gap HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1003 of 2189

Forward Clutch

Reassembly {cont'd)

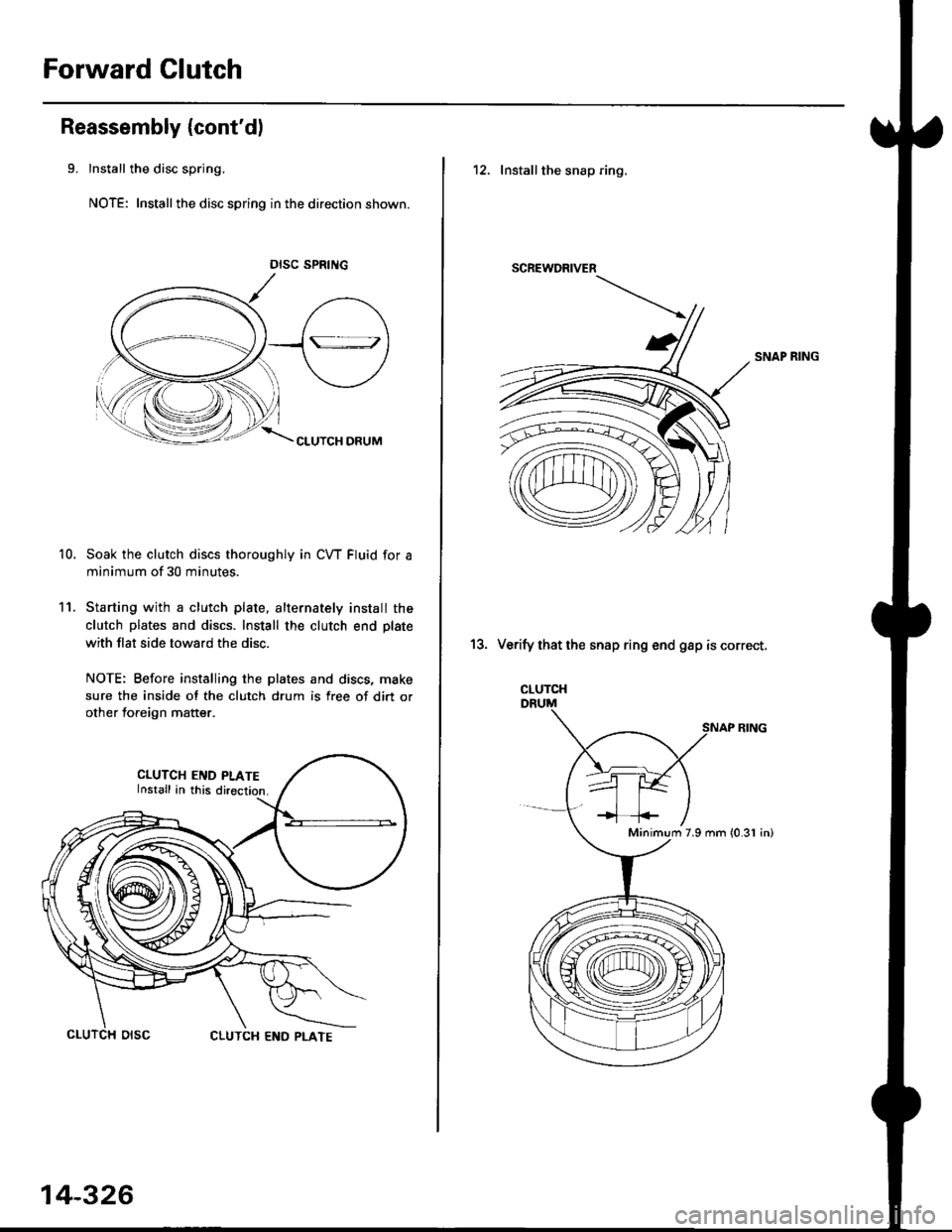

9. Install the disc spring.

NOTE: Installthe disc spring in the direction shown.

- "arr"" o"u*

11.

Soak the clutch discs thoroughly in CW Fluid for a

minimum of 30 minutes.

Starting with a clutch plate. alternately install the

clutch plates and discs. Install the clutch end plate

with flat side toward the disc.

NOTE: Before installing the plates and discs, make

sure the inside of the clutch drum is free of dirt or

other toreign matter.

CLUTCH END PLATEInstall in this dir€ction.

10.

DISC SPRING

14-326

12. Installthe snap ring.

13. Verify that the snap ring end gap is correct.

SNAP RING

CLUTCH

Minimum 7.9 mm (0.31 ini

Page 1011 of 2189

Transmission Housing Bearings

Driven Pulley Shaft Bearing Replacement

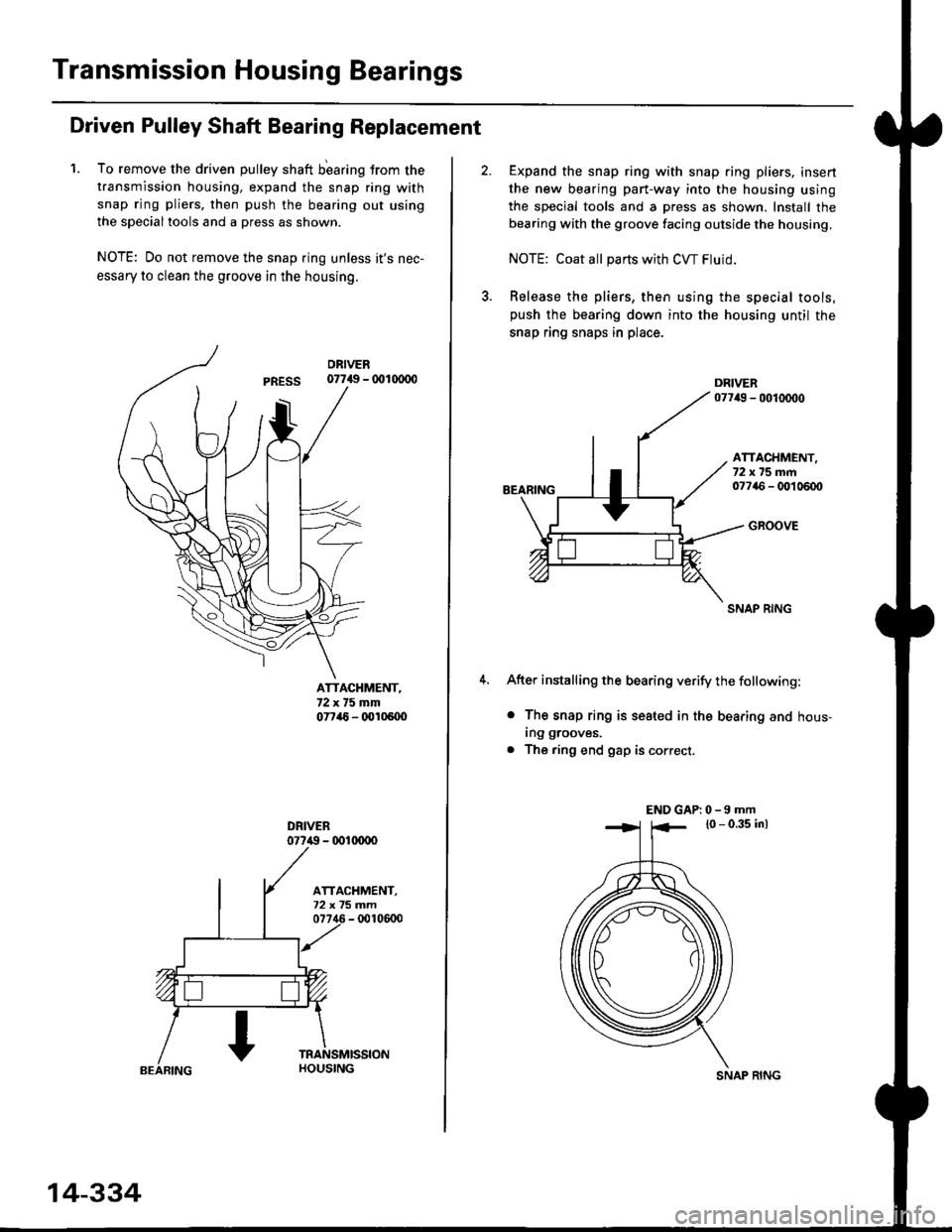

1. To remove the driven pulley shaft b'earing trom the

transmission housing, expand the snap ring with

snap ring pliers, then push the bearing out using

the specialtools and a press as shown.

NOTE: Do not remove the snap ring unless it's nec-

essary to clean the groove in the housing.

07749 - 001(xDo

ATTACHMENT,72x75mm07746 - (x'l05U)

077i() - 001(xrco

14-334

SNAP RING

Expand the snap ring with snap ring pliers, insert

the new bearing part-way into the housing using

the special tools and a press as shown. Install the

bearing with the groove facing outside the housing.

NOTE: Coat all pans with CW Fluid.

Release the pliers, then using the special tools,push the bearing down into the housing until the

snap ring snaps in place.

BEARING

ATTACHMENT,72x75mm07746 - OO1 0600

GROOVE

SNAP RING

After installing the bearing verify the following:

o The snap ring is seated in the bearing and hous-

ing grooves.

. The ring end gap is correct.

END GAP| 0 -9 mm

l0 - 0.35 inl

Page 1015 of 2189

1.

7.

lnstall the ATF feed pipe in the transmission hous-

ing, and install the three ATF feed pipes with new

O-rings in the transmission housing,

Install the two dowel pins and new transmission hous-

ing gasket on the transmission housing.

Push the control shaft assembly toward the outside

of the transmission housing, then install the inter-

mediate housing assembly (four bolts).

lnstall the manual valve body separator plate and

the two dowel pins on the intermediate housing,

then install the rnanual valve body with the detent

spring (five bolts).

Put the control shaft assembly back, then install the

roller in the intermediate housing.

lnstall the reverse brake piston in the intermediate

housing.

Install the spring retainer/return spring assembly on

the reverse brake Piston.

NOTE: Installthe return springs on the spring guides

of the reverse brake piston securely

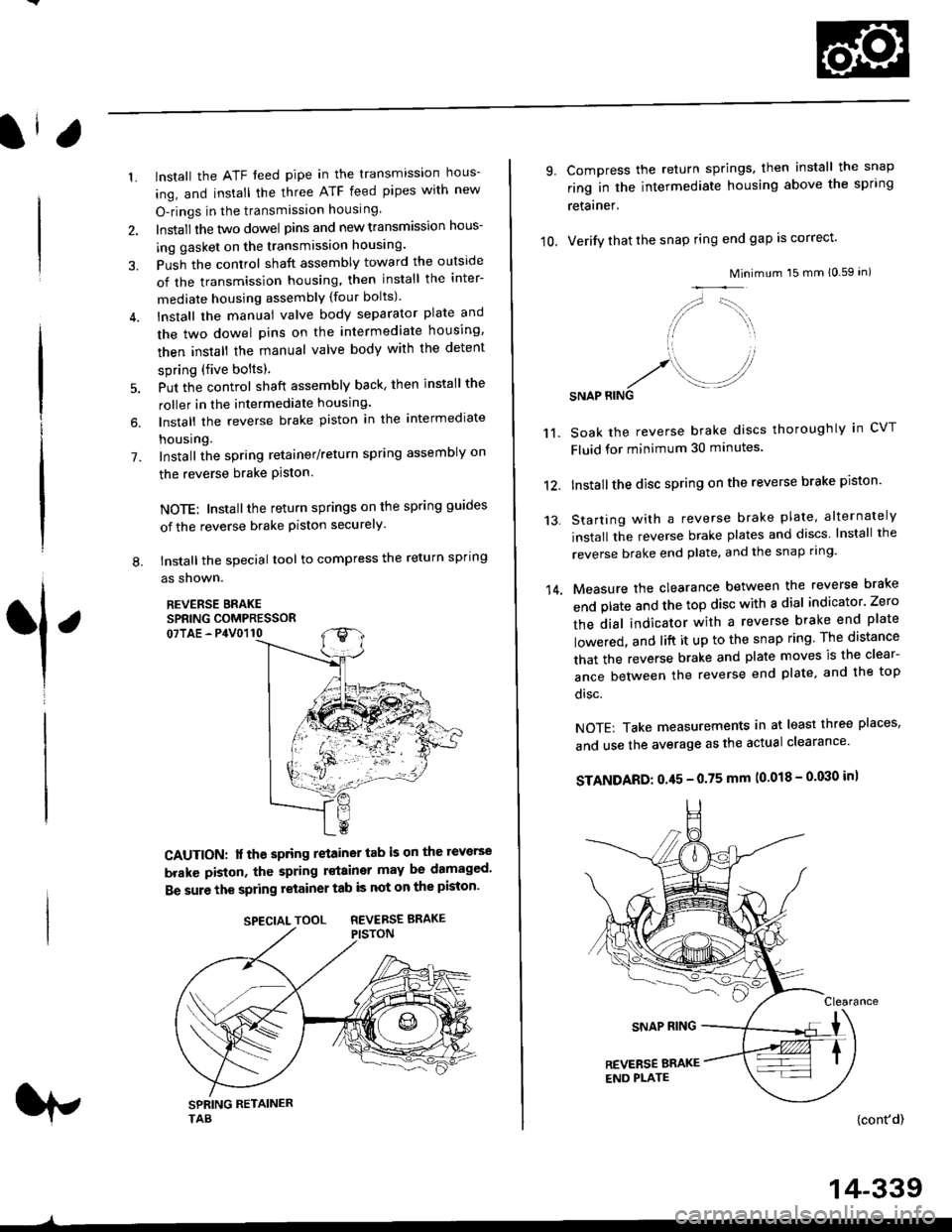

tnstall the special tool to compress the return spring

as shown.

REVERSE BRAKESPRING COMPRESSOR07TAE - P4V0110

6.

L

1

CAUTION: lf the spring retainer tab is on the reverse

brakc piston, the spring rstainer may be damaged'

Be sure the spring retainer tab is not on the piston'

rp

SPECIALTOOL REVERSEBRAKE

-^

14-339

10.

9.

14.

Compress the return springs, then install the snap

ring in the intermediate housing above the spring

retainer.

Verify that the snap ring end gap is correct'

Mini

/,,- '-t,,,,.

// \i/ ',r

'1 ,

.r' //'/. .-J?RINGSNAP

mum 15 mm 10.59 in)

Soak the reverse brake discs thoroughly in CVT

Fluid for minimum 30 minutes.

Installthe disc spring on the reverse brake piston'

Starting with a reverse brake plate, alternately

install the reverse brake plates and discs lnstall the

reverse brake end plate, and the snap ring'

Measure the clearance between the reverse brake

end plate and the top disc with a dial indicator' Zero

the dial indicator with a reverse brake end plate

lowered, and lift it up to the snap ring The distance

that the reverse brake and plate moves is the clear-

ance between the reverse end plate, and the top

disc.

NOTE: Take measurements in at least three places'

and use the average as the actual clearance'

STANDARD: 0.45 - 0.75 mm (0.018 - 0'030 in)

{cont'd)

11.

12.

13.

Page 1018 of 2189

Transmission

Reassembly (cont'd)

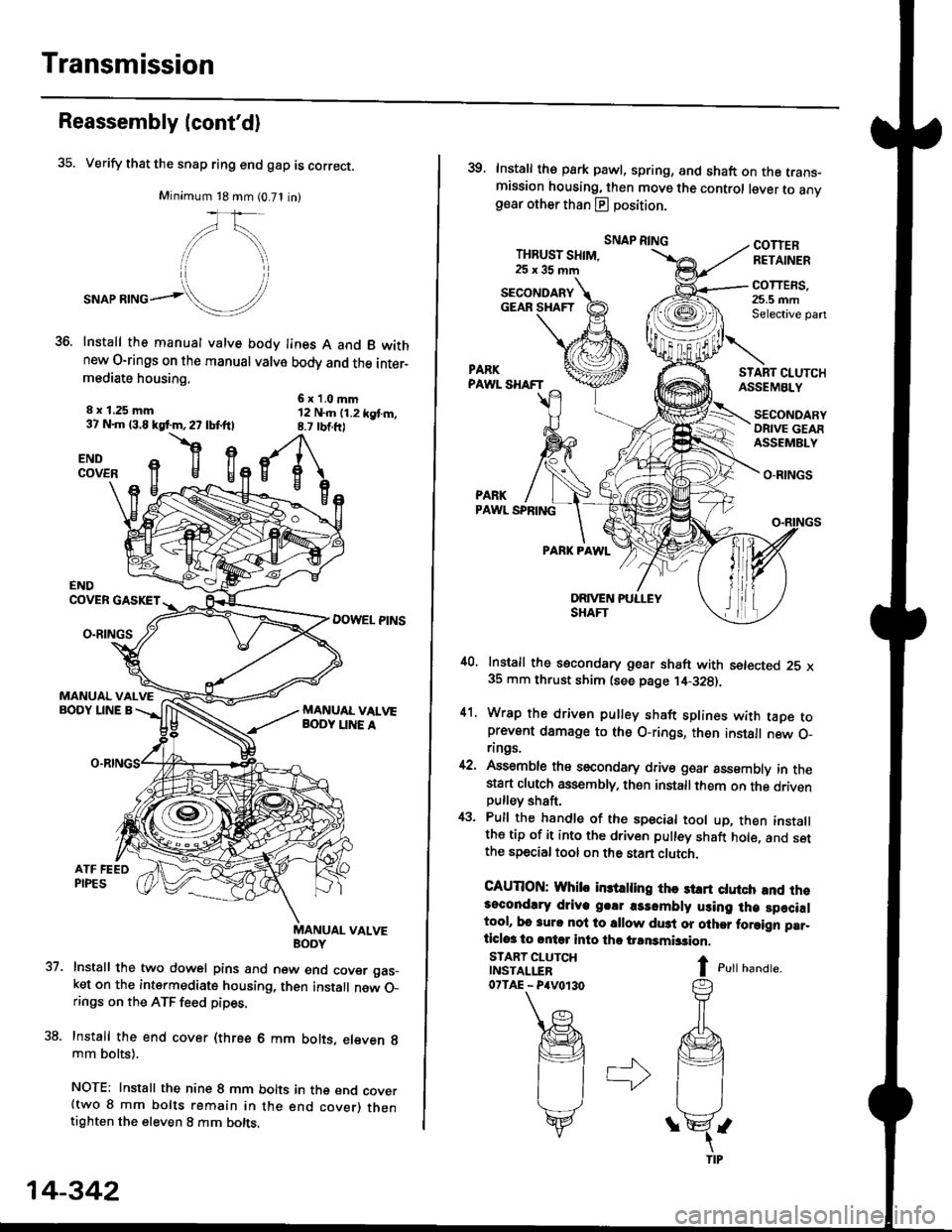

35. Verify that the snap ring end gap is correct.

Minimum 18 mm (0.71 in)

,/\,

."or**ol!/'

Install the manual valve body lines A and B wkhnew O-rings on the manual valve body and the inter-mediate housing.

6x1.0mm12 N..n (1.2 kgt m,8.7 rbtft)

8 x 1.25 mm37 N.m 13.8 kgf.m,27 lbf.ftl

flgENDCOVER

37.

ENDCOVER GASKET

DOWEL PINSO-RINGS

MANUAL VALVEBODY LINE A

uaNYuAL VALVE

Install the two dowel pins and new end cover gas_ket on the intermediate housing, then install new O_rings on the ATF feed pipes.

Install the end cover (three 6 mm bolts, eleven g

mm bolts).

NOTE: Install the nine 8 mm bolts in the end cover(two 8 mm bolts remain in the end cover) thentighten the eleven 8 mm bolts.

14-342

39. Install the park pawl, spring, and shaft on the trans-mission housing, then move the control lever to anvgear other than E position.

THBUST SHIM,25x35mm

SNAP RINGCOTTERRETAINER

COTTERS,25.5 mmSelective pan

START CI.UTCHASSEMBLY

O.RINGS

PARKPAWL SPRING

PARK PAWL

,10, Install the secondary gear shaft with setected 25 x35 mm thrust shim (see page ,14-328).

41. Wrap the driven pulley shaft splines with taDe toprevent damage to the O-rings, then install new O_rings.

42, Assemble ths secondary drive goar assembly in thestart clutch assembly, then installthem on the drivenpulley shaft,

43. Pull the handle of the special tool up, then installthe tip of it into the driven pulley shaft hole, and setthe special tool on the stan clutch.

CAUTION: Whib in3trling thc st rt ctutch and rh.3ocondlry driye g.!r a3sombly using lh€ specialtool, bo 3urc nol to sllow du3t or olher foraign par_ticlos to ontq into tho iransmbsion.

I c,rr r,unar".

SECONDARYGEAR SHAFT

START CLUTCHINSTALLER07TAE - P4V0r30

SECONDARYORIVE GEAFASSEMBLY

Page 1124 of 2189

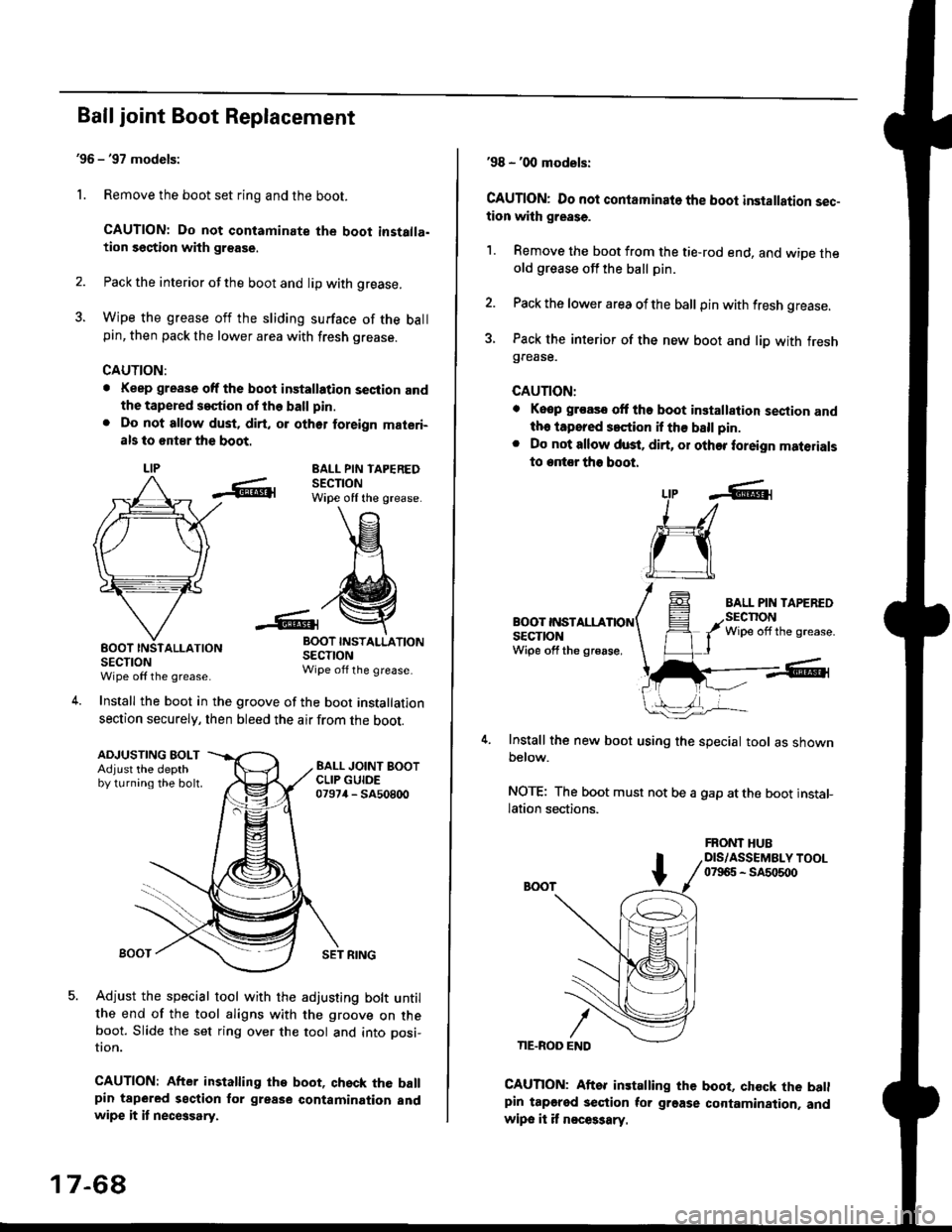

Ball joint Boot Replacement

'96 - '97 models:

1. Remove the boot set ring and the boot.

CAUTION: Do not contaminate the boot installa.tion section with grsase.

2. Pack the interior of the boot and lip with grease.

3. Wipe the grease off the sliding surface of the ballpin, then pack the lower area with fresh grease.

CAUTION:

. Keep grease off the boot installation seciion andthe tapered s€ction ot the ball pin.

. Do not allow dust, dirt, or oth6r foreign materi-

als to 6nt8r the boot.

LIPEALL PIN TAPEREDSECTIONWipe off the grease.

INSTALLATION

SECTIONWipe off the grease.

Install the boot in the groove of the boot installation

section securely, then bleed the air from the boot.

-6lrBOOTSECTIONWipe off the grease

4.

ADJUSTING BOLTAdjust the depthby turning the bolt.

SET RING

Adjust the special tool with the adjusting bolt untilthe end of the tool aligns with the groove on theboot. Slide the set ring over the tool and into posi-

UOn.

CAUTION: After installing the boot, qhsck the ballpin tapered section for grease contamination andwipe it it necGsary.

17-68

'98 - '00 models:

CAUTION: Do not contaminato the boot installation sec-tion with grease.

1. Remove the boot from the tie-rod end, and wiDe theold grease off the ball pin.

2. Pack the lower area ofthe ball pin with fresh grease.

3. Pack the interior of the new boot and liD with freshgrease.

CAUTION:

. Keop groasc ott tho boot installalion sestion andth. iapored s.ction if th€ ball pin.

. Do not allow dust. dirt, or other foreign materials

to entor tho boot.

BOOT INSTALLASECTIONWipe off the gr€ase,

Install the new boot using the special tool as shownbelow.

NOTE: The boot must not be a gap atthe boot installation sections.

LtP .6r

J_/

ru

CAUTION: Aftor installing the boot, chock the batlpin tapgred section tor grgase cortamination. andwipe it it n€ces3ary.

FRONT HUBDIS/ASSEMBLY TOOL07965 - SA5o500

Page 1229 of 2189

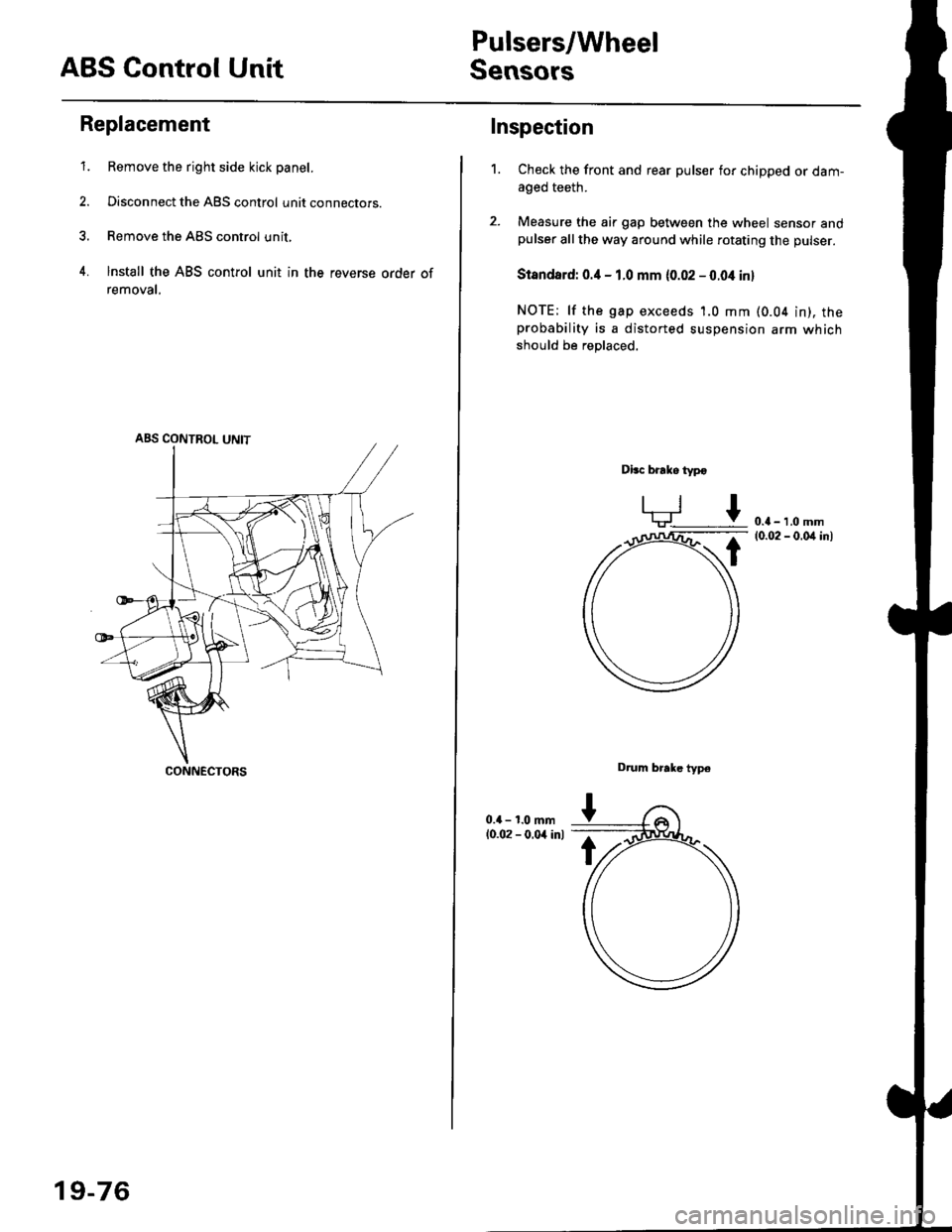

ABS Control Unit

Pulsers/Wheel

Sensors

Replacement

1. Remove the right side kick panel.

2. Disconnect the ABS control unit connecrors.

3. Remove the ABS control unit,

4. lnstall the ABS control unit in the reverse order of

removal,

CONNECTORS

19-76

Inspection

Check the front and rear pulser for chipped or dam-aged teeth.

Measure the air gap between the wheel sensor andpulser all the way around while rotating the pulser.

Slandard: 0.4 - 1.0 mm (0.02 - 0.04 in,

NOTE; lf the gap exceeds 1.0 mm (0.04 in), theprobability is a distorted suspension arm which

should be replaced.

Dbc brake typo

0.{ - 1.0 mm(0.02 - 0.04 in)

Drum brake typ6

1.

Page 1252 of 2189

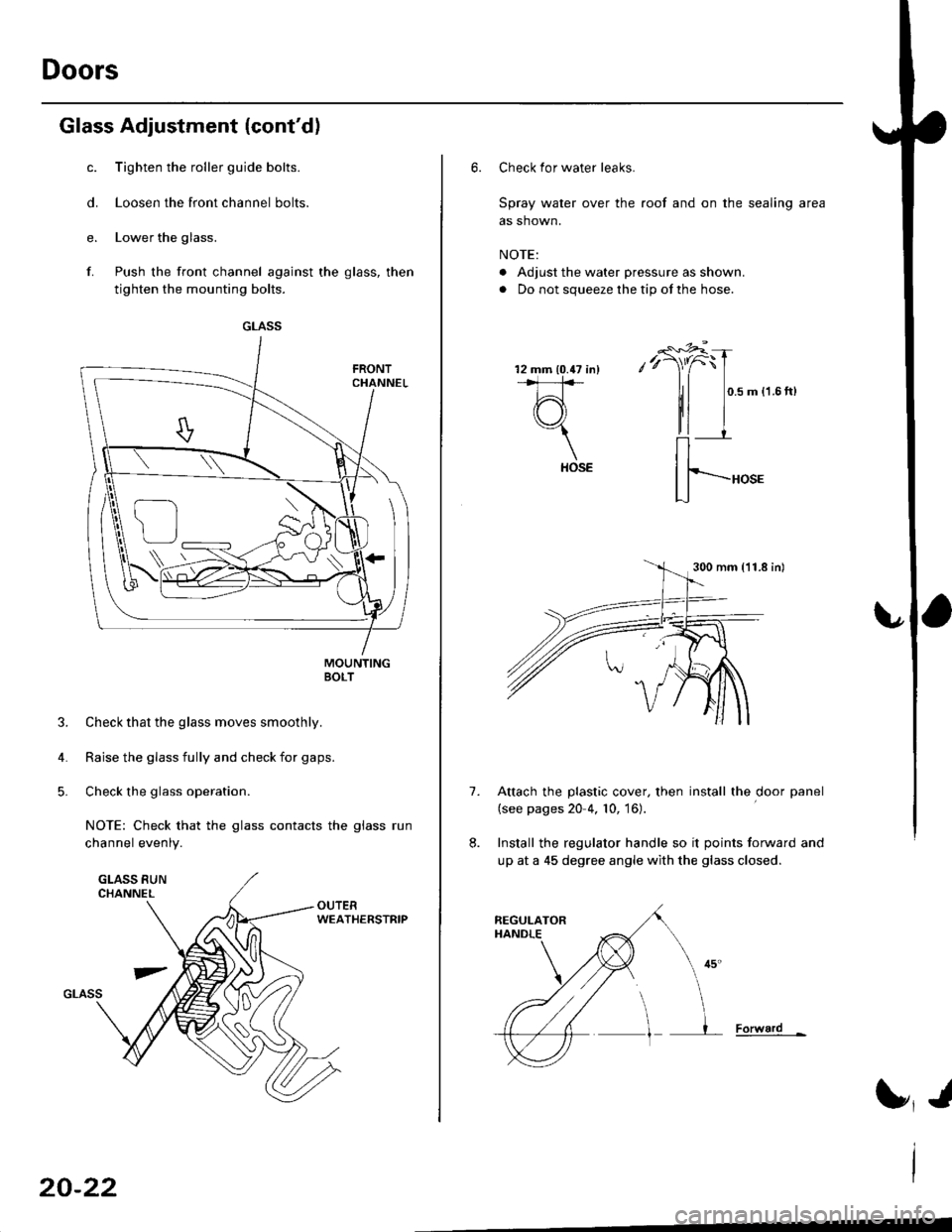

Doors

Glass Adjustment {cont'd)

c. Tighten the roller guide bolts.

d. Loosen the front channel bolts.

e. Lower the glass.

f. Push the front channel against the glass, then

tighten the mounting bolts.

MOUNTINGBOLT

3. Check that the glass moves smoothly.

4. Raise the glass fully and check for gaps.

5. Check the glass operation.

NOTE: Check that the glass contacts the glass run

channel evenly.

WEATHERSTRIP

GLASS

U

-\,

20-22

6. Check for water leaks.

Spray water over the roof and on the sealing area

as shown.

NOTE:

. Adjust the water pressure as shown.

. Do not squeeze the tip of the hose.

0.5 m {1.6ft)

HOSE

Attach the plastic cover, then install the door panel

(see pages 20 4, 10, 16).

Install the regulator handle so it points forward and

up at a 45 degree angle with the glass closed.

Forward -

1.

HOSE

300 mm {11.8 in)

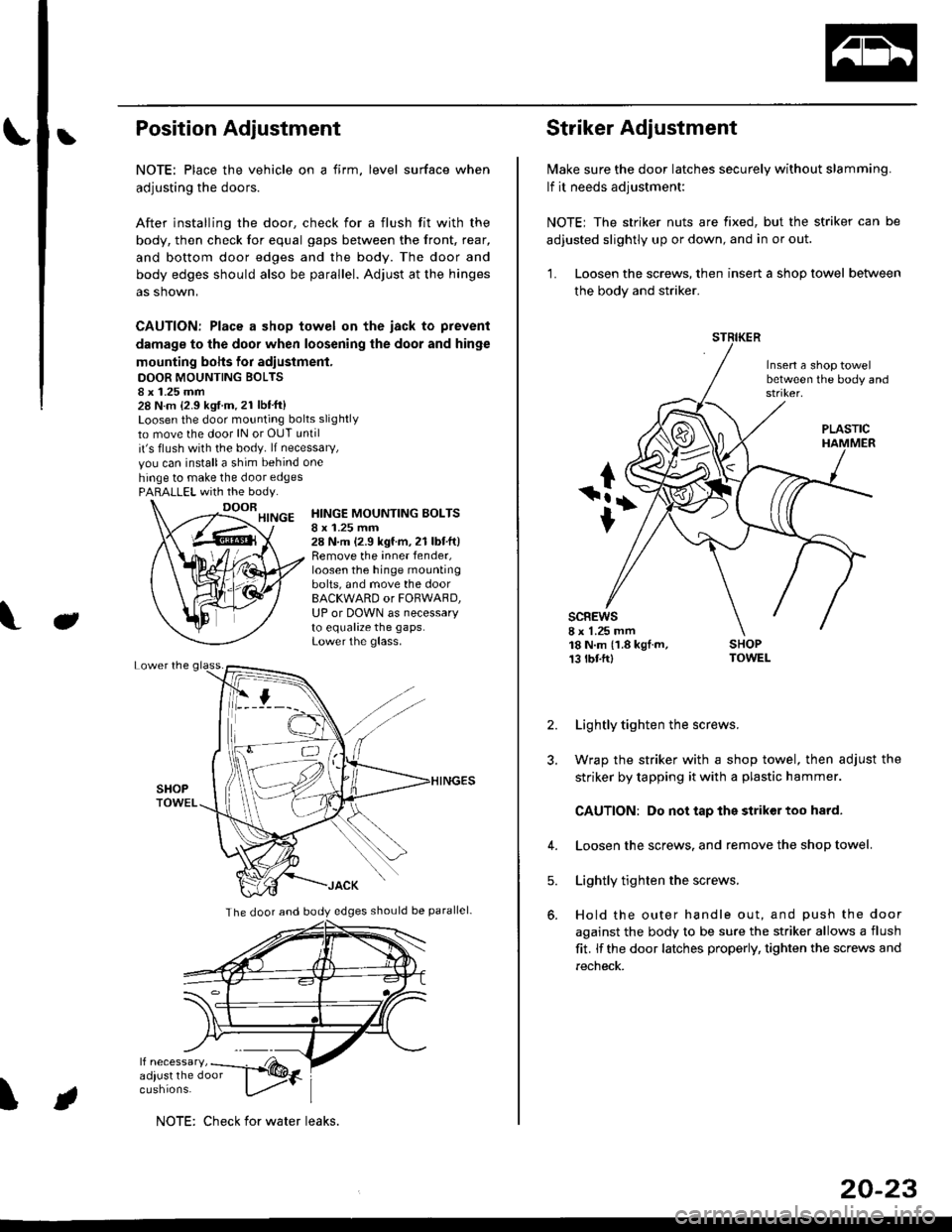

Page 1253 of 2189

bPosition Adjustment

NOTE: Place the vehicle on a firm, level surface when

adjusting the doors.

After installing the door, check for a flush fit with the

body, then check for equal gaps between the front, rear,

and bottom door edges and the body. The door and

body edges should also be parallel. Adjust at the hinges

as shown,

CAUTION: Place a shop towel on the iack to prevent

damage to the door when loosening the door and hinge

mounting bohs for adiustment.

DOOR MOUNTING BOLTS8 x 1.25 mm28 N.m {2.9 kgf.m.21 lbt'ft}Loosen the door mounting bolts slightly

to move the door lN or OUT until

it's flush with the body. lf necessary,

vou can installa shim behind one

hinge to make the door edgesPARALLEL with the body.

J

HINGE MOUNTING BOLTSI x 1.25 mm28 N.m (2.9 kgf.m,21 lbtft)Remove the inner fender,loosen the hinge mountingbolts, and move the doorBACKWARD or FORWARD,UP or DOWN as necessaryto equalize the gaps.Lower the glass.

\

The door and body edges should be parallel-

ifF t

NOTE: Check for water leaks.

20-23

Striker Adjustment

lvlake sure the door latches securely without slamming.

lf it needs adjustment:

NOTE; The striker nuts are fixed, but the striker can be

adjusted slightly up or down, and in or out.

'L Loosen the screws, then insert a shop towel between

the body and striker.

Insert a shop towelbetween the body and

sc8Ews8 x 1.25 mm18 N.m (1.8 kgf.m,13 tbtftl

PLASTIC

2. Lightly tighten the screws.

3. Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striker too hard.

4. Loosen the screws. and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door

against the body to be sure the striker allows a flush

fit. lf the door latches properly, tighten the screws and

recheck.

5.

Page 1281 of 2189

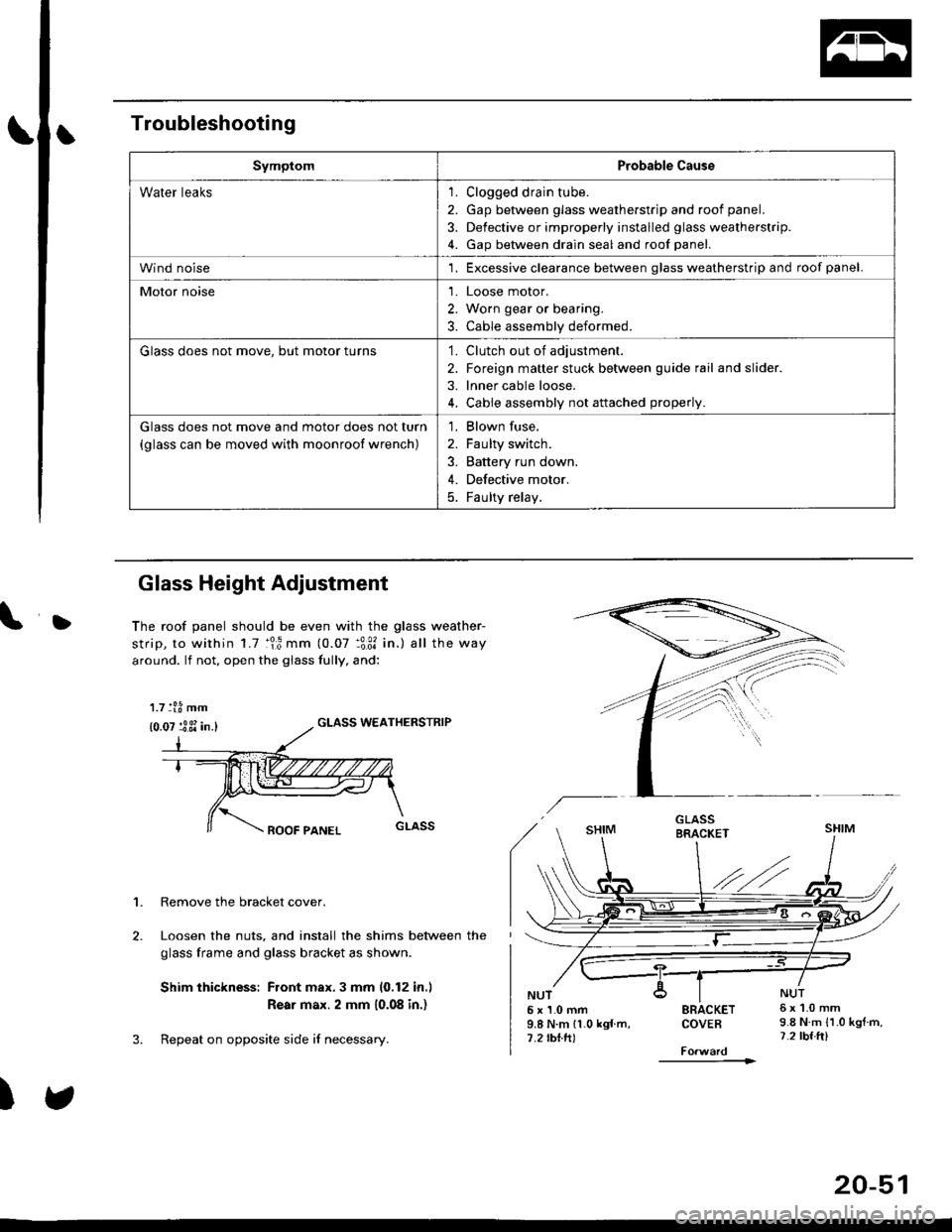

Troubleshooting

SymptomProbable Cause

Water leaks1. Clogged drain tube.

2. Gap between glass weatherstrjp and roof panel.

3. Defective or improperly installed glass weatherstrip.

4. Gap between drain seal and roof panel.

Wind noise'1. Excessive clearance between glass weatherstrip and roof panel.

Motor noise1. Loose motor.

2. Worn gear or bearing.

3. Cable assembly deformed.

Glass does not move, but motor turns'1. Clutch out of adjustment.

2. Foreign matter stuck between guide rail and slider.

3. lnner cable loose.

4. Cable assembly not attached properly.

Glass does not move and motor does not turn

{glass can be moved with moonroof wrench)

1. Blown fuse,

2. Faulty switch.

3. Battery run down.

4. Defective motor.

5. Faulty relay.

D

Glass Height Adjustment

The roof panel should be even with the glass weather-

strip, to within 1.7 :lr3 mm (0.07 :3:31 in.) all the way

around. lf not, open the giass fully, and:

GLASS WEATHERSTRIP

1. Remove the bracket cover.

Loosen the nuts, and install the shims between the

glass frame and glass bracket as shown.

Shim thickness: Front max.3 mm 10,12 in.l

Rear max. 2 mm 10.08 in.)

Repeat on opposite side i{ necessary.

)

5x1.0mm9.8 N.m 11.0 kgf m,7.2 rbtft)

SRACKETCOVEB

----------1>

6x1.0mm9.8 N.m {1.0 kgtm,7.2 tbf.ft)

1.7 tl.8 mm

{0.07 :3 3i in.}

20-51

Page 1324 of 2189

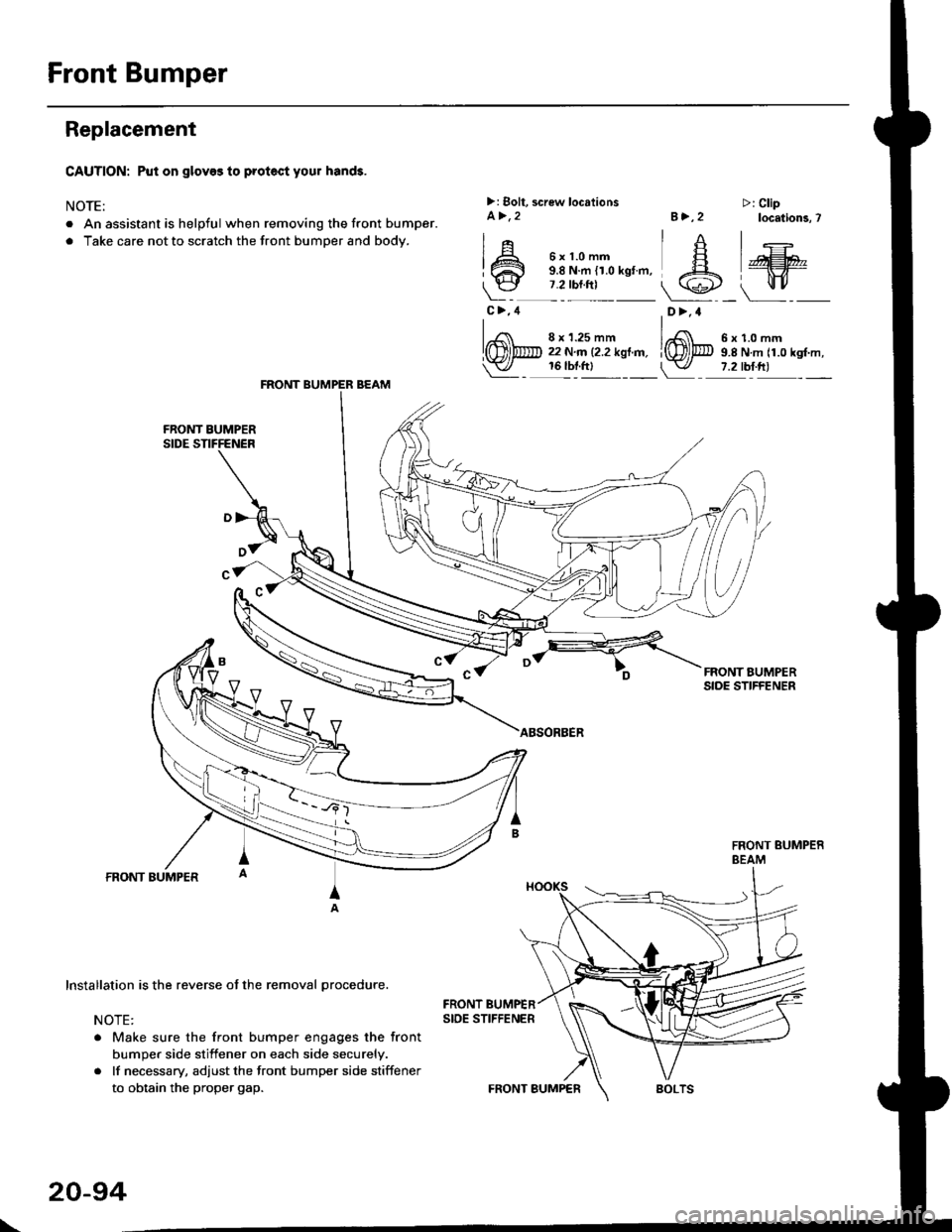

Front Bumper

Replacement

CAUTION: Put on glov$ to protect your hands.

NOTE:

. An assistant is helpful when removing the front bumper.

. Take care not to scratch the front bumDer and bodv.

FRONT BUMPERSIDE SNFFENER

lnstallation is the reverse of the removal orocedure.

NOTE:

. Make sure the front bumper engages the front

bumper side stiffener on each side securely.

. lf necessary, adjust the front bumper side stiffener

to obtain the proper gap.

>: golt, screw locationsa>,2B>,2>: Cliplocations, 7

iAerr:ore. A lm

L.'* fl'T;Ll'

o'n' -'

\€5>_ JIc>,4 ,D>,4

| -.6a 8 x 't.25 mm l,Rt o x 1.0 mm

l(Dl[m 22N.n'.t2.2kstnf'. j(Qll@ s.e N.m rr.o rsf.m,t'KJ) 16 tbf.ft, |. -ll 7.2 tbf.hJ

ABSORBER

FRONT EUMPERBEAM

FRONT BUMPERSIDE STIFFENER

FRONT BUMPER BEAM

:l

I ir

\

20-94