power win HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1239 of 2189

\L

lJ\

\flREAR CHANNEL N\

\,\

\

\i\Ill

ld 1l

6P lll

REo" c"AN"..: | 1lcoLLAR J I

)€)\IJ

6/

\3-

REGULATORHANOLE

:& fr\

r lll'All criss lLl

l'A sroeeen lll

W-*d

t a)" u\

*)u*ro* \

Repracement, pase 20 ,tt

l5[1tfCHANNEL

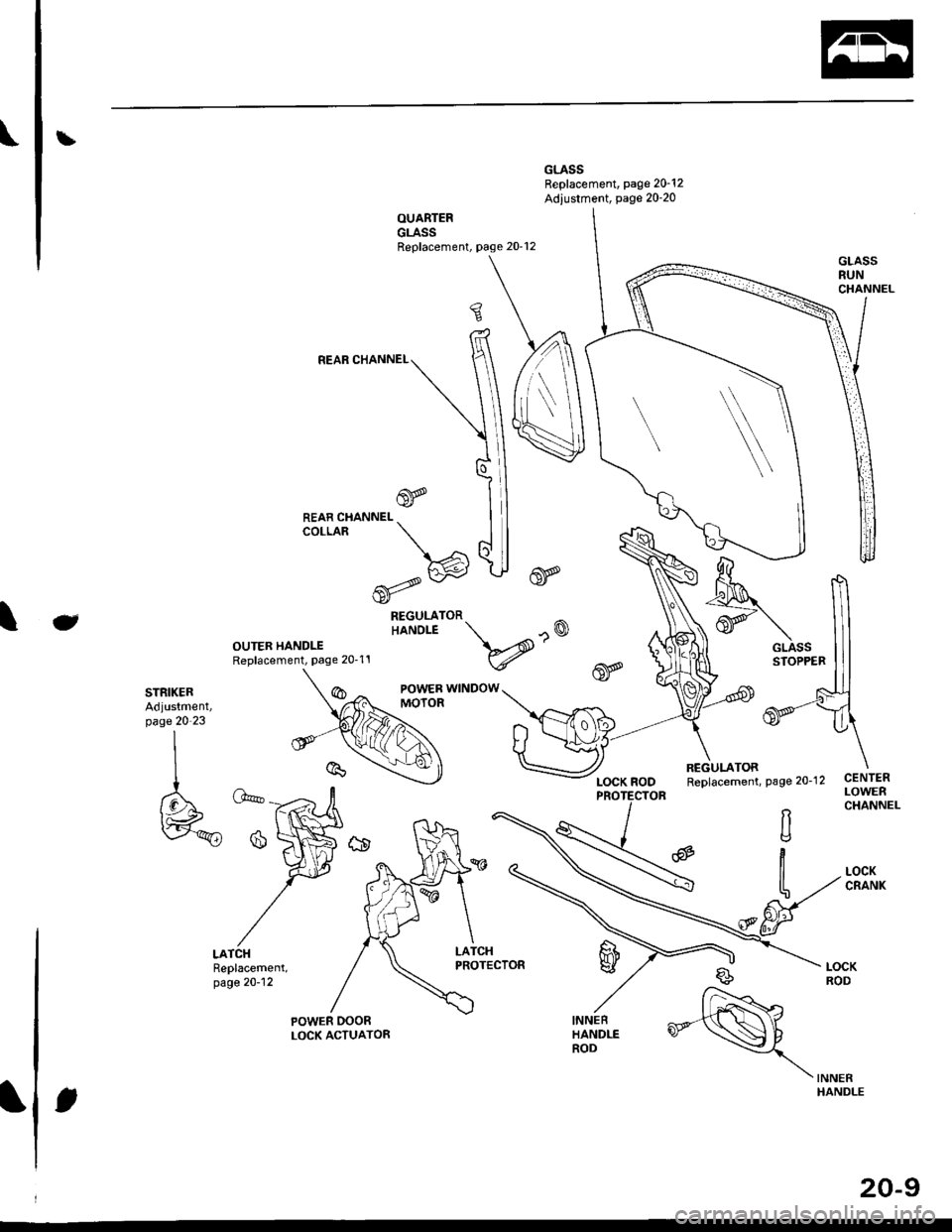

OUTER HANDLEReplacement, Page 20-11

STRIKERAdjustment,page 20'23

I

I

%grc

POWER WINDOWMOTOR

LOCK RODPROTECTOR

LATCHPROTECTORReplacement,page 20-12

POWER OOORLOCK ACTUATOE

t

20-9

Page 1243 of 2189

t}

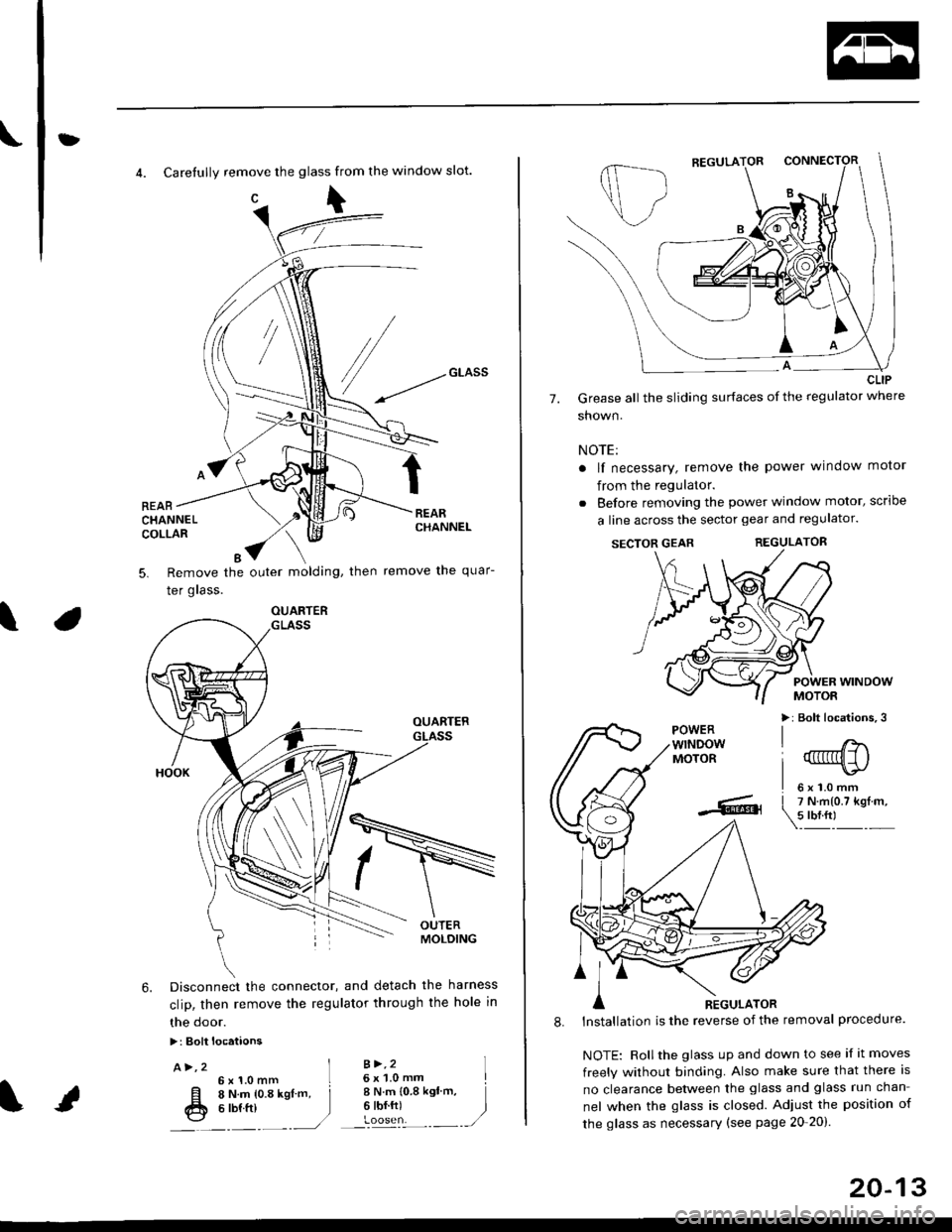

4. Carefully remove the glass from the window slot.

c\

REARCHANNELCOLLAR

Remove the outer molding, then

Ier grass.

remove the quar-5.

\

6. Disconnect the connector, and detach the harness

clip, then remove the regulator through the hole in

the door.

>: Bolt locataons

A>,2 ]6x1.0mm L

[l o t't.- to.a rsl -. j

fr e ttt ttt )---�.---.-,/

B >,26 x 'l.0 mmI N.m {0.8 ksl'm,6 tbf.ft)

I

)

OUARTER

20-13

7.

CLIP

Grease all the sliding surfaces of the regulator where

shown.

NOTE:

a lf necessary, remove the power window motor

from the regulator.

. Before removing the power window motor, scrloe

a line across the sector gear and regulator.

SECTOR GEARREGULATOR

POWER WINDOWMOTOR

>: Bolt locations,3POWERwTNDOWMOTOR

l'

-... er

A nicuuron

8. lnstallation is the reverse of the removal procedure.

NOTE: Rollthe glass up and down to see if it moves

freely without binding. Also make sure that there is

no clearance between the glass and glass run chan-

nel when the glass is closed. Adjust the position of

the glass as necessary (see page 20-20).

Page 1246 of 2189

Doors

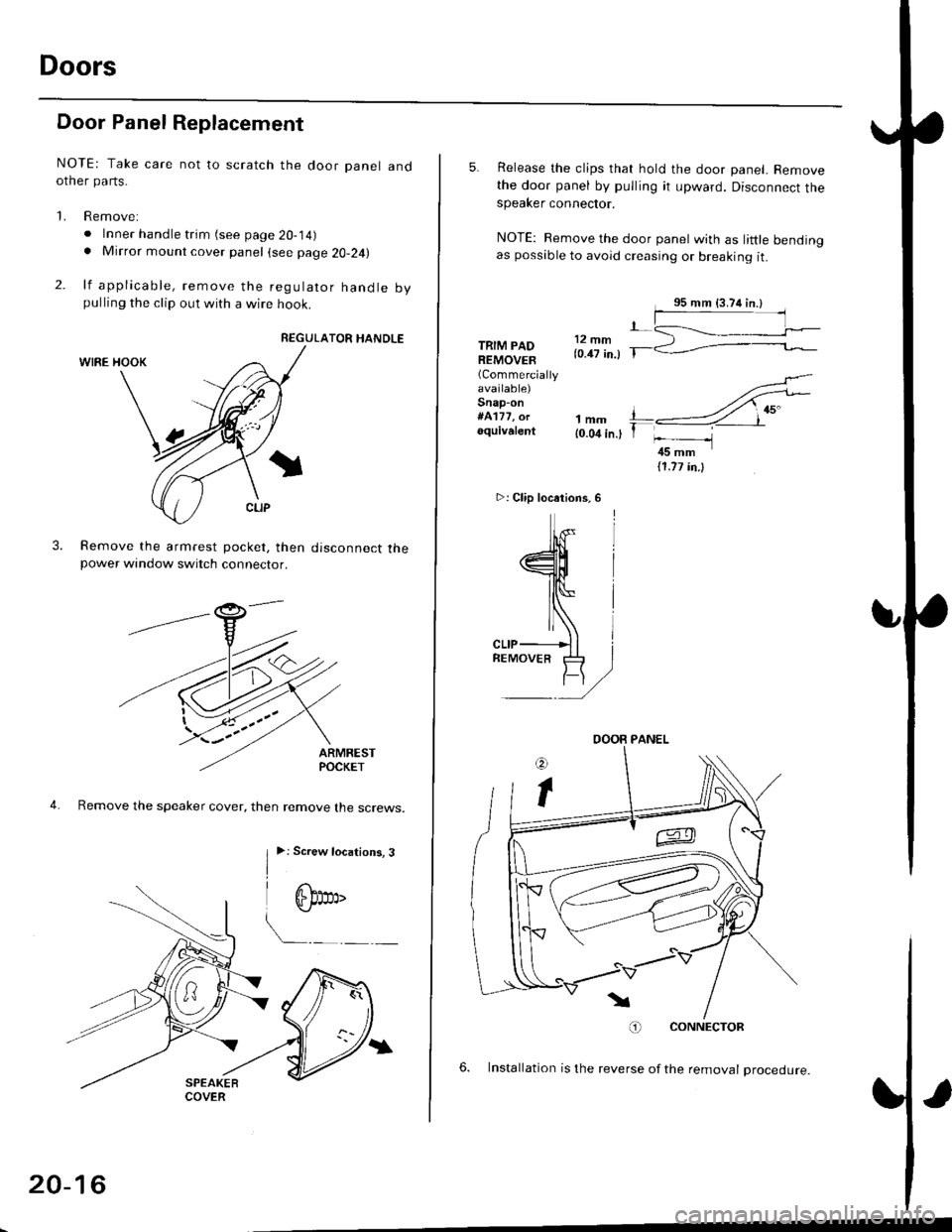

Door Panel Replacement

NOTE: Take care not to scratch the door panel andother pa rts.

'1. Remove:

. Inner handle trim (see page 20-14). Mirror mount cover panel (see page 20-24)

2. lf applicable, remove the regulator handle bypulling the clip out with a wire hook.

REGULATOR HANDLE

WIRE HOOK

Remove the armrest pocket, then disconnect thepower window switch connector.

ARMRESTPOCKET

4. Remove the speaker cover, then remove lhe screws.

3.

I

>: Screw locations, 3

| 6b:a,'

L"_

COVER

20-16

TRIM PADREMOVER(Commercially

available)Snap-on#A'177, orequivalent1mm{0.04 in.)

5. Release the clips that hold the door panel. Removethe door panel by pulling it upward. Disconnect thespeaker connector.

NOTE: Remove the door panel with as little bendingas possible to avoid creasing or breaking it.

.L12 fim(0.47 in.) T-

>: Clip locations,

l^

J[

=l$

ll,\*

atr-

,,)

REMoVER tl-)

11.77 in.l

O) CONNECTOR

6. lnstallation is the reverse of the removat oroceoure.

DOOR PANEL

Page 1250 of 2189

Doors

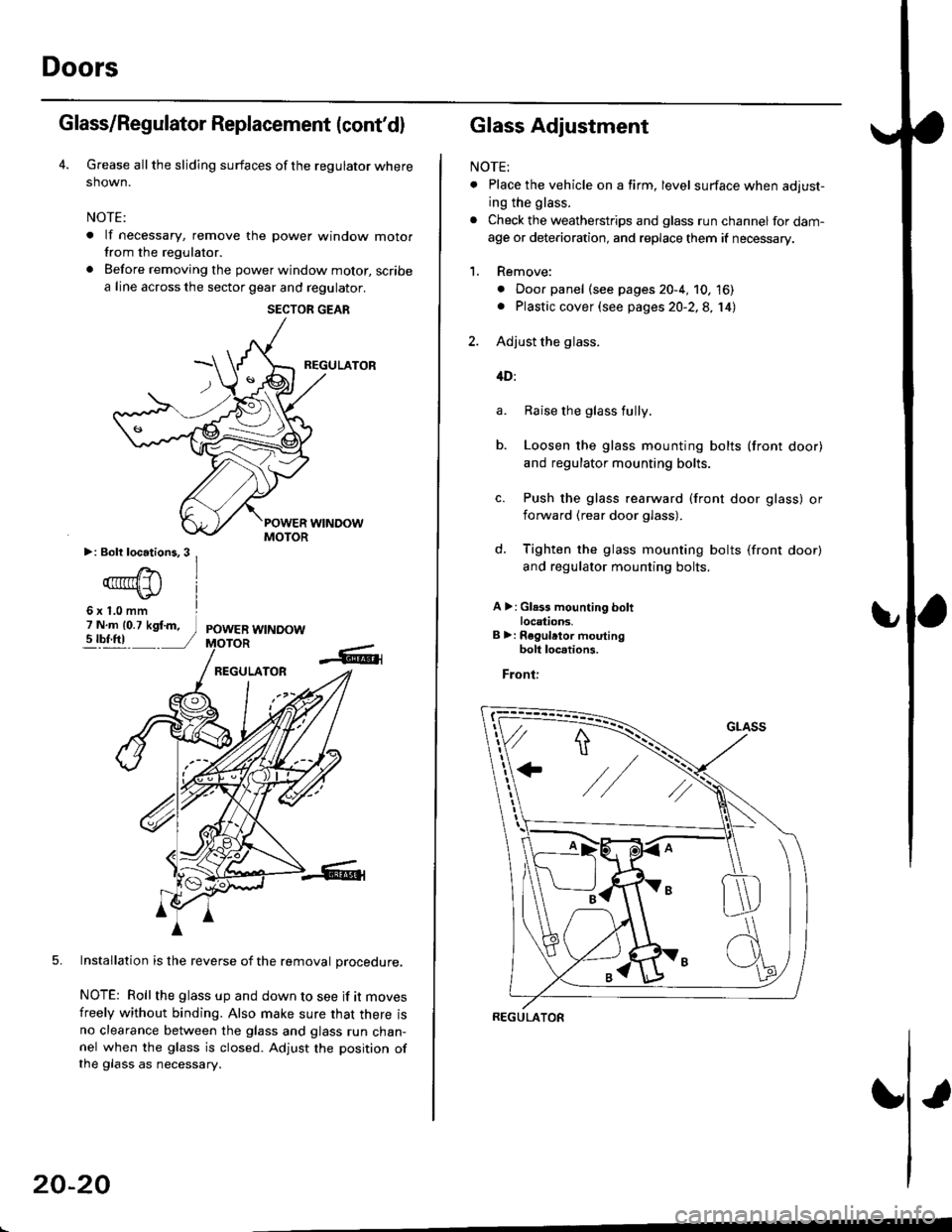

Glass/Regulator Replacement (cont'dl

Grease all the sliding surfaces of the regulator where

shown.

NOTE:

. lf necessary, remove the power window motorfrom the regulator.

. Before removing the power window motor, scribe

a line across the sector gear and regulator.

REGULATOR

5. Installation is the reverse of the removal orocedure.

NOTE: Roll the glass up and down to see if it moves

freely without binding. Also make sure that there isno clearance between the glass and glass run chan-nel when the glass is closed. Adjust the position ofthe glass as necessary.

SECTOR GEAR

20-20

Glass Adjustment

NOTE:

. Place the vehicle on a firm, level surface when adjust-

ing the glass.

. Check the weatherstrips and glass run channel for dam-

age or deterioration, and replace them if necessary.

1. Remove:

. Door panel (see pages 20-4, 10, 16). Plastic cover (see pages 20-2,8, 14)

2. Adjust the glass.

4D:

Raise the glass fully.

Loosen the glass mounting bolts (front door)

and regulator mounting bolts.

Push the glass rearward (front door glass) or

iorward (rear door glass).

Tighten the glass mounting bolts (front door)

and regulator mounting bolts.

A >: Gl.3s mounting boltlocations.B >: Regulrtor moutingbolt loc.tions.

Front:

a.

b.

d.

REGULATOR

Page 1377 of 2189

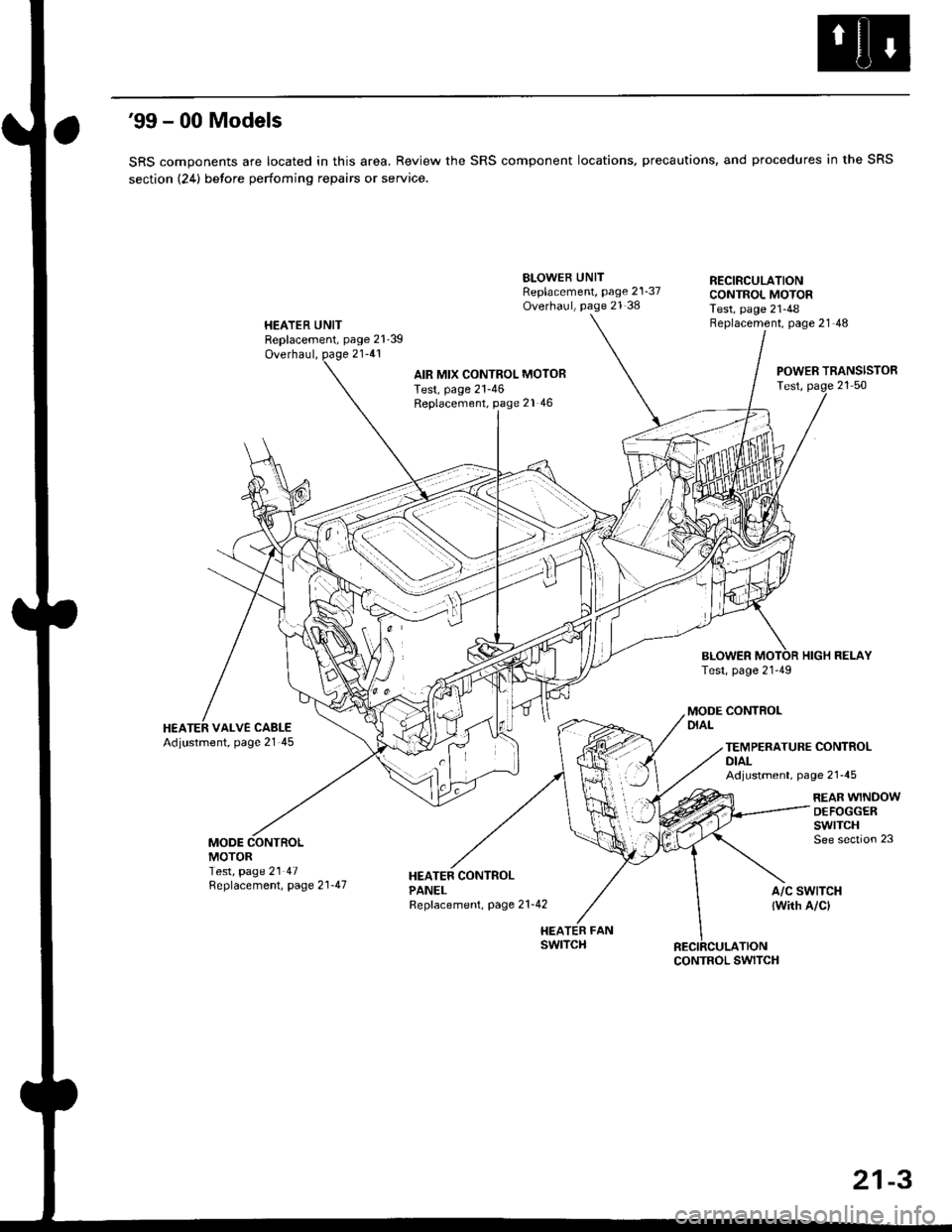

'99 - 00 Models

SRS components are located in this area, Review the SRS component locations, precautions, and procedures in the SRS

section (24) betore perfoming repairs or service.

HEATER UNITReplacement, page 21'39

Overhaul, page 21-41

BLOWEB UNITReplacement, page 21-37Overhaul, page 21 38

HEATER FANswtTcH

RECIRCULATIONCONTROL MOTORTest, page 21-48Beplacement, page 21-48

AIR MIX CONTROL MOTOBTest, page 21-46Replacement, page 21 46

BLOWERTest, page 21-49

POWER TRANSISTORTest, page 21 50

HIGH RELAY

MODE CONTROLDIALHEATER VALVE CABLEAdjustment, page 21 45TEMPERATURE CONTROLDIALAdjustment, page 21-45

REAR WINDOWDEFOGGERswtrcHSee section 23MODEMOTORTest, page 21 47Replacement, page 2 l-47A/C SWTTCH

lwith A/cl

CONTROL SWITCH

21-3

Page 1391 of 2189

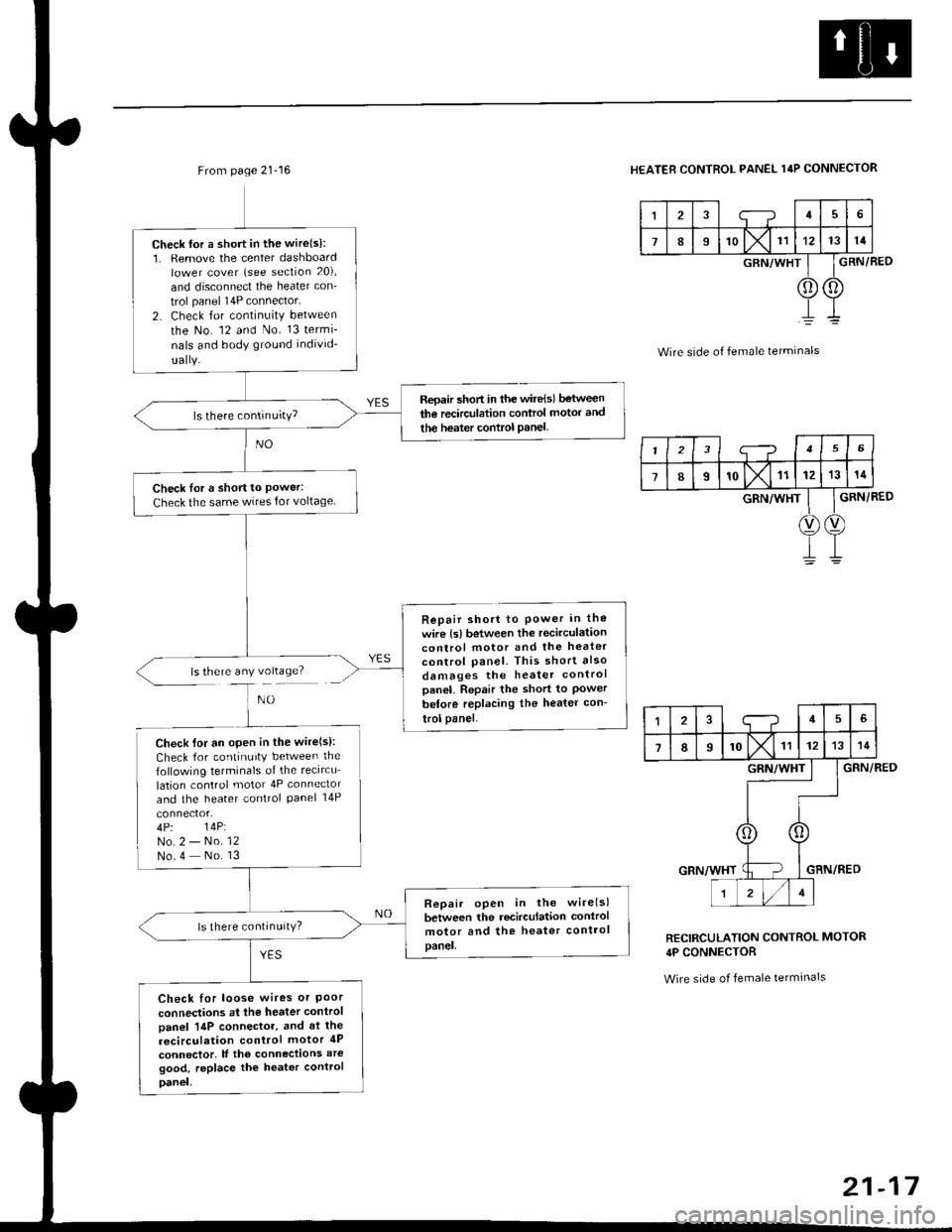

From page 21-16

ls there any voltage?

Check {or a short in the wire(s):1. Remove the center dashboardlower cover (see section 20),

and disconnect the heater con_

trol panel 14P connector'

2. Check for continuity between

the No. 12 and No. 13 termi-

nals and body ground individ-

Repair 5hort in the wire{sl between

the recirculation control motor and

the heater control Panel

Check Ior a short to Power:Check the same wires for voltage

Repair short to Power in the

wire {s) between the recirculationcontrol motor and the heater

control panel. This short also

damages the heater controlpanel. Repair the short to Powerbetore replacing the heater con-

trol panel.

Check lor an open in the wire(s):

Check for continuity between the

following terminals of the recircu

lation control motor 4P connector

and the heater control Panel 14P

4P. 14P:No.2 - No. 12No.4 No. 13

Repair open in the wirelsl

between the recirculation control

motor and the heater controlpanel.

ls there continuitY?

Check for loose wires or Poorconnections at the heater control

Danel 14P connector, and at the

recirculation control motor 4P

connector. lf the connections aregood, replace the heater control

Danel,

HEATER CONTROL PANEL 14P CONNECTOR

I;-?45

789'o lx11121314

GRN/WHT

0) (0

GRN/BED

Wire side of female terminals

GRN/RED

GRN/RED

RECIRCULATION CONTROL MOTOR

4P CONNECTOR

Wire side of female tetminals

I23i--?156

78I'olx11121314

GRN/WHT

V)(v

145

7IIrol\l rr1213

GRN/WHT

r zl/lt

21-17

Page 1398 of 2189

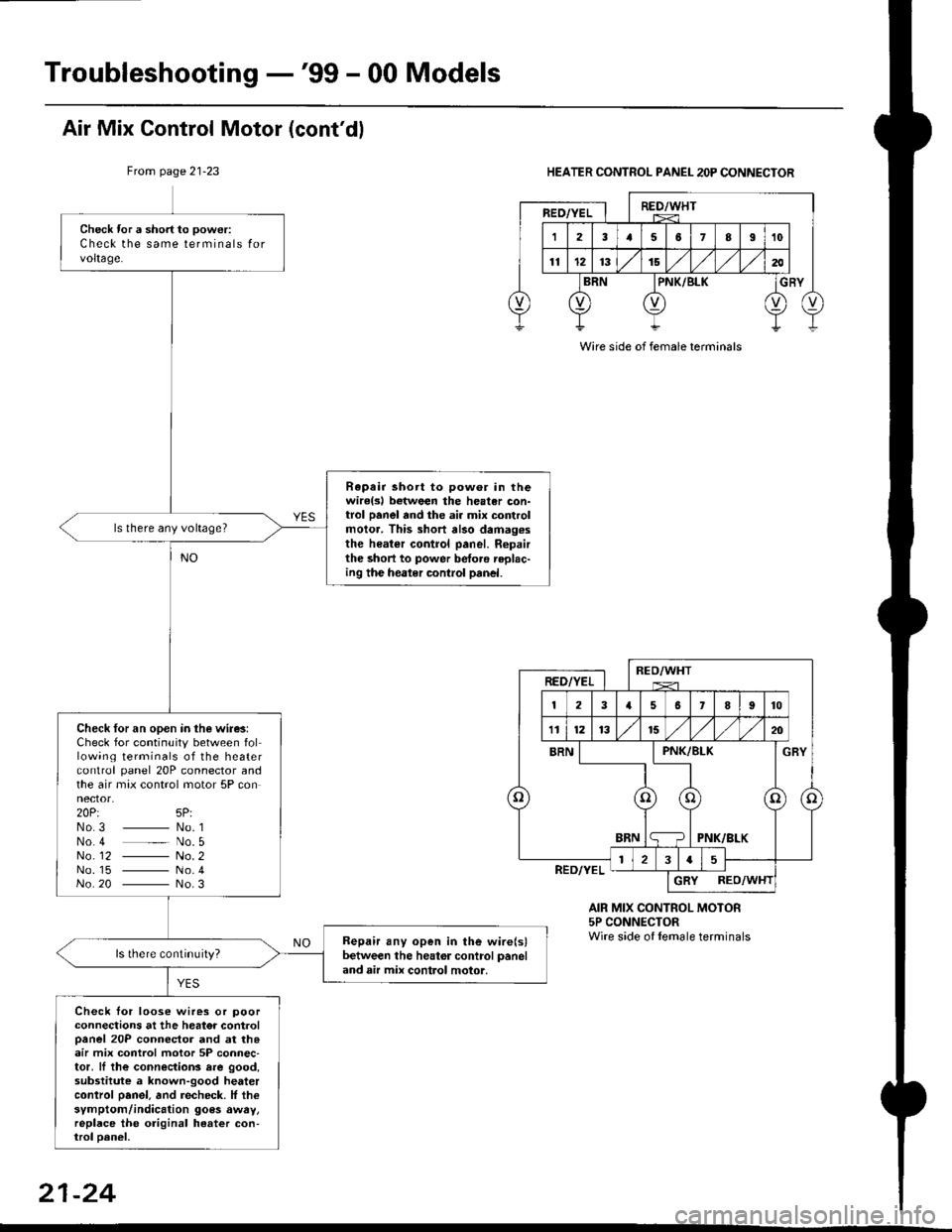

Troubleshooting -'99 - 00 Models

Check tor a short to power:

Check the same terminals forvoltage.

Rapair short to pow6r in thewirelsl botween the heater con-trol panel and the ai. mix controlmolor. This short also damag.sthe heater control panel. Ropairthe short to power betoro replac-ing the heater control panel.

ls there any voltage?

Check for an open in the wire3:Check for continuity between following terminals of the heatercontrol panel 20P connector andthe air max control motor 5P connector.20Pt 5P:No3 _ No. 1No 4 _ No. 5No_ 12 - No. 2No. 15 - No.4No 20 - No.3

Bepair any open in the wire(s)between the heator control paneland air mix control motor,

Check tor loose wires or poorconnections at the heator controloanel 20P connector and at th.air mix control motor 5P connec-tor, ll the connections rre good,substitute a known-good heatercontrol oanel. and recheck. lf thesymptom/indication goes awry,replace the original heater con-trol oanel,

Air Mix Control Motor (cont'dl

From page 21-23HEATER CONTROL PANEL 2OP CONNECTOR

AIR MIX CONTROL MOTOR5P CONNECTORWire side of lemale terminals

Wire side of female terminals

21-24

Page 1402 of 2189

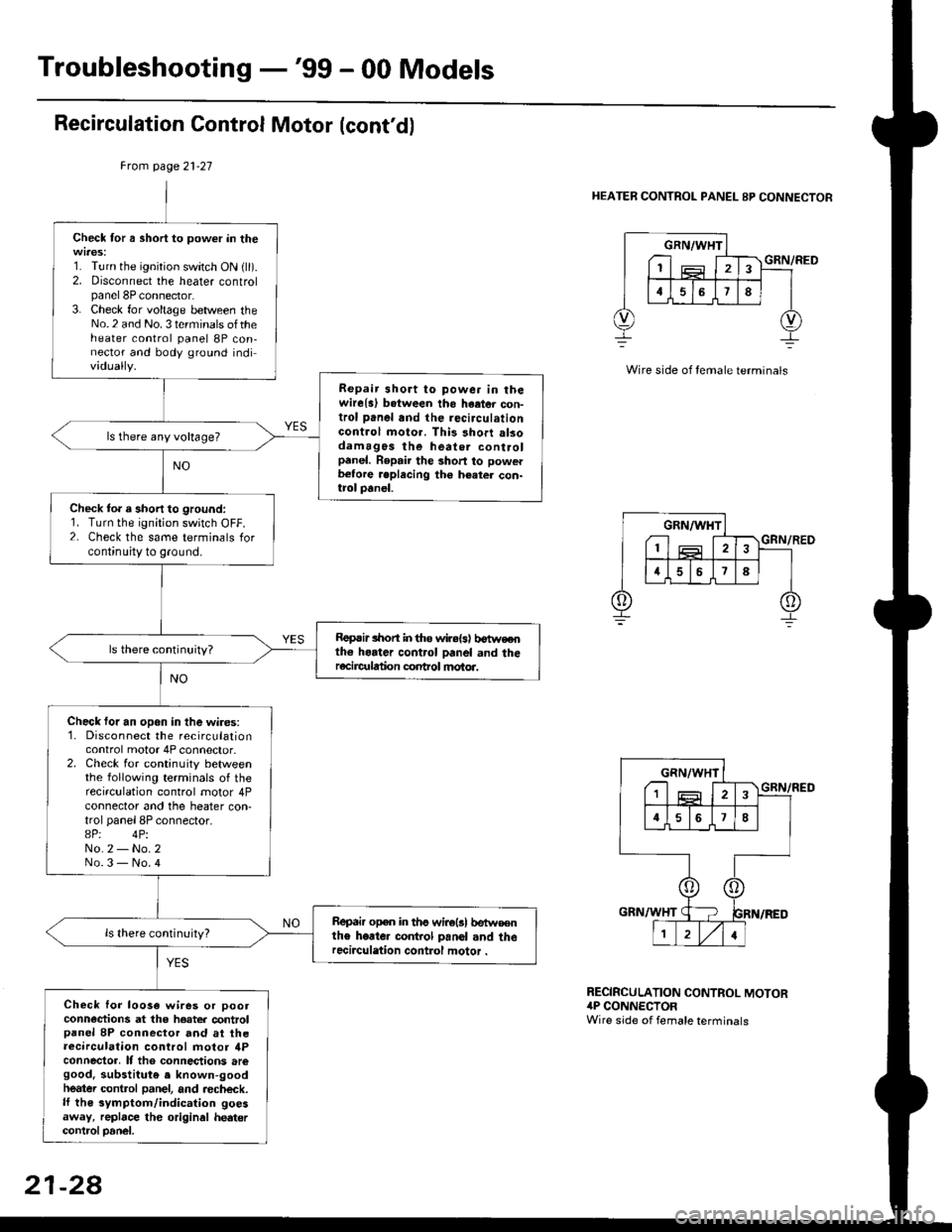

Troubleshooting -'99 - 00 Models

Recirculation Control Motor (cont'd)

Frcm page 21-27

HEATER CONTROL PANEL 8P CONNECTOR

Check for a short to power in the

1. Turn the ignition switch ON {ll).2. Disconnect the heater controlpanel 8P connector.3. Check for voltage between theNo.2 and No. 3 terminals oftheheater control panel 8P con,nector and body ground individually.

Repair 3hort to powe. in thewire{a) b.tween tho haetor con-trol panel and the recirculationGontrol moto.. This short alsodamagos the heate. controlpanel. Repair the short to powerb€tore .eplecing the h€ater con-trol panel.

ls there any voltage?

Check to. a short to ground:1. Turn the ignition switch OFF.2- Check the same terminals forcontinuity to ground.

Roprir lhon in tho wir.{s) b€tweothe horter control panel and theracircr alion conhol motoa.

Check for an open in the wires:1. Disconnect the recirculationcontrol motor 4P connector.2. Check for continuity betweenthe following terminals of therecirculation control motor 4Pconnector and the heater con,trol panel 8P connector.8P: 4PiNo.2 - No.2No.3 - No.4

Repair open in ths wirolsl betw€€nthe heate. co.rkol panol and therecirculation control motor .

Check lor loo3a wires or pootconn€ctions at the hoater controlpanel 8P connector and at theaecirculation control motor ilPconnector, It tho connections aregood. substitut€ e known-goodheatei control panel, and aecheck.lf th€ symptom/indication goesaway, replace the original hedtercontrcl Danel.

GRN/WHT

I1

GRN/RED

RECIRCULATION CONTROL MOTOR4P CONNECTORWire side of female terminals

21-28

Page 1410 of 2189

Troubleshooting -'99 - 00 Models

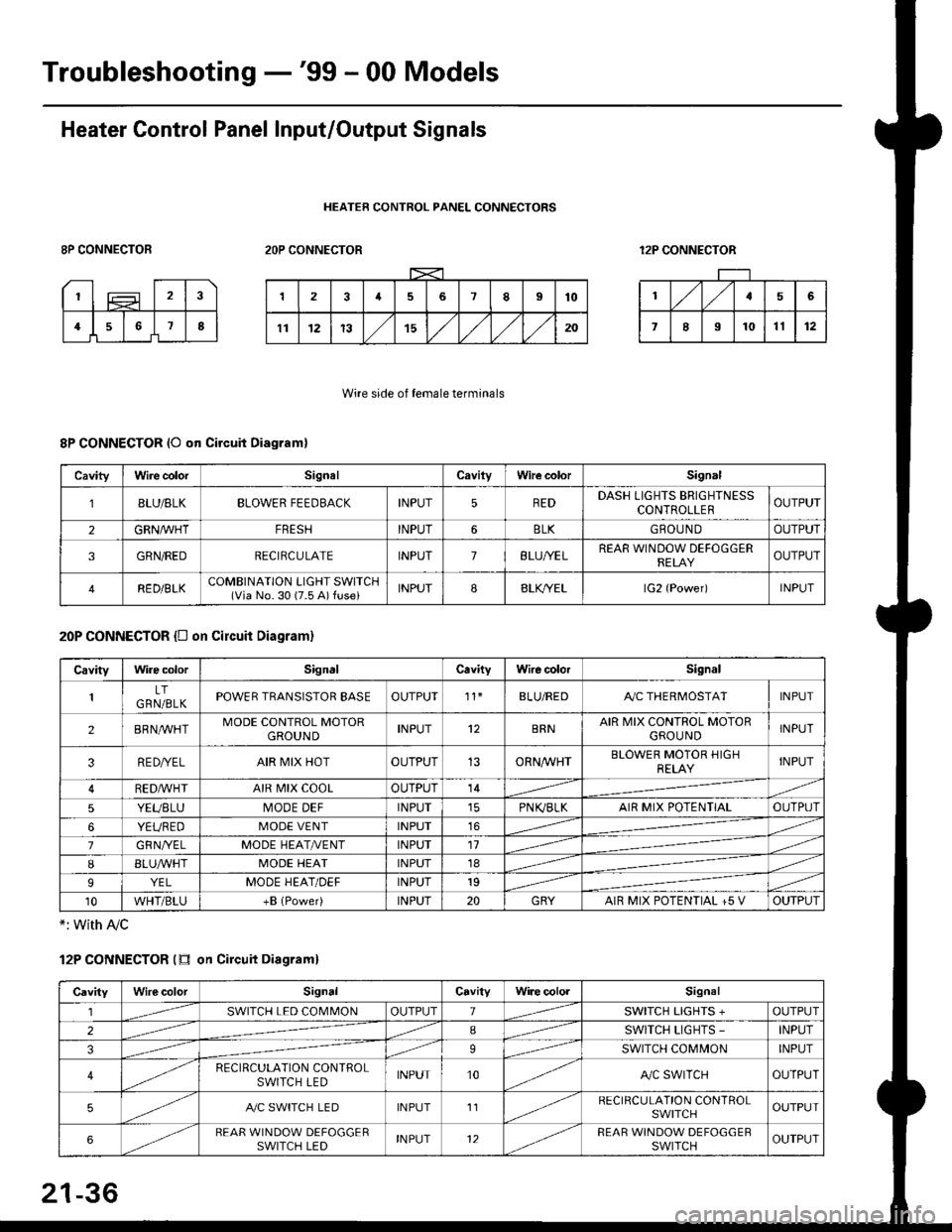

Heater Control Panel Input/Output Signals

HEATER CONTROL PANEL CONNECTORS

8P CONNECTOR2OP CONNECTOR12P CONNECTOR

Wire side of female terminals

8P CONNECTOR (O qn Circuit Diagram)

20P CONNECTOR {D on circuit Diagram}

*: with Ay'c

12P CONNECTOR (tr on Circuit Diagraml

CavityWire colorSignalCavilyWhe colorSignal

BLU/8LKBLOWER FEEDBACKINPUT5REDDASH LIGHTS BRIGHTNESSCONTROLLEROUTPUT

2GRN/lVHTFRESHINPUT6BLKGBOU N DOUTPUT

3GRN/REDRECIRCULATEINPUT7BLU/YELREAR WINDOW DEFOGGERRELAYOUTPUT

4RED/BLKCOMBINATION LIGHT SWITCH(Via No. 30 (7.5 A) fuse)INPUT88LfiELlG2 {Power)INPUT

CavityWire colorSignalCavityWire colorSignal

LTGRN/BLKPOWER TRANSISTOR EASEOUTPUT't1BLU/REDAy'C THERMOSTATINPUT

2BRNMHTMODE CONTROL MOTORGROUNDINPUT12BRNAIR MIX CONTROL MOTORGROU NDINPUT

3RE D/YELAIR MIX HOTOUTPUT13ORNAA/HTBLOWER MOTOR HIGHRELAYINPUT

RED,ryvHIAIR MIX COOLOUTPUT14

5YEUBLUMODE DEFINPUTPN K,/BLKAIR MIX POTENTIALOUTPUT

6YEUREDMODE VENTINPUT16

7GRNI/ELMODE HEAT/r'ENTINPUT11

IBLUAVHTMODE HEATINPUT18

9YELMODE HEAT/DEFINPUT19

10WHT/BLU+B (Power)INPUT20GRYAIR MIX POTENTIAL +5 VOUTPUT

CavityWilecolorSignalCavityWi.e cololSignal

lSWITCH LED COMMONOUTPUT1SWITCH LIGHTS +OUTPUT

2ISWITCH LIGHTS -INPUT

39SWITCH COMMONINPUT

4RECIRCULATION CONTROLSWITCH LEDINPUT10A,/C SWITCHOUTPUT

5A./C SWITCH LEDINPUT11RECIRCULATION CONTROLSWITCHOUTPUT

6REAR WINDOW DEFOGGERSWITCH LEDINPUT12REAR WINDOW DEFOGGEBSWITCHOUTPUT

21-36

Page 1455 of 2189

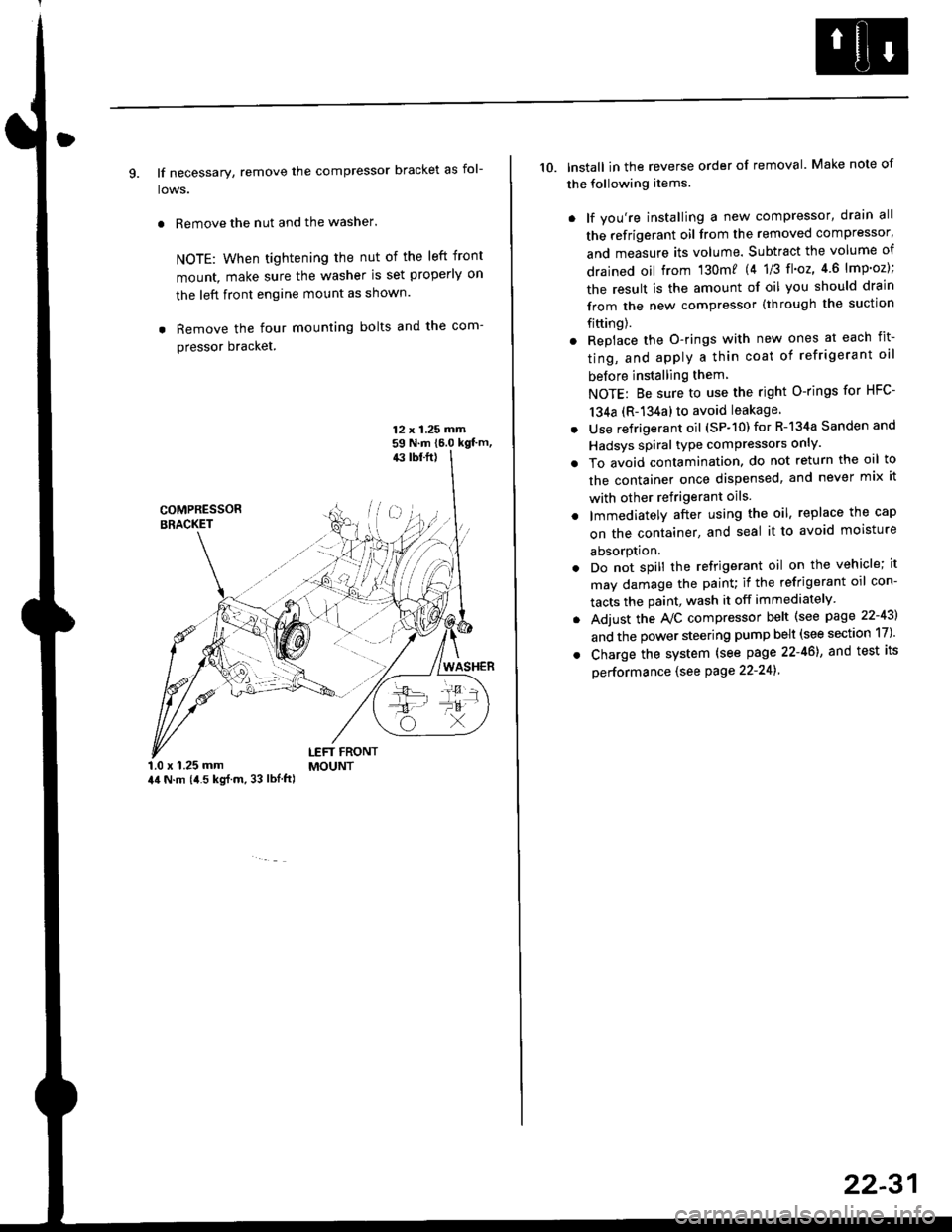

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31