installation transmission HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 748 of 2189

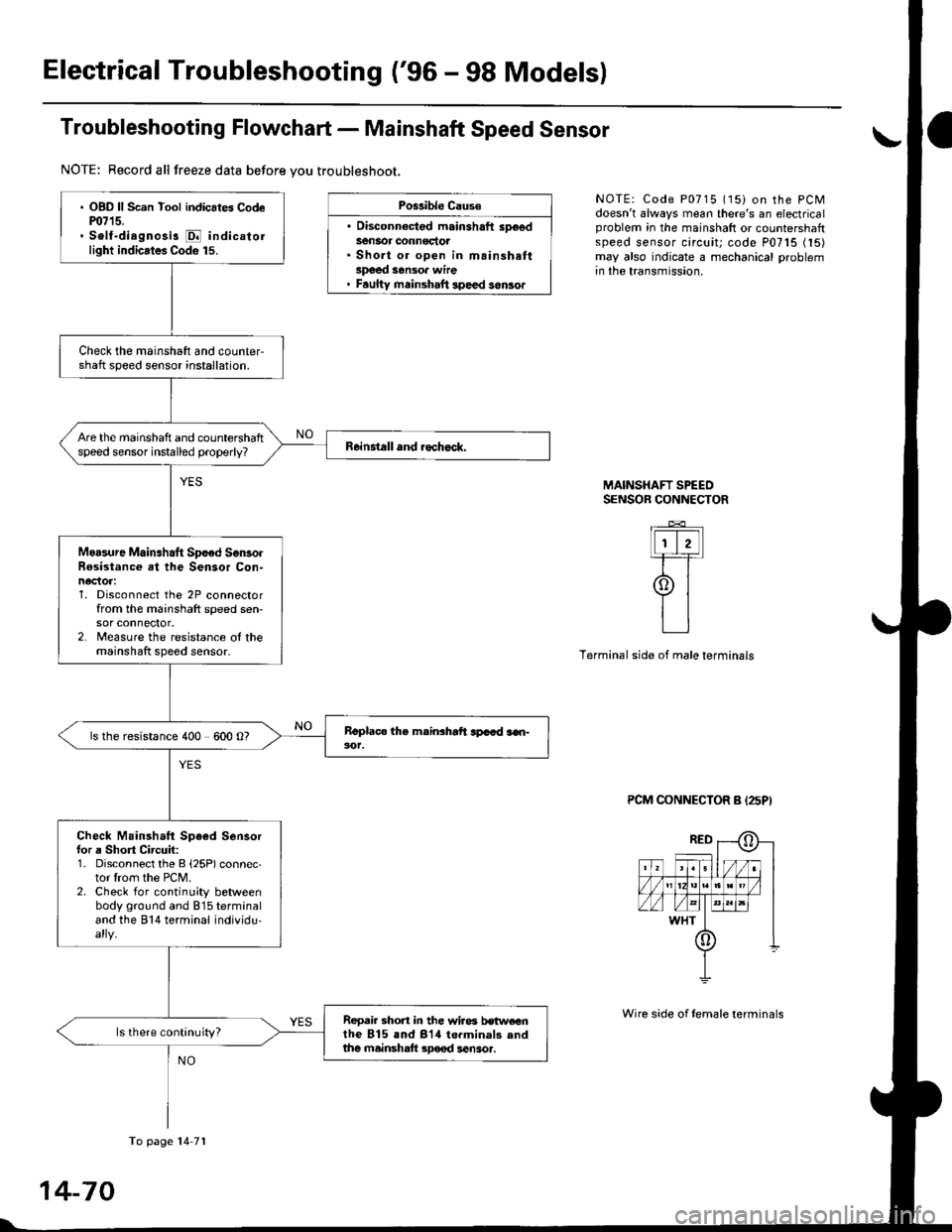

Electrical Troubleshooting ('96 - 98 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

NOTE: Record all freeze data before you troubleshoot.

Po$ible Cause

. Disconnect€d mainshaft sD€edSensor @nnoctot. Short or open in mainshattsJt€ed s6nsoa wire. Faulty mainshaft lpeed s6nso.

NOTE: Code P0715 (15) on the PCMdoesn't always mean there's an electricalproblem in the mainshaft or countershaftspeed sensor circuit; code P0715 (15)may also indicate a mechanical problemin the transmission.

MAINSHAFT SPEEOSENSOR CONNECTOR

Terminal side of male terminals

PCM CONNECTOR B I25PI

. OBD ll Scan Tool indicates Codem715.. Self-dirgnosi3 E indicatorlight indicstes Code 15.

Check the mainshaft and counter-shaft speed sensor installation.

Are the mainshaft and countershaftspeed sensor installed properly?

Moasure Mainshaft Spoed SgnsolRosistance at the Sensor Con-n€ctor:1. Disconnect the 2P connectorfrom the mainshaft speed sen-sor connector.2. Measure the resistance ot themainshaft speed sensor.

ls the resistance 400 600 O?

Check Mainshaft Sp6ed Sensorfor a Short Circuil:1. Disconnect the B {25P) connec'tor lrom the PCM.2. Check for continuity betweenbody ground and 815 terminaland the 814 terminal individu,

Repai. shon in the wi.os bstwoenthe 815 and 814 te.minals andthe mainshatt .Dood 3ensor.

ls there continuity?

To page 14-71

14-70

Wire side of female terminals

Page 847 of 2189

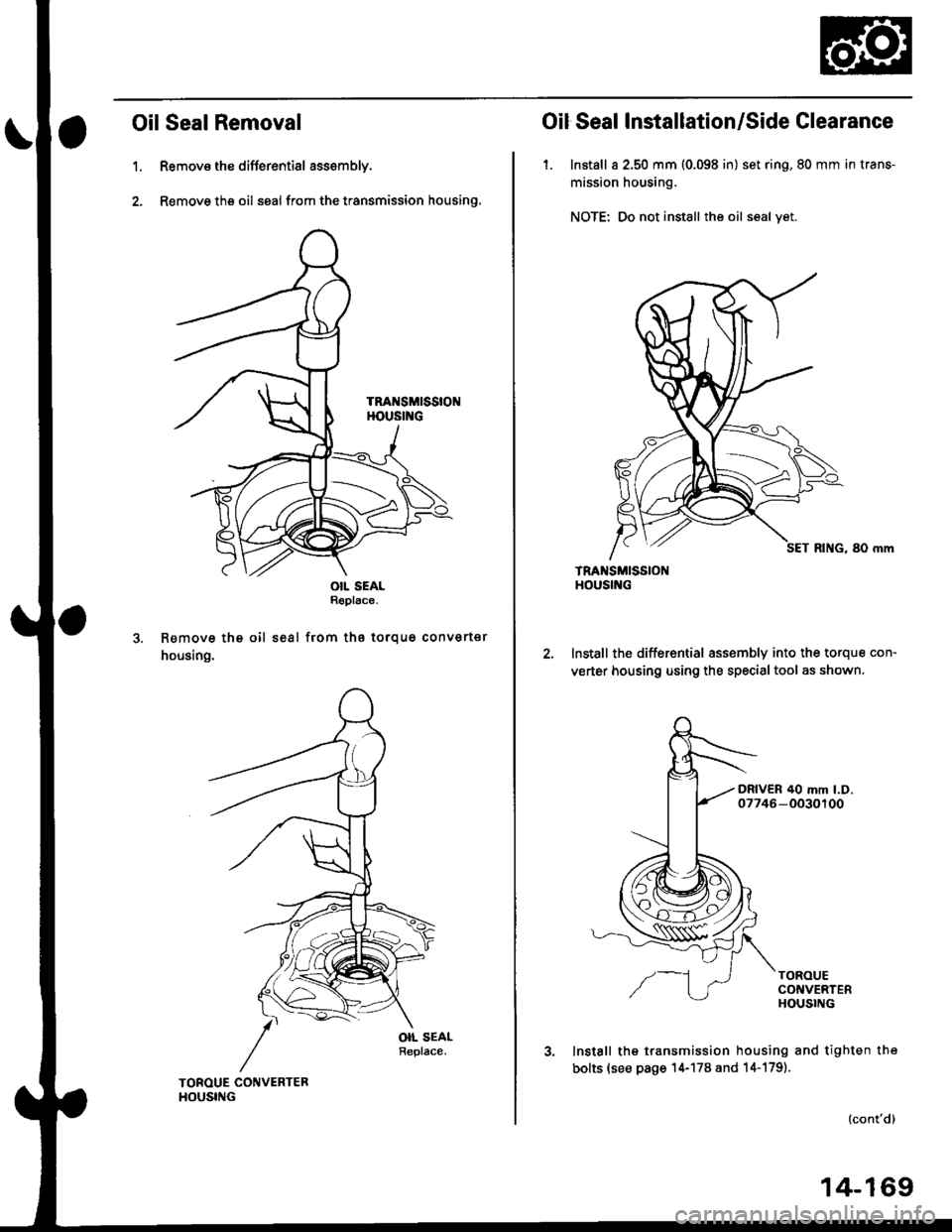

OilSealRemoval

1. Remov€ the differential assembly.

2, Remove the oil seal from the transmission housing,

OIL SEALRoplace.

the oil seal from ths torque converterRemove

housing.

OIL SEALReplace.

TOROUE CONVERTEFHOUSING

Oil Seal Installation/Side Glearance

1. Install a 2.50 mm (0.098 in) set ring,80 mm in trans-

mission housing.

NOTE: Do not install the oil seal vet.

RING, 80 mm

TRAITISMISSlONHOUS|l{G

Install the differential assembly into the torque con-

verter housing using the specialtool as shown.

Install the transmission housing and tighten the

bolts {see page 14-178 and 14-179).

{cont'd)

14-169

Page 848 of 2189

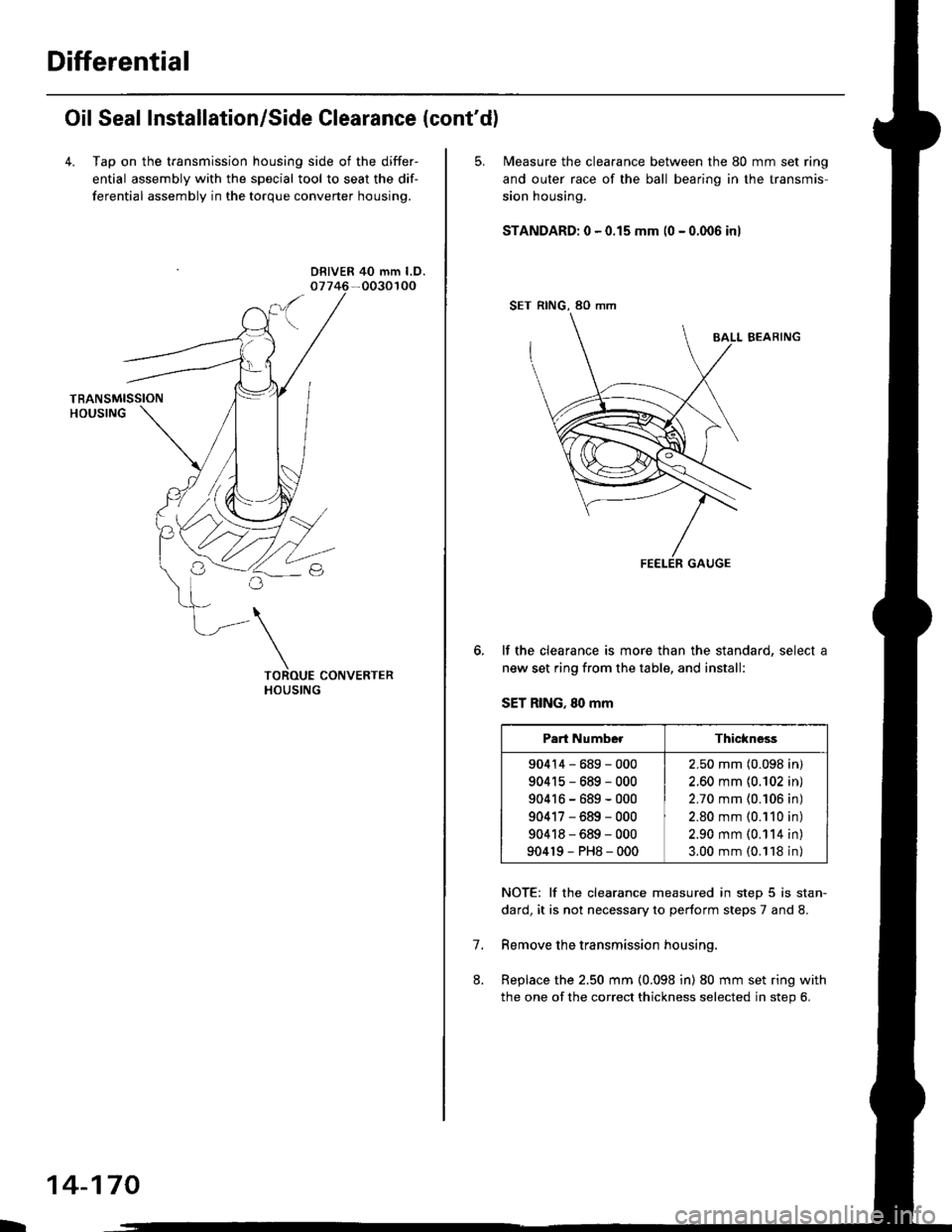

Differential

Oil Seal Installation/Side Clearance (cont'd)

4. Tap on the transmission housing side of the differ-

ential assembly with the special tool to seat the dif-

ferential assembly in the torque converter housing.

DRIVER 40 mm l.D.

L

14-170

5. N4easure the clearance between the 80 mm set ring

and outer race of the ball bearino in the transmis-

sion housing.

STANDARD: 0 - 0.15 mm (0 - 0.006 inl

SET RING, 80 mm

BALL BEARING

lf the clearance is more than the standard, select a

new set ring from the table, and install:

SET RING, 80 mm

NOTE: lf the clearance measured in step 5 is stan-

dard, it is not necessary to perform steps 7 and 8.

Remove the transmission housing.

Replace the 2.50 mm (0.098 in) 80 mm set ring with

the one of the correct thickness selected in step 6.

7.

Part NumberThickness

90414-689-000

904r5-689-000

90416-689-000

90417-689-000

90418-689-000

904r9-PH8-000

2.50 mm (0.098 in)

2.60 mm {0.102 in)

2.70 mm {0.106 in)

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0.118 in)

Page 852 of 2189

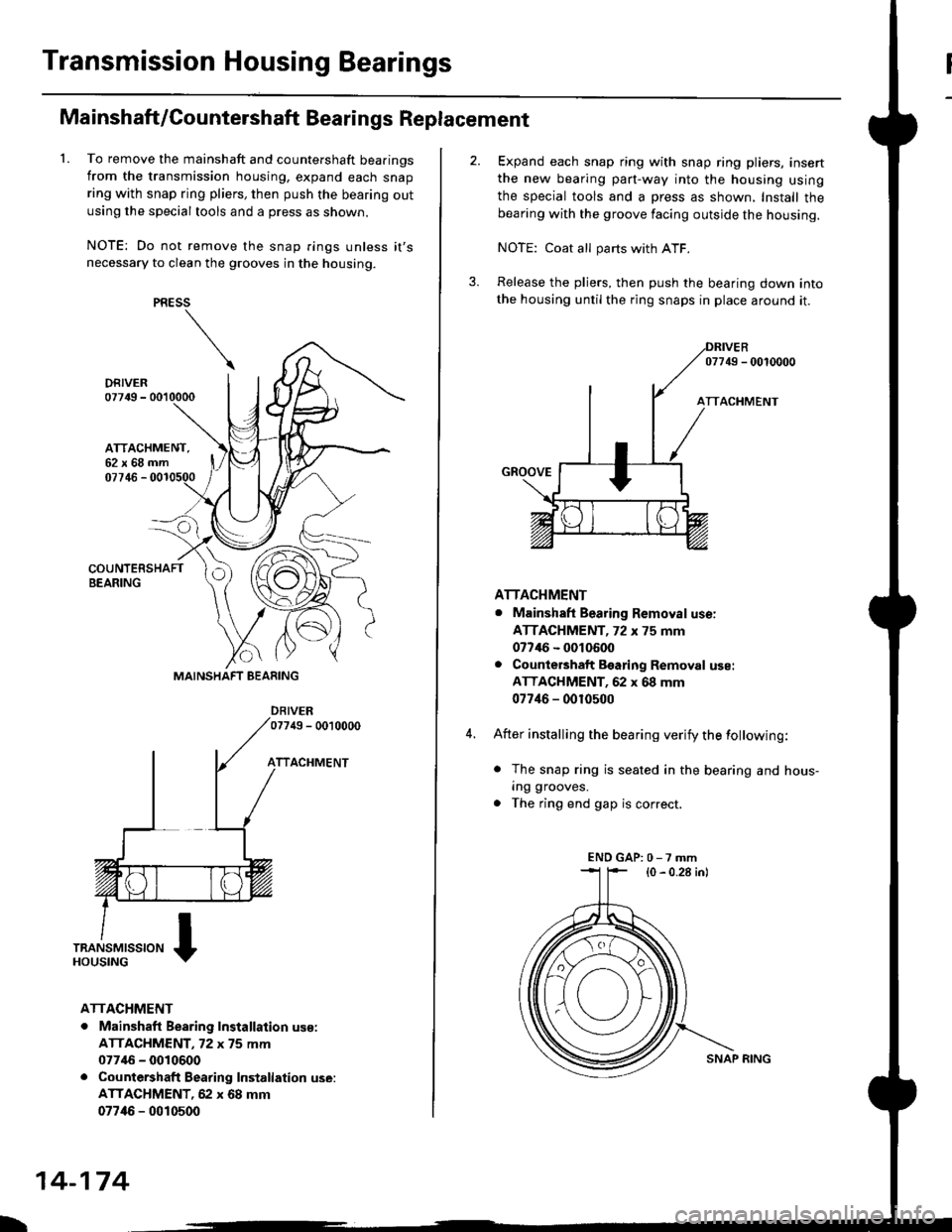

Transmission Housing Bearings

L

Mainshaft/Countershaft Bearings Replacement

To remove the mainshaft and countershaft bearings

from the transmission housing, expand each snap

ring with snap ring pliers, then push the bearing out

using the special tools and a press as shown.

NOTE: Do not remove the snap rings unless it's

necessary to clean the grooves in the housing.

DRIVER07749 - 0010000

ATTACHMENT,62x68mm

PRESS

\

07746 -

DFIVEB07749 - 0010000

TTACHMENT

ATTACHMENT

. Mainshaft Bearing Installation us€:

ATTACHMENT. 72 x 75 mm

07746 - 0010600. Countershaft Bearing Installation use:

ATTACHMENT, 62 x 68 mm

077/16 - 0010500

IRN{L{r.)n

\bZ

MAINSHAFT BEARING

L

14-174

SNAP RING

Expand each snap ring with snap ring pliers, insert

the new bearing part-way into the housing using

the special tools and a press as shown, Install thebearing with the groove facing outside the housing.

NOTE: Coat all parts with ATF.

Release the pliers, then push the bearing down intothe housing until the ring snaps in place around it.

07749 - 0010000

ATTACHMENT

. Mainshaft Bearing Removal use:

ATTACHMENT, 72 x 75 mm

077/16 - 0010600. Counte6haft Bsaring Removal use:

ATTACHMENT, 62 x 68 mm

07746 - 0010500

After installing the bearing verify the following:

. The snap ring is seated in the bearing and hous-

ing grooves.

. The ring end gap is correct.

(0 - 0.28 in)ENDGAP:0-7mm

Page 862 of 2189

Transmission

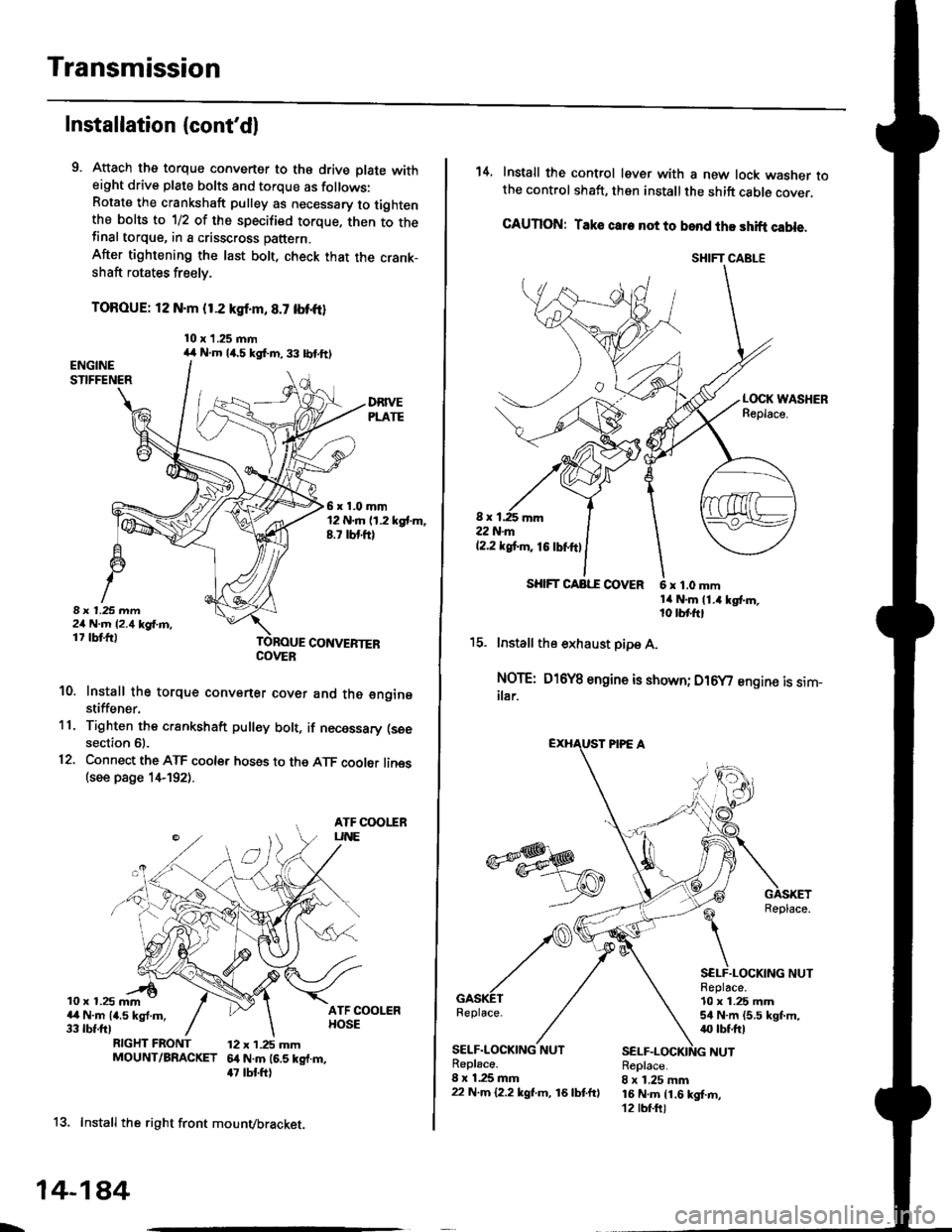

Installation (cont'dl

9. Attach the torque converter to the drive plate witheight drive plate bolts and torque as follows:Rotate the crankshaft pulley as necessary to tightenthe bolts to 1/2 of the specified torque. then to thefinal torque, in a crisscross pattern.

After tightening the last bolt, check that the crank-shaft rotates freely.

TOROUE: 12 N.m {1.2 kgl.m, 8.7 tbt{r}

10 x 1.25 mm

6x1.0mm12 N.m (1.2 kgt m,8.7 rbt ft)

I 1.25 mm2/t N.m {2.4 kg{.m,17 tbt ftlCONVERTEB

10. Install the torque convener cover and the €nginestiffener.'11. Tighten the crsnkshaft pull€y bolt, if necessary (see

section 61.

12. Connect the ATF cooler hoses to the ATF cooler lines(see page 1,t192).

ATF COOIIRUNE

10 x 1.25 mma,l N.m {4.5 kgl.m,33 rbt.fttRIGHT FRONT 12 x 1.25 mmMOUNT/BRACKET 6.t N.m (6.5 kg{.m,47 tbt ftl

13. Install the right front mounvbracket.

4,r N.m 14.5 kgf.m,33 lbtft)

COVER

L,

14-1A4

SHIFT CABLE

SHIFT CAAE COVER

14. Install the control lever with a new lock washer tothe control shaft, then install the shift cable cover.

CAUION: Taks care not to bend the shift cable.

L(rcK WASHERReplace.

8 x 1,25 r'|m22N-m12.2 tgt m. 16lbnftl

x 1.0 mmtit N.m 11.4 kgt m,10 tbr,ft,

15. lnstall the exhaust pipe A.

NOTE: D16Y8 engine is shown; D16y/ engine is sim_ilar.

Replace.

GASKETReplace.

SELF.LOCKING NUTReplace.10 x 1.25 mm54 N.m (5.5 lgf.m,40 tbt ftl

NUTSELF.LOCKING NUTReplace.8 x 1.25 mm22 N.m {2.2 kgl.m, 16lbtfrl

Replace.8 x 1.25 mm16 N.m {1.6 kgI.m,12 tbf.ft)

Page 864 of 2189

Transmission

Installation {cont'd)

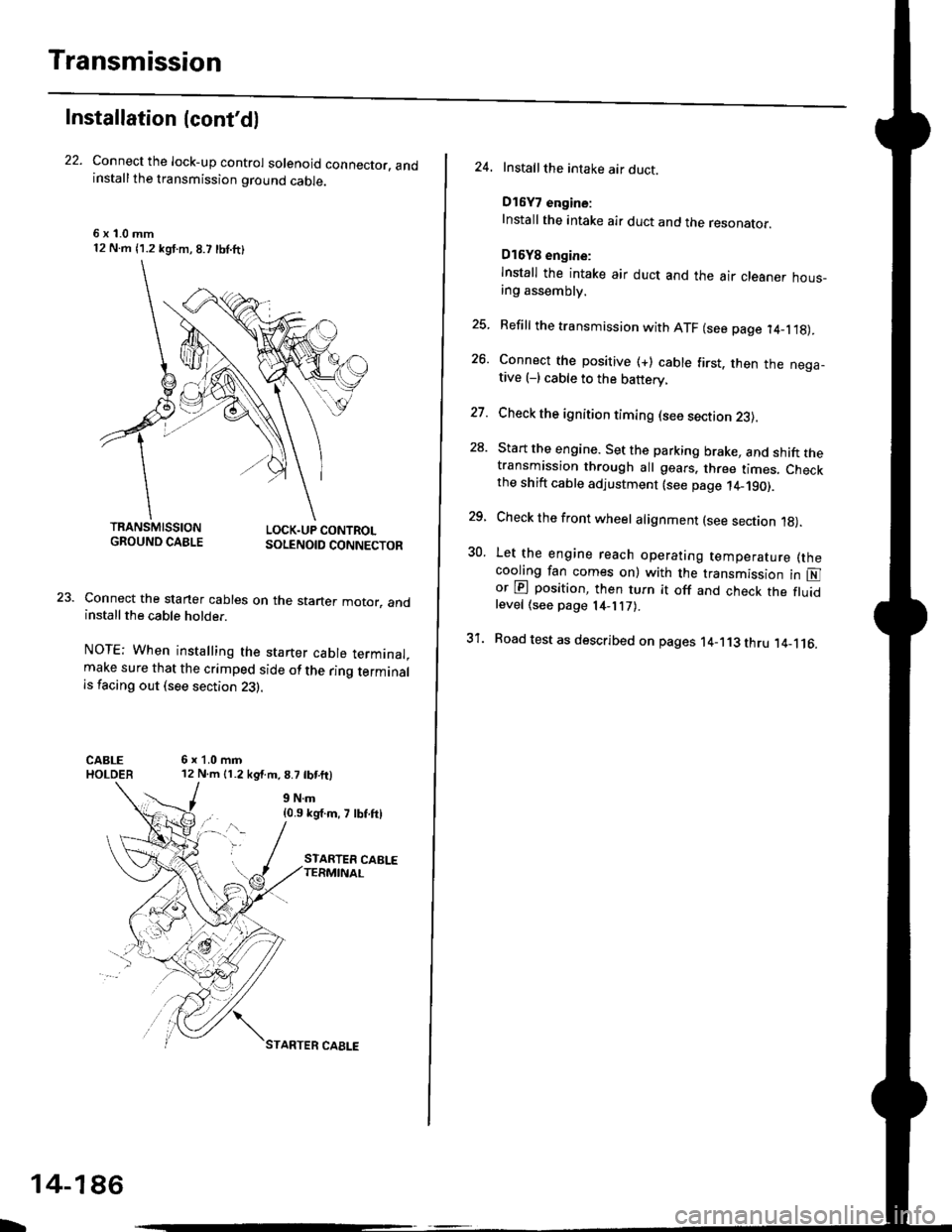

Connect the lock-up control solenoid connector. andinstall the transmission ground cable.

6 x '1.0 mm12 N.m {1.2 kgf.m, 8.7 lbl.ft}

LOCK.UP CONTROLSOLENOID CONNECTOR

Connect the staner cables on the staner motor. andinstall the cable holder.

NOTE; When installing the starter cable terminal.make sure that the crimped side of the ring terminalis facing out (see section 23).

6x1.0mm12 N.m 11.2 kg{.m.8.7 tbtftl

{0.9 kg'f.m, 7 lbf.ftl

TRANSMISSIONGROUND CABLE

b

14-186

STARTER CAELE

24. Installthe intake air duct.

D16Y7 engine:

Install the intake air duct and the resonaror.

D16Y8 engine:

lnstall the intake air duct and the air cleaner hous_ang assembly.

25. Refill the transmission with ATF (see page 14_1.18).

26. Connect the positive (+) cable first. then the nega-tive (-) cable to the battery.

27. Check the ignition timing (see section 23).

28. Start the engine. Set the parking brake, and shift thetransmission through all gears. three times. Checkthe shift cable adjustment (see page 14_190).

29, Check the front wheel alignment (see section 1g).

30. Let the engine reach operating temperature (thecooling fan comes on) with the transmission in Nor @ position, then turn it off and check the fluidlevel (see page 14- 7).

31. Road test as described on pages 14-113 thru ,14_116.

Page 871 of 2189

Continuously Variable Transmission (CVTI

Special Tools ................ 14-194

Description .................... 14-195

Clutches/Reverse Brake/Planetary

Gear/Pulleys .......... 14-198

power Flow ..............,..... 14-200

Electronic Control SYstem(,96 - 98 Modets) ......14-203

Electronic Control System

('99 - oo Models) " 14-205

Hydraulic Control '....... 14-208

Hydraulic Flow .'..-.....'... '14-212

Park Mechanism .....-...'.' 14-222

Eleqtrical Systom

Component Locations'96 - 98 Models """"""' 14-224,99 - 00 Modets ............. 14-225

TCM Circuit Diagram ('96 - 98 Models) ............. 14-226

TCM Terminal Voltage/Measuring Condiiions ('96 - 98 Models) '.... 14-228

PcM Circuit Oiaqram{A/T Control System: '99 - 00 Models} ...--.... 14-230

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)

A/4 Control System .'.'...14-232

Troubleshooting Procedures ... . .... .....',........."' '14-234

Symptom-to-ComPonent Chart

Electrical System - '96 - 98 Models ......'..... '14-234

Electrical System -'99 - 00 Models ..'....-..-. '11-210

Electrical Troubleshooting

Troubleshooting Flowcharts('96 - 98 Models) """'11-242

Troubleshooting Flowchart

('99 - 0O Modets) ...... 14-265

Linear Solenoids/lnhibitor Solenoid

Test ......................... . ...... 14-29f

Drive Pulley/Driven Pulley/Secondary Gear

Shaft Speed Sensors

Replacement .........'...... .14-292

Start Clutch Control

Start Clutch Calibration Procedure ....... ....,. 14-293

Hydraulic SYstem

Symptom-to-ComPonent Chart

Hydraulic System '.'.......14-294

Road Test ............................ 14-296

Stall Speed

Test......................... ...... 14-294

Fluid Level

Checking/Changing ....... 14-299

Pressure Testing ................. 14-300

Lower Valve BodY AssemblY

Replacement ..........,... 14-302

ATF Filter

Removal/lnstallation ..... 14-303

Transmission

Transmission

Removal ........... . 14-304

lllustrated Index

Transmission/Lower Valve BodY

Assembly ................. 14-308

Transmission Housing/Flywheel Housing ... 14-310

End Cover/f ntermediate Housing ..........'.'.... 14-312

Transmission Housing/Lower Valve Body Assembly

Removal ..........'.... .. " 14-314

Transmission Housing/Flywhesl Housing

Removal ................. ........ 1+316

End Cover/lntermediate Housing

14-318Removal .........,...............

Manual Valve Body

Disassembly/lnspection/Reassemblv .'.'.'..... 1 4-320

Forward Clutch

lltustrated Index ........................................ 14-321

Disassemblv .................. 14-322

Reassemblv , ,, . ',','......14-324

Secondary Gear Shaft

25 x 35 mm Thrust Shim Selection ..'.'....-... 14-324

Differential

lllustrated lndex ...,.....................,.,...-.-.-...'... 14-329

Backlash Inspection .-....14-329

Bearing Replacement ......'........'....'... ....'... 14-330

Differential Carrier Replacement ........'........ 14-330

Oil Seal Removal ........... 14-331

Oil Seal Installation/Side Clearance ....... . . 14-331

Flywheel Housing Input Shaft Oil Seal

Replacement .....,.... ...'.'.. 14-333

Transmission Housing Bearings

Driven Pulley Shaft Bearing

Replacenient ...................'. . ...................'.. 14-334

Secondary Gear Shaft Bearing

Reolacbment ...................... . .......... . ........ 14-335

Flywheel Housing Beating

Secondary Gear Shaft BearingReo1acement..................,........................... 14-335

Ring Gear Bearing

Replacement......... ........ 14-336

Control Shaft Assembly

Removal/lnstallation ....................'........... 14-336

Transmission

Reassembly .................. 14-338

Flywheel/Drive Plate .. . ...... . ...... ... . ....-.....'.'...14-341

Transmission

lnstalation ..................... 14-348

Cooler Flushing .'......... 14-352

shift cable

Removal/lnstallation....'........." """ 14-354

Adjustment .......'........ 14-355

Shift Lever ........................,. 14'356

Shift Indicator Panel

Adjustment ................ 14-357

ATF Cooler/Hoses

lnsta llation ......,,...... .... 14-357

Page 1008 of 2189

l.

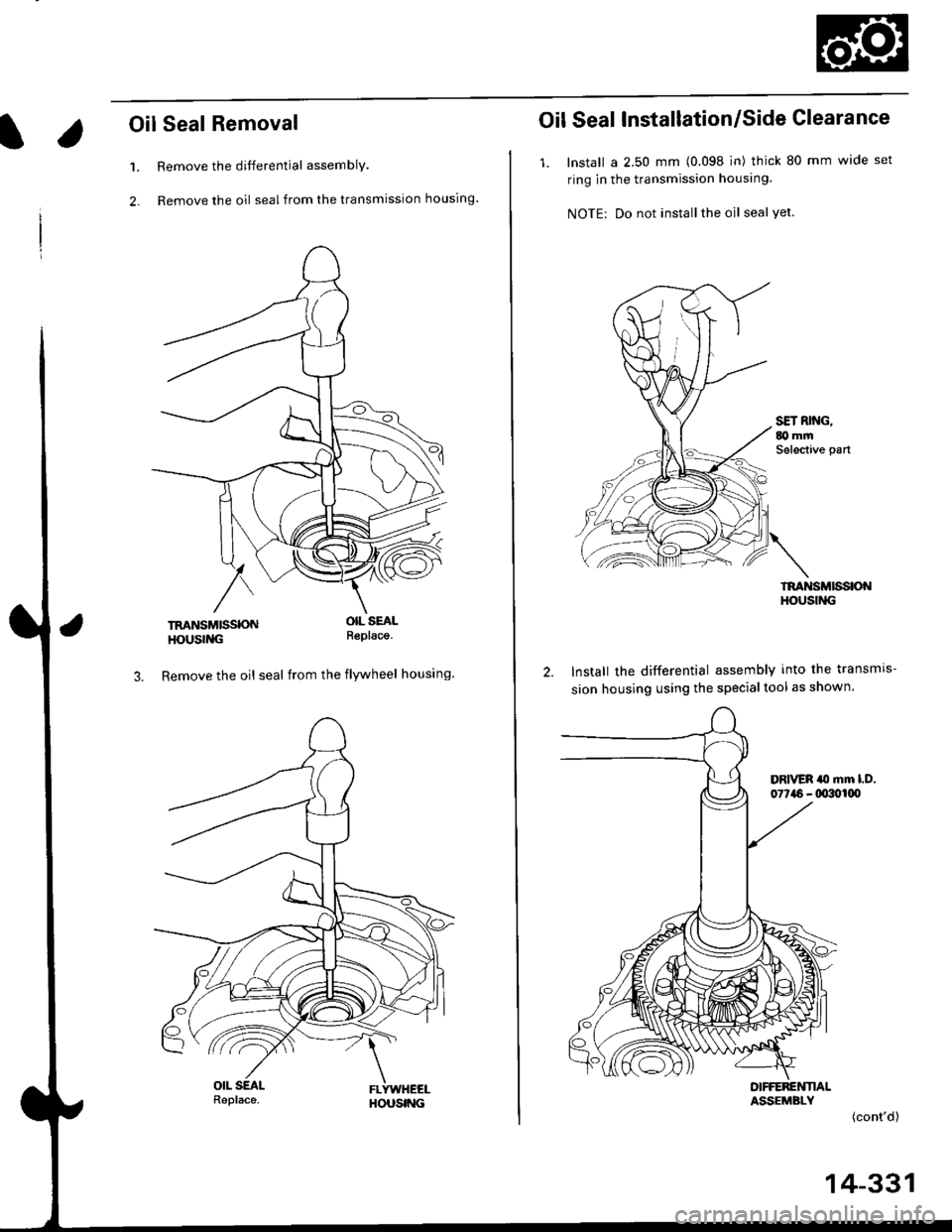

Oil Seal Removal

Remove the differential assembly.

Remove the oil seal from the transmission housing.

1.

2.

TRANSMISSONHOUSING

OIL SEALR€placa.

3. Remove the oil seal from the flywheel housing.

Oil Seal Installation/Side Clearance

1. lnstall a 2.50 mm (0.098 in) thick 80 mm wide set

ring in the transmission housing.

NOTE: Do not installthe oil seal yet.

TRANSMISSIONHOUStl{G

lnstall the differential assembly into the transmrs-

sion housing using the specialtool as shown

DIFFEREI{NALASSEMBLY(cont'd)

14-331

Page 1024 of 2189

Transmission

Installation

Flush the ATF cooler as described on pages 14-352and 14-353.

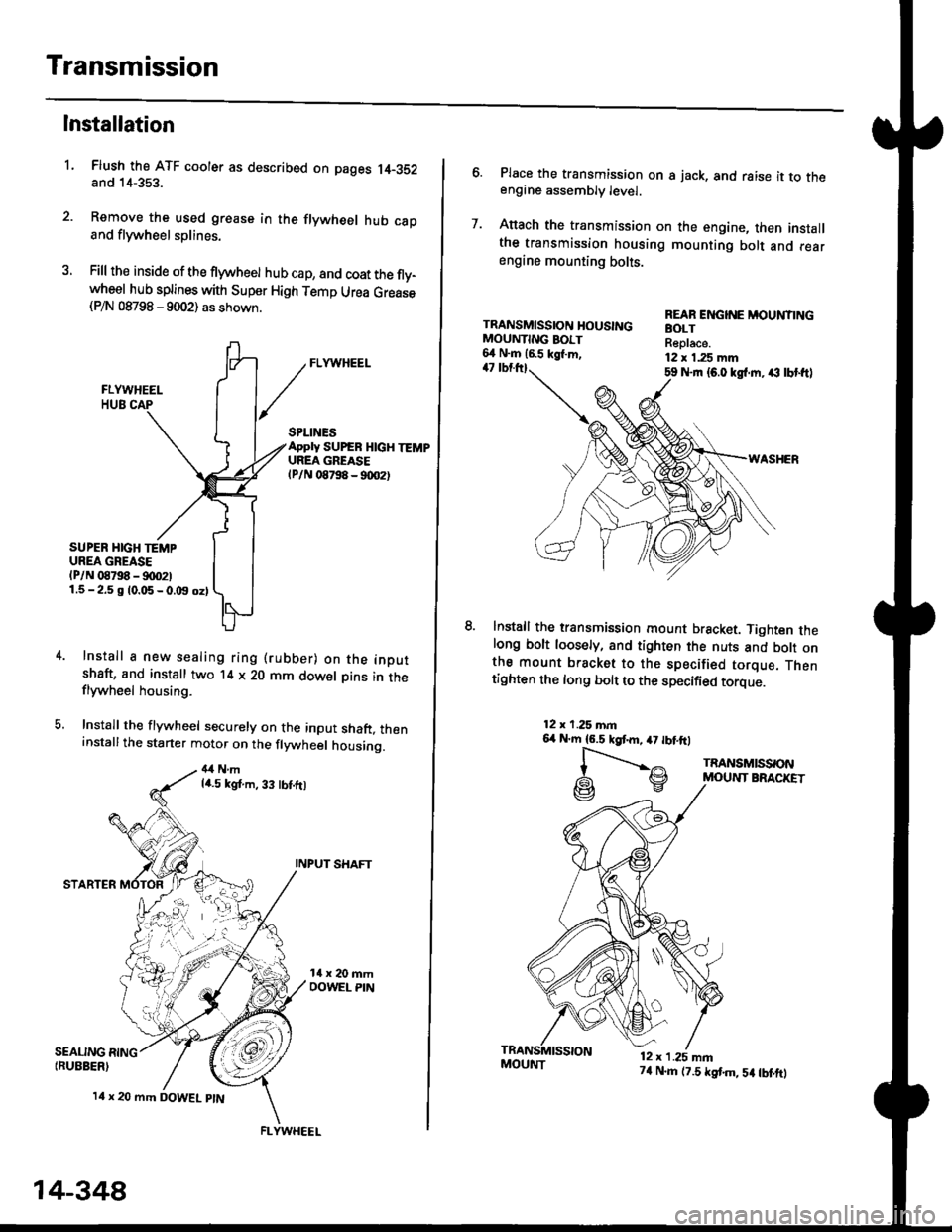

Remove the used grease in the flywheel hub caDand flywheel splines.

Fill the inside of the flywheel hub cap, and coat the fly-wheel hub splines with Super High Temp Urea Grease(P/N 08798 - 9002) as shown.

L

SEALING RING{RUEBER)

SPLINESApply SUPEB HlcH TEMPUREA GREASElPlN 08798 - 90O2t

SUPER HIGH TEMPUREA GREASE(P/N 08798 - !)00211.5-2.5 g 10.05-0.t9 oz)

Install a new sealing ring (rubber) on the inoutshaft, and install two '14 x 20 mm dowel Dins in theflywheel housing.

Install the flywheel securely on the input shaft, theninstallthe starter motor on the flywheel housing.

4,1Nmla.5 kgt.m, 33 tbt.ft)

INPUT SHAFT

STARTER

l4 x 20 mm DOWEL ptN

.4;i "lrj

,i rr,"r., ., a

14-348

FLYWHEEL

MOUI{T74 N.m (7.5 tstm,5a tbtftt

6. Place the transmission on s jack, and raise it to theengine assembly level.

7. Anach the transmission on the engine, then installthe transmission housing mounting bolt and rearengine mounting bolts.

TRANSMISSION HOUSINGMOUNTING BOIT6,1 N.m 16.5 kgl.m,47 tbtttl59 Nrn {6.0 kgl.m. ,€ lbt ftl

WASHER

lnstall the transmission mount bracket. Tighten thelong bolt loosely, and tighten the nuts and bott onthe mount bracket to the specified torque. Thentighten the long bolt to the specified torque.

REAR ENGINE MOUNTINGBOLTReplace.12 x 1.25 mm

12x 1.25 mn6,r N'm 16.5 kgtm,47 tbtftl

l-".--..-,^

G\V

TRANSMISSONMOUNT BRACKET

12 x 1.25 mn

Page 1026 of 2189

Transmission

17.

Installation (cont'd)

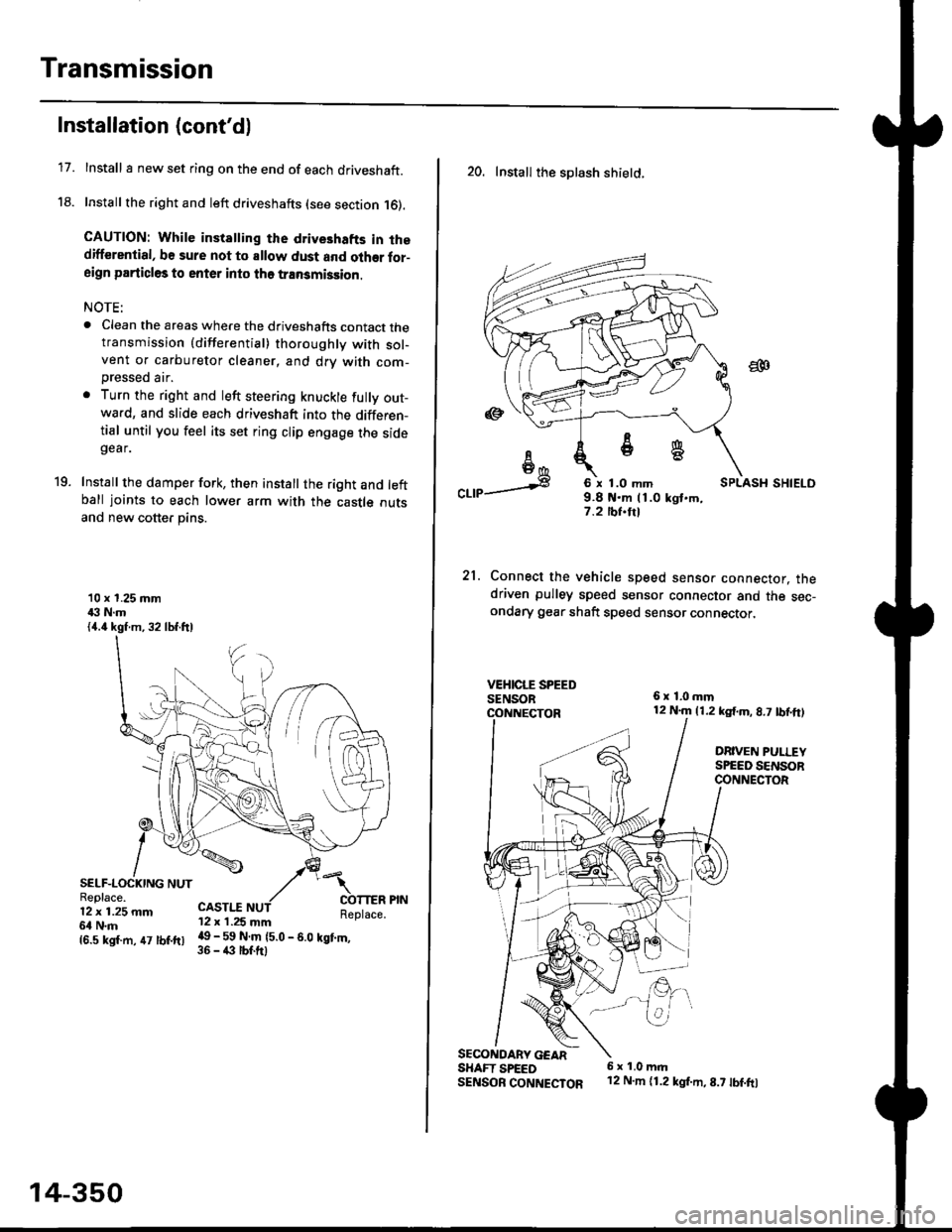

Install I new set ring on the end of each driveshaft.

Install the right and left driveshafts (see section 16).

CAUTION: While instatling the drive3hafts in thedifferential, be sure not to allow dust and olher for-aign particles to enter into tho transmission.

NOTE:

. Clean the areas where the driveshafts contact thetransmission {differential} thoroughly with sol-vent or carburetor cleaner, and drv with com-

Dressed air.

. Turn the right and left steering knuckle fully out-wa.d, and slide each driveshaft into the differen-tial until you feel its set ring clip engage the sidegear.

Install the damper fork, then install the right and leftball joints to each lower arm with the castle outsand new cotter pins.

19.

10 x 1.25 mm43 N.m{4.4 kgf.m, 32 lbf.ftl

SELF-LOCKING NUTReplace.12 x 1.25 mm6l N.m

CASTI.I'12 x 1.25 mm

{6.s ksr.m. 47 tbr.ftr l! _ ll ffiteo

- s.o tet'.,

14-350

20. Install the splash shietd.

aa

I6I6*

"a,a s

21.

SECONOARY GEARSHAFT SPEEDSENSOB CONNECTOR

6 x 1.0 mm9.8 t{.m 11.0 kgt.m,7.2 tbf.trl

Connect the vehicle speed senso. connector. thedriven pulley speed sensor connector and the sec-ondary gear shaft speed sensor connector,

6x1,0mm12 N.m {1.2 kg{.m, 8.7 tbf,ft)

DRIVEN PULLEYSPEED SENSORCONNECTOR

E.

6 x 1.0 m.rl'12 N.m {1.2 kg{.m,8.7 tbf.fo