Heater radiator HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 414 of 2189

Primary Heated Oxygen Sensor (Primary HO2S) (Sensor 1l

The scan tool indicates Diagnostic Trouble Code (DTC) P0133: A slow response problem in the Primary Heated

Oxygen Sensor {Primary H02S) (Sensor 1) circuit.

The scan tool indicates Diagnostic Trouble code (DTC) Pl163: A slow response problem in the Primary Heated

Oxygen Sensor (Primary HO2S) (Sensor 1)circuit

Description

By controlling the airlfuel ratio with a Primary Ho2S {Sensor 1) and a secondary HO2S {Sensor 2), the deterioration of the

primary HO2S (Sensor 1) can be evaluated by its feedback period. when the feedback period of the Ho2s exceeds a cer-

tain value during stable driving conditions, the sensor will be judged as deteriorated

when deterioration has been detected during two consecutive trips. the MIL comes on and DTC P0133 or P1163* will be stored'

NOTE: tf DTC P0131, P0132 and/or P0135 are stored at the same time as DTC P0133, troubleshoot those DTCS first' then

troubleshoot DTC P0133. lf DTC Pl 162, P1168 and/or P1169 are stored at the same time as DTC P1163, troubleshoot those

DTCS first, then recheck for DTC Pl163.

Possible Cause

o Primary HO2S (Sensor 'l) Deterioration

o Primary HO2S Heater (Sensor 1)Deterioration

. Exhaust system leakage

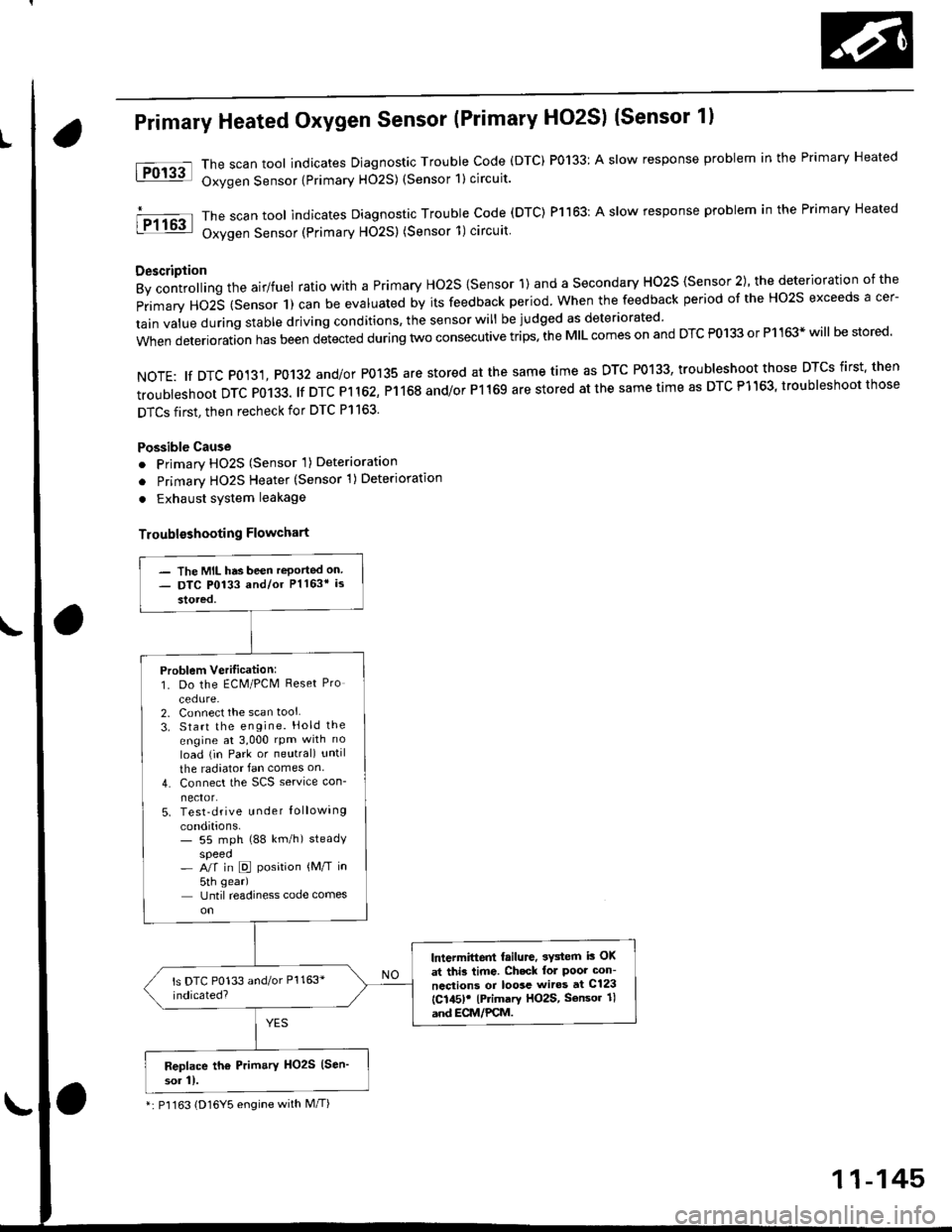

Troublsshooting Flowchart

tFol3al

I P1163

- The MIL has been reported on- DTC P0133 and/or Pl163* is

stored,

Problem Verilication:1. Do the ECM/PCM Reset Pro

cedure-2. Connect the scan tool

3. Start the engine. Hold the

engine at 3,000 rpm with no

load (in Park or neutral) until

the radiator fan comes on

4. Connect the SCS service con-

nector.5. Test-drive u nder Iollowing

conditions.- 55 mph (88 km/h) steadyspeed- A/f in D position {M/T in

5th gear)

Until readiness code comes

lntermittent failure, 3Y3tem i3 OK

at thi3 time. Ch.ck lol Poor con-

ncctions or loosc wiros at C123

{C145)! lPrimary HO2S, Sensor 1l

and ECM/PCM.

Replace th6 Prim.ry HO2S (Sen'

sor 11.

*: P'l163 (D16Y5 engine with M/T)

11-145

Page 432 of 2189

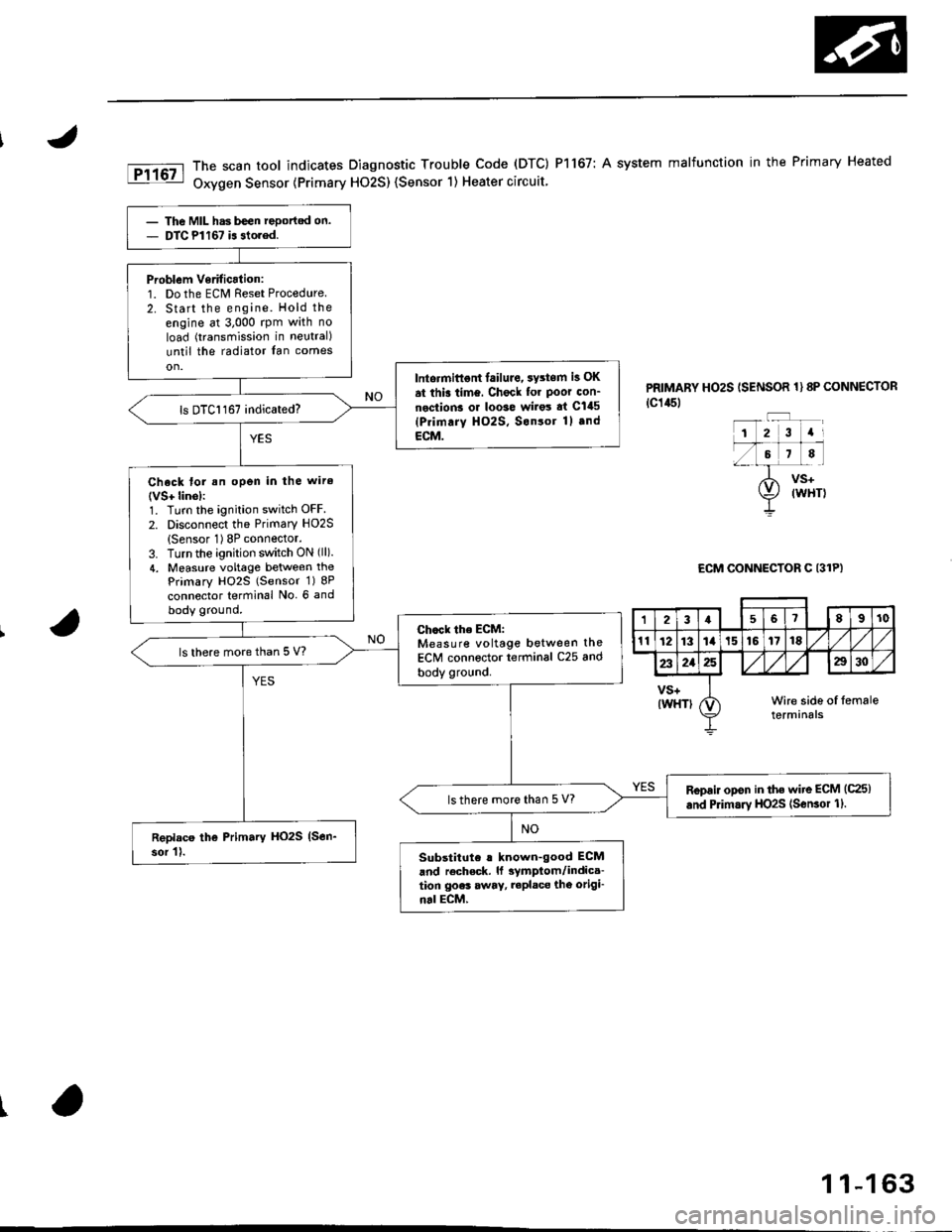

The scan tool indicates Diagnostic Trouble Code (DTC) Pl167: A system malfunction in the Primary Heated

Orygen Sensor {Primary HO2S) (Sensor 1) Heater circuit

PRIMABY HO2S ISENSOR 1} 8P CONNECTOR

tc145l

ECM CONNECTOR C (31P)

- The MIL has be€n reported on.- DTC Pl167 i3 3tored.

Problem Veritication:1. Do the ECM Reset Procedure.

2. Start the engine. Hold the

engine at 3,000 mm with no

load (transmission in neutral)

until the radiator fan comes

on.Intormittont failure, system i3 OK

at thia time. Chock for Poor con_

noction3 or looso wilgt ai Cl45(Primary HO2S, Son3or 1l andECM.

ls DTC1167 indicated?

Check lor sn open in the wire(VS+ linel:1. Turn the ignition switch OFF

2. Disconnect the Primary HO2S

{Sensor 1) 8P connector.

3. Turn the ignition switch ON (ll).

4. Measure voltage betwe€n thePrimary HO2S (Sensor '1) 8P

connector terminal No 6 and

body ground.

Ch.ck the ECM:Measure voltage between the

ECM connector terminsl C25 and

body ground.

ls there more than 5 V?

Repair opon in the wite ECM (C25)

and P m.ry HO2S (S€n3or 11.ls there more than 5 V?

Replaco the Primary HO2S (Son-

sor 11.Substitute ! known-good ECM

and r6check. lf symptom/indica-tion gos6 away, r.place tho origi'

nd ECM,

,l23458910

111213t415161718

a2125a30

VS+{WHTIWire side of femaleterminals

1 1-163

Page 489 of 2189

ldle Control System

ldle Speed Setting

Inspection/Adiustmenl

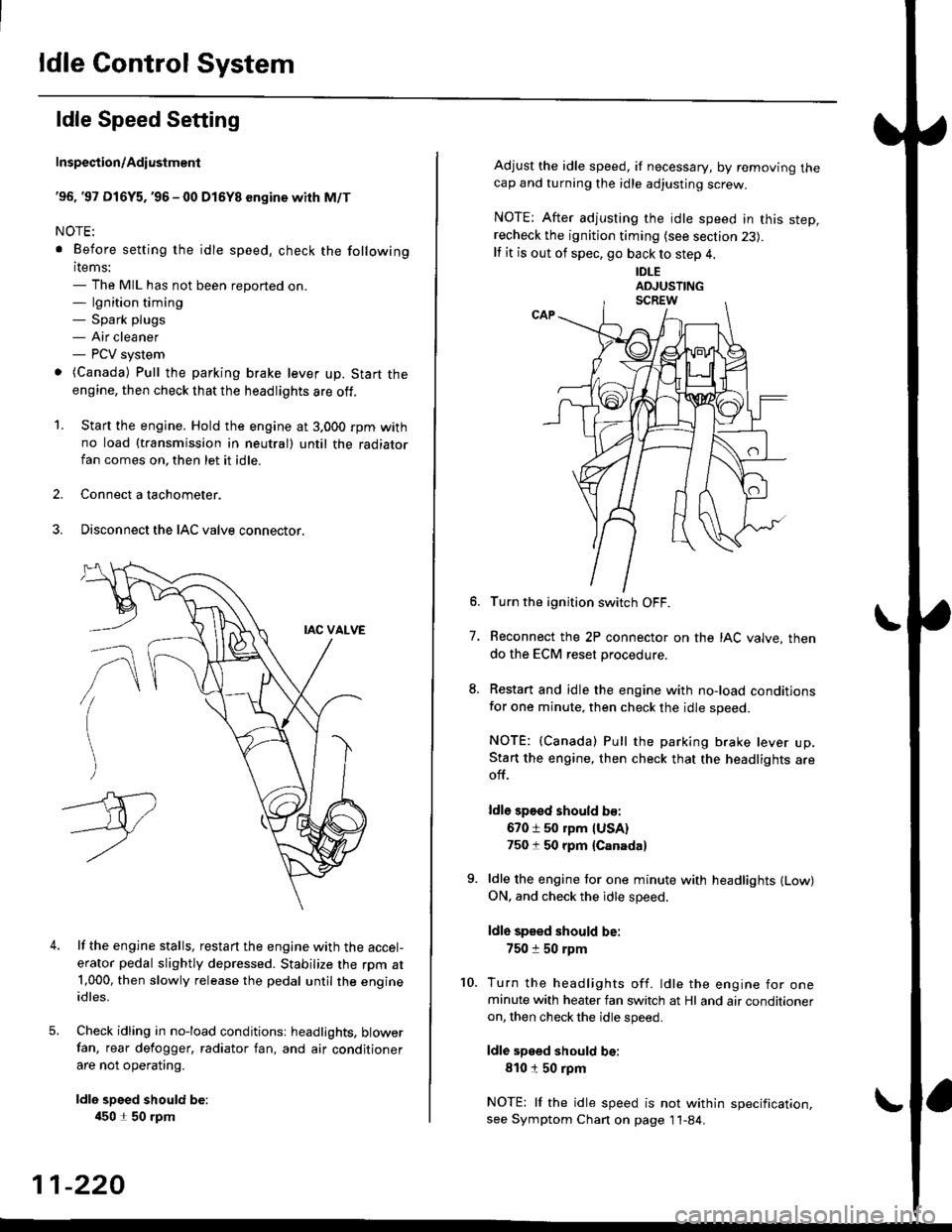

'96, '97 Dl6Y5. '96 - 00 Dl5Y8 sngine with M/T

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

o (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3.000 rpm withno load (taansmission in neutral) until the radiatorfan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the IAC valve connector.

4.lf the engine stalls, restart the engine with the accel-

erator pedal slightly depressed. Stabilize the rpm at1,000, then slowly release the pedal until the engineidles.

Check idling in no-load conditionsr headlights. blowerfan. rear defogger, radiator fan, and air conditioner

are not operating.

ldle spsed should be:

450 1 50 rpm

11-220

Adjust the idle speed, if necessary, by removing thecap and turning the idle adjusting screw.

NOTE; After adjusting the idle speed in this step,recheck the ignition timing (see section 23).

lf it is out of spec, go back to step 4.

IDLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

do the ECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

ldle sp€sd should b€:

670 i 50 rpm IUSA)750 t 50 rpm {Canada}

9. ldle the engine tor one minute with headlights {Low)ON. and check the idle speed.

ldle speed should be:

750 :r 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air conditioneron, then check the idle speed.

ldle speed should be:

810150 rpm

NOTE: lf the idle speed is not within specification,see Symptom Chan on page 11-84.

Page 490 of 2189

t

t

I

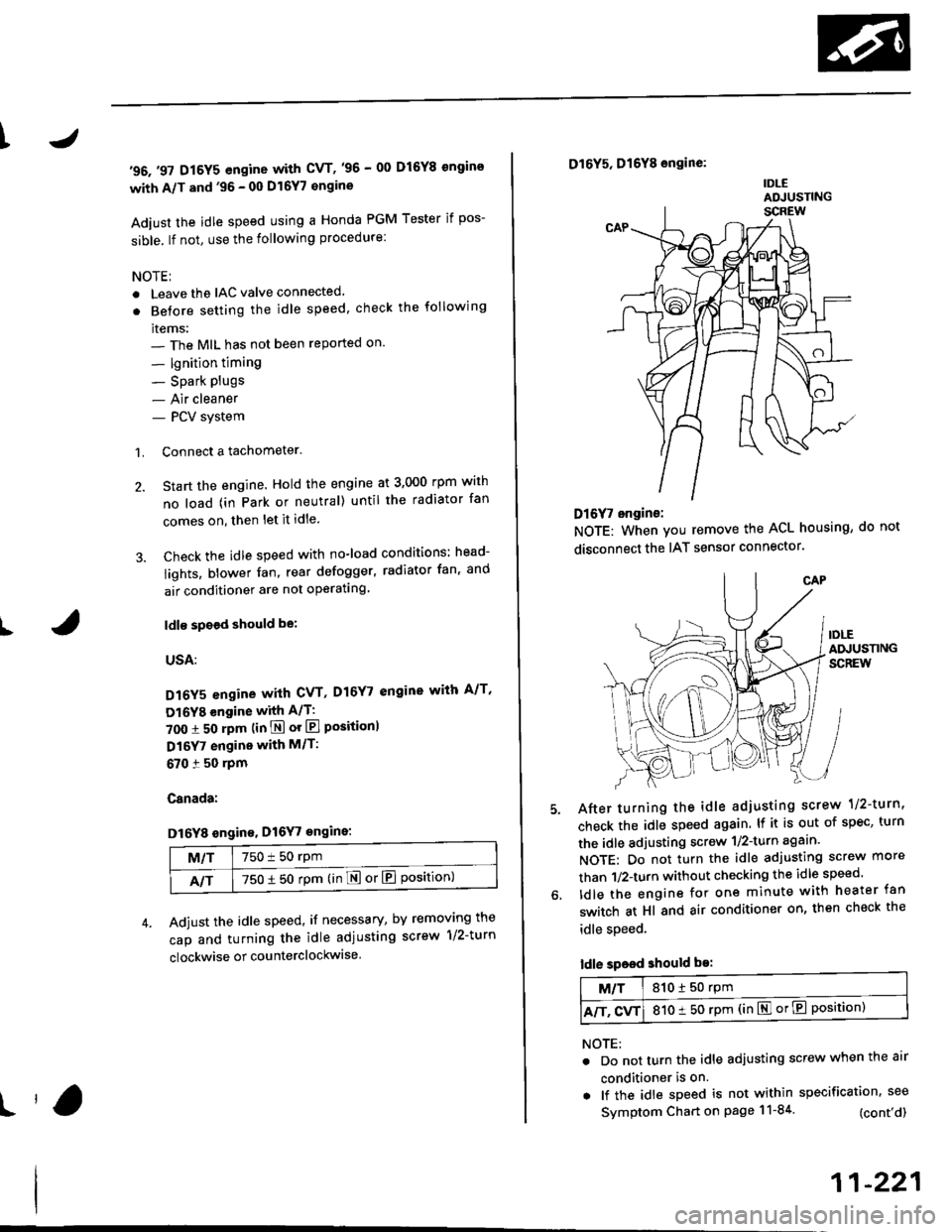

'96.'97 D16Y5 engine with CVT,'96 - 00 D16Y8 ongins

with A/T and'96 - 00 Dl6Y7 €ngine

Adiust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTEI

. Leave the IAC valve connected

. Betore setting the idle speed. check the following

items:- The MIL has not been reported on'

- lgnition timing

- Spark Plugs- Air cleaner- PCV system

1. Connect a tachometer.

2. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

3. Check the idle speed with no-load conditions: head-

iights, blower fan, rear defogger, radiator fan, and

air conditioner are not operatlng

ldl€ spoed should be:

USA:

D16Y5 engine with CVT, D16Y7 engine with A/T'

Dl6YB engine with A/T:

700 :r 50 rpm (in E or El Positionl

D16Y7 engine with M/T:

670 i 50 rpm

Canada:

Dl6Y8 sngin€, Dl6Y7 engins:

M/T750 t 50 rpm

NT750 1 50 rpm (in E or El Position)

Adjust the idle speed, if necessary, by removing the

cap and turning the idle adiusting screw 1/2-turn

clockwise or counterclockwise

D16Y5, D16Y8 engine:

IDLEADJUSTING

Dl6f, ongine:

NOTE: When you remove the ACL housing, do not

disconnect the IAT sensor connector

After turning the idle adjusting scrow 1/2-turn'

check the idle speed again. lf it is out of spec, turn

the idle adjusting screw 1/2-turn agaan'

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed'

ldle the engine for one minute with heater fan

switch at Hl and air conditioner on, then check the

idle speed.

ldle speed should be:

M/T810150 rpm

A/T. CvT810 t 50 rpm (in El or E Position)

NOTE:

. Do not turn the idle adjusting screw when the air

conditioner is on.

. lf the idle speed is not within specification. see

Symptom Chart on page 11-84 (cont'd)

11-221

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

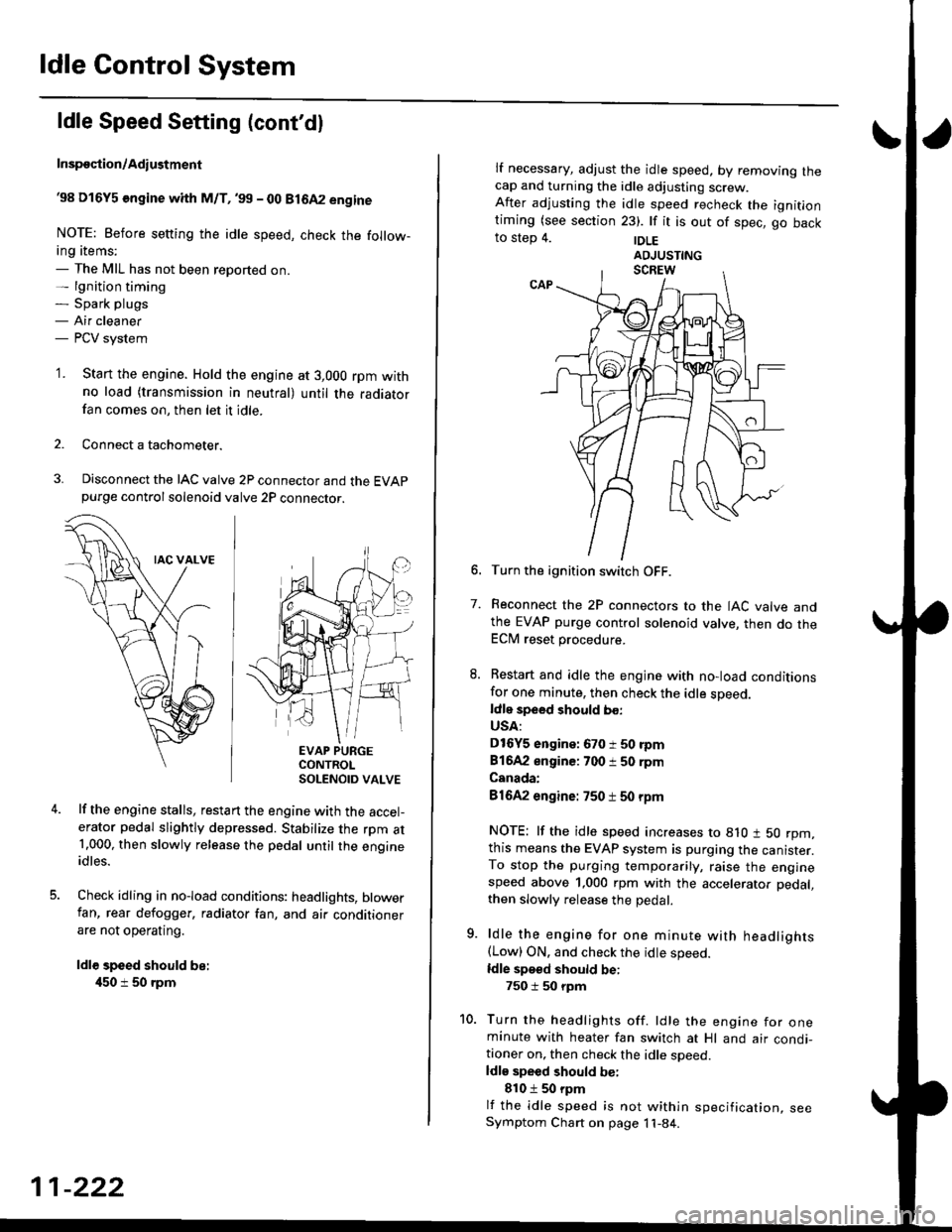

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

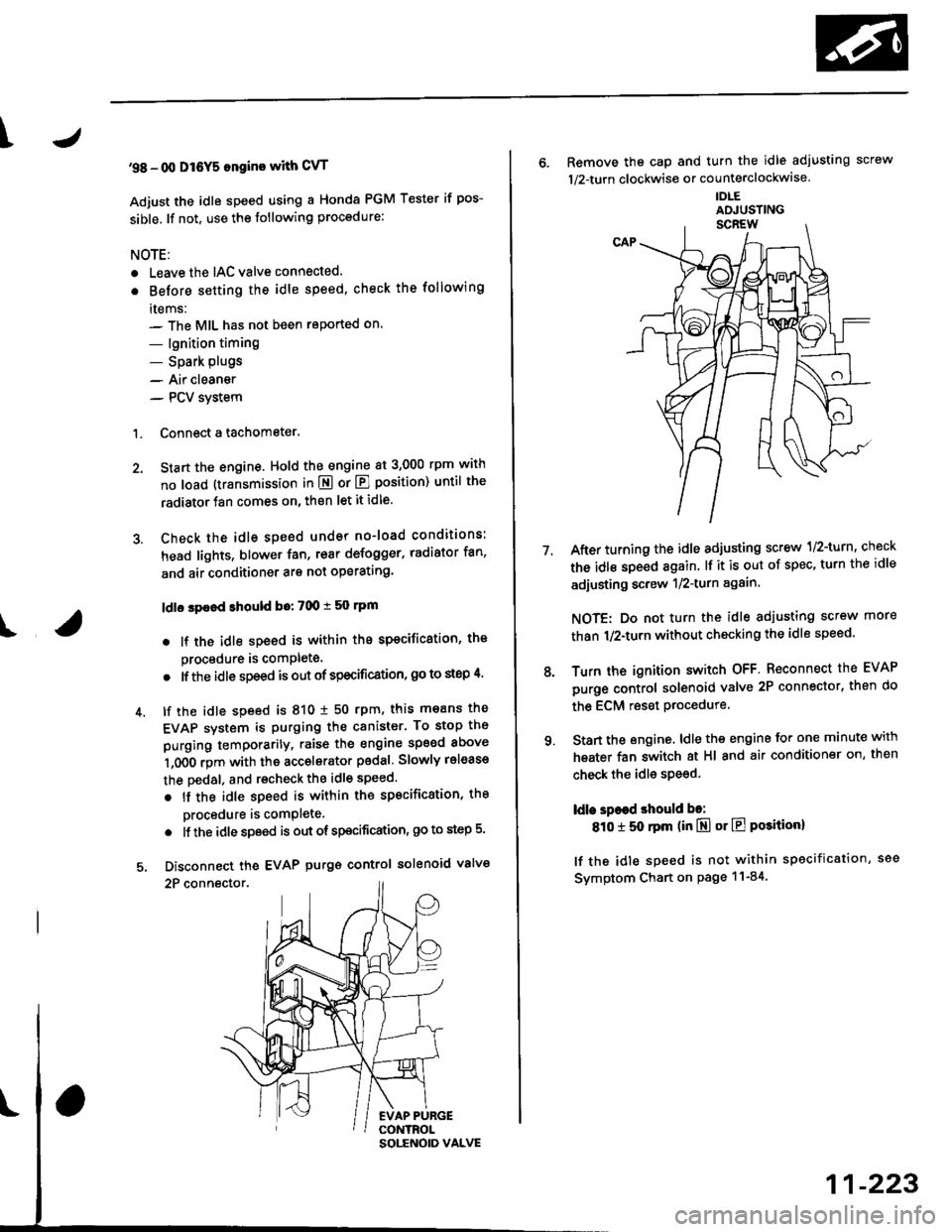

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 521 of 2189

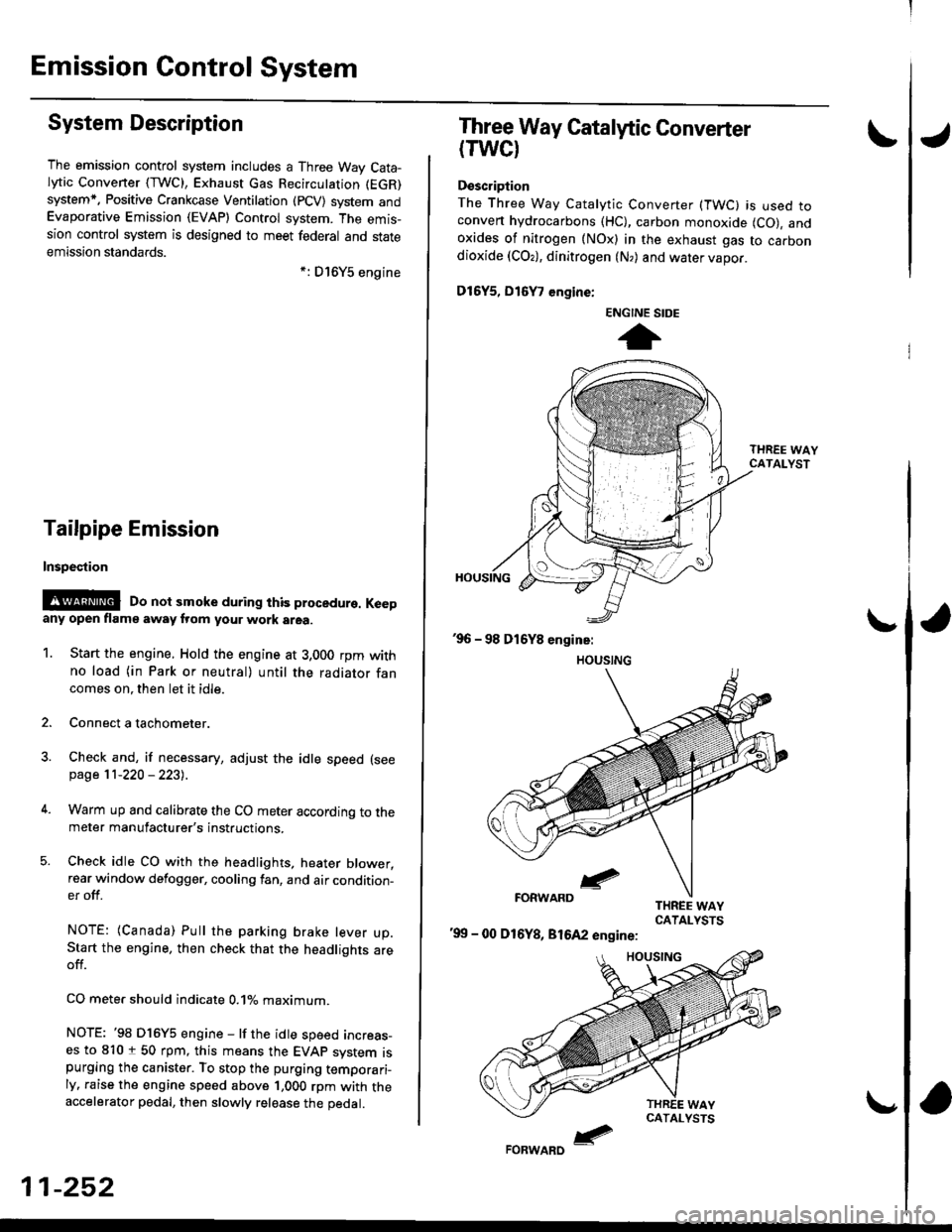

Emission Gontrol System

System Description

The emission control system includes a Three Way Cata-lytic Convener (TWC), Exhaust Gas Recirculation (EGR)

system,. Positive Crankcase Ventilation (pCV) system andEvaporative Emission (EVAP) Control system. The emis-sion control system is designed to meet federal and stateemission standards.*: D16Y5 engine

Tailpipe Emission

Inspestion

@@ Do not smoke during ihis procedure. Keepany open flame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm withno load (in Park or neutral) until the radiator fancomes on. then let it idle.

2. Connect a tachometer.

Check and, if necessary, adjust the idle speed (see

page 11-220 - 223).

Warm up and calibrate the CO meter according to themeter manufacturer's instructions.

Check idle CO with the headlights, heater blower,rear window defogger, cooling fan, and air condition-er off.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

CO mete. should indicate 0.1% maximum.

NOTE: '98 Dl6Y5 engine - lf the idle speed incress-es to 8101 50 rpm, this means the EVAp system ispurging the canister. To stop the purging temporari-ly. raise the engine speed above 1,000 rpm with theaccelerator pedal, then slowly release the pedal.

11-252

eFORWARD -

Three Way Catalytic Converter

(TWCI

Doscription

The Three Way Catalytic Converter (TWC) is used toconven hydrocarbons (HC), carbon monoxide (CO), andoxides of nitrogen (NOx) in the exhaust gas to carbondioxide (COr), dinitrogen (N,) and water vapor.

D15Y5, D16

, engine:

'99 - 00 D16Y8, 81642 engine:

ENGINE SIDE

t

Page 522 of 2189

\

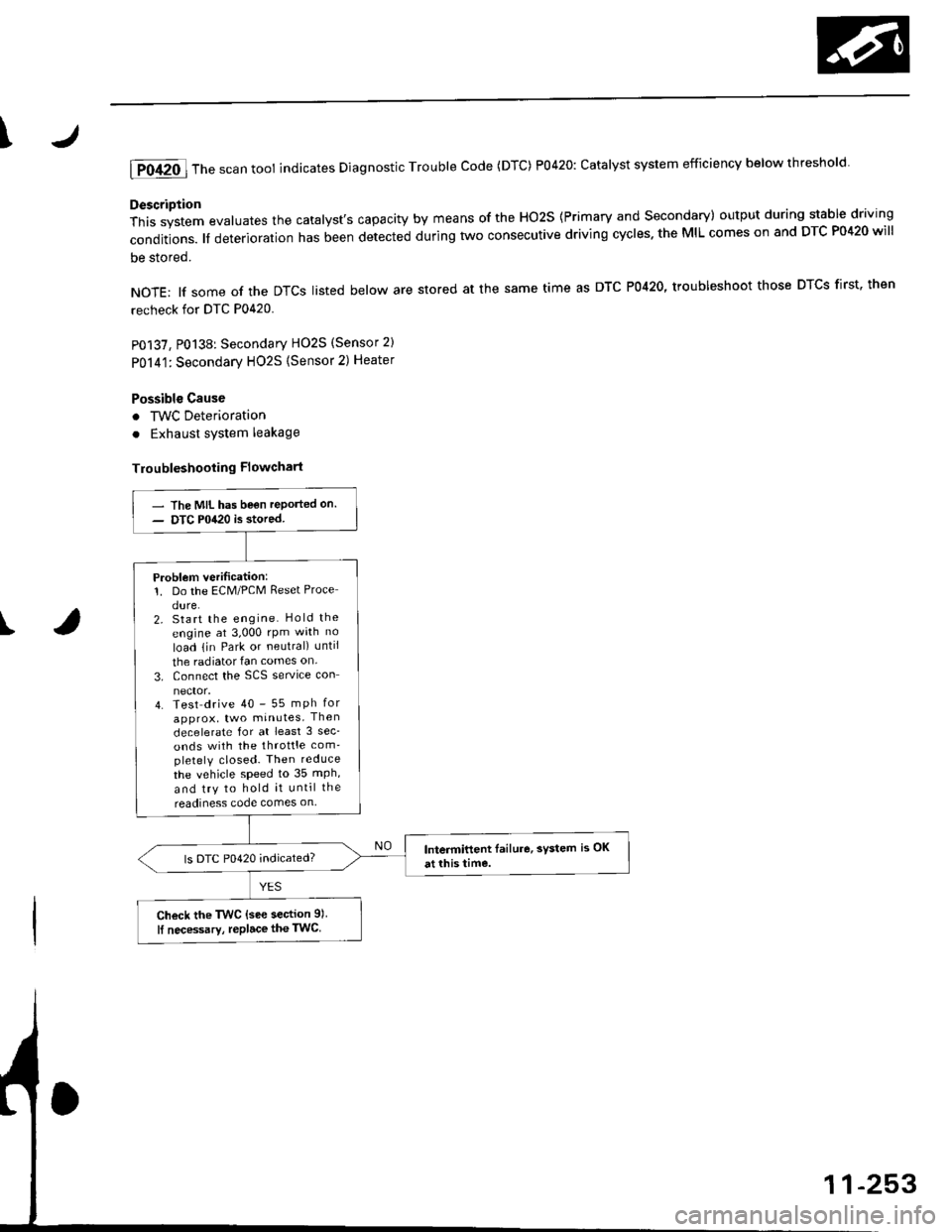

lTo420l Th" """n toot indicates Diagnostic Troubte code (DTc) p0420: catatyst sysrem efficiency below threshold.

Description

This system evaluates the catalyst's capacity by means of the Ho2s {Primary and secondary) output during stable driving

conditions. ll deterioration has been detected during two consecutive driving cycles. the MIL comes on and DTC P0420 will

be stored.

NOTE: lf some of the DTCS tisted below are stored at the same time as DTC P0420, troubleshoot those DTCS first. then

recheck for DTC P0420

P0137, P0138: Secondary HO2S (Sensor 2)

Po14'1:Secondary H02S {Sensor 2) Heater

Possibl€ Cause

. TWC Deterioration

. Exhaust system leakage

Troubleshooting Flowchart

I

The MIL has been reported on.

DTC P0420 is stored

Problem verilication:1. Do the ECM/PCM Reset Proce

dure.2. Start the engine Hold the

engine at 3,000 rpm wath no

load {in Park or neutral) until

the radiator fan comes on.

3. Connect the SCS service con

4. Test drive 40 - 55 mph for

approx, two minutes Then

decelerate for at least 3 sec_

onds with the throttle com'pletely closed- Then reduce

the vehicle speed to 35 mph,

and try to hold it until the

readiness code comes on

Intermittent Iailure, system is OK

at this time.ls DTC P0420 indicated?

Check the TWC {see section 9l

lf necessary, replace the TwC

Page 970 of 2189

Start Clutch Control@

T

Start Clutch Calibration Procedure

NOTE: When the following parts are replaced, the TCM

must memorize the feedback signal for the start clutch

control.

. TCM

. Transmissionassembly

. Stan clutch assembly

. Lower valve bodv assembly

. Engine assembly or overhaul

'96 Model Only

CAUTION: Do not uso this procsdure on'97 - (X) mod-

els or you will damage the transmission. On '97 - 00

models, the TCM or PCM memorizes ths loodback sig'

nals when you drive the vehicle.

1. Engage the parking brake, and block the front

wheels securely.

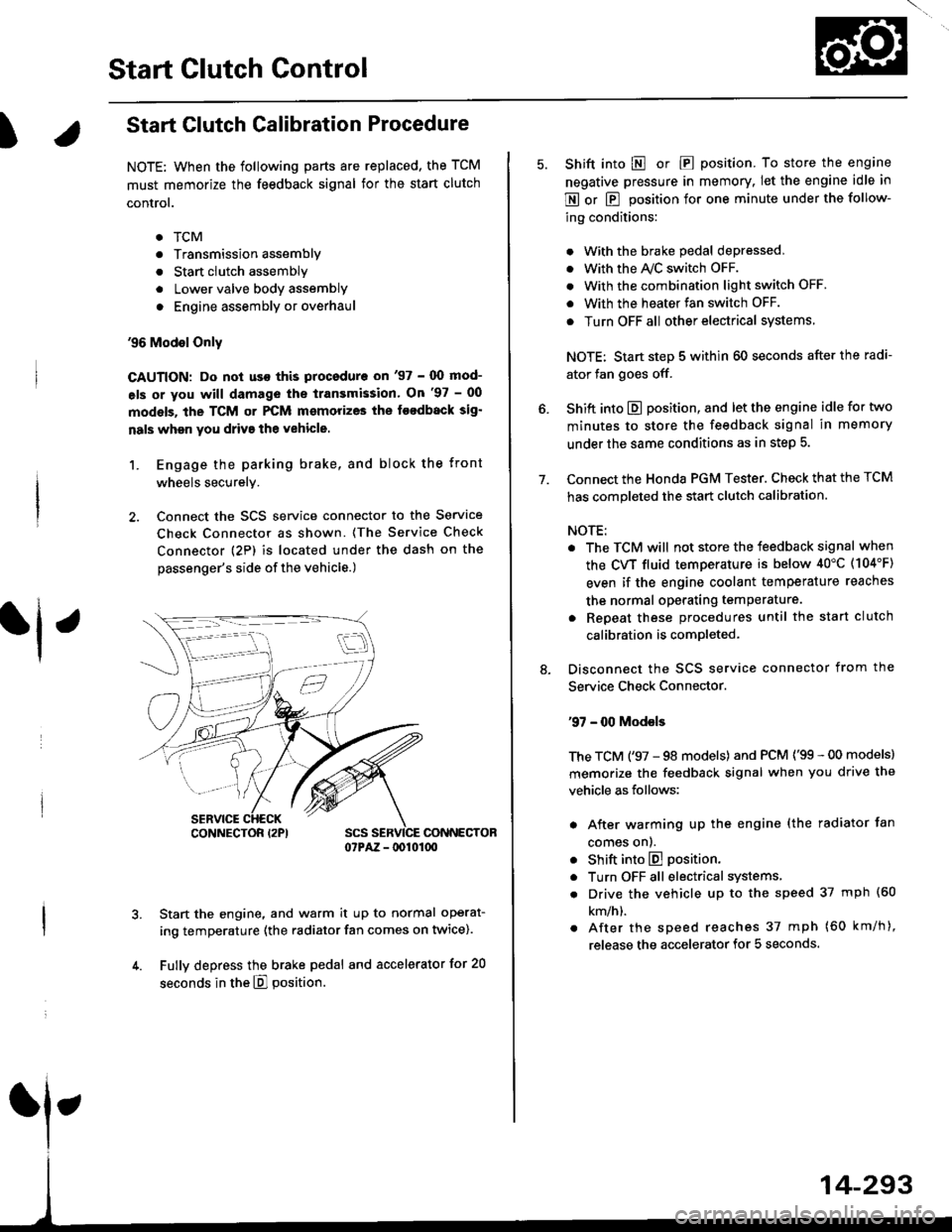

2. Connect the SCS service connector to the Service

Check Connector as shown. (The Service Check

connector (2P) is located under the dash on the

passenger's side of the vehicle.)

CONNECTOR07PAZ - lDl01(xt

Start the engine, and warm it up to normal operat-

ing temperature (the radiator fan comes on twice).

Fully depress the brake pedal and accelerator for 20

seconds in the E] position.

rl ,

CONNECTOR I2PI

14-293

7.

Shift into E o|. E position. To store the engine

negative pressure in memory. Iet the engine idle in

E or E position for one minute under the follow-

ing conditions:

. With the brake pedal depressed,

. with the y'\/c switch oFF.

. With the combination light switch OFF.

. With the heater fan switch OFF.

. Turn OFF all other electrical systems

NOTE: Start step 5 within 60 seconds after the radi-

ator fan goes off.

Shift into E position, and let the engine idle for two

minutes to store the feedback signal in memory

under the same conditions as in step 5.

Connect the Honda PGM Tester. Check that the TCM

has completed the start clutch calibration.

NOTE:

. The TCM will not store the feedback signal when

the CVT fluid temperature is below 40"C (104'F)

even if the engine coolant temperature reaches

the normal operating temperature.

. Repeat these procedures until the start clutch

calibration is completed-

Disconnect the SCS service connector from the

Service Check Connector.

'97 - 00 Models

The TCM ('97 - 98 models) and PCM ('99 - 00 models)

memorize the feedback signal when you drive the

vehicle as follows:

. After warming up the engine (the radiator fan

comes onl.

. Shift into E position.

. Turn OFF all electrical systems,

. Drive the vehicle up to the speed 37 mph (60

km/h).

. After the speed reaches 37 mph (60 km/h),

release the accelerator for 5 seconds.

Page 1413 of 2189

Heater Unit

Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24} before performing repairs or ser-

L Disconnect the negative cable from the battery.

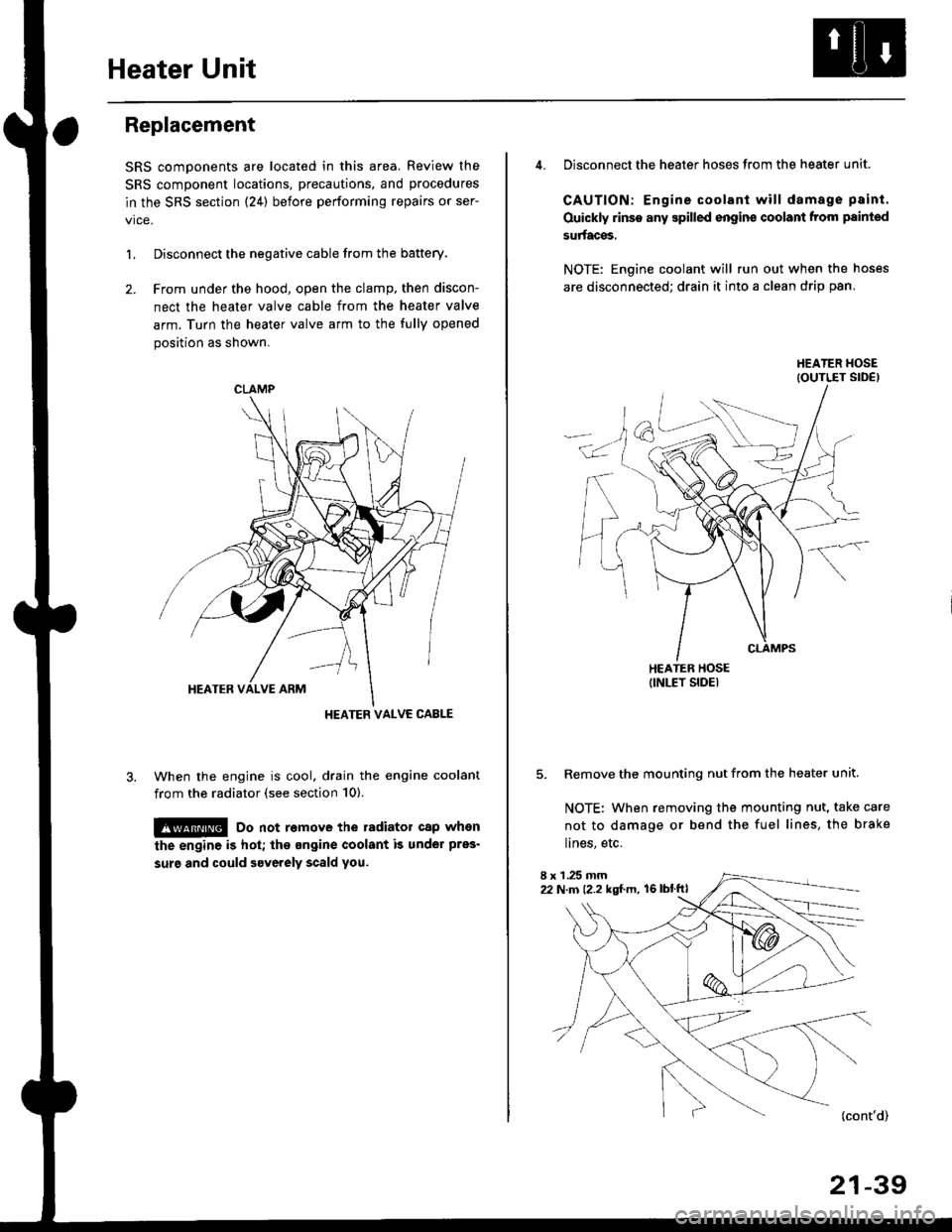

2. Frcm under the hood, open the clamp, then discon-

nect the heater valve cable from the heater valve

arm. Turn the heater valve arm to the fully opened

position as shown.

When the engine is cool. drain the engine coolant

from the radiator (see section 10).

!@ Do not remove the radiator cap when

the engine is hot; the ongine coolant is under pres'

surg and could severely scald you.

CLAMP

HEATER VALVC CABLE

4. Disconnect the heater hoses from the heater unit.

CAUTION: Engine coolant will damage p8int.

Ouickly rinse any spilled engins coolant from painted

su aces,

NOTE: Engine coolant will run out when the hoses

are disconnected; drain it into a clean drip pan.

5. Remove the mounting nut from the heater unit.

NOTE: When removing the mounting nut, take care

not to damage or bend the fuel lines, the brake

lines, etc.

I x 1 .25 mm22 N.m {2.2 kgl.m, 16lblftl

21-39