Set idle HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 465 of 2189

![HONDA CIVIC 1996 6.G User Guide ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt HONDA CIVIC 1996 6.G User Guide ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt](/img/13/6068/w960_6068-464.png)

ldle Gontrol System

ldle Air Control (lAG) Valve ('99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt AC) vatve- CtrCUtt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM inorder to maintain the proper idle speed.

IAC VALVE 2P CONNECTOR IC138'

la rcprI - {YEL/8LKI 2t--d,

Y-=

Wire side ot female terminals

Wire side of lemale terminals

VALVE

The MIL has boon r€oorted on.DTC P1508 is srored.

Probl6m verification:1. Do the ECM/PCM Reset Pro-cedure.2. Start the engine, and warm itup to normal operating lem-perature.

Intermittent tailure, system is OKat this timg. Check to. poor con-noctions or loose wires at C138{lAC valvel and ECM.

ls DTC P1508 indicated?

Ch6ck for an open in the wir€{lGPl lino}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the IAC valve 2Pconneclor termina I No.2,

Repair opon in the wire bgtwoenIAC valve and PGM-Fl main relay.

Check tof an open or short in thewire {IACV line}l1. Turn the ignition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connectorB {25P).3. Turn the ignition switch ON (ll).

4. Measure voltage betweenbody ground and ECM conn€ctor terminal 823.

(To page 11-197)

1 1-1 96

Page 467 of 2189

ldle Control System

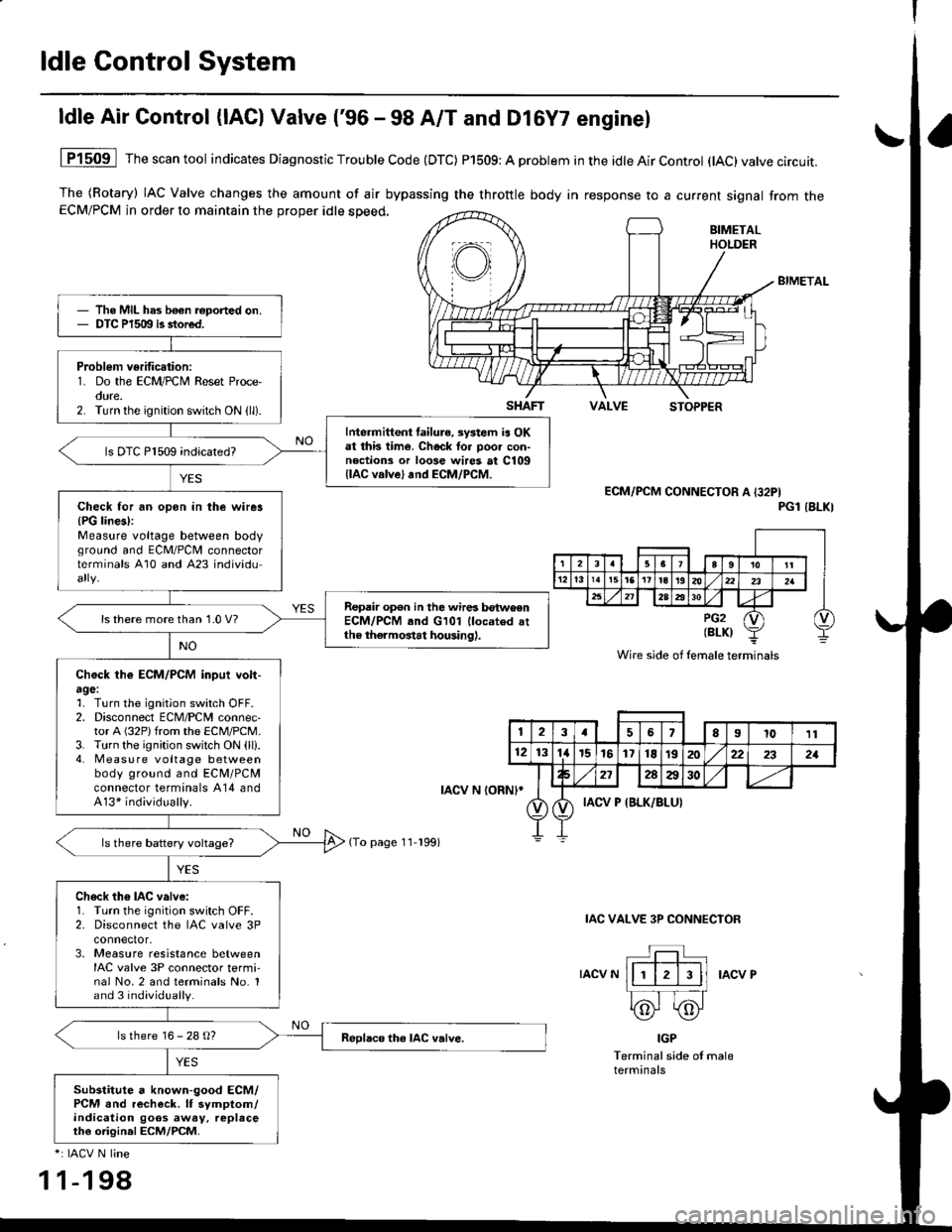

ldle Air Control (lAC) Valve ('96 - 98 A/T and Dl6Y7 enginel

The (Rotary) IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from theECM/PCM in order to maintain the proper idle speed,

BIMETAL

VALVESTOPPER

1P1509 Thescantool indicates Diagnostic Trouble Code (DTC) P1509: A problem in the idle Air Control (tAC)valve circuit.

ECM/PCM CONNECTOR A I32PIPGl IBLKI

IAC VALVE 3P CONNECIOR

IACV NIACV P

IGP

Terminal side of maleterminals

*: IACV N line

1 1-198

The MIL has b€€n roported on.DTC P1509 is stored.

Problem verification:1. Do the ECM/PCM Reset Proce-oure.2. Turn the ignition switch ON (ll).

Intermittent failura, systom ia OKat this time. Check tor poo. con-noctions or loose wires at C109llAC valve) and ECM/PCM.

ls DTC P1509 indicated?

Check for an opon in the wirer{PG lines):Measure voltage between bodvground and ECM/PCII connectorterminals A10 and A23 individu

Repair op€n in the wires betwoenECM/PCM and G101 llocated attho thermostat housing).

ls there more than 1.0 V?

Chock th€ ECM/PCM inpui volt-agel1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P)from the ECM/PCM.3. Turn the ignition switch ON (ll).4. Measu re voltage betweenbody ground and ECM/PCMconnector terminals A14 andA13* individually.

Ch6ck th6 IAC valve:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 3Pconnector,3, Measure resistance betweenIAC valve 3P connector termi-nal No.2 and terminals No. 1and 3 individually.

ls there 16 - 28 g?

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goos away, replaceth€ origin.l ECM/PCM.

SHAFT

rAcv N loRNl*

(To page 11-199)

Wire side of lemale terminals

123a56El011

121314r5161718t9202:22321

272AA30

IACV P {BLK/BLUI

Page 469 of 2189

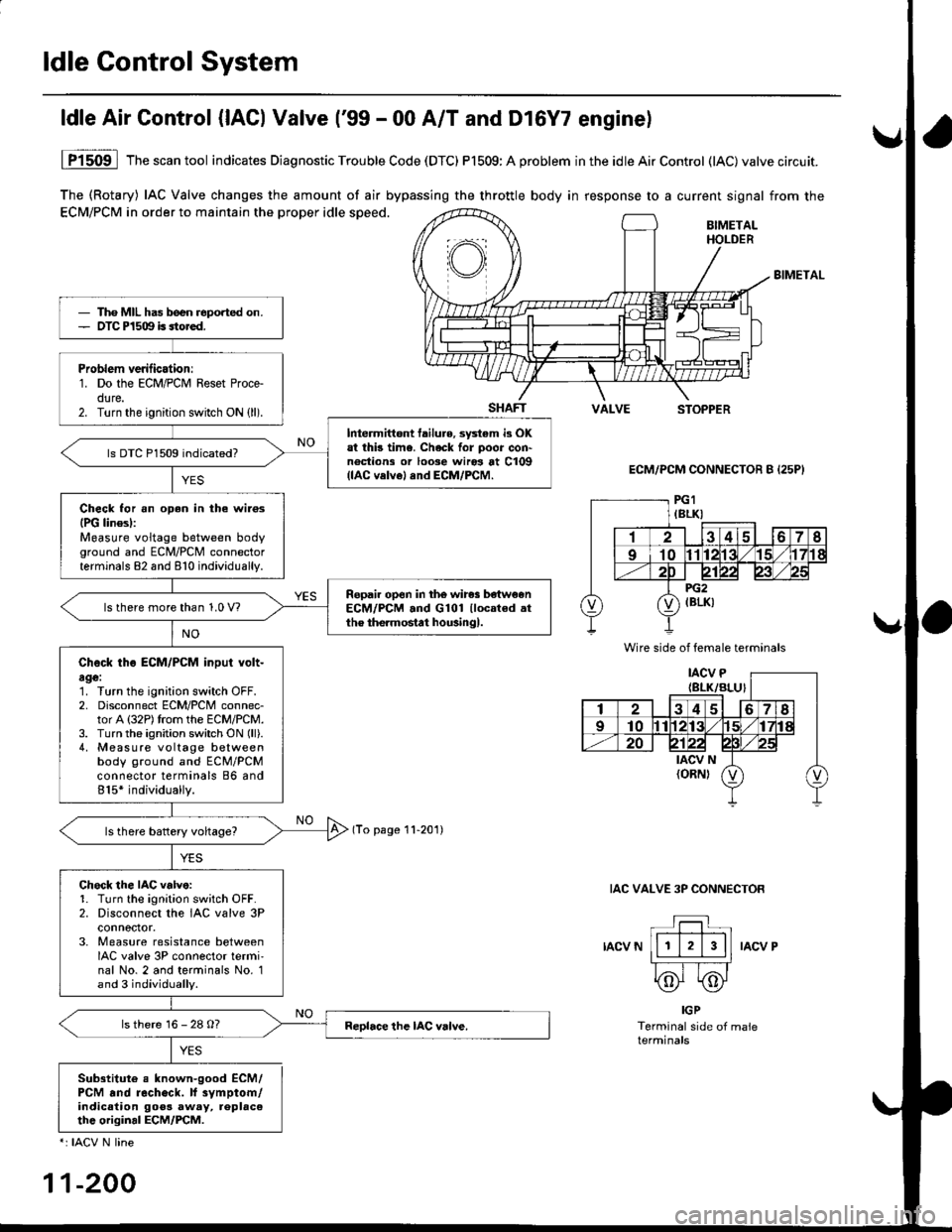

ldle Gontrol System

The (Rotary) IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the

ECM/PCM in order to maintain the proper idle speed.BIMETALHOLDER

BIMETAL

SHAFTVALVESTOPPER

ECM/PCM CONNECTOR B {25P}

(To page 11-201)

IAC VALVE 3P CONNECTOR

IACV NIACV P

ldle Air Control {lACl Valve ('99 - 00 A/T and Dl6Y7 enginel

YES

1P1509 lThescantool indicates Diagnostic Trouble Code (DTC) P1509:A problem inthe idleAirControl (lAC)valve circuit.

IGP

Terminal side of maleterminals

Sub3titute e known-good ECM/PCM .nd recheck. lf 3vmptom/indicalion goos away, replac6thc original ECM/PCM.

*: IACV N line

11-200

Tho MIL has b€en reported on.OTC P1509 is sto.ed.

Problem verilicationr1. Do the ECM/PCM Reset Proce-dure.2. Turn the ignition switch ON (ll).

Intermittont tailure, sy3tem i3 OKat thb time. Check for poor con'noctions or loose wiros at C109(lAC velvel and ECM/PCM.

ls DTC P1509 indicated?

Check for an oDen in the wilosIPG linesl:Measure voltage between bodyground and ECM/PCM connectorterminals 82 and 810 individually.

Ropail open in the wires be'tw€enECM/PCM .nd G101 llocated .tthe the.mostat housingl.ls there more than 1.0 V?

Check tho ECM/PCM input volt-age:1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P)trom the ECM/PCM.3. Turn the ignition switch ON (ll).

4, Measure voltage betweenbody ground and ECM/PCMconnector terminals 86 and815* individually.

Chock the IAC v.lve:1. Turn the ignition sw;tch OFF.2. Disconnect the IAC valve 3Pconnoctor.3. Measure resistance betweenIAC valve 3P connector termi'nal No. 2 and terminals No. 1and 3 individually.

ls there 16 - 28 O?

Wire side of female terminals

Page 489 of 2189

ldle Control System

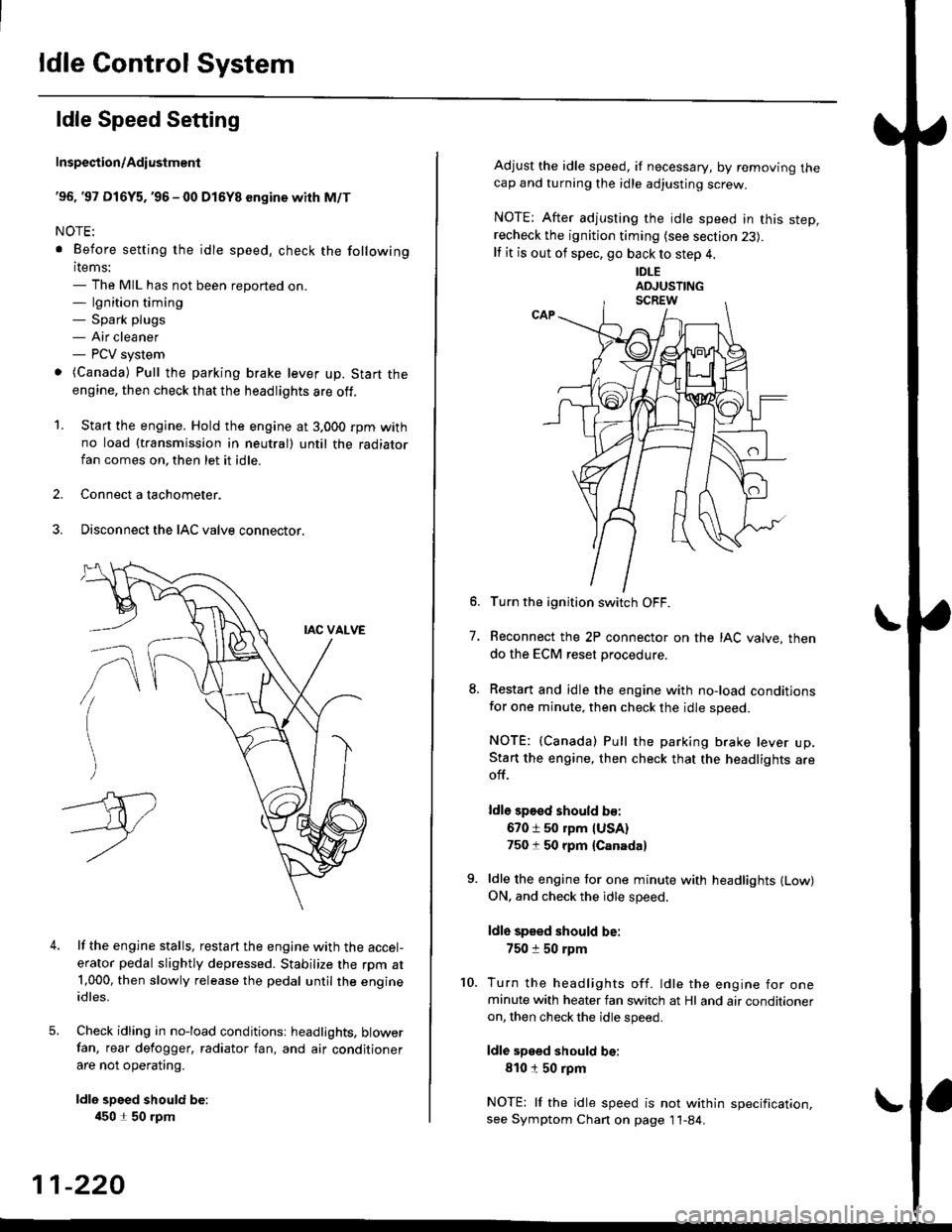

ldle Speed Setting

Inspection/Adiustmenl

'96, '97 Dl6Y5. '96 - 00 Dl5Y8 sngine with M/T

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

o (Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3.000 rpm withno load (taansmission in neutral) until the radiatorfan comes on, then let it idle.

2. Connect a tachometer.

3. Disconnect the IAC valve connector.

4.lf the engine stalls, restart the engine with the accel-

erator pedal slightly depressed. Stabilize the rpm at1,000, then slowly release the pedal until the engineidles.

Check idling in no-load conditionsr headlights. blowerfan. rear defogger, radiator fan, and air conditioner

are not operating.

ldle spsed should be:

450 1 50 rpm

11-220

Adjust the idle speed, if necessary, by removing thecap and turning the idle adjusting screw.

NOTE; After adjusting the idle speed in this step,recheck the ignition timing (see section 23).

lf it is out of spec, go back to step 4.

IDLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connector on the IAC valve, then

do the ECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle speed.

NOTE: (Canada) Pull the parking brake lever up.Start the engine, then check that the headlights areoff.

ldle sp€sd should b€:

670 i 50 rpm IUSA)750 t 50 rpm {Canada}

9. ldle the engine tor one minute with headlights {Low)ON. and check the idle speed.

ldle speed should be:

750 :r 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air conditioneron, then check the idle speed.

ldle speed should be:

810150 rpm

NOTE: lf the idle speed is not within specification,see Symptom Chan on page 11-84.

Page 490 of 2189

t

t

I

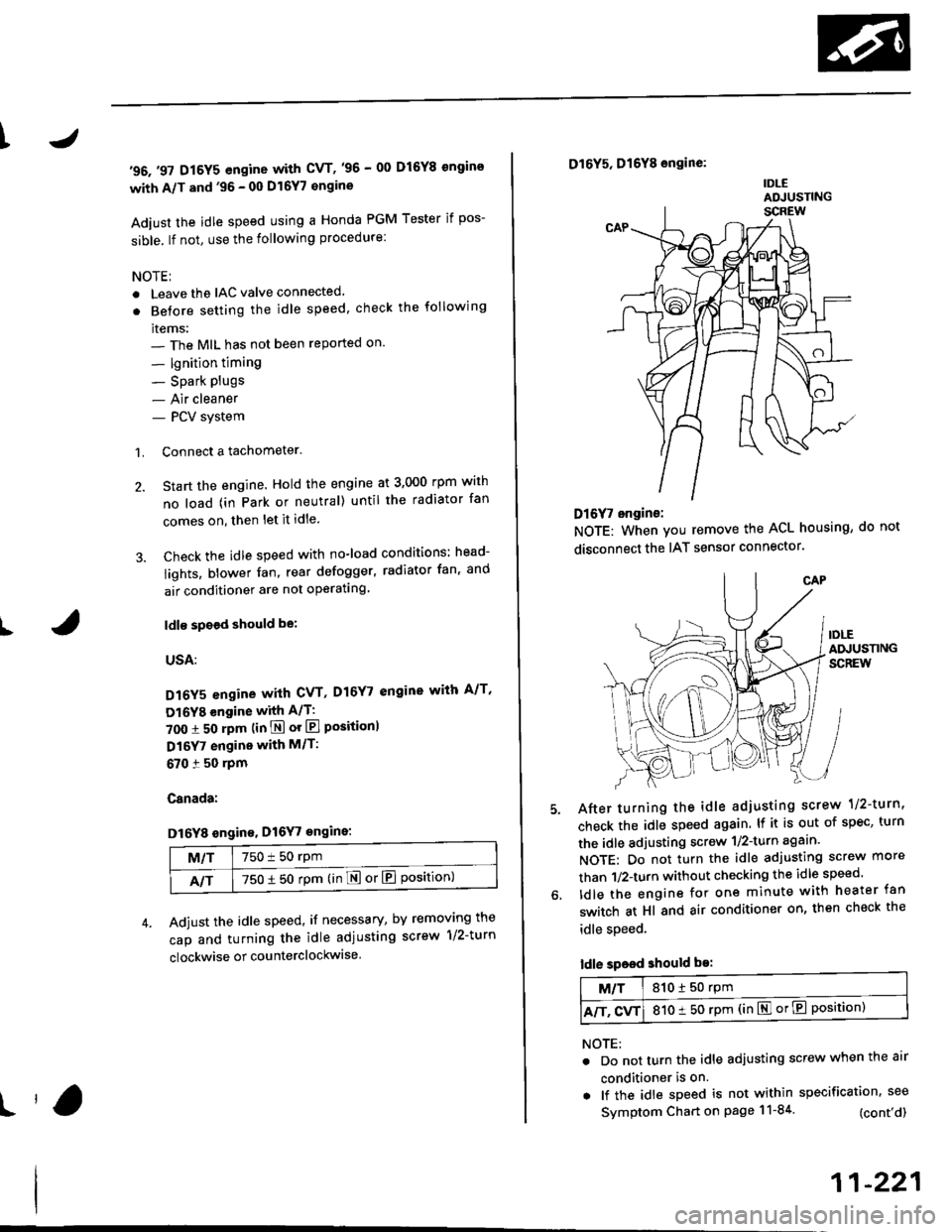

'96.'97 D16Y5 engine with CVT,'96 - 00 D16Y8 ongins

with A/T and'96 - 00 Dl6Y7 €ngine

Adiust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTEI

. Leave the IAC valve connected

. Betore setting the idle speed. check the following

items:- The MIL has not been reported on'

- lgnition timing

- Spark Plugs- Air cleaner- PCV system

1. Connect a tachometer.

2. Start the engine. Hold the engine at 3,000 rpm wirh

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

3. Check the idle speed with no-load conditions: head-

iights, blower fan, rear defogger, radiator fan, and

air conditioner are not operatlng

ldl€ spoed should be:

USA:

D16Y5 engine with CVT, D16Y7 engine with A/T'

Dl6YB engine with A/T:

700 :r 50 rpm (in E or El Positionl

D16Y7 engine with M/T:

670 i 50 rpm

Canada:

Dl6Y8 sngin€, Dl6Y7 engins:

M/T750 t 50 rpm

NT750 1 50 rpm (in E or El Position)

Adjust the idle speed, if necessary, by removing the

cap and turning the idle adiusting screw 1/2-turn

clockwise or counterclockwise

D16Y5, D16Y8 engine:

IDLEADJUSTING

Dl6f, ongine:

NOTE: When you remove the ACL housing, do not

disconnect the IAT sensor connector

After turning the idle adjusting scrow 1/2-turn'

check the idle speed again. lf it is out of spec, turn

the idle adjusting screw 1/2-turn agaan'

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed'

ldle the engine for one minute with heater fan

switch at Hl and air conditioner on, then check the

idle speed.

ldle speed should be:

M/T810150 rpm

A/T. CvT810 t 50 rpm (in El or E Position)

NOTE:

. Do not turn the idle adjusting screw when the air

conditioner is on.

. lf the idle speed is not within specification. see

Symptom Chart on page 11-84 (cont'd)

11-221

Page 491 of 2189

ldle Control System

ldle Speed Setting (cont'dl

Inspeqtion/Adiustment

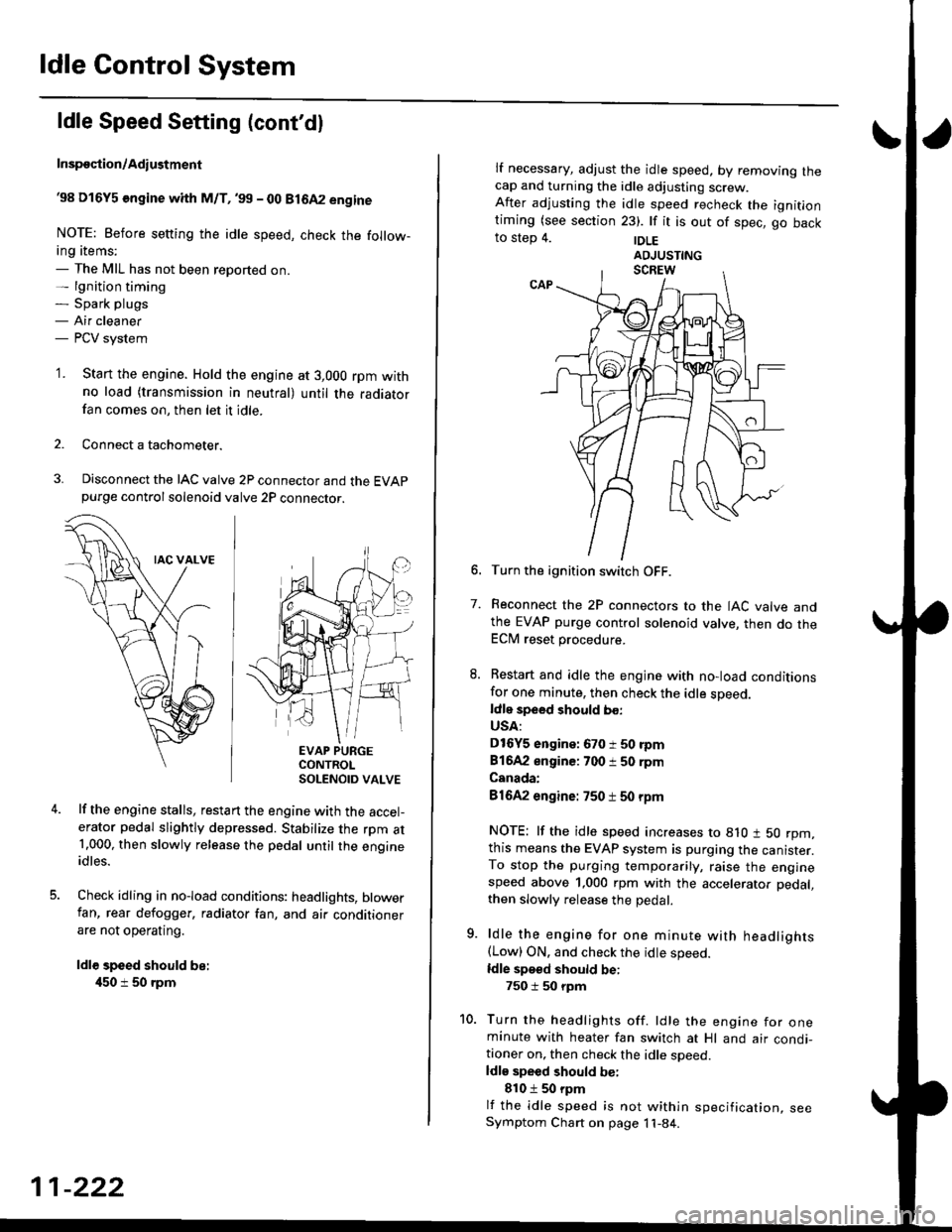

38 D16Y5 engine whh M/T,'99 - 00 81642 engine

NOTE: Before setting the idle speed, check the follow-ing items;- The MIL has not been reported on.- lgnition timing- Spark plugs- Air cleaner- PCV system

'1. Start the engine. Hold the engine at 3,000 rpm withno load (transmission in neutral) until the radiatorfan comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAPpurge controlsolenoid valve 2P connector.

EVAP PURGECONTROLSOLENOID VALVE

lf the engine stalls, restart the engine with the accel-erator pedal slightly depressed. Stabilize the rpm at1.000, then slowly release the pedal until the engineidles.

Check idling in no-load conditions: headlights, blowerfan, rear defogger, radiator fan, and air conditionerare not operating.

ldl€ speed should be:

450 i 50 rpm

11-222

lf necessary, adjust the idle speed, by removrng lnecap and turning the idle adjusting screw.After adjusting the idle speed recheck the ignitlontiming (see section 23). lf it is out of spec, go backto step 4. |DLE

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve andthe EVAP purge control solenoid valve, then do theECM reset procedure.

8. Restart and idle the engine with no-load conditionsfor one minute, then check the idle sDeed.ldle speed should bo:

USA:

D16Y5 engine: 670 i 50 rpm

81642 engine: 700 i 50 rpm

Canada:

81642 engine: 750 t 50 rpm

NOTE: lf the idle speed increases to 8lO t 50 rpm,this means the EVAP system is purging the canister.To stop the purging temporarily, raise the enginespeed above 1,000 rpm with the accelerator pedal,

then slowly release the pedal.

9. ldle the engine for one minute with headlights(Low) ON. and check the idle speed.

ldle speed should be:

750 i 50 rpm

10. Turn the headlights off. ldle the engine for oneminute with heater fan switch at Hl and air condi-tioner on, then check the idle soeed.ldls speed should be:

810 t 50 rpm

lf the idle speed is not within specification, seeSymptom Chart on page 11-84.

Page 492 of 2189

\

I

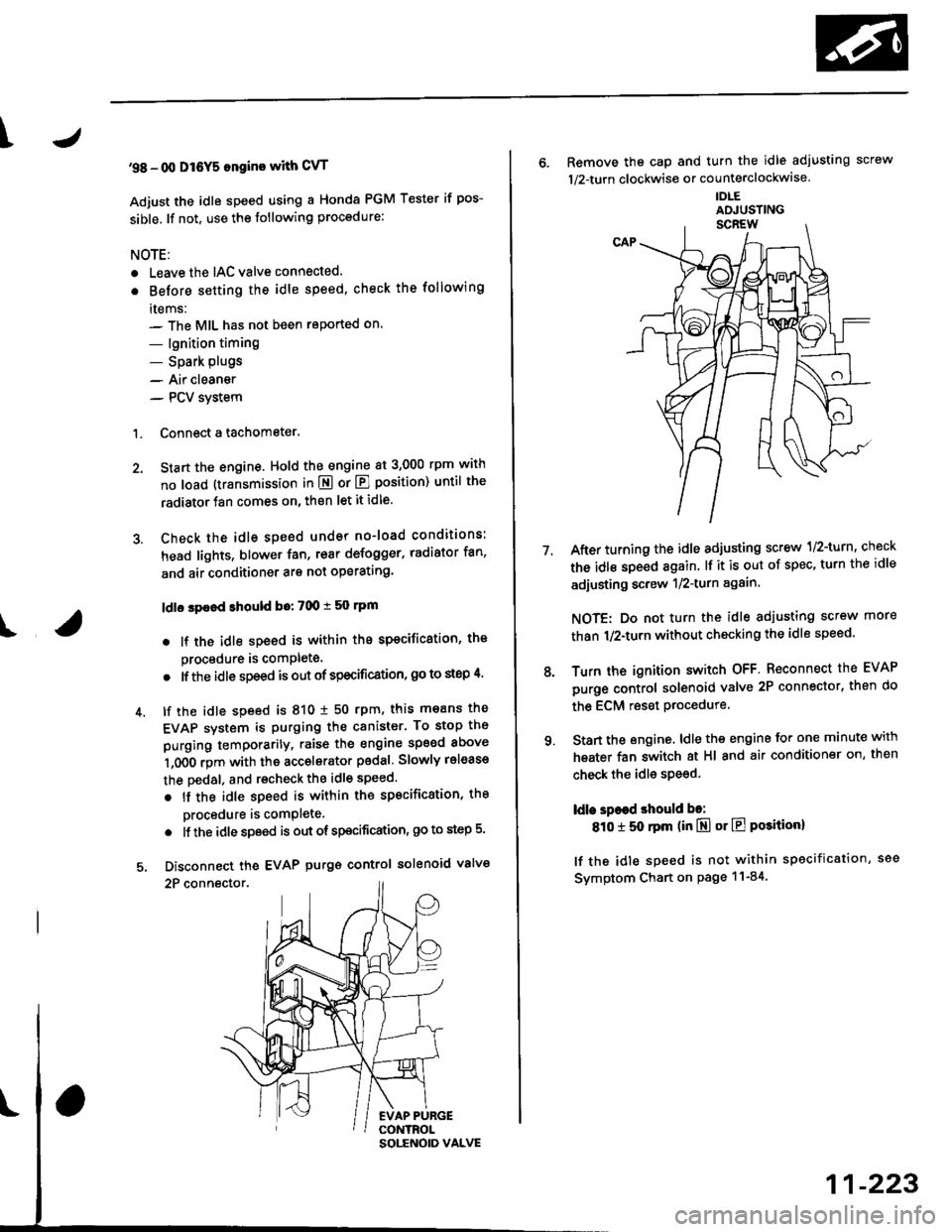

'98 - 0O D16Y5 ongine with CvT

Adjust the idle speed using a Honda PGM Tester if pos-

sible. lf not, use the following procedure:

NOTE:

. Leave the IAC valve connected.

. Before s€tting the idle speed, check the following

rtems:- The MIL has not been reported on.

- lgnition timing

- Spark Plugs- Air clean€r

- PCV svstem

'1. Connect a tachometer.

2. Stan the engine. Hold the engine at 3,000 rpm w'th

no load (transmission in E or E] position) until the

radiator Jan comes on, then let it idle.

3. Check the idle speed under no-load conditions:

head lights, blower fan, rear defogger, radiator fan,

and air conditioner are not operatlng.

ldlo spaod ehould bo: 700 t 50 rpm

. lf the idle speed is within the specification, the

procedure is comPlete.

. lf the idle sDeed is out of specitication, 9o to step 4'

4. tf the idle speed is 810 1 50 rpm, this means the

EVAP system is purging the canister. To stop the

purging temporarily, raise the engine speed above

l,OO0 rgm with the accelsrator pedal. Slowly release

the pedal. and rscheck the idl€ speed.

. tf the idle speed is within the specificstion, the

Drocedure is comPlete.

. lf the idle sp€ed is out of spocification, go to step 5.

5. Disconnect th€ EVAP purgs control solenoid valve

2P connector.

EVAP PURGECONTROL

6. Remove the cap and turn the idle adiusting screw

1/2-turn clockwise or counterclockwlse

IDLE

7.After turning the idle adjusting screw 1/2-turn, check

the idl€ speed again. lf it is out of spec, turn the idle

adjusting screw 1/2-turn again.

NOTE: Do not turn the idle adjusting screw more

than 1/2-turn without checking the idle speed.

Turn the ignition switch OFF. Reconnect the EVAP

purge control solenoid valve 2P connector' then do

the ECM reset Procedure.

Start the engine. ldle the engine for one minute with

heater fan switch at Hl and air conditioner on, then

check the idle speed.

ldle spaed should be:

810 t 50 rpm (in El or E Posiiion)

lf the idle speed is not within specification, see

Svmptom Chart on Page 11-84.

9.

SOLENOID VALVE

11-223

Page 515 of 2189

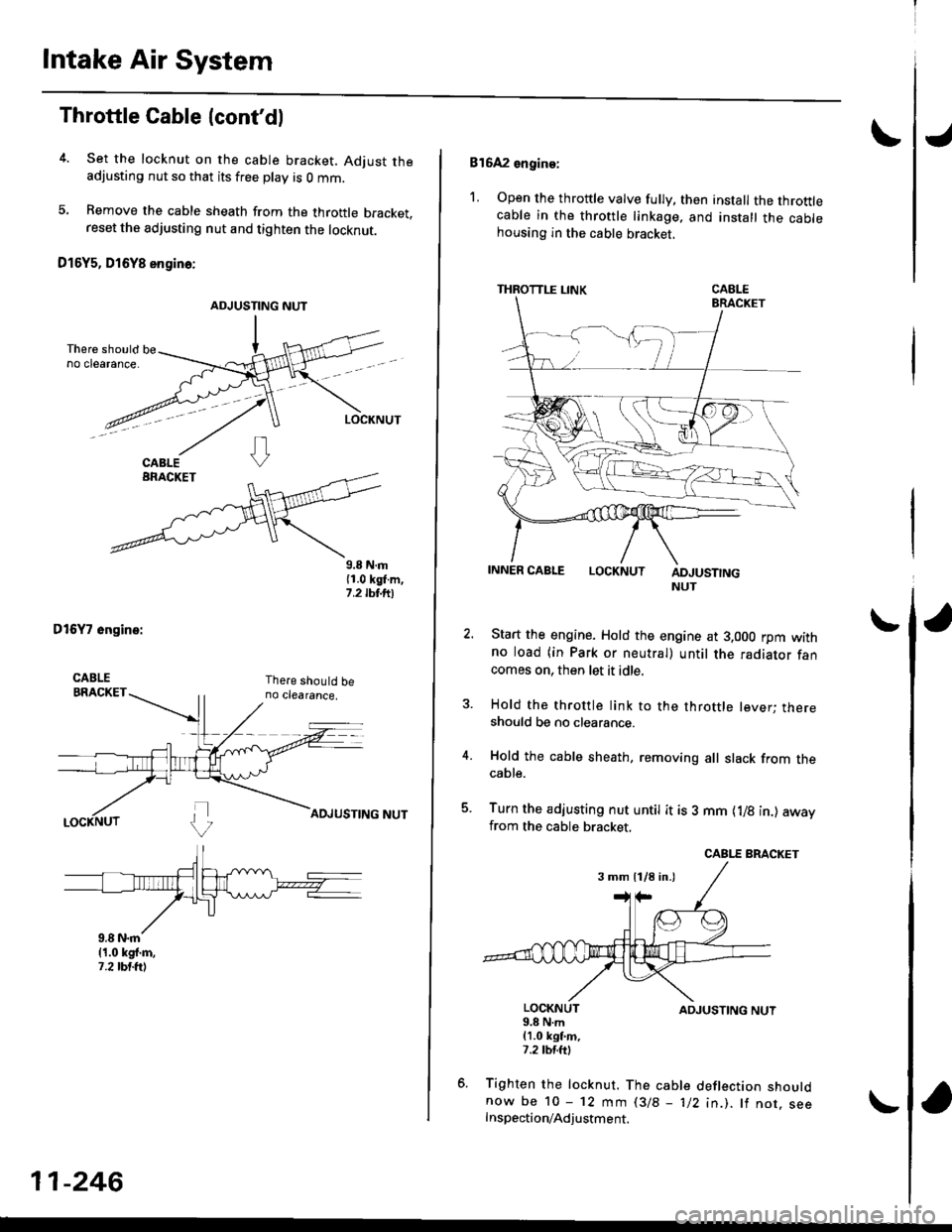

Intake Air System

Throttle Cable (cont'dl

4. Set the locknut on the cable bracket. Adjust theadjusting nut so that its free play is O mm.

5. Bemove the cable sheath from the throttle bracket,reset the adjusting nut and tighten the locknut.

O16Y5, D16Y8 engino:

ADJUSTING NUT

9.8 N.m{1.0 kgl.m,1.2 tbt.ttl

DtGYT 6ngine:

11-246

816A2 engine:

1. Open the throttle valve fully, then install the throttlecable in the throttle linkage. and install the cablehousing in the cable bracket,

THROTTLE LINK

LOCKNUTADJUSTINGNUT

Start the engine. Hold the engine at 3.000 rpm withno load (in Park or neutral) until the radiator fancomes on, then let it idle.

Hold the throttle link to the throttle lever; thereshould be no clearance.

Hold the cable sheath, removing all slack from thecable.

Turn the adjusting nut untit it is 3 mm {1/8 in.) awayfrom the cable bracket,

LOCKNUT9.8 N.m(1.0 kgt m,7.2 tM.ttl

ADJUSTING NUT

Tighten the locknut. The cable deflection shouldnow be 10 - 12 mm l3/B - 1/2 in.). lf nor. seeInspection/Adjustment.

3 mm 11/8 in.)

Page 525 of 2189

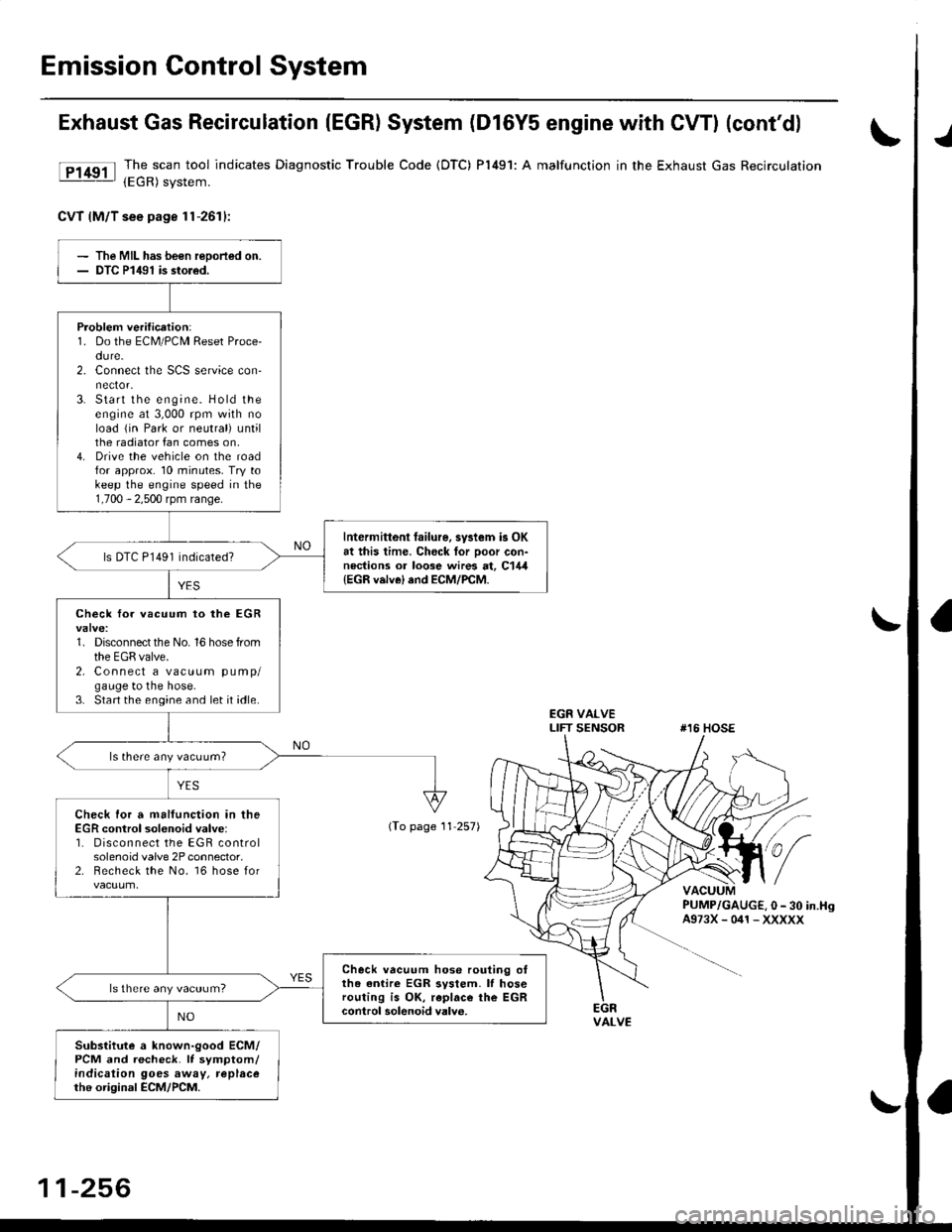

Emission Control System

Exhaust Gas Recirculation (EGR) System (D16Y5 engine with GWI (cont'dl

lTl49il T_he scan tool indicates Diagnostic Trouble Code (OTC) P1491: A malfunction in the Exhaust Gas Recirculation- lEgh) svstem.

CvT lM/T see page 1l-2611:

J

EGR VALVELIFT SENSOR#16 HOSE

PUMP/GAUGE,0- 30 in.HsA973X-041-XXXXX

EGRVALVE

The MIL has been reoorted on.DTC P1491 is stoled.

Problem verification:1. Do the ECM/PCM Reset Proce-du re.2. Connect the SCS service con'

3. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untilthe radiator fan comes on,4. Drive the vehicle on the roadfor approx. 10 minutes. Try tokeep the engine speed in the1,700 - 2,500 rpm range.

Intermittonl failure, system is OKat this time. Check for Door con-nections or loose wires at, C144{EGR velve} and ECM/PCM.

ls DTC P l49l indicated?

Check fo. vacuum to ihe EGR

1. Disconnect the No. 16 hose fromthe EGR valve.2. Connect a vacuum pump/gauge to the hose.3. Start the engine and let it idle.

ls there any vacuum?

Check tor a malfunction in theEGR control solenoid valve:'1. Disconnect the EGR controlsolenoid valve 2P connector,2. Becheck the No. 16 hose for

Check vacuum hose routing o,the entire EGR svstem. lf hoserouting is OK, replac€ the EGRcontrol solenoidvalv6.

ls there any vacuum?

Substitute a known-good ECM/PCM and recheck. It symptom/indicalion goes away, replacethe original ECM/PCM.

(To page 11 257)

11-256

Page 530 of 2189

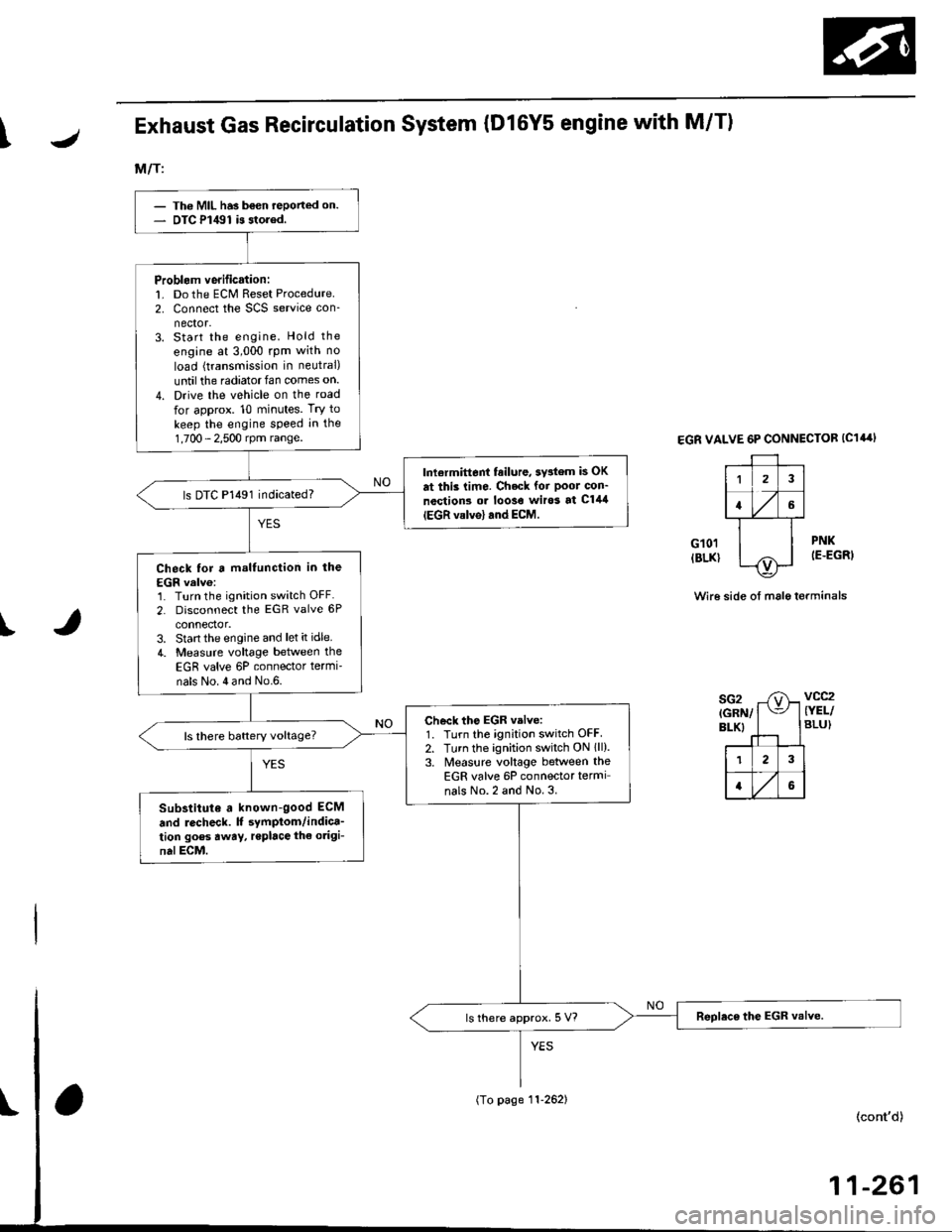

\JExhaust Gas Recirculation System (D16Y5 engine with M/T)

M/T:

EGR VALVE 6P CONNECTOB (C14'rl

G10lIBLK}

1

a

PNK

IE.EGRI

Wi16 side of male terminals

I

sG2{GRN/BLK}

vcc2{YEL/BLU)

- Th6 MIL ha3 b€on reponed on.- DTC Pl,{tl is 3tored.

Prcblem verification:1. Do the ECM Reset Procedure.

2. Connect the SCS service con_nector.3. Start the engine. Hold the

engine at 3,000 rpm with no

load (transmission in neutral)

untilthe radiator fan comes on.

4. Drive the vehicle on the road

for approx. 10 minutes. Try to

keep the engine speed in the

1,700 - 2,500 rpm range.

lnlermittont tailure, svalem is OK

at thi3 tim6. Check foi Poor con'

nections or looso wiro3 at Cl/K

IEGR valvsl and ECM.

ls DTC P1491 indicated?

Check tor a malfunction in the

EGR valv6:1. Turn the ignition switch OFF.

2. Disconnect the EGR valve 6P

connector.3. Stanthe engine and let it idle

4. Measure voltage between the

EGR valve 6P connector termi'

nals No.4and No.6.

Check the EGR valve:1. Turn the ignition switch OFF2. Turn the ignition switch ON lll).3. Measure voltage between theEGR valve 6P connector termi

nals No.2 and No.3.

ls there battery voltage?

Substitute a known-good ECM

and recheck. It symptom/indica_tion goes away, replace th€ origi-

nal ECM.

ls there approx.5V?

(To page 11-262)