Accord HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 886 of 2189

Description

Hydraulic Control

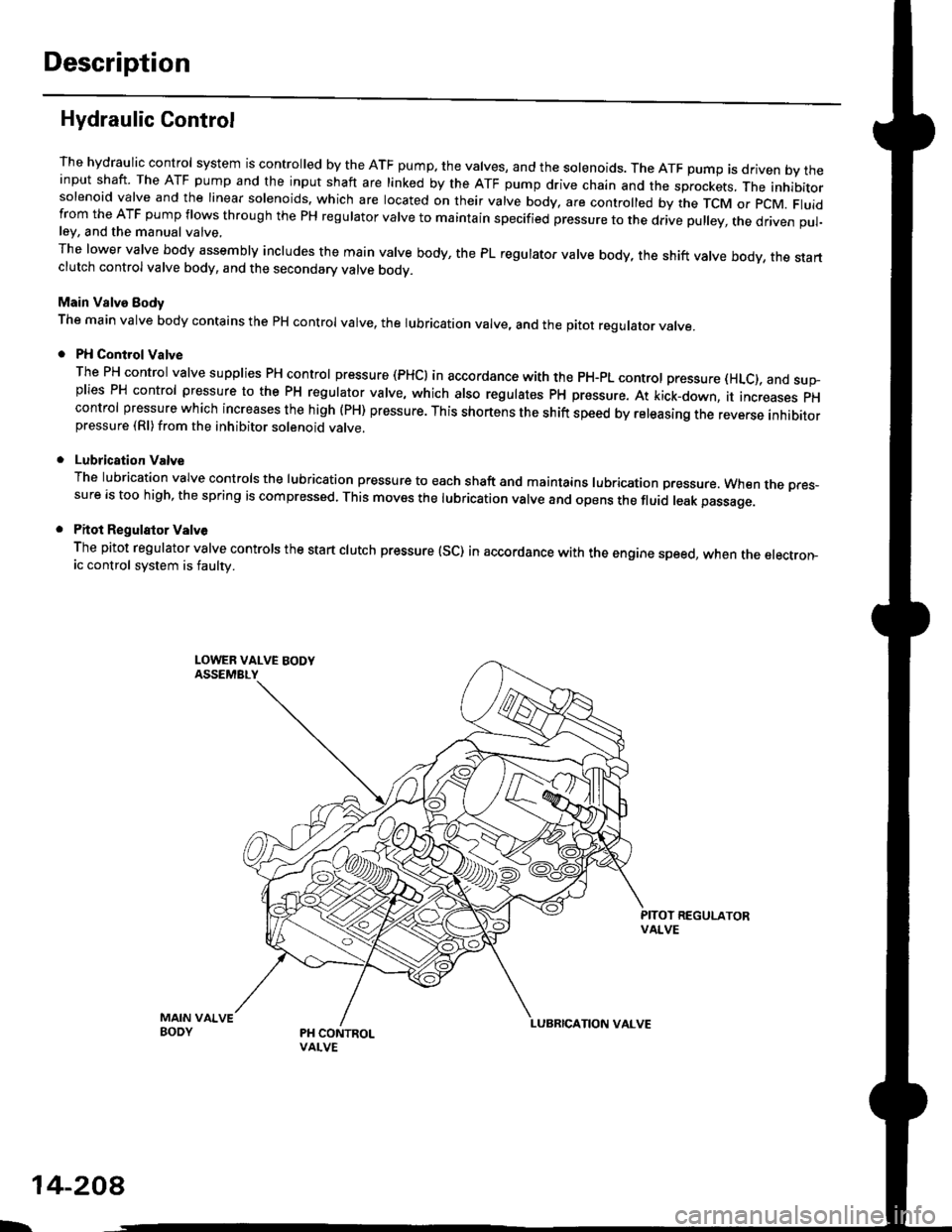

The hydraulic control system is controlled by the ATF pump. the valves, and the solenoids. The ATF pump is driven by theinput shaft. The ATF pump and the input shaft are linked by the ATF pump drive chain and the sprockets, The inhibitorsolenoid valve and the linear solenoids. which are located on their valve body, are controlled by the TCM or pcM. Fluidfrom the ATF pump flows through the PH regulator valve to maintain specified pressure to the drive pulley, the driven pul-ley, and the manual valve,

The lower valve body assembly includes the main valve body, the PL regulator valve body, the shift valve body, the startclutch control valve body, and the secondary valve bodv.

Main Valve Eody

The main valve body contains the pH control valve, the rubrication valve, and the pitot regulator valve.

PH Control Valve

The PH control valve supplies PH control pressure (PHCI in accordance with the pH-pL control pressure (HLc), and sup-plies PH control pressure to the PH regulator valve, which also regulatss PH pressure. At kick-down, it increases pHcontrol pressure which increases the high (PH) pressure. This shortens the shift speed by releasing the reverse inhibitorpressure (Rl)from the inhibitor solenoid valve.

Lubrication Valve

The lubrication valve controls the lubrication pressure to each shaft and maintains lubrication pressure. When rne pres-sure is too high, the spring is compressed. This moves the lubrication valve and opens the fluid leak passage.

Pitot Regulalor Valv6

The pitot regulator valve controls the start clutch pressure (SC) in accordance with the engine speed, when the electron-ic control system is faulw.

MAIN VAIVEBODY

L.

14-208

Page 888 of 2189

Description

Hydraulic Control {cont'dl

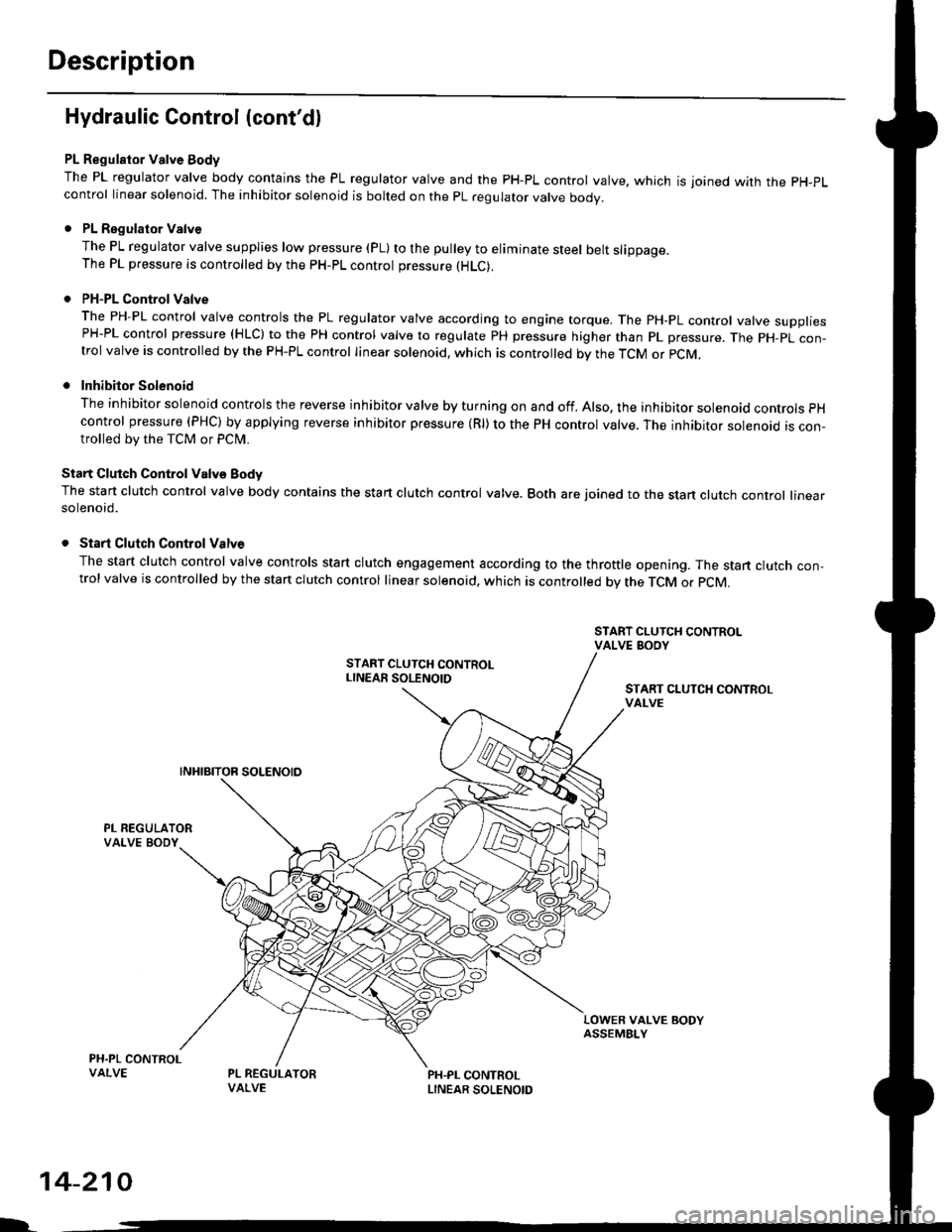

PL Regulator Valve Body

The PL regulator valve body contains the PL regulator valve and the PH-PL control valve. which is joined wirh the pH-pL

control linear solenoid. The inhibitor solenoid is bolted on the pL regulator valve body.

. PL Regulator Valve

The PL regulator valve supplies low p.essure (pL) to the pulley to eliminate steel belt slippage.The PL pressure is controlled by the pH-pL control pressure (HLC).

. PH-PL Control Valve

The PH-PL control valve controls the PL regulator valve according to engine torque. The PH-PL control valve suooliesPH-PL control pressure (HLC) to the PH control valve to regulate PH pressure higher than pL pressure. The pH-pL con-trol valve is controlled by the PH-PL control linear solenoid. which is controlled by the TcM or pcM,

. Inhibitor Solenoid

The inhibitor solenoid controls the reverse inhibitor valve by turning on and off. Also, the inhibitor solenoad controls pH

control pressure (PHC) by applying reverse inhibitor pressure (Rl) to the PH control valve. The inhibitor solenoid is con-trolled by the TCM or Pclvl.

Start Clutch Control Valv€ Body

The start clutch control valve body contains the start clutch control valve. Both are joined to the stan clutch control linearsolenoid.

. Start Clutch Control Valve

The start clutch control valve controls start clutch engagement according to the throttle opening. The start clutch con,trol valve is controlled by the stan clutch control linear solenoid, which is controlled bv the TCM o. pCM.

START CLUTCH CONTROLvAt-vE

LOWER VALVE BODYASSEMBI-Y

PH.PL CONTROLLINEAR SOLENOID

I.

14-210

Page 889 of 2189

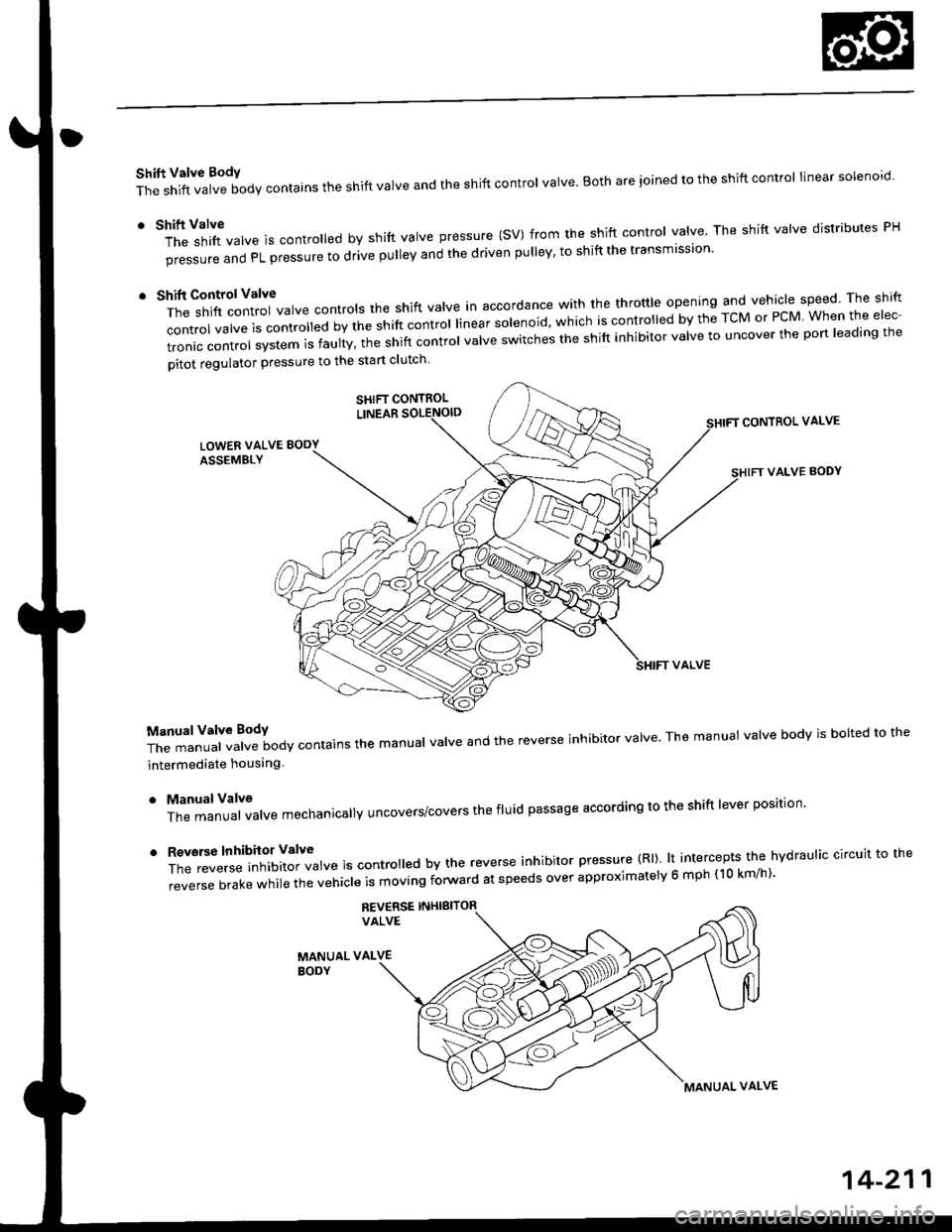

Shift Valve BodY

The shift valve body contains the shift valve and the shift control valve. Both are ioined to the shift control linear solenoro.

r tl'ft1il1rf"","" is controred by shift varve pressure (sV) from the shift contror varve. The shift varve distributes pH

pi""aur" "nO PL pressure to drive pulley and the driven pulley' to shift the transmission'

t t*"rilf:::lr';ivarve contrors the shift varve in accordance with the throttre opening and vehicle speed rhe shift

control valve is convorr"o uv ti" "iirt "ontrol linear solenoid, which is controlled by the TcM or PcM When the elec-

tronic control system is faulty, t;; snift controt uutue "witches the shift inhibitor valve to uncover the port leading the

pitot regulator pressure to the start clutch

CONTROL VALVE

VALVE BODY

T;J:"i"""1ff"t""ilody contains the manuar varve and the reverse inhibitor varve. The manuat varve bodv is borted to the

intermediate houslng

. ManualValve

The manual valve mechanicallY uncovers/covers the fluid passage according to the shift lever position'

'

ff:e;;;.'::'?Xftl::T",* is contro ed by the reverse inhibitor pressure (Rl). lt intercepts the hvdraulic circuit to the

reverse brake while the vehicle is moving forward at speeds over approximatelv 6 mph (10 km/h)'

REV€RSE INHIBITORVALVE

MANUAL VALVEBODY

SHIFT CONTROL

MANUAL VALVE

14-211

Page 913 of 2189

Troubleshooting Procedures

(cont'd)

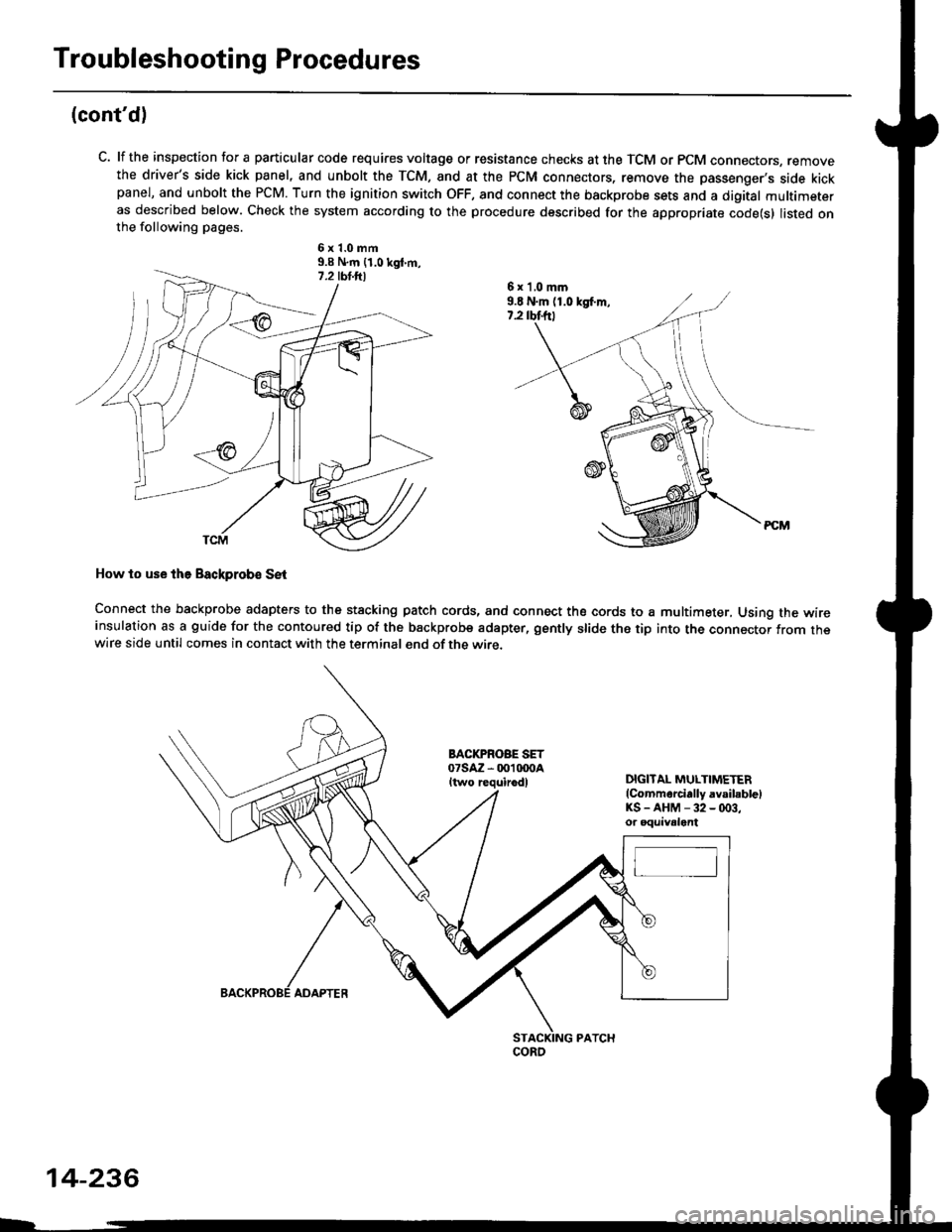

C. lf the inspection for a particular code requires voltage or resistance checks at the TCM or PCM connectors, removethe driver's side kick panel, and unbolt the TCM, and at the PCM connectors, remove the passenger's side kickpanel, and unbolt the PCM. Turn the ignition switch OFF, and connect the backprobe sets and a digital multimeteras described below. Check the system according to the procedure described for the appropriate code(s) listed onthe following pages.

6x1.0mm9.9 N.m {1.0 kgt m,

How to use lhe Backprob€ SE{

Connect the backprobe adapters to the stacking patch cords, and connect the cords to a multimeter, Using the wireinsulation as a guide for the contoured tip of the backprobe adapter, gently slide the tip into the connector from thewire side until comes in contact with the terminal end of the wire.

BACI(PROBE SET07saz - 001 txtoaItwo requirodlDIGITAL MULTIMETER(Commarcially avsibblelKS-AHM-32-(x)3,or oquivalent

6 x 'l,0 mm9.E N.m (1.0 kgf.m,7.2 rbtftt

coRo

14-236

ADAPTER

Page 916 of 2189

lf the self-diagnostic E indicator light does not blink, perform an inspection according to the table below.

SymptomInspectionRef. page

E indicator light does not come on for two seconds after ignition switch

is first turn on (ll).14-262

E indicator light is on constantly (not blinking) whenever the ignition

switch is on (ll).14-264

NOTE:

. lf a customer described the symptom for code P1706 (6), it will be necessary to recreate the symptom by test driving,

then recheck the DTC.

. Sometime the E indicator light and the Malfunction Indicator lamp (MlL) may come on simultaneously. lf so, repair the

pGM-Fl system according to the DTc, then reset the memory by removing the BACK uP fuse in the under-hood

fuse/relay box for more than 10 seconds. Drive the vehicle for several minutes at a speed over 30 mph (50 km/h)' then

recheck the DTC.

14-239

Page 918 of 2189

lf the self-diagnostic E indicator light does not blink. perform an inspection according to the table below.

SYmPtom

IDI indicator light does not come on for two seconds after ignition switch

is first turned ON (ll).

lE1 indicator light is on constantly (not blinking) whenever the ignition

switch is ON { ll).

InspectionRef. page

14-284

14-290

NOTE:

. lf a customer described the symptom for code Pl706 (6), it will be necessary to recreate the symptom by test driving,

then recheck the DTC.

. iometimes, tfre E indicator light and the Malfunction Indicator lamp (MlL) may come on simultaneously lf so, repair

the PGM-Fl system accordrng to the DTC, then reset the memory by removing the BACK UP RADIO fuse in the under-

hood fuse/relay box for more than 10 seconds. Drive the car for several minutes at a speed over 30 mph {50 km/h)' then

recheck the DTC.

14-241

Page 1076 of 2189

System Description

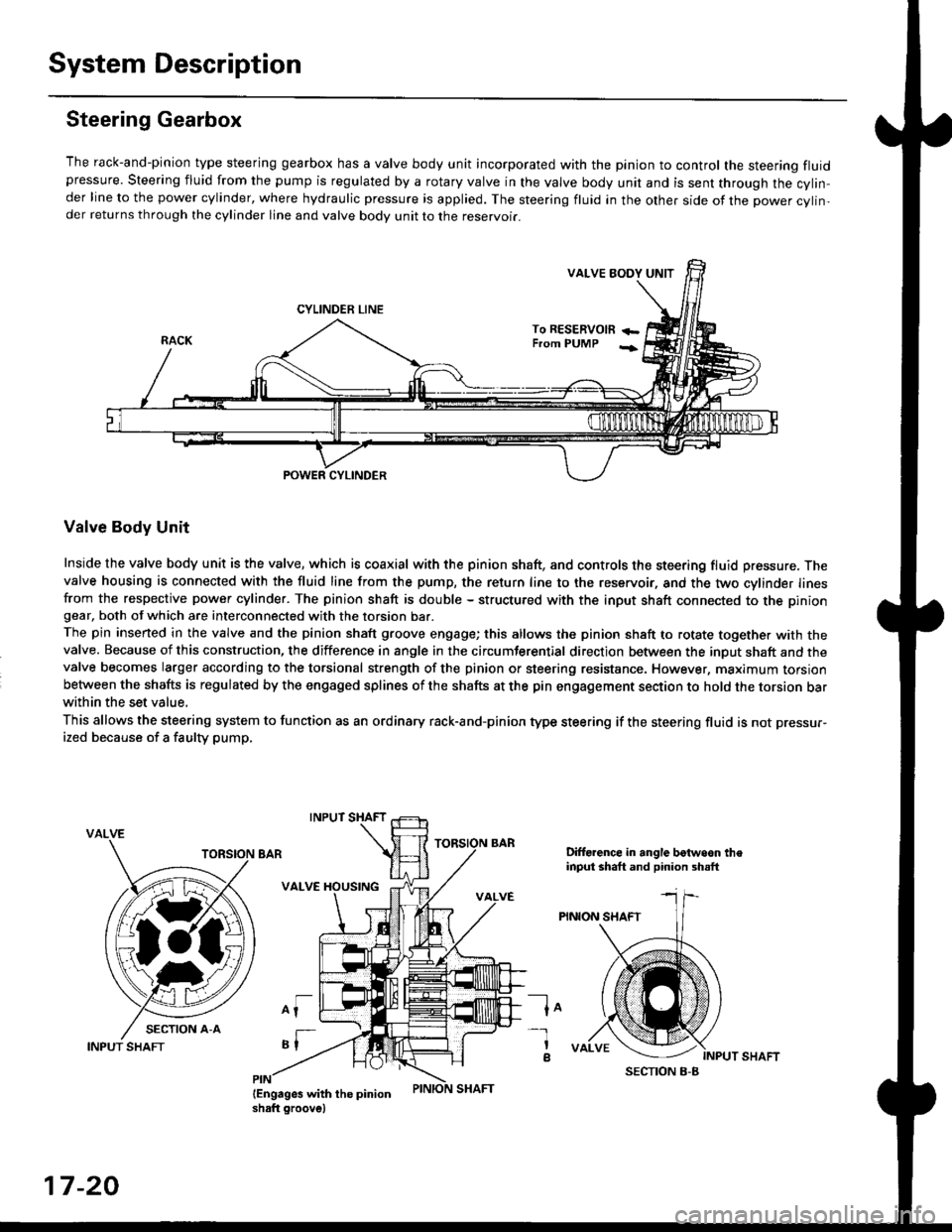

Steering Gearbox

The rack-and-pinion type steering gearbox has a valve body unit incorporated with the pinion to control the steering fluidpressure. Steering fluid from the pump is regulated by a rotary valve in the valve body unit and is sent through the cylin,der line to the power cylinder, where hydraulic pressure is applied. The steering fluid in the other side of the power cylin,der returns through the cylinder line and valve body unit to the reservoii.

VALVE EODY UNIT

CYLINDER LINE

To RESERVOm +-From PUMP -;

POWER CYLINDER

Valve Body Unit

Inside the valve body unit is the valve, which is coaxial with the pinion shaft, and controls the steering fluid pressure. Thevalve housing is connected with the fluid line from the pump, the return line to the reservoir, and the two cylinder linesfrom the respective power cylinder. The pinion shaft is double - structured with the input shaft connected to the piniongear, both of which are interconnected with the torsion bar.

The pin inserted in the valve and the pinion shaft groove engage; this allows the pinion shaft to rotate together with thevalve. Because of this construction, the difference in angle in the circumferential direction between the input shaft and thevalve becomes larger according to the torsional strength of the pinion or steering resistance. However, maximum torsionbetween the shafts is regulated by the engaged splines of the shafts at the pin engagement section to hold the torsion barwithin the set value,

This allows the steering system to function as an ordinary rack-and-pinion type steering if the steering fluid is not pressur-

ized because of a faulty pump,

VALVE

Difforence in angle botwoon theinput shaft and pinion shsft

PINION SHAFT

lo

INPUT SHAFT

-l

a

17-20

INPUT SHAFT

Page 1142 of 2189

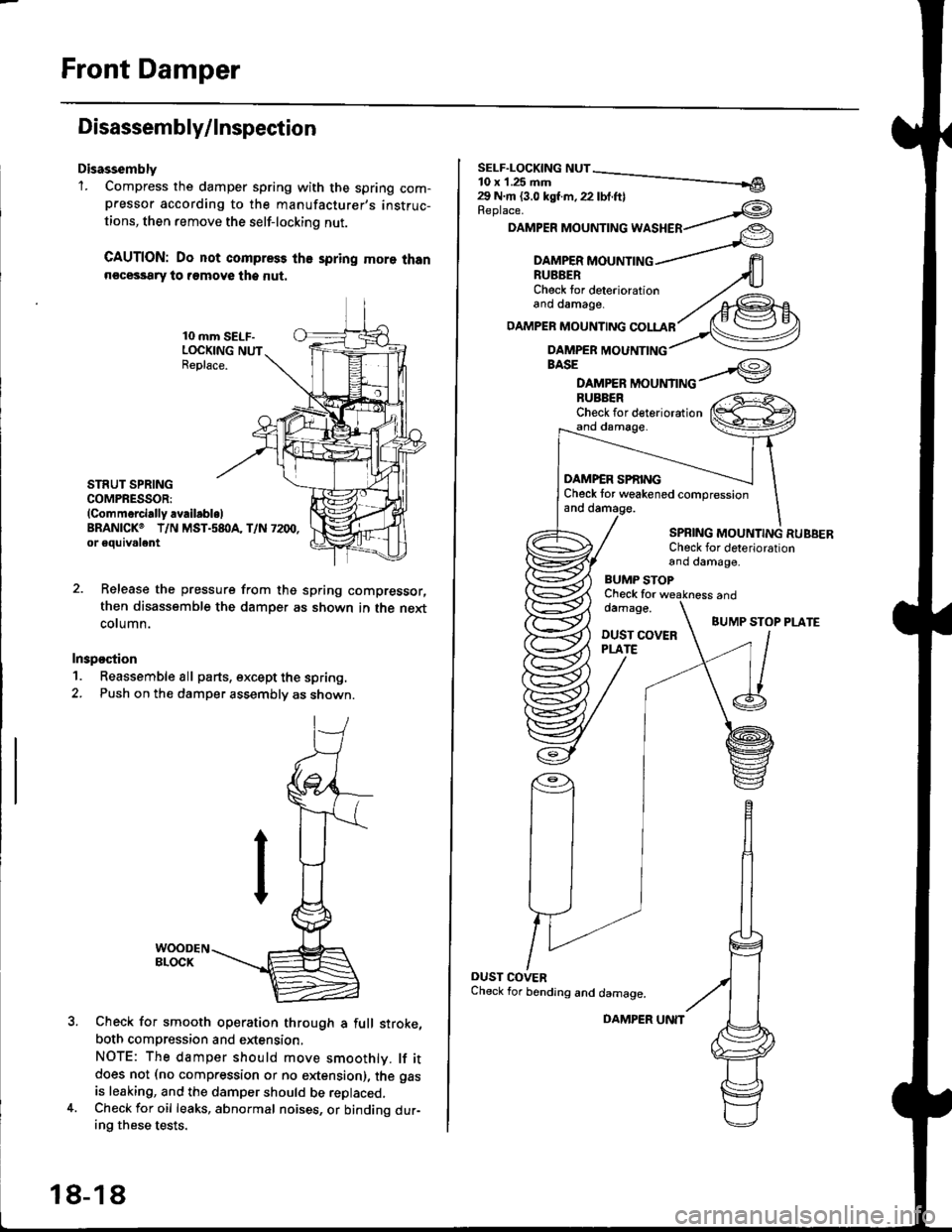

Front Damper

Disassembly/lnspection

Disassembly'1. Compress the damper spring with the spring com-pressor according to the manufacturer,s instruc-

tions, then remove the self-lockino nut.

CAUTION: Do not compress the spring more thann€cessary to remove the nut.

10 mm SELF-LOCKING NUTReplace.

STRUT SPRINGCOMPRESSOR:(Commerci.lly availabl.lBRANICKO T/N MST.s8I}A, T/N 7200,or eouivalent

Release the pressure from thg spring compressor,

then disassemble the damper as shown in the next

column.

Inspostion

1. Reassemble all parts, except the spring.

2. Push on th€ damper assembly as shown.

Check for smooth operation through a full stroke,

both compression and extension,

NOTE: The damper should move smoothlv. lf itdoes not (no compression or no extension), the gas

is leaking, and the damper should be replaced.Check for oil leaks, abnormal noises, or binding dur-ing these tests.

18-18

DAMPER UNIT

Replace.

DAMPER MOUNTING WASHER

BASE

DAMPER MOUNTINGBUBBERCheck for deteriorationand damage.

DAMP€R SPf,INGCheck tor weakened compressionand damage.

SPBING MOUNTING RUBBERCheck for deteriorationand damage,

BUMP STOPCheck fordamage.

DUST COVERPLATE

and

BUMP STOP PLATE

OUST COVERCheck for bending and damage.

Page 1151 of 2189

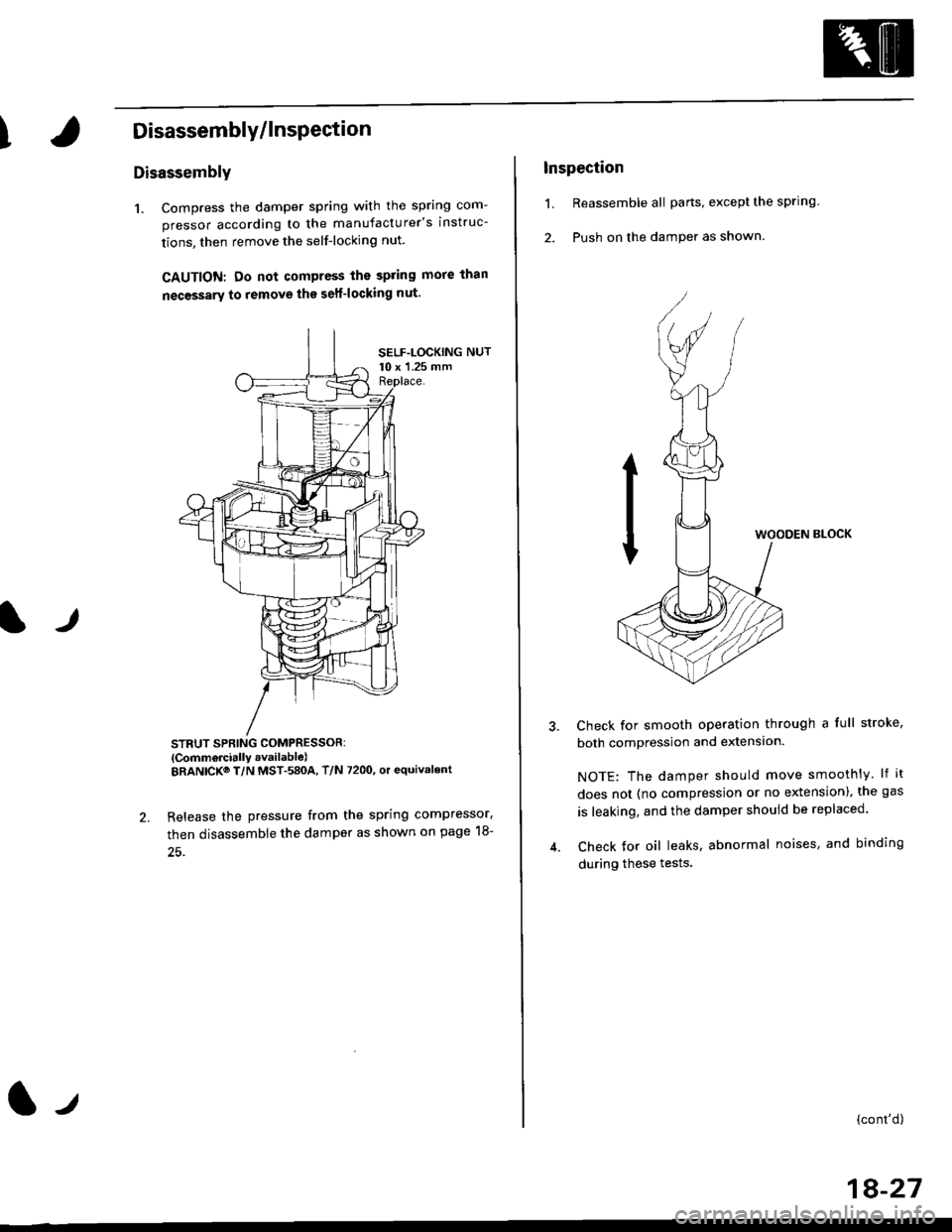

IDisassembly/lnsPection

lr

Disassembly

1. Compress the damper spring with the spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut.

GAUTION: Do not compress the spring more than

necessary to remove the sell-locking nut.

STNUT SPRING COMPRESSOR:

lComm6rcially .vailablelERANICKo T/N MST-580A, T/N 7200, or equivalent

Release the pressure from the spring compressor.

then disassemble the damper as shown on page 18-

(|-r

lnspection

1. Reassemble all parts, except the sprlng.

2. Push on the damPer as shown.

WOODEN BLOCK

Check for smooth operation through a full stroke,

both compression and extension.

NOTE: The damper should move smoothly lf it

does not (no compression or no extension), the gas

is leaking, and the damper should be replaced.

Check Jor oil leaks, abnormal noises, and binding

during these tests.

{cont'd)

18-27

Page 1202 of 2189

L

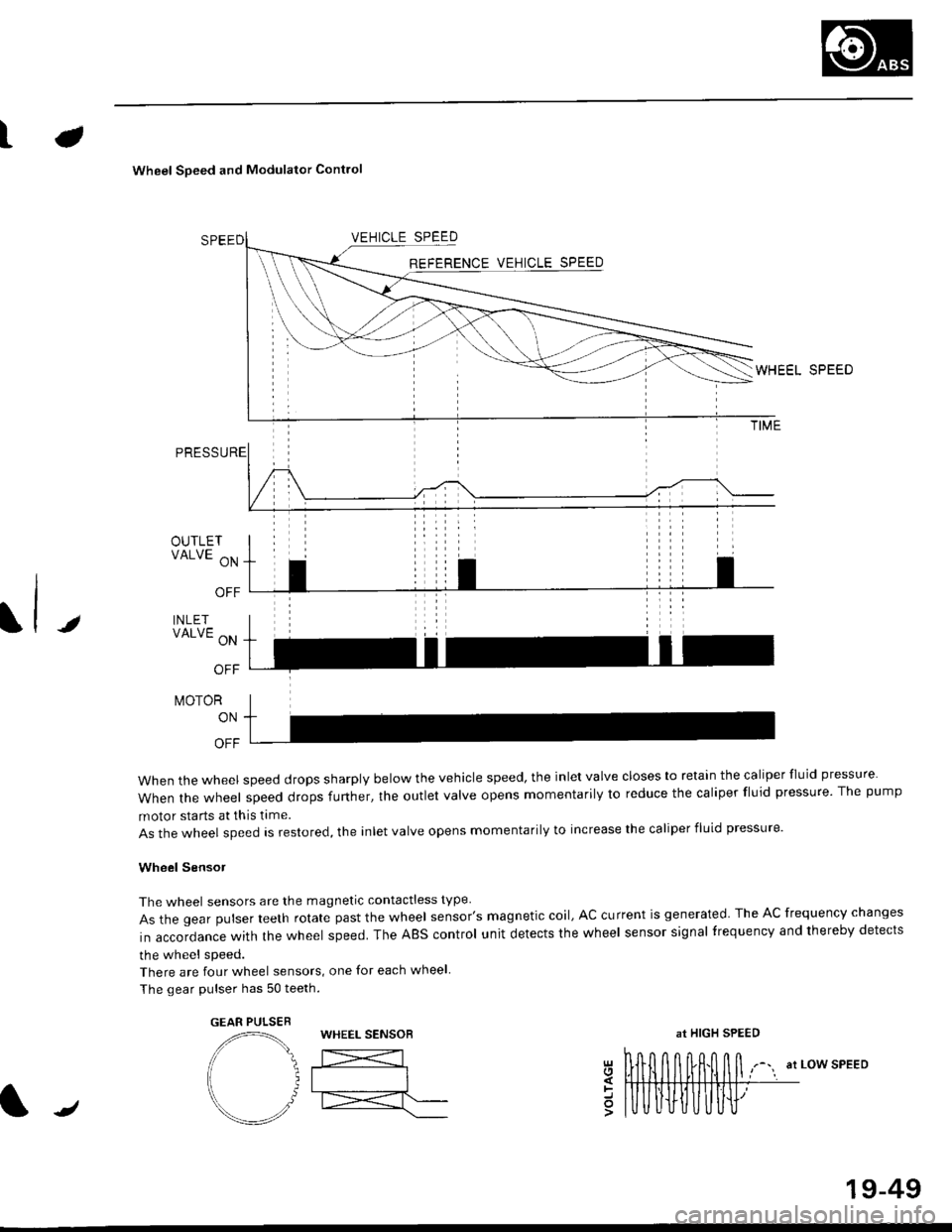

Wheel Soeed and Modulator Contlo

t

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

t\,40ToR

ON

OFF

when the wheel speed drops sharply below the vehicle speed, the inlet valve closes to retain the caliper fluid pressure

When the wheel speed drops further, the outlet valve opens momentarily to reduce the caliper fluid pressure. The pump

motor starts at this time.

As the wheel speed is restored, the inlet valve opens momentarily to increase the caliper fluid pressure.

Wheel SensoJ

The wheel sensors are the magnetic contactless type

As the gear pulser teeth rotate past the wheel sensor's magnetic coil, AC current is generated The AC frequency changes

in accordance with the wheel speed. The ABS control unit detects the wheel sensor signal frequency and thereby detects

the wheel speed.

There are four wheel sensors, one for each wheel

The gear pulser has 50 teeth.

EEL SPEED

at LOW SPEEDgl

=o

GEAR PULSEBWHEEL SENSOBat HIGH SPEED

/

19-49