page 112 HONDA CIVIC 1996 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1337 of 2189

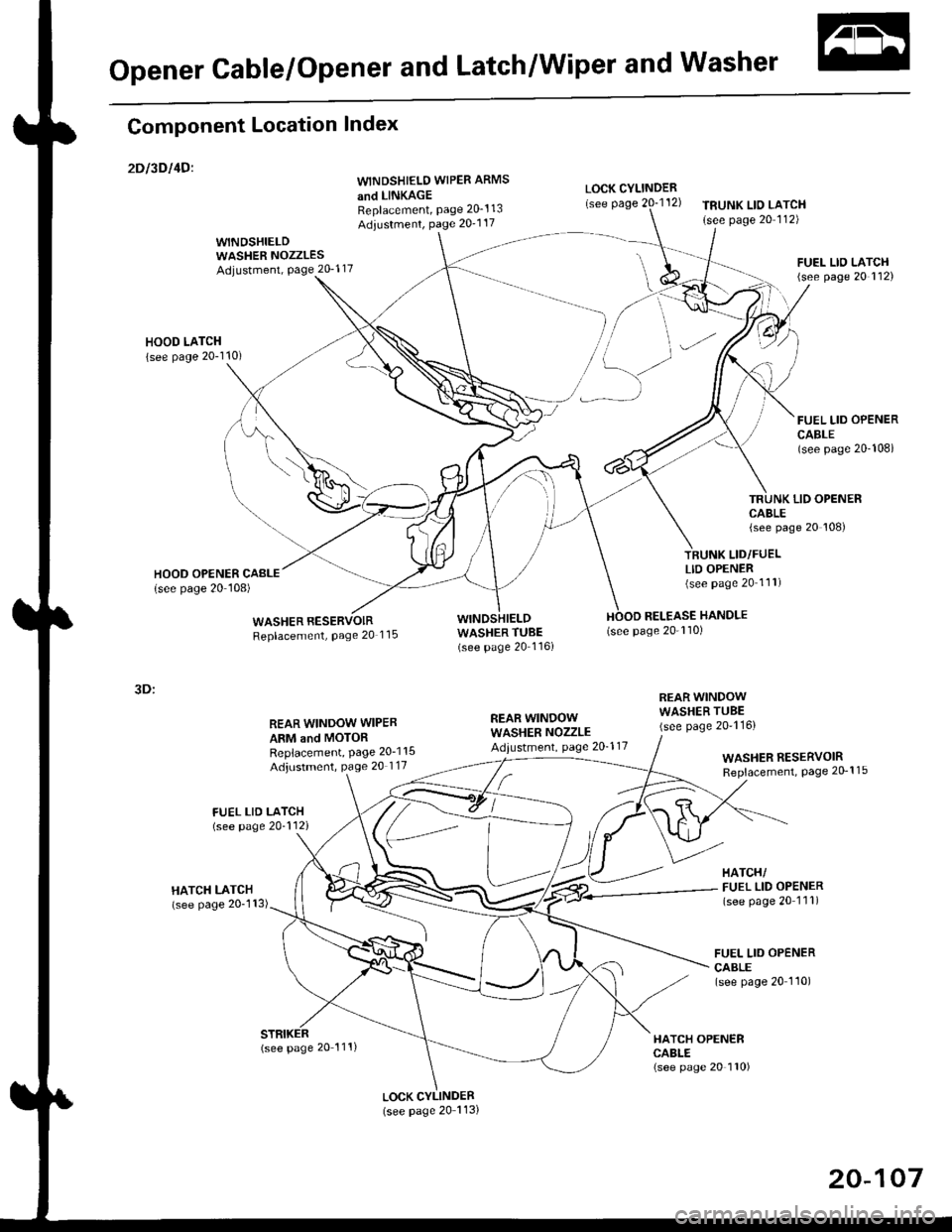

Opener Cable/Opener and Latch/Wiper and Washer

Component Location Index

2Dt3DItD'

y"Tl,"nll,ib?*'r.* o*t"

Replacement, Page 20_1 13

Adiustment, Page 20'1 17

WINDSHIELDWASHER NOZZLESAdjustment, Page 20_1 17

HOOD LATCH

{see page 20-110)

REAR WINDOW WIPER

ARM and MOTORReplacement, Page 20-1 15

Adjustment, page 20 117

LOCK CYLINDER(see page 20 113)

LOCK CYLINDER

TRUNK LIO LATCH

{see page 20 112)

FUEL LID OPENERCABLE(see page 20-108i

LID OPENERCABLE(see page 20 108)

LID/FUELLID OPENER(see page 20 111)

RELEASE HANDLE(see page 20-110)

3D:

REAR WINDOWWASHER NOZZLEAdiustment, page 20-1 17

REAR WINDOWWASHER TUBE(see page 20-116)

HATCH OPENERCABLE(see page 20 110)

WASHER RESERVOIRReplacement, Page 20-1 15

HATCH/FUEL LID OPENER(see page 20 1'11)

FUEL LID OPENERCABLE(see page 20 110)

(see page 20 111)

20-107

Page 1339 of 2189

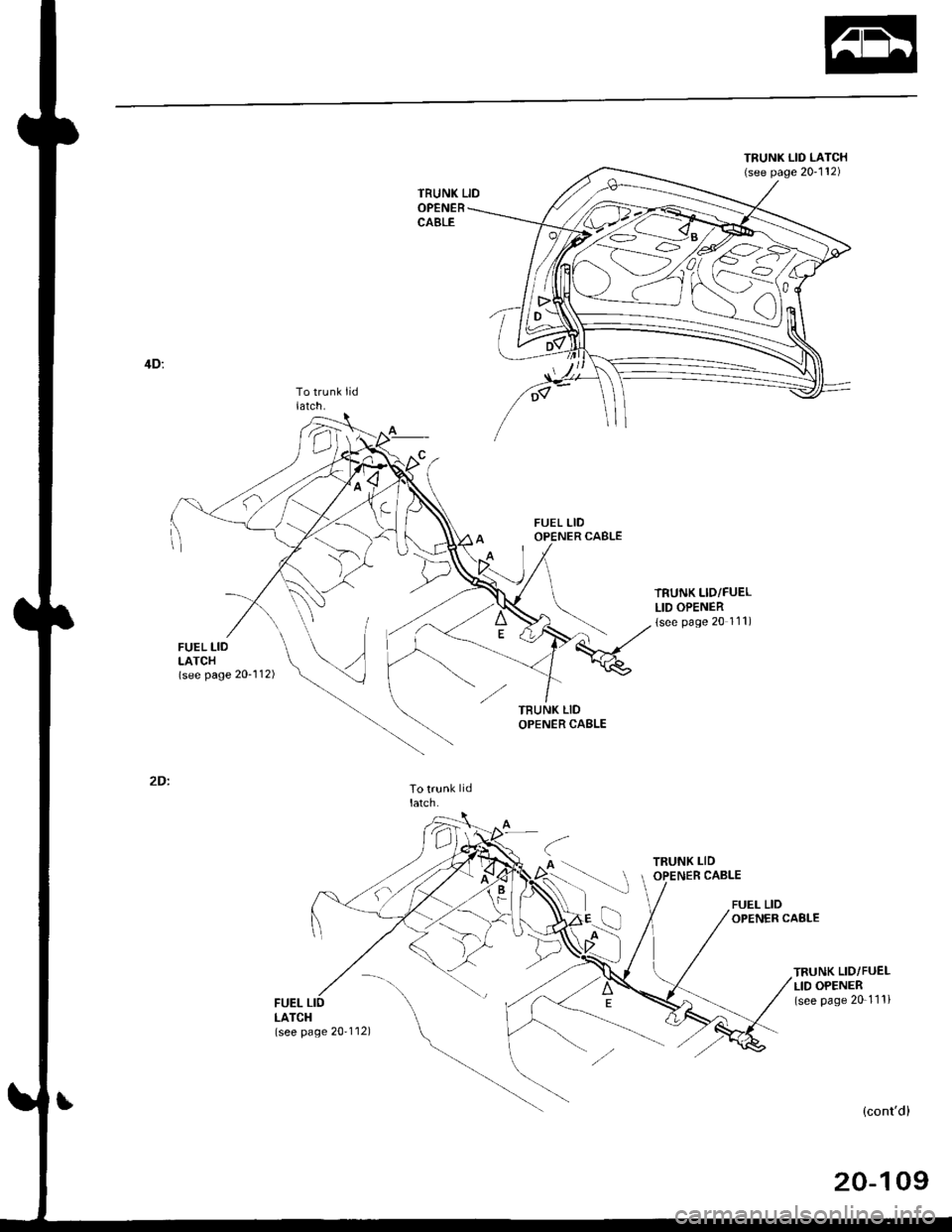

TRUNK LID LATCH(see page 20'112)

?e-=....-

4D:

To trunk lidlatch.

latch.

TRUNK LID/FUELLID OPENER(see page 20 111)

TRUNK LID

OPENER CABLE

aA '--!

\- - -l

N"La

FUEL LIDOPEN€R CAELE

TRUNK LID/FUELLID OPENER(see page 20-111)FUELLATCH

(cont'd)

20-109

(see page 20'112)

Page 1340 of 2189

Opener CablesOpener and Latch

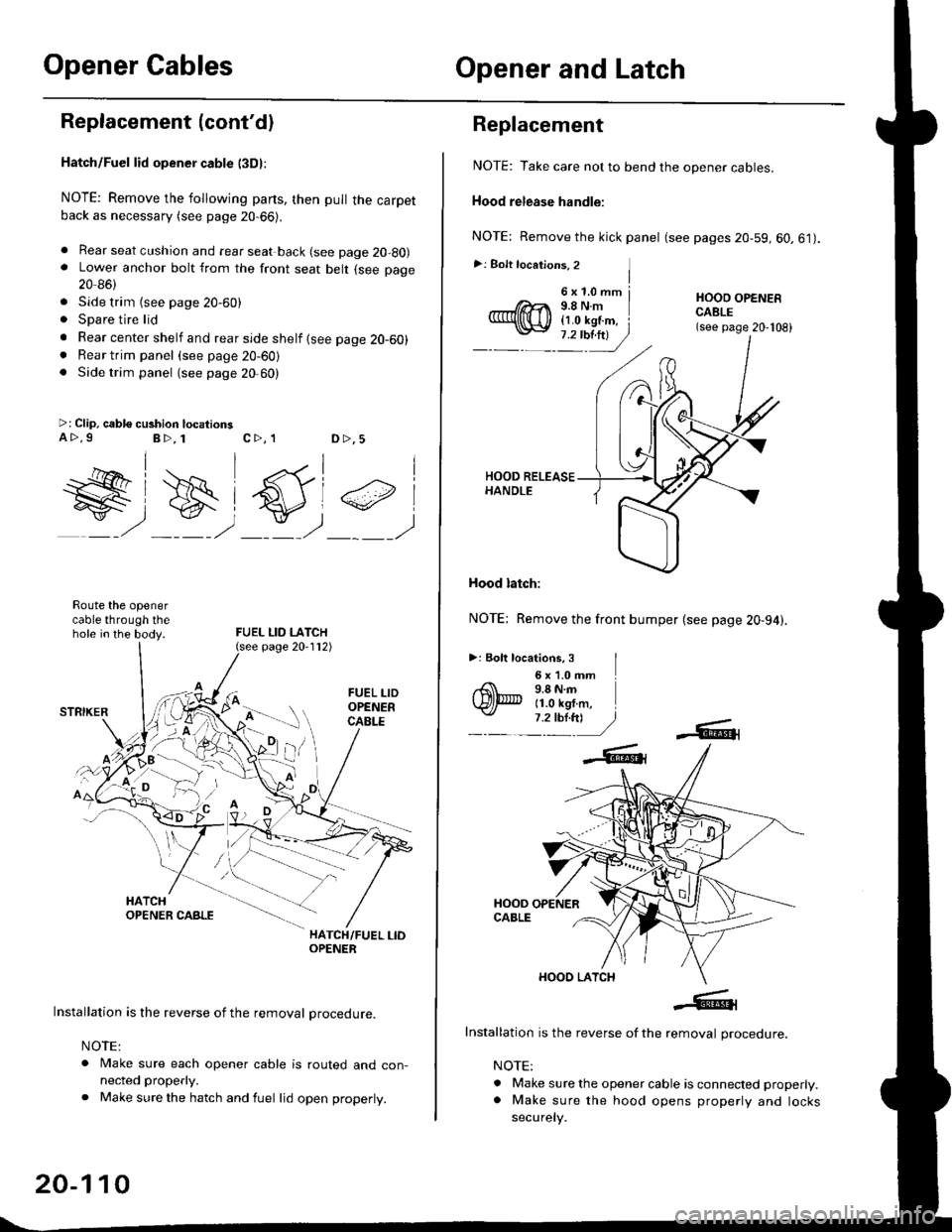

Replacement (cont'dl

Hatch/Fuel lid opener cable l3Dl:

NOTE: Remove the following parts, then pull the carpetback as necessary (see page 20-66).

. Rear seat cushion and rear seat back (see page 20-80). Lower anchor bolt from the front seat belt (see page

20 86)

. Side trim {see page 20-60). Spare tire lid

. Rear center shelf and rear side shelf {see page 20-60). Rear trim panel (see page 20-60). Side trim panel (see page 20,60)

>: Clip, cable cushion locationsa>.9B>, 1c>, 1D >,5

W#)

FUEL LID LATCH

#,

Route the openercable through thehole in the body.

HATCH/FUEL LIOOPENER

Installation is the reverse of the removal procedure.

NOTE:

. Make sure each opener cable is routed and con-nected properly.

. Make sure the hatch and fuel lid open properly.

page 20-112)

20-110

6x1.0mm j9.8Nm{1.0 kgf.m, i

Replacement

NOTE: Take care not to bend the opener cables.

Hood release handle:

NOTE: Remove the kick panel (see pages 20-59, 60.61).

>: Bolt locations, 2 ]I

HOOO OPENERCABLE(see page 20-108)

Hood latch:

NOTE: Remove the front bumper (see page 20-94).

>: Eolt locations, 3 I6 x '1.0 mm9.8 N.m11.0 kgf.m,

Installation is the reverse of the removal procedure.

NOTE:

. Make sure the opener cable is connected properly.. Make sure the hood opens properly and locks

securely.

Page 1342 of 2189

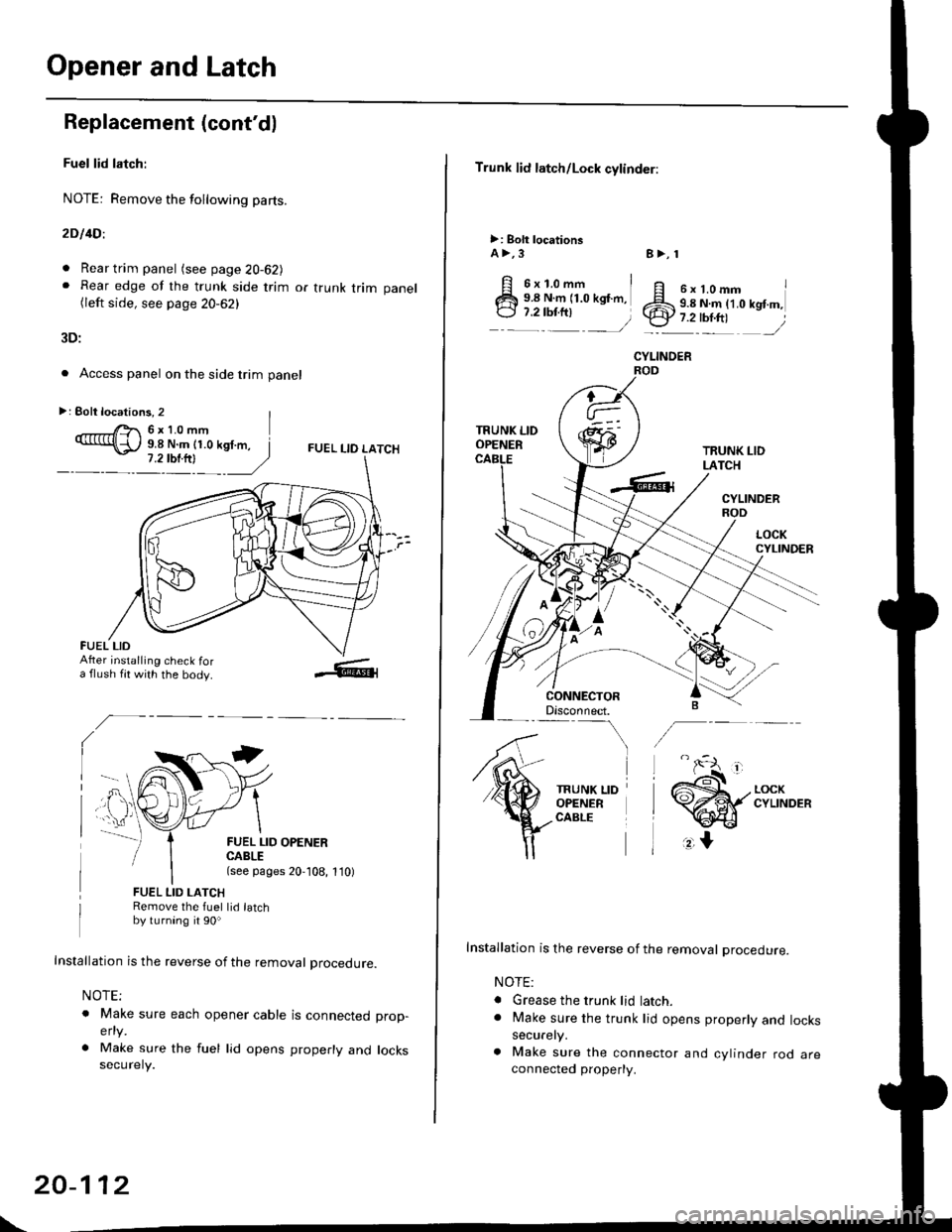

Opener and Latch

Replacement (cont'd)

Fuel lid latch:

NOTE: Remove the following pa(s.

2D l4Dl

. Rear trim panel (see page 20-62J. Rear edge of the trunk side trim or trunk trim panel(left side, see page 20-62)

3D:

. Access panel on the side trim panel

FUEL I-IO LATCH

II

FUEL LID OPENERCABLE(see pages 20,108, 1'10)

FUEL LID LATCHRemove the fuel lid latchby turning it 90o

Installation is the reverse of the removal procedure.

NOTE;

o Make sure each opener cable is connectedelty

. Make sure the fuel lid opens properly andsecurely.

prop-

locks

>: Eolt locations, 2 |r'- 6x10mm9.8 N.m (1.0 kgf.m, I

FUEL LIDAfter installing check fora flush fit with the body.

\

20-112

Trunk lid latch/Lock cylinder:

>: Bolt locationsA >,3

6x1.omm i9.8 N.m (1.0 kgf.m,

:::^ _=)

TRUNK LIDOPENER

CONNECTORDisconnect.-\

TRUNK LIDOPENERCABLE

8>, 1

ff e rt.omm IZS 9.8 N.ln (1.0 kgt m,.ty 7.2-tbr.ftt ,/

CYLINOER

TRUNK LIDLATCH

CYLINDERROD

Installation is the reverse of the removal procedure.

NOTE:

. Grease the trunk lid latch.. Make sure the trunk lid opens properly and lockssecurely.

a Make sure the connector and cylinder rod areconnected property.

Page 1391 of 2189

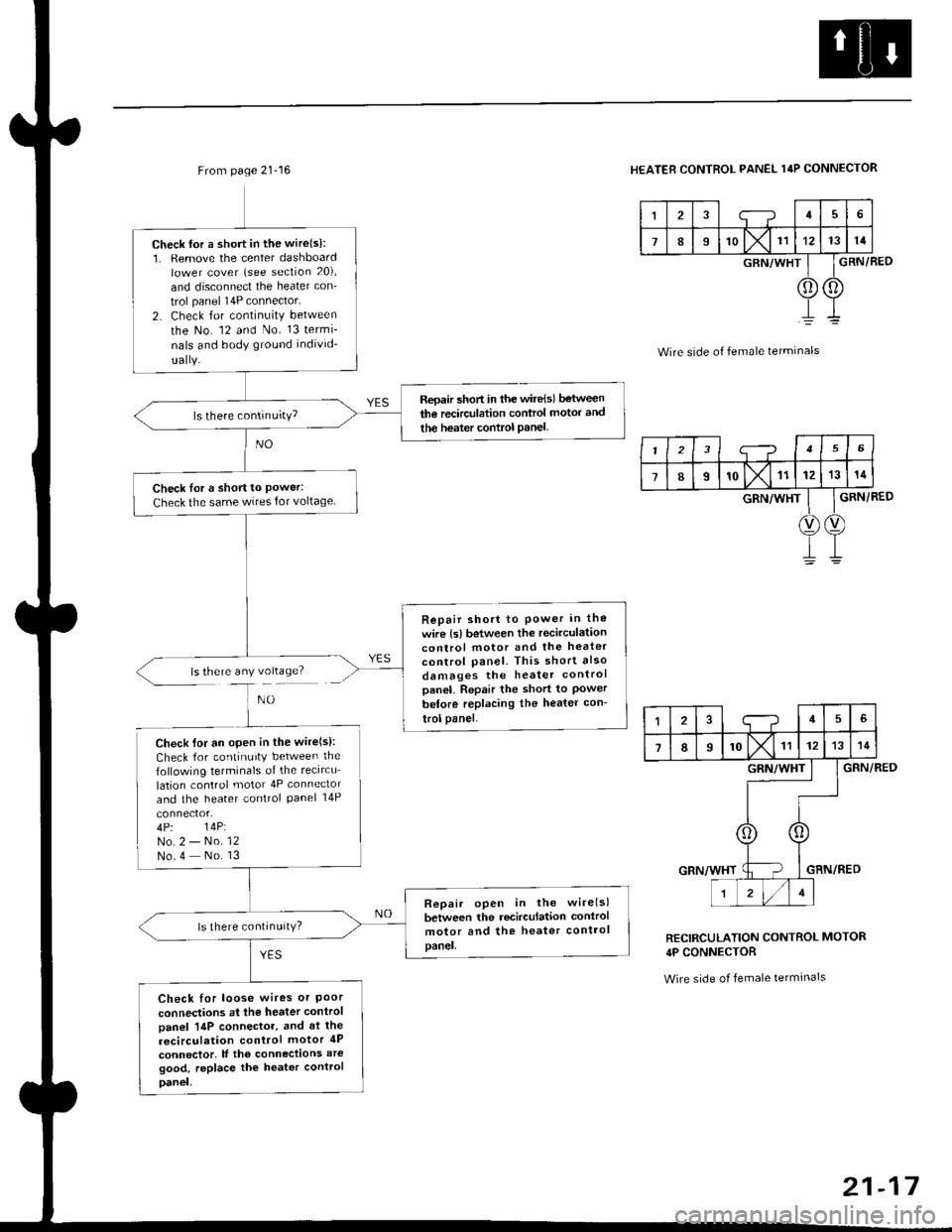

From page 21-16

ls there any voltage?

Check {or a short in the wire(s):1. Remove the center dashboardlower cover (see section 20),

and disconnect the heater con_

trol panel 14P connector'

2. Check for continuity between

the No. 12 and No. 13 termi-

nals and body ground individ-

Repair 5hort in the wire{sl between

the recirculation control motor and

the heater control Panel

Check Ior a short to Power:Check the same wires for voltage

Repair short to Power in the

wire {s) between the recirculationcontrol motor and the heater

control panel. This short also

damages the heater controlpanel. Repair the short to Powerbetore replacing the heater con-

trol panel.

Check lor an open in the wire(s):

Check for continuity between the

following terminals of the recircu

lation control motor 4P connector

and the heater control Panel 14P

4P. 14P:No.2 - No. 12No.4 No. 13

Repair open in the wirelsl

between the recirculation control

motor and the heater controlpanel.

ls there continuitY?

Check for loose wires or Poorconnections at the heater control

Danel 14P connector, and at the

recirculation control motor 4P

connector. lf the connections aregood, replace the heater control

Danel,

HEATER CONTROL PANEL 14P CONNECTOR

I;-?45

789'o lx11121314

GRN/WHT

0) (0

GRN/BED

Wire side of female terminals

GRN/RED

GRN/RED

RECIRCULATION CONTROL MOTOR

4P CONNECTOR

Wire side of female tetminals

I23i--?156

78I'olx11121314

GRN/WHT

V)(v

145

7IIrol\l rr1213

GRN/WHT

r zl/lt

21-17

Page 1408 of 2189

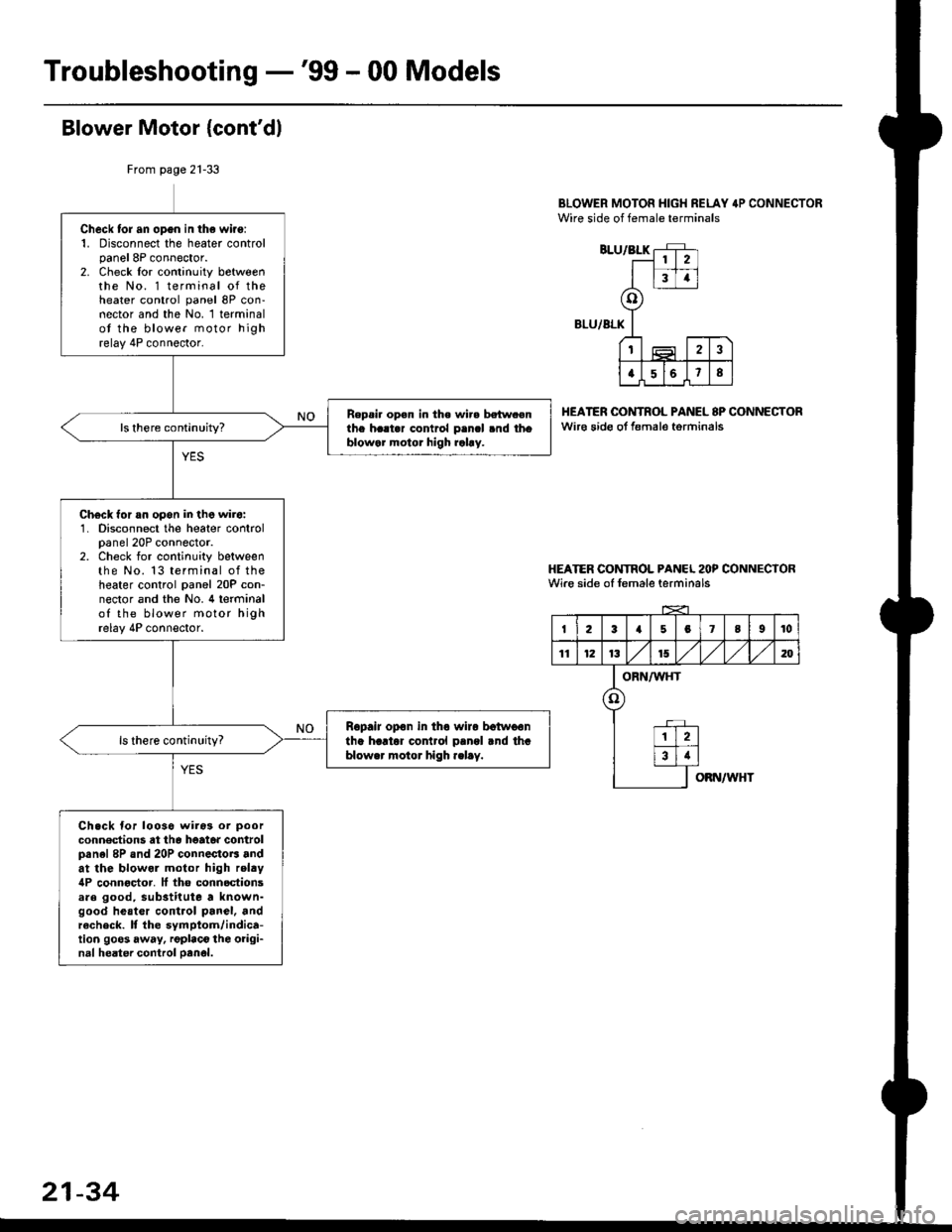

Troubleshooting -'99 - 00 Models

Blower Motor {cont'dl

BLOWER MOTOR HIGH RELAY 4P CONNECTORWire side of female terminals

BLU/BLK

BLU/ALK

HEATER OONTROL PANEL 8P CONNECTORwir€ sido ot f€male torminals

HEATER CONTROL PANCL 2OP CONNECTORWire side of female terminals

From page 21-33

Check tor an opgn in the wiro:1. Disconnect the heater controlpanel 8P connector.2. Check lor continuity betweenthe No. 1 terminal of theheater control panel 8P con-nector and the No. 1 terminalot the blower motor highrelay 4P connector.

Repsi. op€n in the wir. betw.enthe h..t.r contrcl p.ncl .nd thoblowar motor high rahy.

Ch€ck for an opon in the wir6:1. Disconnect the heater controlpanel 20P connector.2. Check for continuity betweenthe No. 13 terminal of theheater control panel 20P con-nector and the No. 4 terminalof the blower motor highrelay 4P connector.

Ropair opon in tho wiro botwoontha hartor cor rol pangl rnd thablower motor high .elay.

Ch.ck for looso wiros or poor

conn€dions at th6 heato. controlpanel 8P and 20P connectoB andat the blowol motor high relty4P connoctor. It tho connoctionsare good, substitute a known-good heatcr control panel, andrecheck. It the symptom/indica-tion goos away, rgplaco the oiigi-nal heater control oanol.

2

34

o

t2

a568

I23a5078I10

11121315,/1,/1,/m

ORN/WHT

o

12

34

OBN/WHT

21-34

Page 1442 of 2189

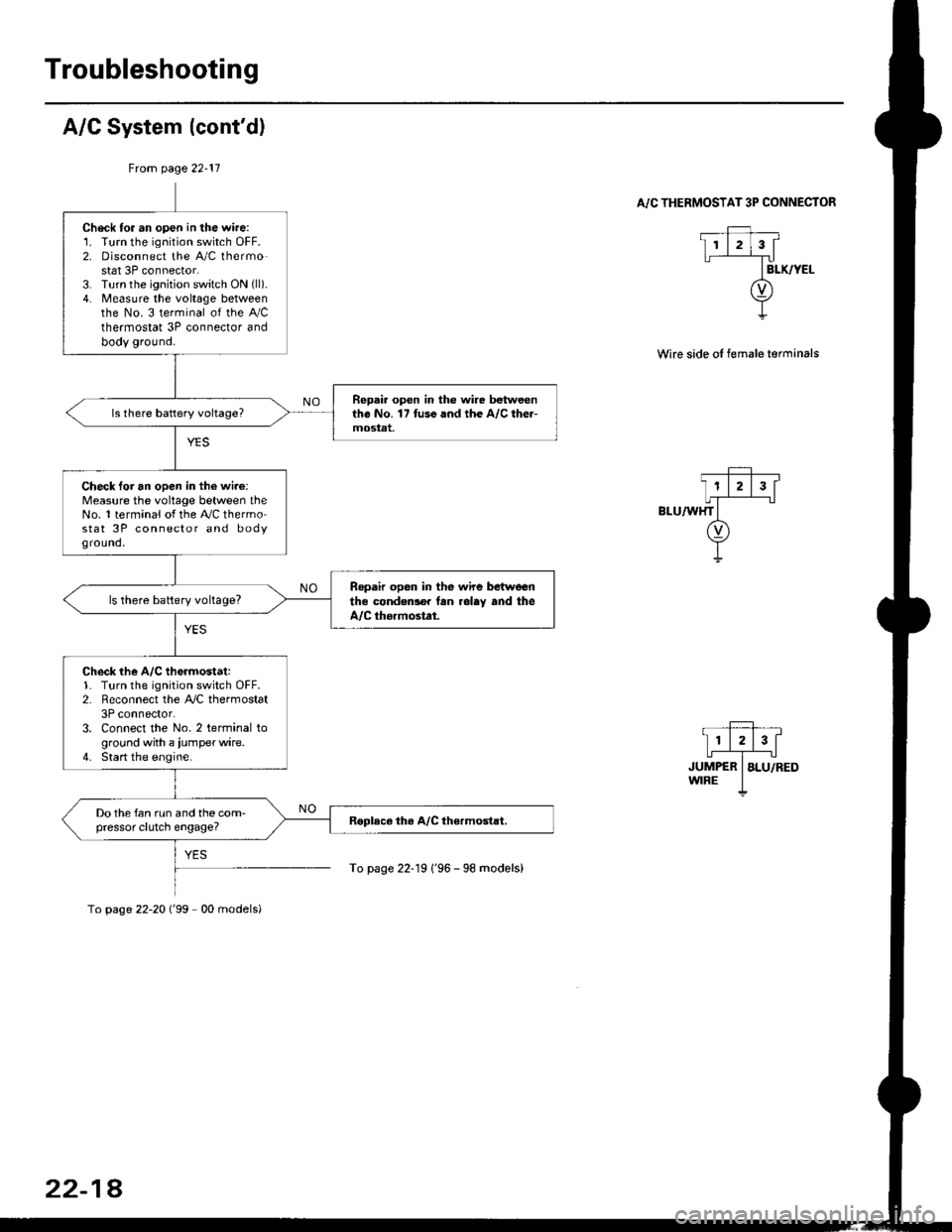

Troubleshooting

A/C System (cont'd)

From page 22-11

. _Ff,, __

I11213[

,r,il*"-T",-.r-'..owrRE I

To page 22-19 1'96 - 98 models)

A/C THERMOSTAT 3P CONNECTOR

Wire side oI female terminals

Check tor an open in the wire:1. Turn the ignition switch OFF.2. Disconnect the A/C thermostat 3P connector.3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe No. 3 terminal of the Ay'Cthermostat 3P connector andbody ground.

Repai. open in the wire betweentho No. 17 tuso and the A/C the.-mostat.

Check loi an open in the wi.e:Measure the voltage between theNo. 1 terminal of the A,/C thermostat 3P connector and bodyground,

Ropair open in the wire betwoenthe condedlo. lan rolay and theA/C thormostat.

ls there battery voltage?

Check the A/C th6rmostat:1. Turn the ignition switch OFF.2. Reconnect the A,/C thermostat3P connector.3. Connect the No. 2 terminal toground with a iumperwire.4. Start the engine.

Do the fan run and the com-pressor clutch engage?

To page 22-20 ('99 - 00 models)

22-18

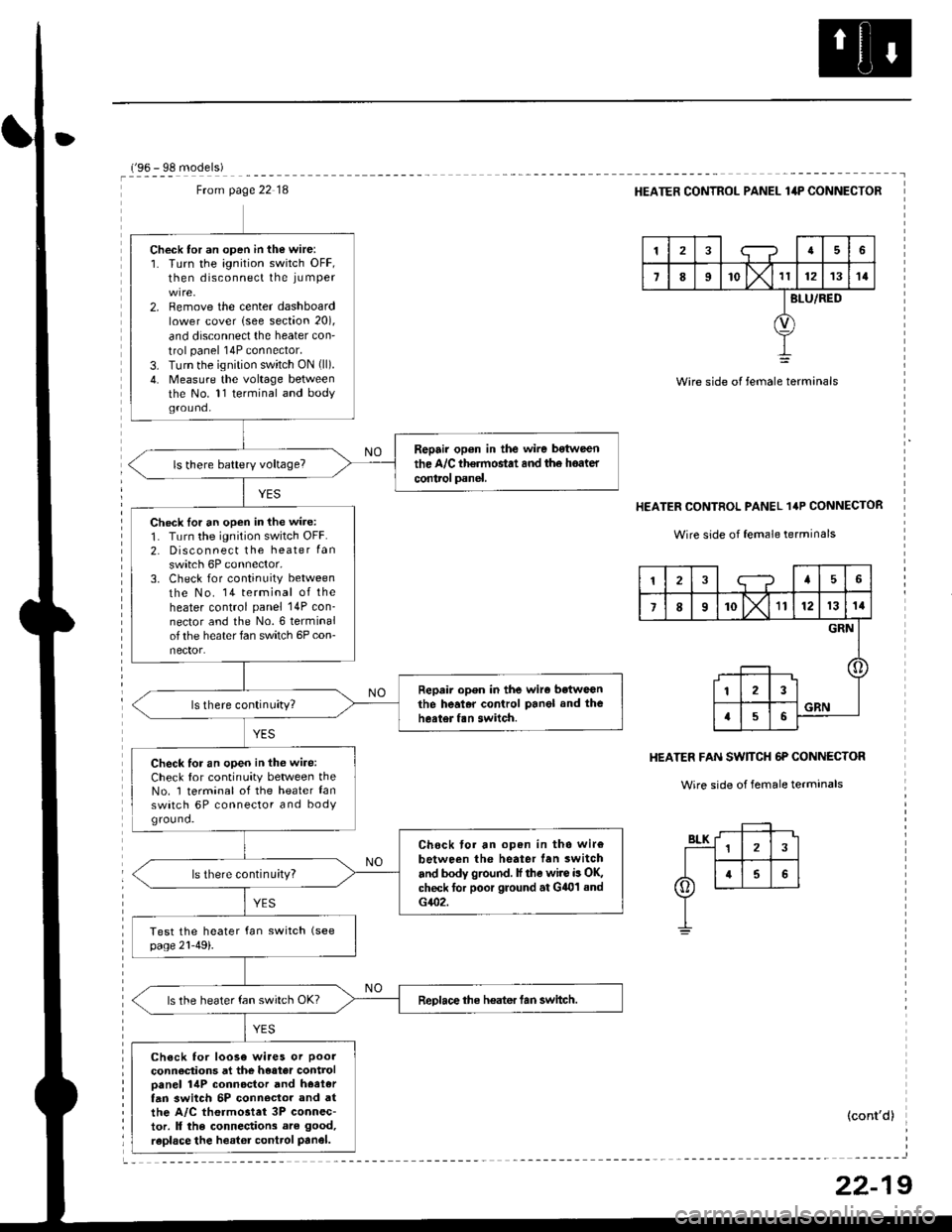

Page 1443 of 2189

Ftom page 22 18

Check tor an open in the wire:1. Turn the ignition switch OFF,then disconnect the iu mper

2. Remove the center dashboardlower cover lsee section 20),

and disconnect the heater con'

trol panel 14P connector.

3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe No. 11 terminal and bodyground.

Repair op6n in the wire bstween

the A/C th€rmostat and th6 hoater

control panel.

Check lor an open in the wire:

1. Turn the ignition switch OFF.2. Disconnect the heater Ian

switch 6P connector,3. Check for continuity between

the No. 14 terminal of theheater control panel 14P con_nector and the No.6 terminalof the heater fan switch 6P con-nector.

Repair open in the wiro betweGnthe heal.r control Panel and theheater fan switch.

Check for an open in thG wire:Check for continuity between theNo. 1 terminal of the heater lanswatch 6P connector and bodYground.

Chock tor an open in tho wir€

between the heater lan switch

and body ground. lf the wire is OK,check for poor ground at G401 sndG402.

ls there continu;ty?

ReDlace the heater tan switch.ls the heater fan switch OK?

Check for loose wiaes or poor

connections at the heater controloanel 14P connoctor and hoetertan 3witch 5P conn€clor and atthe A/C thermostet 3P connec-tor. ll the connections are good,

raplace the heator control Panel.

r'oA - qe m^.lalal

HEATER CONTROL PANEL lilP CONNECTOR

tra6

7II'o lx't1121314

BLU/RED

Wire side of female terminals

HEATER CONTROL PANEL 1'P CONNECTOR

Wire side of female terrninals

HEATER FAN SW]TCH 6P CONNECTOR

Wire side of female terminals

(cont'd)

12;--?45

7I10X'll121314

GRN

123

a56GRN

22-19

Page 1444 of 2189

Troubleshooting

('99 00 models)

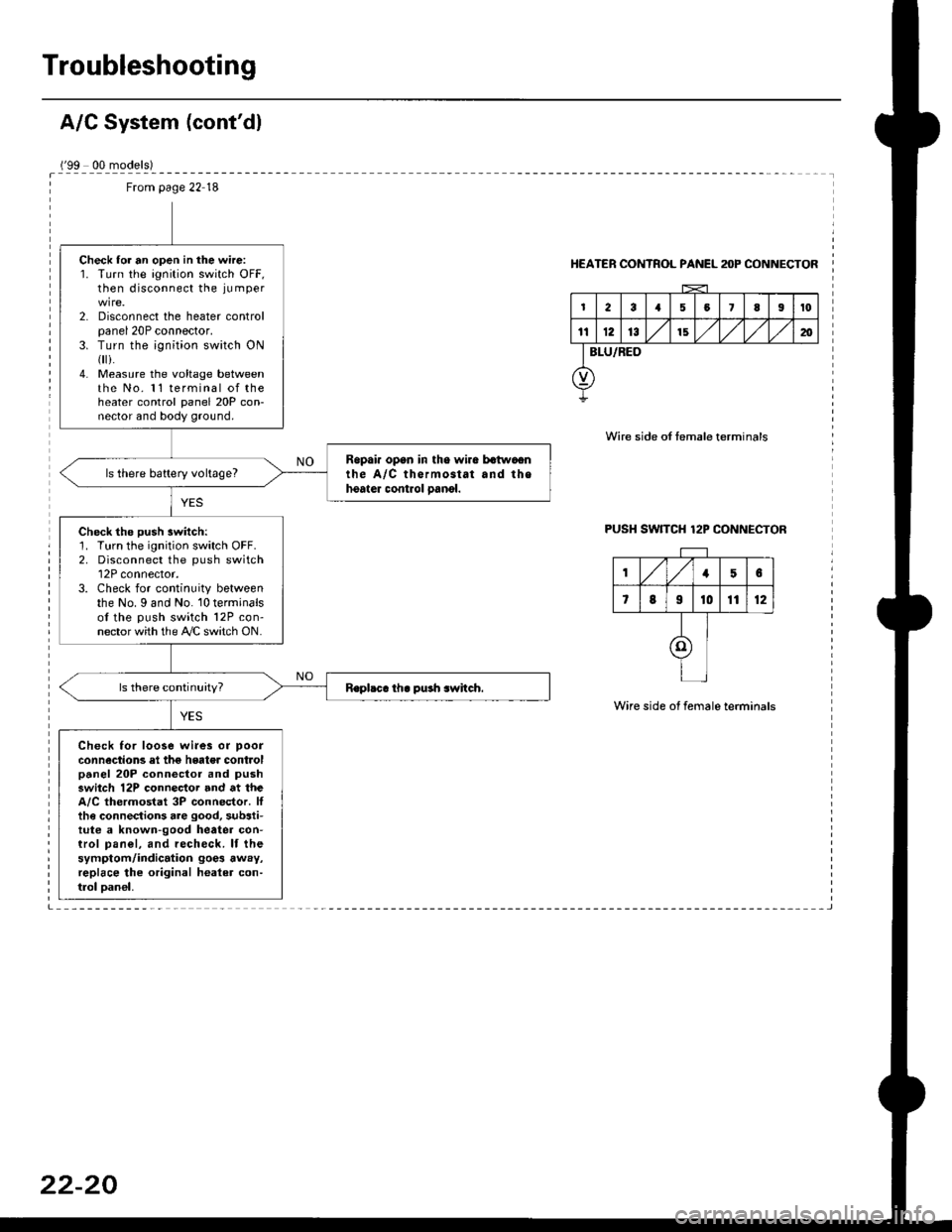

From page 22 18

Check lor an open in the wire:1. Turn the ignition switch OFF,then disconnect the ju mper

2. Disconnect the heater controlpanel 20P connector.3. Turn the ;gnition switch ON{

i.4. Measure the voltage betweenthe No. 11 terminal of theheater control panel 20P con-nector and body ground.

Ropai. opan in tho wira batwaonthe A/C thermostat and thehoater control oanol.ls there battery voltage?

Check the push switch:1. Turn the ignition switch OFF.2. Disconnect the push switch12P connector.3. Check for continuity betweenthe No. I and No. 10 terminalsof the push switch 12P con-nector with the A/C switch ON.

Check for loose wi.es or poor

connections el the hgater controlpanel 20P connector and pushswitch 12P connector and at theA/C thermostat 3P connector. Ittha connections are good, substi-tute a known-good heatea con-trol pan€|, and recheck. lf thesymptom/indication goe3 away,replace lhe original healer con-trol oan€|,

HEATER CONTROL PANEL anP CONNECTOR

Wire side of temale terminals

PUSH SW]TCH 12P CONNECTOR

Wire side of female terminals

,/1,/156

7819t01112

I

I

I

Page 1457 of 2189

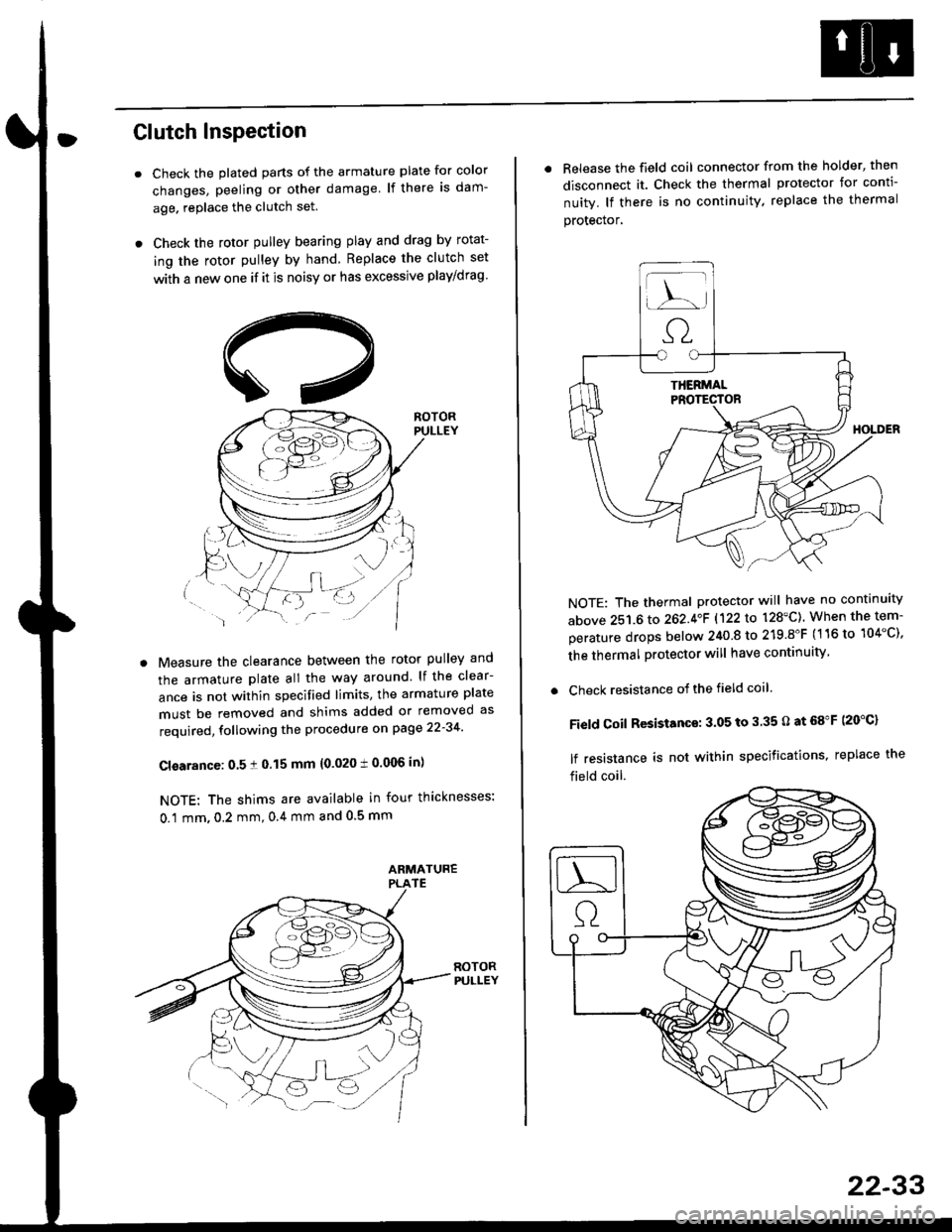

Clutch InsPection

Check the plated parts of the armature plate for color

changes, peeling or other damage lf there is dam-

age. replace the clutch set.

Check the rotor pulley bearing play and drag by rotat-

ing the rotor pulley by hand Replace the clutch set

with a new one if it is noisy or has excessive play/drag

Measure the clearance between the rotor pulley and

the armature plate all the way around lf the clear-

ance is not within specified limits, the armature plate

must be removed and shims added or removed as

required, following the procedure on page 22-34

Cl€arance: 0.5 ! 0.15 mm {0.020 t 0.006 in)

NOTE: The shims are available in four thicknesses:

0.1 mm,0.2 mm,0.4 mm and 0.5 mm

. Release the field coil connector from the holder' then

disconnect it. Check the thermal protector for conti-

nuity. lf there is no continuity. replace the thermal

protecror,

NOTE: The thermal protector will have no continuity

above 251.6 to 262.4oF 1122lo 128'C). When the tem-

perature drops below 240 8 to 219.8"F (116 to 104"C),

the thermal protector will have continuity

. Check resistance of the field coil

Field Coil Resistance: 3.05 to 3.35 O at 68"F (20"C)

lf resistance is not within specifications, replace the

field coil.

22-33