inhibitor HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 915 of 2189

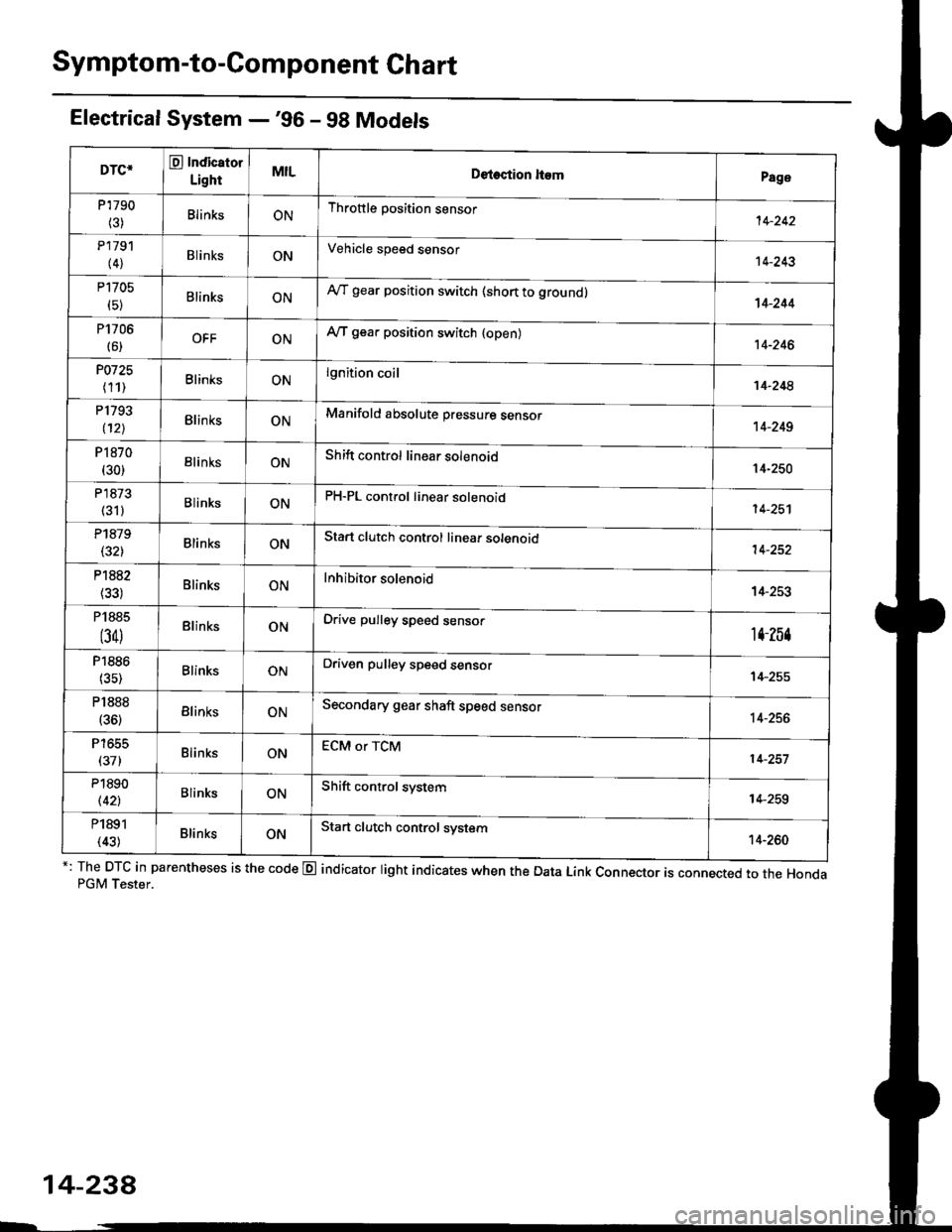

Symptom-to-Component Chart

Electrical System -'96 - 98 Models

*: The DTC in parentheses is the code @ indicator light indicates when the Data Link Connector is connected to the HondaPGM Tester.

DTC*O Indicator

LightMILDetection ltemPage

P1790

(3)BlinksONThrottle position sensor14-242

P179'l

(4)BlinksONVehicle speed sensor14-243

P1705

(5)BlinksONAy'T gear position switch (short to groundl't 4-244

P1706

(6)OFFONA/T gear position switch {open)14-246

P0725

(11)BlinksONlgnition coil14-248

P1793

112lBlinksONManifold absolute pressure sensor14-249

P 1870(30)BlinksONShift control linear solenoid14-250

P'1873

(311BlinksONPH-PL control linear solenoid14-25'l

P1879(32)BlinksONStart clutch control linear sotenoid14-252

P1882BlinksONInhibitor solenoid14-253

P1885

(34)BlinksONDrive pulley speed sensor1l-Zb4

P1886(35)BlinksONDriven pulley speed sensor14-255

P1888

(36)BlinksONSecondary gear shaft speed sensor14-256

T to55

(37)BlinksONECM or TCM14-257

P1890

l42lBlinksONShift control system14-259

P1891

(43)BlinksONStart clutch control svstem14-260

14-23a

Page 917 of 2189

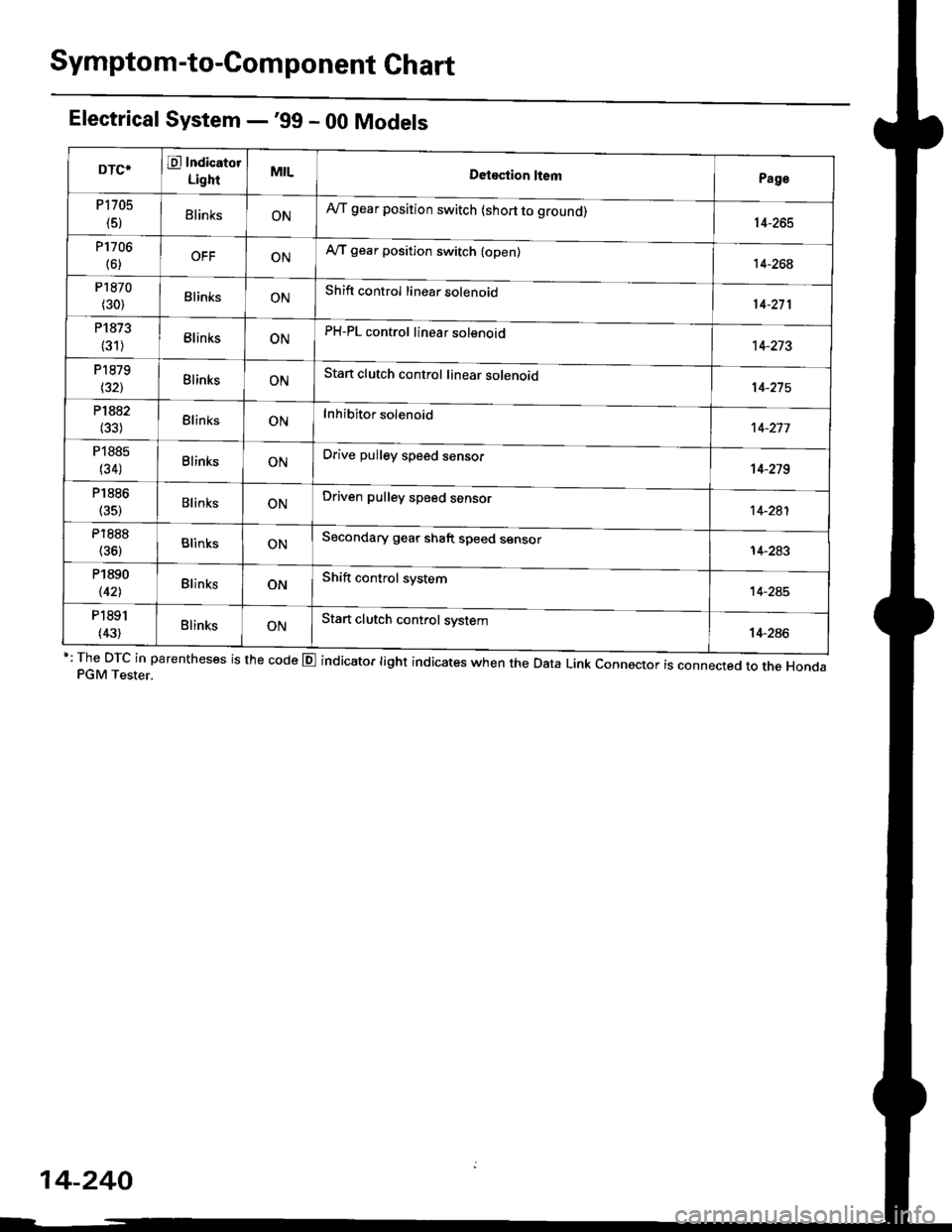

Symptom-to-Com ponent Chart

Electrical System -'99 - 00 Models

r: The DTc in parentheses is the code E indicator light indicates when the Data Link connector is connected to the HondaPGM Tester.

DTCTE Indicatot

LighrMILDetostion ltemPage

P1705

(5)ElinksONA,/T gear position switch (short to grouno,14-265

P1706

(6)OFFONA"/T gear position switch (open)14-26€

P1870

(30)BlinksONShift control linear solenoid14-271

P1873

(31)BlinksONPH-PL control linear solenoid14-213

P1879

t32lBlinksONStan clutch control linear solenoid

Inhibitor solenoid

14-215

P1882(33)BlinksON't 4-277

P1885

(34)BlinksONDrive pulley speed sensol't 4-279

P1886

(35)BlinksONDriven pulley speed sensor14-281

P1888

(36)BlinksONSecondary gear shaft speed sensor

Shift control system

14-283

P1890

\421BlinksON14-245

P1891

(43)BlinksONStart clutch control system14-286

14-240

Page 930 of 2189

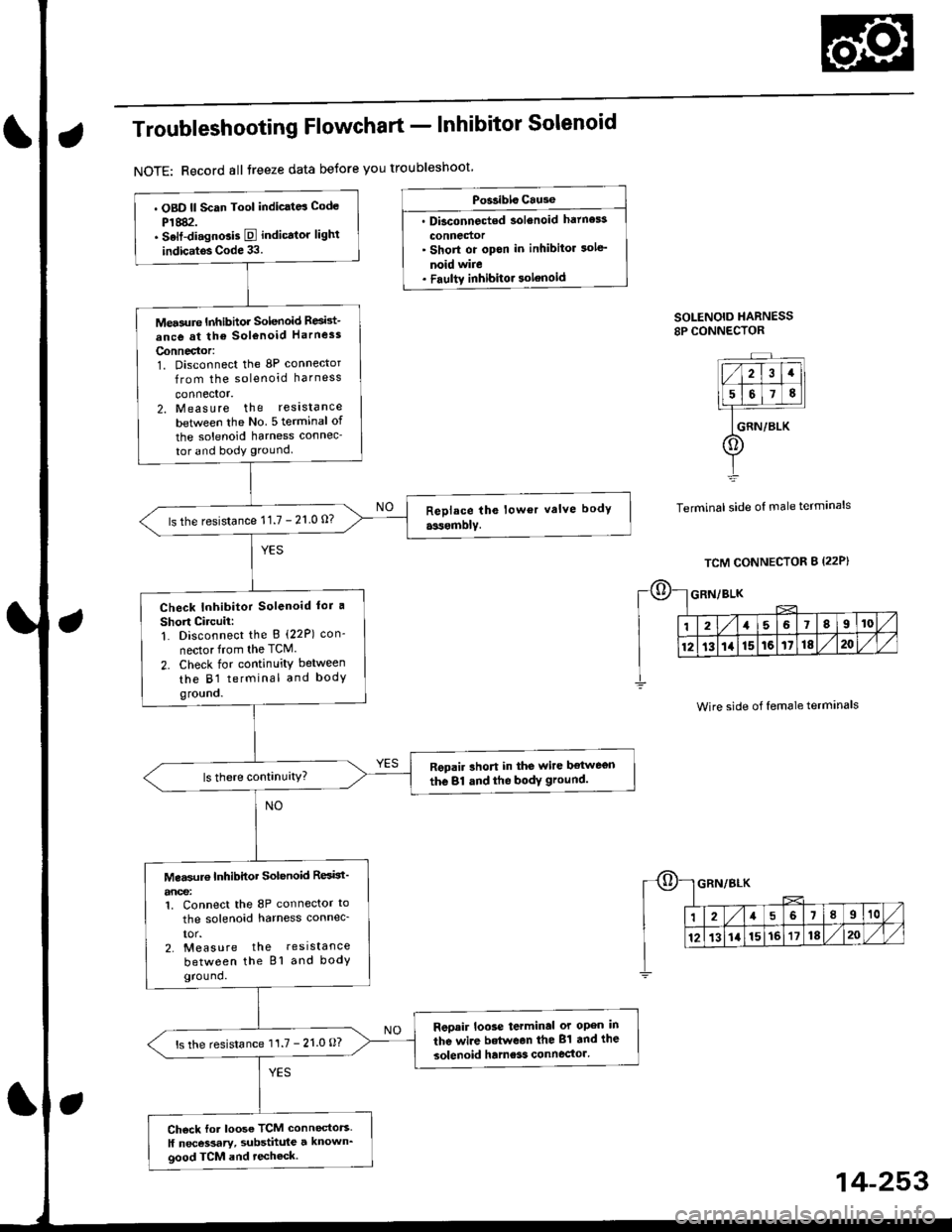

Troubleshooting Flowchart - Inhibitor Solenoid

NOTE: Record all treeze data betore you troubleshoot

Po$ibls Cause

. Dbconnected solenoid hatness

connedor' Short or opon in inhibitor sole'

noid wire. Faultv inhibitor solenoid

SOLENOID HARNESS8P CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indic.td Code

P1882.. Selt-di.gnGis E indicator lighl

indic.tos Code 33.

Mea3ure Inhibhor Solenoid Resid-

ance at the sol€noid Harness

Connector:1. Disconnect the 8P connector

from the solenoid harness

connector.2. Measure the reslstance

betlveen the No 5 terminal of

the solenoid harness connec-

tor and body ground.

ls the resistance 11.7 - 21 0 0?

Check Inhibitor Solenoid lor a

Short Circuii:1. Disconnect the B (22P) con-

nector from the TCM.

2. Check for continuity between

the B1 terminal and bodygro!no.

Repair rhort in the wire ltetwegn

the 81 dnd the bodY ground.

Mea$rr€ Inhibitor Solenoid ResBt'

anoe:1. Connect the 8P connector to

the solenoid harness connec_

IOr.2. Measure the resistance

between the Bl and bodyground.

Reoair loose terminal or open in

the wire betwean the 81 and the

solenoid hame3s connector'ls the resistance 11.7 - 21.0 O?

Ch6ck for loose TCM connectors.

ll necessary, substhule a known_good TCM and techeck.

Wire side of female terminals

14-253

Page 954 of 2189

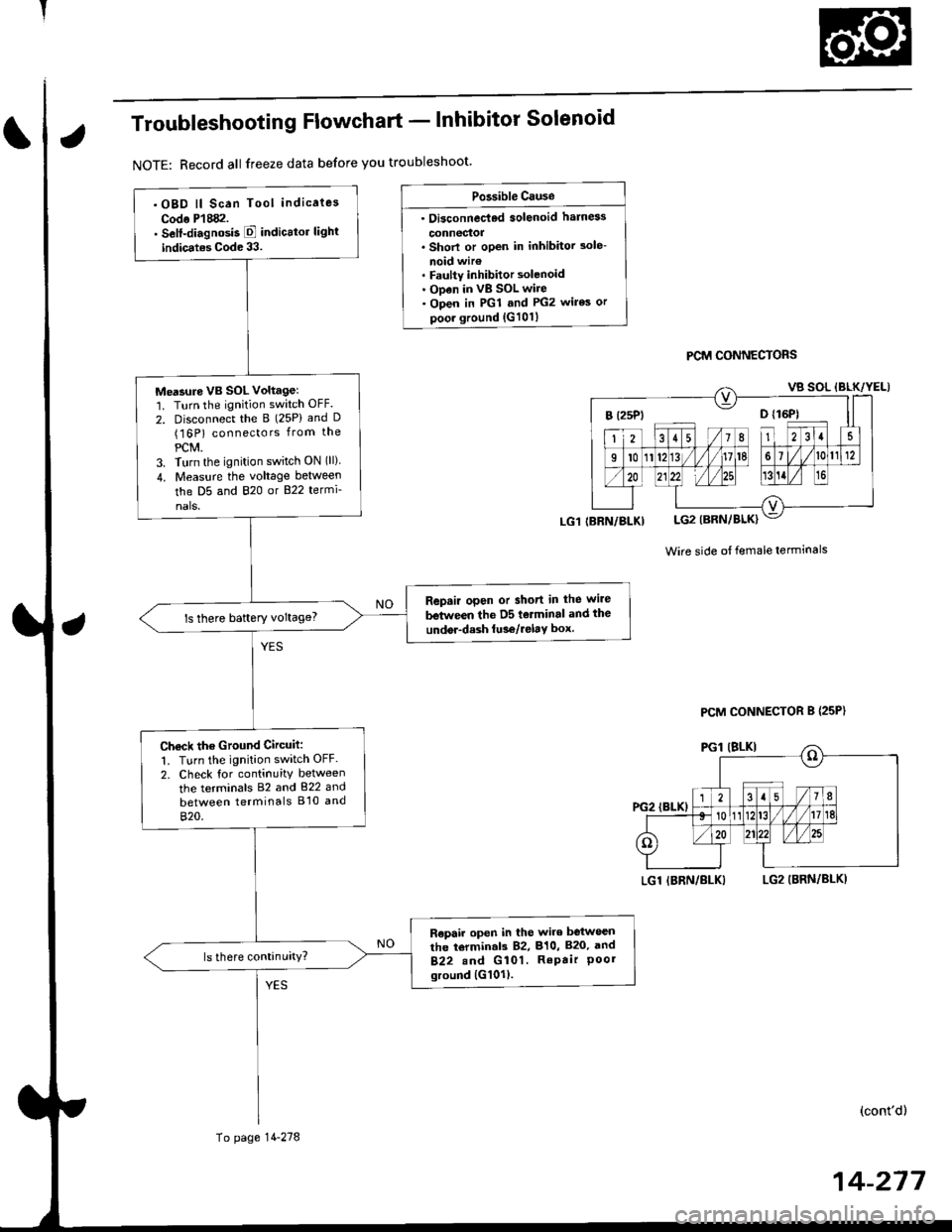

Troubleshooting Flowchart - lnhibitor Solenoid

NOTE: Record all freeze data before you troubleshoot'

Po3sible Cause

. Oi3connec'ted solenoid harn6s

connectoa. Shorl or open in inhibitor 3ole-

noid wir€. Faulty inhibitor solenoid. ODen in vB SOL wire. Open in PGl and PG2 wires or

poor ground {G101}

PCM CONNECTORS

Wire side ot female terminals

LGl IBRN/BLKILG2 (BRN/BLKI

(cont'd)

14-217

.OBD ll Scan Tool indicaies

Codo P'l882.. Self-diagnosis E indicttor light

indic.tes Code 33.

Me'sure VB SOL voltagel'1. Turn the ignition switch OFF.

2. Disconnect the B (25P) and D(16P) connectors from the

PCM.3. Turn the ignition switch ON (ll)

4. Measu.e the voltage between

the D5 and 820 or B22 termi-

nals.

Repair open or short in the wire

between the D5 tolminal and the

undor-dash lu36/relay box.ls there baftery voltage?

Ch€ck the Ground Circuit:

1. Turn the ignition switch OFF.

2. Check tor continuity between

the terminals 82 and 822 and

between terminals B'10 and

820.

R€pair open in the wire between

the torminal3 82, 810, B20, and

B22.nd G 101. RePair Poorground {G101).

(BRN/BLKI

To page 14-278

PCM CONNECTOR B {25P}

Page 955 of 2189

Electrical Troubleshooting ('99 - 00 Models)

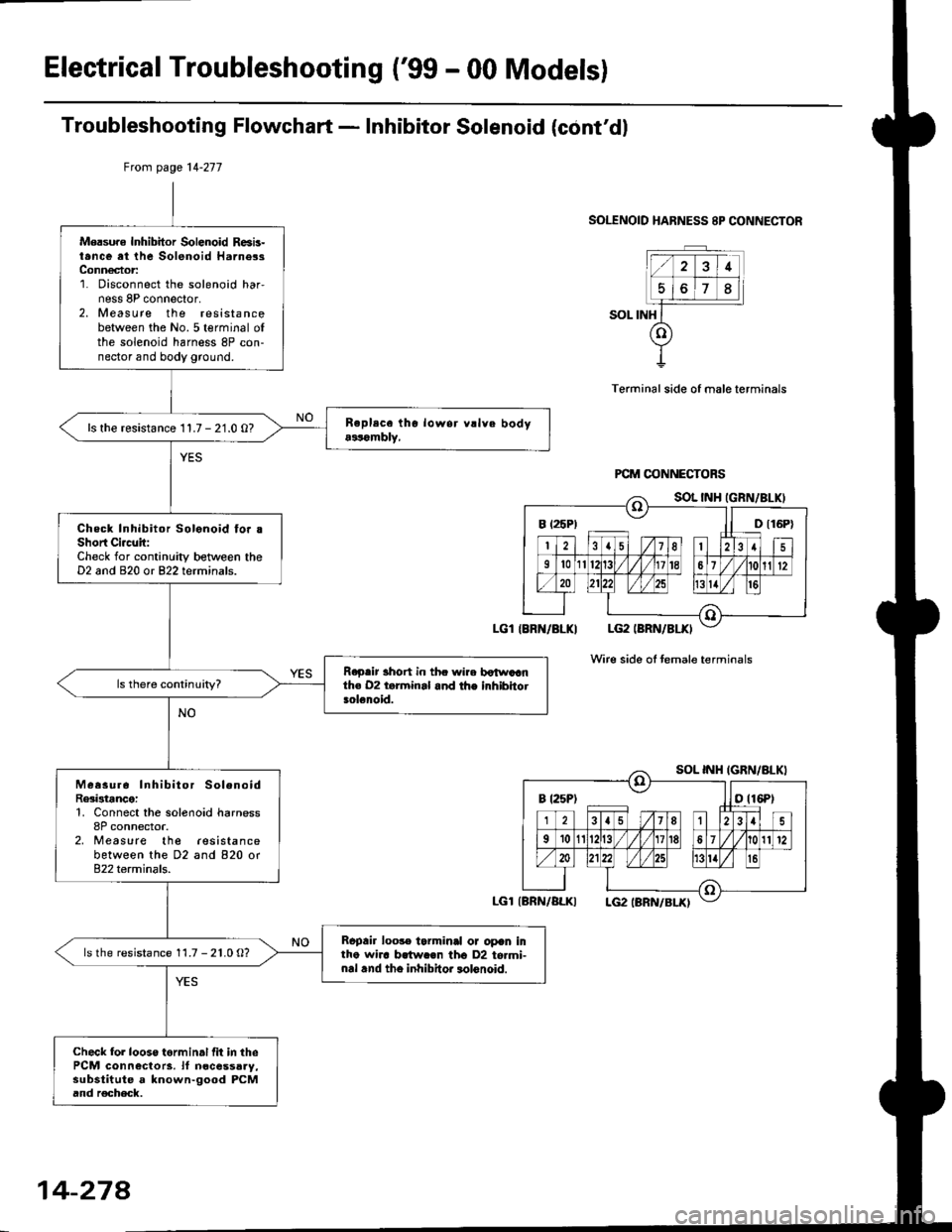

Troubleshooting Flowchart - Inhibitor Solenoid (cont'dl

SOLENOID HARNESS 8P CONNECTOR

SOL INH

Terminal side of male terminals

Wire side oI temale terminals

Mersure Inhibitor Solenoid R6b-t.nce at the Solenoid Harne3sConn€ctor:1. Disconnect the solenoid har,ness 8P connector,2. Measure the resistancebetween the No.5 terminal ofthe solenoid harness 8P con-nector and body ground.

ls the resistance 11.7 - 21.0 O?

Check Inhibitor Solonoid fo. .Short Ci.c!it:Check for continuity between theD2 and 820 or 822 terminals.

R.p.ir 3hort in thc wire botwaanth€ 02 t.rminal and the inhibhotsolenoid.

Measur6 Inhibitor SolenoidRe3istance:1, Connect the solenoid harness8P connector.2, Measure the lesistancebetween the D2 and 820 or822 terminals.

Rcpair loo3. tarminal or opan intho wha brtw.€n tho D2 to.mi-nal .nd tho inhibitor lolonoid.

ls the resistance 11.7 - 21.0 O?

Check fol looso torminal fit in thePCM connectors. lf n€cessaay,substitute a known-good PCMand r€check.

Ftom page 14-277

LGl IBRN/BLKI

LGl{BRN/ALKI

B t25P) ll D t16P)

B t25Pt otl6Pt

14-274

Page 968 of 2189

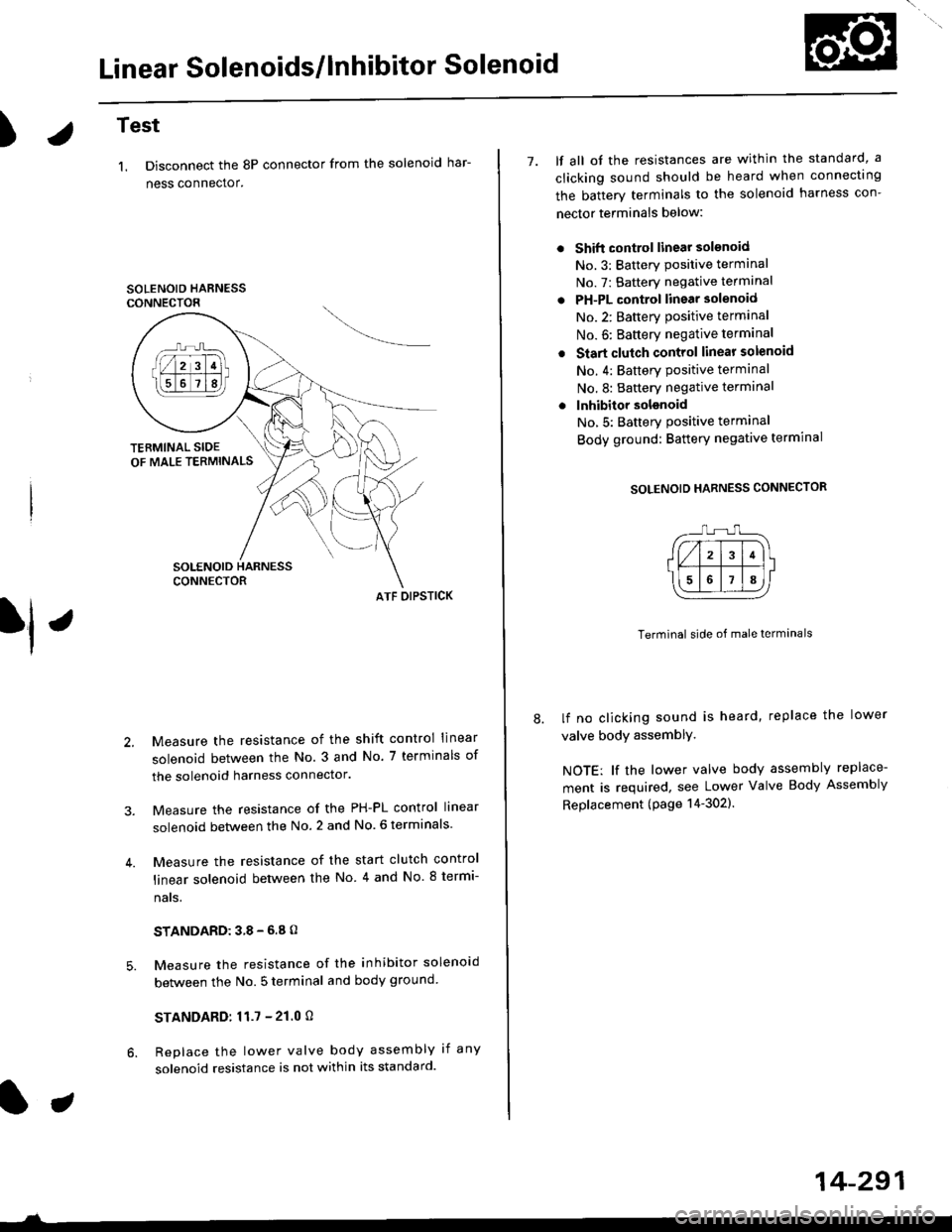

Linear Solenoids/lnhibitor Solenoid

)Test

1. Disconnect the 8P connector from the solenoid har-

ness connector.

SOLENOID HARNESSCONNECTOR

ATF OIPSTICK

Measure the resistance of the shift control linear

solenoid between the No. 3 and No. 7 terminals of

the solenoid harness connector.

Measure the resistance of the PH-PL control linear

solenoid between the No. 2 and No. 6 terminals

Measure the resistance of the start clutch control

linear solenoid between the No 4 and No. 8 termi-

nats,

STANDARD:38-6.8O

Measure the resistance of the inhibitor solenoid

between the No. 5 terminal and body ground

STANDARD:11.7 - 21.0 O

Replace the lower valve body assembly if any

solenoid resistance is not within its standard.

7. lf all ot the resistances are within the standard, a

clicking sound should be heard when connectrng

the batterv terminals to the solenoid harness con-

nector terminals below:

Shift control linear solsnoid

No.3: Batterv Positive terminal

No. 7: Battery negative terminal

PH-PL control linear solenoid

No.2: Batterv oositive terminal

No. 6: Baftery negative terminal

Start clutch control linear solenoid

No. 4: Battery Positive terminal

No.8: Battery negative terminal

lnhibitor solsnoid

No,5: Batterv Positive terminal

Body ground: Battery negative termrnal

SOLENOID HARNESS CONNECTOR

Terminal side of male terminals

lf no clicking sound is heard, replace the lower

valve body assemblY,

NOTE: lf the lower valve body assembly replace-

ment is required, see Lower Valve Body Assembly

Replacement (page 14-302).

14-291

Page 972 of 2189

t.

rl,

fl,

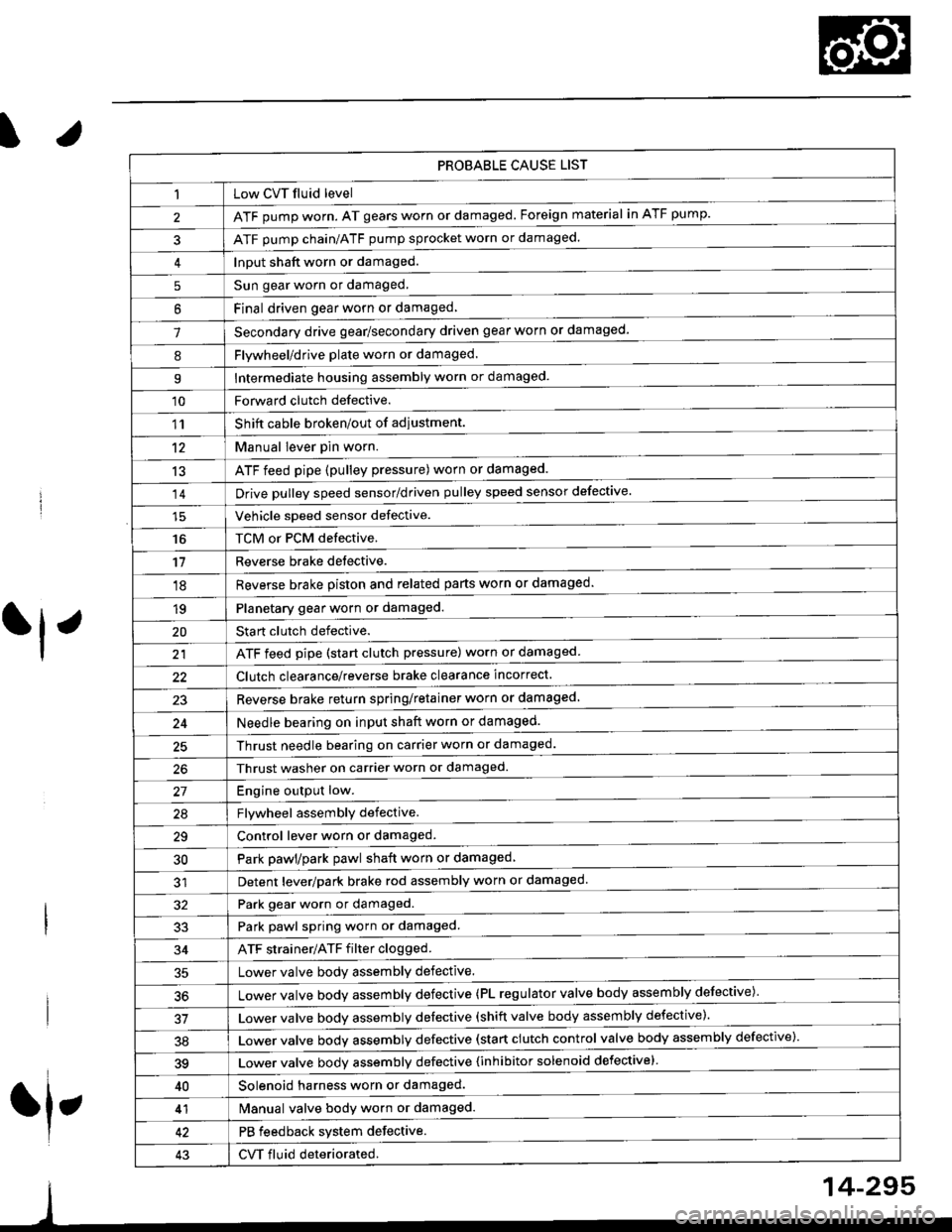

PROBABLE CAUSE LIST

Low CVT fluid level

ATF pump worn. AT gears worn or damaged. Foreign material in ATF pump.

ATF pump chain/ATF pump sprocket worn or damaged.

Input shaft worn or damaged.

Sun gear worn or damaged.

Final driven oear worn or damaqed,

Secondary drive gear/secondary driven gear worn or damaged-

5

6

1

8Flywheel/drive plate worn or damaged.

Intermediate housing assembly worn or damaged.9

'10Forward clutch defective.

Shift cable broken/out of adiustment.

M"nu"t t"uffi

ATF feed pipe (pulley pressure) worn or damaged.

Vchiclc speed sensor defective.

TCM or PCM defective.

Reverse brake detective.

1'�r

't2

13

14

16

'11

'18

1qPlanetary gear worn or damaged.

Sta rt clutch defective.

ATF feed pipe (start clutch pressure) worn or damaged

20

t't

Clutch clearance/reverse brake clearance incorrect.

23Reverse brake return spring/retainer worn or damaged

24Needle bearing on input shaft worn or damaged.

25Thrust needle bearing on carrier worn or damaged.

Thrust washer on carrier worn or damaged.

Enoine outout low.------------------------

Flvwhcel assemblv defective.

Control lever worn or damaged.

Park pawl/park pawl shaft worn or damaged

Detent lever/park brake rod assembly worn or damaged

27

29

30

32Park gear worn or damaged.

Park pawl spring worn or damaged.

ATF strainer/ATF filter clogged.

Lower valve body assembly defective.

Lower valve bodv assemblv defective (PL regulator valve body assembly defective)'

33

34

50

Lower valve bodv assembly defective (shift valve body assembly defective).

Lower valve bodv assemblv defective (start clutch control valve body assembly defective)'

39Lower valve bodv assemblv defective {inhibitor solenoid defective}

40Solenoid harness worn or damaged.

Manual valve body worn or damaged.

PB feedback system defective.

CVT fluid deteriorated.

41

43

14-295

Page 997 of 2189

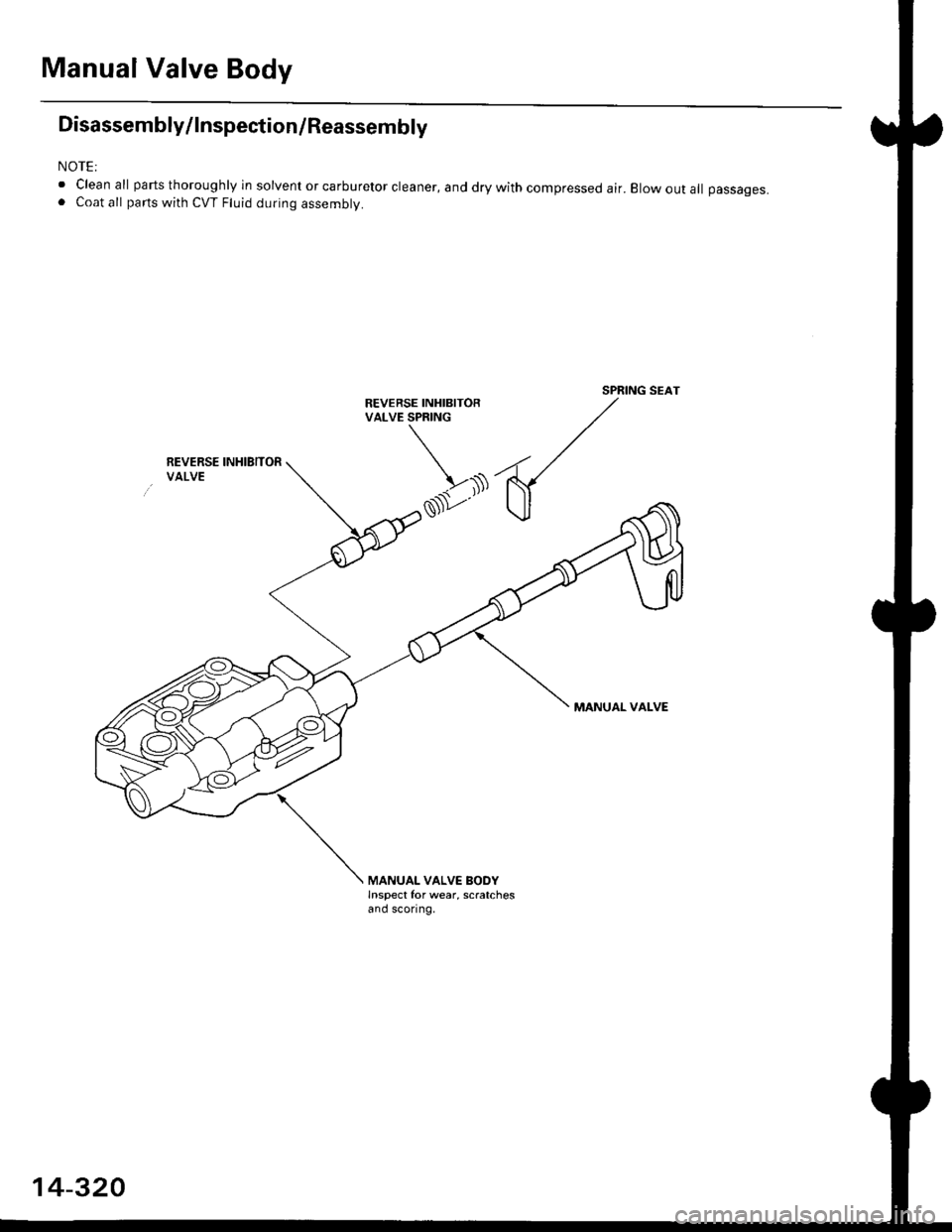

Manual Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Clean all parts thoroughly in solvent or carburetor cleaner, and dry with compressed air. Elow out all passages.. Coat all parts with CVT Fluid during assembly.

SPRING SEATREVERSE INHIBITORVALVE SPRING

REVERSE INHIBITORVALVE

MANUAL VALVE

MANUAL VALVE BODYInspect for wear, scratchesand sconng,

14-320