washer pump HONDA CIVIC 1996 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 978 of 2189

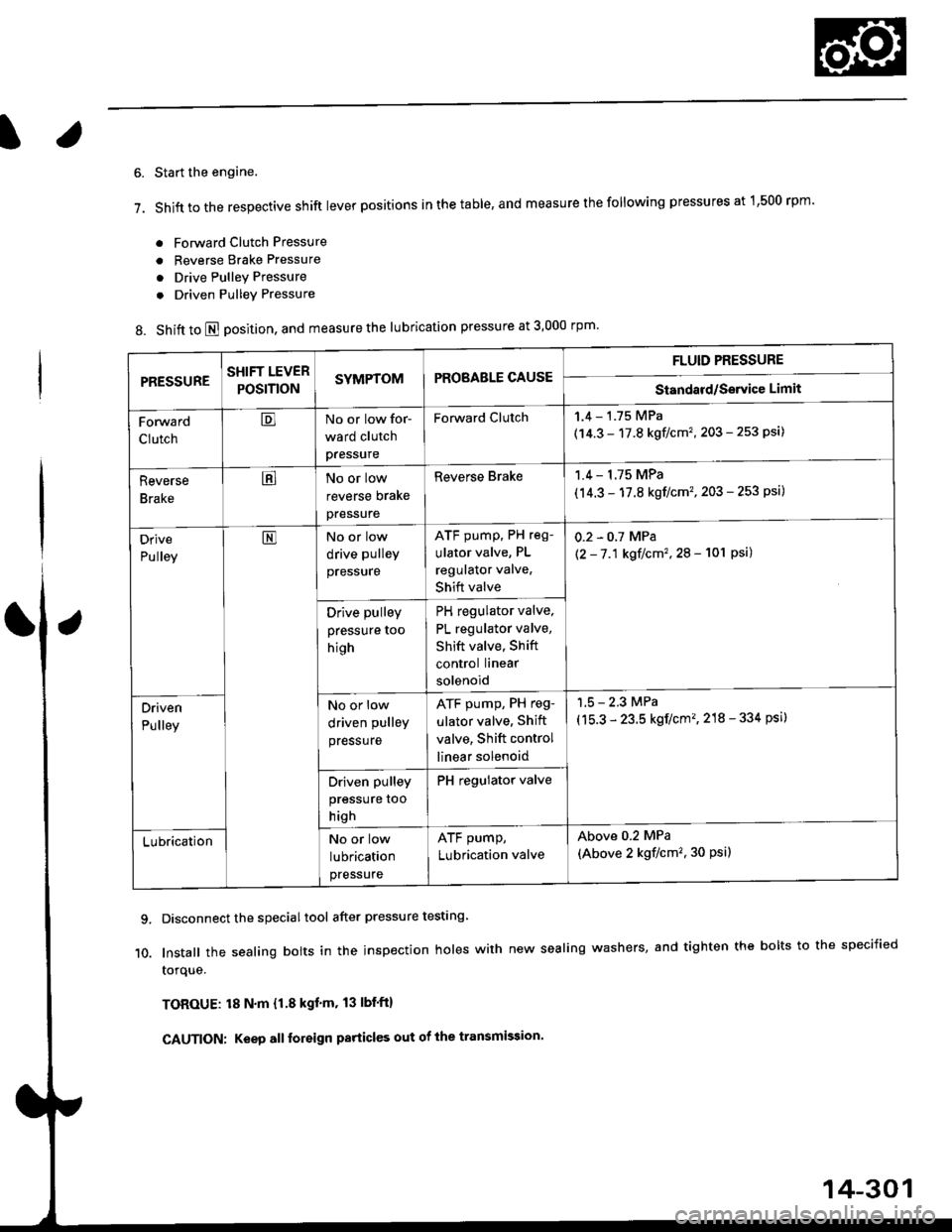

1.

Start the engine.

Shift to the respective shift lever positions in the table, and measure the following pressures at 1'500 rpm'

. Forward Clutch Pressure

. Reverse Brake Pressure

. Drive Pulley Pressure

. Driven Pulley Pressure

8. Shift to E posltion, and measure the lubrication pressure at 3,000 rpm'

Disconnect the special tool after pressure testlng

Install the sealing boits in the jnspection holes with new sealing washers, and tighten the bolts to the specified

toroue.

TOROUE: 18 N.m {1.8 kgf'm, 13 lbf'ft}

CAUTION: Keep all foreign particles out of the transmission'

9.

10.

PBESSURESHIFT LEVER

POSmONSYMP{OMPROBABLE CAUSE

FLUID PRESSURE

Standard/Ssrvice Limit

Forwa rd

Clutch

ENo or low for-

ward clutch

pressure

Forward Clutch1.4 - 1.75 MPa

(14.3 - 17.8 kgtcm'�, 203 - 253 Psi)

Reverse

Brake

tsNo or low

reverse brake

pressure

Reverse Brake1.4 - 1.75 MPa

(14.3 - '17.8 kg7cm'�, 203 - 253 Psi)

Drive

Pulley

NNo or low

drive pulley

pressure

ATF pump, PH reg-

ulator valve, PL

regulator valve,

Shift valve

0.2 - 0.7 MPa

(2 - 7.1 kgflcm'�, 28 - 101 Psi)

Drive pulley

pressure roo

high

PH regulator valve,

PL regulator valve,

Shift valve. Shift

control linear

solenoid

Driven

Pulley

No or low

driven pulley

pressure

ATF pump, PH reg-

ulator valve, Shift

valve, Shift control

linear solenoid

1.5 - 2.3 MPa

(15.3 - 23.5 kg?cm'�, 218 - 334 Psi)

Driven pulley

pressure too

h igh

PH regulator valve

LubricationNo or low

lubrication

pressure

ATF pump,

Lubrication valve

Above 0.2 MPa

(Above 2 kgf/cm'�. 30 Psi)

14-301

Page 988 of 2189

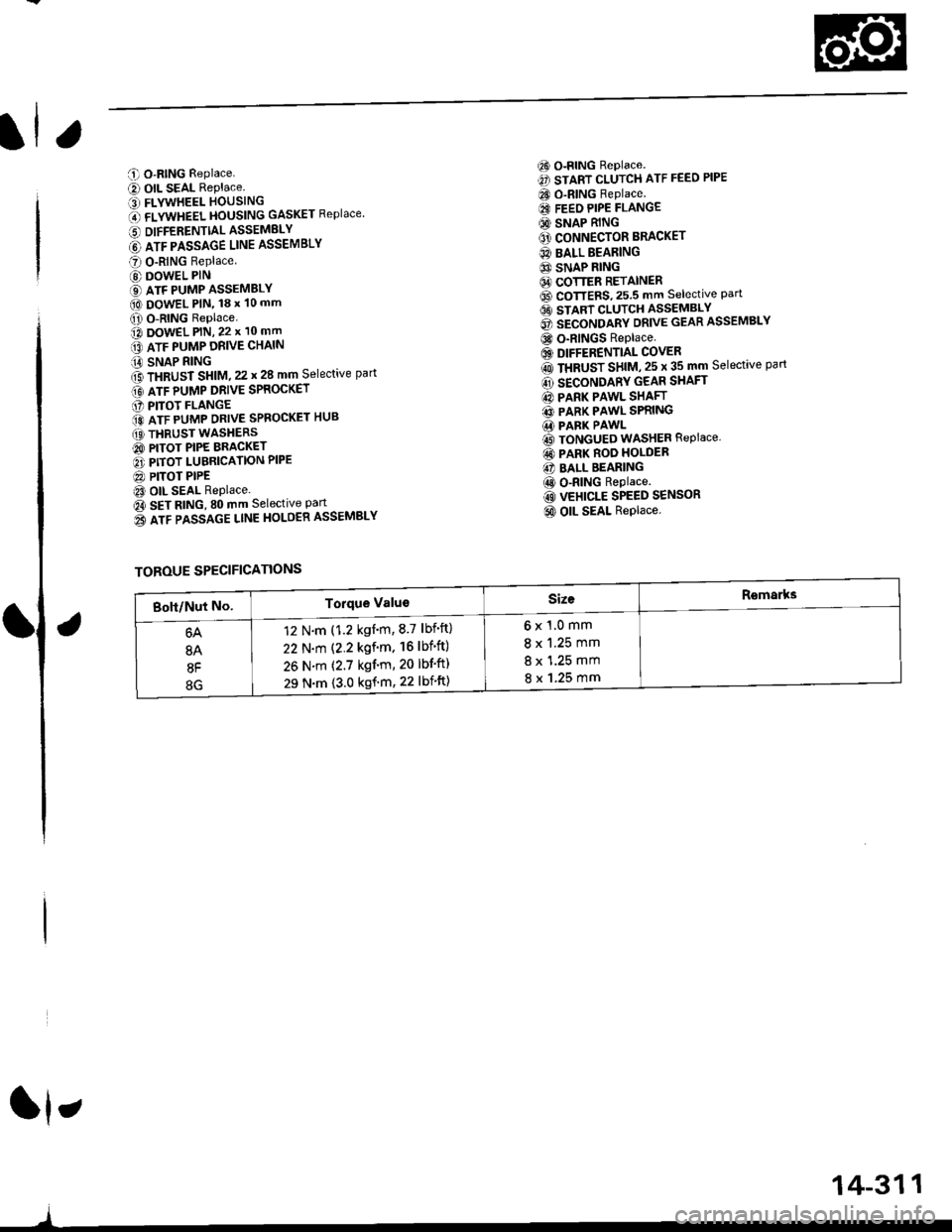

C O-RING Replace.

e) OIL SEAL RePlace.' FLYWHEEL HOUSING

O flVWneel }|OUSttttG GASKET Replace

6 DIFFERENTTALASSEMELY

@ lrr plsslce uruE ASSEMBLY

O O-RING Replace

@ DOWEL PIN

€) ATF PUMP ASSEMBLY(O DowEL PlN, 18 x 10 mm

O O-RING Replace.o DowEL PlN, 22 x 10 mm

lrr puup oRve cxltttt

iA SNAP RING

f3 fxaUst St|t|l, zz t 28 mm Selective part

Gt lrr punp ontve spaocxer

O PITOT FLANGE

ito nTF purrap ontve SPRoGKET HUB

(O THRUST WASHERS

@ PITOT PIPE BRACKET

O PITOT LUBRICATION PIPE

@ PITOT PIPEt3 OIL SEAL Replace.

Oa SEt AtitC, SO mm Selective Part

o3 lrr passlce ltnE HoLOER ASSEMBLY

6) o-RING Replace.

€) START CLUTCH ATF FEED PIPE

CO O-RING Replace.

€I FEEO PIPE FLANGE

@ SNAP RING

O' CONNECTOR BRACKET

@ BALL BEARING

6} SNAP RING64 COTTER RETAINER6D CoTTERS,25.5 mm selective Part6t stlnt cLutcH asseMsLv

@ secoruomv ontvE GEAR ASSEMBLY

@ o-RINGS Replace

6) DIFFERENTIAL COVER

rO ttaUSr SntU, zs t 35 mm Selective part

@ SECONDARY GEAR SHAFT

@ PARK PAWL SHAFT

@ PARK PAWL SPRING.1i PARK PAWL

@ TONGUED WASHER REPIACE,

@ PARK ROO HOLDER

@ BALL BEARING

@ o-RING Replace.

@ VEHICLE SPEED SENSOR

@ OIL SEAL Replace.

ft,

)

TOROUE SPECIFICATIONS

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgnm,8.7 lbf'ft)

22 N.m (2.2 kgf'm. 16lbf'ft)

26 N.m (2.7 kgf'm, 20 lbf'ft)

29 N.m {3.0 kgf'm, 22 lbift)

14-311

Page 993 of 2189

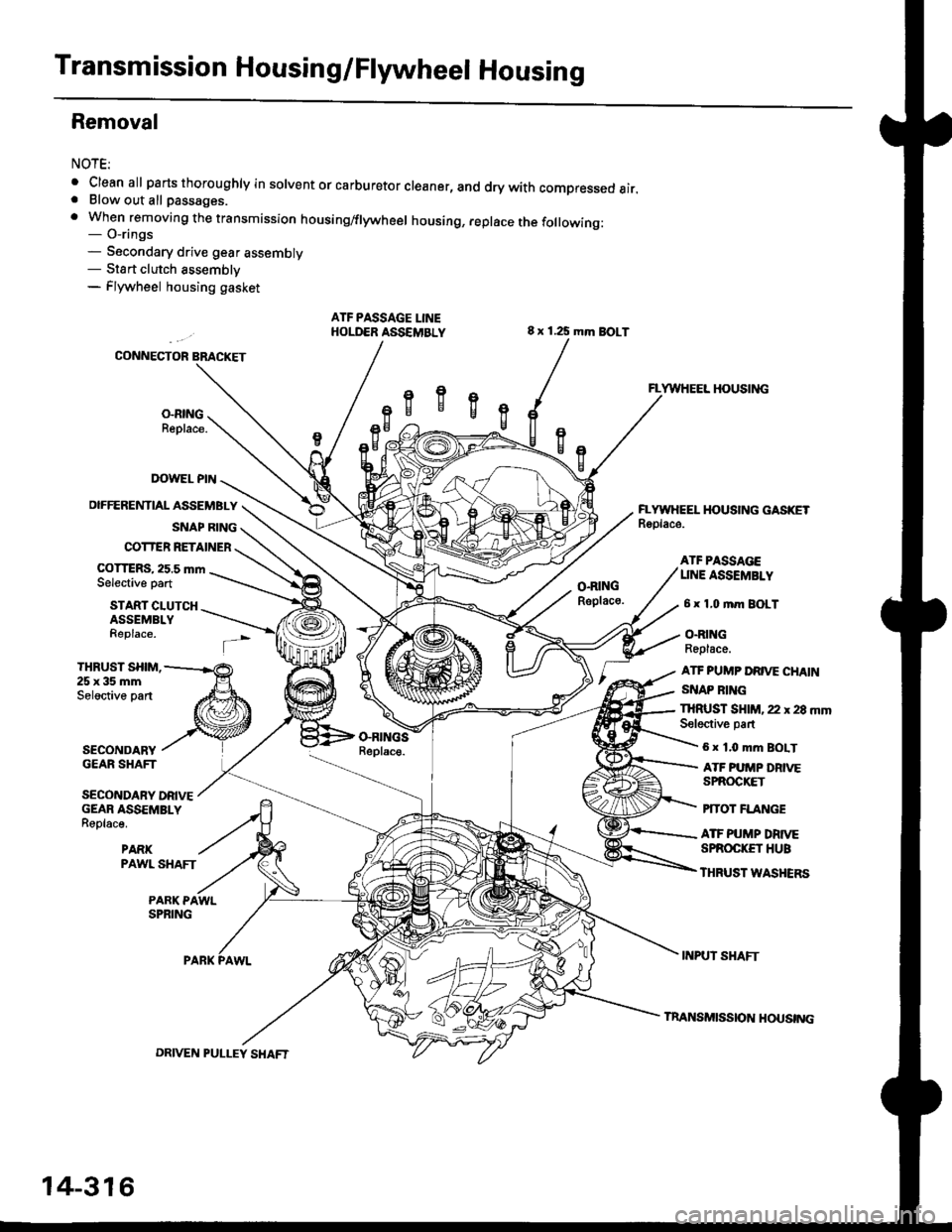

Transmission Housing/Flywheel Housing

Removal

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner, and dry with compressed air.. Blow out all passages.

. When removing the transmission housing/flywheel housing, replace the following:- O-rings- Secondary drive gear assembly- Sta rt clutch assemblv- Flywheel housing gasket

ATF PASSAGE LINEHOLD€R ASSEMBLY

IX)WEL PIN

OIFFERENTIAL ASSEMBLY

SNAP RING

COTTER RETAINER

COTTERS, 25.5 mmSelective part

8 x 125 mm BOLT

O.RINGRsplaco.

VWHEEL HOUSING

EYWIIEEL HOUSING GASKETRoolace.

START CLUTCHASSEMBLYReplace.

ATF PA$gAGEUNE ASSEMBLY

6 x 1,0 mm BOLT

O.RINGReplace.

ATF PUMP DRIVE CHAIN

SNAP RING

THRUST SHIM,25x35mmSeloctive part

SECONDARYGEAR SHAFT

SECONDARY DRIVEGEAR ASSEMBLYReplace.

PARKPAWL SHAFT

THRUST SHIM, 22 r 28 mmSeloctive partGRII{GSReplac€.6 x 1.0 mm BOIT

ATF PUMP DRIVESPROCKET

PfTOT FLANGE

ATF PUMP DRTVESPROC|(ET HUB

THRUST WASHERS

PARK PAWLSPRING

INPUT SHAFT

14-316

DRIVEN PULLEY SHAFT

InANSMISS|O]{ HOUSTNG

Page 1019 of 2189

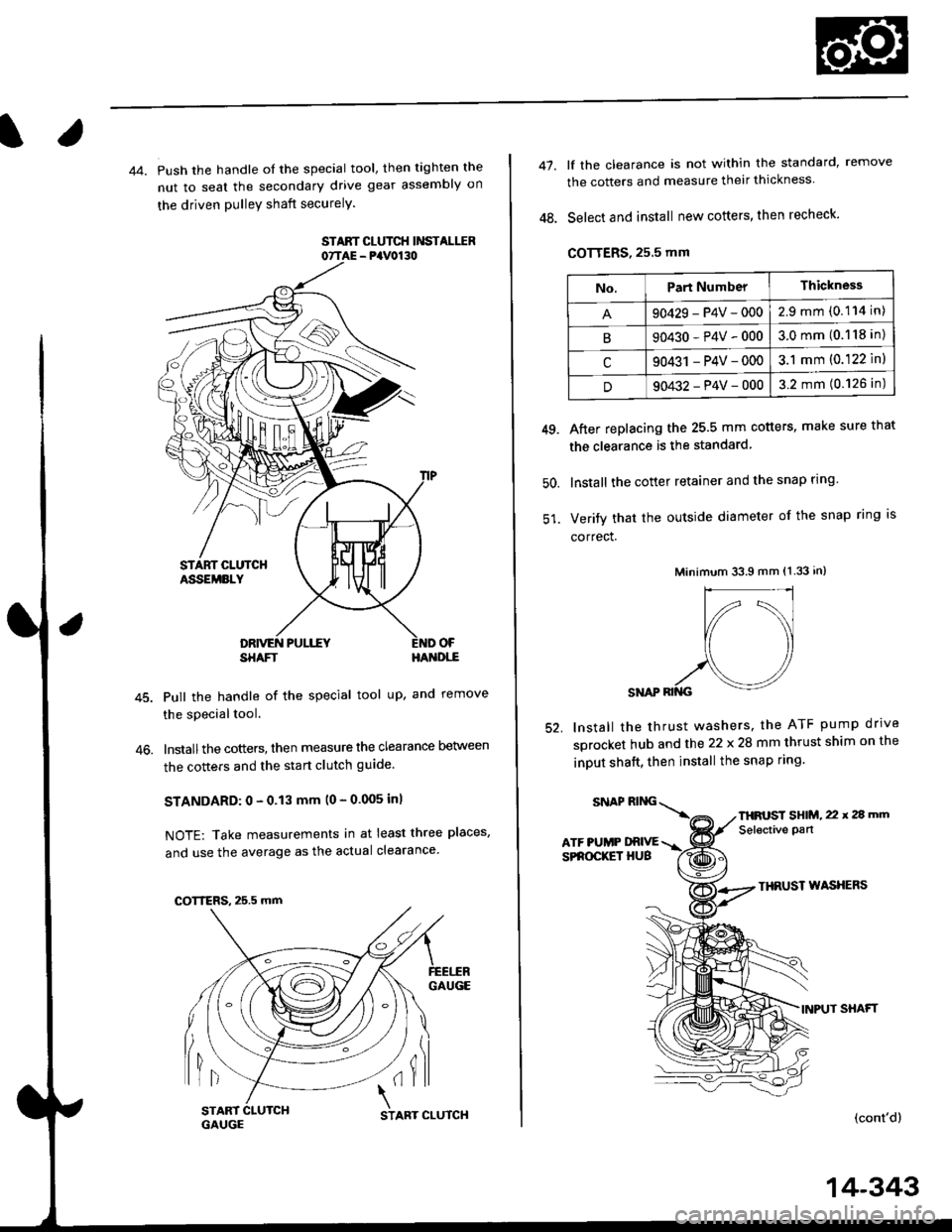

44. Push the handle of the special tool, then tighten the

nut to seal the secondary drive gear assembly on

the driven pulleY shaft securelY.

STAAT CLUTCH Ii'ISTALIIR07TAE - PaV0130

OF

46.

SHAFTHA'{DI,-E

Pull the handle of the special tool up, and remove

the special tool.

lnstallthe cotters, then measure the clearance Delween

the cotters and the start clutch guide

STANDARD: 0 - 0.13 mm (0 - 0.005 inl

NOTE: Take measurements in at least three places,

and use the average as the actual clearance

GAUGE

lil(il

COTTERS, 25.5 mm

START 1

GAUGCSTART CLUTCH

14-343

47.

48.

lf the clearance is not within the standard, remove

the cotters and measure their thickness

Select and install new cotters, then recheck.

COTTERS, 25.5 mm

After replacing the 25.5 mm cotters, make sure that

the clearance is the standard

lnstall the cotter retainer and the snap rlng

Verify that the outside diameter of the snap ring is

correct.

Minimum 33.9 mm (1.33 in)

SNAP RII{G

lnstall the thrust washers. the ATF pump drrve

sprocket hub and the 22 x 28 mm thrust shim on the

inDUt shaft, then install the snap ring.

49.

50.

52.

THRUST WASXERS

INPUT SHAFT

(cont'd)

No.Part NumberThickness

90429-P4V-0002.9mm(0.114 in)

B90430-P4V-0003.0mm(0.118 in)

c90431 -P4V-0003.1 mm (0.122 ln)

D90432-P4V-0003.2 mm (0.126 in)

SNAPRING\

ATF PUMP DRIVESPROCKET HUB

THFUST SHIM, 22 x 2a mm

Selective pan

Page 1455 of 2189

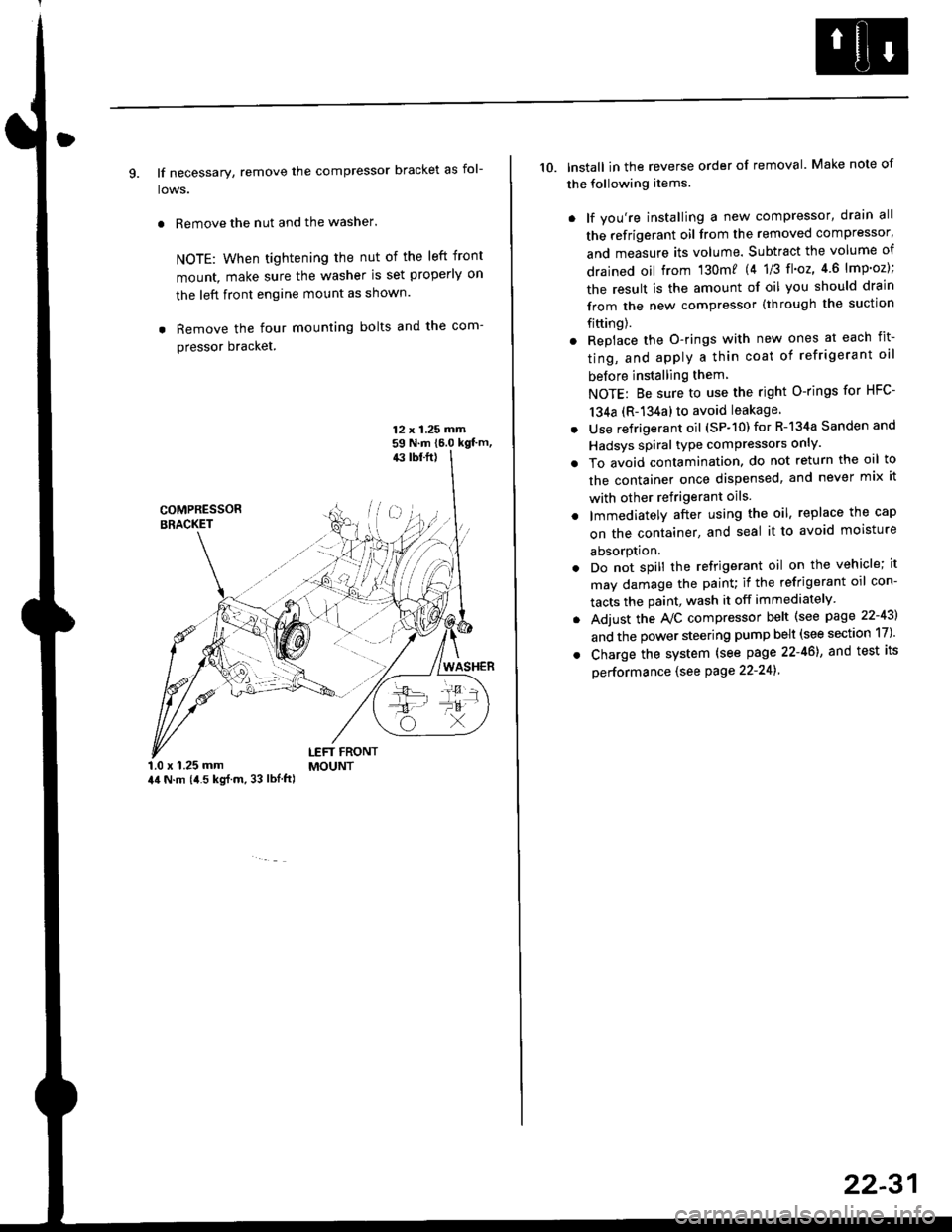

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

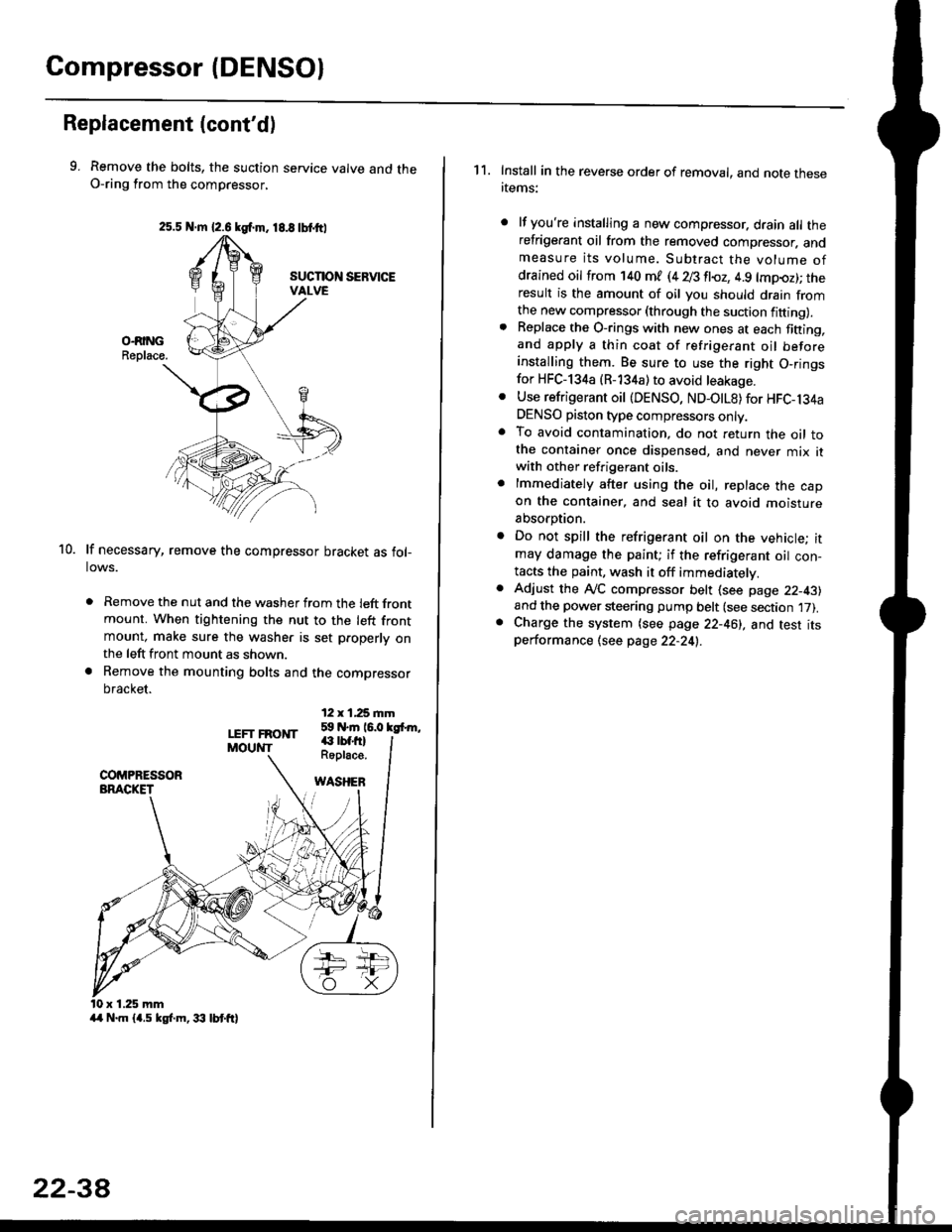

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..

Page 1535 of 2189

lr-

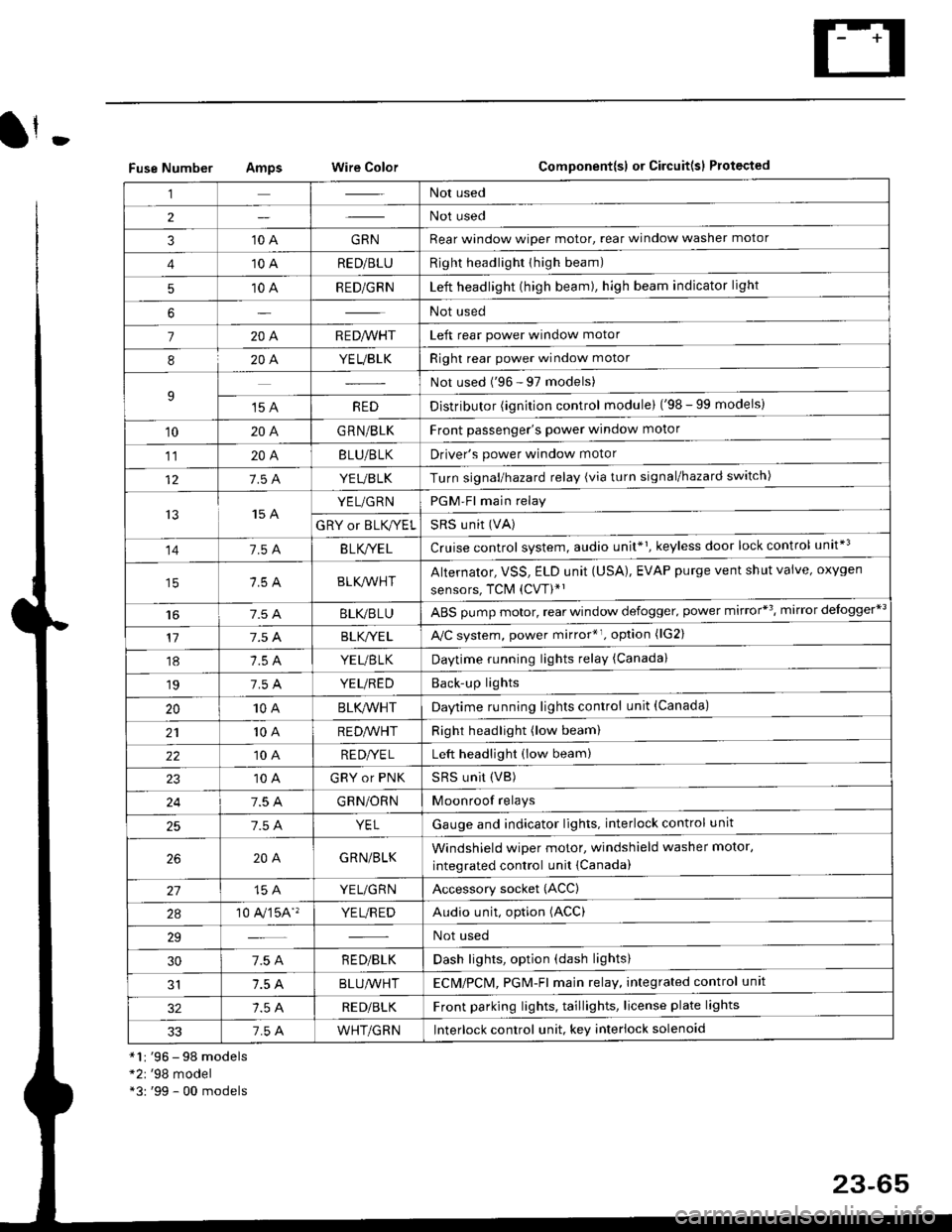

Fuse NumberAmpswire ColorComponent{sl or Circuit(sl Protected

*1r '96 - 98 models*2r '98 model*3: '99 - 00 models

,lNot used

2Not used

310 AGRNRear window wioer motor, rear window washer motor

410 ARED/BLURight headlighr thigh beam)

510 ARED/GRNLeft headlight (high beam), high beam indicator light

6Not used

7204R E D/VVHTLeft rear power window motor

820A.YEUBLKRight rear power window motor

9Not used ('96 - 97 models)

't5 AREDDistributor (ignition control module) ('98 - 99 models)

10204G RN/BLKFront passenger's power window motor

1120ABLU/BLKDriver's power window motor

127.5 AYEUBLKTurn signal/hazard relay (via turn signal/hazard switch)

t515 AYEL/GRNPGM-Fl main relay

GRY or BLK,^/ELSRS u nit (VA)

141.54B LK/YE LCruise control system, audio unit*1, keyless door lock control unit*3

BLK/lr'r'HTAlternator, VSS, ELD unit (USA), EVAP purge vent shut valve, oxygen

sensors, TCM (CVT)*'

t6BLI(,/BLUABS pump motor, rear window defogger. power mirror*3, mirror delogger*3

177.5 ABLK,/YE LA,/C system, power mirror*r. option (lG2)

18YEUBTKDaytime running lights relay (Canada)

197.5 AYEUREDBack'up lights

2010ABLK/VVHTDaytime running lights control unit (Canada)

2110 AREDA/VHTRight headlight (low beam)

2210 ARE DI/E LLeft headlight (low beam)

10 AGRY or PNKSRS UNit (VB)

247.5 AGRN/ORNMoonroof relays

257.5 AYELGauge and indicator lights. interlock control unit

204GRN/BLKWindshield wiper motor, windshield washer motor,

integrated control unit {Canada)

15 AYEL/GRNAccessory socket (ACC)

2a10 A,/'�]5A''YE L/R EDAudio unit, option (ACC)

29Not used

307.5 AR ED/BLKDash lights, option (dash lights)

1.5 ABLUA/VHTECM/PCl\4, PGM-Fl majn relay, integrated control unit

RED/BLKFront parking lights, taillights, license plate lights

337.5 AWHT/GRNlnterlock control unit. key interlock solenoid

23-65

Page 1688 of 2189

Wipers/Washers

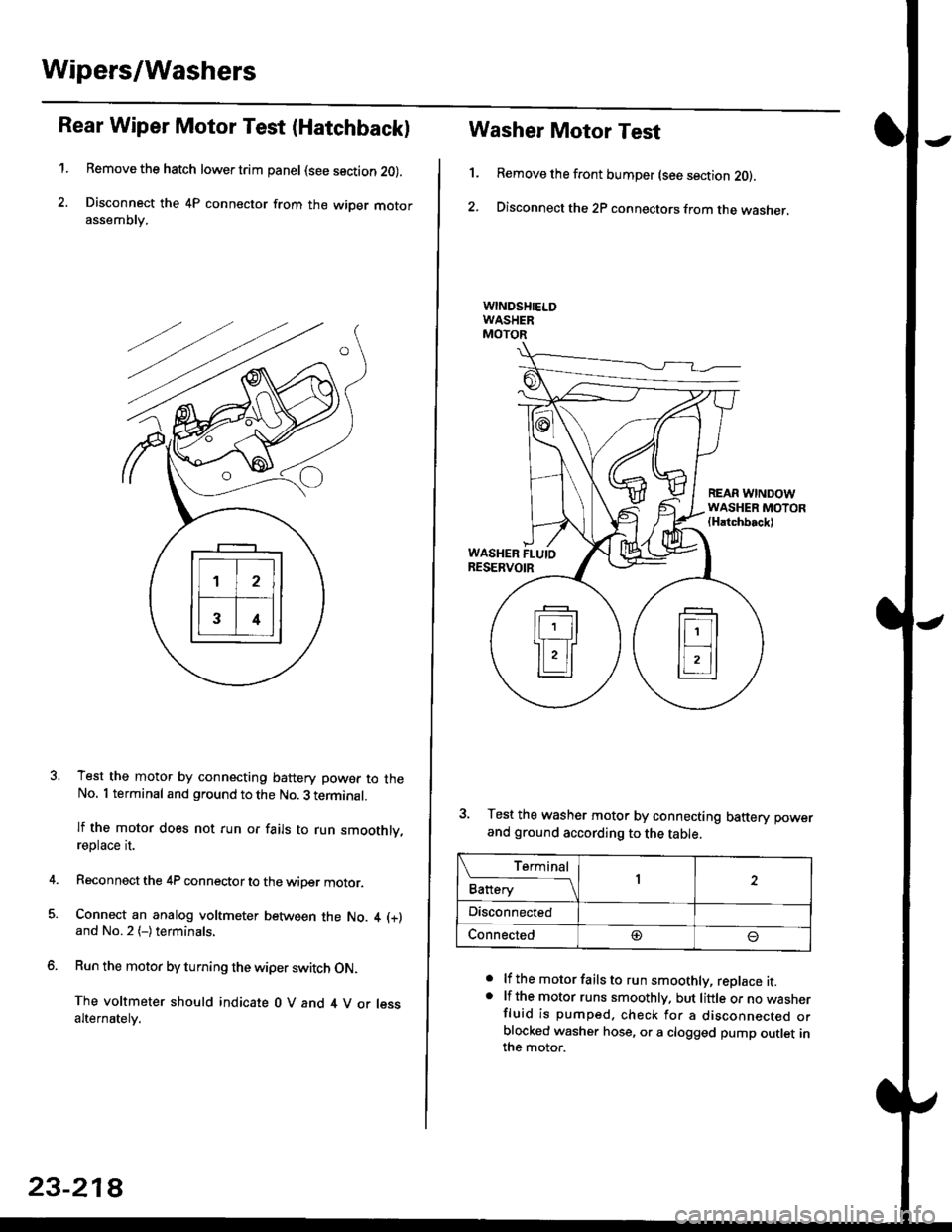

Rear Wiper Motor Test (Hatchback)

1.Remove the hatch lower trim panel (see section 20).

Disconnect the 4P connector from the wiper motorassemDry,

Test the motor by connecting battery power to theNo. 1 terminal and ground to the No. 3 terminal.

lf the motor does not run or fails to run smoothly,reptace rI.

Reconnect the 4P connector to the wiper motor.

Connect an analog voltmeter between the No. 4 (+)

and No.2 (-)terminals,

Run the motor by turning the wiper switch ON.

The voltmeter should indicate 0 V and 4 V or lessalternately.

23-218

1.

Washer Motor Test

Remove the front bumper (see section 20).

Disconnect the 2P connectors from the washer,

a

a

lf the motor fails to run smoothly, replace it.lf the motor runs smoothly. but little or no wasnerfluid is pumped. check for a disconnecr€o orblocked washer hose, or a clogged pump outlet inthe motor.

REAR WINDOWWASHER MOTOR(Hatchbackl

WASHER FLUIORESERVOIR

3. Test the washer motor by connecting battery power

and ground according to the table.

L f:,ry1Battery1

Disconnected

Connected@

Page 1835 of 2189

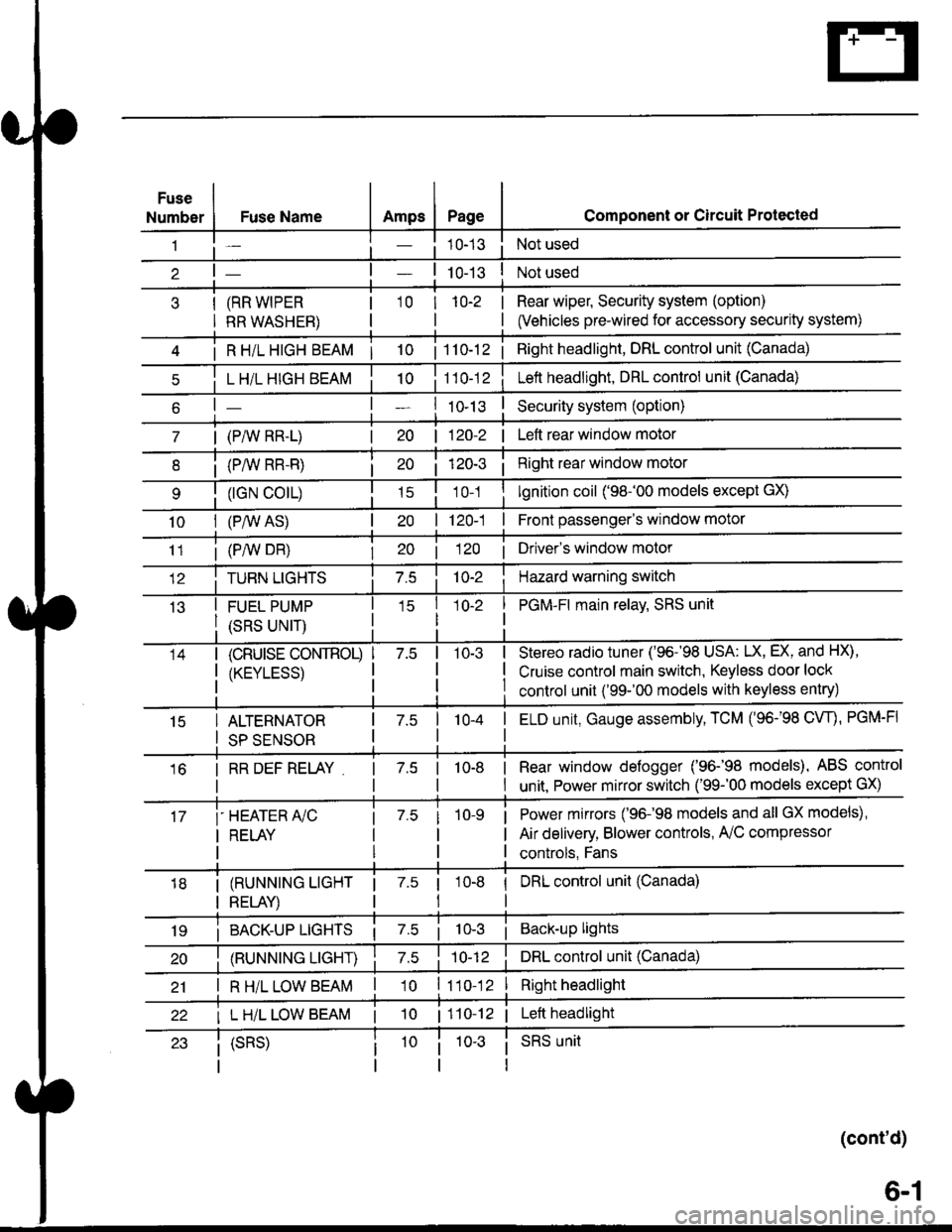

Fuse

NumberAmpsPageFuse Name

(RR WIPER

RR WASHER)

i R HiL HIGH BEAM | 10

L H/L HIGH BEAM

| (PAIV RR-L)

i (P/vv RR-R)

(rGN CO|L)

10I (P,^/V AS)

Component or Circuit Protected

Not used

Not used

Rear wiper, Security system (option)

(Vehicles pre-wired for accessory security system)

'10r 1n-2

I

| 1 10-12i Right headlight, DRL control unit (Canada)

Lett headlight, DRL control unit (Canada)

I ro-rsSecurity system (option)

| 120-2 | Left rear window motor

Right rear window motor

lgnition coil ('98-'00 models except GX)

| 120-1 | Front passenger's window motor

i (PiW DH)| 20 1 12O I Driver's window motor

TURN LIGHTSHazard warning switch

FUEL PUMP

(SRS UNIT)

PGM-FI main relav, SRS unit

(cRUrsE CoNTROL)

/KtrVt trSS\

Stereo radio tuner ('96-'98 USA: LX, EX, and HX),

Cruise control main switch, Keyless door lock

control unit ('99-'00 models with keyless entry)

15ALTERNATOR

SP SENSOR

l-a10-4I ELD unit, Gauge assembly, TCM (96-'98 CW, PGM-FI

16I RR DEF RELAY7.510-8I Rear window defogger ('96-'98 models), ABS control

I unit. Power mirror switch ('99-'00 models except GX)

i-HEATER r/C

I RELAY

Power mirrors ('96-98 models and all GX models),

Air delivery, Blower controls, AilC compressor

controls, Fans

I (RUNNING LIGHT

I RELAY)

1 7.5 1

tl

I DRL control unit (Canada)

i BACK-UP LTGHTSi Back-up lights

(RUNNING LIGHT)DRL control unit (Canada)

I R H/L LOW BEAM'10 l11o-12Right headlight

I L H/L LOW BEAM | 101110-12 | Left headlight

(cont'd)

(SRS)SRS unit

6-1

Page 1840 of 2189

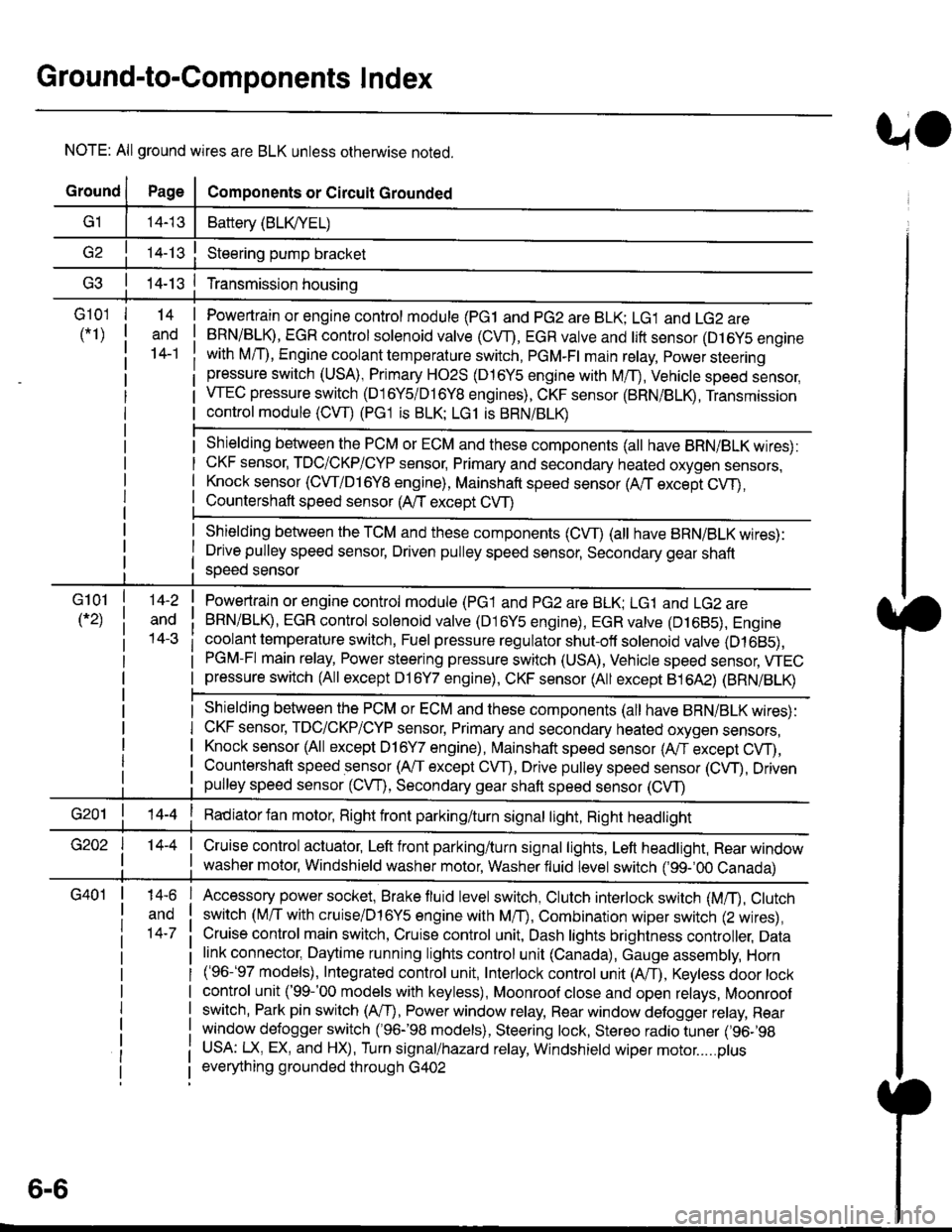

Ground-to-Components I ndex

f.,lONOTE: All ground wires are BLK unless otherwise noted.

GroundPageComponents or Circuit Grounded

Battery (BLKYEL)

Steering pump bracket

t+-rg ITransmission housing

l

G101

(-1)

G101

(-2)

14-2

and

14-3

ano

14-1

Powertrain or engine control module (PG1 and pG2 are BLK: LG1 and LG2 are

BRN/BLK), EGR control solenoid valve (CW, EGR valve and lift sensor (Dt6yS enginewith M,/T), Engine coolant temperature switch, pGM-Fl main relay, power steeringpressure switch (USA), Primary HO2S (D16Y5 engine with l\/,/T), Vehicle speed sensor,VTEC pressure switch (D16Y5/D16Y8 engines), CKF sensor (BRN/BLK), Transmission

control module (CYf) (Pc1 is BLK: LG1 is BRN/BLK)

Shielding betvveen the PCM or ECM and these components (all have BRN/BLK wires):

CKF sensor, TDC/CKP/CYP sensor. Primary and secondary heated oxygen sensors.

Knock sensor (CWDl6YB engine), Mainshaft speed sensor (AiT except CVT),

I Countershaft speed sensor (A/T except CVf)

Shielding between the TCM and these components (CVT) (all have BRN/BLK wires):

Drive pulley speed sensor, Driven pulley speed sensor, Secondary gear shaft

speed sensor

Powertrain or engine control module (PG1 and pG2 are BLK; LG1 and LGz are

BRN/BLK), EGR control solenoid valve (D16Y5 engine), EGR valve (Dt685), Engine

coolant temperature switch, Fuel pressure regulator shut-off solenoid valve (D1685),

PGM-FI main relay, Power steering pressure switch (USA), Vehicle speed sensor, VTECpressure switch (All except D16Y7 engine), CKF sensor (A

except 81642) (BRN/BLK)

Shielding between the PCM or ECM and these components (all have BRN/BLK wires):

CKF sensor, TDC/CKP/CYP sensor, Primary and secondary heated oxygen sensors,

Knock sensor (All except D16Y7 engine), i/ainshaft speed sensor (Arf except CW),

Countershaft speed sensor (A,/T except CVf), Drive pulley speed sensor (CW), Drivenpulley speed sensor (CVT), Secondary gear shaft speed sensor (CVf)

I Badiator fan motor, Right front parking/turn signat tight, Right headtight

G20214-4I Cruise control actuator, Left front parking/turn signal lights, Left headlight, Rear window

I washer motor, Windshield washer motor, Washer fluid level switch (,99-'00 Canada)

G401| +-o

and

14-7

Accessory power socket, Brake fluid level switch, Clutch interlock switch (M/T), Clutchswitch (lillT with cruise/D16Y5 engine with MfD, Combination wiper switch (Z wires),

Cruise control main switch, Cruise control unit, Dash lights brightness controller, Data

link connector, Daytime running lights control unit (Canada), Gauge assembly, Horn('96-'97 models), Integrated control unit, Interlock control unit (ArI), Keyless door lock

control unit ('99-'00 models with keyless), Moonroof close and open relays, Moonroof

switch, Park pin switch (A/r), Power window relay, Rear window defogger relay, Rear

window defogger switch ('96-'98 models), Steering lock, Stereo radio tuner (,96-,98

USA: LX, EX, and HX), Turn signal/hazard relay, Windshield wiper motor.....plus

everything grounded through G402

6-6