Elect HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 202 of 2189

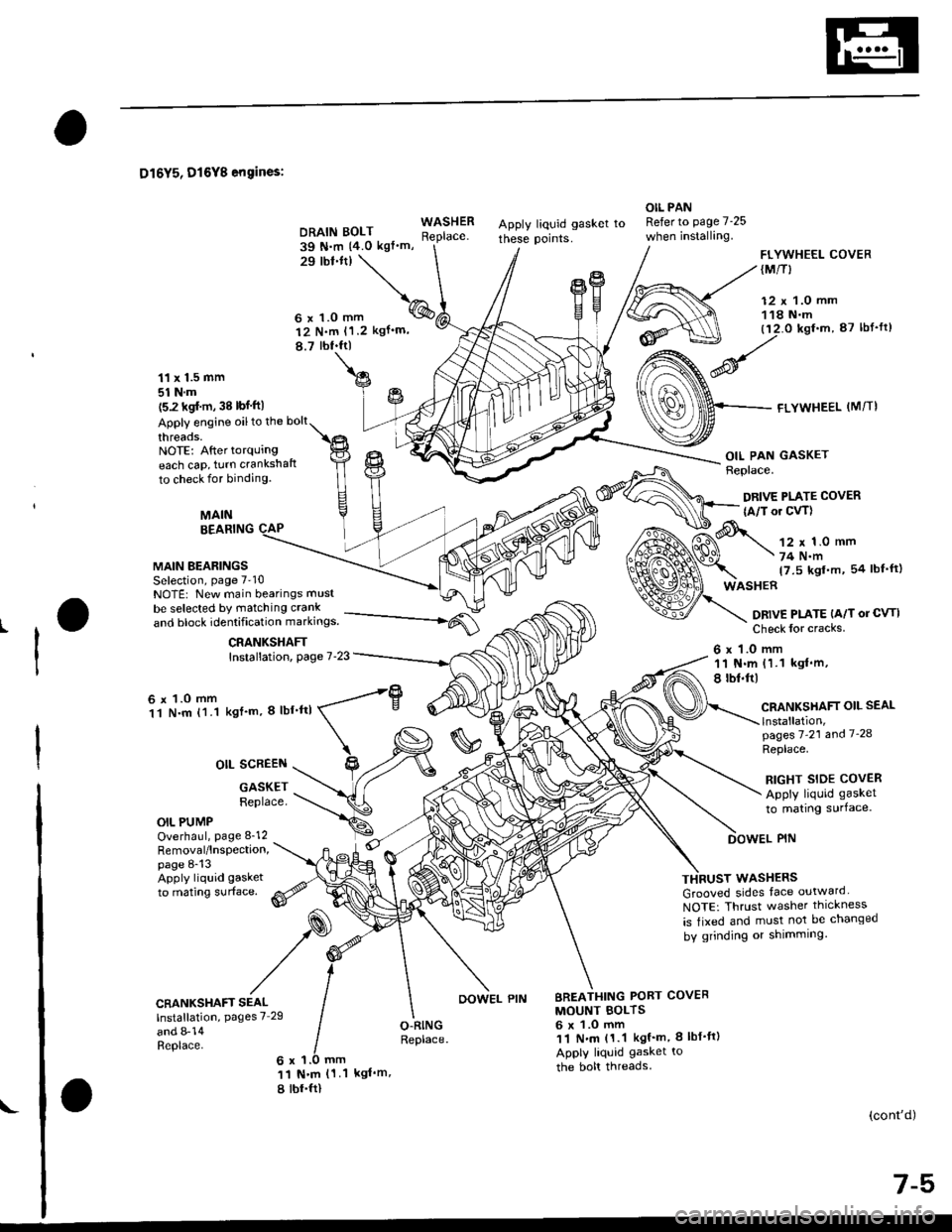

D16Y5, D16Y8 engines:

DRAIN BOLT39 N.m 14.0 kgt'm,

Apply liquid gasket to

these points.

OIL PANRefer to page 7-25

when installing.WASHERReplace.

29 lbl.tt)

\

\^

6 x 1.0 mm q%

P

I

FLYWHEEL COVER(M/T}

12 x 1.0 mm118 N.m(12.0 kgt.m, 87 lbt'ft)

FLYWHEEL (M/TI

t2 N.m 11.2 kgf'm,

8.7 lbl.ftl

11 x 1.5 mm

51 N.m(5.2 kgf'm, 38 lbf ftl

Apply engine oiltothe bolt

threads.NOTE: Aftertorquingeach cap, turn crankshaft

to check for binding.

MAINBEARING

MAIN BEARINGSSelection, page 7-10NOTE: New main bearings must

be selected by matching crank

"nJ lr."i io"irriti"",ion-markings. --------*-i6{\

CRANKSHAFTInstallation, page 7-23

6 r 1.0 mm11 N.m (1 1 kgf'm, I lbf'ttl

OII PAN GASKETReplace.

DRIVE PLATE COVER

{A/T or CVT)

12 r 1.0 mm

74 N.m

17.5 kgl.m, 54 lbf'ft)

DBIVE PLATE {A/T or CVTI

Check for cracks

6 x 1.O mm11 N.m {1.1 kgl'm,

8 tbl.ftl

CRANKSHAFT OIL SEAL

lnstallation,pages 7'?1 and '1 '28

Replace.

RIGHT SIDE COVER

Apply liquid gasket

to mating surface.

OIL SCREEN

GASKETReplace.

OIL PUMPOverhaul, page 8_12Removal/lnspection,page 8-13Apply liquid gasket

to mating surface.

DOWEL PIN

WASHEFS

Grooved sides tace outward

NOTE: Thrust washer thickness

is fixed and must not be changed

bV grinding or shimming.

CRANKSHAFT SEALInstallation, pages 7 29

and 8-14Replace.

BREATHING PORT COVER

MOUNT BOLTS6 x 1.O mm11 f{..n (1.1 kgf'm, 8 lbf'fl)

Apply liquid gasket to

the bolt threads.

O.RINGReplace.

6 x 1.0 mm

11 N.m (1 1 kgl'm,

8 tbr.ftl

(cont'd)

7-5

\

OOWEL PIN

Page 203 of 2189

lllustrated Index

(cont'd)

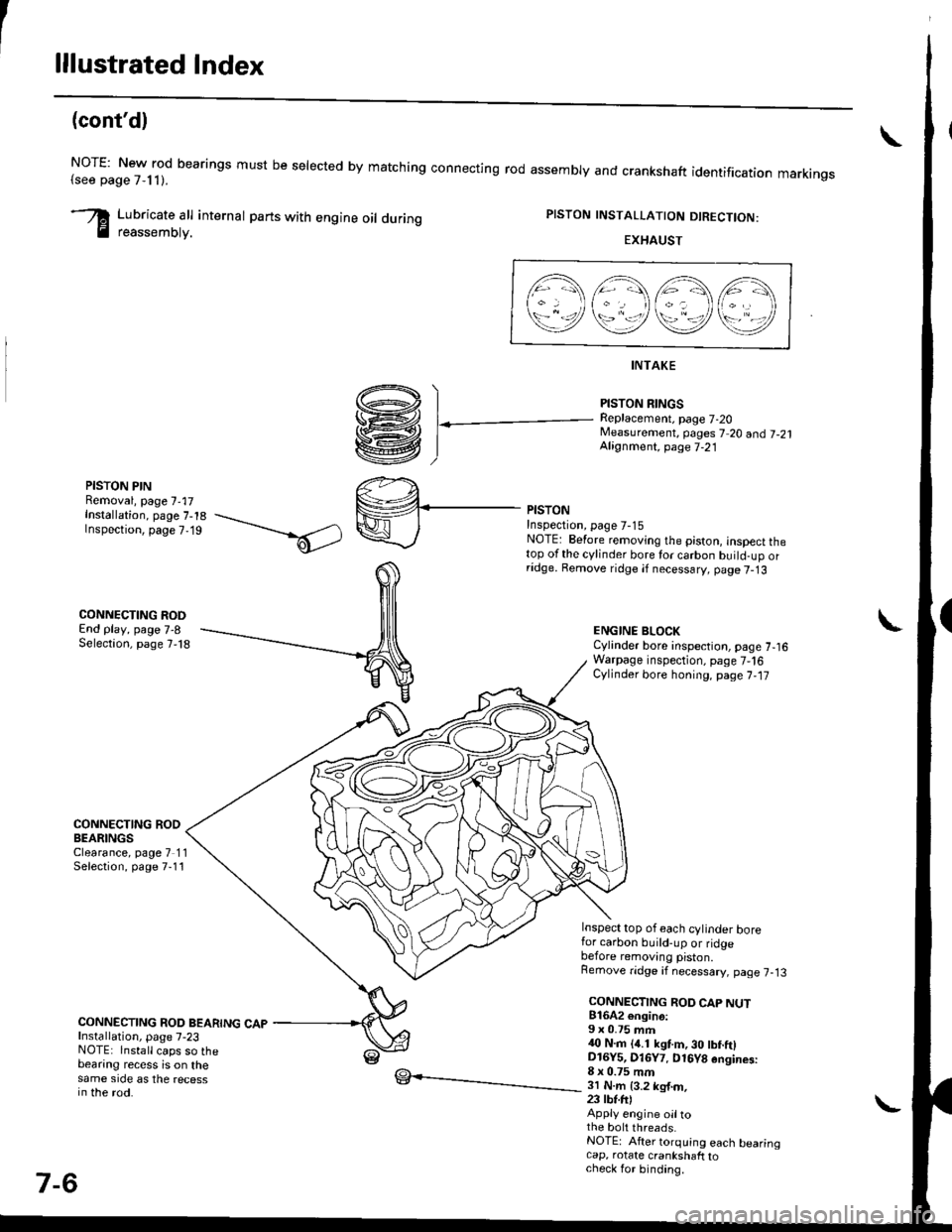

NOTE: New rod bearings must be selected by matching connecting rod assembly and crankshaft(see page 7,11).identification markings

Lubricate all internal parts with engine oil duringreassembtv.

PISTON INSTALLATION DIRECTION:

EXHAUST

4\/=\6\z\

\e/!rqrf/

INTAKE

PISTON RINGSReplacement. page 7-20Measurement, pages 7 20 andj-21Alignment, page 7-21

PISTON PINRemoval, page 7,17Installation, page 7-18Inspection, page 7,19

CONNECTING RODEnd play, page 7-8Selection, page 7,18

CONNECTING RODBEARINGSClearance, page 7 11Selection, page 7-11

CONNECTING ROD BEARING CAPInstallation, page 7-23NOTE: lnstall caps so thebearing recess is on thesame side as the recessin the rod.

PISTONInspectron, page 7-15NOTE: Betore removing the piston, inspect thetop of the cylinder bore for carbon build-up orridge. Bemove ridge if necessary, page 7-13

ENGINE BLOCKCylinder bore inspection, page 7-16Warpage inspection, page 7,'16Cylinder bore honing, page 7,17

Inspect top of each cylinder borefor carbon build-up or ridgebefore removing piston.Remove ridge if necessary, page 7-13

CONNECTING ROD CAP NUT816A2 €ngin6:9 x 0.75 mm{0 N.m (4.1 kgt m, 30 tbf.ftlD16Y5, Dl6Y7. D16Y8 engines:8 x 0.75 mm3l N.m {3.2 kg{.m,23 tbt.fr)Apply engine oiltothe bolt threads.NOTE: After torquing each bearingcap, rotate crankshaft tocheck for binding.

7-6

Page 206 of 2189

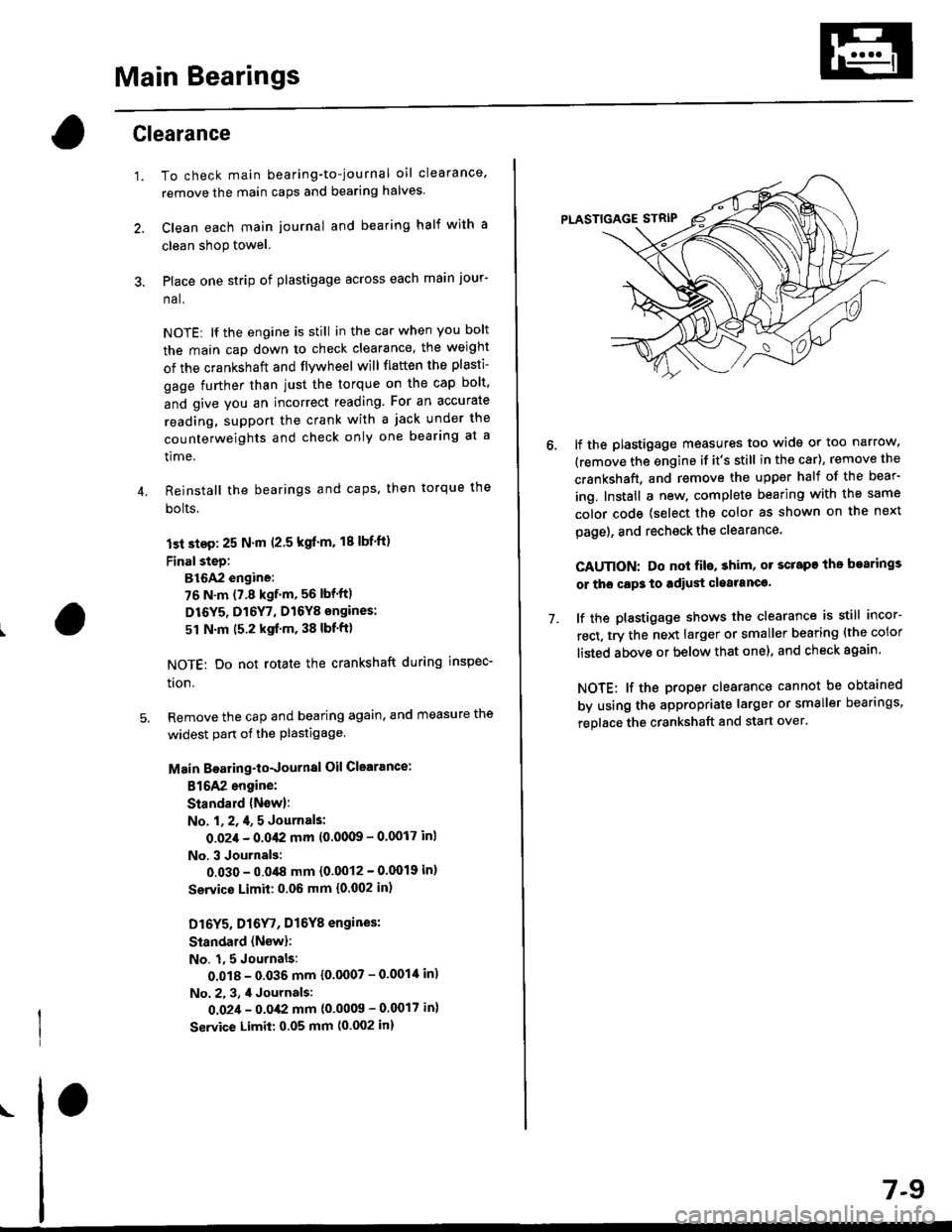

Main Bearings

4.

Glearance

1.To check main bearing-to-journal oil clearance.

remove the main caps and bearing halves.

Clean each main journal and bearing half with a

clean shop towel.

Place one strip of plastigage across each main jour-

na l.

NOTE: lf the engine is still in the car when you bolt

the main cap down to check clearance, the weight

of the crankshaft and flvwheel will flaften the plasti-

gage further than just the torque on the cap bolt.

and give you an incorrect reading. For an accurate

reading, support the crank with a jack under the

counterweights and check only one bearing at a

time,

Reinstall the bearings and caps, then torque the

bolts.

lst step: 25 N'm (2.5 kgl'm. 18 lbf'ft)

FinalsteD:

B16A2 engine:

76 N.m (7.8 kgf.m, 56 lbf'ft)

D16Y5, Dl6Y7, D16Y8 engines:

51 N.m (5.2 kgf'm, 38 lbf'ft)

NOTE: Do not rotate the crankshaft during inspec-

tron.

Remove the cap and bearing again, and measure the

widest part ot the plastigage.

Main Boaring-toJournal Oil Clearance:

816A2 engine:

Standald {New}:

No. l, 2, 4, 5 Journals:

O.O2,l - 0.042 mm 10'00(B - 0.0017 in)

No. 3 Journals:

0.030 - 0.048 mm {0'0012 - 0'0019 in)

Servico Limit: 0.06 mm {0.002 in,

Dl6Y5, Dl6

r, Dl6Y8 engines:

Standard (Nsw):

No. 1,5 Journals:

0.018 - 0.035 mm {0.0007 - 0'001'[ in)

No. 2. 3, 4 Journals:

0.02,1 - 0.0,(2 mm {0'0009 - 0.0017 in}

Service Limit: 0.05 mm (0.002 in)

\

7-9

7.

lf the plastigage measures too wide or too narrow,

(remove the engine if it's still in the car), remove the

crankshaft, and remove the upper half of the bear-

ing. Install a new. complete bearing with the same

color code {select the color as shown on the next

page), and rechsck the clearance.

CAUTION: Do nol fil€, shim, or scrape the bearings

or tho cap3 to adiust cleatanc€.

lf the plastigage shows the clearance is still incor-

rect, try the next larger or smaller bearing (the color

listed above or below that one), and check again

NOTE: lf the proper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

Page 207 of 2189

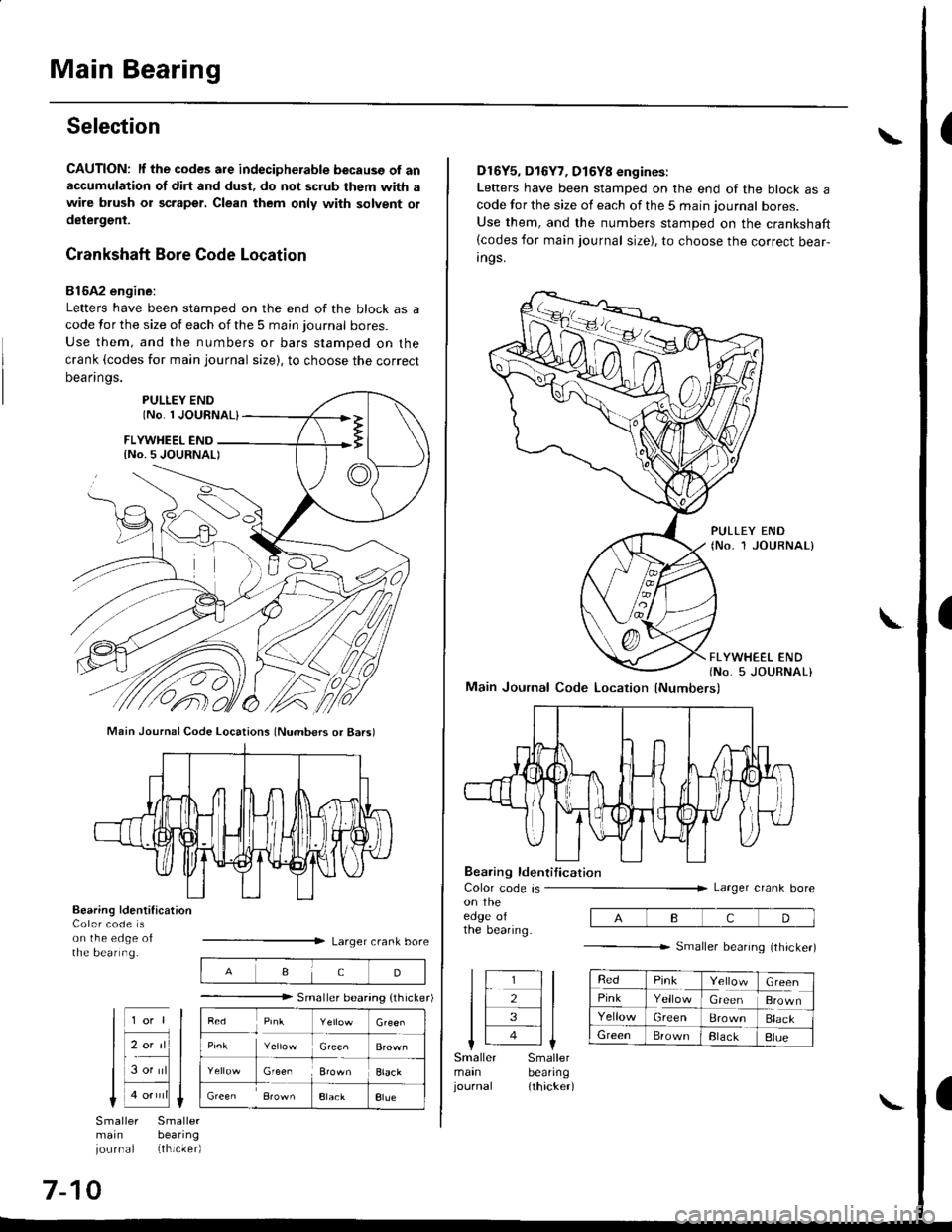

Main Bearing

Selection

CAUTION: lf the codes are indecipherable because of anaccumulation of dirt and dust, do not scrub them with a

wire brush or scraper. Clean them only with solvent ol

deiergent.

Crankshaft Bore Code Location

81642 engine:

Letters have been stamped on the end of the block as acode for the size of each of the 5 main journal bores.

Use them, and the numbers or bars stamped on the

crank {codes for main journal size), to choose the correct

beaflngs.

Main JournalCode Locations {Nombers or Barc)

Eearing ldentificationColor code rson lhe edge ofthe bear ng.Larger crank bore

acD

-----------""' Smallerbeanngtlhrcker)

9""1B':""

Alack

Black

Alue

7-10

\

D16Y5, D16Y7, D16Y8 engines:

Letters have been stamped on the end of the block as acode for the size of each of the 5 main journal bores.

Use them, and the numbers stamped on the crankshaft(codes for main journal size), to choose the correct bear-

Ings.

Main Journal Code Location (Numbers)

\

Color codeon theedge ofthe bearing-

Ldrger crank bore

Smaller bea ng {th'cker)

lr-l

t#lt+,tlf l 4 tlf '- 't

Smaller Smallermaan bearingjournal {thicker)

RedPinkGreen

PinkGreenBrown

GreenBrownBlack

GreenBrownBlackElue

I

Bearing ldentification

BcD

Page 208 of 2189

Connecting Rod Bearings

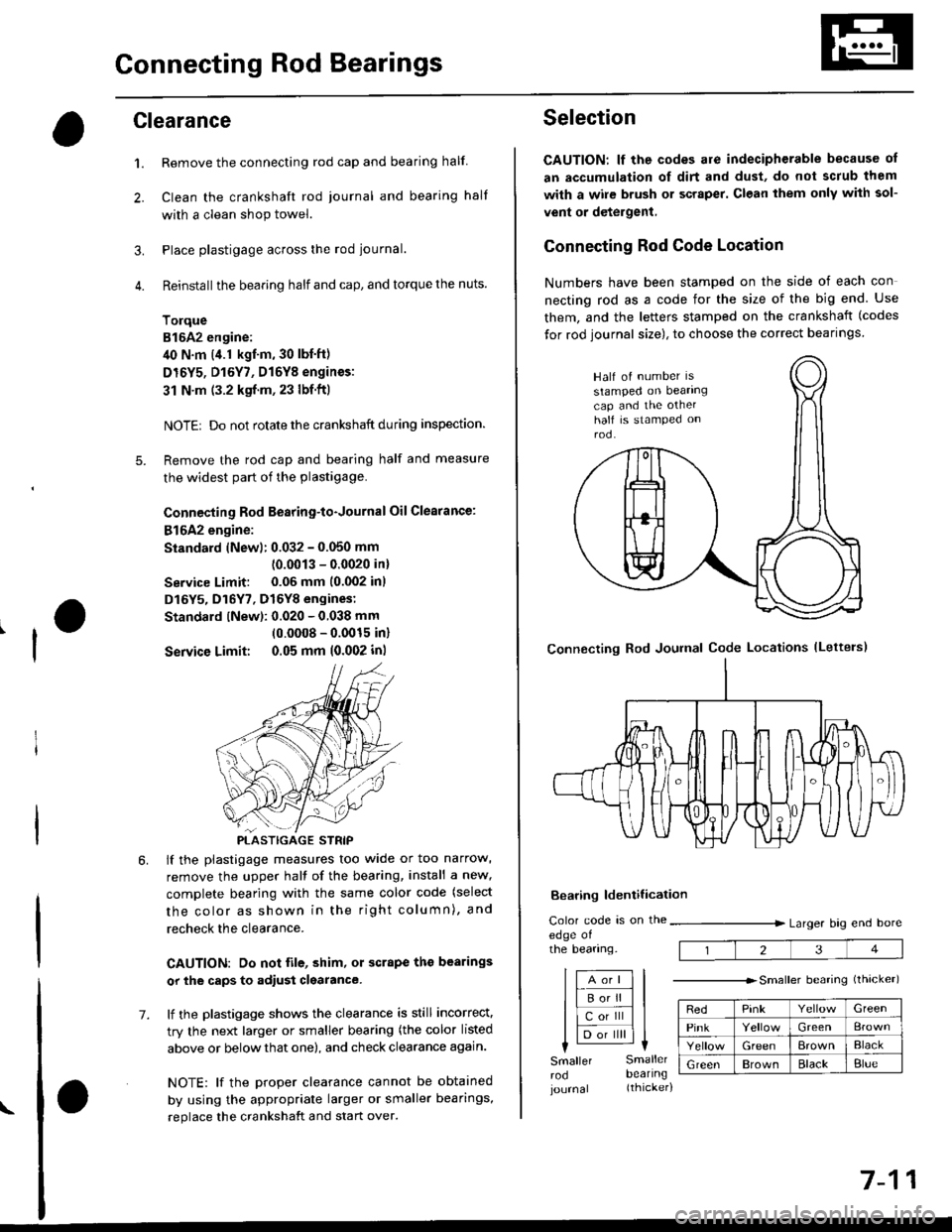

Clearance

Remove the connecting rod cap and bearing half

Clean the crankshaft rod iournal and bearing half

with a clean shop towel.

Place plastigage across the rod journal.

Reinstall the bearing half and cap, and torque the nuts.

Torque

Bl6A2 engine:

40 N.m (4.1 kgl.m, 30 lbf'ft)

Dr6Y5, D16Y7, D16Y8 enginss:

31 N'm (3.2 kgf.m, 23 lbf ftl

NOTE| Do not rotate the crankshaft during inspection.

Remove the rod cap and bearing half and measure

the widest part of the plastigage.

Connecting Rod Bearing-to.Journal Oil Glearance:

816A2 engine:

Standard lNewl: 0.032 - 0.050 mm

10.0013 - 0.0020 in)

Service Limit: 0.06 mm 10.002 inl

D16Y5, D16Y7, D16Y8 engines:

Standard lNew): 0.020 - 0.038 mm

(0.0008 - 0.0015 in)

Service Limit 0.05 mm 10.002 inl

'1.

4.

lf the plastigage measures too wide or too narrow'

remove the upper half of the bearing, install a new,

complete bearing with the same color code (select

the color as shown in the right column), and

recheck the clearance.

CAUTION: Do not lile, shim, or scrape the bearings

or the caps to adiust clgarance.

lf the plastigage shows the clearance is still incorrect.

try the next larger or smaller bearing (the color listed

above or below that one), and check clearance again.

NOTE: lf the Droper clearance cannot be obtained

by using the appropriate larger or smaller bearings,

replace the crankshaft and start over.

PLASTIGAGE STRIP

\

7.

7-11

Selection

CAUTION: lf the codes are indecipherable because of

an accumulation of dirt and dust, do not sclub them

with a wile brush or scraper. Clean them only with sol-

vent or detergent,

Connecting Rod Code Location

Numbers have been stamped on the side of each con

necting rod as a code for the size of the big end Use

them, and the letters stamped on the crankshaft (codes

for rod journal size), to choose the correct bearlngs

Half of number ls

stamped on bearingcap and the otherhalf is stamped onrod.

Bearing ldentilication

Color code is on theedge ofthe bearing.

lfA--;T] |

lle"'tt l;llcorlll ll

I lD;;ilril |l-l

Larger brg end bore

Smaller Smallerrod bearlngjournal (thicker)

---------------- Smallerbearing{thrcker)

RedPinkGreen

PinkGreen

GreenErownBlack

GreenBrownBlackBlue

1234

Connecting Rod Journal Code Locations (Lettels)

Page 215 of 2189

Connecting RodsPiston Pins

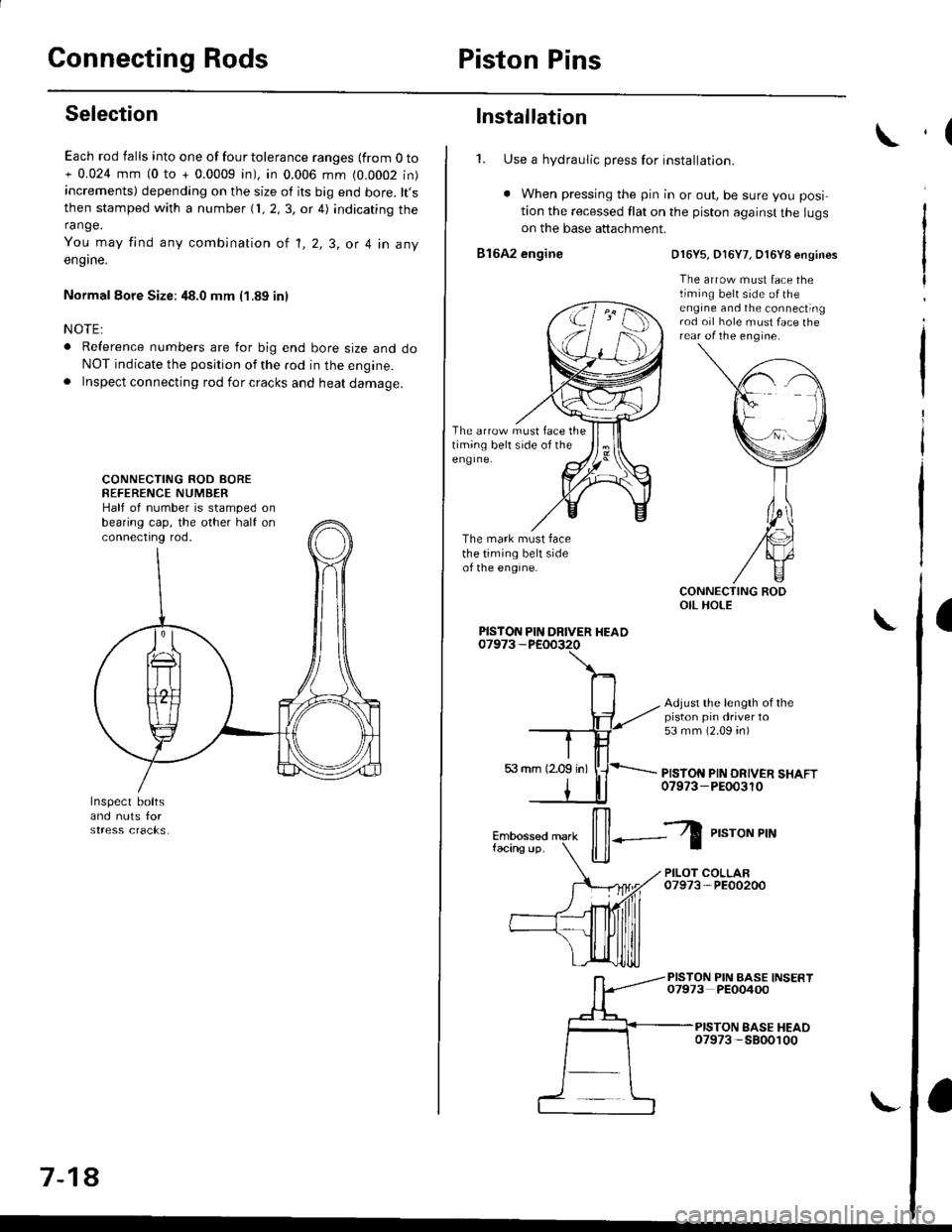

Selection

Each rod falls into one of four tolerance ranges {from O to+ 0.024 mm (0 to + 0.0009 in), in 0.006 mm (0.0002 in)increments) depending on the size of its big end bore. lt,sthen stamped with a number {1, 2,3, or 4) indicating therange.

You may find any combination ot l, 2, 3, or 4 in any

engrne.

Normal Eore Size: 48.0 mm (1.89 in)

NOTE:

o Reference numbers are for big end bore size and doNOT indicate the position of the rod in the engine.. Inspect connecting rod for cracks and heat damage.

CONNECTING ROD AOREREFERENCE NUMBERHalf of number is stamped onbearing cap, the other half onconnectrng rod.

7-18

Installation

1. Use a hydraulic press for installation.

. When pressing the pin in or out, be sure you posi

tion the recessed flat on the piston against the lugson the base attachment.

816A2 engine

The arrow must face thetiming belt side of theeng Ine.

The mark must facethe timing belt sideof the engine.

D16Y5, D16Y7, O16Y8 engines

The arrow must face thetiming belt side o{ theengine and the connectingrod oil hole must face therear of the engine.

Adjust the length of thepiston pin driver to53 mm (2.09 4n)

PISTON PIN DRIVER SHAFT07973-PEOo3r0

PISTON PIN DRIVER HEAD

il--Z

P,"roNPrN

PILOT COLLAR07973-PE00200

PISTON PIN BASE INSERT07973 PEO0400

PISTON EASE HEAO07973 -5800100

,(

a

Page 233 of 2189

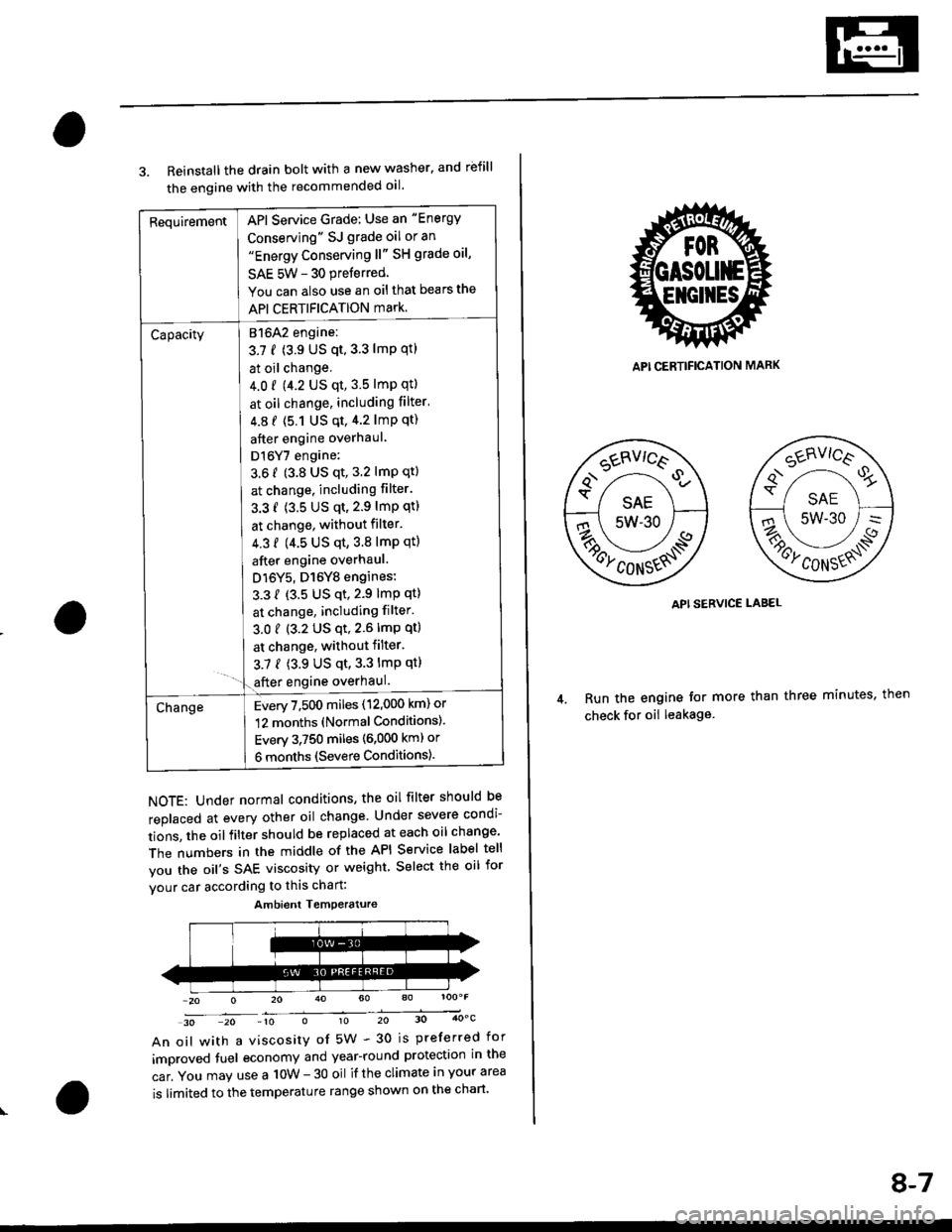

RequirementAPI Service Grade: Use an "Energy

Conserving" SJ grade oil or an"Energy Conserving ll" SH grade oil,

SAE 5W - 30 preferred

You can also use an oil that bears the

API CERTIFICATION mark.

Capacity[atolz engine:

3.7 f (3.9 US qt,3.3 lmp qtl

I at oil change.

J 4.0 r 9.2 US qt, 3.5 lmp qtl

I at oil change, including filter'

| 4.8 f (5.1 Us qt,4.2 lmp qt)

I after engine overhaul

I Dl6Y7 engine:

3.6 f (3.8 US qt, 3.2 lmP qt)

I at change. including filter.

I 3.3 f (3.5 US qt,2.9 lmP qtl

I at change, without filter.

I 4.3 f (4.5 us qt,3.8 lmp qtl

I after engine overhaul.

J D16Y5, D16Y8 engines:

L 3.3 { {3.5 US qt,2.9 lmp qt}

I at change, including filter.

3.01 (3.2 US qt,2.6lmp qt)

I at change, withoutfilter.

3.7 { (3.9 US qt,3.3 lmp qt}- '1.€fter engine overhaul.

ChangeEvery 7,500 miles (12,000 km) or

12 months (Normal Conditions).

Every 3,750 miles (6,000 kml or

6 months (Severe Conditions).

3. Reinstall the drain bolt with a new washer. and rbfill

the engine with the recommended oil.

NOTE: Under normal conditions, the oil filter should be

replaced at every other oil change Under severe condi-

tions, the oilfilter should be replaced at each oil change'

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight Select the oil for

vour car according to this chart:

30 20 -10 010 20 30 4OoC

An oil with a viscosity of 5W - 30 is preferred for

improved tuel economy and year-round protection in the

car. You may use a 10W - 30 oil if the climate in your area

is limited to the temperature range shown on the chart'

Ambient Temoerature

API CERTIFICATION MARK

API SERVICE LABEL

Run the engine tor more than three minutes, then

check for oii leakage

8-7

Page 270 of 2189

!

Fuel and Emrsslons

SoecialToofs .....,...."..,. 11-2

Component Locations

lndex ....................., ......... 11-3

Svstem Description

Vacuum Connections ................,,..,.. ......... 11-12

Electrical Connections ...............,.,.,... ....... 11-29

System Connectors ........,.,.,.......................... 1 1-51

Troubleshooting

Troubleshooting Procedures ................. .. 11-81

Engine Control Module/PowertrainControl Module TerminalAfiangement ....,.,..... 11-88

Diagnostic Trouble Code Chart .................,., 11.97

How to Read Flowcharts .,.......................... . 11-103

PGM-Fl System

System Description ...... 11-10,1

Troubleshooting Flowcharts

Engine Control Module/PowertrainContlol Module ........ 11-107

Manitold Absolute Pressure Sensor .....'. . ... 11-115

fntake Air Temperatuie Sensor ..... . . ., . 11'121

Engine Coolant Temperatuae Sensol ........., 11-128

Throttle Position Sensor ...................,........... 11-132

Primary Heated Orygen Sensor (Sensor 1l ... 11-139

Secondary Heated Oxygen Sensor(Sensor 21.................................................... 1 1-153

Heated Oxygen Sensor Heater ...................,. 11-157

Fuel Supply System ...... 11-164

Random Mislire ......., ..11-166

Misfire Detected in One Cylindsr ................. 11-167

Knock Sensor .,.,............ 11-170

CKP/TDC/CYP Sensor ................................... 11'172

Vehicle Speed Sensor ...........,......,...,.,........... 1t-176

Barometric Pressure Sensor ...............,......... I 1-178

Electrical Load Detector,.,,............................ 1 1-179

CKF Sensor .................... 11-183

ECM/PCM Internal Circuit ............................. I 1-188

A/T Signal {TMA/TMBI .................................. I 1-189

ldle Control System

System Doscriplion ............ 11-190

Troubleshooting Flowcharts

ldle Control System ...... 11-192

ldle Air Control Va1ve .................................... I 1-19i1

Starter Switch Signal .................................... 1 1'202

Air Conditioning Signal ................................. 11'201

Ahernator FR Signal .................................... . 1 1-208

BrakeSwitch Signal ..................................... f 1"210

Power Sleering Prossure Switch Signal ......11-212

A/T Gear Position Signal ............................... 11-216

Clutch Swiich Signal ................................-.... 11-214

ldte Speed Setting . .............11-220

Fuel Supply System

Fuel Lines .,...................,.,.,.,11-221

Fuef Tube/Ouick-Connect Fittings ..........,.,........ 11 -227

System Description ....'.... 11-230

Fuel Pressure .......,.,,........... 11-230

Fuef fniectors ......................11-232

Fu€f Pressure Regulator .....,.......................'...,. 11-231

Fuef Fifter ............................11-235

Fuel Pump .............'.......'.... 11-236

PGM-FI Main Relay .............11'237

Fuel Tank ................ ....,...'.'.' 11'211

Intake Air System

System Description ....-.-.....11-243

Air Cfeaner ...........,......."". .11-211

Throttle Cable .....................11-211

Throttfe Body ........ ..'... . . .,.11-211

Fuel Iniestion Air Control System ,.,.,....-........... 11-250

Emission Control System

System Description .-..........11-252

Taifpip€ Emission ...............11-252

Three Way Catafytic Convert€r ............,.,,.,.,.,.... 11 -252

Exhaust Gas Racirculaiion System ...,.,,,,.,.,.,.,,. 11'254

Positive Crankcas€ Ventilation System .... . . .. 11-266

Evaoorative Emission Controls ..................,,..,.,. 11 -267

Page 272 of 2189

Gomponent Locations

L

lndex

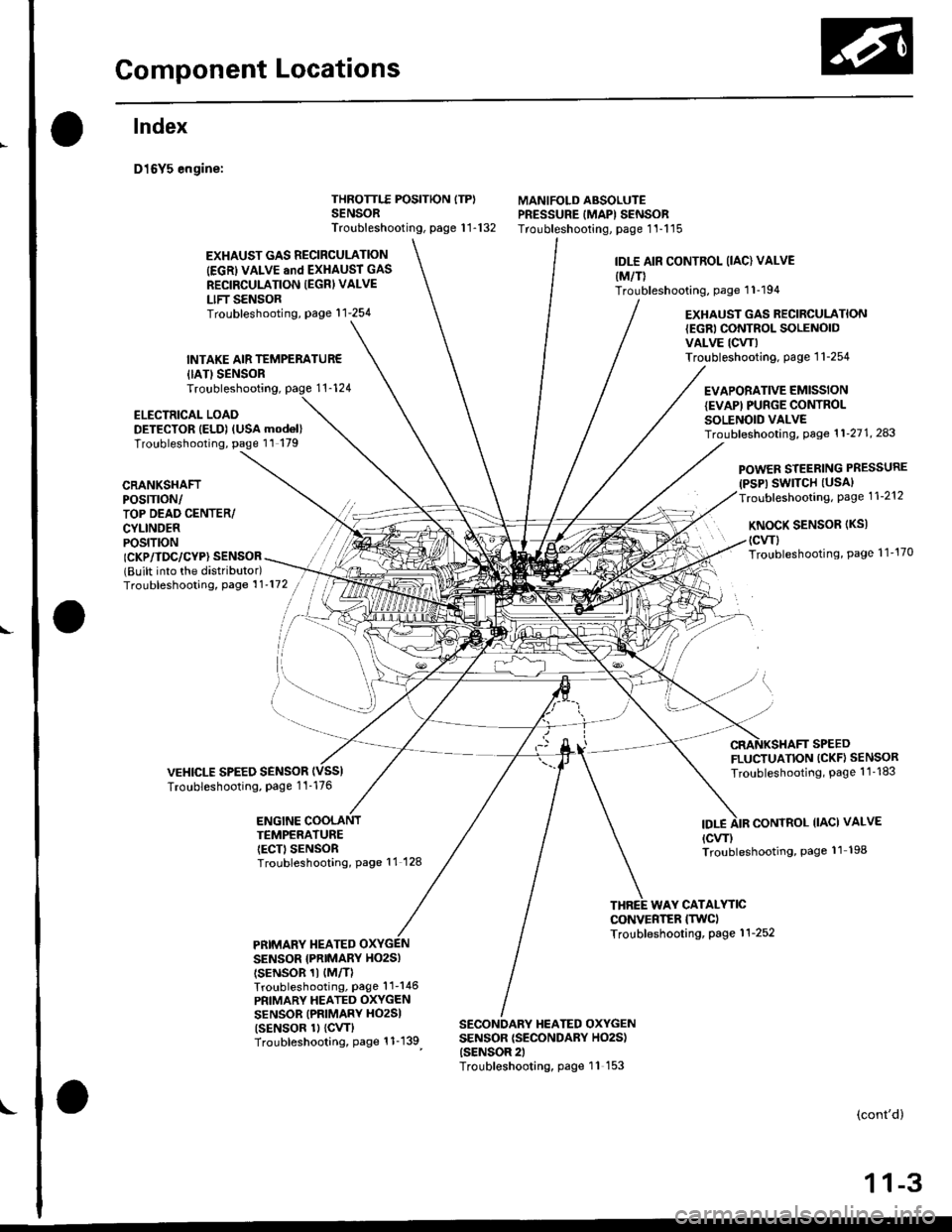

D16Y5 engine:

{IATISENSORTroubleshooting,

ELECTRICAL LOADDETECTOR IELD) (USA mod6l)Troubleshooting, page 11 179

THROTTLE POSITION ITP)SENSORTroubleshooting, page 1 1-132

MANIFOLD ABSOLUTEPRESSURE IMAPI SENSORTroubleshooting, page 1'l-115

EXHAUST GAS RECIRCULATION

IEGRI VALVE and EXHAUST GAS

RECIRCULATION IEGRI VALVE

LIFT SENSORTroubleshooting, page'l 1-254

INTAKE AIR TEMPERATUR€

IDLE AIR CONTROL (IAC) VALVE

{M/T)Troubleshooting, page 1 1-194

EXHAUST GAS RECIRCULATION{EGRI CONTROL SOLENOIDVALVE ICW)Troubleshooting. page 1 1-254

EVAPORATIVE EMISSIONIEVAPI PUNGE CONTROLSOLENOID VALVETroubf eshooting, Page 1 1'21 1, 243

CRANKSHAFTPOS|TTON/TOP DEAD CENTER/CYLINDERPOS|T|ON

POWER STEERING PRESSURE(PSP) SWITCH (USAI

Troubleshooting, Page 1 1-212

KNoCK SENSoR (Ks)

(cwl

Troubleshooting, Page 1 1'170ICKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, Page 1 1'172

VEHICLE SPEED SENSORTroubleshooting, Page 1 1-176

FLUCTUATION (CKF} SENSOR

Troubleshooting, Page 1 1 -183

ENGINE COOLANTTEMPERATUREIECT) SENSORTroubleshooting, Page 11 128

IDT.ECONTROL IIACI VALVE

{cw)Troubleshooting, Page 11 198

WAY CATALYTICCONVERTER ITWCITroubleshooting, Page 1 1-252PRIMARY TIEATEDSENSOR {PNIMARY HO2SI

tsENsoR 1t {M/TlTroubleshooting, Page'l 1-146

PRIMARY HEATED OXYGENSENSOR (PRIMARY HO2SI

tsENsoR 1l {cw}Troubleshooting, Page 1 1-139

SECONDARY HEATED OXYGENSENSOR {SECONDARY HO2S){SENSOR 2)Troubleshooting, page 11 153

(cont'd)

1 1-3

Page 273 of 2189

Component Locations

Index (cont'd)

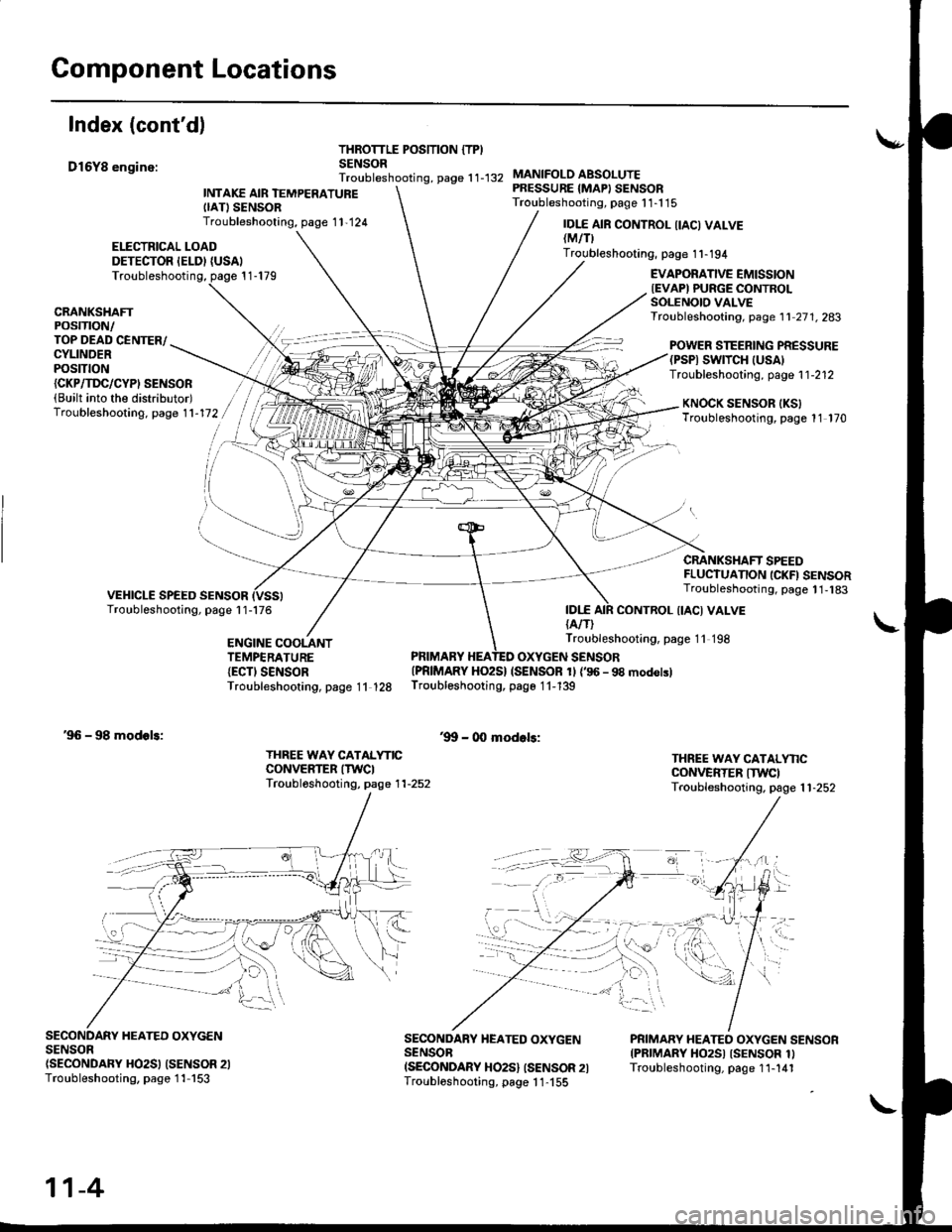

D16Y8 enginc:

THROTTLE POSITION {TPISENSORTroubleshooting, page 1 1-132

ELECTRICAL LOADDETECTOR IELDI {USAI

INTAKE AIR TEMPERATUREIIATISENSORTroubleshooting, page 1 1,124

MANIFOLO ABSOLUTEPRESSURE {MAPI SENSORTroubleshooting, page 1 1-1 15

IDI.E{A/T)

IDI.E AIR CONTROL IIACI VALVElMtflTroubleshooting, page 1 1-194

Troubleshooting, page 1 1-179EVAPORATIVE EMISSIONIEVAPI PURGE CONTROLSOLENOIO VALVETroubleshooting, page 1 1 27 1. 283CRANKSHAFTPOSTTTON/TOP DEAD CENTER/CYLINDERPOStTtON

POWER STEERING PRESSURE(PSPI SWTTCH |USA)Troubleshooting, page 1 1-212{CKP/TI'C/CYPI SENSOR(Built into the distributor)Troubleshooting. page 1 1-172KNOCK SENSOR IKSITroubleshooting, page 11 170

CRANKSHAFT SPEEDFLUCTUANON ICKFI SENSORTroubleshooting, page 1 1,183

CONTROL {IACI VALVE

ENGINE COOLANTTEMPERATURE{ECTI SENSORTroubleshooting, page 11 128

Troubleshooting, page 11 198

PRIMARY HEATED OXYGEN SENSOR{PRIMARY HO2S} (SENSOR 1l {'96 - 98 modolslTroubleshooting, page 1 1-139

'9!t - 00 modols:'96 - 98 modols:

THREE WAY CATALYNCCONVERTER ITWCITroubl6shooting, page 1 1-252

THREE WAY CATALYNCCONVERTER ITWCITroubleshooting. page 1 1-252

SECONDARY HEATED OXYGENSENSOn(SECONDARY HO2SI (SENSOR 2ITroubleshooting, page 1 1-153

SECONDARY HEATED OXYGENSENSOBISECONDARY HO2S} ISENSOR 2ITroubloshooting, page 1 1-155

PRIMARY HEATEO OXYGEN SENSORIPRIMARY HO2SI ISENSOR 1ITroubleshooting, page 1 1-141

11-4