compressor HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 160 of 2189

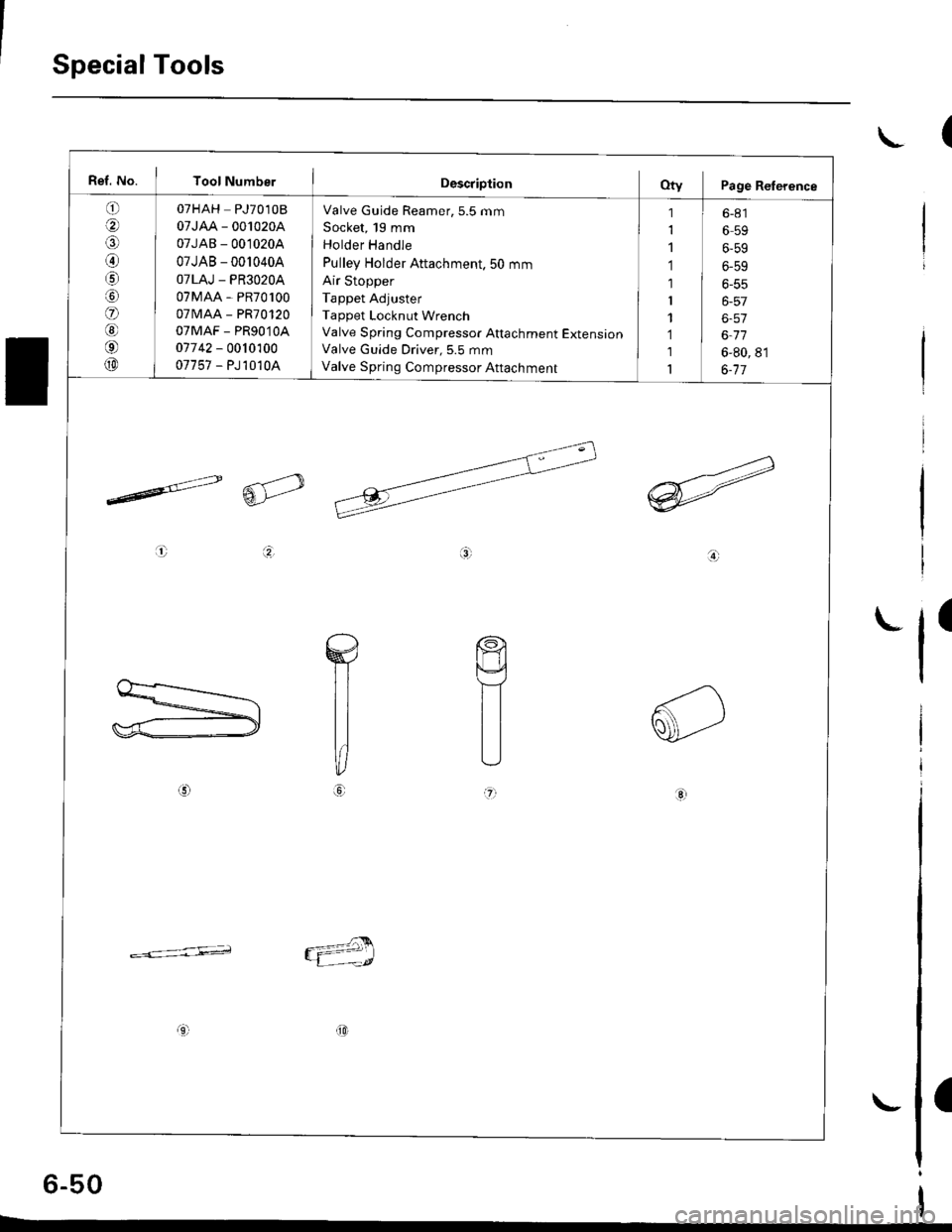

Special Tools

(\

Ref. No. I Tool NumberDescriptionOty Page Relerence

q oTHAH PJ7010B

g I 07JAA-001020A

g I 07JAB-0010204

I 07JAB - 0010404

g 07LAJ - PR3020A

|6) 07MAA - PR70100

g I ozvu,r - enu orzo

g 07MAF - PR9010A

g 07742 - 0010100(!D I 07757-PJ10104

Valve Guide Reamer,5.5 mm

Socket, 19 mm

Holder Handle

Pulley Holder Attachment. 50 mm

Air Stopper

Tappet Adjuster

Tappet Locknut Wrench

Valve Spring Compressor Attachment ExtensionValve Guide Driver, 5.5 mm

Valve Spring Compressor Attachment

1 I 6-81

1 659

1 6-59

1 ] 6-5s

1 I 6-55

1 6-57

1 6-57

1 J 6-77

1 6-80, 81

1 6-71

ta;

aL)'n

-=<-,,LE;;

(D

a

6-50

\-

Page 172 of 2189

Timing Belt

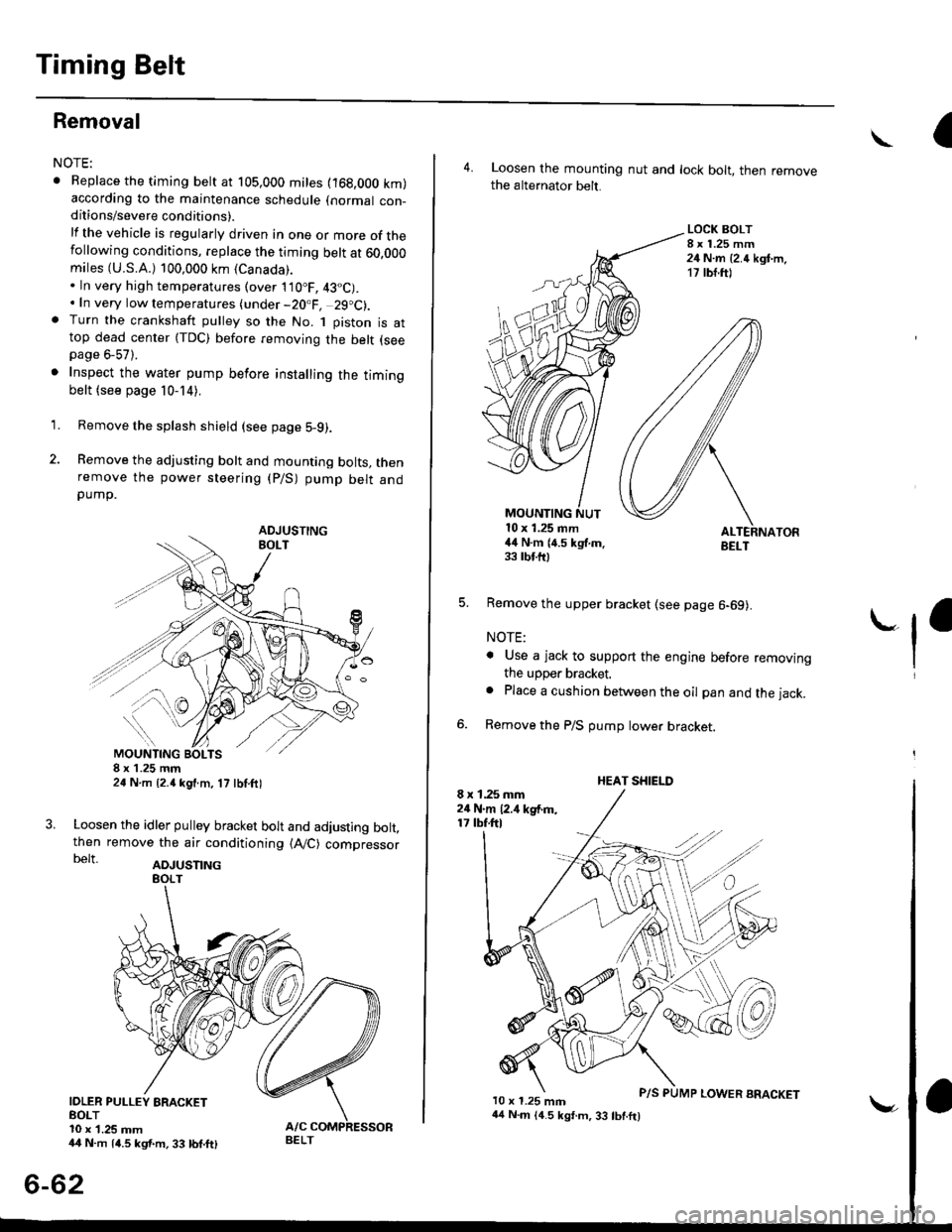

Removal

NOTE:

. Replace the timing belt at 105,000 mites (168,000 km)according to the maintenance schedule (normal con-ditions/severe conditions).

lf the vehicle is regularly driven in one or more of thefollowing conditions, replace the timing belt at 60,OOOmiles (U.S.A.) 100,000 km {Canada).. In very high temperatures (over 110"F, 43"C).. In very low temperatures (under -20.F, 29.C).. Turn the crankshaft pulley so the No. 1 piston is attop dead center (TDC) before removing the belt (seepage 6-57).

. Inspect the water pump before installing the timingbelt {see page 10-14).

1.

IOLER PULLEY BRACKETEOLT10 x 1.25 mm44 N.m 14.5 kgf.m, 33 bnft)

6-62

Remove the splash shield (see page 5-9).

Remove the adjusting bolt and mounting bolts, thenremove the power steering (P/S) pump belt andpump.

8xL25mm24 N m {2.{ kgf.m, 17 lbf.ft)

Loosen the idler pulley bracket bolt and adjusting bolt,then remove the air conditioning (A,/C) compressorbelt aDJUsnNG

44 N.m 14.5 kgt.m, 33 lbf.ft)

P/S PUMP LOWER ARACKET

a\

4. Loosen the mounting nut and lock bolt, then removethe alternator belt.

LOCK BOLT8 x 1.25 mm24 N.m {2.4 kgt.m.17 rb{.ftl

5. Remove the upper bracket (see page 6-69).

NOTE:

. Use a jack to support the engine before removingthe upper bracket.

o Place a cushion between the oil pan and the jack.

Remove the P/S pump lower bracket

8 x 1.25 mm24 N.m 12.,1 kgf.m,17 tbf.ftl

l0 x 1.25 mm

'-f'

MOUNTING10 x 1.25 mm44 N.m (4.5 kgf.m.33 rbf.fttBELT

HEAT SHIELD

Page 174 of 2189

Timing Belt

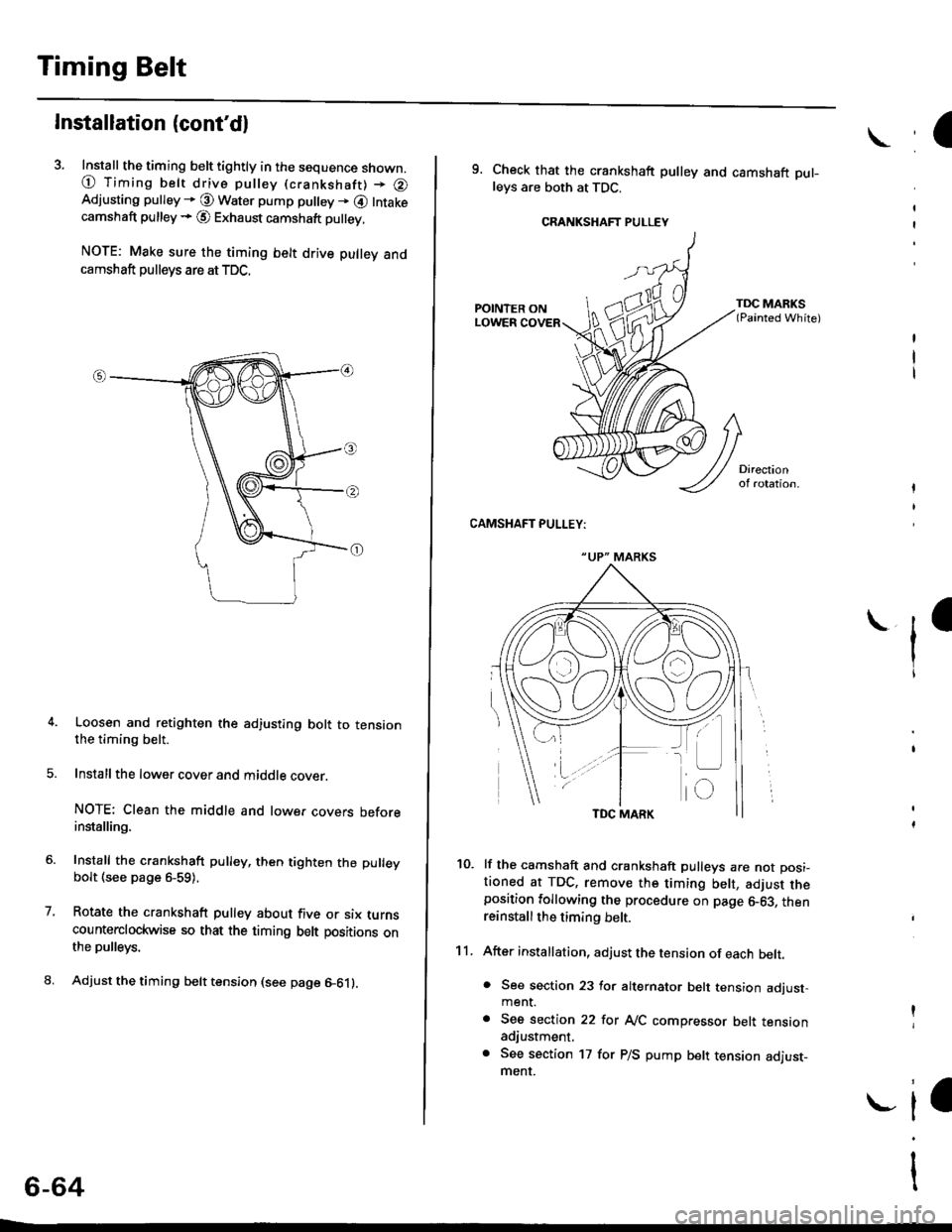

lnstallation (cont'dl

3. Install the timing belt tightly in the sequence shown.

@ Timing belt drive pulley (crankshaft) + @Adjusting pulley * @ Water pump pu ey + @ Intakecamshaft pulley + @ Exhaust camshaft pulley,

NOTE: Make sure the timing belt drive pulley andcamshaft pullevs are at TDC,

Loosen and retighten the adjusting bolt to tensionthe timing belt.

Install the lower cover and middle cover.

NOTE: Clean the middle and lower covers beforeinstalling.

Install the crankshaft pulley, then tighten the pulleybolt (see page 459).

Rotate the crankshaft pulley about five or six turnscounterclockwise so that the timing belt positions onthe pulleys.

Adjust the timing belt tension (see page A611.

7.

6-64

a

9. Check that the crankshaft pulley and camshaft pul-leys are both at TDC.

CRANKSHAFT PULLEY

CAMSHAFT PULLEY:

lf the camshaft and crankshaft pulleys are not posi-tioned at TDC, remove the timing belt, adjust theposition following the procedure on page &63, thenreinstall the timing belt.

After installation, adjust the tension of each belt.

. See section 23 for alternator belt tension adjust-ment.

. See section 22lor NC compressor belt tensionadiustment,

. See section 17 for P/S pump belt tension adjust-ment.

'l

10.

11.

I

"UP" MARKS

Page 187 of 2189

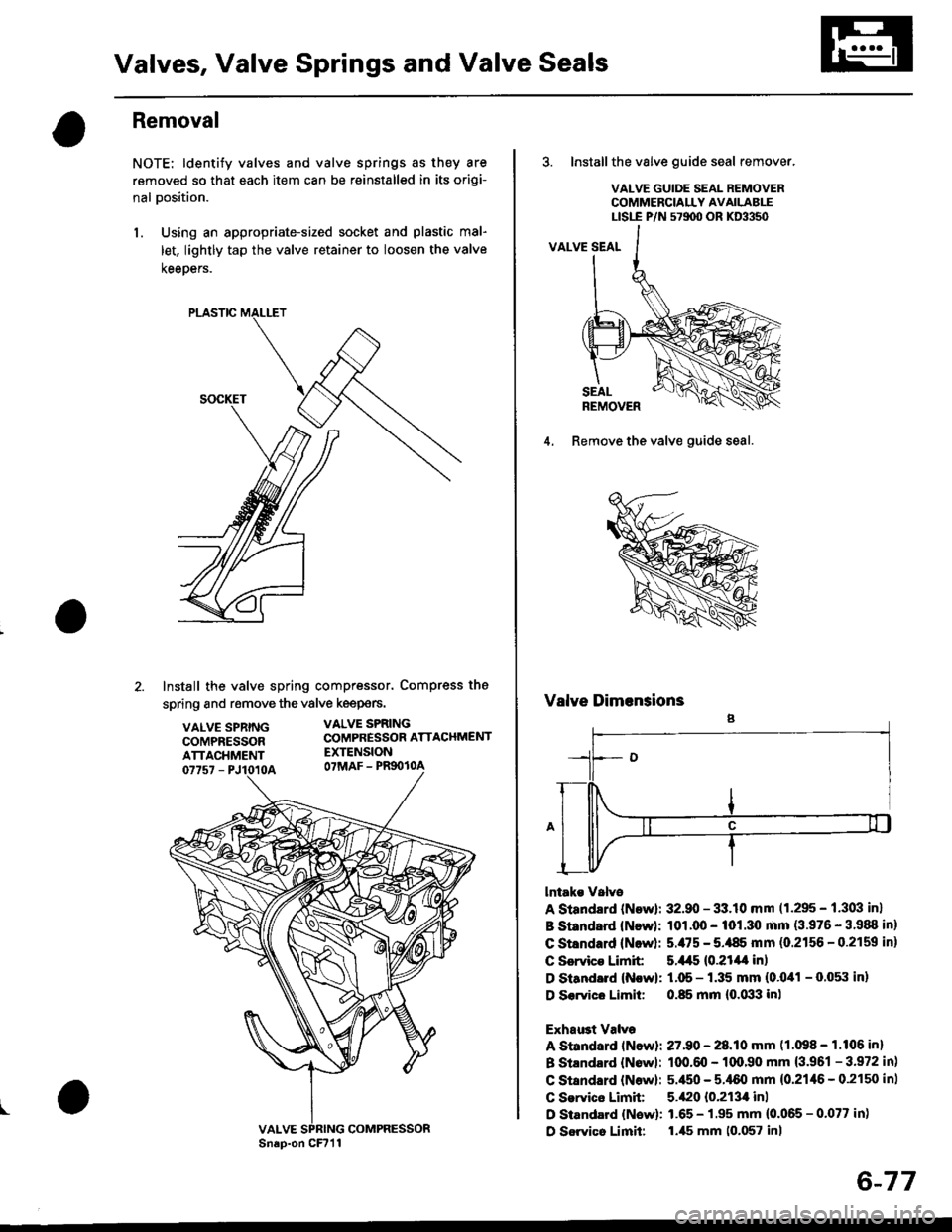

Valves, Valve Springs and Valve Seals

Removal

NOTE: ldentify valves and valve springs as they are

removed so that each item can be reinstalled in its origi-

nal Dosition.

l. Using an appropriate-sized socket and plastic mal-

let, lightly tap the valve retainer to loosen the valve

keeoers.

PLASTIC

Install the valve spring compressor. Compress the

spring and remove the vSlve keepers.

VALVE SPRINGCOMPRESSORATTACHMENT07757 - PJ1010A

VALVE SPRINGCOMPRESSOR ATTACHMENTEXTENSIONOTMAF - PRgOIOA

I

Sn.p-on CFr1lCOMPRESSOR

6-77

3. Installthe valve guide seal remover.

VALVE GUIDE SEAL REMOVERCOMMERCIALLY AVAILABLELtst-E P/N 571100 ()R KD3350

4. Remove the valve guide seal.

Valve Dimensions

lntake Valvo

A Standsrd {Newl; 32.90 - 33.10 mm (1.295 - 1.303 in}

B St ndard {New}: 101.00 - 101.30 mm (3.976 - 3'988 in}

C Stsndard (Nowl: 5./t5 - 5.,185 mm (0.2156 - 0.2159 in)

C Servico Limit 5.445 {0.21/l| in)

D Siandard (N!w): 1.05 - 1.35 mm (0.041 - O.05il inl

D S€.vice Limit: 0.85 mm {0.033 inl

Exhaust Valve

A Standard lNewli 27.90 - 28.10 mm (1.098 - 1.106 in)

B Stlndard {Nowl: 100.m - 1qr,90 mm {3.961 - 3.972 in)

C Stsndard {Now}: 5.450 - 5.,[60 mm {0.21,16 - 0.2150 in)

C Service Limit 5.420 10.213,0 inl

D Standard {New): 1.65 - 1.95 mm (0.065 - 0.077 in)

D Sorvico Limit: l.ils mm 10.057 inl

Page 192 of 2189

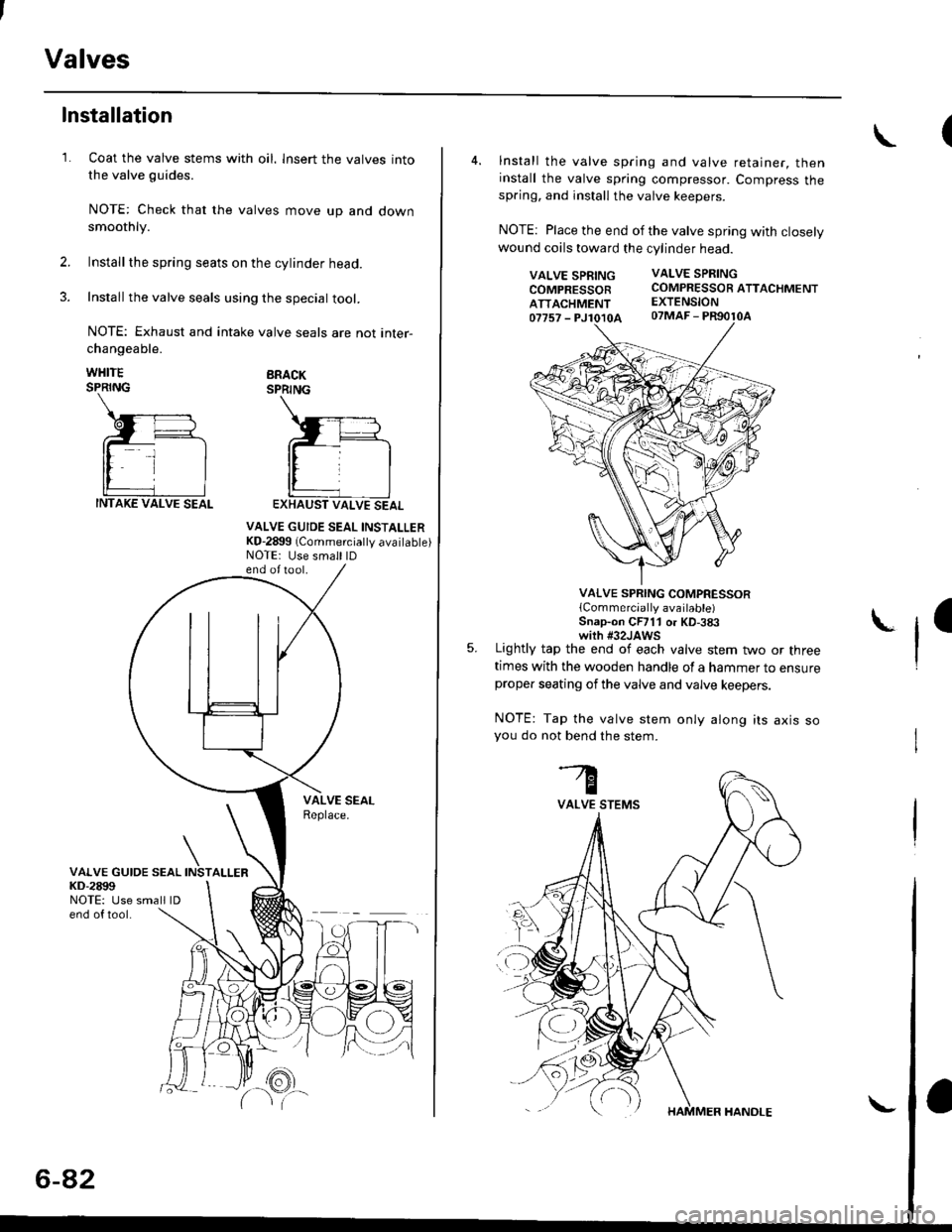

Valves

1.

Installation

Coat the valve stems with oil. lnsert the valves into

the valve guides.

NOTE: Check that the valves move up and downsmoothly.

Installthe spring seats on the cylinder head.

Install the valve seals using the special tool.

NOTE: Exhaust and intake valve seals are not inter-

changeable.

WHITESPRING

VALVE GUIDE SEAL INSTALLERKD-28)g (Commercially available)NOTE: Use small lDend of tool,

2.

BRACKSPRING

VALVE SEALReplace.

tNsTALLERVALVE GUIDE SEALKD-2899NOTE: Use small lDend of tool

(

4. lnstall the valve spring and valve retainer, theninstall the valve spring compressor. Compress thespring, and install the valve keepers.

NOTE: Place the end of the valve spring with closely

wound coils toward the cylinder head.

VALVE SpRtNG VALVE SPRTNG

COMpRESSOR COMPRESSORATTACHMENT

ATTACHMENT EXTENSTON

0775? _ pJlOl0A o?MAF - PR9010A

VALVE SPRING COMPRESSORlCommercially available)Snap-on CF711 or KD-3tXlwith #32JAWSLightly tap the end of each valve stem two or threetimes with the wooden handle of a hammer to ensureproper seating of the valve and valve keepers.

NOTE: Tap the valve stem only along its axis soyou do not bend the stem.

I

5.

Page 220 of 2189

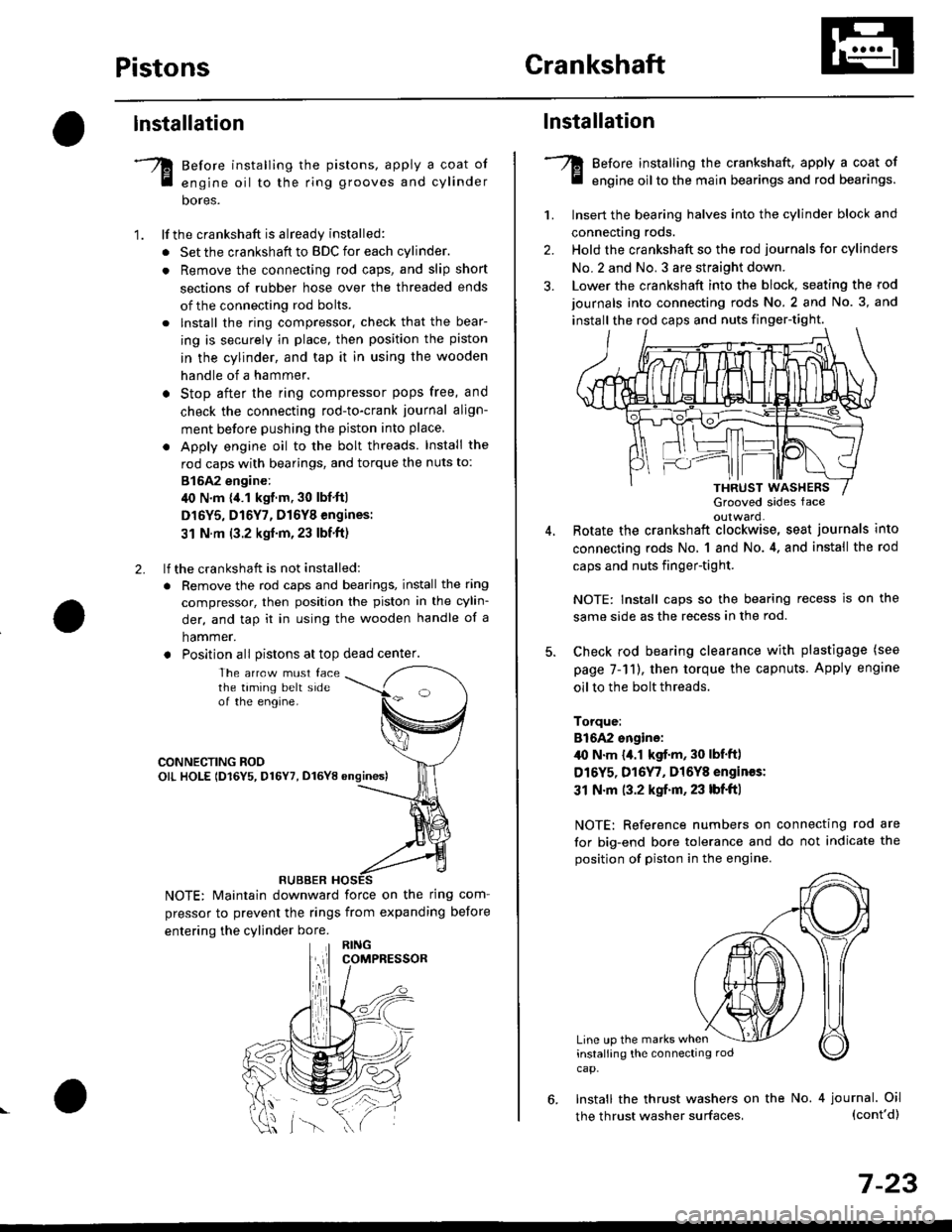

PistonsGrankshaft

lnstallation

Before installing the pistons, apply a coat of

engine oil to the ring grooves and cylinder

bores.

lf the crankshaft is already installed:

. Set the crankshaft to BDC for each cylinder.

. Remove the connecting rod caps, and slip short

sections of rubber hose over the threaded ends

of the connecting rod bolts.

. lnstall the ring compressor. check that the bear-

ing is securely in place, then position the piston

in the cylinder, and tap it in using the wooden

handle of a hammer.

o Stop after the ring compressor pops free, and

check the connecting rod-to-crank journal align-

ment before pushing the piston into place

. Apply engine oil to the bolt threads. Install the

rod caps with bearings, and torque the nuts to:

815A2 engine:

40 N.m {,1.1 kgf.m, 30 lbf'ft|

D16Y5, D16Y7, D16Y8 engines:

31 N.m (3.2 kgf'm,23 lbf'ft)

lf the crankshaft is not installed:

. Remove the rod caps and bearings, install the ring

compressor, then position the piston in the cylin-

der, and tap it in using the wooden handle of a

hammer.

. Position all Distons at top dead center.

1.

2.

The arrcw must facethe taming belt sideof the engine.

CONNECTING ROOOIL HOLE lD16Y5, D16Y7, D16YB ongines)

NOTE: Maintain downward force on the ring com-

pressor to prevent the rings from expanding before

entering the cylinder bore.

RUBBER

,lll

lnstallation

Before installing the crankshaft, apply a coat of

engine oil to the main bearings and rod bearings.

Insert the bearing halves into the cylinder block and

connecting rods.

Hold the crankshaft so the rod journals for cylinders

No.2 and No. 3 are straight down.

Lower the crankshaft into the block, seating the rod

journals into connecting rods No. 2 and No. 3, and

install the rod caps and nuts finger-tight.

1.

2.

3.

5.

Grooved sides faceoulward.Botate the crankshaft clockwise, seat journals into

connecting rods No, 1 and No.4, and install the rod

caps and nuts finger-tight.

NOTE: Install caps so the bearing recess is on the

same side as the recess in the rod.

Check rod bearing clearance with plastigage (see

page 7-11), then torque the capnuts. Apply engine

oil to the bolt threads.

Torque:

816A2 sngine:/l{, N.m {a.l kgf.m, 30 lbf'ftl

D16Y5, D16Y7, Dl6Y8 engines:

31 N.m (3.2 kgf.m, 23 lbf'ft|

NOTE: Reference numbers on connecting rod are

for big-end bore tolerance and do not indicate the

position of piston in the engine.

Line up the marks wheninstalling the connectrng rod

cap.

6. Install the thrust washers on the No. 4 journal. Oil(cont'd)

7-23

the thrust washer surfaces,

Page 357 of 2189

Troubleshooting

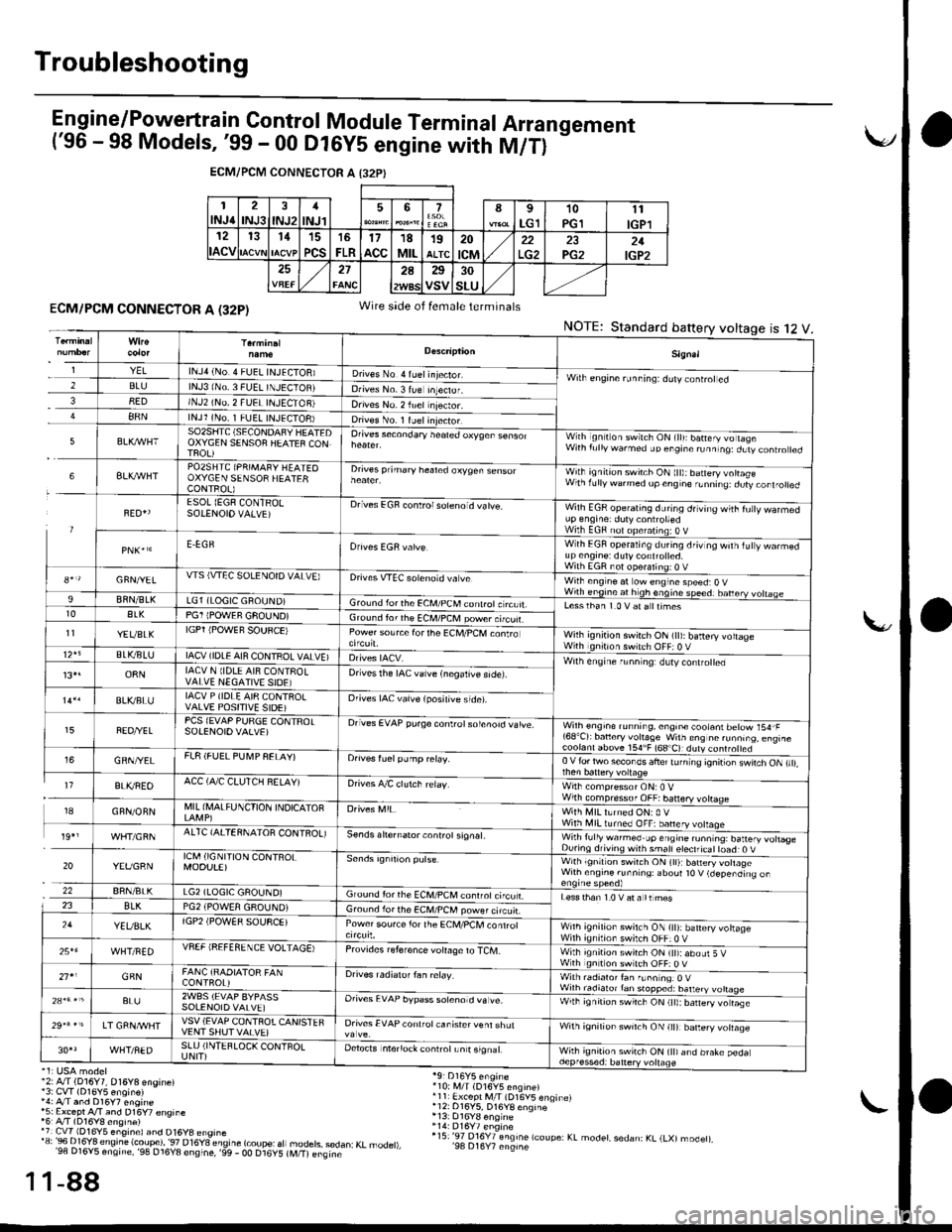

E n gine/P_o,weft ra in Control Module Term inal Arra n gement('96 - 98 Models, '99 - 00 Dl6yS engine with M/T)

-

ECM/PCM CONNECTOR A I32PI

1INJ62INJ3INJ21

INJl567I

LG110PGll1

IGPl12

ACV

131115

PCS

16

FLR17acc18MIL19ALTC20

tcM22PG221IGP2272A25

VSV30

SLU

ECM/PCM CONNECTOR A (32P)

'2: A./T (D16Y7, 016Y8 engine)13: CvT (D16Y5 enoin€)',4: A/T and D16y7 engine*5: Except A/T and D16Y7 €nsine'6r A/T (D16Y8 ensine)'7 Cw 1D16Y5 eng,nel and D16y8 ensrne'"'3:Bi..I?'Jt;".'e'.!ti.?i?l'""."T8"_";btfr

"fl

1-88

Wire side of female terminals

NOTE:Standard battery voltage12ts

'10i i,4/T (D16V5 engine)r11 Ex.ept M/l (D16V5 enqinelr12: 016Y5, D16YB enqine

r15:'97 016Y7 engine lcoupe: KL modet, sedan: KL (LXl modet),'98 D16Y7 engine

1

1

Sign.l

YELlNJ4 (No.4 FUEL INJECIOB)D ves No 4 ruel injector.Wilh engine runninq: ddly coniroted2BLUlNJ3 lNo. 3 FUEL TNJECTOBJDrives No. 3 lue Inteclor.38EDINJ2 (NO, 2 FUEI INJECTON)Drives No. 2 iuel njector.88NlNJl (No. 1 FUEL INJECTOB)Dives No. 1 ruelinjector.

5SO2SIITC (SECONDAFY HEATEDOXYGEN SENSOF HEATEF CONTFOL)

Orives secondary heated oxyqen sensorWith ignilion switch ON (lll: batery vo lageWith f!llywarmed up engine runninq:dLtv controled

6BLXAVHTPO2SHTC (PRIMAFY HEATEOOXYGEN SENSOR HEATERCONTROL)

Drives prihary healed oxygen sensorWith ignition switch ON ltt):baneryvottasewlhrdllywdrmedupcngne,Lnnrrq dury,orl.otred

FED{ESOL (EGF CONTRO!SOIENOIO VALVE)Drives EGF conlrolsoleno d vatve.Wilh EGR operating during drving wiih fu|y warmedup engrne: duty controttedWilh EGF nol opefating:O VE.EGRWith EGF operating du.ing driv og wilh iuty warmedup en9ine: dutycont.olted.With EGR not ooeralino; o V8*r/GFN/YELWS (VTEC SOLENOTD VALVE)Drives VTEC solenoid va veWilh eng ne at ow engine speed:O VWirh engine at h gh enqine speedr banery vohaae9BflN/BLKLG1 (LOGIC GROUND)Gro!nd lorthe €CM/PCM conlrotc rcuit.Lesslhan 1.0 V at a ttimest0ALKPG1 IPOWEF GFOUND)Ground ior rhe ECM/PCM power.tcuf.11YEVBLKIGPT iPOWEF SOUFCE)Power source forthe Ec[,l/PcM conlroWilh ignition swirch ON (tt): battery voltageWith gntron switch OFF: 0 VBLVBLUIACV (IDLE AIN CONTROL VALVE)Wilh engine r!nn ng: dlty contro ed13,.o8NIACV N lIDLE AI8 CONTFOLVALVE NEGATIVE SIOE)Drivesthe IAC valve {negalive side).

BLVBLUIACV P (IDLE AI8 CQNTROLVALVE POSITIVE SIDE)Orives IAC vaive (posilive side).

FEO/YELPCS (EVAP PURGE CONTFOTSOIENOIOVALVE)Drives EVAP pu.ge controtsolenoid vatve.Wilh engioe running, engin€ cootani betow 154,F'68'Cr bancry vohaSe w'ln ens nc runn,.o. eng,rc

GRN/YELFL8 (FUEL PU[4P FELAY)Orives fuelpump relay.0 V {or two secor os ahe' tJ n ng 'onir or \wnch ON ,,,,,

I7BLI(REOACC (A,/C CLUTCH RELAY)Drives A/C clutch relay.Wirh compressor ONr0 VWilh compressof OFF:banery votrage18GFN/ONNMIL (I\,lALFUNCTION INDICATOFWith MIL lLrned ON: 0 VWith illl turned OFF: banery volaqe19',AITC {AITERNAIOR CONIROL)se.ds ahernator controt signat.Wirh fully warmed.up engine ru.ntng: battery votlas€During drivins wnh smatl eteclricat toad: O V

20YEVGRNICM (IGNI'TION CONTROLMOOU!E)with ignltlon swilch ON (tl):b6n€ry vohageWilh ensine runnins: aboul t0 V (depending on

22BRN/BLKLG2 (LOGIC GAOUND)Ground for the ECM,/PCM conrrot ci'cu LLess than 1.0 V at a tt mes23BLKPG2 iPOWEA GROUND)Gro!nd lor the ECM/PCM power circuir.24YEUBLKlGP2 (POW€R SOUSCE)Power sou.ce lor the ECM/PCl, conrrolWnh ignilion swilch ON {it):battery vohageWilh ignilion switch OFF:0 V25*6WHT/FEDVSEF IREFEfl ENCE VOLTAGE)Provrdes reference voIaOe to TCM.With ignition switch ON (tt):abour 5 VWth gnition swltch OFF: O V21'1GFNFANC {RAOIATOR FANCONTFOL)Drives radialof fan ielay.With radialor fan f!nn nqr O VWilh radiato.tan stopped: batteryBL!2WBS (EVAP BYPASSSOLENOIO VALVE]Orives EVAP bypass sotenotd va !e.With ignirion swrrch ON (tt):barery vo rase

LT GRNA/VHTVSV (EVAP CONTFOTCANISTEFVENT SHUT VAIVE)Drives EVAP conlfot canisrer venl shulwnh ignirion sw'tch ON lr|l barery volaqe

WHT/NEDSLU (INTEFLOCK CONTFOLUNIT)Detects intenock conlrotLn t signalWhh ignition switch ON (tt)and brake pedadepf essed: battery vollage

Page 361 of 2189

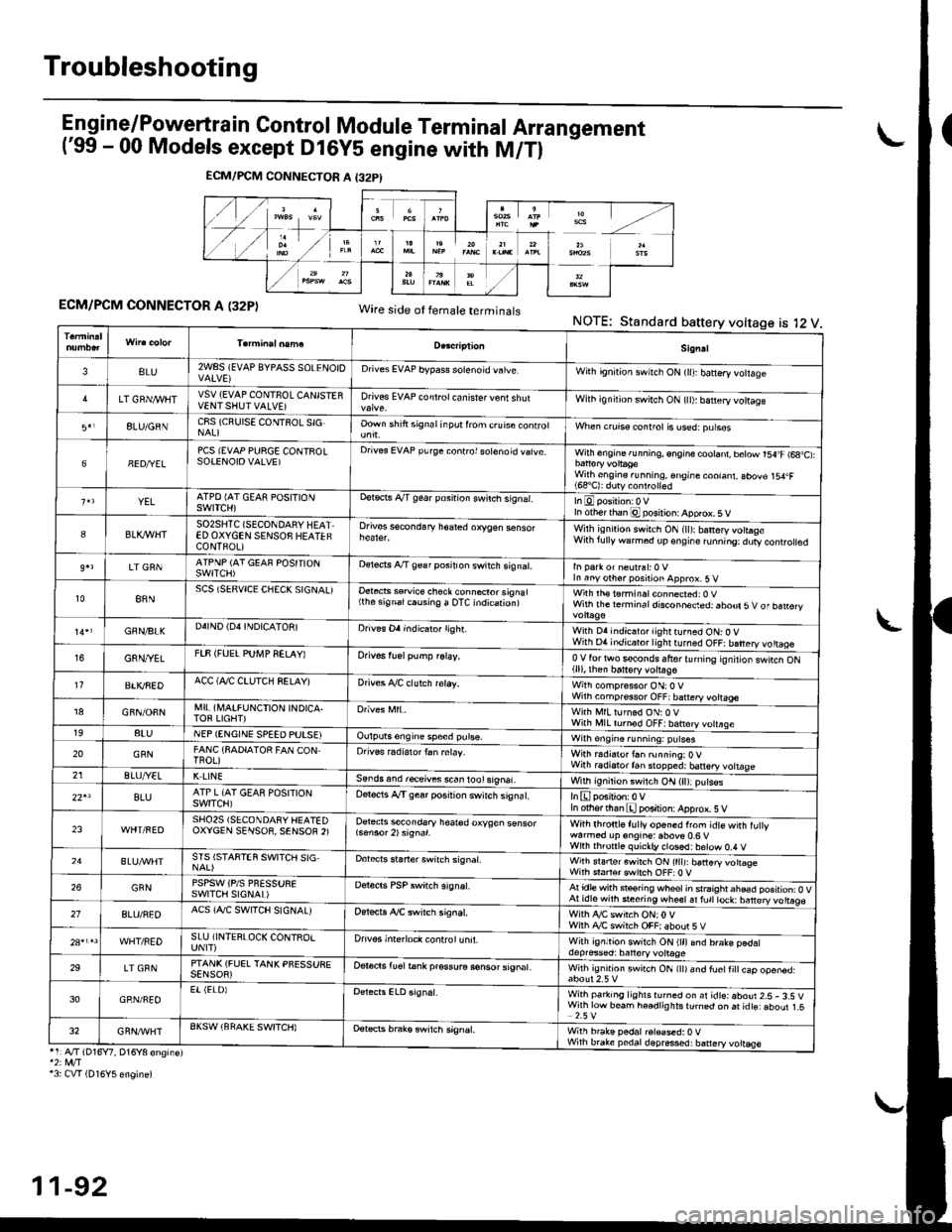

Troubleshooting

Engine/P_o,wertrain Control Module Terminal Arrangement('99 - 00 Models except Dl6Y5 engine with M/Tl

ECM/PCM CONNECTOR A (32P)Wire side ot temale terminalsNOTE:Standard battery voltage is l2 V

ECM/PCM CONNECTOR A I32PI

Sign!l

3BLU2WSS (EVAP 8YPAsS SOLENOIDDrives EVAP bypass solenoid vatve,With gn'tion swnch ON (lll banery votlage

LT GRN/I/VIITVSV {EVAP CONTNOL CANISTERVENTSHUTVALVE]Drives EVAP controt ca n isrer v€nt shutWilh ignilion switch ON {tl): b€ttery vottage

8LU/GNNC8S (CRUISE CONTSOL SIGOown shift signal inpot lrom c.uise conrrolWhen crurss control is used:purses

68ED/YELPCS {EVAP PURGE CONTROLSOTENOIOVALVE)Drives EVAP purge conrrol sotenoid vatve.With engine running, engine cootant, betow r54.F (6a,C):

With engine.unning, €ngine coolant, abov€ 154.F(68'C): duty conlrolled

YELATPD {AT GEAR POSITIONSWITCH)ootects A/T gear posnion swilch s,gnar.In otherthan @ posilion: Apprcx. 5 V

8BLK,IflHTSO2SHTC (SECONDARY HEATED OXYGEN SENSOS HEATEFCONTFOL)

Drives sscondary h€ared oxygen senso.Wilh isn,rion swirch ON (ll):banery votraseWith lully warm6d dp€ngire runn'ng:dury controled

LT GRNATPNP (AT GEAF POSITIONSWITCH)oereds A/T 9€a r position switch signat.In Parr or neulrsl:0 VIn anyother position approx.5 v

t088NSCS (SERVICE CHECK SIGNAL)Oetects ssruice check connecror signal(the signalcausing a OTC indication)with rh€ t6rminal connected: 0 vWith the rerm ina I disconneded: abour 5 V of ban€ry

GNN/BIKD4IND (D4INDICATON]Drives Oa indicaio. lighr.With D4 indicator lightturned ON: O VWith D4 indicator lightturned OFF: battery vo ttageG8N/YETFTF (FUEL PUI\,4P SELAY)Orivos tuel pump relay,0V for two s€conds lfrer turnrng rgnilior swtcn ON(ll), then batt€ry voltage11BTI(REDACC (Al/C CTUTCH SELAY)Drives A./C clutch reray.With compressor ON:O VWilh comp.ssor OFF; battery vottage18GFN/OFNMI! (A,IAIFUNCTION INDICA.TOF LIGHT)With MlLturned ON:0 VWith l\,llL tornod OFF|batrery votrsge198tuNEP (ENGINE SPEED PUTSEIOulputs6ngine speed pulse,Wilh engin6.unning: putses

20GFNFANC {SADIATOR FAN CONTnoL)Orives radiarortan relay.Wirh r.distor t6n running:OVWith radiatortan stopped: banery vottage21ELUA/ELK LINESends and r€ceives s.an lool signal.With ignition switch ON (ll):p!ts€s

22'lBLUATP L {AT GEAS POSITIONswtTcH)Oelocis A"/T gear posirion switch siSnat.In othfflhan E position: Apprcx. 5 V

23SHO25 (SECONOARY HEATEDOXYCEN SENSOR, SENSOF 2)Detects secondsry hoar€d oxygen sensorWith lhronle f! lly or'6ned from idte with fu ywarmod up engine: above 0.6 vWiih th.onl6 quickb, closd:below 0,4 V24STS ISTAFTEN SWITCH SIGDebcrs staner switch signat.Wirh srarterswitch ON (tttJ: batteryvottogeWith sraftsr cwirch OFF:0 V26GFNPSPSW iPlS PNESSURESWITCII SIGNAL)Derecrs PSP switch signat.Atidle with steoring wheolin srraightahead position: O VAt idl6with steering wheetal fult lock: barery vo ttags27BLU/REOACS (AJC SWITCH SIGNALJOer*ts ,ay'C swirch signat.Wiih ty'C switch ON;0VWilh Ay'C switch OFF|aboor 5VWHT/REDSLU iINTERLOCK CONTROIUNIT)Drivos interloct control unit.With ignltion switch ON (ll)and brake pedaldepresed: batlory volrage29LT GRNPTANK (FUEL TANK PFESSUEESENSOR)Oer6ds lu€l tank pr€ssura sonsor signat.Wilh ig.rrrd swirch ON rttr and fuetti

cap ooen6d.

30GRN/FEOEr (ELOIWith parking lighlsrurned on ar idteiaboui 2.5- 3.S VWirh low beam he€dlig hts turnqd on ai idts: aboul 1.52.5 V32GRN/'WHTAKSW (BFAKE SWITCH)Detets brak€ swrtch signEt,With brake pedal r6l€ased:0 VWhh brake pedaldepres*d: battery voltEse'1:A./T (D16Y7, D16Y8 engine)*2: rvt/T13: CVT (D16Y5 engine)

11-92

Page 373 of 2189

PGM-FI System

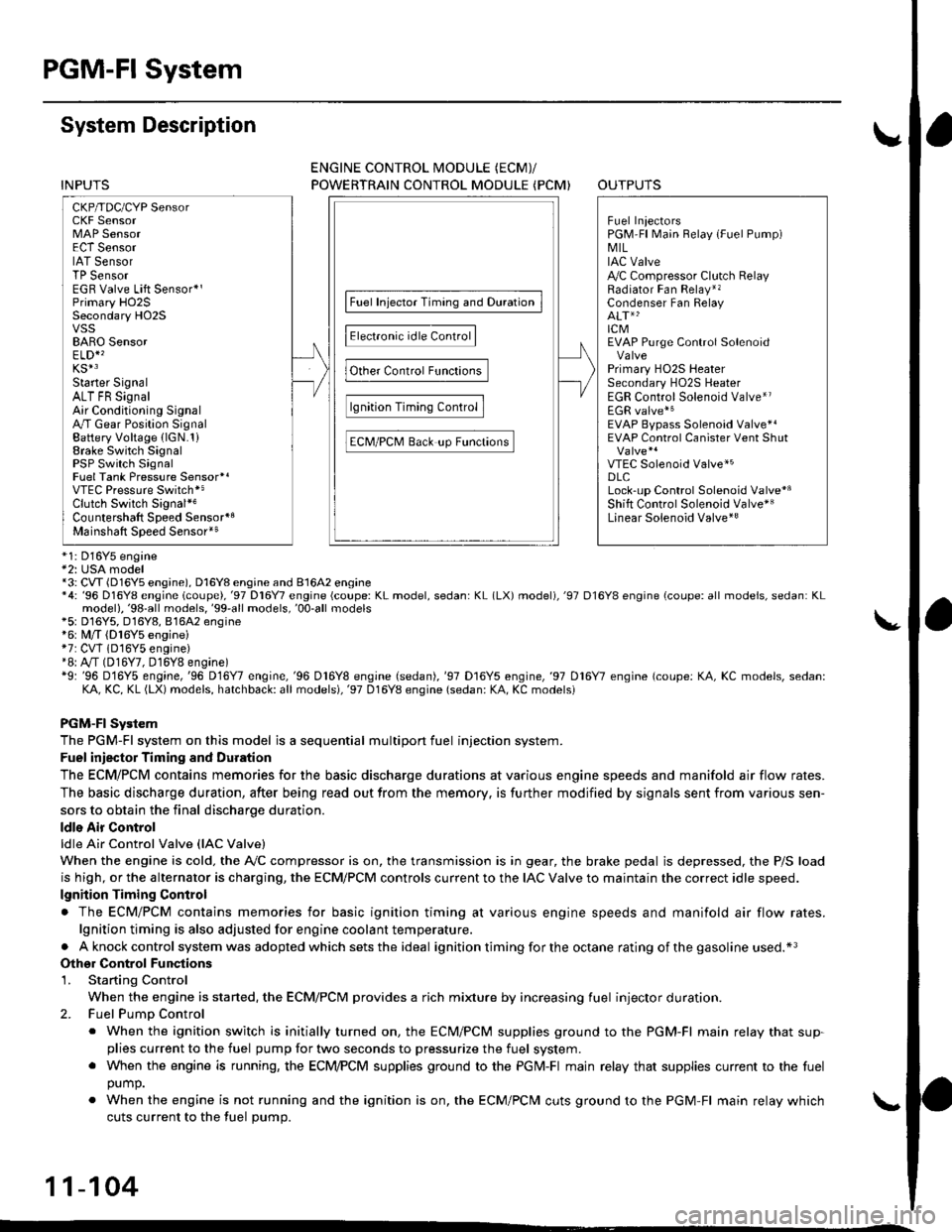

System Description

CKP/TDC/CYP Sensor

MAP Sensor

IAT SensorTP SensorEGR Valve Lift Sensor*'Primary H02SSecondary HO2SVSSBARO SensorELD*'KS€Starter SignalALT FR SignalAir Conditioning SignalA/T Gear Position SignalBattery Voltage {lGN.1}Erake Switch SignalPSP Switch SignalFuel Tank Pressure Sensor*iVTEC Pressure Switch*5Clutch Switch Signal*6Countershaft Speed SensornBMainshaft Speed Sensorrs

-\

----t /

F;ilrr j"-----fi-tri-'r.;l

Fb"t."'i" d" c;;il

F,h"'c;;tr*".io";-l

@."r.l"sc;;ll

EaM/PcM B""k-p F"""till

r\

-:/

Fuel IniectorsPGM-Fl Main Belay {Fuel Pump)MILIAC Valve!y'C Compressor Clutch RelayRadiator Fan Relay*,Condenser Fan RelayALT*'lcMEVAP Purge Control Solenoid

Primary HO2S HeaterSecondary H02S HeaterEGR Control Solenoid Valve*rEGR valve*6EVAP Bypass Solenoid Valve*'EVAP Control Canister Vent Shut

VTEC Solenoid Valve*5DLCLock-up Control Solenoid Valve*aShift Control Solenoid Valve*3Linear Solenoid Valve*3

*1: Dl6Y5 engine*2: USA model*3: CW (D16Y5 ensine), D16Y8 engine and 81642 ensine*4: '96 D16Y8 engine lcoupe),'97 Dl6Y7 engine (coupe: KL model, sedan: KL (LX) model),'97 D16Y8 engine {coupe: all models, sedan: KLmodel),'98-all models,'99'all models,'00-all models+5: D16Y5, D16Y8,816A2 engine*6: M/T (D16Y5 enginei*7: CVT 1D'l6Y5 engine)+8: A/T (D16Y7, D16Y8 engine)*9: '96 D16Y5 engine,'96 D16Y7 engine,'96 Dl6Y8 engine (sedan),'97 D16Y5 engine,'97 Dl6Y7 engine (coupe: KA, KC models, sedan:KA, KC, KL (LX) models, hatchback: all models),'97 D16Y8 engine (sedan: KA, KC modelsi

PGM-FI Sy3lem

The PGM-Fl system on this model is a sequential multipon fuel injection system.

Fuel iniector Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold air flow rates.

The basic discharge duration, after being read out from the memory. is further modified by signals sent from various sen-

sors to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve llAC Valve)

When the engine is cold. the A,/C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

. The ECM/PCM contains memories for basic ignition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. Aknockcontrol system was adopted which sets the ideal ignition timing for the octane rating ofthegasoline used.*3

Othgr Control Funqtions

1. Starting Control

When the engine is started, the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on, the ECM/PCM supplies ground to the PGM-Fl main relay that sup-plies current to the fuel pump for two seconds to pressurize the fuel system.. When the engine is running, the ECI\4PCM supplies ground to the PGM-FI majn relay that supplies current to the fuel

oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

11-104

INPUTS

ENGINE CONTROL MODULE (ECMY

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

Page 374 of 2189

3.

5.

6.

1.

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors is cut off to improve fuel economy at

speeds over the following rpm:. D16Y5 engine (M/T):850 rpm. D]6Y5 engine (CVT), D'16Y8 engine (USA M/T): 920 rpm

. Dl6Y8 engine (USA A,/I), D16Y7 engine (USA A,/T);910 rpm

. D16Y8 engine (Canada M/T), D16Y7 engine (canada): 990 rpm

' D16Y8 engine (Canada M/T): 1,000 rpm

. 816A2 engine: 970 rpm

. Fuel cut-off action also takes place when engine speed exceeds 6,900 rpm (D16Y5, D16Y7 engine; D'16Y8 engine:

7,000 rpm. 816A2 engine: 8.100 rpm), regardless of the position of the throttle valve, to protect the engine from

over-rewing. With '99 Dl6Y7 engine (A,/T) and '99 D16Y8 engine (A./T), the PCM cuts the fuel at engine speeds over

5,000 rpm when the vehicle is not moving.

IVC Compressor Clutch Relay

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure smooth transition to the A,/C mode

Evaporative Emission (EVAP) Purge Control Solenoid Valve*'

When the engine coolant temperature is above 154'F (68'C). the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister.

Evaporative Emission (EVAP) Purge Control Solenoid Valve*a

When the engine coolant temperature above 154"F (68"C), intake air temperature above 32"F (0'C) and vehicle speed

above 0 mile (0 km/h) or [Ay'C compressor clutch on and intake air temperature above 160"F (41'C)], the ECM/PCM

controls the EVAP purge control solenoid valve which controls vacuum to the EVAP purge control canister.

Exhaust Gas Recirculation (EGR) Control Solenoid Valve*?

When EGR is required for control of oxides of nitrogen (NOx) emissions. the ECM controls the EGR control solenoid

valve which supplies regulated vacuum to the EGR valve

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode,

which reduces the engine load to improve the fuel economy.

ECM/PCM Fail-safe/Back-up Functions

1. Fail safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pro-

grammed value for that sensor that allows the engine to continue to run.

2. Back-uD Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self diagnosis Function lMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the lvllL and stores the DTC

in erasable memory. When the ignition is initially turned on, the ECM/PCM supplies ground for the MIL for two sec-

onds to check the MIL bulb condition.

4. Two Trip Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S, fuel metering-related. idle control

system, ECT sensor, EGR system and EVAP control system self-diagnostic functions. When an abnormality occurs,

the ECM/PCM stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and

ON 0l) again, the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is

cancelled when you jump the service check connector. The MIL will then blink immediately when an abnormality

occurs,

5. Two (or Three) Driving Cycle Detection Method

A "Driving Cycle" consists ot starting the engine. beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions is detected during two consecutive driving cycles, or TWC deterioration is detected dur-

ing three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to ease troubleshooting, this function

is cancelled when you jump the service check connector. The MIL will then blink immediately when an abnormality

occurs.

(cont'd)

1 1-1 05

.1.