tension HONDA CIVIC 1996 6.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 1191 of 2189

t-

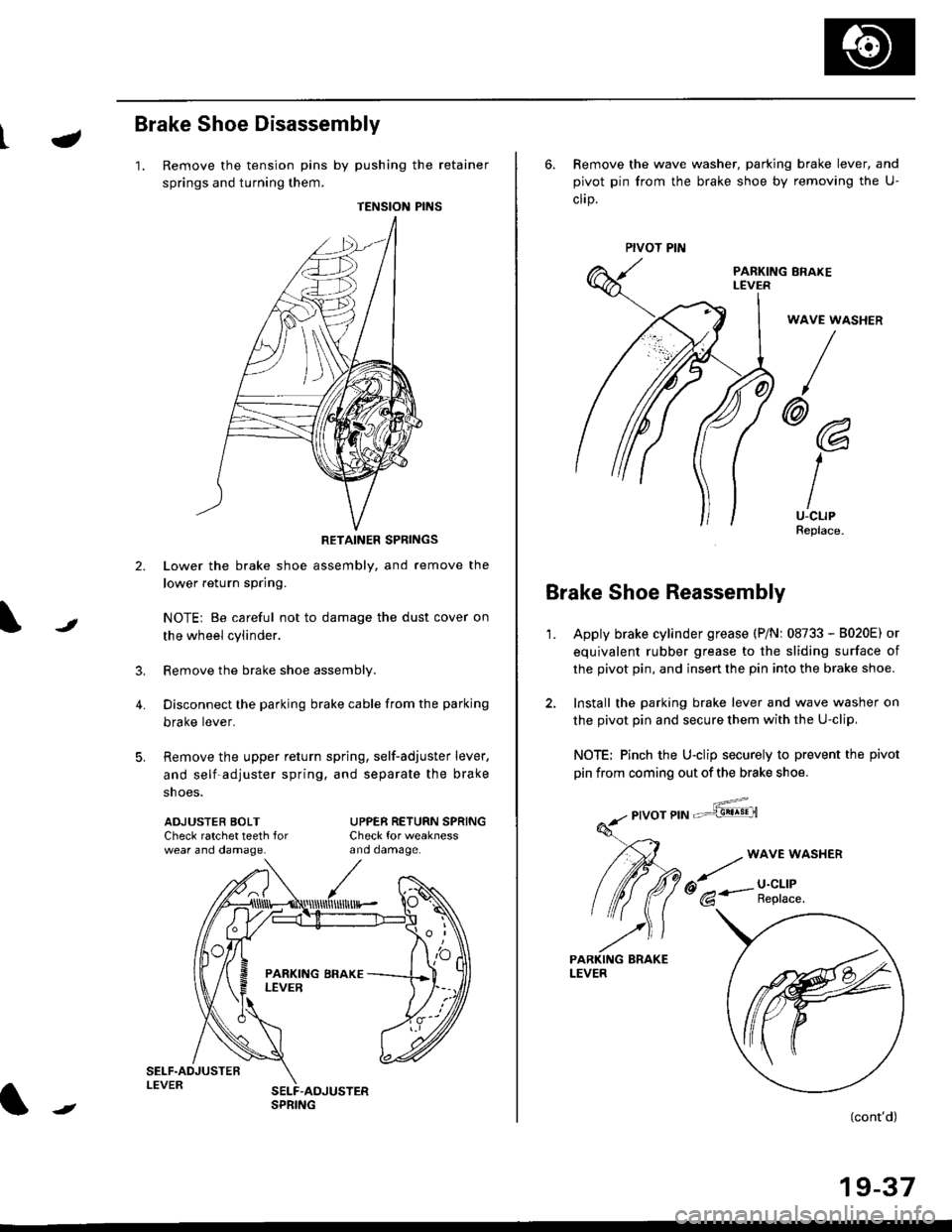

Brake Shoe Disassembly

1. Remove the tension pins by pushing the retainer

springs and turning them.

TENSION PINS

RETAINER SPRINGS

Lower the brake shoe assembly, and remove the

lower return spring.

NOTEi Be careful not to damage the dust cover on

the wheel cylinder.

Remove the brake shoe assembly.

Disconnect the parking brake cable from the parking

brake lever.

Remove the upper return spring, self-adjuster lever,

and self-adjuster spring, and separate the brake

snoe5.

t

3.

4.

ADJUSTEB BOLTCheck ratchet teeth forwear ano oamage.

UPPER RETURN SPRINGCheck for weaknessano oamage.

ll

,'/

N

r

//

t

6. Remove the wave washer, parking brake lever, and

pivot pin from the brake shoe by removing the U-

clrp.

PARKING ERAKEI-EVER

WAVE WASHER

/

@@

I

IU-CLIPReplace.

Brake Shoe Reassembly

1.Apply brake cylinder grease (P/Nr 08733 - B020E) or

equivalent rubber grease to the sliding surface of

the pivot pin, and insert the pin into the brake shoe.

Install the parking brake lever and wave washer on

the pivot pin and secure them with the U-clip,

NOTE: Pinch the U-clip securely to prevent the pivot

pin from coming out of the brake shoe.

,6;::"'

(cont'd)

19-37

LEVER

Page 1192 of 2189

Rear Drum Brake

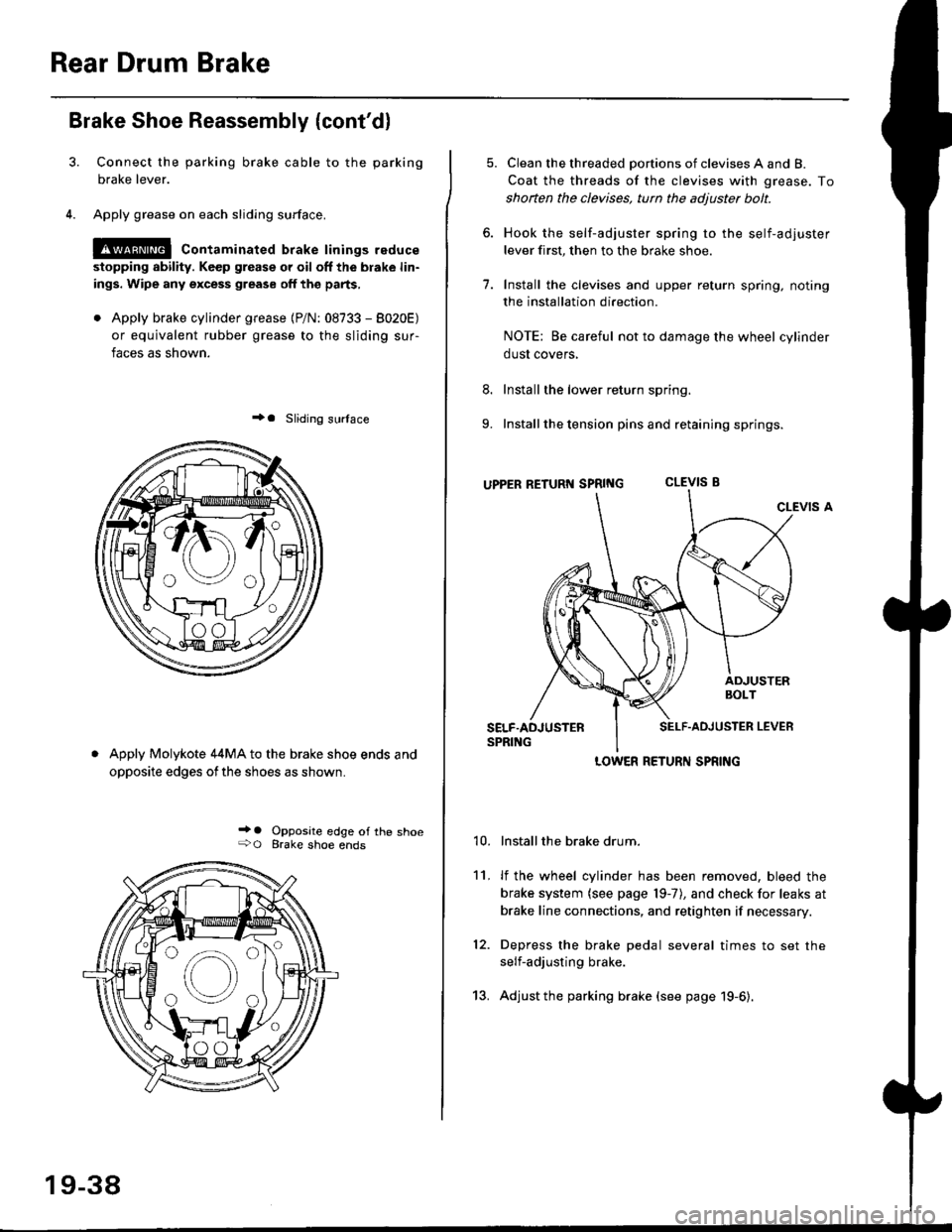

Brake Shoe Reassembly {cont'dl

Connect the parking brake cable to the parking

brake lever.

Apply grease on each sliding surface.

!@ contaminated brake linings reduce

stopping ability. Keep grease or oil off the blake lin-

ings. Wipe any excess grease off the parts,

. Apply brake cylinder grease {P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

+a Sliding surlace

Apply Molykote 44MA to the brake shoe ends and

opposite edges ofthe shoes as shown.

_' o Opposite edge of the shoe+O Brake shoe ends

19-38

13.

5. Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shoften the clevises, tun the adjuster bolt.

6. Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe

7. Install the clevises and upper return spring. noting

the installation direction.

NOTE: Be careful not to damage the wheel cylinder

dust covers,

8. Install the lower return spring.

9. Install the tension pins and retaining springs.

uppER RETURT{ SpRtNG CLEVIS B

CLEVIS A

Installthe brake drum.

lf the wheel cylinder has been removed, bleed the

brake system (see page 19-7), and check for leaks at

brake line connections, and retighten if necessary.

Depress the brake pedal several times to set the

self-adjusting brake.

Adjust the parking brake (see page 19-6).

't0.

11.

12.

LOWER RETURN SPRING

Page 1287 of 2189

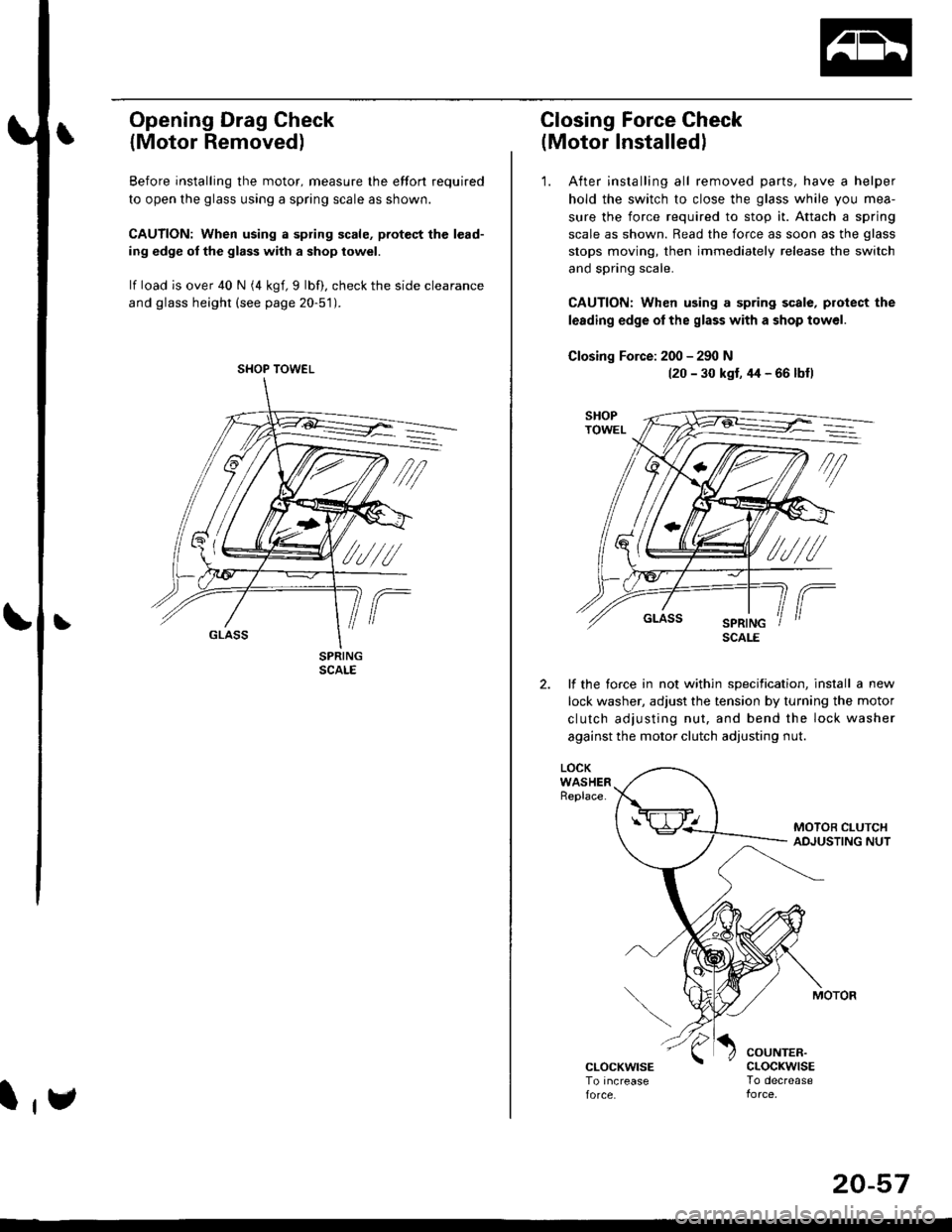

Opening Drag Check

{Motor Removed)

Before installing the motor, measure lhe effort required

to open the glass using a spring scale as shown.

CAUTION: When using a spring scale, pfotest the lead-

ing edge ol the glass with a shop towel.

lf load is over 40 N (4 kgf,9 lbf), check the side clearance

and glass height (see page 20-51).

SHOP TOWEL

l,e

20-57

Closing Force Check

(Motor Installedl

'1. After installing all removed parts, have a helper

hold the switch to close the glass while you mea-

sure the force required to stop it. Attach a spring

scale as shown. Read the force as soon as the glass

stops moving, then immediately release the switch

and spring scale.

CAUTION: When using a spring scale, protect the

lerding edge ol the glass with a shop towel.

Closing Force: 200 - 290 N(20 - 30 kst, 44 - 66 lbfl

lf the torce in not within specification, install a new

lock washer, adjust the tension by turnang the motor

clutch adjusting nut, and bend the lock washer

against the motor clutch adjusting nut.

LOCKWASHERReplace.

COUNTER.cLocKwrsETo decrease

SCALE

Page 1426 of 2189

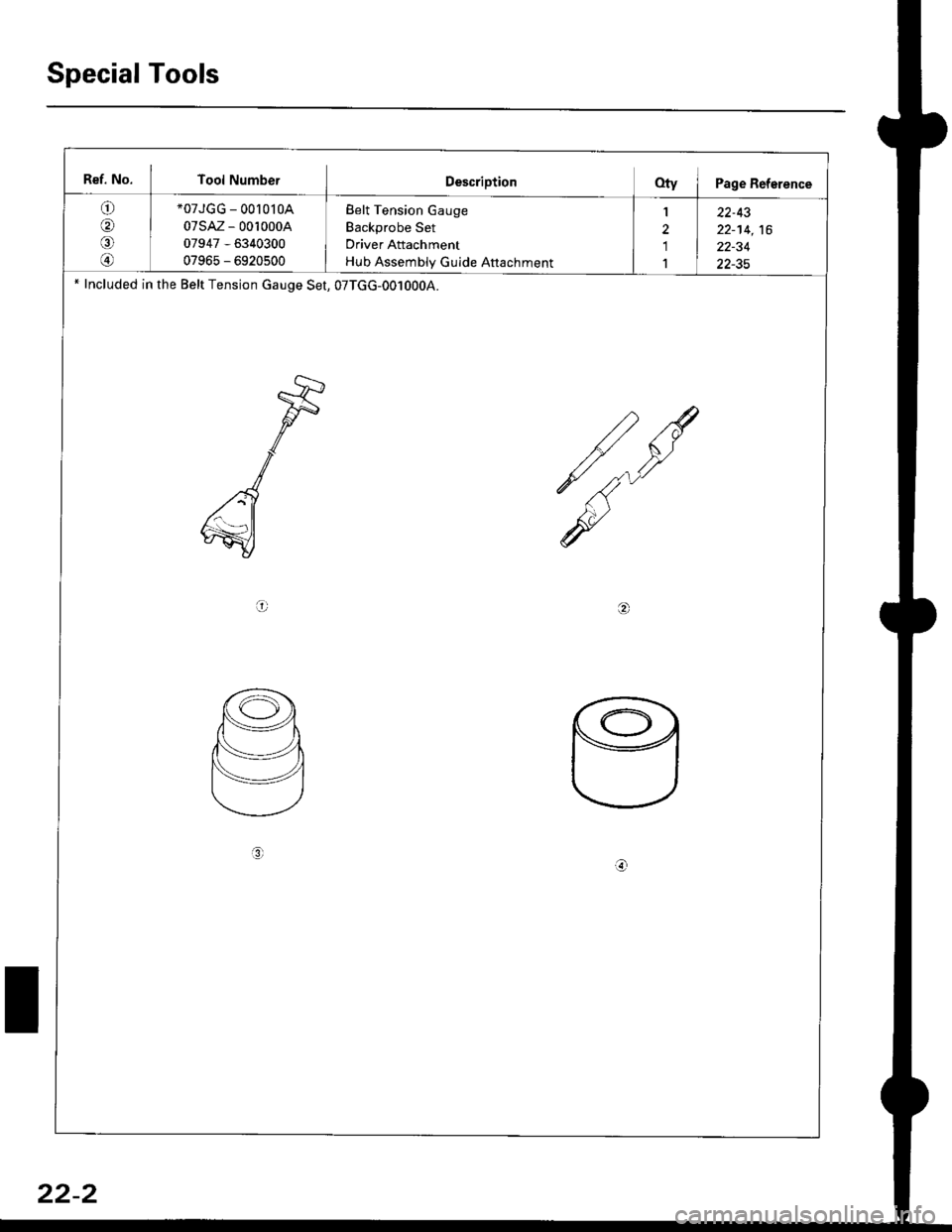

Special Tools

Bef. No. Tool NumberDescriptionQty I Page Reference

o

@

*07JGG - 00l0l0A

07sAz - 0010004

07947 - 6340300

07965 - 6920500

Belt Tension Gauge

Backprobe Set

Driver Attachment

Hub Assembly Gulde Attachment

1

'1

1

22-43

22-14,16

22-34

22-35' Included in the Belt Tension cauge Set, 07TGG-0010004.

a6r

L

3r

22-2

Page 1467 of 2189

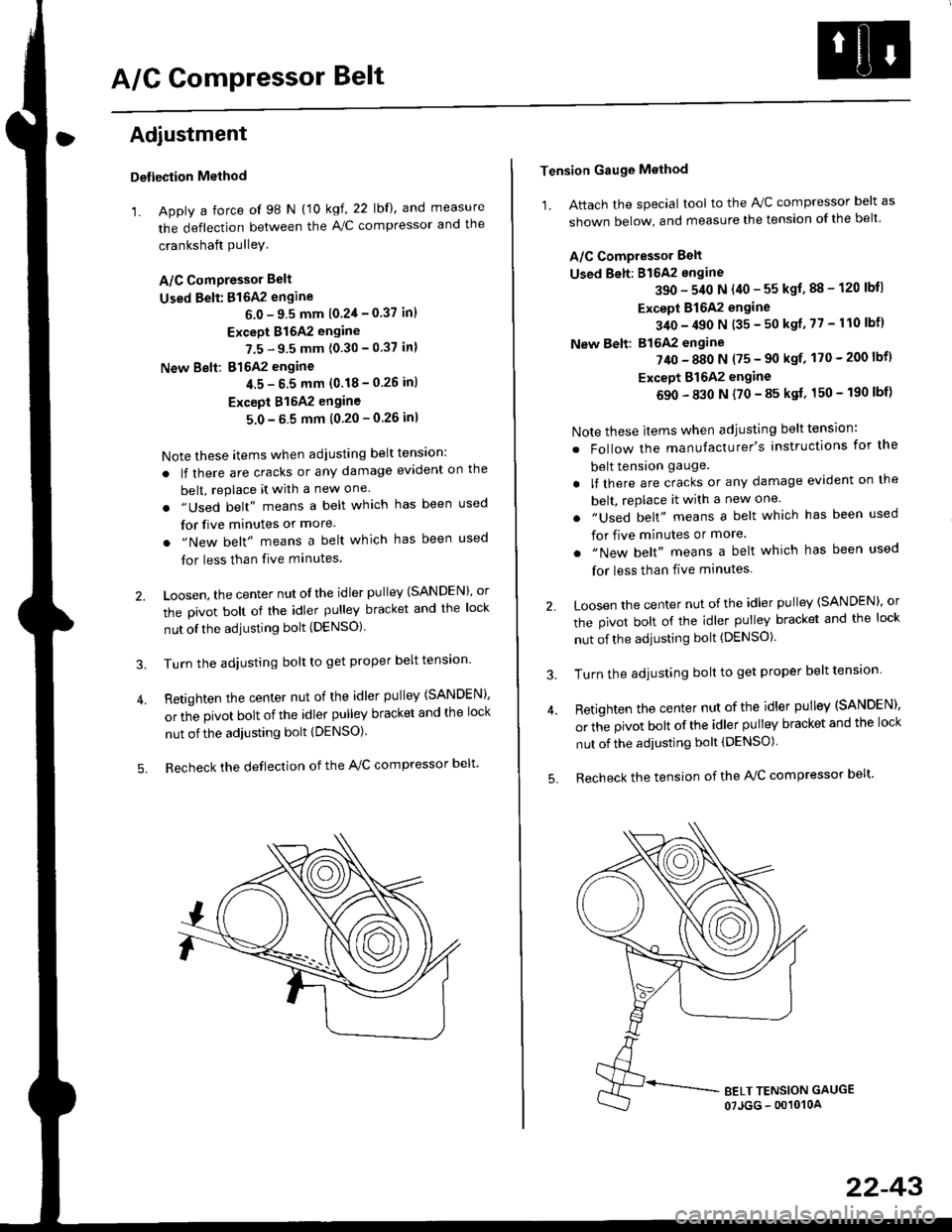

A/G GomPressor Belt

Adjustment

Detlection Method

'1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft PulleY

A/C ComPressor Belt

Used Belt: 816A2 engine

6.0 - 9.5 mm 10 2'l - 0.37 inl

Except 816A2 engine

7.5 - 9.5 mm (0.30 - 0.37 in)

New Belt: 816A2 engine

4.5- 6 5 mm (0.18-0.26 in)

Except 815A2 engine

5.0-5 5 mm (0.20-0.26 inl

Note these items when adjusting belt tens'on:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes.

2. Loosen, the center nut ofthe idler pulley (SANDEN), or

the pivot bolt of the idler pulley bracket and the lock

nut ofthe adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension'

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

5. Recheck the deflection of the A,/C compressor belt'

Tension Gauge Method

1. Attach the special tool to the IVC compressor belt as

shown below, and measure the tension of the belt

A/C Compressor Belt

Used Belt: 816A2 engine

390 - 540 N (40 - 55 kgf, 88 - 120 lbll

Except 816A2 engine

340 - 490 N (35 - 50 ksf, 77 - 110 lbfl

New Belt: B16A2 engine

?40 - 880 N {75 - 90 ksf' 170 - 200 lbf)

Except Bl642 engine

690 - 830 N (70 - 85 ksf, 150 - 190 lbf)

Note these items when adjusting belt tension:

. Follow the manufacturer's instructions for the

belt tension gauge.

. lf there are cracks or any damage evident on the

belt, rePlace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes

2 Loosen the center nut of the idler pulley (SANDEN)' or

the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO)

5. Recheck the tension of the A/C compressor belt'

22-43

Page 1472 of 2189

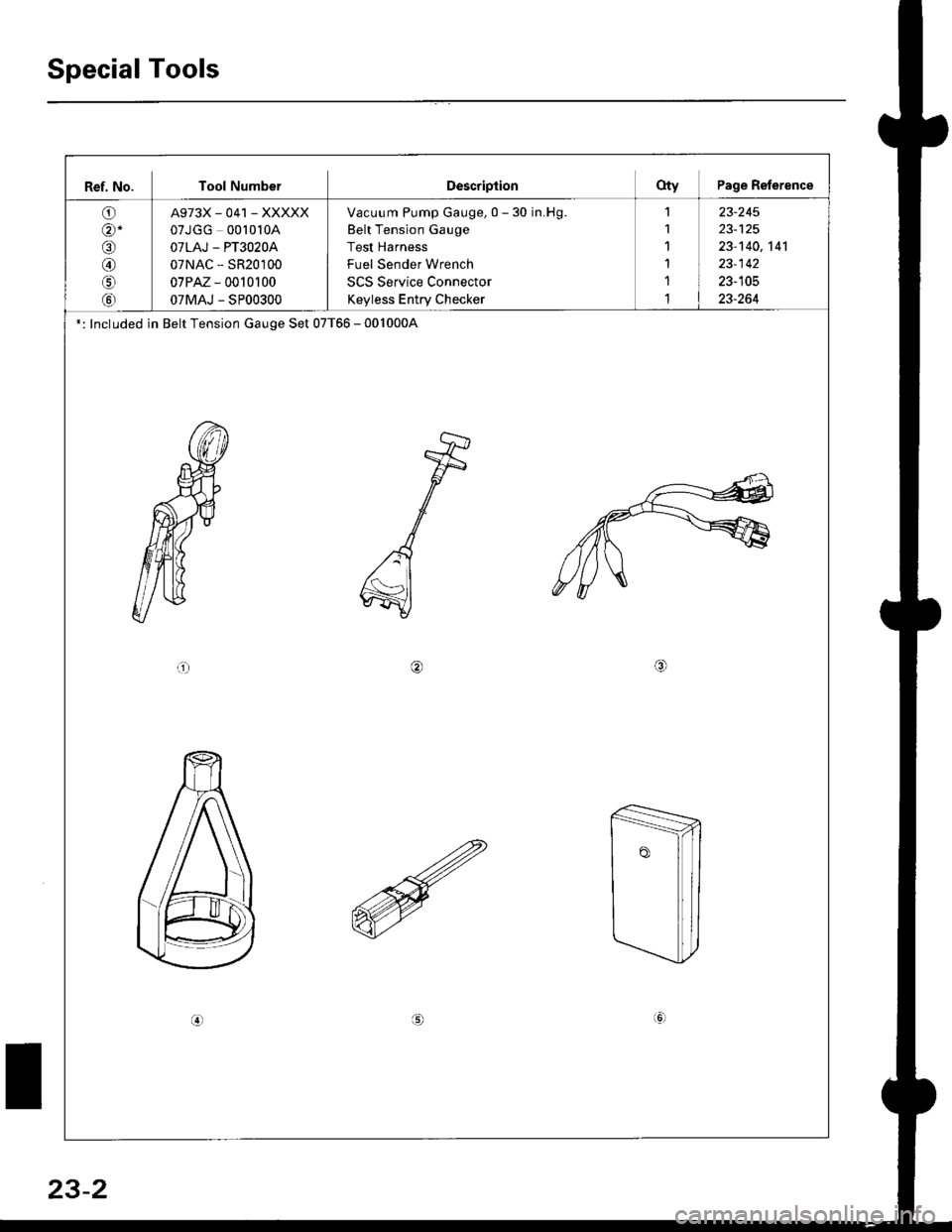

Special Tools

Ref. No. Tool NumberDescriptionOty Page Reference

O)

@-

o

@

o

tol

A973X_041 _XXXXX

07JGG 00l0l0A

OTLAJ - PT3O2OA

07NAC - SR20100

07PM - 0010r 00

07MAJ - SP00300

Vacuum Pump Gauge, 0 - 30 in.Hg.

Belt Tension Gauge

Test Harness

Fuel Sender Wrench

SCS Service Connector

Keyless Entry Checker

1

1'I

1

1

1

23-245

23-140,141

23-142

23-105

23-264

': Included in Belt Tension Gauge Set 07T66 - 0010004

or/4,

(!

23-2

Page 1473 of 2189

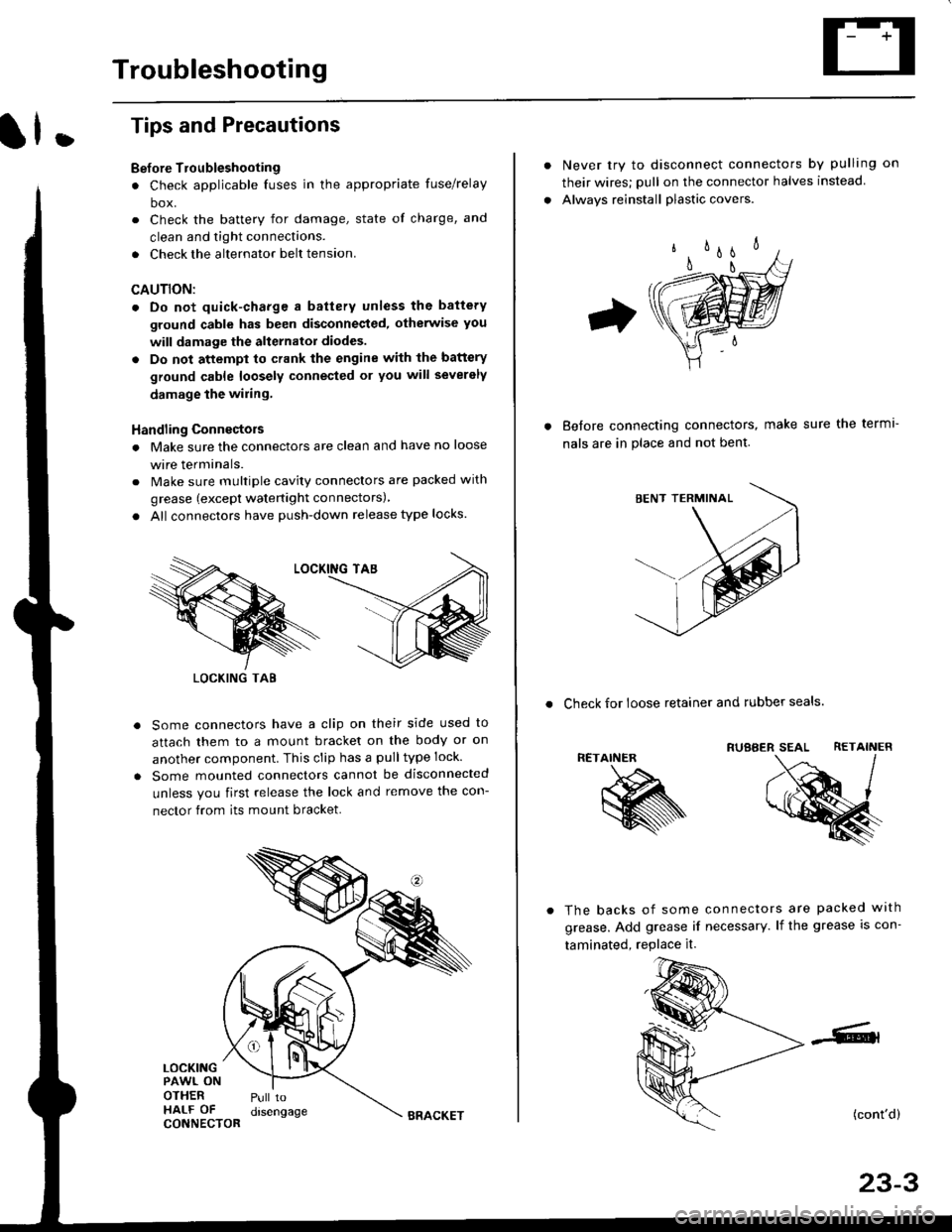

Troubleshooting

ll.

Tips and Precautions

Bef ore Troubleshooting

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconneqted, otherwise you

will damage the alternator diodes.

. Do not attempt to crank the engine with the battery

ground cable loosely connecled or you will severely

damage the wiling,

Handling Connectois

. Make sure the connectors are clean and have no loose

wire terminals.

. Make sure multiple cavity connectors are packed with

grease (except watertight connectors)

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pulltype lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFCONNECTOR

Pull todrsengage

LOCKING TAB

BRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead

Alwavs reinstall plastic covers.

Before connectang connectors,

nals are in place and not bent.

make sure the terml-

. Check for loose retainer and rubber seals.

RETAINER

The backs of some connectors are packed with

grease. Add grease if necessary. lf the grease is con-

taminated, replace it.

(cont'd)

23-3

Page 1569 of 2189

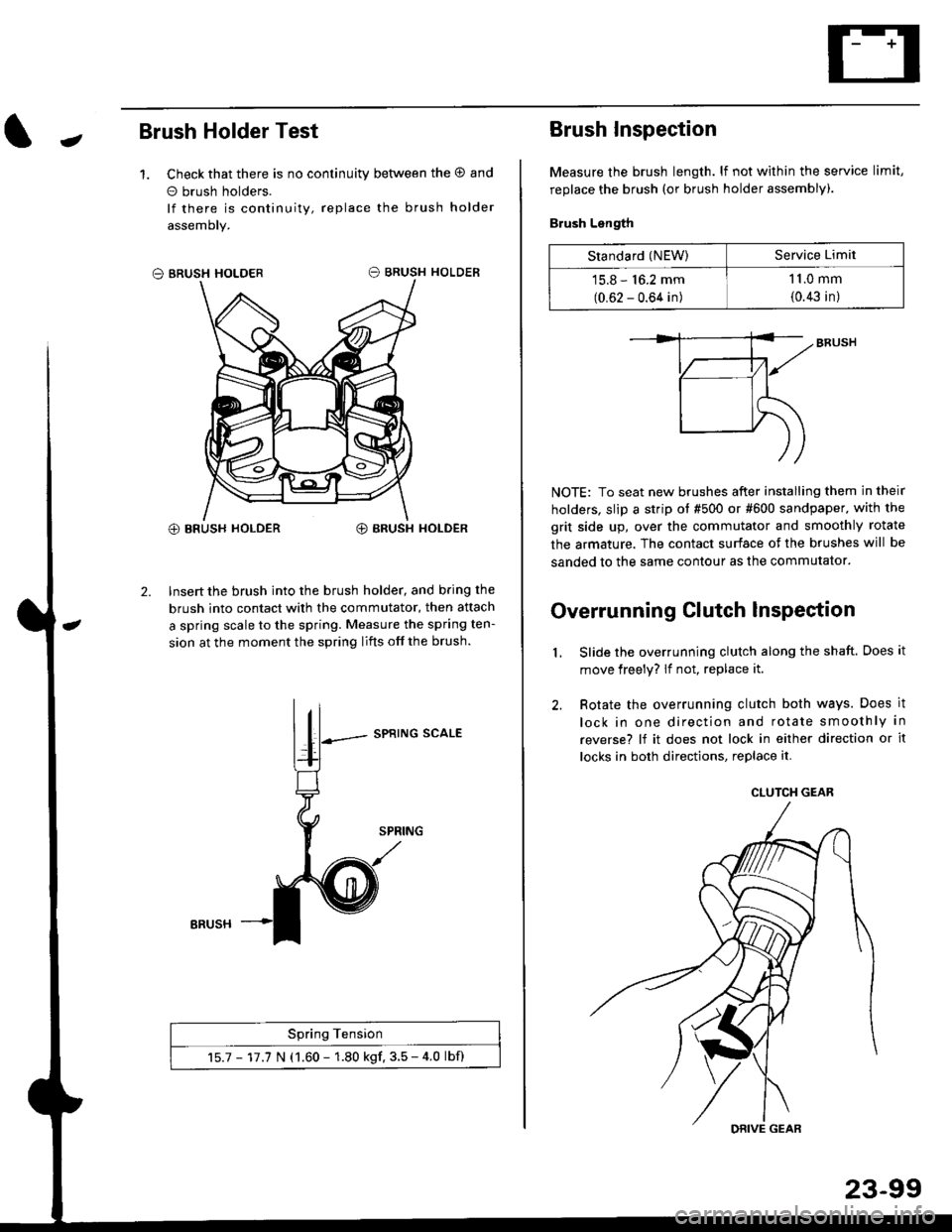

JBrush Holder Test

1. Check that there is no continuity between the O and

o brush holders.

lf there is continuity, replace the brush holder

assemoly.

O BRUSH HOLDER

@ BRUSH HOLDER€) BRUSH HOLDER

2. Insert the brush into the brush holder, and b.ing the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension

15.7 - 17.7 N (1.60 - 1.80 kgf. 3.5 - 4.0 lbf)

ERUSH

Brush Inspection

Measure the brush length. lf not within the service limit,

replace the brush (or brush holder assembly).

Brush Length

NOTE: To seat new brushes after installing them in their

holders, slip a strip ot #500 or #600 sandpaper. with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

Overrunning Clutch lnspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, replace it.

2.

L

Standard (NEW)Service Limit

15.8 - 16.2 mm

(0.62 - 0.64 in)

1 1.0 mm

{0.43 in)

CLUTCH GEAR

DRIVE GEAR

Page 1590 of 2189

Charging System

Alternator Replacement

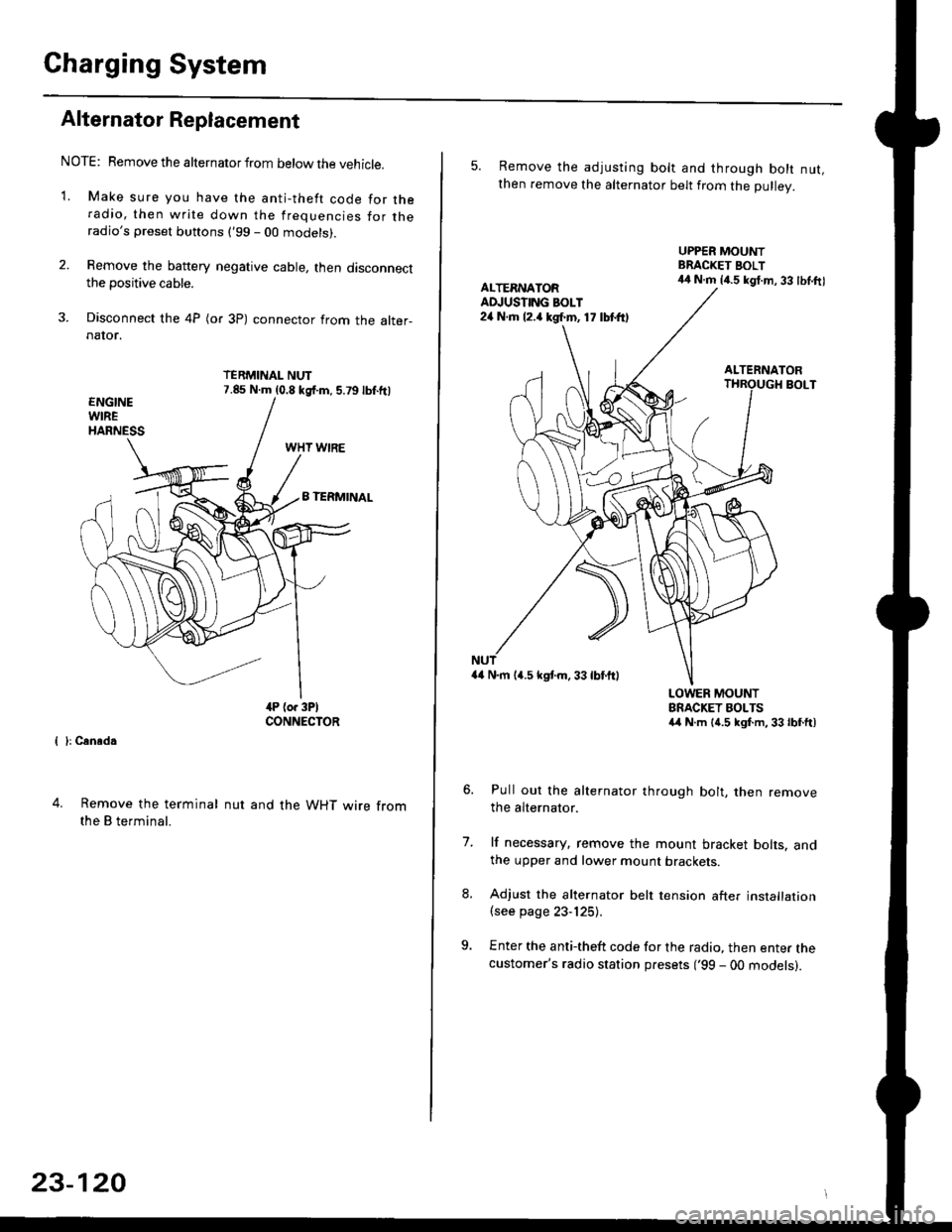

NOTE: Remove the alternator from below the vehicle.

'1. Make sure you have the anti-theft code for theradio, then write down the frequencies for theradio's preset buttons ('99 - 00 models).

2. Remove the battery negative cable, then disconnectthe positive cable.

3. Disconnect the 4P (or 3P) connector from the alter-naIor.

TERMINAL NUT7.85 N.m (0.8 kgf.m, 5.79lbf.ftl

{ }: Cansd.

4. Remove the terminal

the B terminal.

nut and the WHT wire from

23-120

5. Remove the adjusting bolt and through bolt nut,then remove the alternator belt from the Dullev.

UPPER MOUNTBRACKET BOLT44 N.m 14.5 kgt.m, 33 lbl.ftlALTERNATORAD.'USTING BOLT24 N.rh l2.a kgf.m, 17 lbtft)

ALTERNATORBOLT

a4 N.m 14.5 kstm.33lbf'ftl

LOWER MOUNTBRACKET BOLTSa4 N.m l{.5 kgf.m,33lbfft)

Pull out the alternator through bolt, then removethe alternator.

lf necessary, remove the mount bracket bolts. andthe upper and lower mount brackets

Adjust the alternator belt tension after installation(see page 23-125).

Enter the anti-theft code for the radio, then enter thecustomer's radio station presets ('99 - 00 models).

7.

Page 1595 of 2189

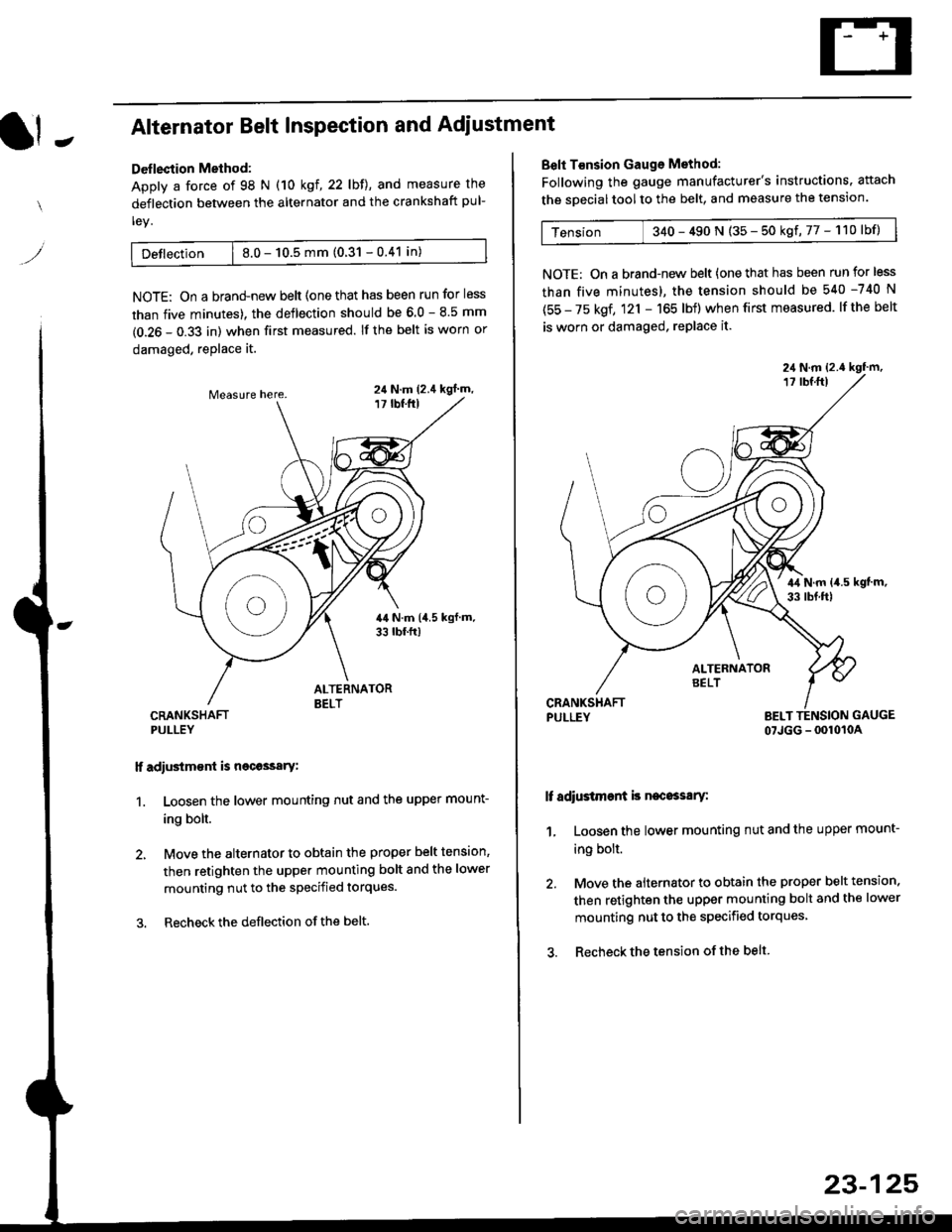

It -Alternator Belt Inspection and Adiustment

Deflection Method:

Apply a force of 98 N (10 kgl,22lbll, and measure the

deflection between the alternator and the crankshaft pul-

ley.

Detlection | 8.0 - 10.5 mm (0.31 - 0.41 in)

NOTE: On a brand-new belt {one that has been run for less

than five minutes). the deflection should be 6.0 - 8.5 mm

(0.26 - 0.33 in) when first measured. If the belt is worn or

damaged, replace it.

CRANKSHAFTPULLEY

lf adiustm€nt is necossary:

1. Loosen the lower mounting nut and the upper mount-

ing bolt.

2, Move the alternator to obtain the proper belt tension,

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques.

3. Recheckthe deflection ofthe belt.

24 N.m (2.4 kgl m,

Belt T€nsion Gauge Method:

Following the gauge manufacturer's instructions. attach

the soecial tool to the belt, and measure the tension.

Tension 340 - 490 N (35 - 50 kgf,77 - 110lbf)

NOTE: On a brand-new belt {one that has been run for less

than five minutes), the tension should be 540 -740 N

(55 - 75 kgf, 121 - 165 lbf) when first measured. lf the belt

is worn or damaged, replace it.

PULLEY BELT TENSION GAUGE

07JGG - 0010104

It adiustment is necossary:

1, Loosen the lower mounting nut and the upper mount-

ing bolt.

2. Move the alternator to obtain the proper belt tension.

then retighten the upper mounting bolt and the lower

mounting nut to the specified torques

3. Recheck the tension of the belt

23-125