piston assembly HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 166 of 2189

VTEC Rocker Arms

4.

Inspection Using Special Tools (cont,dl

Loosen the valve on the regulator and apply thespecified air pressure.

Specified Air Pressuro:

250 kPa {2.5 kgtlcm,, 36 psil- 490 kPa {5.0 kgtcm,, 7t psil

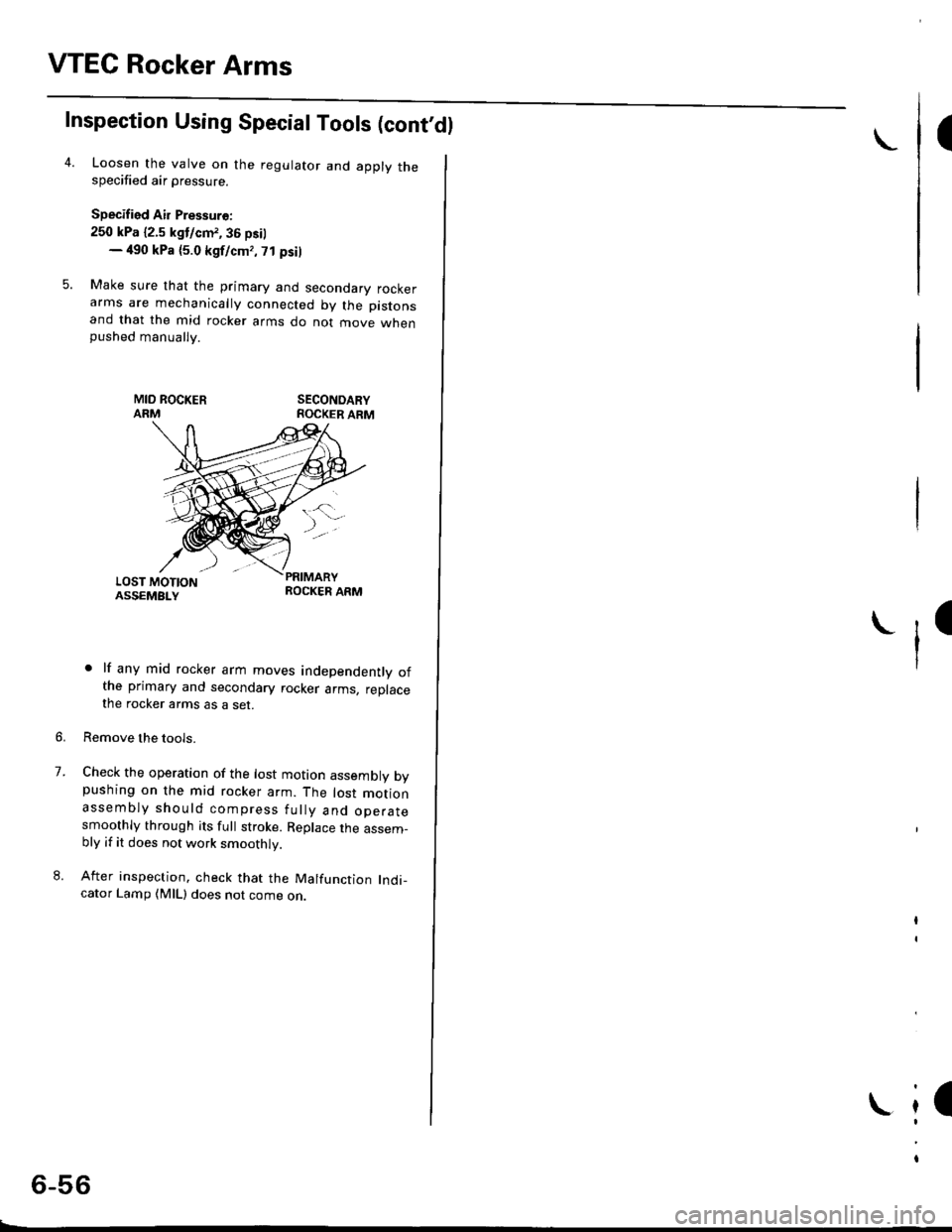

Make sure that the primary and secondary rockerarms are mechanically connected by the pistonsand that the mid rocker arms do no. move wnenpushed manually.

SECONDARYROCKER ARM

. lf any mid rocker arm moves independently ofthe primary and secondary rocker arms, replacethe rocker arms as a set.

Remove the tools.

Check the operation of the lost motion assembly bypushing on the mid rocker arm. The lost motionassembly should compress fully and operatesmoothly through its full stroke. Replace the assem_bly if it does not work smoothly.

After inspection. check that the Malfunction Indi_cator Lamp {MlL) does not come on.

7.

6-56

I

ll

;l

Page 183 of 2189

Rocker Arms and Lost Motion Assemblies

Inspection

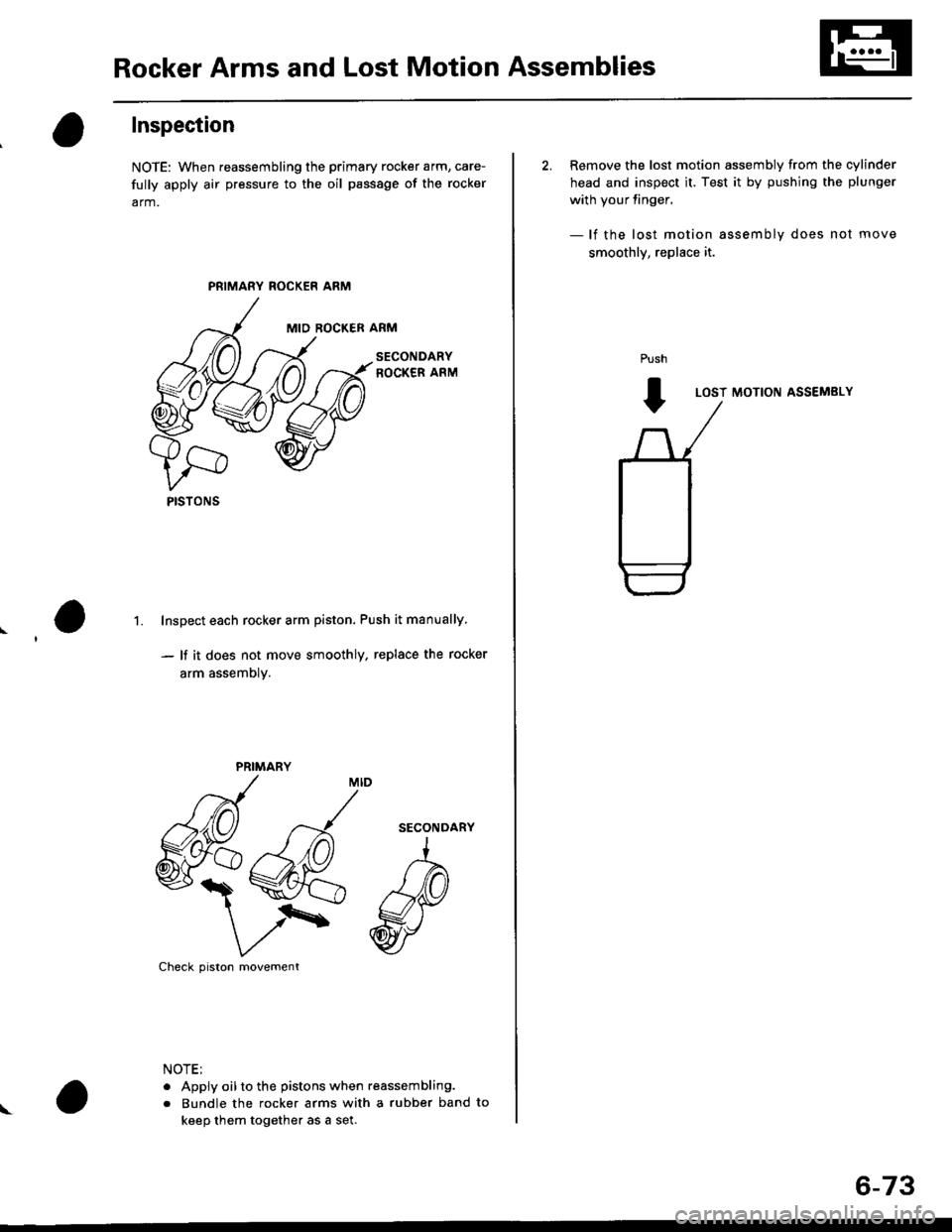

NOTE: When reassembling the primary rocker arm, care-

fully apply air pressure to the oil passage of the rocker

arm.

PRIMARY ROCKER ARM

MID ROCKER ARM

Inspect each rocker arm piston. Push it manually

- lf it does not move smoothly. replace the rocker

arm assemDly.

1.

SECONDARY

Check prston movement

NOTE:

. Apply oilto the pistons when reassembling.

. Bundle the rocker arms with a rubber band to

keep them together as a set.

PISTONS

PRIMARY

\

6-73

2. Remove the lost motion assembly from the cylinder

head and inspect it. Test it by pushing the plunger

with your finger,

- lf the lost motion assembly does not move

smoothly, replace it.

LOST MOTION ASSEMBLY

Push

I

Page 203 of 2189

lllustrated Index

(cont'd)

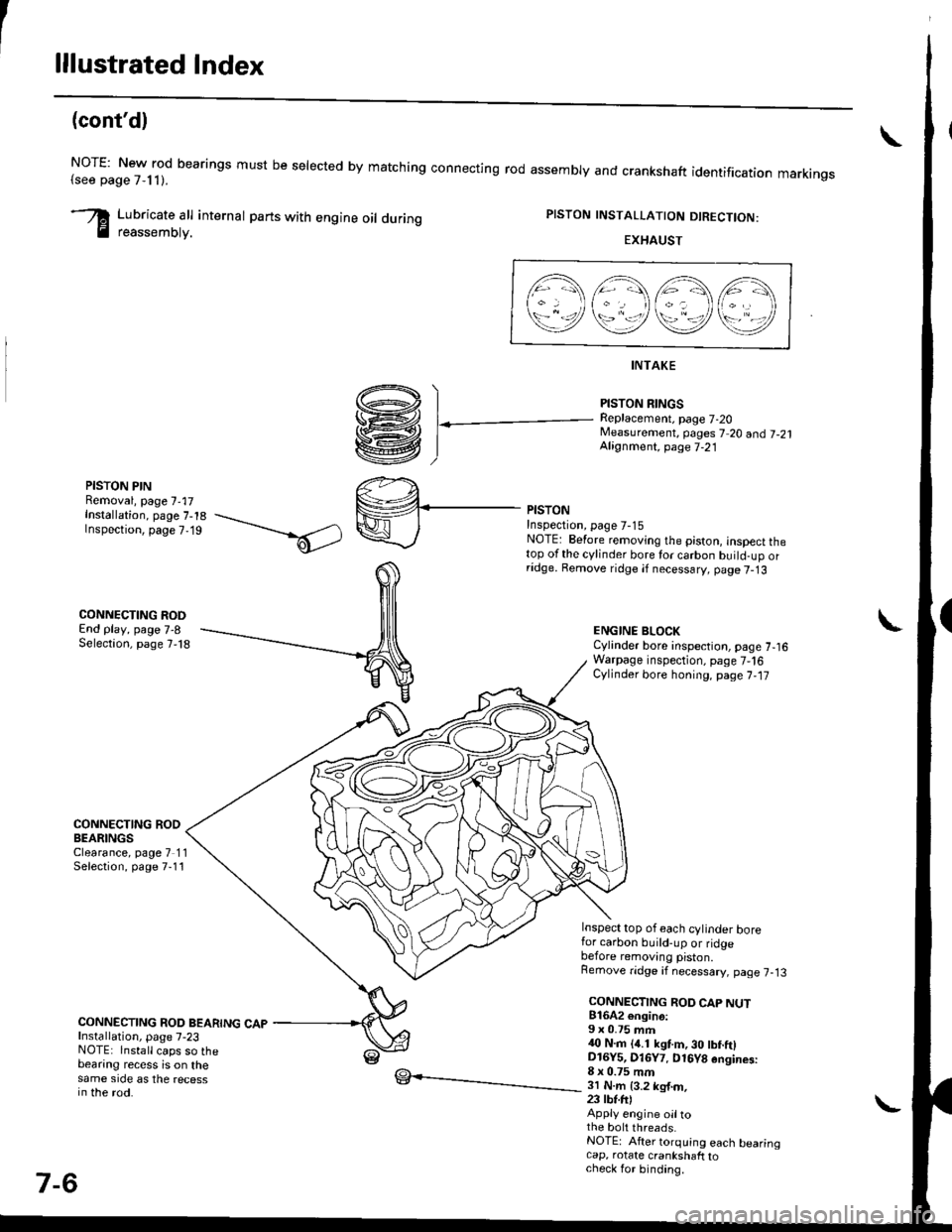

NOTE: New rod bearings must be selected by matching connecting rod assembly and crankshaft(see page 7,11).identification markings

Lubricate all internal parts with engine oil duringreassembtv.

PISTON INSTALLATION DIRECTION:

EXHAUST

4\/=\6\z\

\e/!rqrf/

INTAKE

PISTON RINGSReplacement. page 7-20Measurement, pages 7 20 andj-21Alignment, page 7-21

PISTON PINRemoval, page 7,17Installation, page 7-18Inspection, page 7,19

CONNECTING RODEnd play, page 7-8Selection, page 7,18

CONNECTING RODBEARINGSClearance, page 7 11Selection, page 7-11

CONNECTING ROD BEARING CAPInstallation, page 7-23NOTE: lnstall caps so thebearing recess is on thesame side as the recessin the rod.

PISTONInspectron, page 7-15NOTE: Betore removing the piston, inspect thetop of the cylinder bore for carbon build-up orridge. Bemove ridge if necessary, page 7-13

ENGINE BLOCKCylinder bore inspection, page 7-16Warpage inspection, page 7,'16Cylinder bore honing, page 7,17

Inspect top of each cylinder borefor carbon build-up or ridgebefore removing piston.Remove ridge if necessary, page 7-13

CONNECTING ROD CAP NUT816A2 €ngin6:9 x 0.75 mm{0 N.m (4.1 kgt m, 30 tbf.ftlD16Y5, Dl6Y7. D16Y8 engines:8 x 0.75 mm3l N.m {3.2 kg{.m,23 tbt.fr)Apply engine oiltothe bolt threads.NOTE: After torquing each bearingcap, rotate crankshaft tocheck for binding.

7-6

Page 209 of 2189

Pistons and Crankshaft

Removal

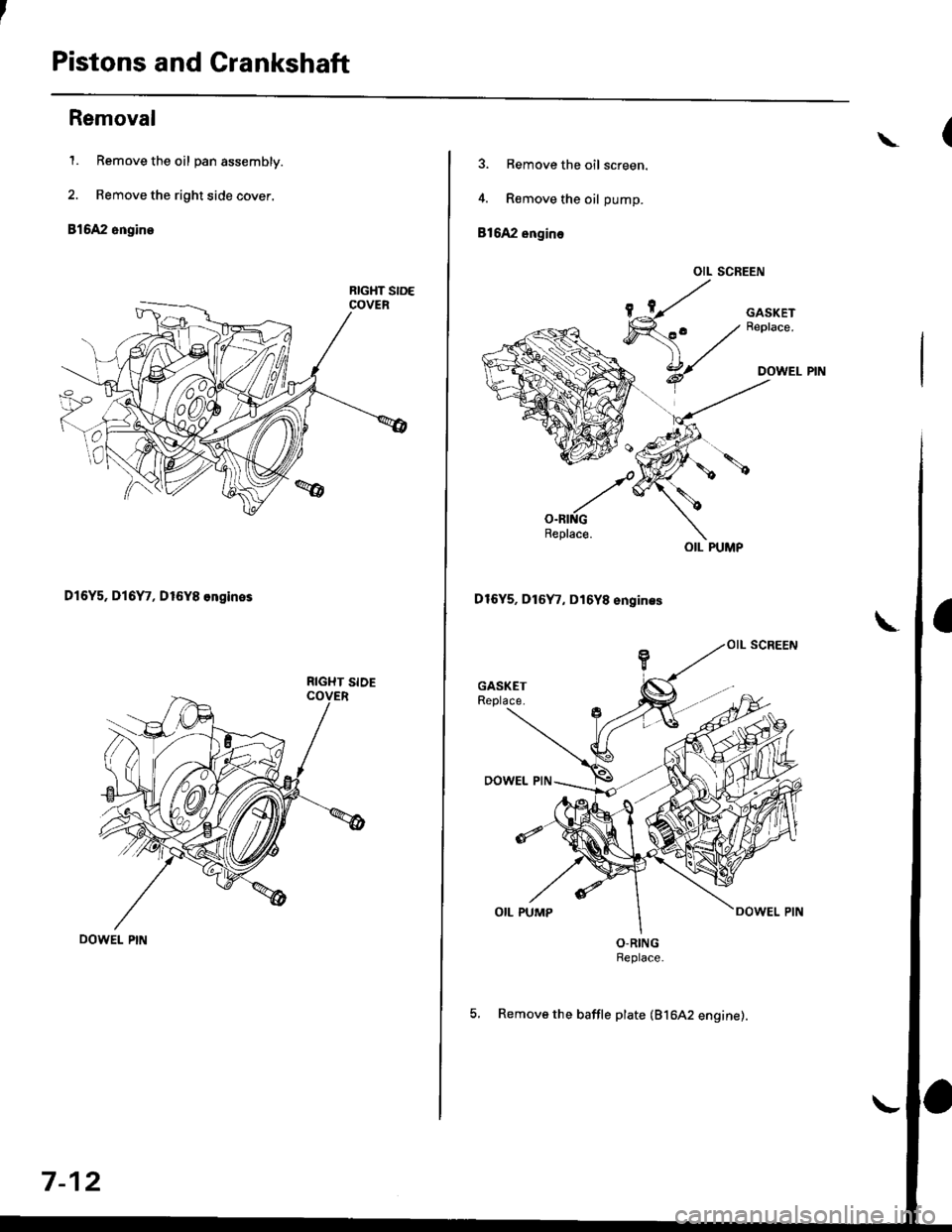

1. Remove the oil pan assembly.

2. Remove the right side cover.

816A2 engine

D16Y5, Dl6Y7, D16Y8 ongines

RIGHT SIDE

7-12

\

3. Remove the oil screen.

4. R€move the oil pump.

816A2 engin€

OIL SCREEN

D16Y5, D1oyr, D16Y8 engin.s

O-RINGReplace.

5, Remove the baffle plate (816A2 engine).

OIL PUMP

Page 210 of 2189

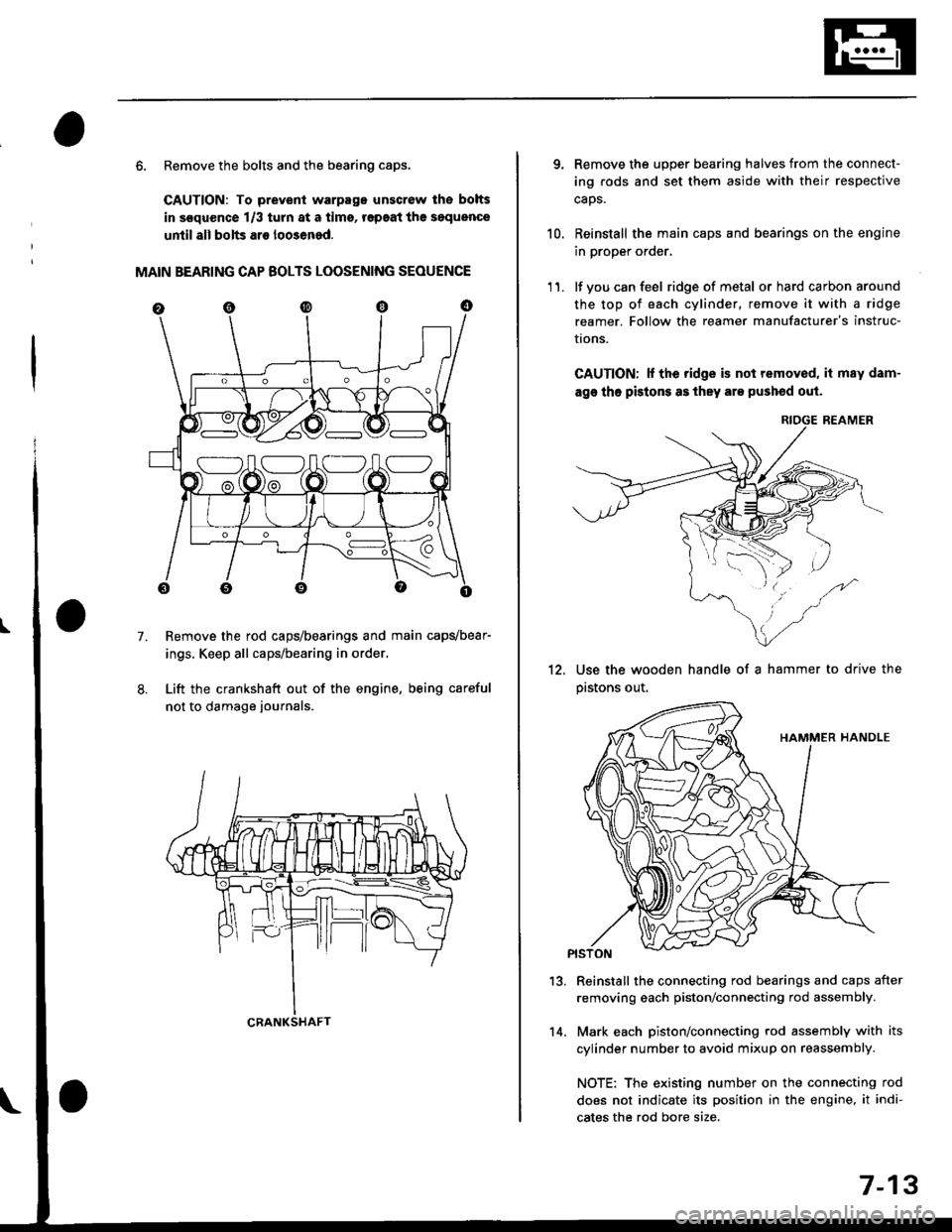

6. Remove the bolts and the bearing caps.

CAUTION: To prevenl warpago unscrow lhe bolts

in s€quence 1/3 turn at a tims, r€paat the soquence

until all bolts ar€ loo3ened.

MAIN BEARING CAP BOLTS LOOSENING SEOUENCE

Remove the rod caps/bearings and main capvbear-

ings. Keep all caps/bearing in order.

Lift the crankshaft out of the engine, being careful

not to damage journals.

7.

S:_]ILOJLOAO

CRANKSHAFT14.

7-13

qRemove the upper bearing halves from the connect-

ing rods and set them aside with their respective

caos.

Reinstall the main caps and bearings on the engine

in proper order,

lf you can feel ridge of metal or hard carbon around

the top of each cylinder, remove it with a ridge

reamer. Follow the reamer manufacturer's instruc-

I|ons.

CAUTION; lf the ridge is not removed, it may dam-

age tho pistons as they are pushod out.

RIOGE REAMER

10.

11.

12.Use the wooden handle of a hammer to drive the

pastons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

Mark each piston/connecting rod assembly with its

cylinder number to avoid mixup on reassembly.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 790 of 2189

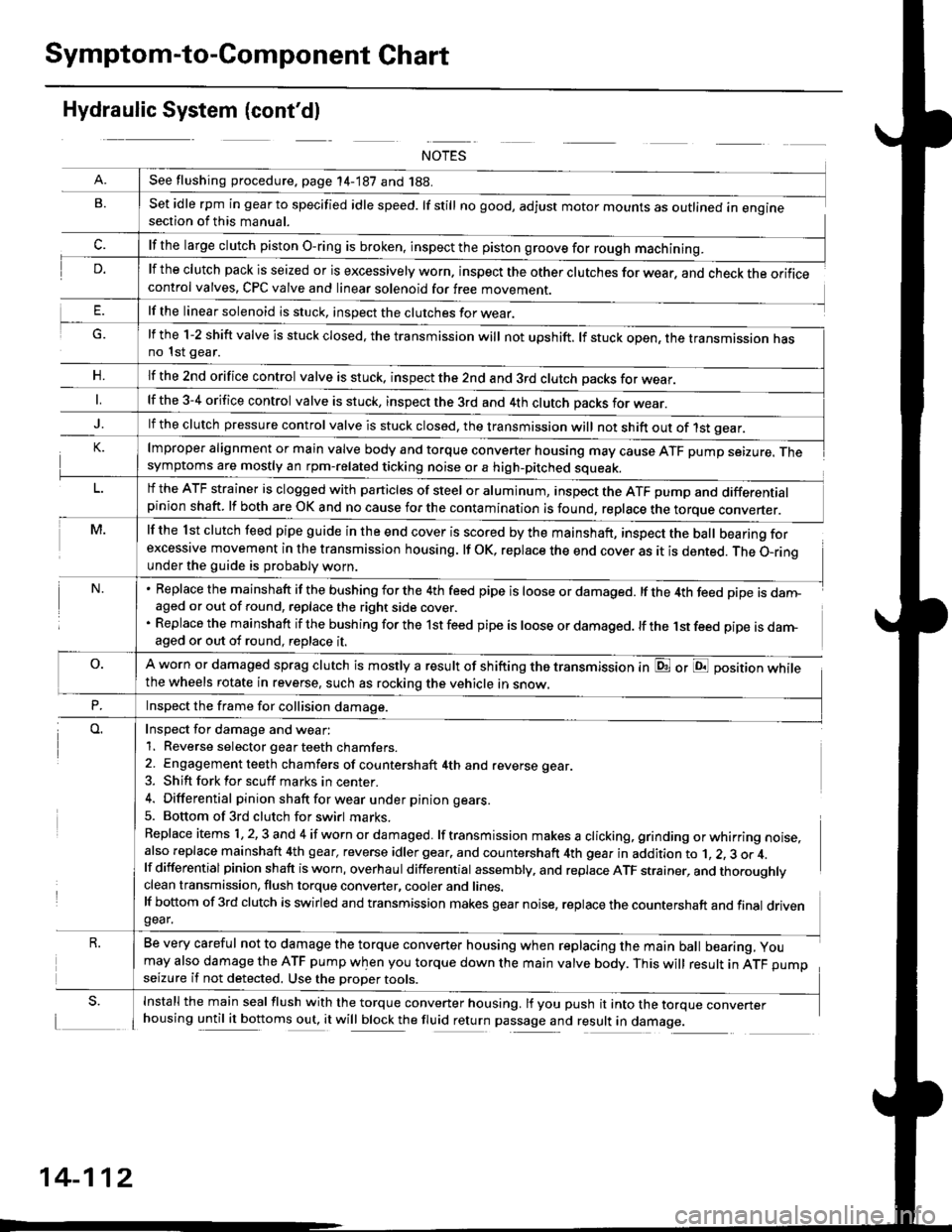

Symptom-to-Component Chart

Hydraulic System (cont'dl

G.

n,

set idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

lf the clutch pack is seized or is excessively worn. inspect the other clutches for wear, and check the orificecontrol valves, CPC valve and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lmproper alignment or main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

lf the l st clutch feed pipe guide in the end cover is scored by the mainshaft, inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged. lf the 4th feed pipe is danFaged or out of round, replace the right side cover.

Replace the mainshaft if the bushing for the 1st feed pipe is loose or damaged. lf the 1st feed pipe is darn-aged or out of round, replace it.

A worn or damaged sprag clutch is mostly a result of shifting the transmission inthe wheels rotate in reverse, such as rocking the vehicle in snow.

or E position while

Inspect for damage and wear:

1. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear u nder pin ion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1,2,3 and 4 if worn or damaged. lf transmission makes a clicking, grinding orwhirring noise,also replace mainshaft 4th gear, reverse idler gear. and countershaft 4th gear in addition to 1, 2, 3 or 4.lf differential pinion shaft is worn, overhaul differential assembly, and replace ATF strainer, and thoroughlyclean transmission, flush torque converter, cooler and lines.lf bottom of 3rd clutch is swirled and transmission makes gear noise, replace the countershaft and final drivengear.

Be very careful not to damage the torque converter housing when replacing the main ball bearing, you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the oroper roors.

Install the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

See flushing procedure, page 14-187 and 188.

lf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

lf the l-2 shift valve is stuck closed, the transmission will not upshift. lf stuck open, the transmission hasno 1st gear.

lf the znd orifice control valve is stuck. inspect the 2nd and 3rd clutch oacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch oacks for wear.

lf the clutch pressure control valve is stuck closed, the transmission will not shift out of 1st gear.

lf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Inspect the frame for collision damage.

14-112

Page 824 of 2189

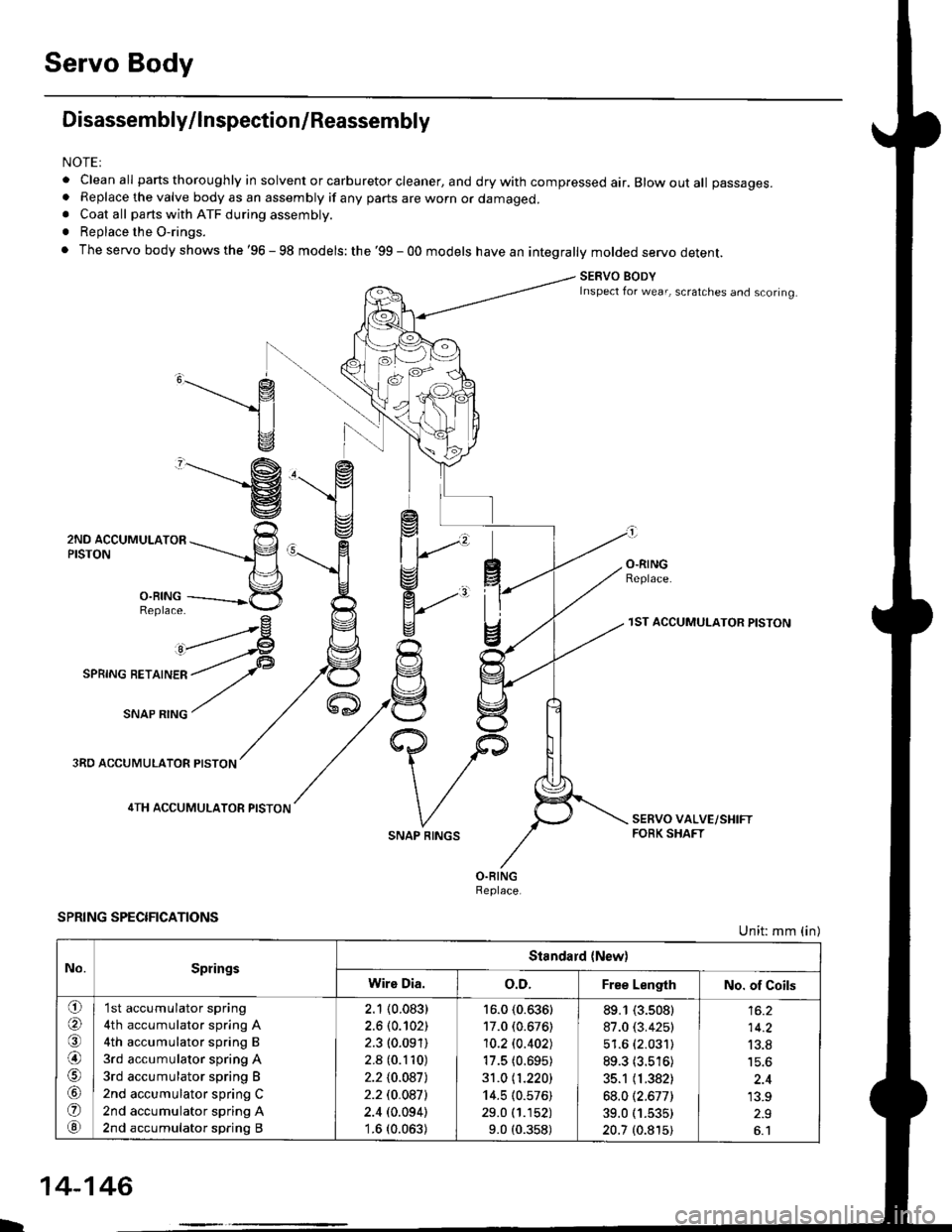

Servo Body

Disassembly/lnspection/Reassembly

NOTEI

. clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air. Blow out all passages.. Replace the valve body as an assembly if any parts are worn or damaged.. Coat all parts with ATF during assembly.

. Replace the O-rings.

. The servo body shows the '96 - 98 models: the '99 - 00 models have an integrally molded servo detent.

SERVO BODYInspect for wear, scratches and scoring.

,______.- g

1l

v

"-------'g

ZruO lCCUr,irUr-nrOn ---rrr___-p

n\='l

3,ii11---------*5

^rrr4

I

O.RINGReplace.

3RO ACCUMULATOR PISTON

4TH ACCUMULATOR PISTON

SPRING SPECIFICATIONS

SNAP RINGS

1ST ACCUMULATOR PISTON

Unit: mm (in)

No.SpringsStandard {New)

Wire Dia.o.D.Free LengthNo. of Coils

o(a

@)

o

@

'I st accumulator spring

4th accumulator spring A

4th accumulator spring B

3rd accumulator spring A

3rd accumulator spring B

2nd accumulator spring C

2nd accumulator spring A

2nd accumulator spring B

2.1 (0.083)

2.6 (0.102)

2.3 (0.091)

2.8 (0.110)

2.210.0871

2.2 t0.0a7l

2.4 (0.094)'1.6 (0.063)

16.0 (0.636)

17.0 (0.676)

10.2lo.402J

17.5 (0.695)

31.0 11.220)

14.5 (0.576)

29.0 (1.152)

9.0 (0.358)

89.1 (3.s08)

87.0 (3.425)

51.6 (2.031)

89.3 (3.516)

35.1 (1.382)

68.012.677)

39.0 (1.535)

20.7 (0.815)

14.2

13.8

'13.9

L

14-146

Page 840 of 2189

Clutch

Reassembly

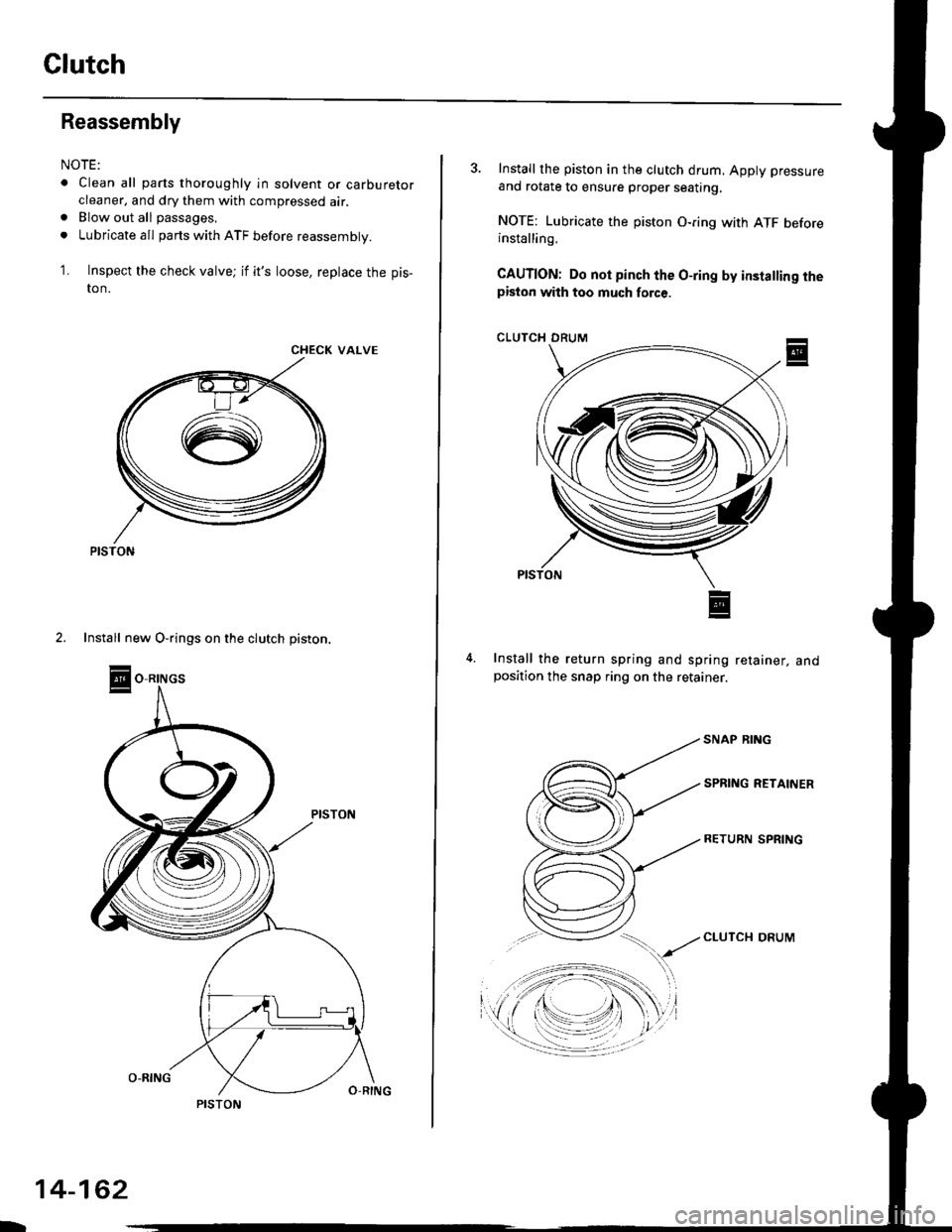

NOTE:

. Clean all parts thoroughly in solvent or carburetor

a

cleaner, and dry them with compressed air.

Blow out all passages.

Lubricate all parts with ATF before reassembly.

Inspect the check valve; if it's loose, replace the pis-

to n.

1.

CHECK VALVE

2. Install new O-rings on the clutch piston.

O RINGS

PISTON

-

14-162

3. Install the piston in the clutch drum, Apply pressure

and rotate to ensure proper seating,

NOTE: Lubricate the piston O-ring with ATF beforeinstalling.

CAUTION: Do not pinch the O-ring by insta ing thepiston with too much force.

CLUTCII DRUM

Install the return spring and spring retainer, andposition the snap ring on the retainer.

CLUTCI{ DRUM

Page 876 of 2189

Description

Clutches/Reverse Brake/Planetary Gear/Pulleys

Clulches/Reverse Brake

The CVT uses the hydraulically-actuated clutches and brake to engage or disengage the transmission gears. When

hydraulic pressure is introduced into the clutch drum and the reverse brake piston cavity, the clutch piston and the reverse

brake piston move. This presses the friction djscs and the steel plates together, locking them so they don't slip. Power is

then transmitted through the engaged clutch pack to its hub-mounted gear. and through engaged ring gear to pinion

gears.

Likewise, when the hydraulic pressure is bled from the clutch pack and the reverse brake piston cavity, the piston releases

the friction discs and the steel plates, and they are free to slide past each. This allows the gear to spin independently on its

shaft, transmitting no power.

Start Clutch

The start clutch, which is located at the end of the driven pulley shaft, engages/disengages the secondary drive gear.

The start clutch is supplied hydraulic pressure by its ATF feed pipes within the driven pulley shaft.

Forward Clutch

The forward clutch, which is located at the end of the drive pulley shaft, engages/disengages the sun gear.

The forward clutch is supplied hydraulic pressure by its ATF feed pipe within the drive pulley shaft.

Reverse Brake

The reverse brake, which is located inside the inte.mediate housing around the ring gear, locks the ring gear in E posi-

tion. The reverse brake discs are mounted to the ring gear and the reverse brake plates are mounted to the intermediate

housing. The reverse brake is supplied hydraulic pressure by a circuit connected to the internal hydraulic circuit.

Planetary Gear

The planetary gear consists of a sun gear, a carrier assembly, and a ring gear. The sun gear is connected to the input shaft

with splines. The pinion gears are mounted to the carrier which is mounted to the fo.ward clutch drum. The sun gear

inputs the engine power via the input shaft to the planetary gear, and the carrier outputs the engine power. The ring gear

is only used for switching the rotation direction of the pullev shafts,

In E. E, and E positions (forward range), the pinion gears don't rotate and revolve with the sun gear, so the carrier

rotates. In E] positjon {reverse range), the reverse brake locks the ring gear and the sun gear drives the pinion gears to

rotate. The pinion gears rotate and revolve in the opposite direction from the rotation direction of the sun gear, and the

carrier rotates with pinion gear revolution.

Pulleys

Each pulley consists of a movable face and a fixed face, and the effective pulley .atio changes with engine speed. The

drive pulley and the driven pulley are linked by the steel belt.

To achieve a low pulley ratio, high hydraulic pressure works on the movable face of the driven pulley and reduces the

effective diameter of the drive pulley. and a lower hydraulic pressure works on the movable face of the drive pulley to

eliminate the steel belt slippage. To achieve a high pulley ratio, high hydraulic pressure works on the movable face of the

drive pulley and reduces the eifective diameter of the driven pulley, and a lower hydraulic pressure works on the movable

face of the driven pulley to eliminate the steel belt slippage.

b

14-198