lock HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 130 of 2189

Removal

NOTE:

. Replace the timing belt at 105,000 miles (168.000 km)

according to the maintenance schedule (normal con-

ditions/severe conditions).

lf the vehicle is regularly driven in one or more of the

followlng conditions, replace the timing belt at 60.000

miles (U.S.A.) 100,000 km {Canada).

.In very high temperatures (over 110'F.43'C)

. In very low temperatures (under -20'F, -29"C)'

! Turn the crankshaft pulley so the No. 1 piston is at

top dead center (TDC) before removing the belt (see

page 6'21).

. Inspect the water pump before installing the timing

belt {see Page 10-14).

1. Remove the splash shield (see page 5-7).

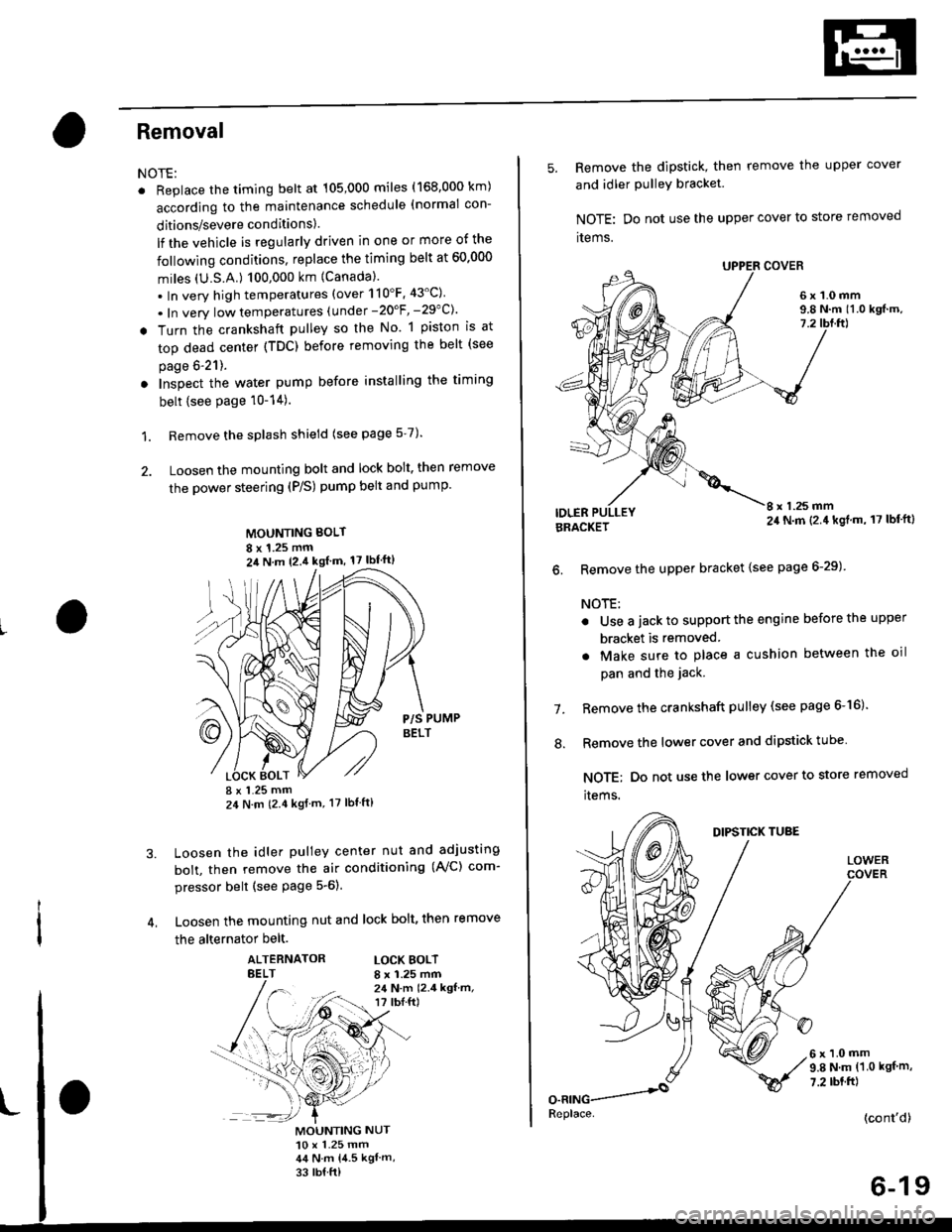

2. Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt and pump

MOUNTING BOLT

8 x 1.25 mm2il N m 12.4 kgl m, 17 lbf'ft)

P/S PUMPBELT

I x 1.25 mm24 N m (2.4 kgf m, 17 lbt ft)

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (AVC) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt, then remove

the alternator belt.

ALTERNATORBELTLOCK BOLTI x 1.25 mm24 N.m 12.4 kgf.m,r? tbI.ft)

3.

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgl m,

33 rb{ ft)

5. Remove the dipstick, then remove the upper cover

and idler PulleY bracket

NOTE: Do not use the upper cover to store removed

items.

6x1.0mm9.8 N.m 11.0 kgf.m,7.2

IDLERI x 1.25 mm24 N.m (2.4 kgl.m, 17 lbf'ft)BRACKET

6. Remove the upper bracket {see page 6-29)

NOTE:

. Use a jack to support the engine before the upper

bracket is removed

. Make sure to place a cushion between the oil

pan and the jack.

Remove the crankshaft pulley (see page 6-16).

Remove the lower cover and dipstick tube

NOTE; Do not use the lower cover to store removed

items.

1.

.'.

DIPSTICK TUBE

LOWER

6x1.0mm9.8 N.m (1.0 kgf m,

7.2 rbt.ft)

(cont'd)

6-19

Replace.

Page 132 of 2189

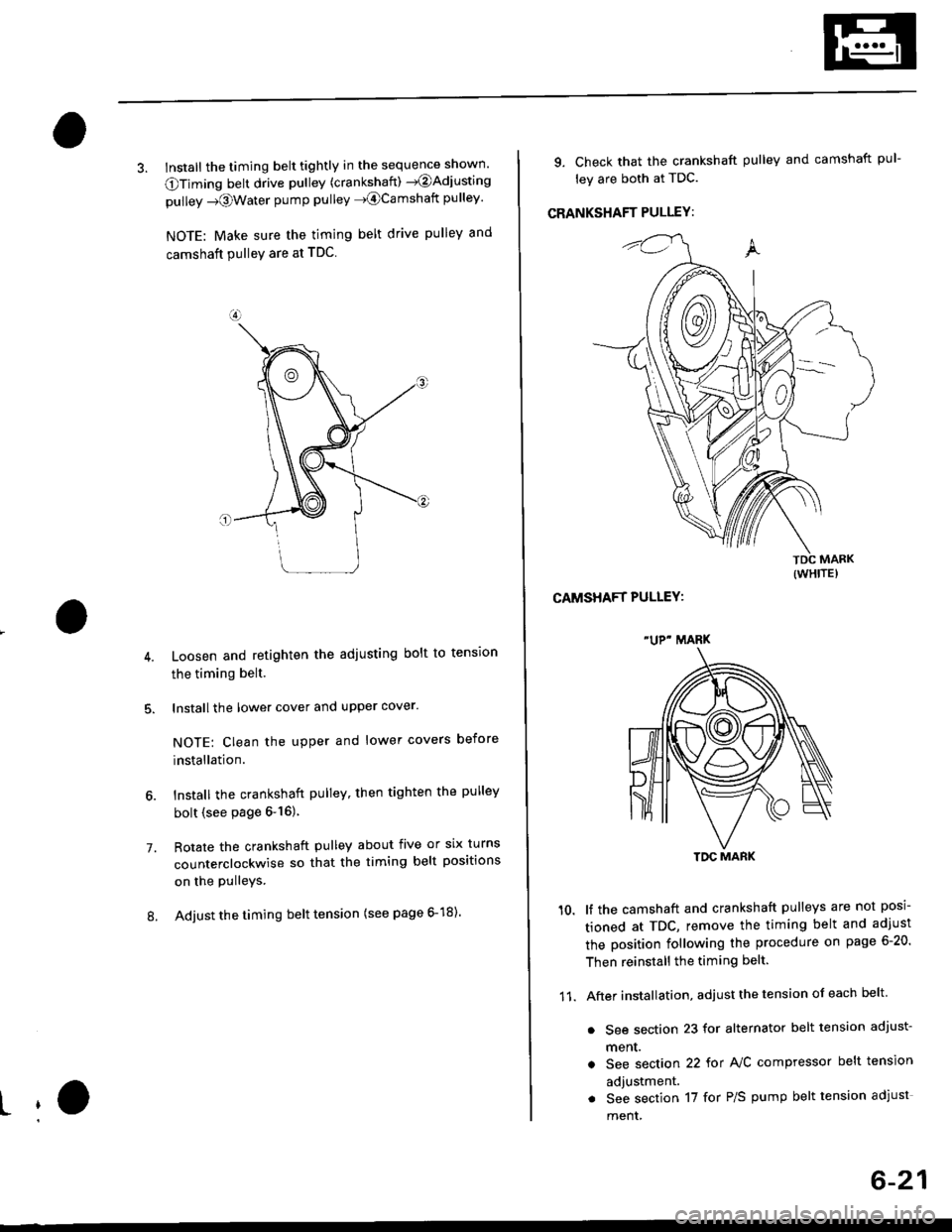

3. Install the timing belt tightly in the sequence shown'

OTiming belt drive pullev (crankshaft) )@Adjusting

pulley -towater pump pulley J@Camshatt pulley'

NOTE: Make sure the timing belt drive pulley and

camshaft PulleY are at TDC

7.

Loosen and retighten the adiusting bolt to tension

the timing belt.

lnstall the lower cover and upper cover.

NOTE: Clean the upper and lower covers before

installation.

lnstall the crankshaft pulley, then tighten the pulley

bolt (see page &16)

Rotate the crankshaft pulley about five or six turns

counterclockwise so that the timing belt positions

on the Pulleys.

Adjust the timing belt tension (see page 6-18).8.

L

9. Check that the crankshaft pulley and camshaft pul-

ley are both at TDC.

CRANKSHAFT PULLEY:

CAMSHAFT PULLEY:

lf the camshaft and crankshaft pulleys are not posi-

tioned at TDC, remove the timing belt and adjust

the position following the procedure on page 6-20'

Then reinstall the timing belt.

After installation, adjust the tension of each belt

. See section 23 for alternator belt tension adjust-

ment.

a See section 22 tot NC compressor belt tension

adjustment.

. See section 17 for P/S pump belt tension adjust

ment,

(wHrTE)

"UP" MARK

TDC MARK

11.

6-21

Page 138 of 2189

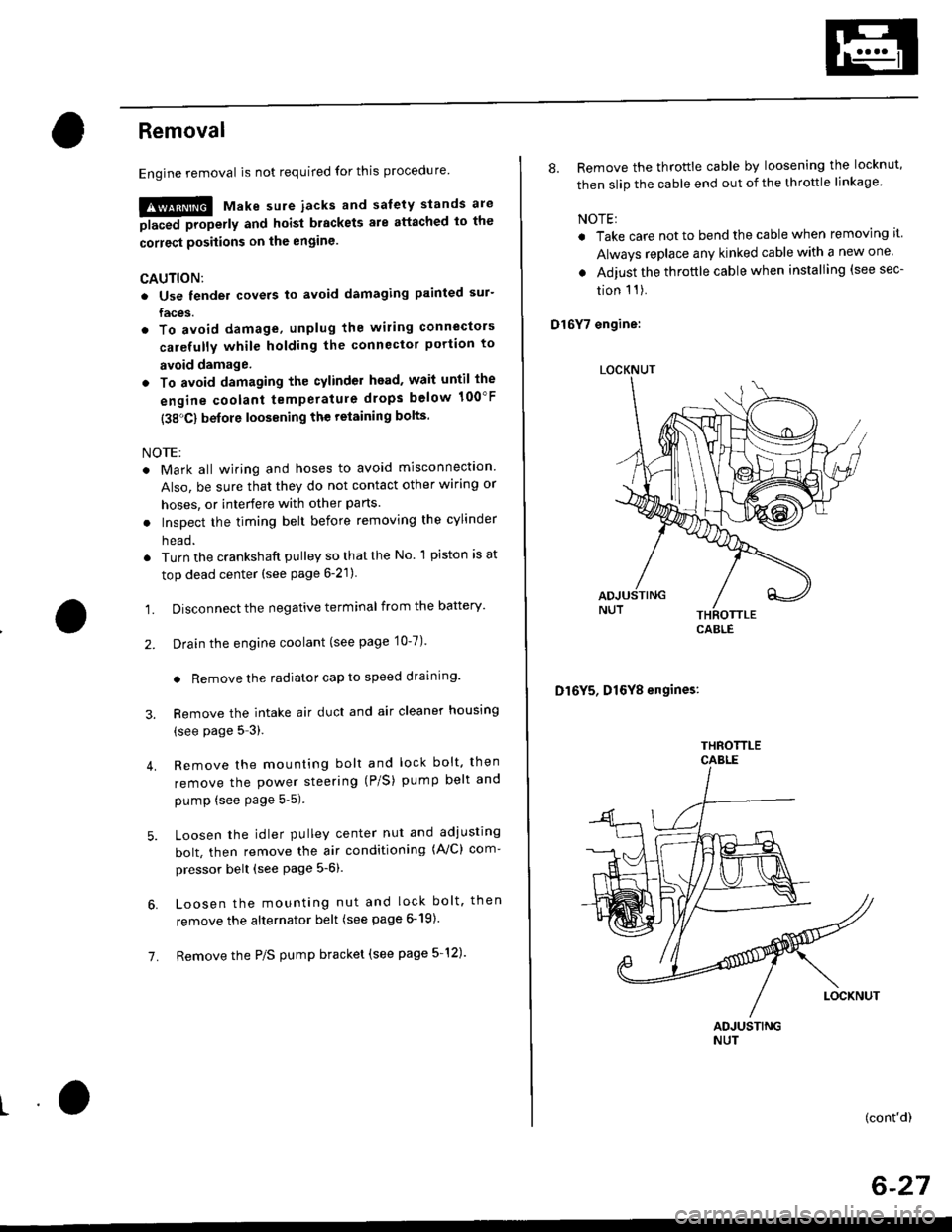

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE

Page 148 of 2189

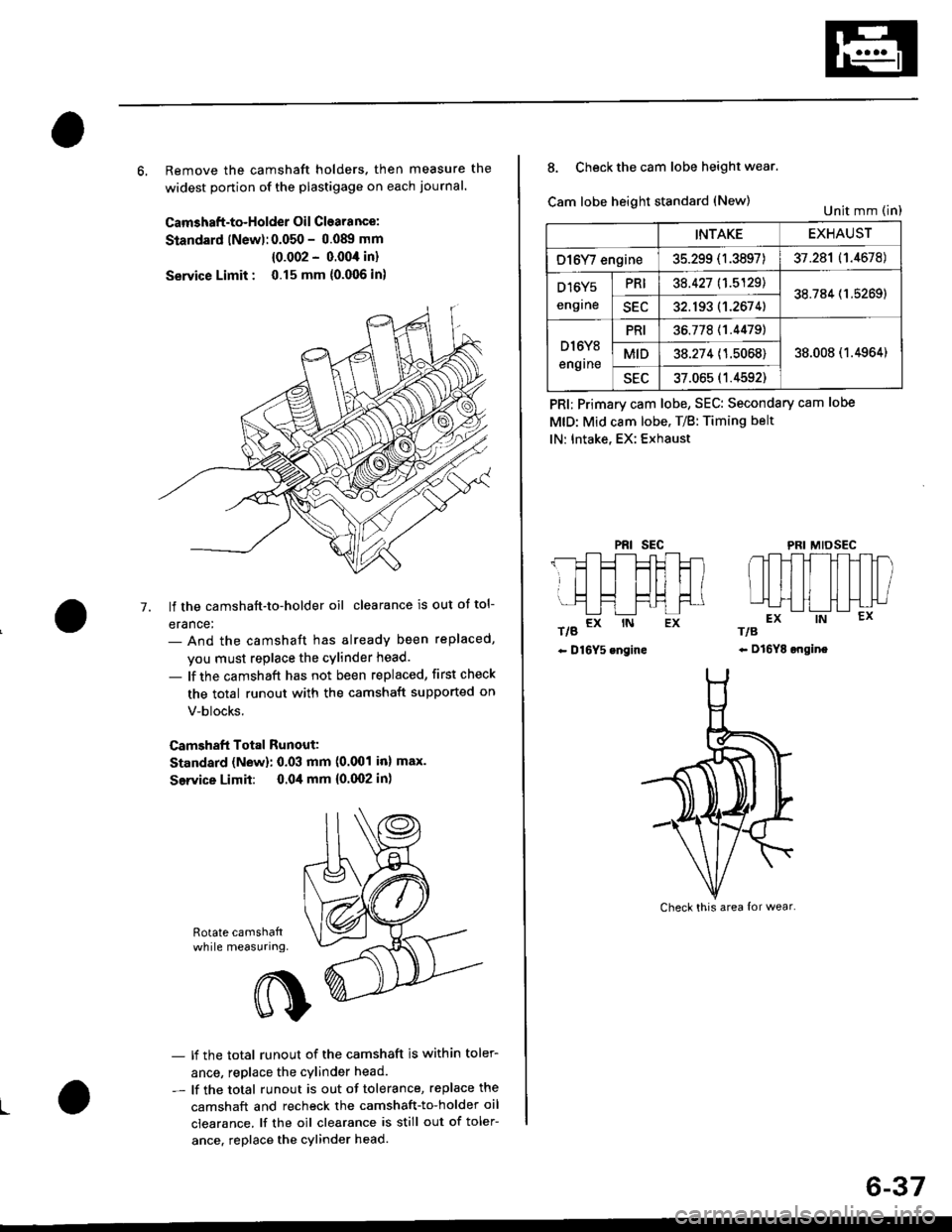

6, Remove the camshaft holders. then measure the

widest ponion of the plastigage on each journal.

Camshaft-to-Holder Oil Clearance:

Standard lNew):0.050 - 0.08!t mm

{0.002 - 0.004 in}

Service Limit : 0.15 mm {0.006 in)

lf the camshaft-to-holder oil clearance is out ot tol-

erance:- And the camshaft has already been replaced,

you must replace the cylinder head.

- lf the camshaft has not been replaced, first check

the total runout with the camshaft supported on

V-blocks.

Camshaft Total Runout:

Standard (New): 0.03 mm (0.001 inl max.

Service Limit: 0.04 mm {0.(X)2 in)

-7.

Rotate camshattwhile measuring.

L

- lf the total runout of the camshaft is within toler-

ance, replace the cylinder head.

- lf the total runout is out of tolerance, replace the

camshaft and recheck the camshaft-to-holder oil

clearance. lf the oil clearance is still out of toler-

ance. replace the cylinder head.

INTAKEEXHAUST

O16Y/ engine35.299 (1.3897)37.281 (1.4678)

D16Y5

engrne

PRI38.427 11.5129138.784 (1.5269)

SEC32.193 (1.2674)

D l6Y8

engrne

PRI36.77811.44791

38.008 (1.4964)MID38.274 (1.5068)

sEu37.065 (1.4592)

8. Check the cam lobe height wear.

Cam lobe height standard (New)

t/g a* rN Ex

- D16Y5 engine

PRI; Primary cam lobe, SEC: Secondary cam lobe

MtD: Mid cam lobe. T/B: Timing belt

lN: Intake, EX: Exhaust

PRIsEcMIDSEC

rts

- Dl6YE ongine

Unit mm (in)

Check this area {or wear.

6-37

Page 154 of 2189

Valves

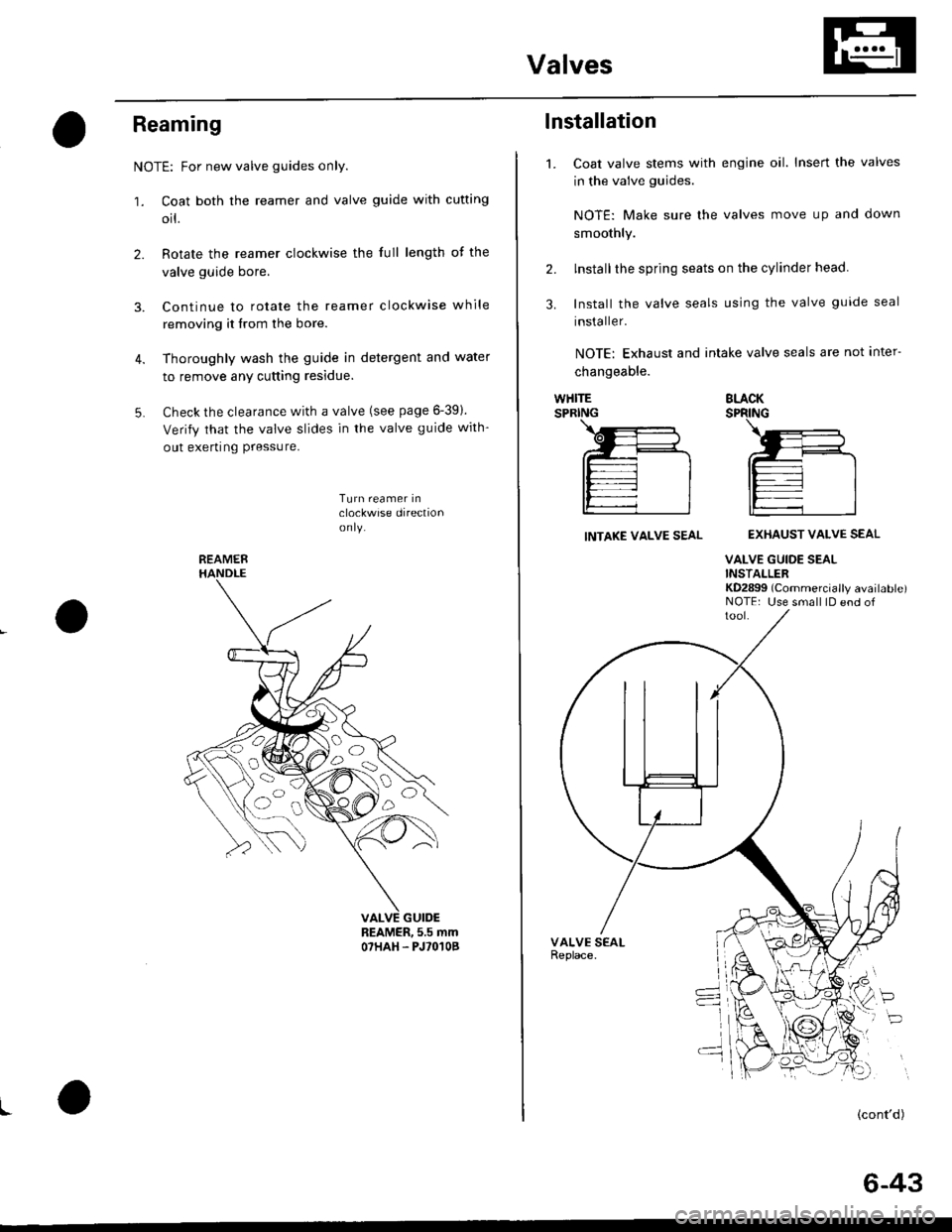

Reaming

NOTE: For new valve guides only.

1. Coat both the reamer and valve guide with cufting

orl.

2. Rotate the reamer clockwise the full length of the

valve guide bore.

3. Continue to rotate the reamer clockwise while

removing it from the bore.

4. Thoroughly wash the guide in detergent and water

to remove any cutting residue.

5. Check the clearance with a valve (see page 6-391.

Verify that the valve slides in the valve guide with-

out exerting Pressure.

Turn reamer inclockwise direclionon ly.

REAMER, 5.5 mmO7HAH. PJ'O'IOB

I

REAMER

oa)o,

o

o

1.

lnstallation

Coat valve stems with engine oil. Insert the valves

in the valve guides.

NOTE: Make sure lhe valves move up and clown

smoothly.

lnstallthe spring seats on the cylinder head.

Install the valve seals using the valve guide seal

installer.

NOTE: Exhaust and intake valve seals are not inter-

changeable.

2.

3.

WHITESPRINGBLACKSPRING

INTAKE VALVE SEALEXHAUST VALVE SEAL

VALVE GUIDE SEALINSTALLERKD2899 (Commercially available)NOTE: Use small lD end of

P

(cont'd)

6-43

Page 155 of 2189

Valves

Camshaft/Rocker Arms and

Camshaft Seal/Pulley

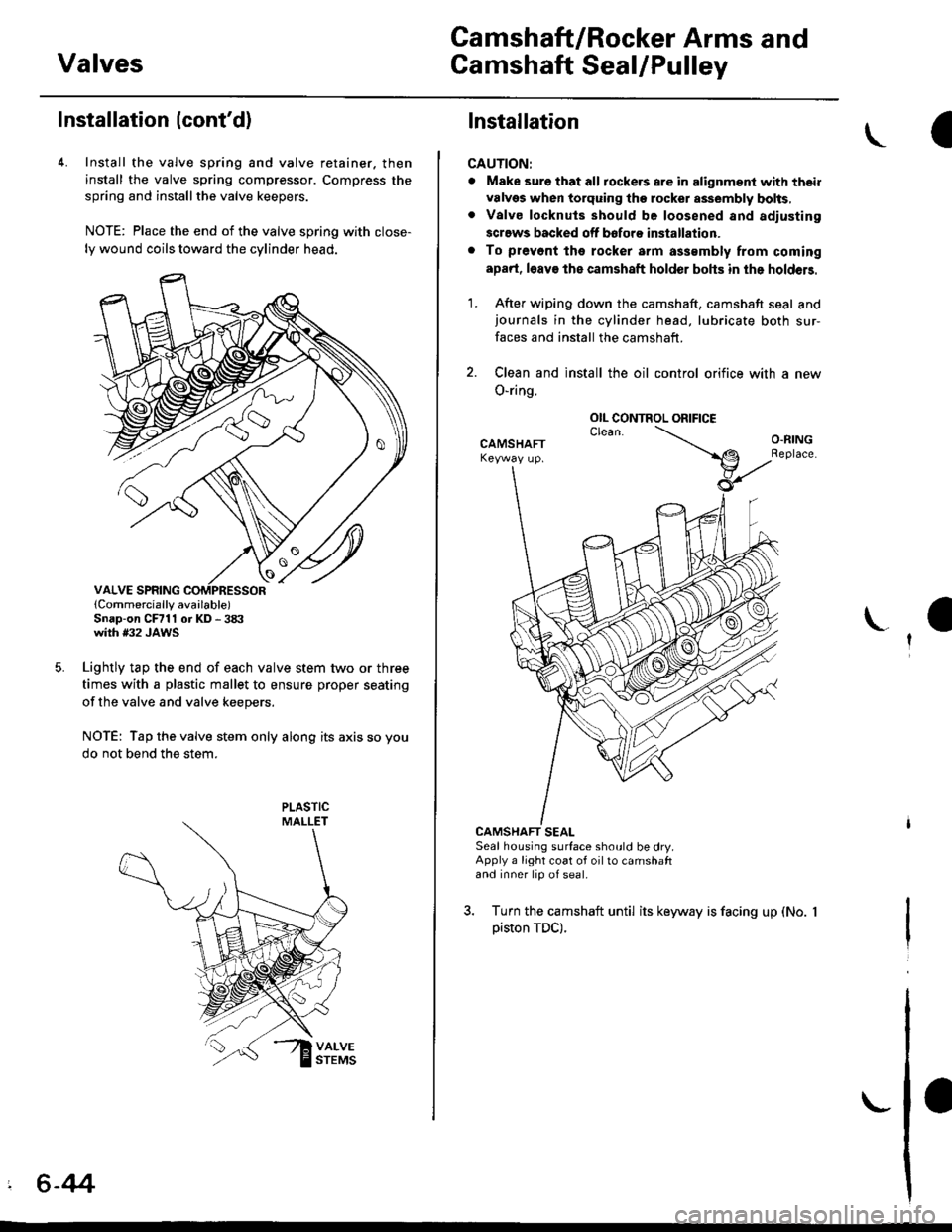

Installation (cont'd)

4. Install the valve spring and valve retainer. then

install the valve spring compressor. Compress the

spring and installthe valve keepers.

NOTE: Place the end of the valve spring with close-

ly wound coils toward the cylinder head.

lCornmercially available)Snap-on CFrll or KD - 3tX'with #32 JAWS

Lightly tap the end of each valve stem two or three

times with a plastic mallet to ensure proper seating

of the valve and valve keepers.

NOTE: Tap the valve stem only along its axis so you

do not bend the stem.

' 6-44

Installation

CAUTION:

. Make sure that all tockers are in alignment with their

valvgs when torquing the rocket assembly bolts,. Valve locknuls should be loosened and adiusting

screws backed off bofore installation.

. To prevont tho rocker arm a$smbly from coming

apad, l6av€ the camshaft holder bohs in the holdeB.

1. After wiping down the camshaft, camshaft seal andjournals in the cylinder head, lubricate both sur-

faces and install the camshaft.

2. Clean and install the oil control orifice with a new

O-ring.

CAMSHAFT SEALSeal housing surface should be dry.Apply a light coat of oil to camshaftand inner lip of seal.

3. Turn the camshaft until its keyway is facing up (No.

piston TDC).

OIL CONTROL ORIFICE

Page 156 of 2189

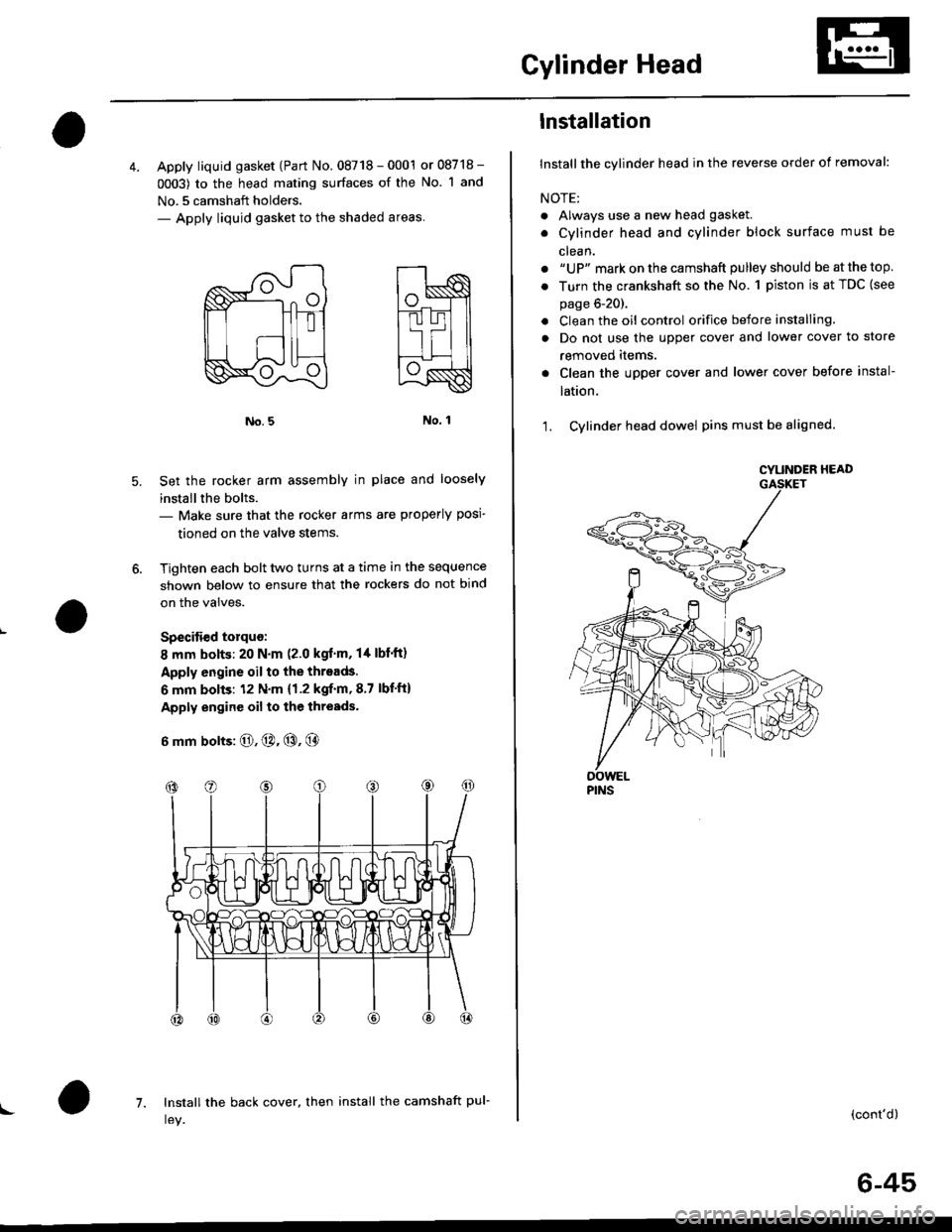

Cylinder Head

4. Apply liquid gasket (Part No. 08718 - 0001 or 08718 -

0003) to the head mating surfaces of the No. 1 and

No.5 camshaft holders.- Apply liquid gasket to the shaded areas

Set the rocker arm assemblY in place and loosely

installthe bolts.- Make sure that the rocker arms are properly posi-

tioned on the valve stems.

Tighten each bolt two turns at a time in the sequence

shown below to ensure that the rockers do not bind

on the valves.

Specitied torquo:

8 mm bolts: 20 N.m (2.0 kgt'm, l/t lbf'ft)

Apply engine oil to the threads.

6 mm bolts: 12 N.m {1.2 kgif'm, 8.7 lbf'ft)

Apply engine oil to the thresds.

6 mm bolts: O, @. @, @

7. Install the back cover. then install the camshaft pul-!

6-45

lnstallation

lnstallthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cylinder block surface must be

clean.

. "UP" mark on the camshaft pulley should be at the top

. Turn the crankshaft so the No. 1 piston is at TDC (see

page 6-20).

. Clean the oil control orifice before installing.

a Do not use the upper cover and lower cover to store

removeo rlems.

Clean the upper cover and lower cover before instal-

taUon.

Cylinder head dowel pins must be aligned.1.

CYUNOER HEAD

PINS

(cont'd)

Page 160 of 2189

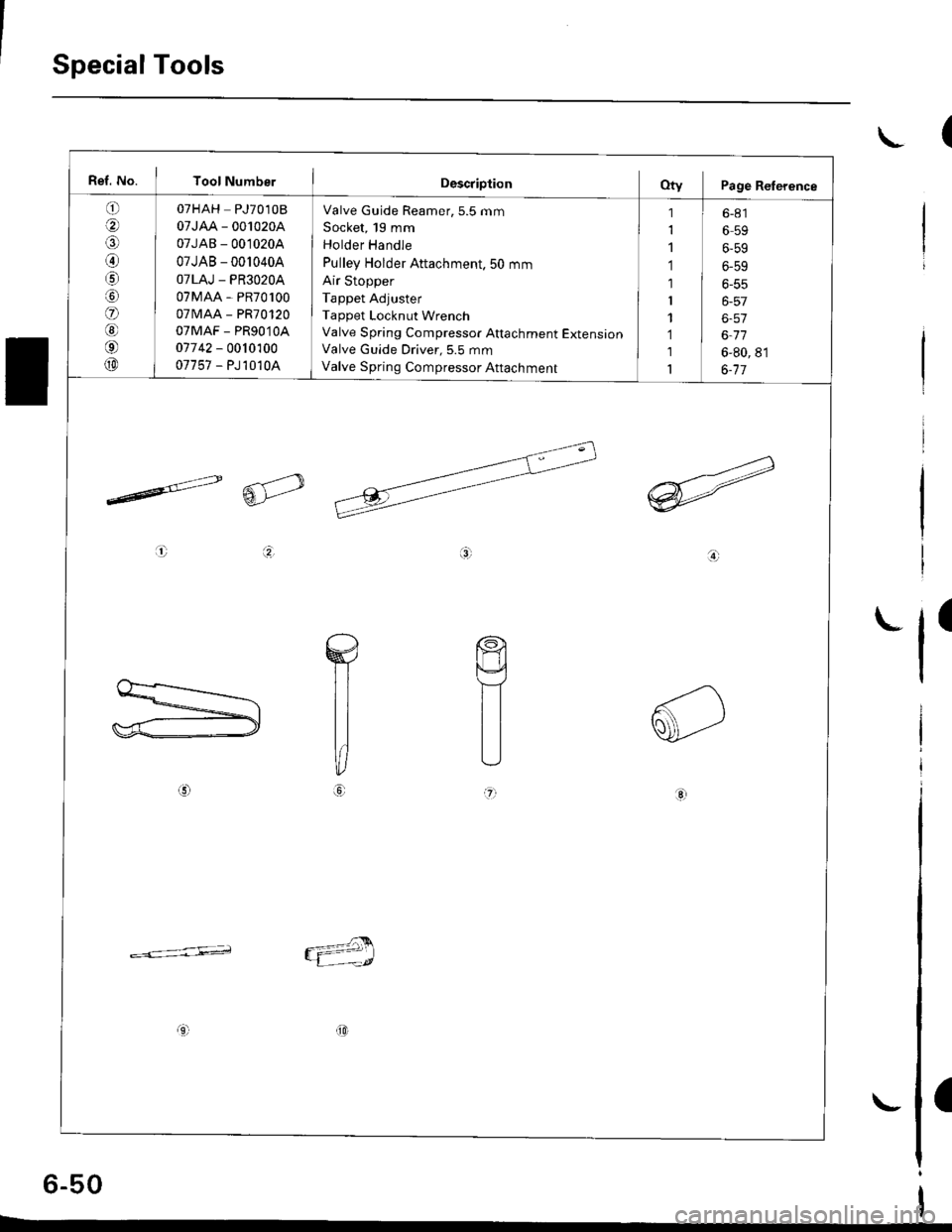

Special Tools

(\

Ref. No. I Tool NumberDescriptionOty Page Relerence

q oTHAH PJ7010B

g I 07JAA-001020A

g I 07JAB-0010204

I 07JAB - 0010404

g 07LAJ - PR3020A

|6) 07MAA - PR70100

g I ozvu,r - enu orzo

g 07MAF - PR9010A

g 07742 - 0010100(!D I 07757-PJ10104

Valve Guide Reamer,5.5 mm

Socket, 19 mm

Holder Handle

Pulley Holder Attachment. 50 mm

Air Stopper

Tappet Adjuster

Tappet Locknut Wrench

Valve Spring Compressor Attachment ExtensionValve Guide Driver, 5.5 mm

Valve Spring Compressor Attachment

1 I 6-81

1 659

1 6-59

1 ] 6-5s

1 I 6-55

1 6-57

1 6-57

1 J 6-77

1 6-80, 81

1 6-71

ta;

aL)'n

-=<-,,LE;;

(D

a

6-50

\-

Page 164 of 2189

VTEC Solenoid ValveVTEC Rocker Arms

a

I

(

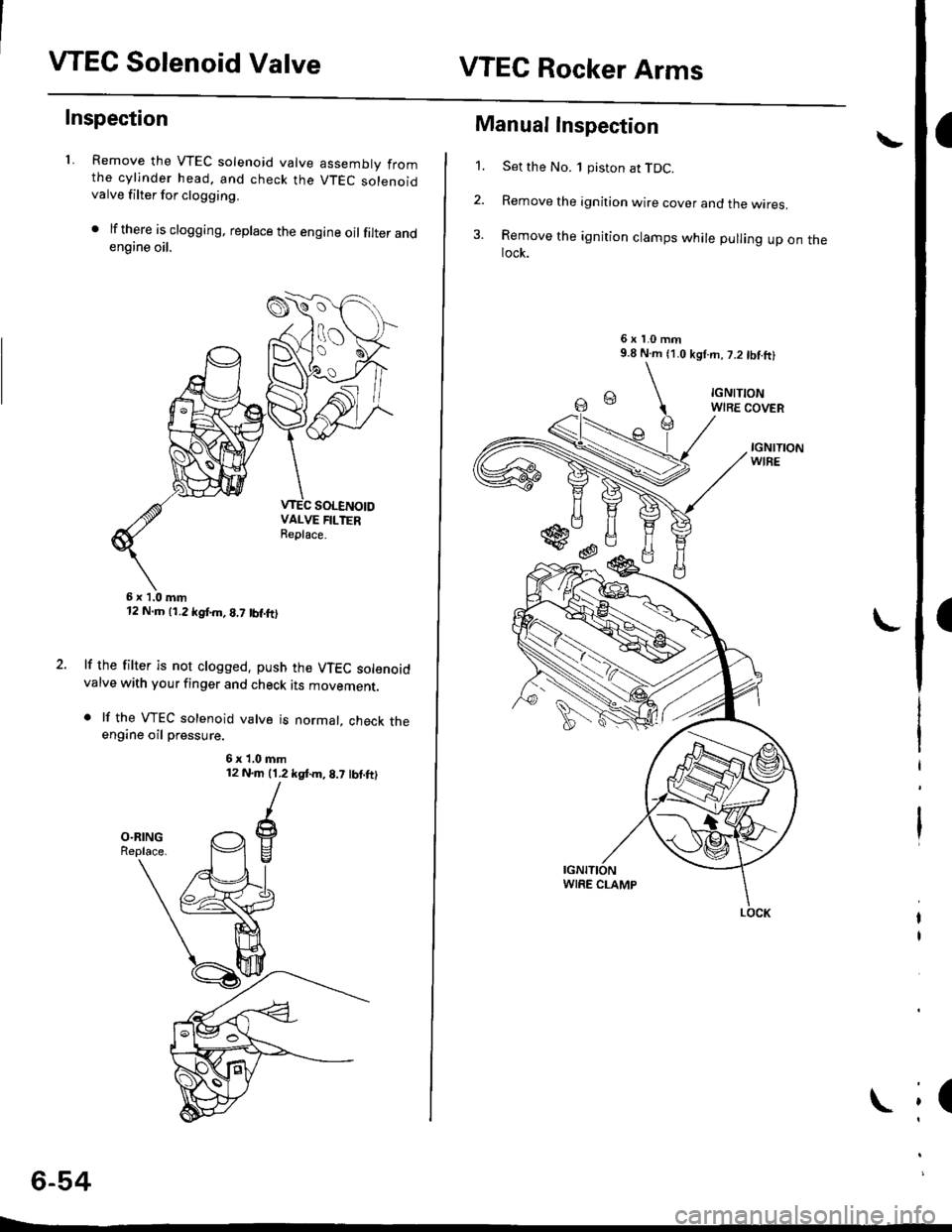

Inspection

1. Remove the VTEC solenoid valve assembly fromthe cylinder head. and check the VTEC solenoidvalve filter for clogging.

. lf there is clogging, replace the engine oilfilter andengine oil.

6x1.0mm12 N.m (1.2 kgf.m, B,7 tbf.ftl

lf the filter is not clogged. push the VTEC solenoidvalve with your finger and check its movemenr.

. lf the VTEC solenoid valve is normal, check theengine oil pressure.

6x1.0mm12 N.m (1.2 kgtm,8.7 lbt.ft)

6-54

L-

SOLENOID

Manual Inspection

1. Set the No. 1 piston at TDC.

2. Remove the ignition wire cover and the wires.

3. Remove the ignition clamps while pulling up on theIock.

6xl.0mm9.8 N.m (1.0 kgl.m, 7.2 tbtftl

IGNITIONWIRE COVER

IGNITIONWIRE

\

LOCK

Page 167 of 2189

Valve Glearance

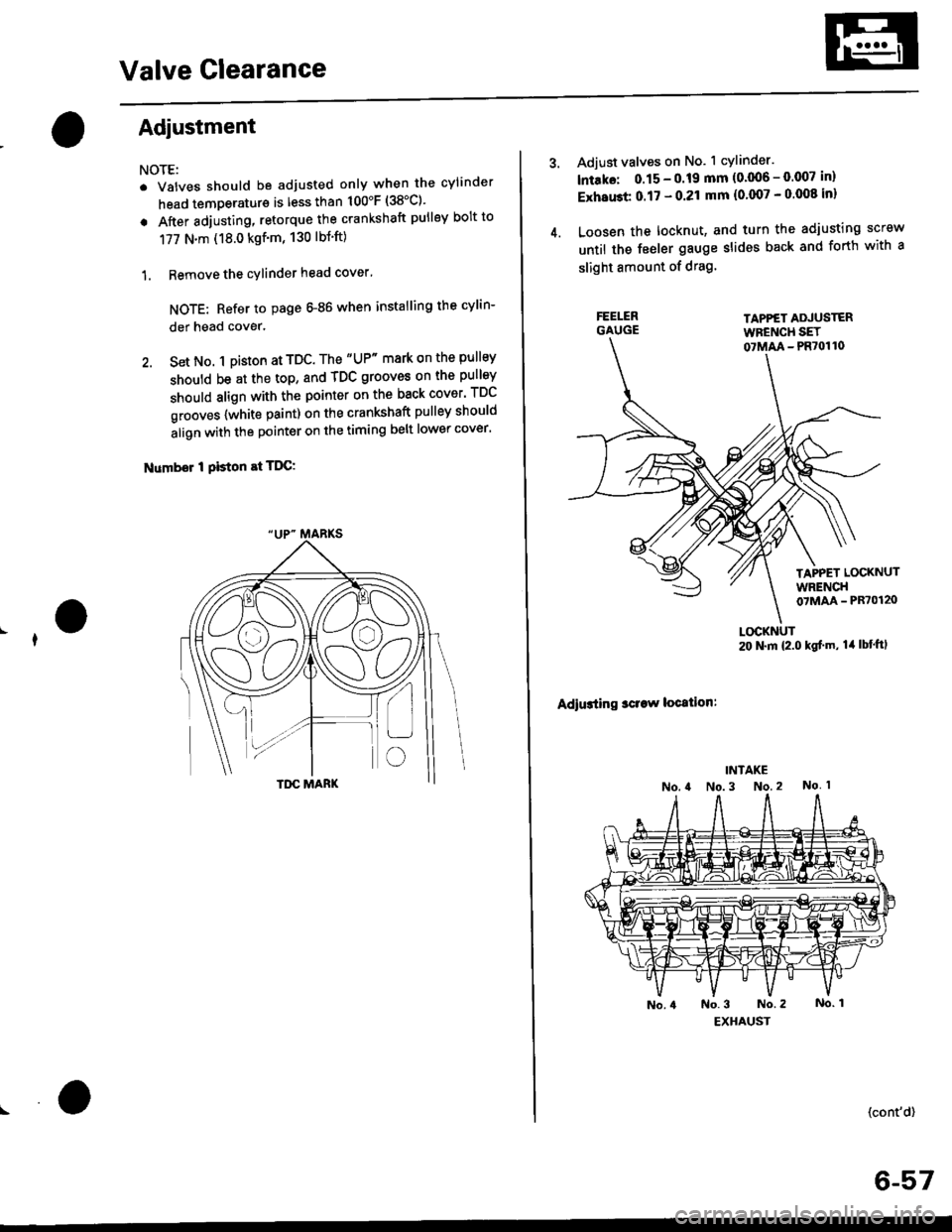

Adjustment

NOTE:

. Valves should be adjusted only when the cylinder

head temperaturs is less than 100'F (38'C)'

. After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf'm, 130 lbt'ft)

1. Remove the cylinder head cover'

NOTE: Refer to page G86 when installing the cylin-

der head cover.

2. Set No. 1 pi$on at TDC. The "UP" mark on the pullsy

should be at the top, and TDC grooves on the pulley

should align with the pointer on the back cover' TDC

grooves {white paint) on the crankshaft pulley should

align with the pointer on the timing belt lower cover'

Number I Piston at TDC:

4.

Adjust valves on No. 1 cylinder.

lntako: 0.15 - 0.19 mm {0'006 - 0.007 in)

ExhaGt 0.17 - 0.21 mm {0'007 - 0 008 inl

Loosen the locknut, and turn the adjusting screw

until the feeler gauge slides back and forth with a

slight amount of drag.

TAPPET ADJUSTERWFENCH SET07MM - PR70110

TAPPET LOCKNUTWRENCH07MAA - PR70120

Adiusting sclaw location:

LOCKNUT20 N.m {2.0 kgf'm, lil lbt'ftl

(cont'd)

6-57