manual transmission GREAT WALL HOVER 2006 Service User Guide

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 102 of 425

Automatic transmission-26

Power transmission

Introduction

It has the following power transmission pointed to different Gear-position:

power transmission N-Gear and P-Gear

power transmission R-Gear

power transmission manual 1

power transmission Automatic 1st-Gear

power transmission Automatic 2nd -Gear

power transmission Automatic 3rd -Gear

power transmission Automatic 3rd-Gear locking

power transmission Automatic 4th -Gear (overspeed -gear)

power transmission Automatic 4th -Gear locking

For description of each kind of power transmission condition, refer to following parts.

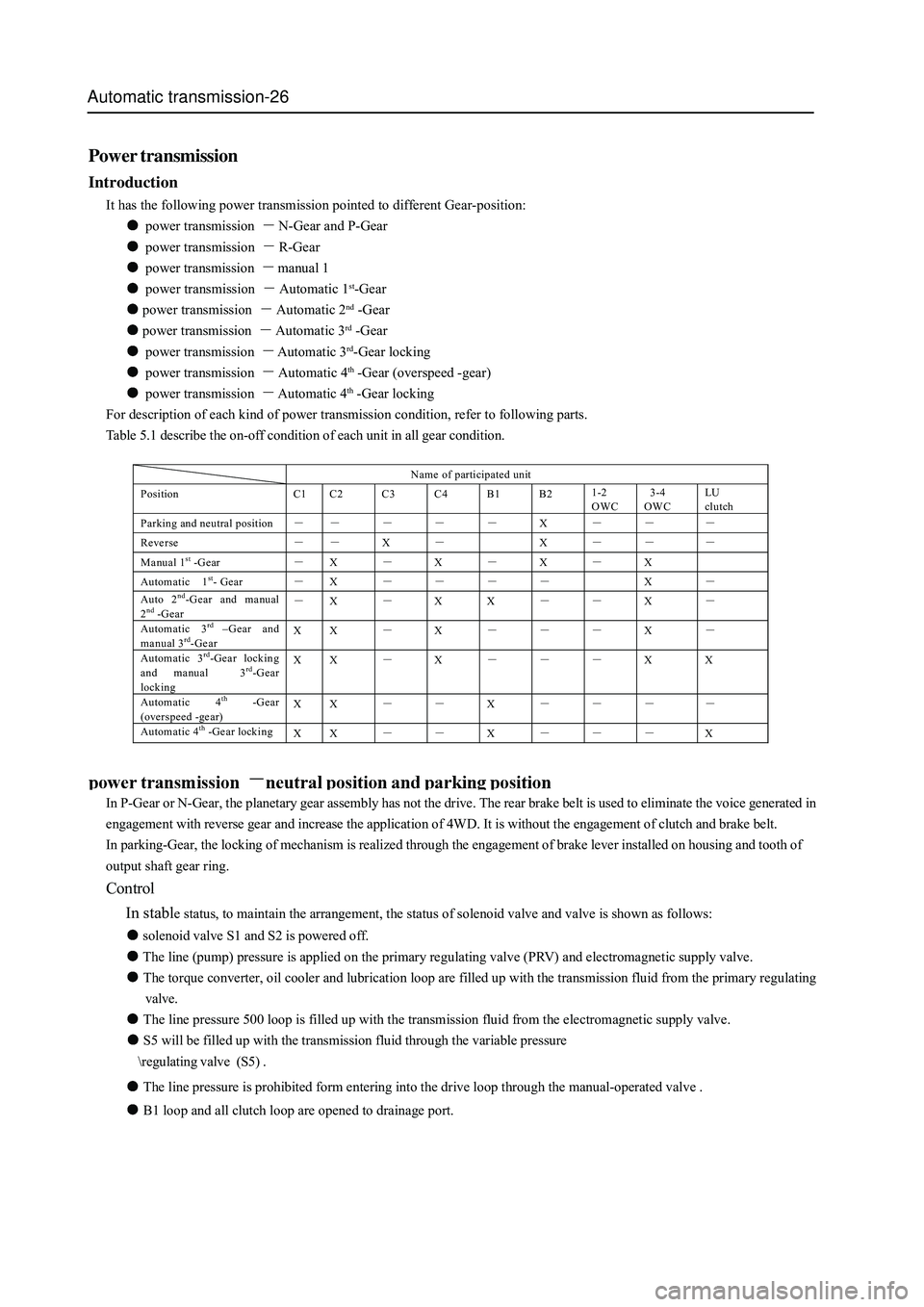

Table 5.1 describe the on-off condition of each unit in all gear condition.

Name of participated unit

Position C1 C2 C3 C4 B1 B2 1-2

OWC 3-4

OWC LU

clutch

Parking and neutral position - - - - - X - - -

Reverse - - X - X - - -

Manual 1st -G ear - X - X - X - X

Automatic 1st- Gear - X - - - - X -

Auto 2nd-Gear and manual

2nd -G ear - X - X X - - X - Automatic 3rd –Gear and

manual 3rd-Gear X X - X - - - X - Automatic 3rd-Gear locking

and manual 3rd-Gear

locking X X - X - - - X X

Automatic 4th -Gear

(overspeed -gear) X X - - X - - - -

Automatic 4th -Gear locking

X X - - X - - - X

In P-Gear or N-Gear, the planetary gear assembly has not the drive. The rear brake belt is used to eliminate the voice generated in

engagement with reverse gear and increase the application of 4WD. It is without the engagement of clutch and brake belt.

In parking-Gear, the locking of mechanism is realized through the engagement of brake lever installed on housing and tooth of

output shaft gear ring.

Control

In stabl

e status, to maintain the arrangement, the status of solenoid valve and valve is shown as follows:

solenoid valve S1 and S2 is powered off.

The line (pump) pressure is applied on the primary regulating valve (PRV) and electromagnetic supply valve.

The torque converter, oil cooler and lubrication loop are filled up with the transmission fluid from the primary regulating

valve.

The line pressure 500 loop is filled up with the transmission fluid from the electromagnetic supply valve.

S5 will be filled up with the transmission fluid through the variable pressure

egulating valve (S5) .

The line pressure is prohibited form entering into the drive loop through the manual-operated valve .

B1 loop and all clutch loop are opened to drainage port.

Page 105 of 425

Automatic transmission-29

In reverse-Gear position, the drive of transmission is sent to the clutch hub through the input shaft and rear clutch piston. In this

condition, the description of each function unit of transmission is shown as follows:

The clutch C3 is engaged and drive the reverse central gear to rotate in clockwise.

The engagement of B2 brake belt cause the rest of the planetary gear carrier, then make the long planetary gear rotates

around its shaft anticlockwise.

The long planetary gear drives the internal gear ring rotates anticlockwise .

Use the spline to connect the inner gear ring to the output shaft and drive the gear ring rotate anticlockwise or in reverse.

Control:

In stable status, to maintain the arrangement, the action of solenoid valve and valve is shown as follows:

A solenoid valve S1 or S2 is closed at least. (Refer to the part in section 3.3.11, related to condition when S1 and S2 is

closed.)

The line pressure reaches the internal surface and external surface of rear servo piston through the reverse lock valve

directly.

The line pressure urges the reverse-Gear loop oil pass through the manual-operated valve.

The reverse-Gear loop oil is circuited to clutch C3 through the manual-operated valve.

In the transmission whiteout HP pump shell, the reverse-Gear loop also can reaches the spring end of the primary

regulating valve to support the spring and push the line-pressure regulating valve.

The oil loop of execution line of all other clutches and brake belts is opened to leaking port.

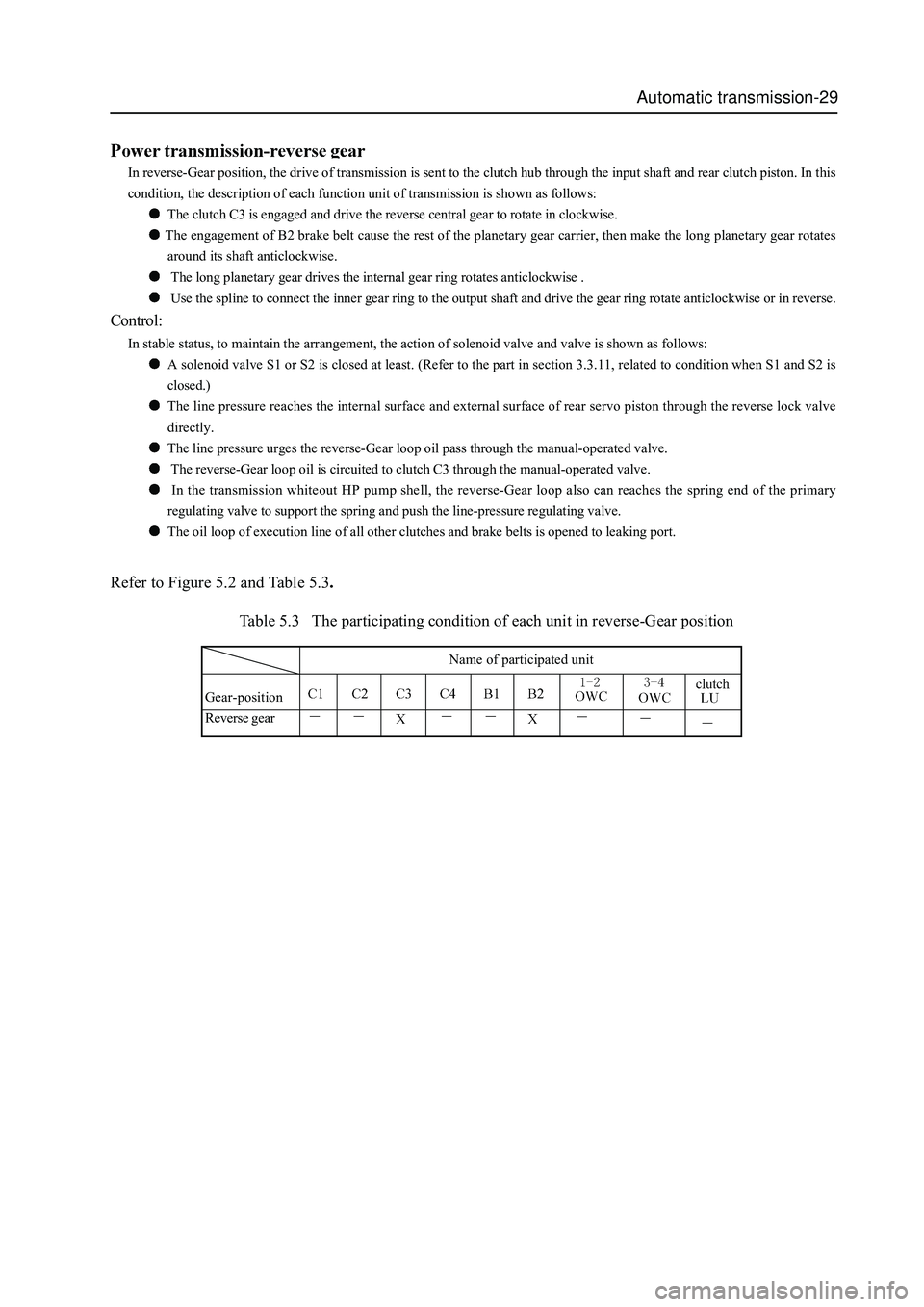

Refer to Figure 5.2 and Table 5.3.

Table 5.3 The participating condition of each unit in reverse-Gear position

Gear-position

Reverse gear

Name of participated unit

Page 107 of 425

Automatic transmission-31

Power transmission manual 1st-Gear

In manual 1st –Gear, the drive of transmission is send to the rear clutch cylinder through the input shaft. In this

condition, each function unit of transmission is shown as follows:

The clutch C2 is engaged through the 3-4 one-way clutch (OWC) to drive the front sun gear.

The engagement of B2 brake belt make the planetary gear carrier to stop.

The front sun gear drive the short planetary gear to rotate in anticlockwise.

The short planetary gear drive the long planetary gear to rotate in clockwise.

The long planetary gear rotate around its axial to drive the internal gear ring and output

shaft to rotate in clockwise to realize the movement in forward direction.

In overspeed, clutch C4 can provides certain brake force through 3-4 one-way clutch .

Control:

In stable status, the action of solenoid valve and valve is shown as follows:

The solenoid valve S1 and S2 is powered on.

In the action of pressure of line 500, the gear shift valve of 1-2, 2-3, 3-4 gear are kept in position of 1st-Gear.

The manual-operated valve transmission fluid (line pressure ) makes the clutch C2 to engagement.

LO-1st (line pressure) oil flows to the clutch C4 through the 1-2 Gear switching valve to engage the B2 brake belt.

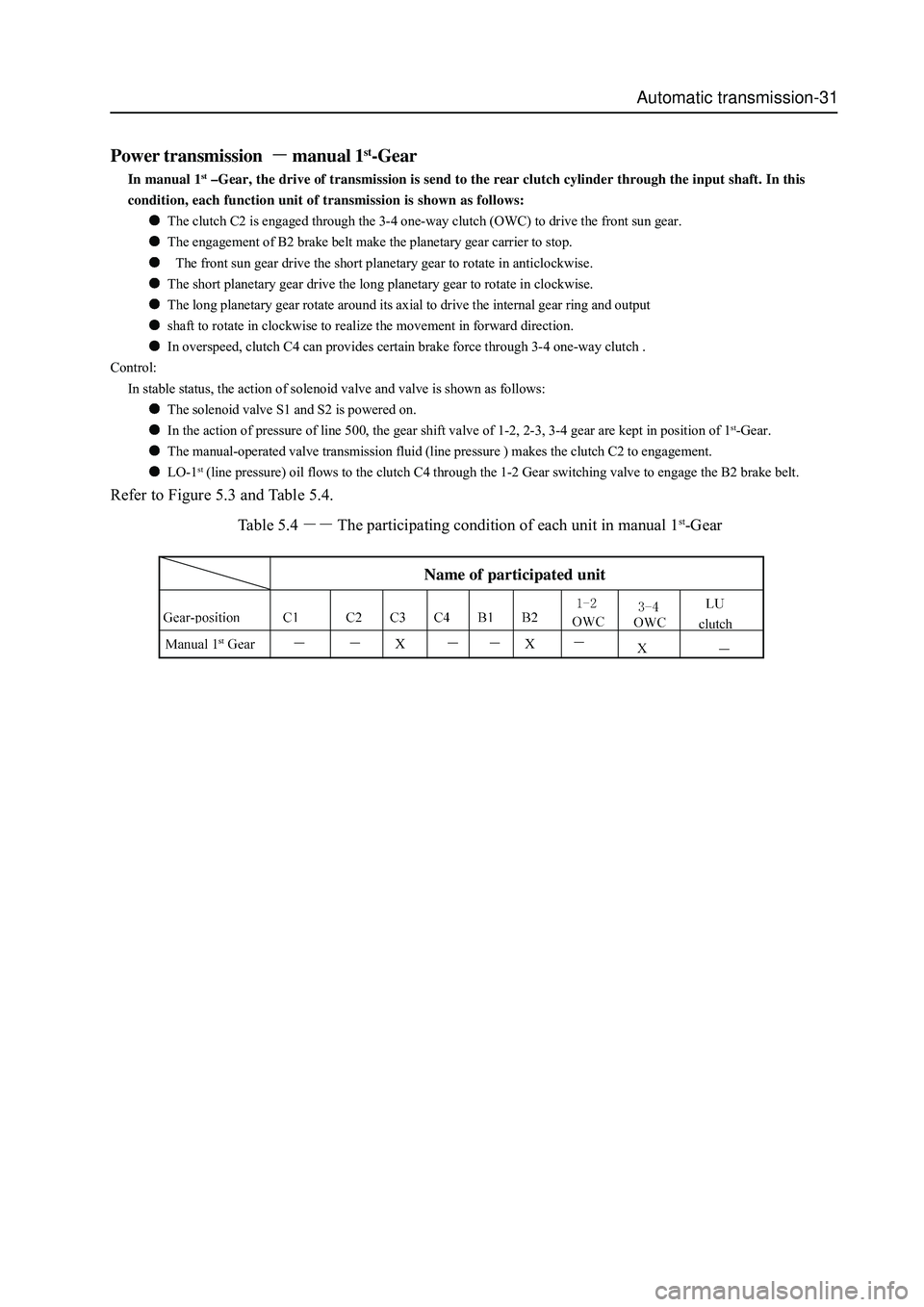

Refer to Figure 5.3 and Table 5.4.

Table 5.4

The participating condition of each unit in manual 1st-Gear

Name of participated unit

X X

Page 109 of 425

Automatic transmission-33

Power transmission automatic 1st-Gear

In automatic 1st -Gear, the drive of transmission reaches the reaches the front clutch cylinder through the input shaft.

In this condition, the operating principle of each function unit of transmission is shown as follows:

The engagement of clutch C2 drives the front sun gear

The front sun gear drive the short planetary gear to rotate in anticlockwise.

The short planetary gear drives the long planetary gear to rotates in clockwise.

1-2 one-way clutch (OWC) stops the rotation of planetary gear carrier in counteracting force. At the same time, the long

planetary gear rotates around its axial to drive the ring gear and output shaft to rotate in clockwise to realize the forward

movement.

Control:

In stable status, the status of solenoid valve and valve is shown as follows:

Solenoid valve S1and S2 is powered on

In the action of line 500 pressure, the gear shift valve of 1-2, 2-3, 3-4 Gear is maintained in 1st-gear position.

The transmission drive oil (line pressure) from the manual-operated valve makes the engagement of clutch C2.

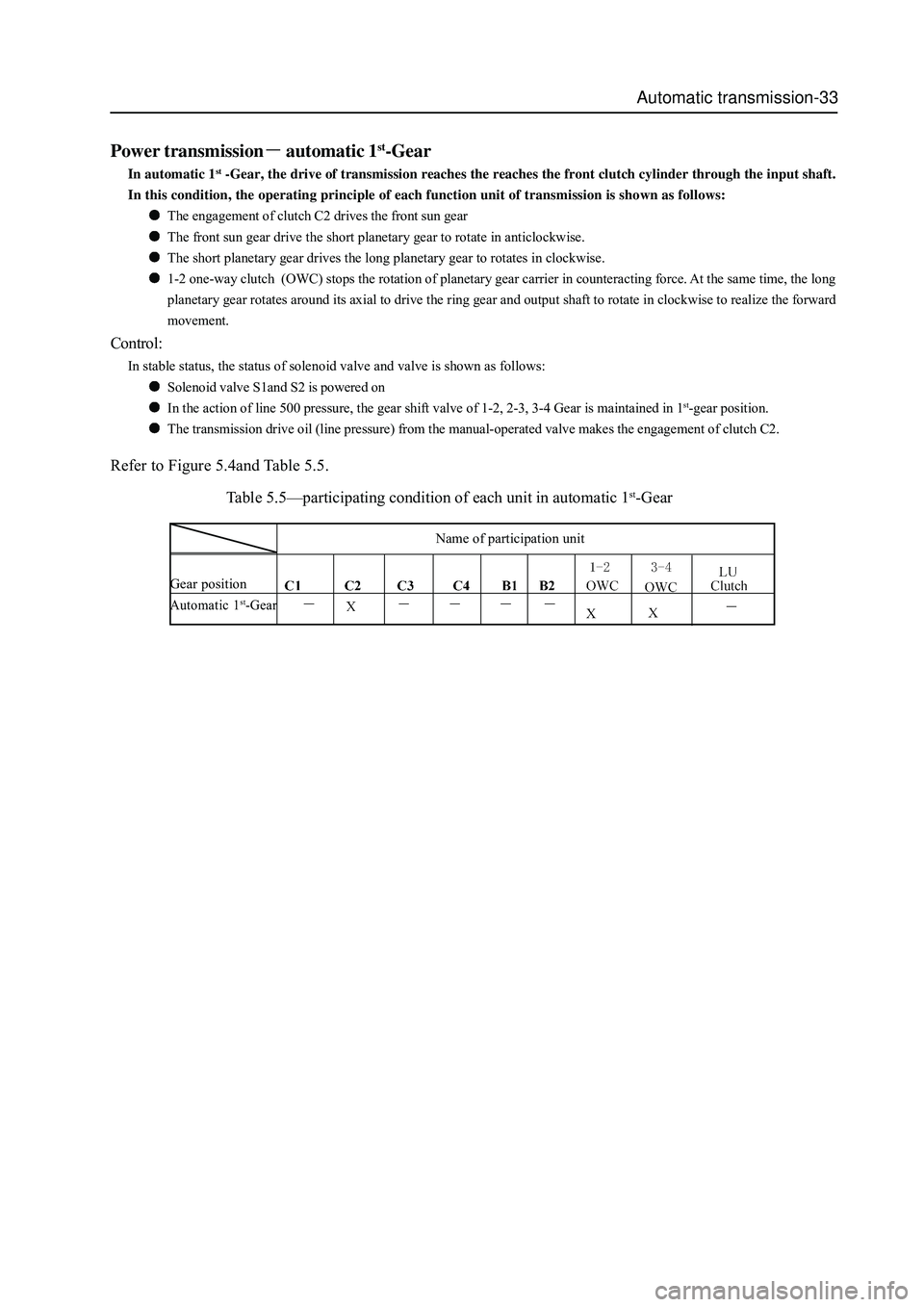

Table 5.5—participating condition of each unit in automatic 1st-Gear

Name of participation unit

Gear position

Automatic 1st-Gear

Refer to Figure 5.4and Table 5.5.

Page 111 of 425

Automatic transmission-35

Power transmission automatic 2nd-Gear and manual 2

In automatic 1st and manual 2nd-Gear, the drive of transmission reaches the front clutch cylinder through the input shaft. In this

condition, the operating principle of each functional unit of transmission is shown as follows:

The engagement of clutch C2 drives the forward central gear.

The forward central gear drives the short planetary gear to rotate in anticlockwise.

The short planetary gear drives the long planetary gear to rotate clockwise.

The engagement of brake belt B1 makes the stop of reverse central gear to make the long planetary gear rotates around the

reverse central gear, then make the internal gear and output shaft rotates in clockwise to make the vehicle moves forwardly.

The clutch C4 is engaged through the 3-4 one-way clutch (OWC) and provides the brake force of engine during overspeed.

Control:

In stable status, the status action of solenoid valve and valve is shown as follows:

The solenoid valve S1 is powered off ; The solenoid valve S2 is powered on.

The drive oil (line pressure) from the manual-operated valve makes the engagement of clutch C2.

When the solenoid valve S1 is powered off, the S1 oil pressure form line pressure 500 pushes the 3-4 Gear shifting valve

moves to left. At the same time, the S1 oil flows into the 1-2 Gear shifting valve to push the 1-2 Gear shifting valve to the

2

nd –Gear.

The line pressure oil from the 1-2 Gear shifting valve flows into the brake belt combination regulating valve, and 2-3 Gar

shifting valve.

The brake belt engagement regulator valve provides the 2nd-Gear oil (controlled by product of line pressure and valve rate)

to brake belt feed loop (BAF).

The brake belt engagement feed loop directly provides the oil to:

External engagement part of front servo piston.

1-2 Gear shifting valve can provide a oil drainage port when the transmission is shifted to 1st-Gear.

Use the 3-4 Gear shifting valve when the transmission is in 4

th-Gear position.

The drive force (line pressure) is sent to the clutch C4 through the 3-4 Gear shifting valve to realize the engagement of

clutch C4.

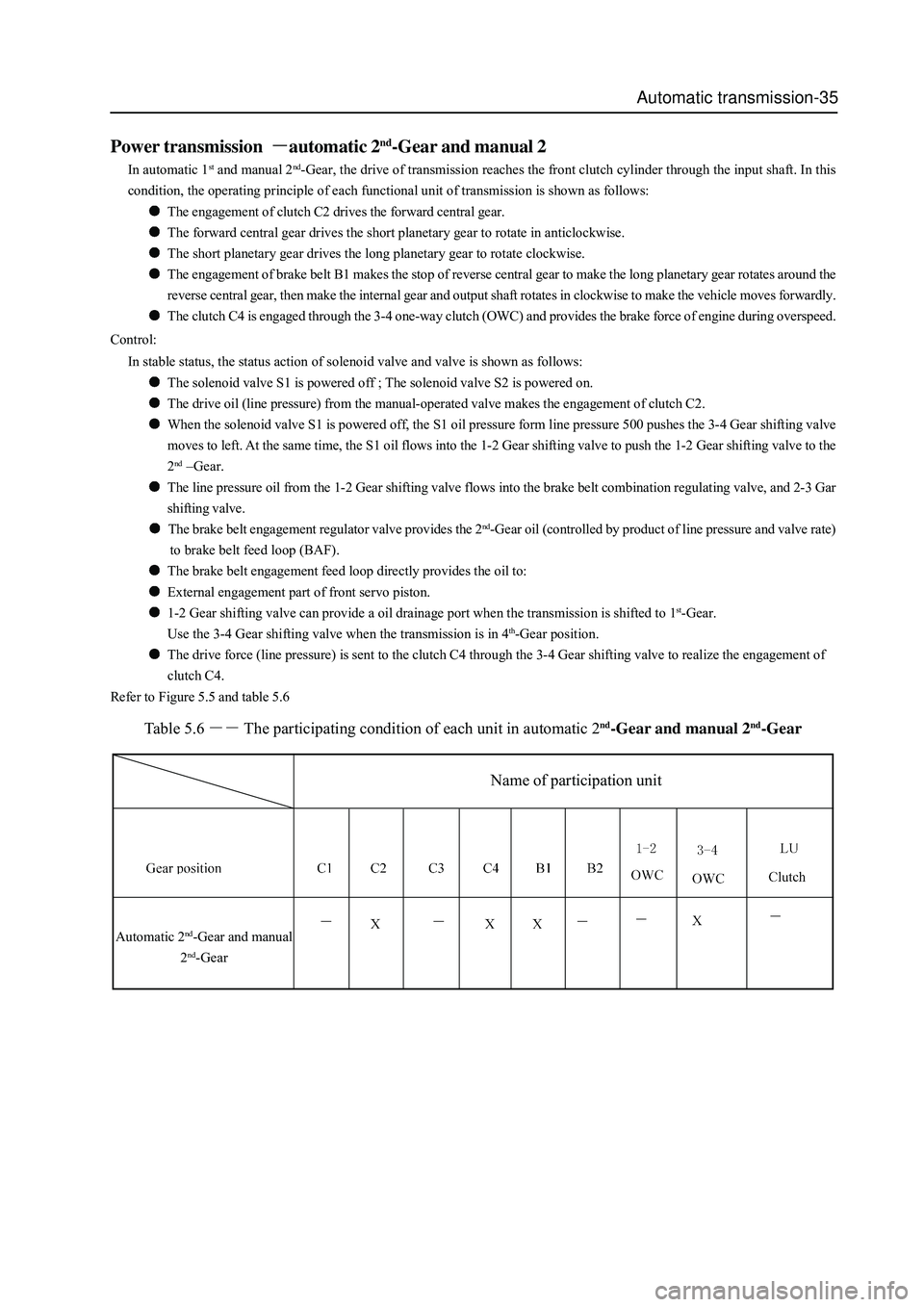

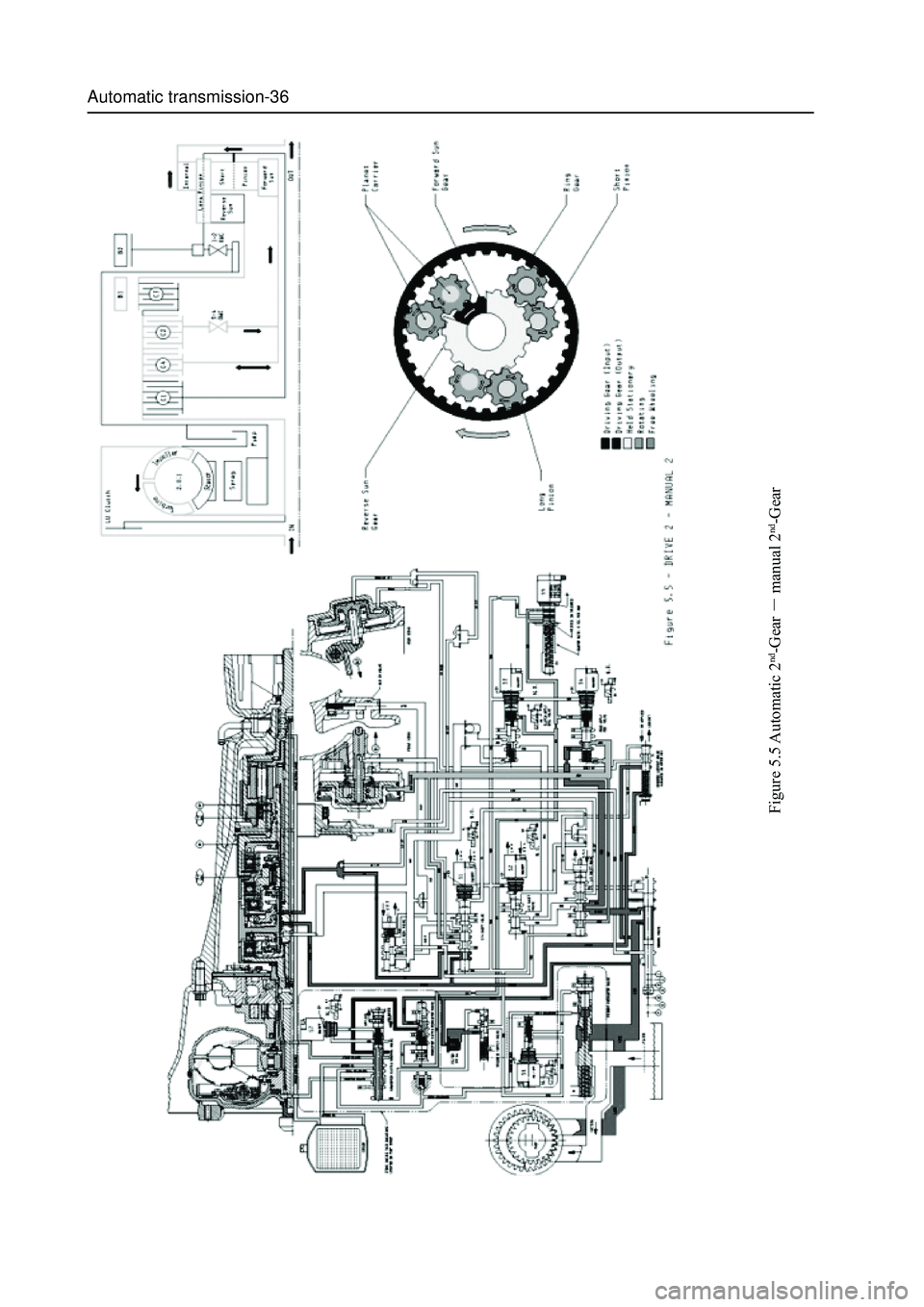

Refer to Figure 5.5 and table 5.6

Table 5.6The participating condition of each unit in automatic 2nd-Gear and manual 2nd-Gear

Automatic 2nd-Gear and manual

2

nd-Gear

Name of participation unit

Page 112 of 425

Automatic transmission-36

Figure 5.5 Automatic 2

nd-Gear

manual 2

nd-Gear

Page 113 of 425

Automatic transmission-37

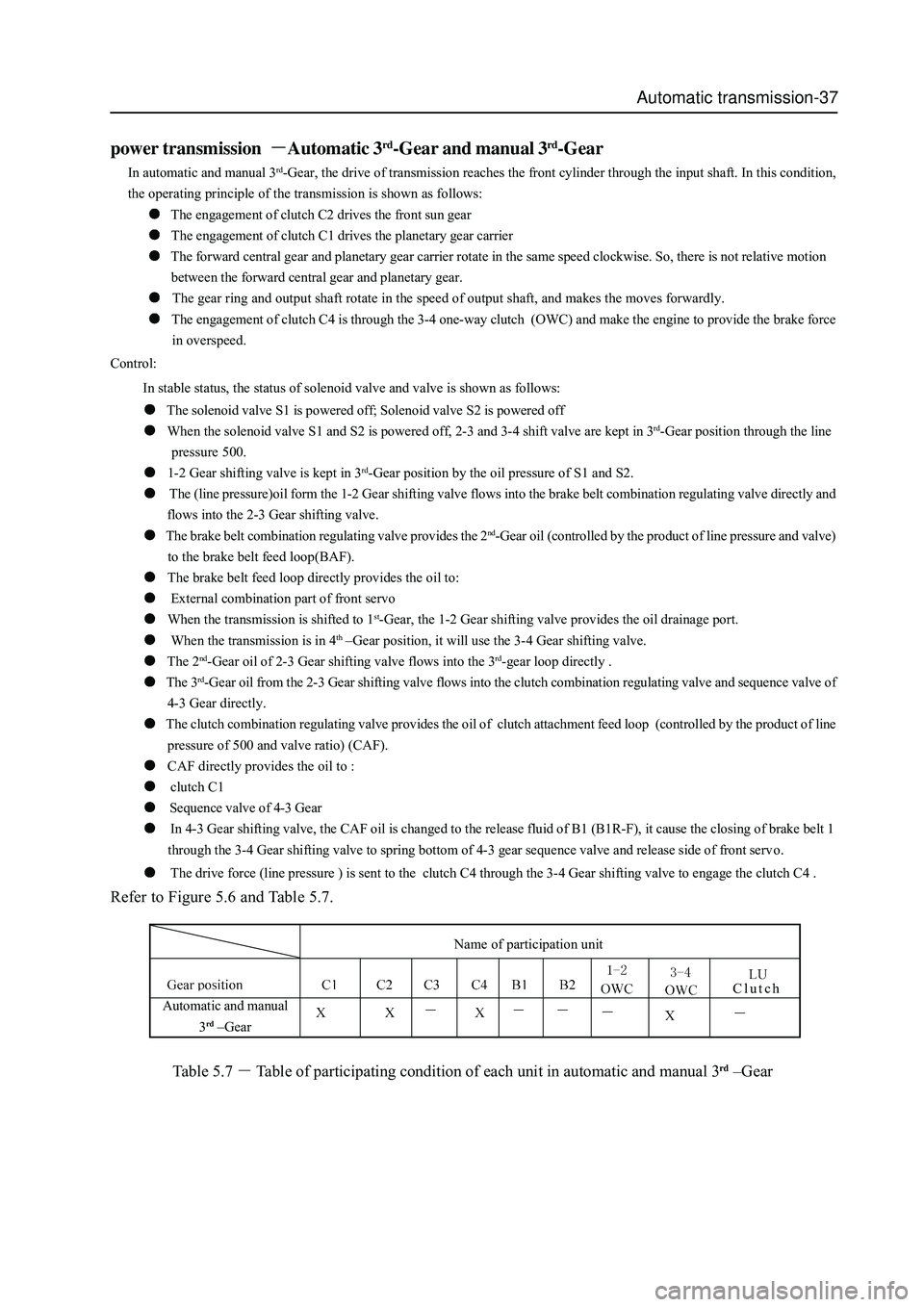

power transmission Automatic 3rd-Gear and manual 3rd-Gear

In automatic and manual 3rd-Gear, the drive of transmission reaches the front cylinder through the input shaft. In this condition,

the operating principle of the transmission is shown as follows:

The engagement of clutch C2 drives the front sun gear

The engagement of clutch C1 drives the planetary gear carrier

The forward central gear and planetary gear carrier rotate in the same speed clockwise. So, there is not relative motion

between the forward central gear and planetary gear.

The gear ring and output shaft rotate in the speed of output shaft, and makes the moves forwardly.

The engagement of clutch C4 is through the 3-4 one-way clutch (OWC) and make the engine to provide the brake force

in overspeed.

Control:

In stable status, the status of solenoid valve and valve is shown as follows:

The solenoid valve S1 is powered off; Solenoid valve S2 is powered off

When the solenoid valve S1 and S2 is powered off, 2-3 and 3-4 shift valve are kept in 3rd-Gear position through the line

pressure 500.

1-2 Gear shifting valve is kept in 3rd-Gear position by the oil pressure of S1 and S2.

The (line pressure)oil form the 1-2 Gear shifting valve flows into the brake belt combination regulating valve directly and

flows into the 2-3 Gear shifting valve.

The brake belt combination regulating valve provides the 2nd-Gear oil (controlled by the product of line pressure and valve)

to the brake belt feed loop(BAF).

The brake belt feed loop directly provides the oil to:

External combination part of front servo

When the transmission is shifted to 1st-Gear, the 1-2 Gear shifting valve provides the oil drainage port.

When the transmission is in 4th –Gear position, it will use the 3-4 Gear shifting valve.

The 2nd-Gear oil of 2-3 Gear shifting valve flows into the 3rd-gear loop directly .

The 3rd-Gear oil from the 2-3 Gear shifting valve flows into the clutch combination regulating valve and sequence valve of

4-3 Gear directly.

The clutch combination regulating valve provides the oil of clutch attachment feed loop (controlled by the product of line

pressure of 500 and valve ratio) (CAF).

CAF directly provides the oil to :

clutch C1

Sequence valve of 4-3 Gear

In 4-3 Gear shifting valve, the CAF oil is changed to the release fluid of B1 (B1R-F), it cause the closing of brake belt 1

through the 3-4 Gear shifting valve to spring bottom of 4-3 gear sequence valve and release side of front servo.

The drive force (line pressure ) is sent to the clutch C4 through the 3-4 Gear shifting valve to engage the clutch C4 .

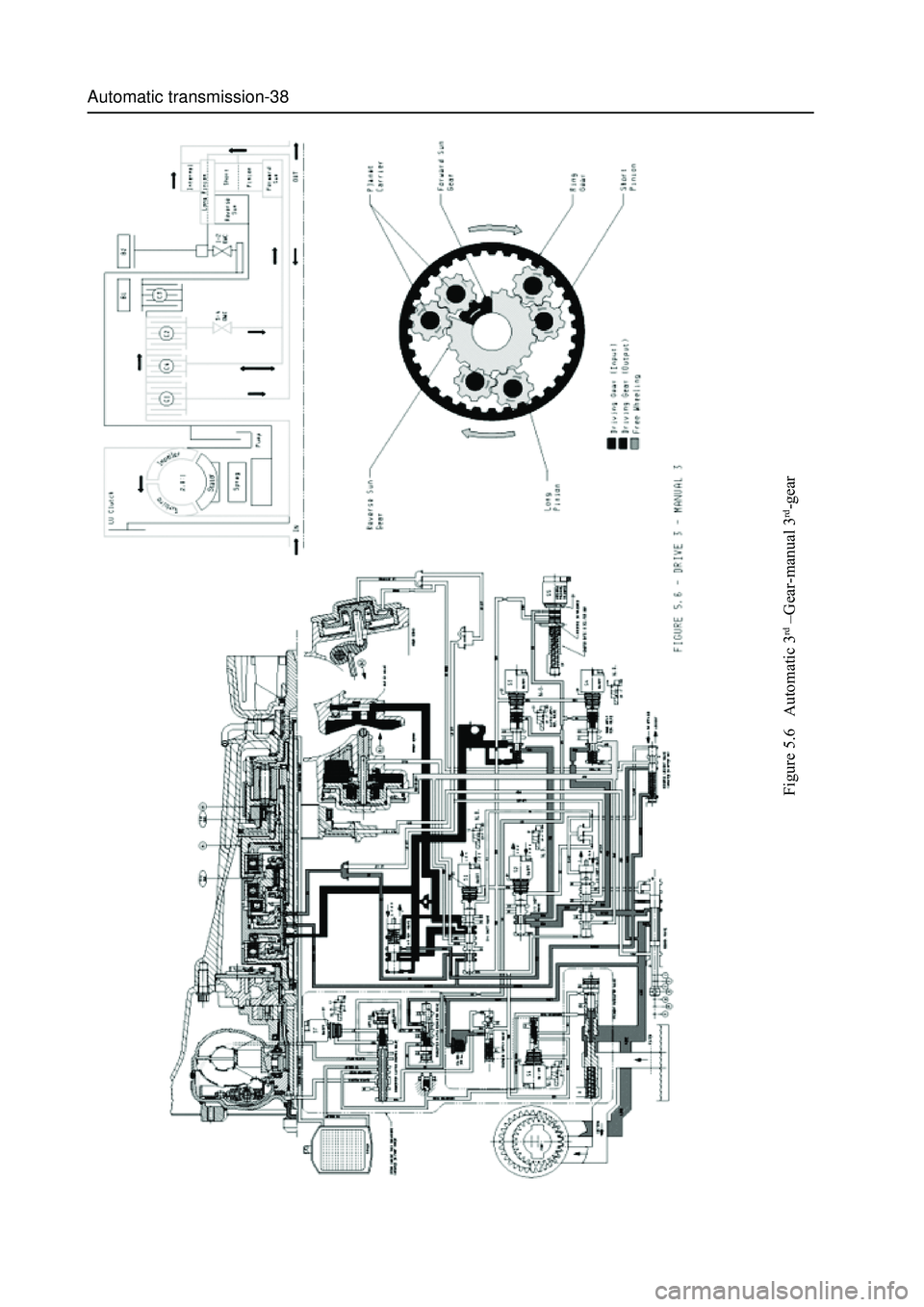

Refer to Figure 5.6 and Table 5.7.

Table 5.7

Table of participating condition of each unit in automatic and manual 3rd –Gear

Clutch

Name of participation unit

Automatic and manual

3

rd –Gear

Page 114 of 425

Automatic transmission-38

Figure 5.6 Automatic 3

rd –Gear-manual 3

rd-gear

Page 115 of 425

Automatic transmission-39

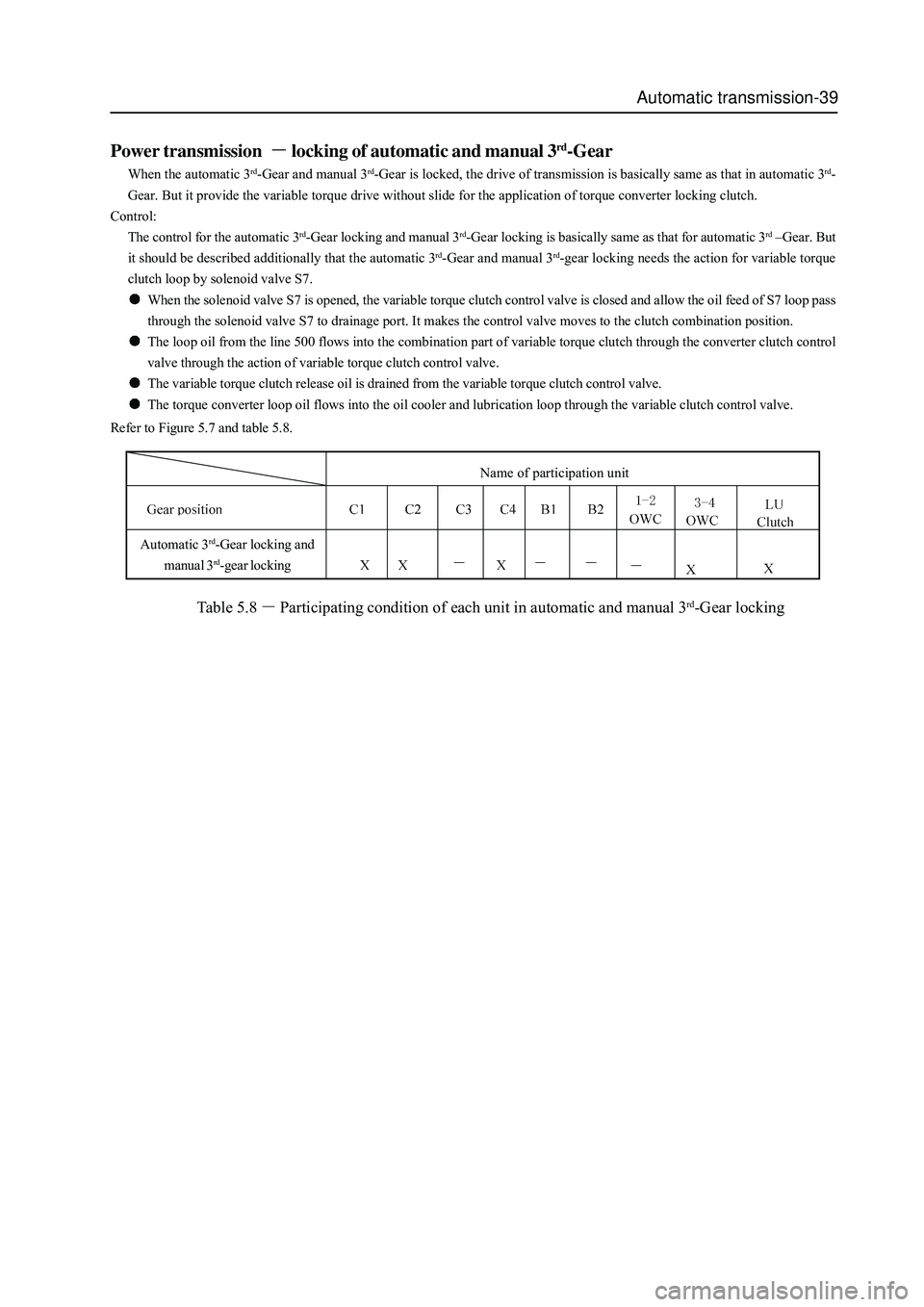

Power transmission locking of automatic and manual 3rd-Gear

When the automatic 3rd-Gear and manual 3rd-Gear is locked, the drive of transmission is basically same as that in automatic 3rd-

Gear. But it provide the variable torque drive without slide for the application of torque converter locking clutch.

Control:

The control for the automatic 3

rd-Gear locking and manual 3rd-Gear locking is basically same as that for automatic 3rd –Gear. But

it should be described additionally that the automatic 3

rd-Gear and manual 3rd-gear locking needs the action for variable torque

clutch loop by solenoid valve S7.

When the solenoid valve S7 is opened, the variable torque clutch control valve is closed and allow the oil feed of S7 loop pass

through the solenoid valve S7 to drainage port. It makes the control valve moves to the clutch combination position.

The loop oil from the line 500 flows into the combination part of variable torque clutch through the converter clutch control

valve through the action of variable torque clutch control valve.

The variable torque clutch release oil is drained from the variable torque clutch control valve.

The torque converter loop oil flows into the oil cooler and lubrication loop through the variable clutch control valve.

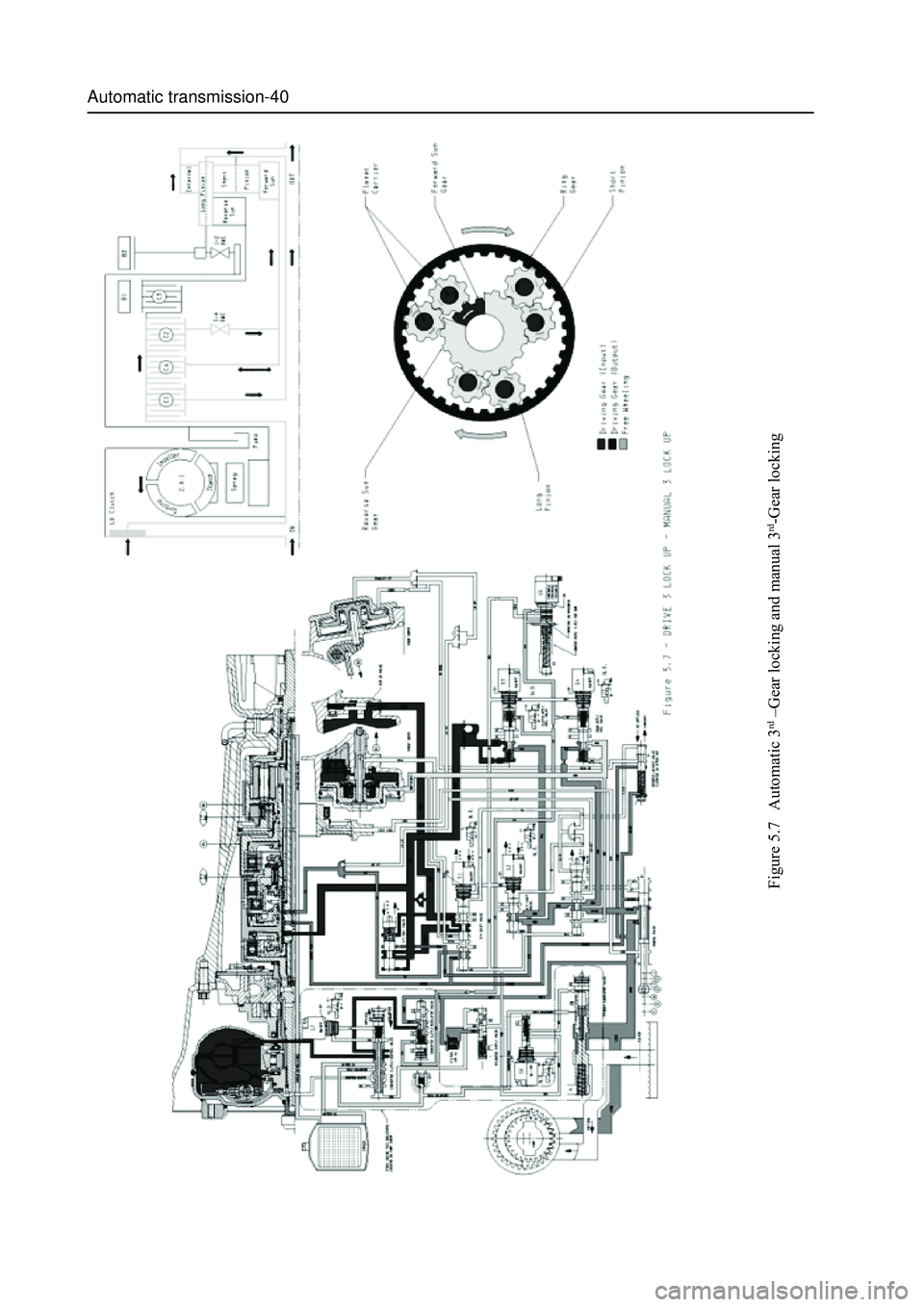

Refer to Figure 5.7 and table 5.8.

Table 5.8Participating condition of each unit in automatic and manual 3rd-Gear locking

Automatic 3rd-Gear locking and

manual 3

rd-gear locking

Name of participation unit

Page 116 of 425

Automatic transmission-40

Figure 5.7 Automatic 3

rd –Gear locking and manual 3

rd-Gear locking