Air conditioner GREAT WALL HOVER 2006 Service Repair Manual

[x] Cancel search | Manufacturer: GREAT WALL, Model Year: 2006, Model line: HOVER, Model: GREAT WALL HOVER 2006Pages: 425, PDF Size: 26.05 MB

Page 21 of 425

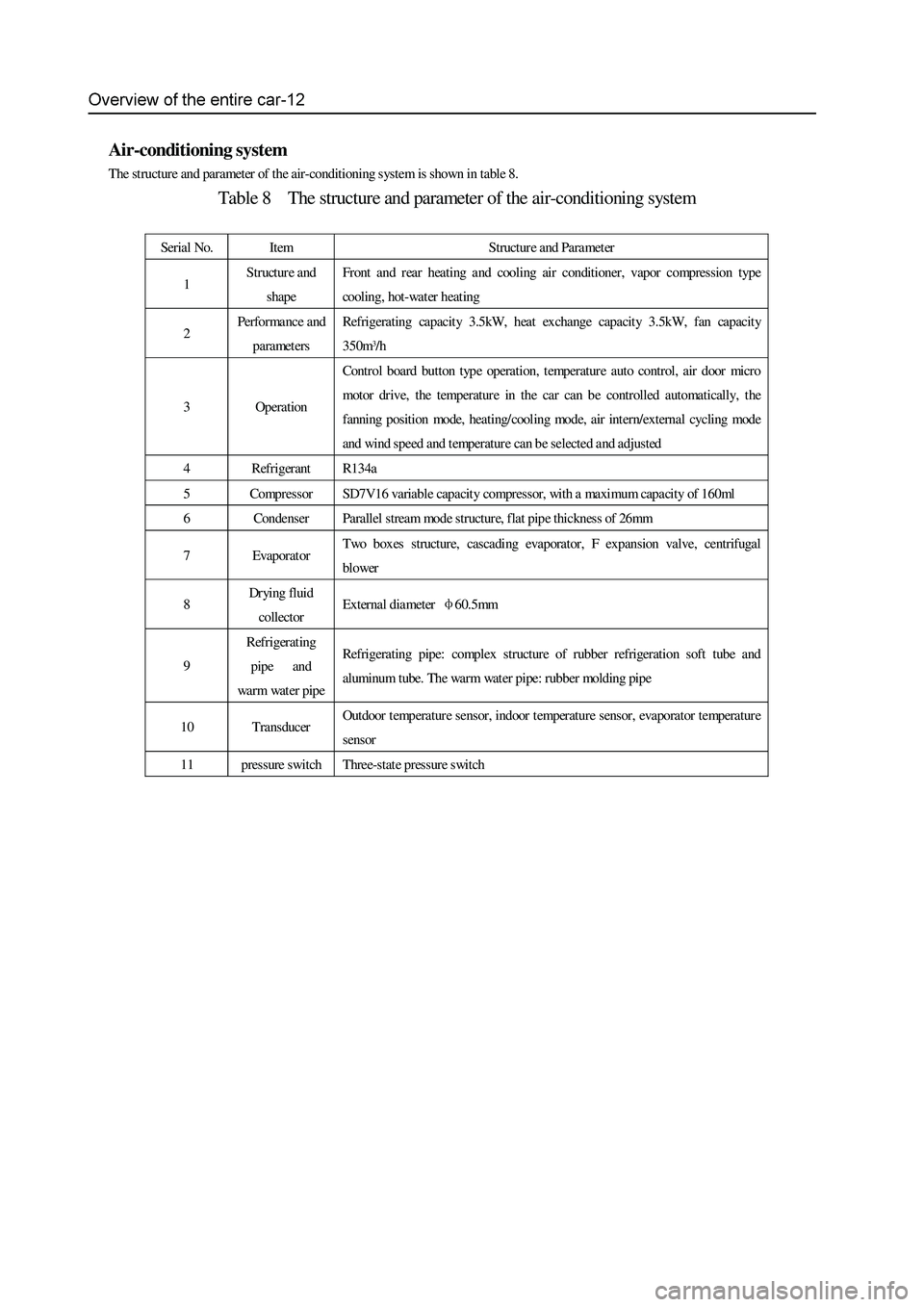

Air-conditioning system

The structure and parameter of the air-conditioning s ystem is shown in table 8.

Table 8 The structure and parameter of the air-conditioning system

Serial No. Item Structure and Paramet er

1 Structure and

shape

Front and rear heating and cooling air conditioner, vapor compression type

cooling, hot-wat er heating

2 Performance and

parameters

Refrigerating capacity 3.5kW, heat exchange capacity 3.5kW, fan capacity

350m

3/h

3 Operation

Control board button type operation, temperature auto control, air door micro

motor drive, the temperature in the car can be controlled automatically, the

fanning position mode, heating/ cooling mode, air int ern/external cycling mode

and wind speed and t emperature can b e selected and adjusted

4 Refrigerant R134a

5 Compressor SD7V16 variable capacity compressor, with a maximum capacity of 160ml

6 Condenser Parallel stream mode structure, flat pipe thickness of 26mm

7 Evaporator Two box es structure, cascading evaporator, F expansion valve, centrifugal

blower

8 Drying fluid

collector

External diameter φ60.5mm

9

Refrigerating

pipe and

wa r m wa t er pi p e

Refrigerating pipe: complex structure of rubber refrigeration soft tube and

aluminum tube. The warm water pipe: rubber molding pipe

10 Transducer Outdoor temp erature sensor, indoor t emperature sensor, evaporator temperature

sensor

11 pressure switch Three-state pressure switch

Page 355 of 425

CD Player and Air Conditioning System-2

CD Player

Function Overview

This product is a kind of car audio system with VFD multi-information integrated display screen with such functions as PLL

electronic tuning radio, CD playing and operation & control of air conditioning system, it can receive AM, FM and FM stereo

radio broadcast programs, play CDs, electronically operate and control the air conditioning system of the car. The integrated

display screen can display the working state of the radio, CD player, air conditioning system, operating mode as well as

information concerning the equalizer, clock and the temperature inside and outside.

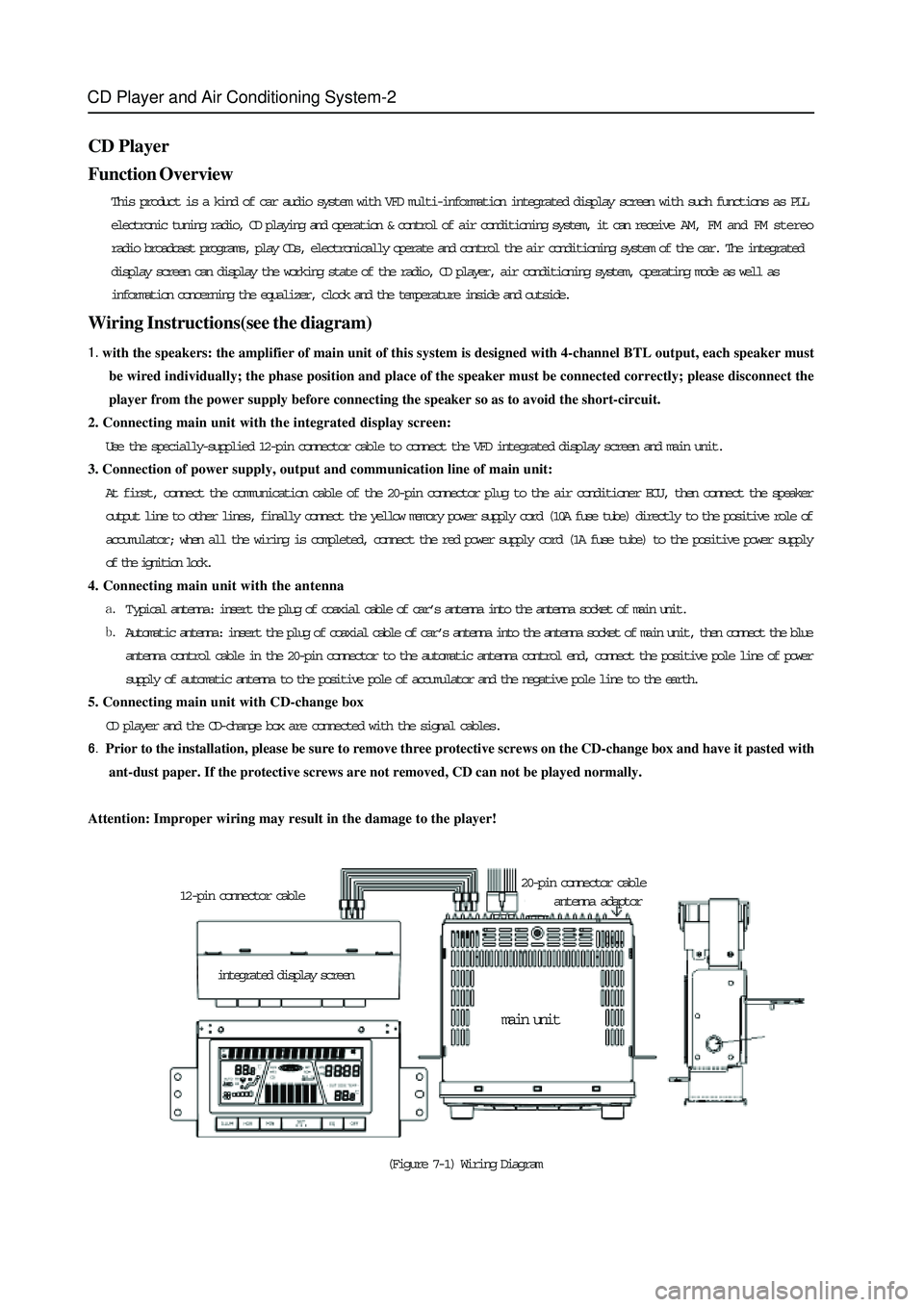

Wiring Instructions(see the diagram)

with the speakers: the amplifier of main unit of this system is designed with 4-channel BTL output, each speaker must

be wired individually; the phase position and place of the speaker must be connected correctly; please disconnect the

player from the power supply before connecting the speaker so as to avoid the short-circuit.

2. Connecting main unit with the integrated display screen:

Use the specially-supplied 12-pin connector cable to connect the VFD integrated display screen and main unit.

3. Connection of power supply, output and communication line of main unit:

At first, connect the communication cable of the 20-pin connector plug to the air conditioner ECU, then connect the speaker

output line to other lines, finally connect the yellow memory power supply cord (10A fuse tube) directly to the positive role of

accumulator; when all the wiring is completed, connect the red power supply cord (1A fuse tube) to the positive power supply

of the ignition lock.

4. Connecting main unit with the antenna

T ypical antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit.

Automatic antenna: insert the plug of coaxial cable of car’s antenna into the antenna socket of main unit, then connect the blue

antenna control cable in the 20-pin connector to the automatic antenna control end, connect the positive pole line of power

supply of automatic antenna to the positive pole of accumulator and the negative pole line to the earth.

5. Connecting main unit with CD-change box

CD player and the CD-change box are connected with the signal cables.

Prior to the installation, please be sure to remove three protective screws on the CD-change box and have it pasted with

ant-dust paper. If the protective screws are not removed, CD can not be played normally.

Attention: Improper wiring may result in the damage to the player!

(Figure 7-1) Wiring Diagram integrated display screen 12-pin connector cable20-pin connector cable

antenna adaptor

main unit

Page 356 of 425

CD Player and Air Conditioning System-3

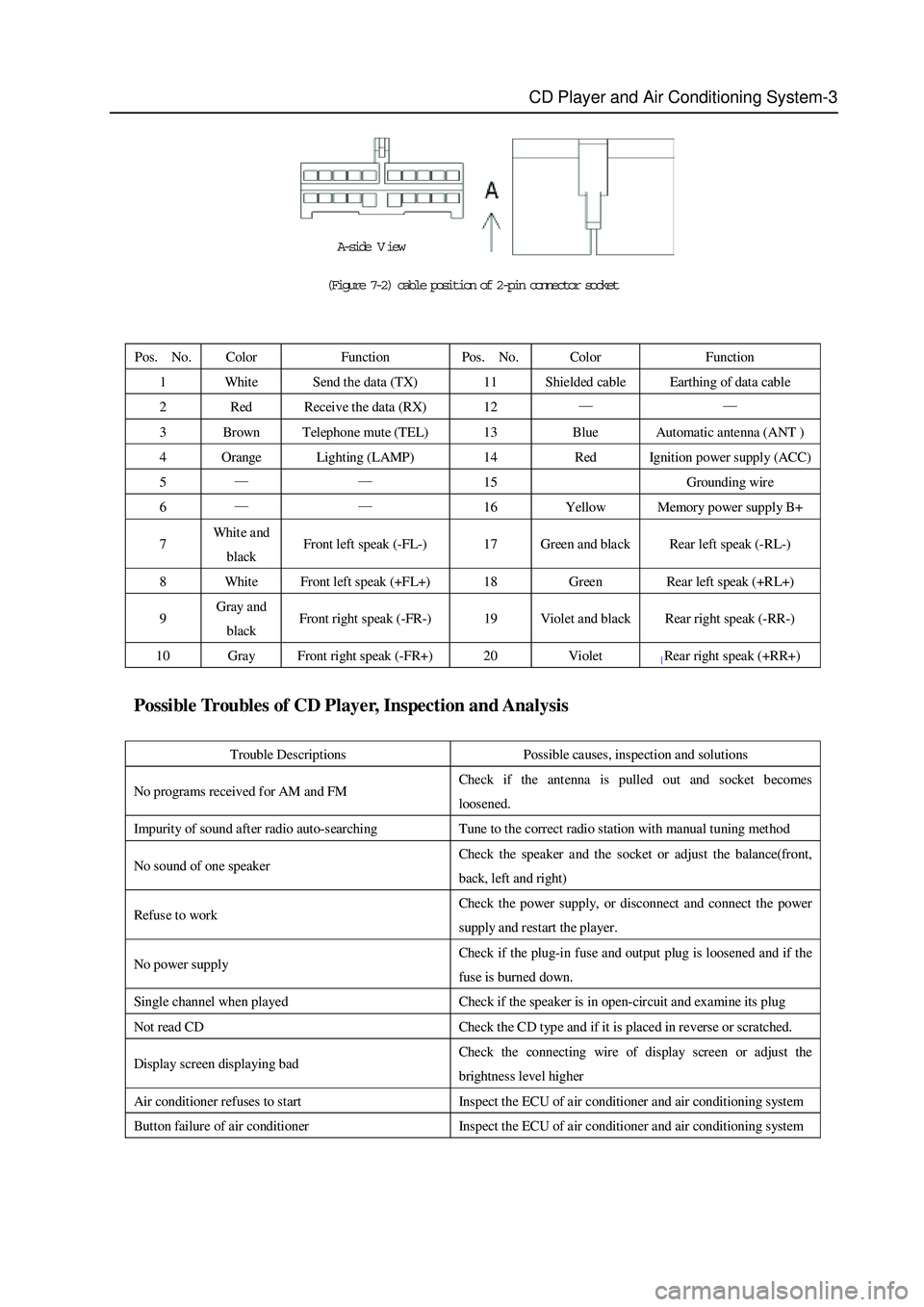

(Figure 7-2) cable position of 2-pin connector socket

Pos. No. Color Function Pos. No. Color Function

1 Whit e Send the data (TX) 11 Shielded cable Earthing of data cable

2 Red Receive the data (RX) 12 — —

3 Brown Telephone mute (TEL) 13 Blue Automatic antenna (ANT )

4 Orange Lighting (LAMP) 14 Red Ignition power supply (ACC)

5 — — 15 Grounding wire

6 — — 16 Yellow Memory power supply B+

7 Whit e and

black Front left speak (-FL-) 17 Green and black Rear left speak (-RL-)

8 White Front left speak (+FL+) 18 Green Rear left speak (+RL+)

9 Gray and

black Front right speak (-FR-) 19 Violet and black Rear right speak (-RR-)

10 Gray Front right speak (-FR+) 20 Violet {Rear right speak (+RR+)

Possible Troubles of CD Player, Inspection and Analysis

Trouble Descriptions Possible causes, inspection and solutions

No programs received for AM and FM Check if the antenna is pulled out and socket becomes

loosened.

Impurity of sound after radio auto-searching Tune to the correct radio station with manual tuning method

No sound of one speaker Check the speaker a nd the socket or adjust the balance(front,

back, left and right)

Refuse to work Check the power supply, or disconnect and connect the power

supply and restart the player.

No power supply Check if the plug-in fuse and output plug is loosened and if the

fuse is burned down.

Single channel when played Check if the speaker is in open-circuit and examine its plug

Not read CD Check the CD type and if it is placed in reverse or scratched.

Display screen displaying bad Check the connecting wire of display screen or adjust the

brightness level higher

Air conditioner refuses to start Inspect the ECU of air conditioner and air conditioning system

Button failure of air conditioner Inspect the ECU of air conditioner and air conditioning system

A-side V iew

Page 357 of 425

CD Player and Air Conditioning System-4

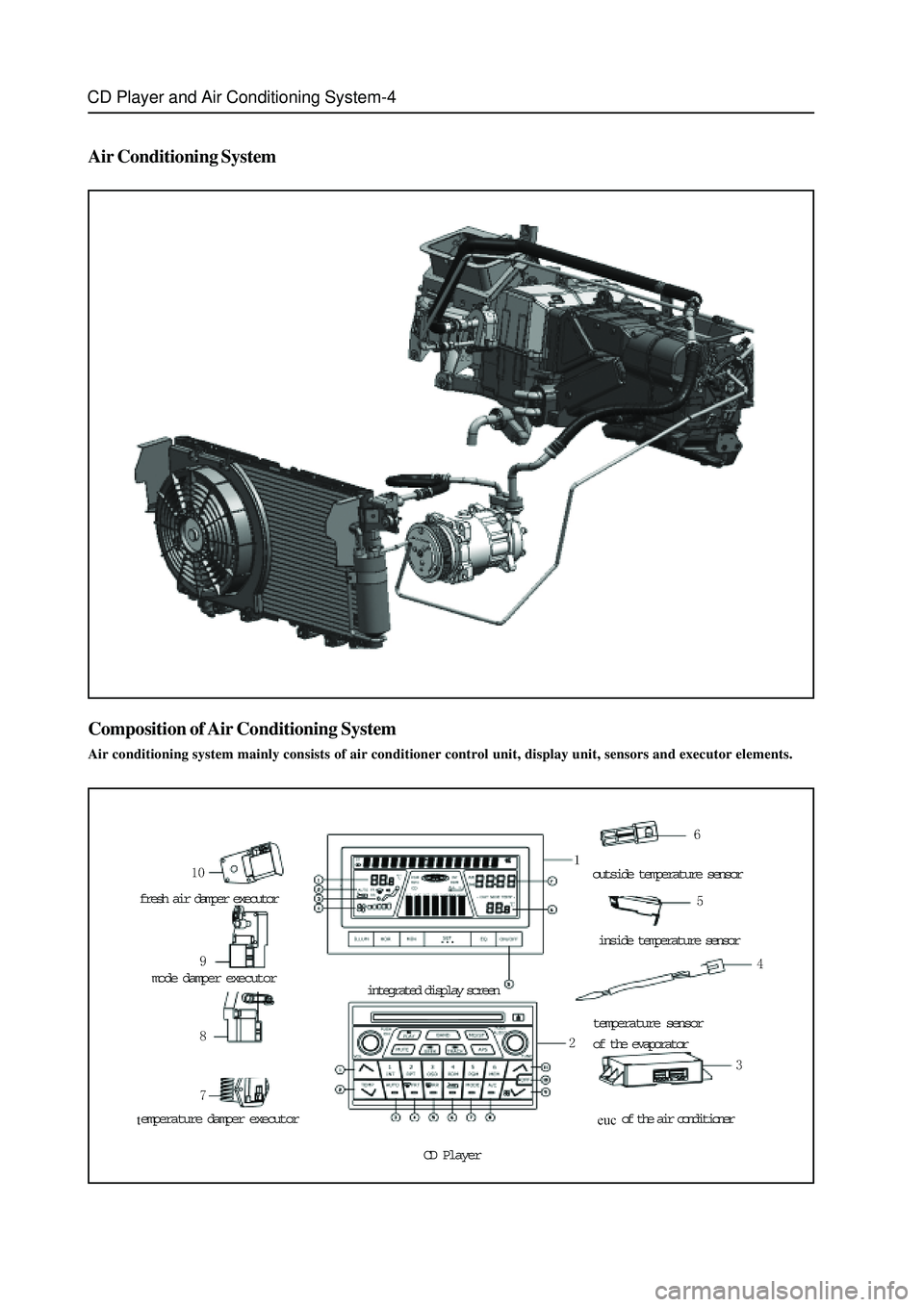

Air Conditioning System

Composition of Air Conditioning System

Air conditioning system mainly consists of air conditioner control unit, display unit, sensors and executor elements.

fresh air damper executor

mode damper executor

emperature damper executor

integrated display screen

CD Player

outside temperature sensor

inside temperature sensor

temperature sensor

of the evaporator

of the air conditioner

Page 358 of 425

CD Player and Air Conditioning System-5

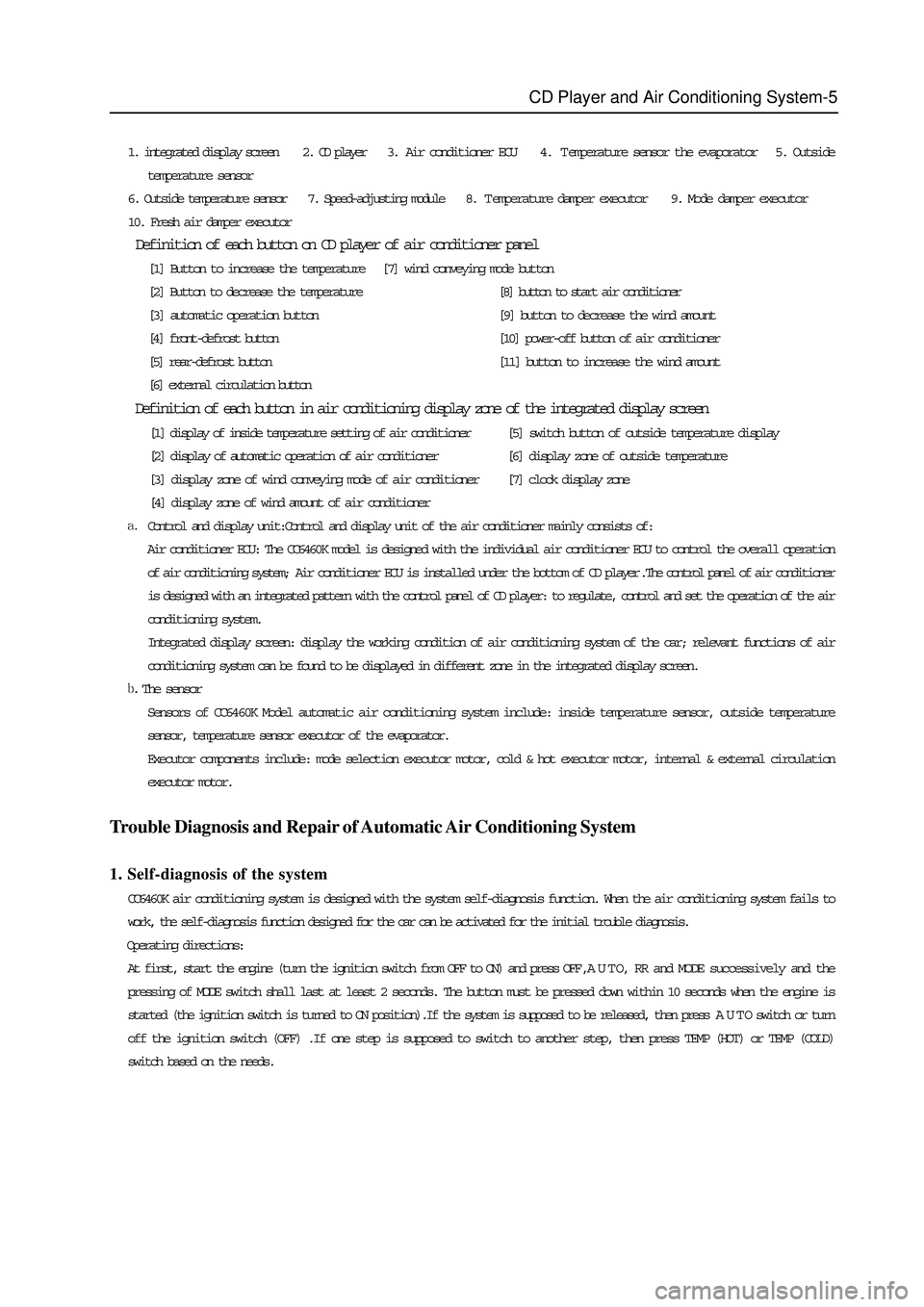

1. integrated display screen 2. CD player 3. Air conditioner ECU 4. Temperature sensor the evaporator 5. Outside

temperature sensor

6. Outside temperature sensor 7. Speed-adjusting module 8. Temperature damper executor 9. Mode damper executor

10. Fresh air damper executor

Definition of each button on CD player of air conditioner panel

[1] Button to increase the temperature [7] wind conveying mode button

[2] Button to decrease the temperature[8] button to start air conditioner

[3] automatic operation button[9] button to decrease the wind amount

[4] front-defrost button[10] power-off button of air conditioner

[5] rear-defrost button[11] button to increase the wind amount

[6] external circulation button

Definition of each button in air conditioning display zone of the integrated display screen

[1] display of inside temperature setting of air conditioner[5] switch button of outside temperature display

[2] display of automatic operation of air conditioner[6] display zone of outside temperature

[3] display zone of wind conveying mode of air conditioner[7] clock display zone

[4] display zone of wind amount of air conditioner

Control and display unit:Control and display unit of the air conditioner mainly consists of:

Air conditioner ECU: The CC6460K model is designed with the individual air conditioner ECU to control the overall operation

of air conditioning system; Air conditioner ECU is installed under the bottom of CD player.The control panel of air conditioner

is designed with an integrated pattern with the control panel of CD player: to regulate, control and set the operation of the air

conditioning system.

Integrated display screen: display the working condition of air conditioning system of the car; relevant functions of air

conditioning system can be found to be displayed in different zone in the integrated display screen.

The sensor

Sensors of CC6460K Model automatic air conditioning system include: inside temperature sensor, outside temperature

sensor, temperature sensor executor of the evaporator.

Executor components include: mode selection executor motor, cold & hot executor motor, internal & external circulation

executor motor.

Trouble Diagnosis and Repair of Automatic Air Conditioning System

1. Self-diagnosis of the system

CC6460K air conditioning system is designed with the system self-diagnosis function. When the air conditioning system fails to

work, the self-diagnosis function designed for the car can be activated for the initial trouble diagnosis.

Operating directions:

At first, start the engine (turn the ignition switch from OFF to ON) and press OFF , A U T O, RR and MODE successively and the

pressing of MODE switch shall last at least 2 seconds. The button must be pressed down within 10 seconds when the engine is

started (the ignition switch is turned to ON position).If the system is supposed to be released, then press A U T O switch or turn

off the ignition switch (OFF) .If one step is supposed to switch to another step, then press TEMP (HOT) or TEMP (COLD)

switch based on the needs.

Page 363 of 425

CD Player and Air Conditioning System-10

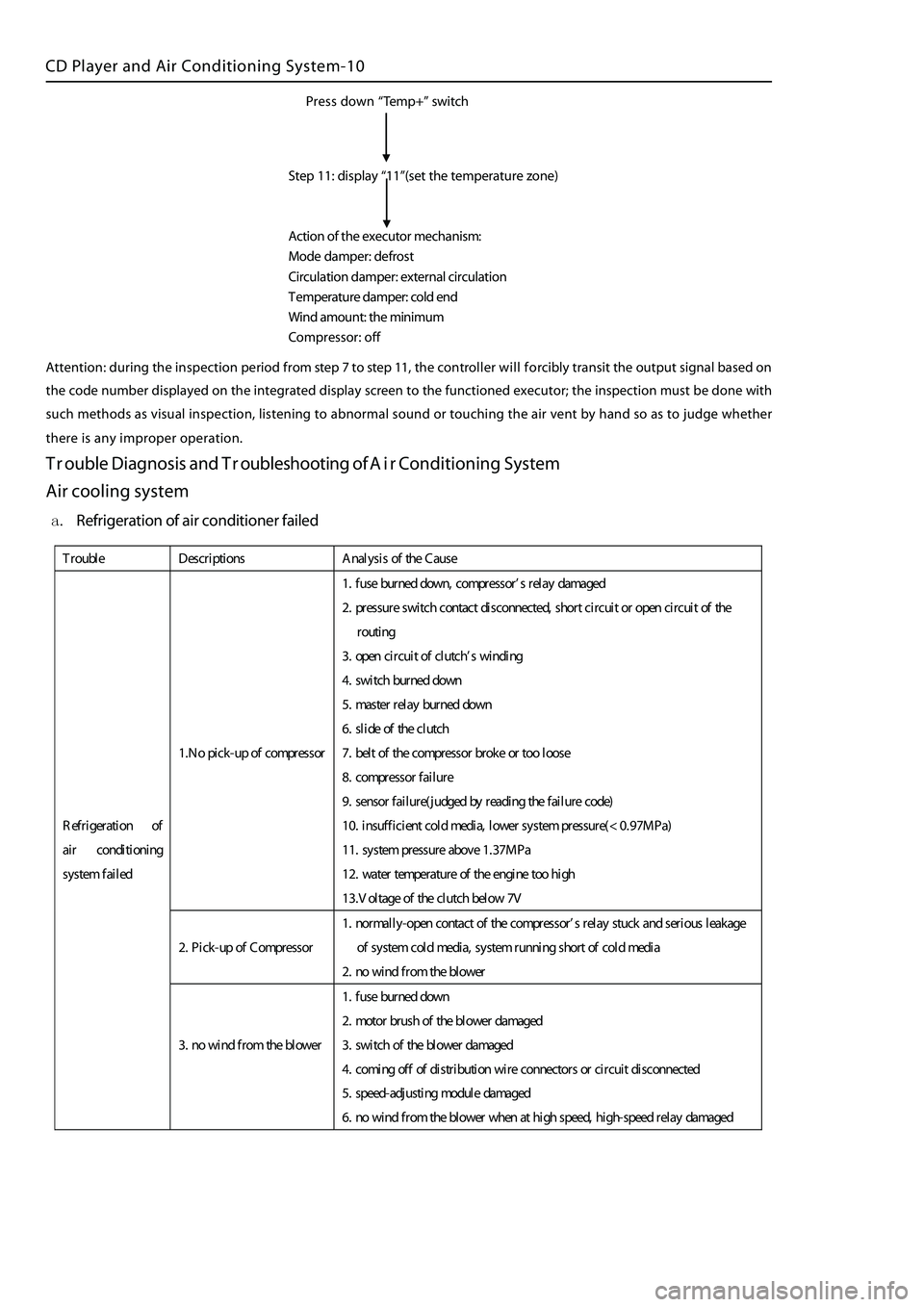

Refrigeration of air conditioner failed

T rou ble Des crip tion s Ana l ysis o f the Cause

1.No pick -up o f com pressor 1.

fuse burned down , com presso r’s r elay dama ge

d

2. pressu re sw itch contac t d isco nn ected, short c ircu itor open circ uit o f the

ro utin

g

3. open circ ui t o f clutch’ s w indi ng

4. sw itch burned down

5. ma ster relay b urne d d ow

n

6.

s lid e o f the clut ch

7. beltof the c om presso r b roke ortoo l oose

8. comp ressor failur

e

9. sens or failur e(ju dg ed by read ing t he failu recode

)

10. insu ffic ient cold me dia, lowe r system p ress ur e(< 0 .97M Pa

)

11. system pressu re abov e 1 .37M Pa

12. water t em peratu re of the e ngine t oo high

13. V oltag e o f the clut ch below 7

V

2. Pick -up o f Com pressor 1.

norm

ally -ope n c ontact of the c om presso r’s r elay stuc k a nd seriou s leaka ge

of system cold me dia, system runn ing s hortof cold me di

a

2. no wind from the b lowe

r

R e frig eratio n of

ai r c ondition in

g

syst emfaile

d

3.no wind from the b lowe

r 1.

fuse burned down

2. mo tor b rush ofthe b lowe r dam aged

3. sw itch ofthe b lowe r dam aged

4. comi ng off o f d istrib utio n w ire c onnector s o r circu itdisc

onne cted

5. speed-ad justin g m odule d amaged

6. no wind from the b lowe r w hen a t high s peed, h igh- sp ee d r elay dama ge

d

Press down “Temp+” switch

Step 11: display “11”(set the temperature zone)

Action of the executor mechanism

:

M ode damper: defrost

Circulation damper: external circulation

Te mperature damper: cold end

Wind amount: the minimum

Compressor: off

Attention: during the inspection period fr om step 7 to step 11, the controlle r

will for cibly transit the output signal based on

the code number displayed on the integrated display screen to the functioned executor; the inspection must be done with

such

m ethods as visual inspection, listening to abnormal sound or touching the air vent by hand so as to judge whether

there is any improper operation.

T rouble Diagnosis and T roubleshooting of A i r Conditioning System

Air cooling system

Page 367 of 425

CD Player and Air Conditioning System-14

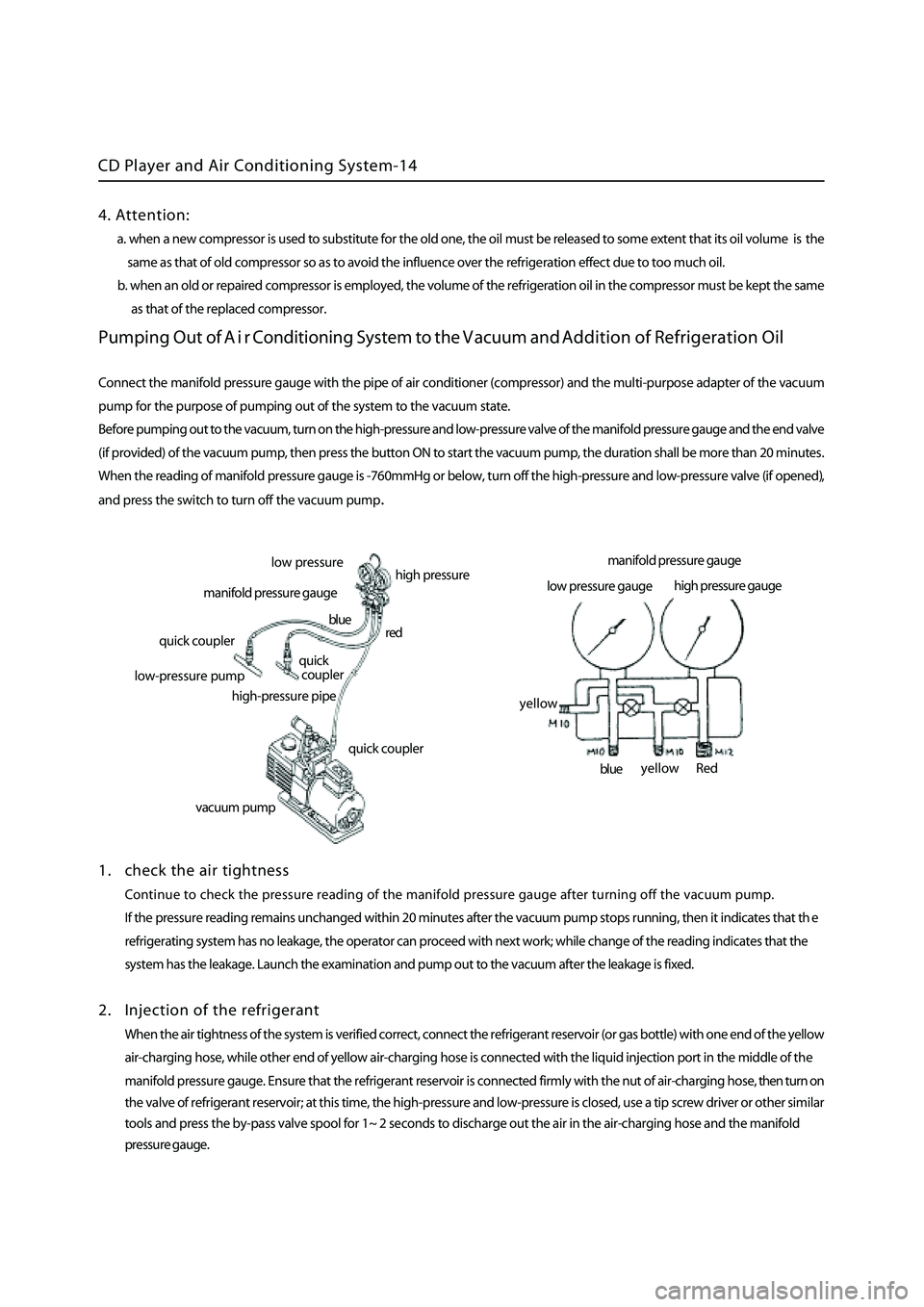

Pumping Out of A i r Conditioning System to the Vacuum and Addition of Refrigeration Oil

Connect the manifold pressure gauge with the pipe of air conditioner (compressor) and the multi-purpose adapter of the vacuum

pump for the purpose of pumping out of the system to the vacuum state.

Before pumping out to the vacuum, turn on the high-pressure and low-pressure valve of the

manifold pressure gauge and the end valve

(if provided) of the vacuum pump, then press the button ON to start the vacuum pump, the duration shall be more than 20 minutes

.

When the reading of manifold pressure gauge is -760mmHg or below, turn off the high-pressure and low-pressure valve (if opened)

,

and press the switch to turn off the vacuum pum

p.

1 . check the air tightness

Continue to check the pressure reading of the manifold pressure gauge after turning off the vacuum pump.

If the pressure reading remains unchanged within 20 minutes after the vacuum pump stops running, then it indicates that th

e

refrigerating system has no leakage, the operator can proceed with next work; while change of the reading indicates that the

system has the leakage. Launch the examination and pump out to the vacuum after the leakage is fixed.

2 . Injection of the refrigerant

When the air tightness of the system is verified correct, connect the refrigerant reservoir (or gas bottle) with one end of the yellow

a ir-charging hose, while other end of yellow air-charging hose is connected with the liquid injection port in the middle of the

manifold pressure gauge. Ensure that the refrigerant reservoir is connected firmly with the nut of air-charging hose, then turn on

the valve of refrigerant reservoir; at this time, the high-pressure and low-pressure is closed, use a tip screw driver or other

similar

tools and press the by-pass valve spool for 1~ 2 seconds to discharge out the air in the air-charging hose and the manifold

pressure gauge.

low p ressure

high pressure

manifold pressure gauge

quick coupler

l ow-pressure pump

high-pressure pipe

quick coupler

quick

coupler

red

blue

vacuum pum

p

manifold pressure gauge

low pressure gauge high

pressure gauge

Red

blue

yellow

yellow

4. Attention:

a. when a new compressor is used to substitute for the old one, the oil must be released to some extent that its oil volume is the

same as that of old compressor so as to avoid the influence over the refrigeration effect due to too much oil.

b. when an old or repaired compressor is employed, the volume of the refrigeration oil in the compressor must be kept the sam

e

as that of the replaced

compressor.

Page 368 of 425

CD Player and Air Conditioning System-15

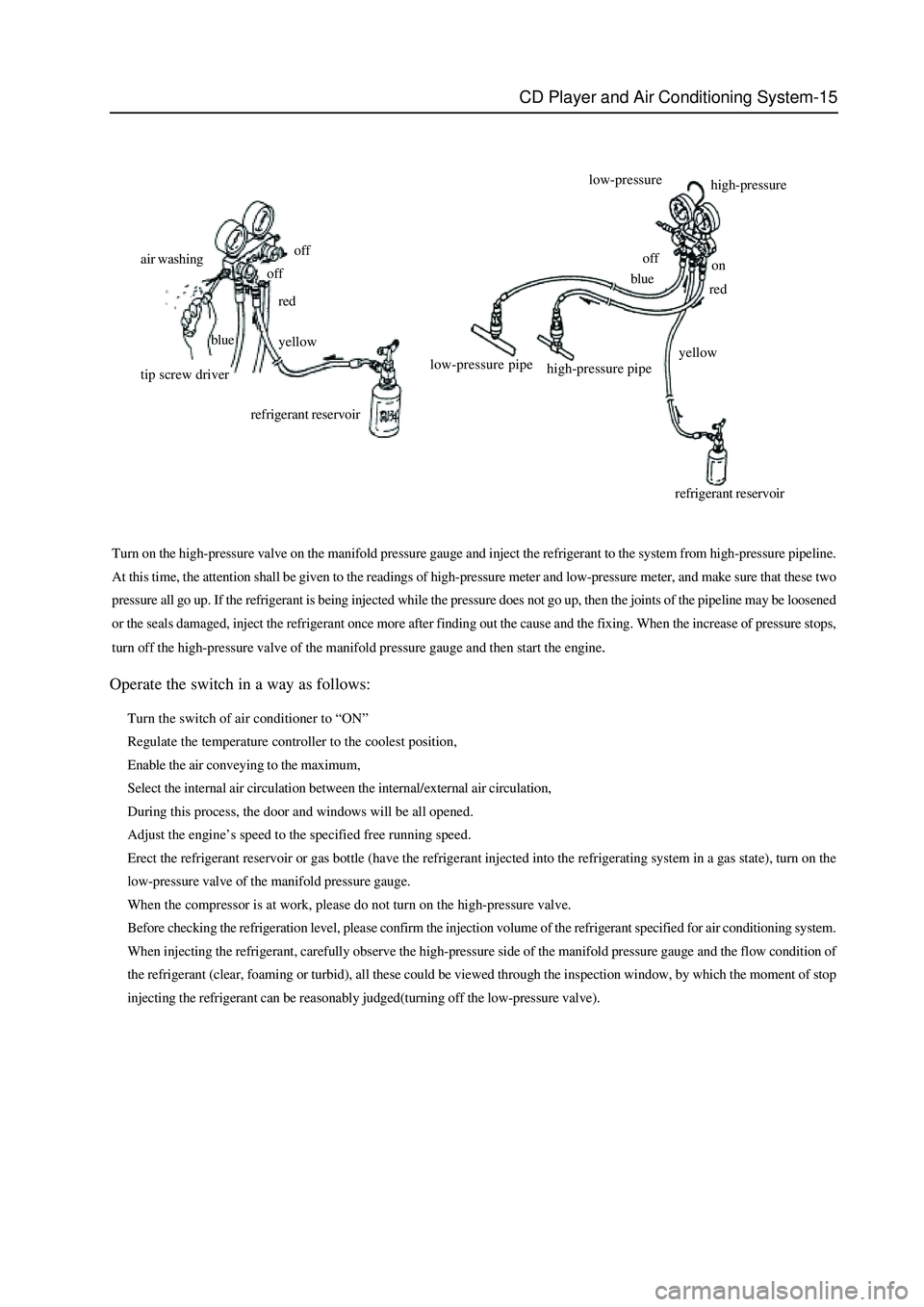

Turn on the high-pressure valve on the manifold pressure gauge and inject the refrigerant to the system from high-pressure pipeline.

At this time, the attention shall be given to the readings of high-pressure meter and low-pressure meter, and make sure that these two

pressure all go up. If the refrigerant is being injected while the pressure does not go up, then the joints of the pipeline may be loosened

or the seals damaged, inject the refrigerant once more after finding out the cause and the fixing. When the increase of pressure stops,

turn off the high-pressure valve of the manifold pressure gauge and then start the engine

.

Operate the switch in a way as follows:

Turn the switch of air conditioner to “ON”

Regulate the temperature controller to the coolest position,

Enable the air conveying to the maximum,

Select the internal air circulation between the internal/external air circulation,

During this process, the door and windows will be all opened.

Adjust the engine’s speed to the specified free running speed.

Erect the refrigerant reservoir or gas bottle (have the refrigerant injected into the refrigerating system in a gas state), turn on the

low-pressure valve of the manifold pressure gauge.

When the compressor is at work, please do not turn on the high-pressure valve.

Before checking the refrigeration level, please confirm the injection volume of the refrigerant specified for air conditioning system.

When injecting the refrigerant, carefully observe the high-pressure side of the manifold pressure gauge and the flow condition of

the refrigerant (clear, foaming or turbid), all these could be viewed through the inspection window, by which the moment of stop

injecting the refrigerant can be reasonably judged(turning off the low-pressure valve).

air washingoff

off

tip screw driverred

yellow blue

refrigerant reservoirhigh-pressure low-pressure

off

low-pressure pipe

high-pressure pipe

refrigerant reservoiryellowred blueon

Page 369 of 425

CD Player and Air Conditioning System-16

refrigerant reservoir high-pressure pipelow pressure

high pressure

yellowred blueon on

low-pressure pipe

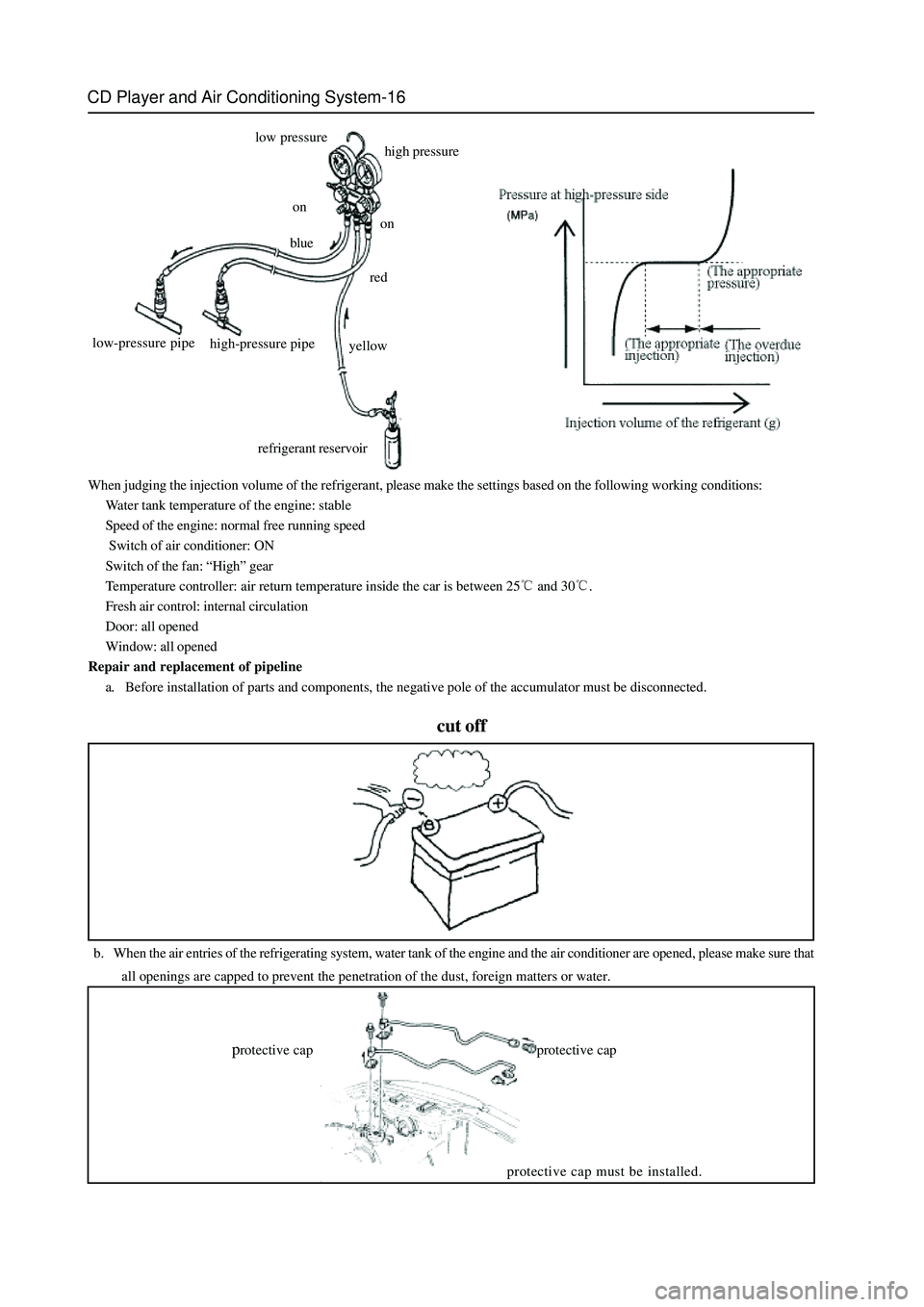

When judging the injection volume of the refrigerant, please make the settings based on the following working conditions:

Water tank temperature of the engine: stable

Speed of the engine: normal free running speed

Switch of air conditioner: ON

Switch of the fan: “High” gear

Temperature controller: air return temperature inside the car is between 25

and 30.

Fresh air control: internal circulation

Door: all opened

Window: all opened

Repair and replacement of pipeline

a. Before installation of parts and components, the negative pole of the accumulator must be disconnected.

cut off

b. When the air entries of the refrigerating system, water tank of the engine and the air conditioner are opened, please make sure that

all openings are capped to prevent the penetration of the dust, foreign matters or water.

protective cap protective cap

protective cap must be installed.