engine wire HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1586 of 2189

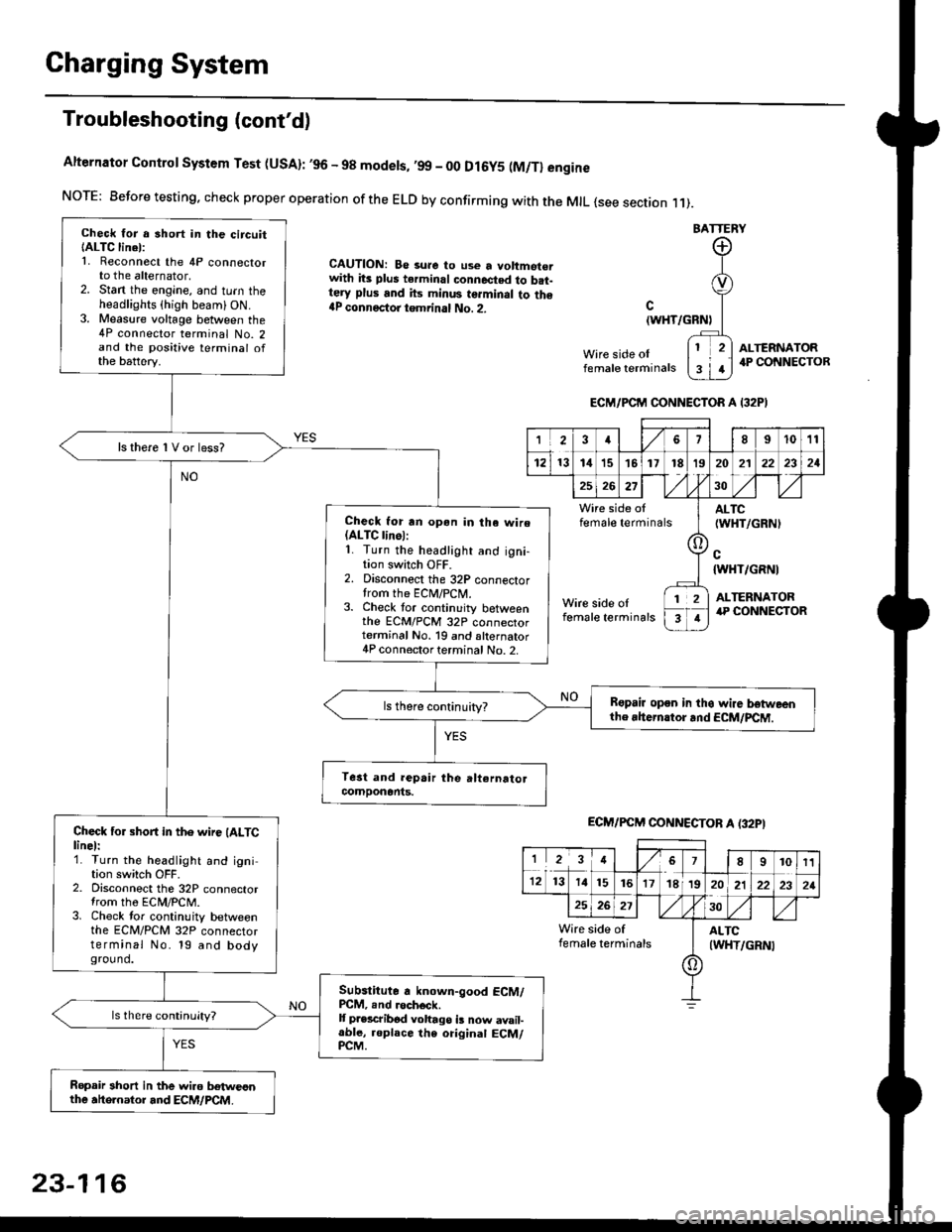

Charging System

Troubleshooting (cont'd)

Alternator Control System Test (USA): ,96 - 98 modets, ,99 _ 00 Dl6y5 (M/Tl engine

NorE: Before testing. check proper operation of the ELD by confirming with the MrL {see section r 1).

BATTERY

CAUTION: Be 3ure to use a voltmot€.with its plus terminal connected to b.t-tery plus and its minus terminal to the{P connectoi tgmrinal No. 2.c

{WHT/GRNt

Wire side oIfemale terminals

ALTERNATOR.P CONNECTOB

Check for a 3hort in the circuitIALTC linel:1. Reconnect the 4P connectorto the alternator,2. Stan the engine, and turn theheadlights {high beam) ON.3. Measure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

ls there 1V or less?

Check for rn opon in tha wire(ALTC linol:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectortrom the ECM/PCN4.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and alternator4P connector terminal No. 2.

Bspair open in thg wire lrstweenthe rhern.tor .nd ECM/PCM.

Check for short in the wire (ALTClinel:1. Turn the headlight and ignition switch OFF.2. Disconnect the 32P connectortrom the ECM/PCM.3. Check tor continuity betweenthe ECM/PCM 32P connectorterminal No. 19 and bodyground.

Subslitute a known-good ECM/PCM, .nd .och6ck.It p.escribod vohago i! now avail-able, replace the original ECM/PCM.

Ropair 3hort in the wiro betweonthe ahe.nator and ECM/PCM.

ECM/PCM CONNECTOR A I32PI

'Ia18I1011

121314151718t9

7

202'l2221

262730

Wire side offemale terminalsALTC(WHT/GRNI

c{WHT/GRNI

ALTERNATORWire side oIfemale terminals

([l

T

12

1

ECM/PCM CONNECTOB A (32PI

I23478910t1

1213 14151617182021222321

262730

Wire side of I AITCfemate terminats

A

(WHT/GRN|

23-116

Page 1587 of 2189

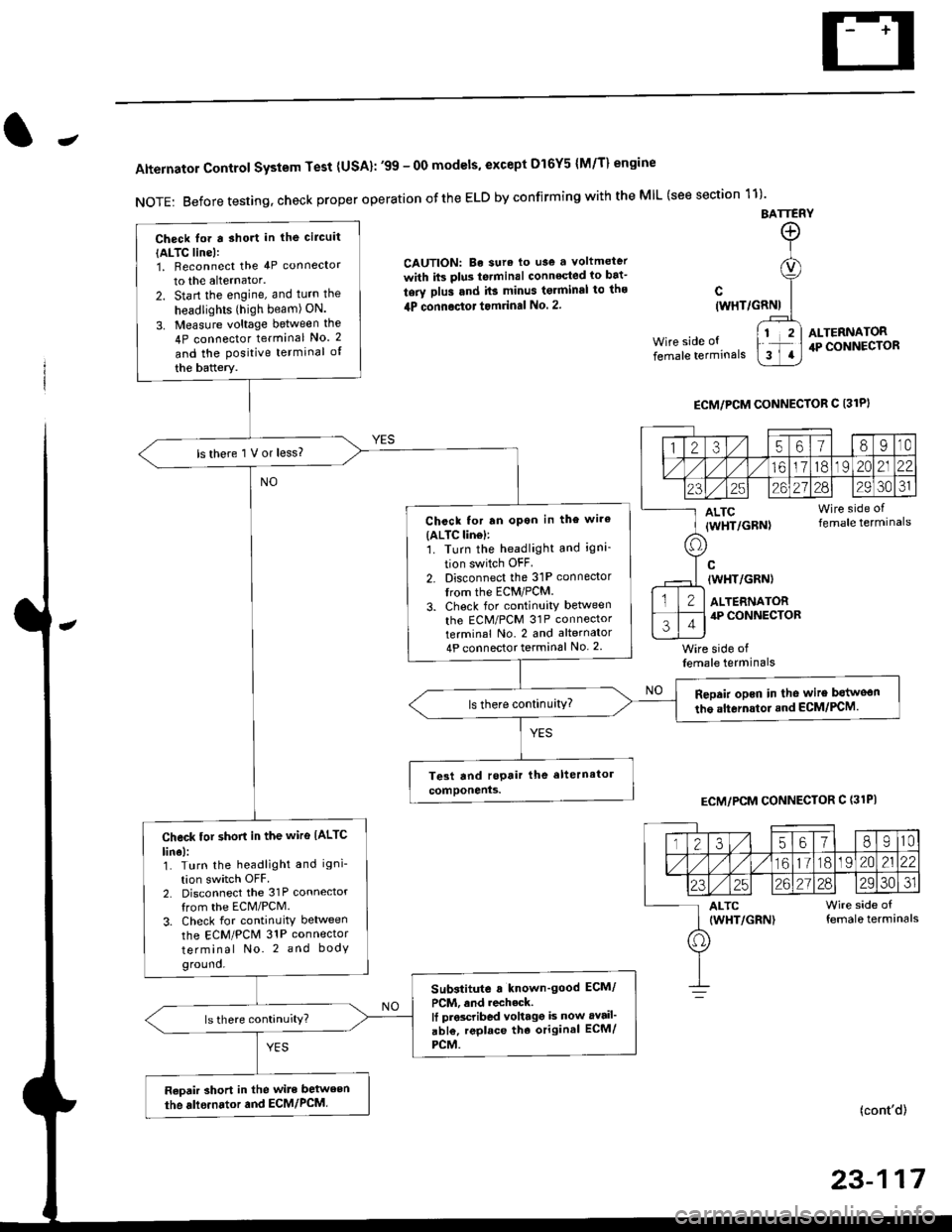

-

Alternator Control System Test {USA}: '99 - 0O models, except Dl6Y5 {M/T} engine

NOTE: Before testing, check proper operation ofthe ELD by confirming with the MIL (see section 11)'

BATTERY

CAUTION: Be sura lo use a voltmeter

with its plus te.minal conneqted io bat-

tery plus and it3 minus tgrminal to ths

4P connoctot tomrinal No. 2.

Wire side of

female terminals

c(WHT/GRNI

wire side offemale terminals

ALTERNATOR.P CONNECTOR

ECM/PCM CONNECTOR C 13lPI

ECM/PCM CONNECTOR C (31PI

(cont'd)

23-117

Check lor a sho.t in the circuit

{ALTC line):1, Beconnect the 4P connector

to the alternator.

2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the

4P connector terminal No. 2

and the Positive terminal of

the battery.

ls there 1 V or less?

Chcck for rn opon in the wire(ALTC lin6l:1. Turn the headlight and igni-

tion switch OFF

2. Disconnect the 31P connector

trom the ECM/PCM.

3. Check for continuity betlveen

the ECM/PCM 31P connectorterminal No. 2 and alternator

4P connector terminal No. 2

Repair opcn in the wire botweon

the alternstoi.nd ECM/PCM.ls there continuity?

Check tor short in the wire IALTC

line):1. Turn the headlight and igni-

tion switch OFF2. Disconnect the 31P connector

from the ECM/PCM.

3. Check for continuity between

the ECM/PCM 31P connector

terminal No. 2 and body

ground.

Substitute a known'good ECM/

PCM, and recheck.It prscribed voltagg is now avail'

abl€, replace tho original ECM/

PCM.

Raoair short in the wite between

the alle.nator and ECM/PCM,

1235618I10

/11611lo191 zo2122

23252621?82930JI

ALTC Wire side of(WHT/GRN) female terminals

o

Page 1610 of 2189

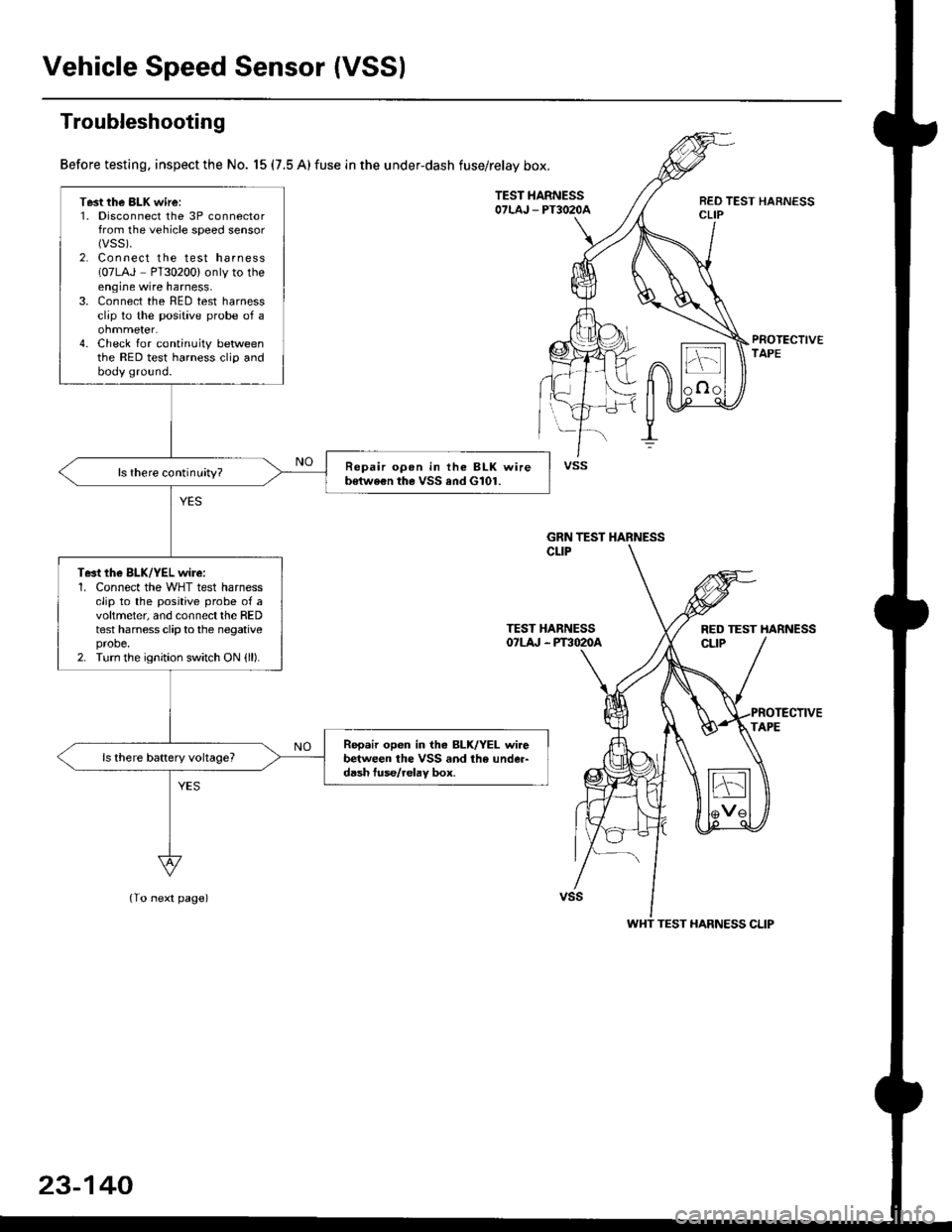

Vehicle Speed Sensor (VSSI

Troubleshooting

Before testing, inspect the No. 15 (7.5 A) fuse in the under-dash fuse/relay box.

TEST HARNESSOTLAJ _ PT3O2OAREO TEST HARNESSCLIP

PROTECTIVETAPE

TEST HARNESSOTLA' . PT3O2OA

(To next page)

Test the BLK wire:1. Disconnect the 3P connectorfrom the vehicle speed sensor(vss).

2. Connect the test harness(07LAJ PT30200) only to theengine wire harness,3. Connect the RED test harnessclip to the positive probe of a

4. Check for continuity betweenthe RED test harness clip andbody ground.

Repair opon in the BLK wireb€twe€n the VSS and G101.ls there continuity?

Te3t the BLK/YEL wire:1. Connect the WHT test harnessclip to the positive probe of avoltmeter, and connectthe REDtest harness clip to the negativeprobe.2. Turn the ignition switch ON {ll).

Repair open in iho BLK/YEL wirebetween the VSS and the under-d6sh tuse/relav box.

vss

GRN TEST HARNESS

RED TEST HARNESS

WHT TEST HARNESS CLIP

23-140

Page 1753 of 2189

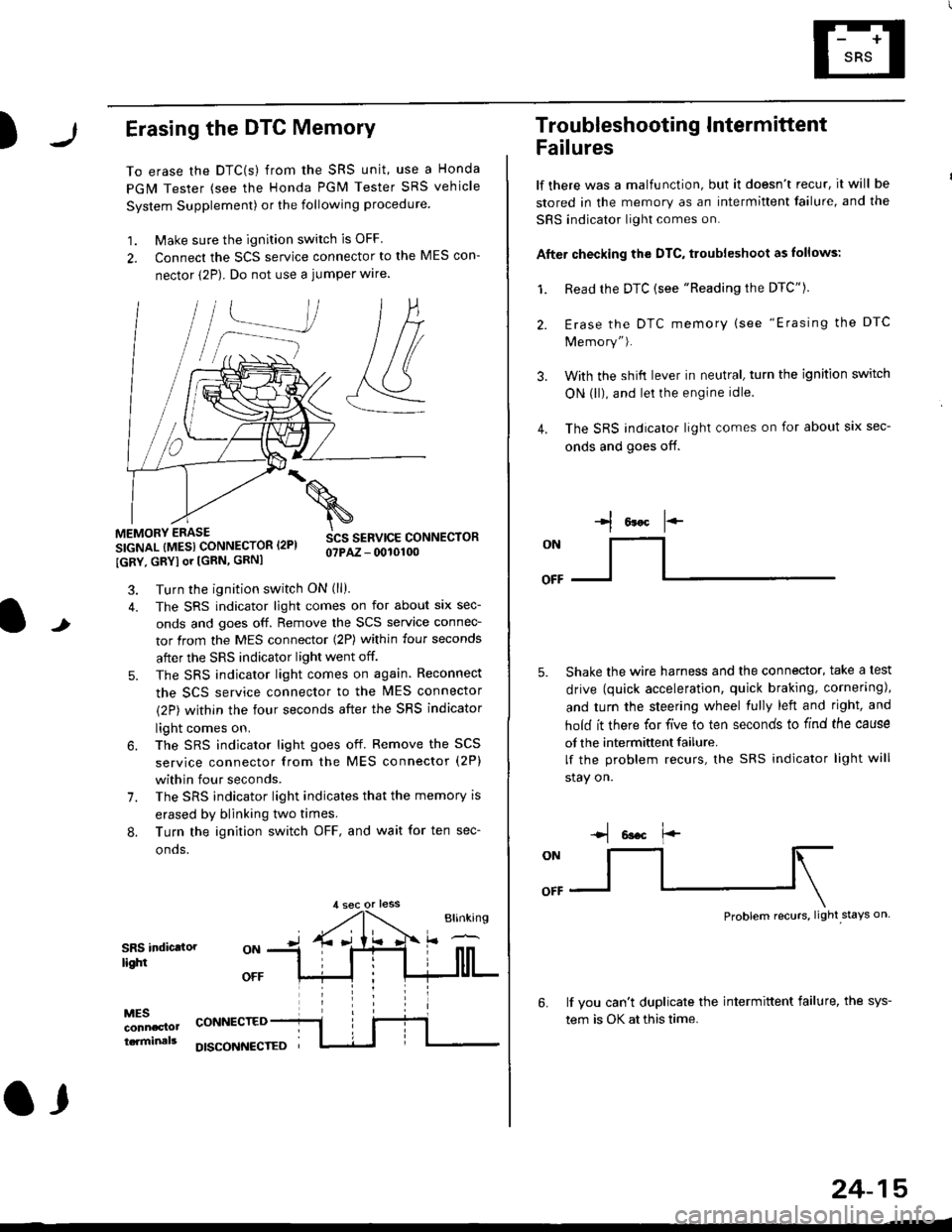

)Erasing the DTC Memory

To erase the DTC(s) from the SRS unit, use a Honda

PGM Tester (see the Honda PGM Tester SRS vehicle

System Supplement) or the following procedure

1. Make sure the ignition switch is OFF

2. Connect the SCS service connector to the MES con-

nector (2P). Do not use a jumper wlre.

]P,

&

.!--J

MEMORY ERASE

SIGNAL (MESI CONNECTOR I2PI

IGRY, GRYI or [GRN, GRNI

SCS SERVICE CONNECTORo?PAZ - 0010100

t

7.

Turn the ignition switch ON (ll).

The SRS indicator light comes on for about six sec-

onds and goes off. Remove the SCS service connec-

tor from the MES connector (2P) within four seconds

after the SRS indicator light went off.

The SRS indicator light comes on again. Reconnect

the SCS service connector to the lvlES connector

(2P) within the four seconds after the SRS indicator

light comes on.

The SRS indicator light goes off. Remove the SCS

service connector from the MES connector (2P)

within four seconds.

The SRS indicator light indicates that the memory is

erased by blinking two times.

Turn the ignition switch OFF, and wait for ten sec-

onos.

8.

SRS indictlorlighi

MESconncclottcaminals

CONNECTED

O,

DISCONI{ECTED

24-15

Troubleshooting Intermittent

Failures

lf there was a malfunction, but it doesn't recur, it will be

stored in the memory as an intermittent failure, and the

SRS indicator light comes on.

Afte. checking the DTC, troubleshoot as lollows:

1. Read rhe DTC {see "Reading the DTC"}.

Erase the DTC memory (see "Erasing the DTC

Memory").

With the shifi lever in neutral, turn the ignition switch

ON (ll), and lei the engine idle.

The SRS indicator light comes on for about six sec-

onds and goes off.

l*F

ON

tl-- -l

Shake the wire harness and the connector, take a test

drive (quick acceleration, quick braking, cornering),

and turn the steering wheel fully left and right, and

hold it there for five lo ten seconds to find the cause

of the intermittent failure.

lf the problem recurs, the SRS indicator light will

stay on.

-q 6a.c f'-

:q

Problem recurs, light stays on

3.

4.

6.lf vou can't duplicate the intermittent failure, the sys-

tem is OK at this time.

Page 1824 of 2189

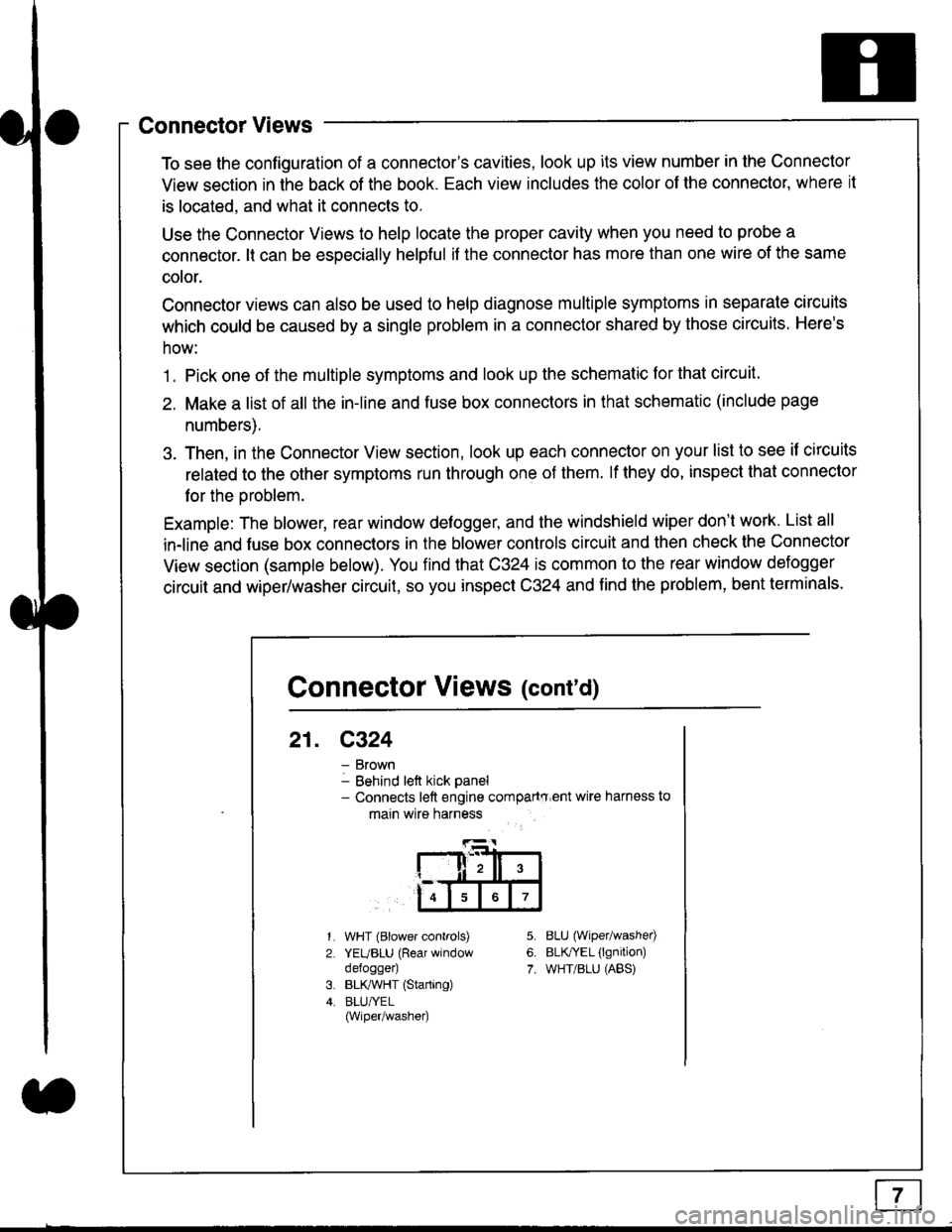

Connector Views

To see the configuration of a connector's cavities, look up its view number in the Connector

View section in the back of the book. Each view includes the color of the connector, where it

is located, and what it connects to.

Use the Connector Views to help locate the proper cavity when you need to probe a

connector. lt can be especially helpful if the connector has more than one wire of the same

cotor.

Connector views can also be used to help diagnose multiple symptoms in separate circuits

which could be caused by a single problem in a connector shared by those circuits. Here's

how:

1. Pick one of the multiple symptoms and look up the schematic for that circuit.

2. Make a list of all the in-line and fuse box connectors in that schematic (include page

numbers).

3. Then, in the Connector View section, look up each connector on your list to see il circuits

related to the other symptoms run through one of them. lf they do, inspect that connector

for the oroblem.

Example: The blower, rear window defogger, and the windshield wiper don't work. List all

in-line and fuse box connectors in the blower controls circuit and then check the Connector

View section (sample below). You find that C324 is common to the rear window defogger

circuit and wiper/washer circuit, so you inspect C324 and find the problem, bent terminals.

5.

6.

7.

1.

2.

WHT (Blower controls)

YEUBLU (Rear window

defogger)

BLK,ryVHT (Starting)

BLU/YEL(Wiper/washe0

8LU (Wiper/washed

BLfiEL (lgnition)

WHT/BLU (ABS)

Connector Views (cont'd)

21. C324

Brown

Behind left kick panel- Connects left engine compartry'ent wire harness to

main wire harness

ll,ll,

567

Page 1829 of 2189

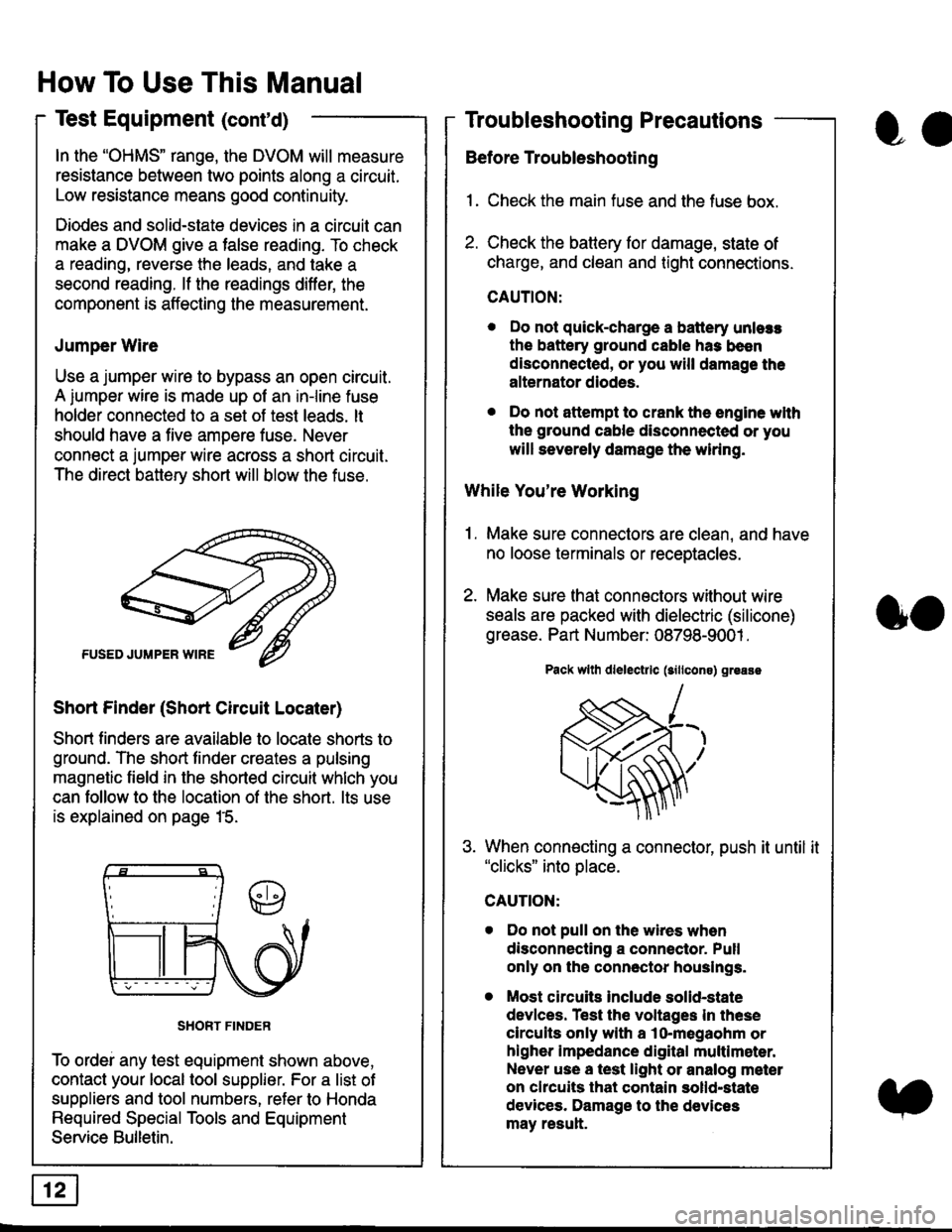

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo

Page 1838 of 2189

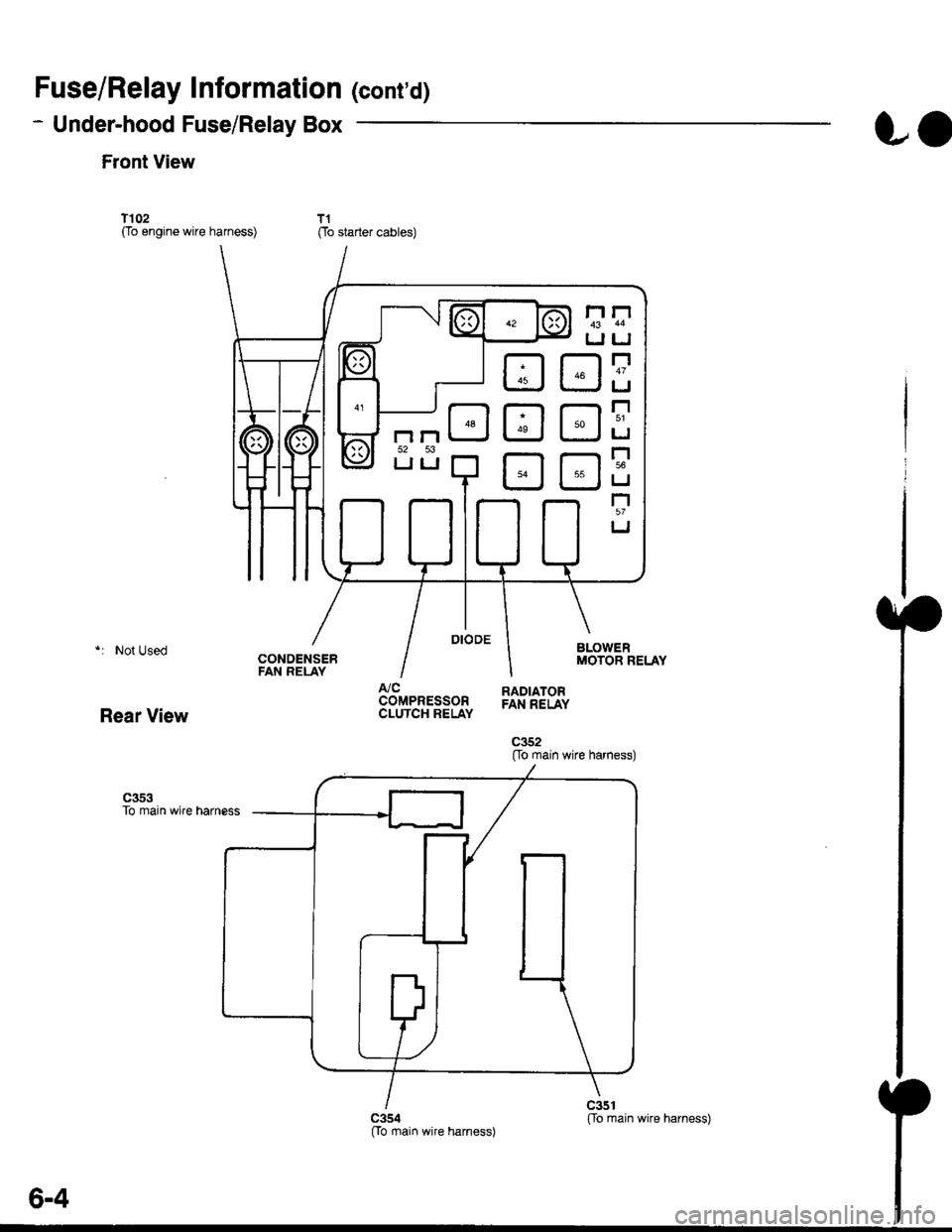

Fuse/Relay Information lcont'd)

- Under-hood Fuse/Relay Box

Front View

T'102(To engine wire harness)

LO

T1Oo starter cables)

*: Not Used

Rear View

c353To main wire harness

DE

tr

tr

tr

t-l

IJ

n

tJ

t-l51

IJ

n

IJ

n5T

IJ

[[o main wire harness)

6-4

ffo main wire harness)fto main wire harness)

Page 1840 of 2189

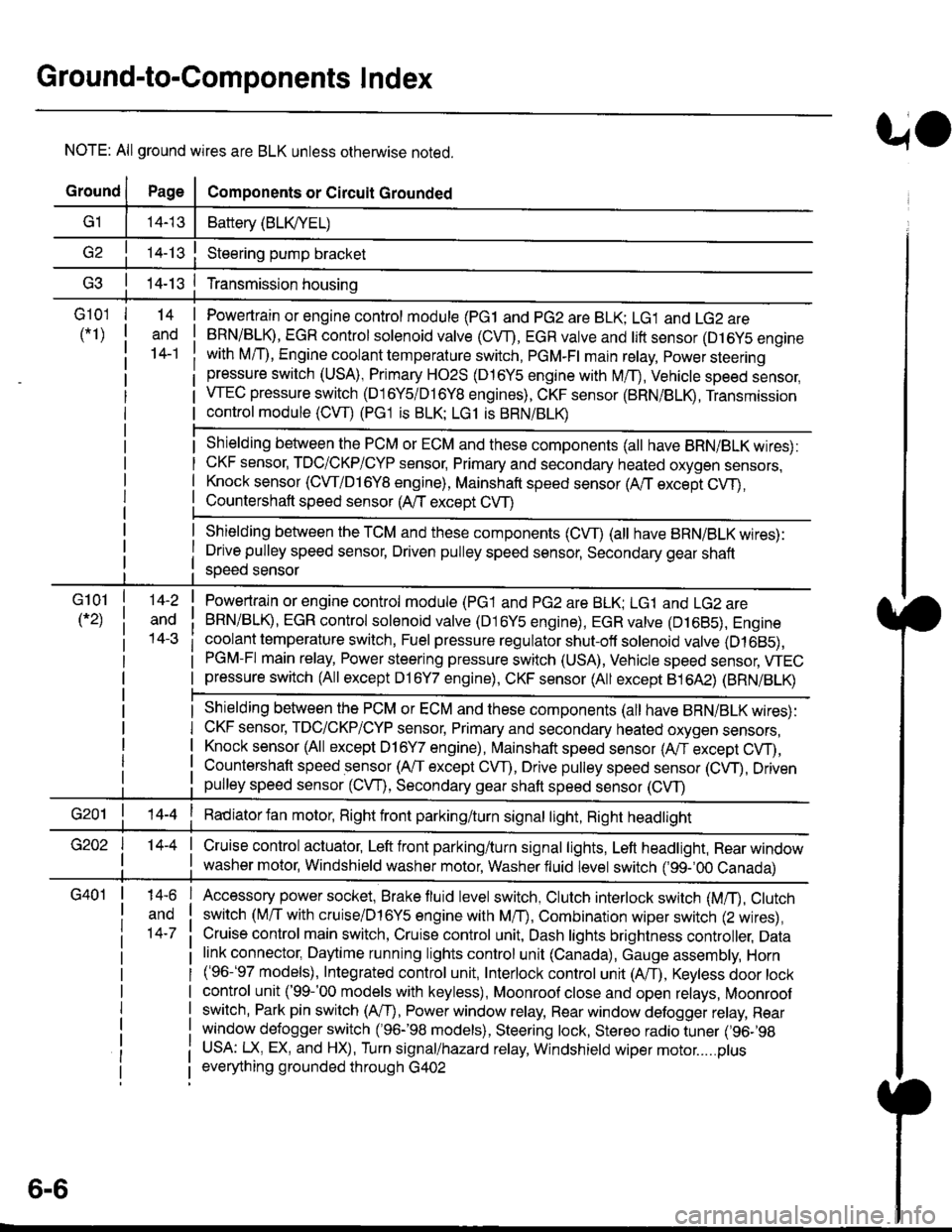

Ground-to-Components I ndex

f.,lONOTE: All ground wires are BLK unless otherwise noted.

GroundPageComponents or Circuit Grounded

Battery (BLKYEL)

Steering pump bracket

t+-rg ITransmission housing

l

G101

(-1)

G101

(-2)

14-2

and

14-3

ano

14-1

Powertrain or engine control module (PG1 and pG2 are BLK: LG1 and LG2 are

BRN/BLK), EGR control solenoid valve (CW, EGR valve and lift sensor (Dt6yS enginewith M,/T), Engine coolant temperature switch, pGM-Fl main relay, power steeringpressure switch (USA), Primary HO2S (D16Y5 engine with l\/,/T), Vehicle speed sensor,VTEC pressure switch (D16Y5/D16Y8 engines), CKF sensor (BRN/BLK), Transmission

control module (CYf) (Pc1 is BLK: LG1 is BRN/BLK)

Shielding betvveen the PCM or ECM and these components (all have BRN/BLK wires):

CKF sensor, TDC/CKP/CYP sensor. Primary and secondary heated oxygen sensors.

Knock sensor (CWDl6YB engine), Mainshaft speed sensor (AiT except CVT),

I Countershaft speed sensor (A/T except CVf)

Shielding between the TCM and these components (CVT) (all have BRN/BLK wires):

Drive pulley speed sensor, Driven pulley speed sensor, Secondary gear shaft

speed sensor

Powertrain or engine control module (PG1 and pG2 are BLK; LG1 and LGz are

BRN/BLK), EGR control solenoid valve (D16Y5 engine), EGR valve (Dt685), Engine

coolant temperature switch, Fuel pressure regulator shut-off solenoid valve (D1685),

PGM-FI main relay, Power steering pressure switch (USA), Vehicle speed sensor, VTECpressure switch (All except D16Y7 engine), CKF sensor (A

except 81642) (BRN/BLK)

Shielding between the PCM or ECM and these components (all have BRN/BLK wires):

CKF sensor, TDC/CKP/CYP sensor, Primary and secondary heated oxygen sensors,

Knock sensor (All except D16Y7 engine), i/ainshaft speed sensor (Arf except CW),

Countershaft speed sensor (A,/T except CVf), Drive pulley speed sensor (CW), Drivenpulley speed sensor (CVT), Secondary gear shaft speed sensor (CVf)

I Badiator fan motor, Right front parking/turn signat tight, Right headtight

G20214-4I Cruise control actuator, Left front parking/turn signal lights, Left headlight, Rear window

I washer motor, Windshield washer motor, Washer fluid level switch (,99-'00 Canada)

G401| +-o

and

14-7

Accessory power socket, Brake fluid level switch, Clutch interlock switch (M/T), Clutchswitch (lillT with cruise/D16Y5 engine with MfD, Combination wiper switch (Z wires),

Cruise control main switch, Cruise control unit, Dash lights brightness controller, Data

link connector, Daytime running lights control unit (Canada), Gauge assembly, Horn('96-'97 models), Integrated control unit, Interlock control unit (ArI), Keyless door lock

control unit ('99-'00 models with keyless), Moonroof close and open relays, Moonroof

switch, Park pin switch (A/r), Power window relay, Rear window defogger relay, Rear

window defogger switch ('96-'98 models), Steering lock, Stereo radio tuner (,96-,98

USA: LX, EX, and HX), Turn signal/hazard relay, Windshield wiper motor.....plus

everything grounded through G402

6-6

Page 1857 of 2189

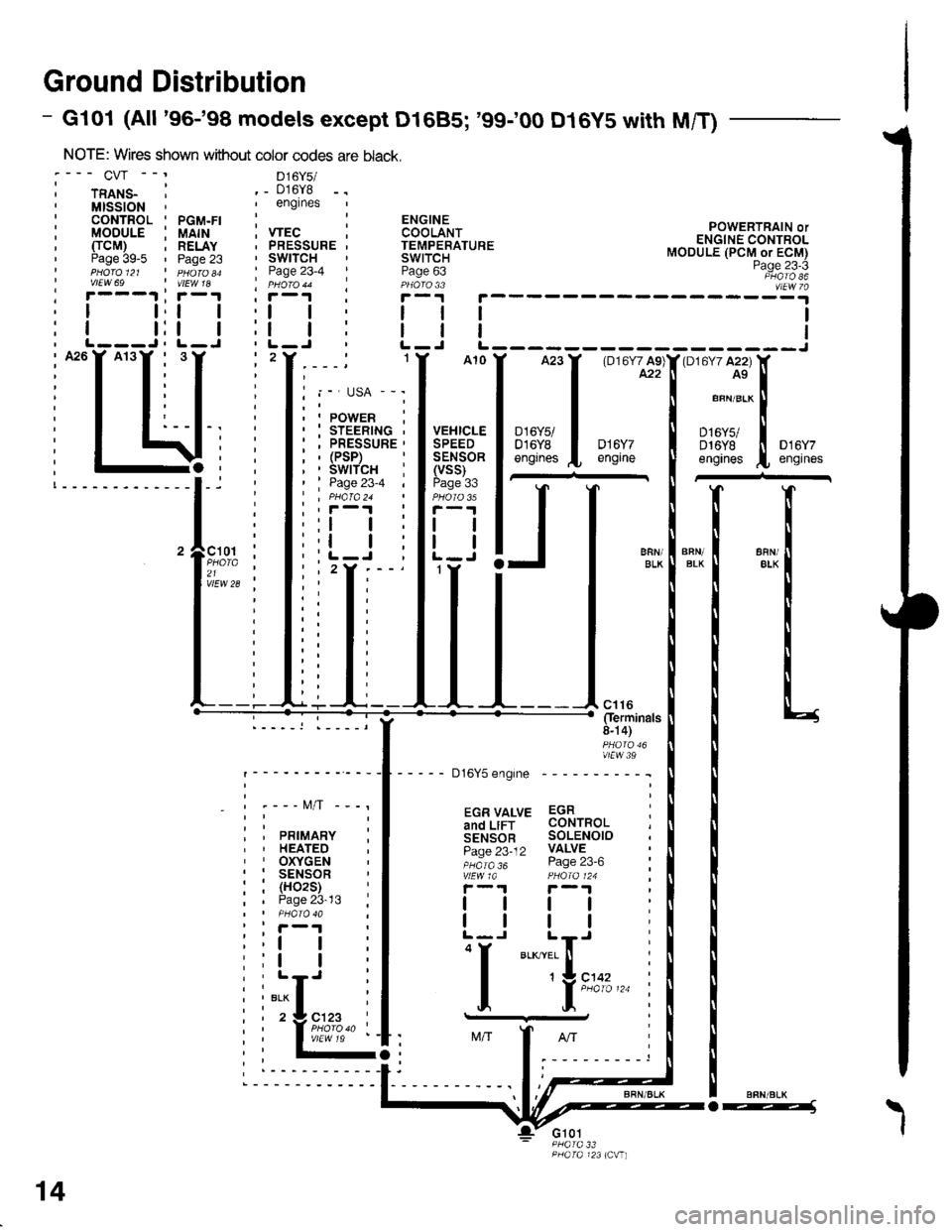

Ground Distribution

- Gl01 (All '96-'98 models except D1685; '99100 D16y5 with M/T)

NOTE: Wires shown without color codes

:--- CVr --' D16y5/

i rnlts_ ' ._ 016y8,MISSION',englnes

: CONTROL ' PGM.FI :: MODULE i UAIH ; VTEC, TTCM) ; RELAY . PRESSURE' Paae 39-5 ' Paoe 23 ' SWITCHI pHdro et ' n 6roao ' Page 23-4I vtEw 69 | vtEw 1a ' pHoro 44' r---.t ' r-1 I i-r

POWERTRAIN orENGINE CONTROLMODULE (PCM or ECM)Page 23-3PHATO 86vlEw 7a; r---1 ;r-1 , r, I t,t | ,l

: I t:t | :l, L---J, L-J ' L-, A26Y A13Y , 3,2

i T T: I I

I I, I t,,-I T T: T i

: I t:--I-. :

i I \li:; -4, ;!-------------l-i '

'lF;% :21 ,vlEw 28 ;

_ - t\4/T -

PRIMARYHEATEDOXYGENSENSOR(H02S)Page 23-13

ll

tl

"i[",..

14

o---1\

I

Page 1859 of 2189

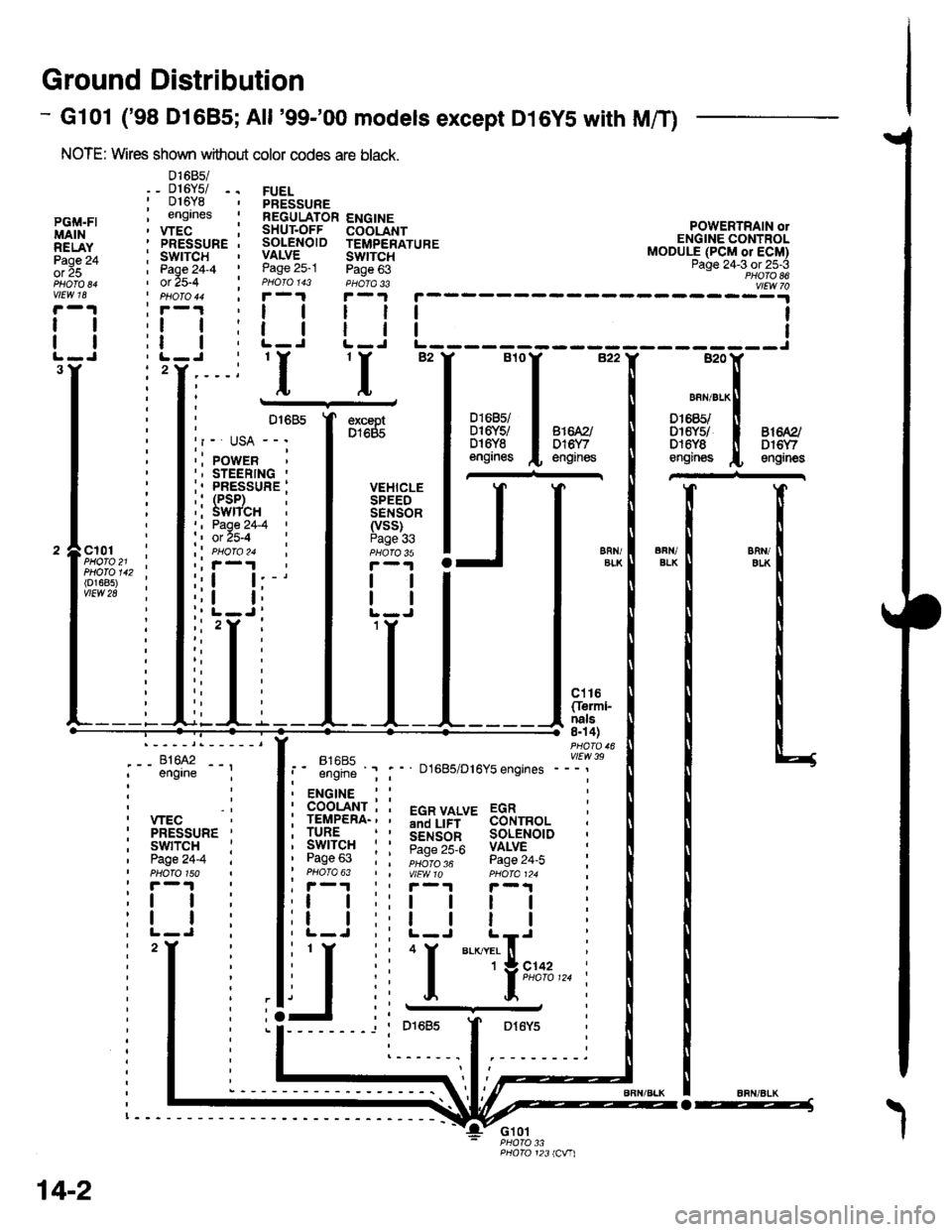

Ground Distribution

- Gl01 ('98 Dl685;All '99-'00 models except D16YS with M/T)

NOTE: Wires shown without color codes are black.

01685/_ D16Y5/ -.016Y8engrnes

.__-;,#'-_,--', engrne ;

, wEc: PRESSURE '

, swtTcH :I Page24-4 iI PHOTO 150: r -'l

:t | :

:l | :,L-J.

FUELPRESSUREREGULATOR ENGINESHUT.OFF COOLANTSOLENOID TEMPERATUREVALVE SWTTCHPage 25-1 Page 63PHOIO 143 PHOTA 33r-1F-.|

llll

lltlL-J L-J

POWERTRAIN olENGINE CONTROLMODULE (PCM or ECM)Page 24-3 ot 25-3PHOTO 86

----:y4

tl

tl

PGi,|.FIMAINRELAYPage 24ol 25

vlEw 18

tl

tl

3Y'I'I

excaptD1685

VEHICLESPEEDSENSOR(vss)Page 336FN/ELKERll/EIKcl01PHOTO 21PHOTO 142(o1685)vtEw 28

ct16Cferml-nals8n 4)

FltaFt( vttw 39t- .''iiti ' " D1685/D16Y5 engrnes ---'

t2

. ENGINE : :

i 933'?il-; i 5"T,Yf,*' 33i,"o, i

i lgfft" i I S.ir1".l^ soL€NorD :' Pase 63 : : ;;;;; - pase 24.i :' PHOTO 63 | | VtEWlO pHOIa124 ;, r-1 | , F-.t r-.r

:l | ;:l | ! | :;t | :,t | | | ;

j,f

ii T.__.,|,,,,,.

j

--

----- --l i otoas I Dr6y5 :

:------.1.--------.

14-2

o-----J