigeration oil, whose volume is listed as follows: the evaporator and

condenser: 30ml; the drier: 20ml; the pipeline: 10ml.

Addition of refrigeration oil can be available with two methods: The direct addition and the vacuum suction

2 .D irect addition method

a. remove the oil filler plug and fill with the specified SP-10P AG refrigeration oil.

b. observe through the hole of oil filter plug and rotate front plate of clutch to make the piston connecting rod right positio n in the

center of the hole of oil filter plug.

c. insert the dipstick along the right side of piston connecting rod till the top of dipstick touches the case of the compresso

r

d. pull out the dipstick and examine the graduations (grooves) of refrigeration oil, the readings shall be within the range of 4-6

scales

.

e. screw firmly the oil filter plug with the fastening torque of 14.7± 4.9N

.m

3. Vacuum suction method:

Firstly pump out the refrigerating system to the vacuum of 0.2x105Pa, and then fill with the specified 0.2x10 5 Pa refrigeration oil;

the detailed steps are as follows:

a. switch off the high-pressure manual valve and the auxiliary valve.

b. dismantle the high-pressure side hose from the manifold pressure gauge and insert it into the oil cu

p

c. open the auxiliary valve and have the refrigeration oil sucked into the refrigerating system from the oil cup.

d. when the refrigeration oil in the oil cup is almost pumped out to the vacuum, then immediately turn off the auxiliary valve

to

prevent the air from being sucked into the system

.

e. secure the hose adapter at high-pressure side to the manifold pressure gauge, start the vacuum pump and turn on the high-

pressure manual valve, then turn on the auxiliary valve to pump the system to the vacuum state of 0.2x10

5Pa, keep such state

for 15mins so as to discharge out the air flowing into the system along with the oil.

V ol ume of Refrigeration Oil Addition and its Methods

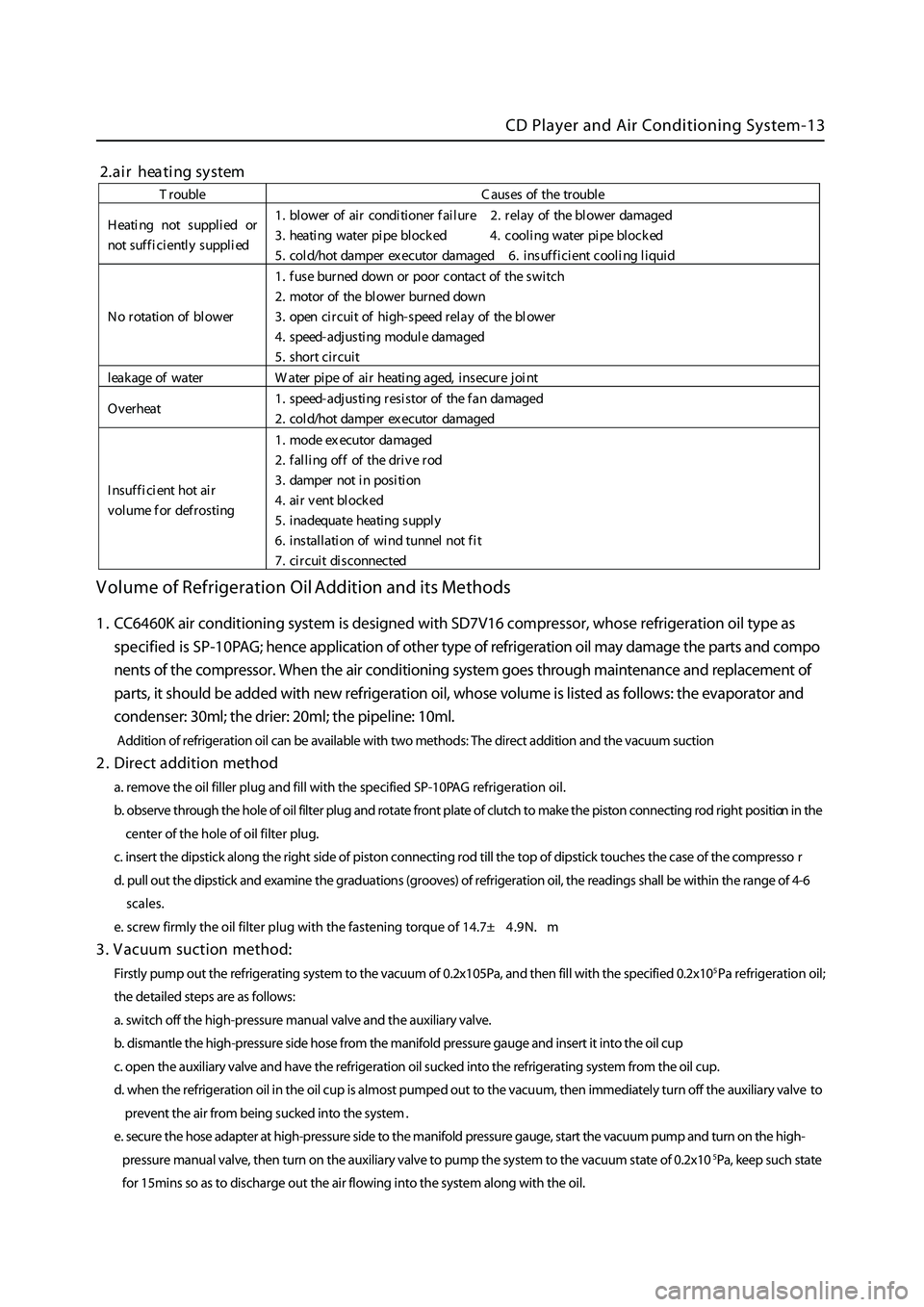

2.ai r h eating system

T r oubl e Cau ses o f the trouble

H e ati n g n otsuppl i ed or

no t s

uf f i cientl y suppl i ed 1.

blow erof air c ondition erf ai l u re 2.relay o f the blow erdamage

d

3. heati n g w ater pipe bloc k e d 4 . coo ling water p i pe b lock ed

5. col d/h ot damp erexecutor damage d 6. ins

uf f i cien t c oo ling l iqu id

N o rotation ofblow er 1.

f use burned

down orpoor contac t o f the switch

2. mo tor o f the blowe r burne d d ow

n

3. op en circ uit o f h igh- sp eed relay o f the blow er

4. speed-ad j usti n g m odule d am aged

5. short c ircu it

leak age o f w ater W ater p ipe o f ai rhe ati n g a ged, inse cu re j oi nt

O v erhe at 1.

speed-ad j usti n g r esi sto r o f the f an d am aged

2. col d/h ot damp erexecutor damaged

I nsu f f i cien t h otair

vo lume f or d efro stin

g 1.

mode executor dama ge

d

2. f al li n g o f fof the d riv e ro

d

3. damp ernot in p osi ti o

n

4. air v ent b l ock ed

5. inad equa te heatin g s

upply

6. inst

alla tion ofwind tunn elno t fi t

7. circ uit d i sco nn ecte

d

Page 370 of 425

CD Player and Air Conditioning System-17

Daily Maintenance of Air Conditioning System

In order to ensure normal operation of air conditioning system, maintenance and care services shall be frequently performed for the

air conditioning system. The daily maintenance of air conditioning system is illustrated as follows:

1. Inspect, wash and clean the condenser of air conditioning system, requiring that radiator pins are clean and there is no dirt

between the pins. After the car runs in the rain or on the muddy road, the fan of the condenser should be inspected to find

whether it bears the earth, sand, stone and etc, and remove them if any.

2. Check the quantity of the working media of the refrigerating system; when the compressor set works normally, observe the

liquid viewing glass, under the normal circumstance, there shall be not air bubbles in the glass.

3. Inspect the drive belt. The belt between the compressor and the engine should be tensioned.

4. Check if there is any abnormal noise or odor in the air conditioning system.

5. Check if the temperature difference between the air inlet and outlet of the compressor is normal.

6. Check if the hose of the refrigerating system is in an apparent good condition and connections of all joints are secure.

7. Check if the pipeline of the refrigerating system collides with other parts and components, and if there is any oil leakage trace

left at each joint.

8. Check if the circuit connection of the refrigerating system is secure and if there is an occurrence of short circuit and falling off

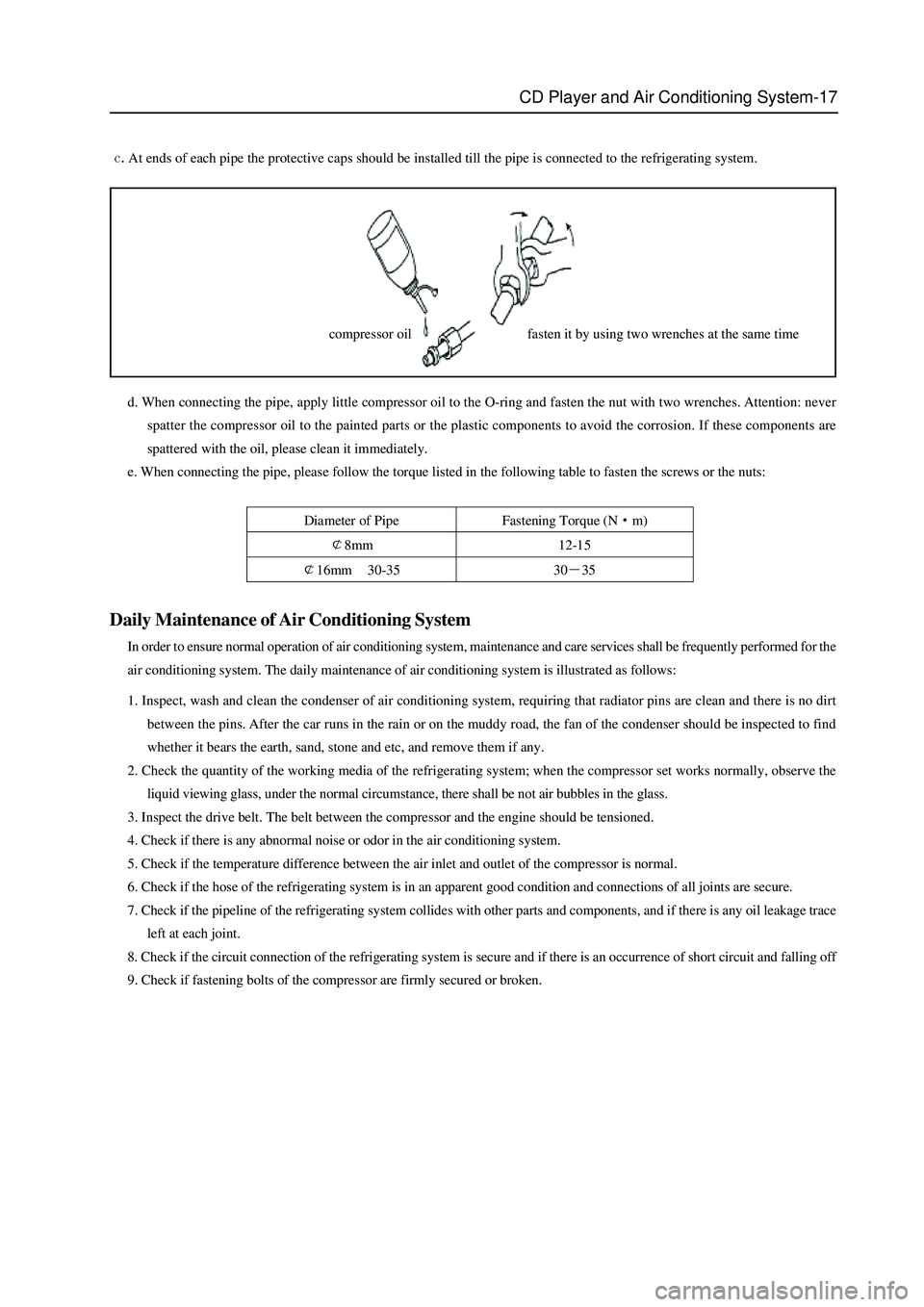

9. Check if fastening bolts of the compressor are firmly secured or broken. d. When connecting the pipe, apply little compressor oil to the O-ring and fasten the nut with two wrenches. Attention: never

spatter the compressor oil to the painted parts or the plastic components to avoid the corrosion. If these components are

spattered with the oil, please clean it immediately.

e. When connecting the pipe, please follow the torque listed in the following table to fasten the screws or the nuts:

Diameter of Pipe Fastening Torque (N·m)

¢8mm 12-15

¢16mm 30-35 30-35

At ends of each pipe the protective caps should be installed till the pipe is connected to the refrigerating system.

compressor oil fasten it by using two wrenches at the same time

Page 372 of 425

Safety airbag-2

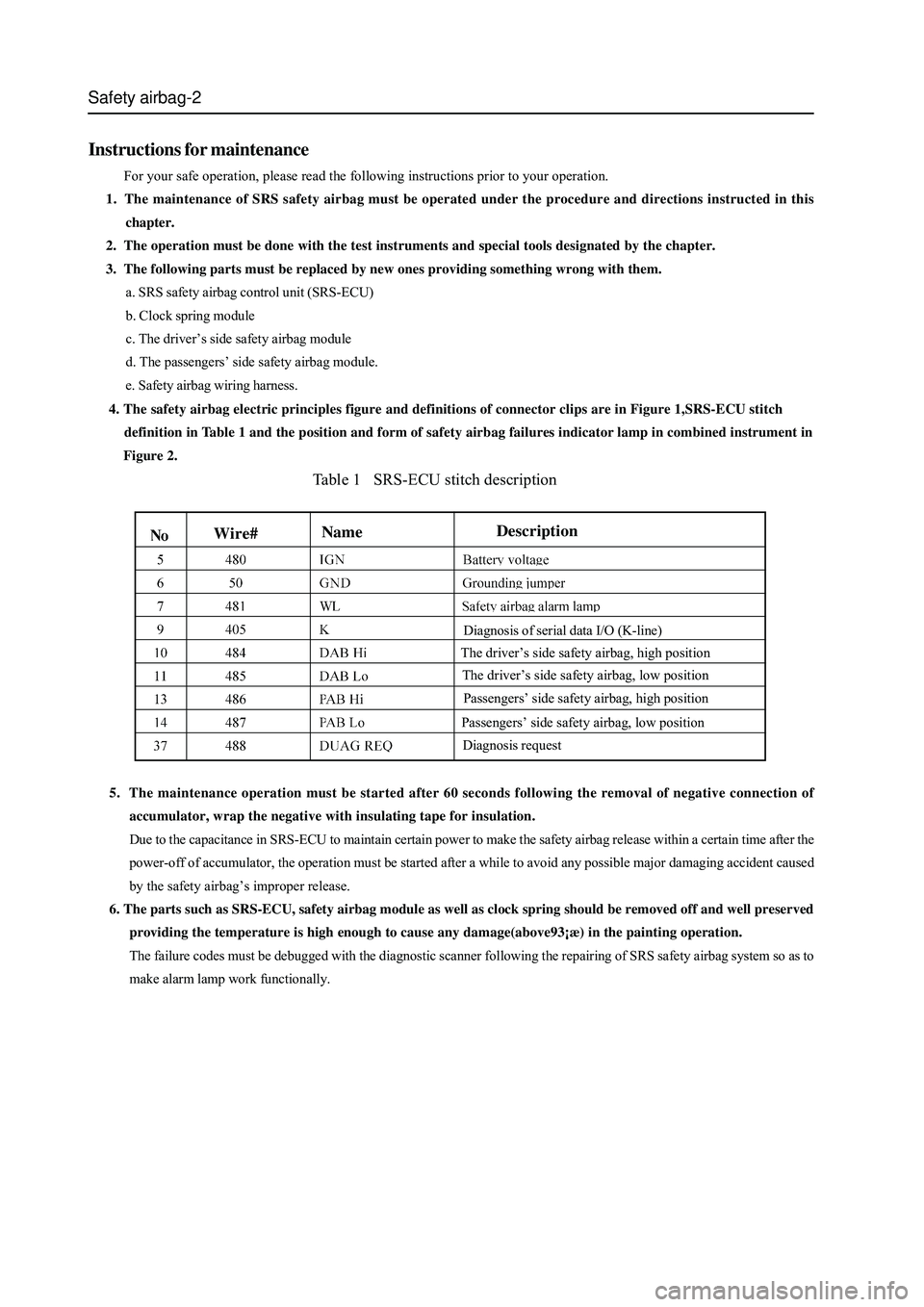

Table 1 SRS-ECU stitch description

5. The maintenance operation must be started after 60 seconds following the removal of negative connection of

accumulator, wrap the negative with insulating tape for insulation.

Due to the capacitance in SRS-ECU to maintain certain power to make the safety airbag release within a certain time after the

power-off of accumulator, the operation must be started after a while to avoid any possible major damaging accident caused

by the safety airbag’s improper release.

6. The parts such as SRS-ECU, safety airbag module as well as clock spring should be removed off and well preserved

providing the temperature is high enough to cause any damage(above93¡æ) in the painting operation.

The failure codes must be debugged with the diagnostic scanner following the repairing of SRS safety airbag system so as to

make alarm lamp work functionally.

Instructions for maintenance

For your safe operation, please read the following instructions prior to your operation.

1. The maintenance of SRS safety airbag must be operated under the procedure and directions instructed in this

chapter.

2. The operation must be done with the test instruments and special tools designated by the chapter.

3. The following parts must be replaced by new ones providing something wrong with them.

a. SRS safety airbag control unit (SRS-ECU)

b. Clock spring module

c. The driver’s side safety airbag module

d. The passengers’ side safety airbag module.

e. Safety airbag wiring harness.

4. The safety airbag electric principles figure and definitions of connector clips are in Figure 1,SRS-ECU stitch

definition in Table 1 and the position and form of safety airbag failures indicator lamp in combined instrument in

Figure 2.

The driver’s side safety airbag, low position

Wire#Description

Name

Diagnosis request

The driver’s side safety airbag, high position

Passengers’ side safety airbag, high position

Passengers’ side safety airbag, low position

Diagnosis of serial data I/O (K-line)