ECO mode HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 475 of 2189

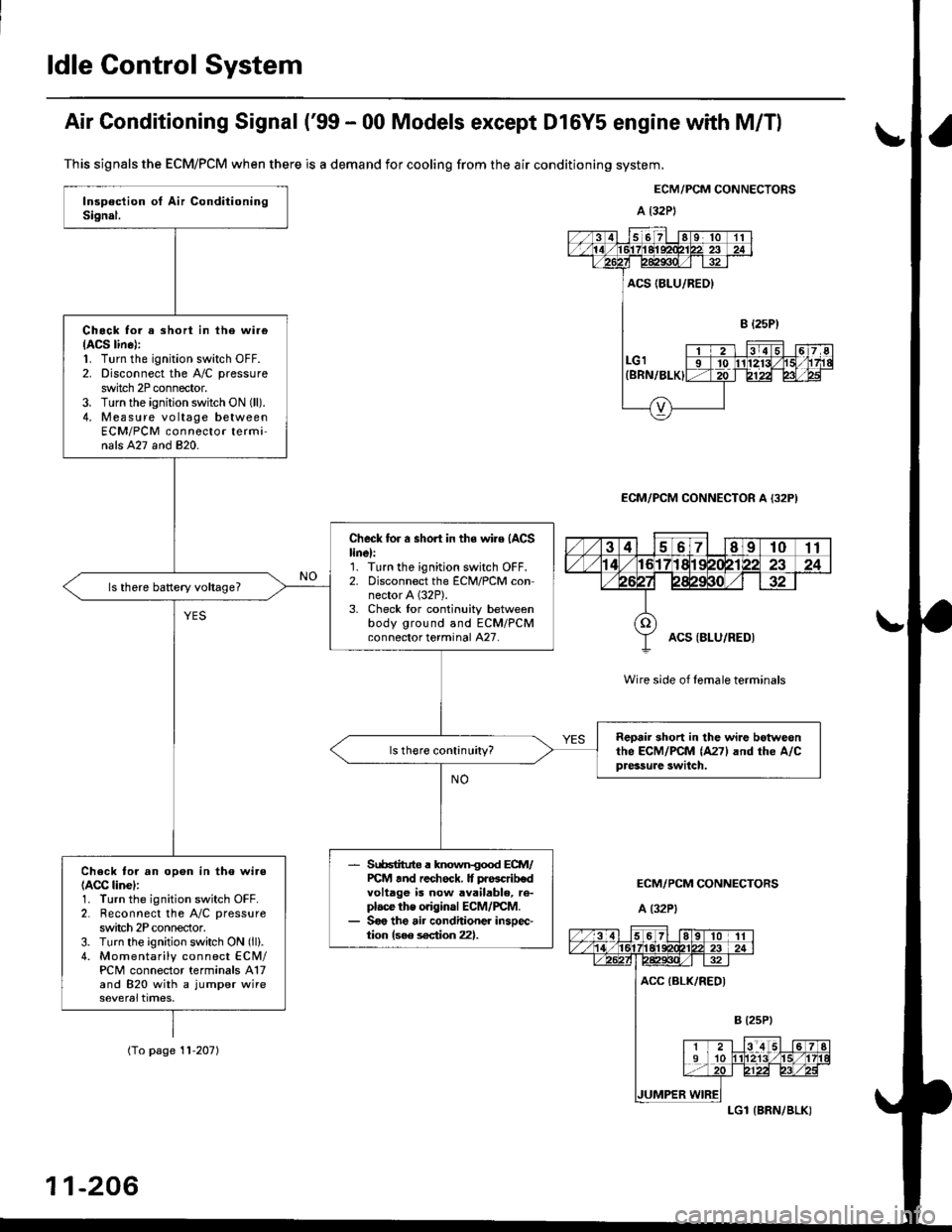

ldle Control System

Air Conditioning Signal ('99 - 00 Models except Dl6Y5 engine with M/Tl

This signals the ECM/PCM when there is a demand for cooling from the air conditioning system.

ECM/PCM CONNECTORS

a l32P)

ECM/PCM CONNECTOR A {32P)

Wire side of female terminals

ECM/PCM CONNECTORS

A (32P1

Chock tor a short in ihe wi.e(ACS lin6):1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch 2P connector.3. Turn the ignition switch ON (ll).

4. Measure vo ltage betweenECM/PCM connector terminals A27 and 820.

Check for a short in the wire (ACS

linel:'1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM connector A (32P).

3. Check lor continuity betweenbody ground and ECM/PCMconnector terminal A27.

Reoair short in lhe wi.e botweonthe ECM/PCM (A271 and rhe A/Cpressure swilch.

Srr66tituto a known{ood ECM/PCt4 tnd rechock. It prascrib€dvoltage is now available, re-plac€ the original ECM/rcM.Soo the air conditioner insoec-tion {see s€ction 22}.

Check to. an opon in tho wi.e(ACC linel:1. Turn the ignition switch OFF.2. Reconnect the A/C pressure

switch 2P conneclor.3. Turn the ignition switch ON (ll).

4. Momentarily connect ECN4/PCM connector terminals A17and 820 with a jumper wire

(To page '! 1-207)

11-206

LGl {BRN/BLK)

Page 477 of 2189

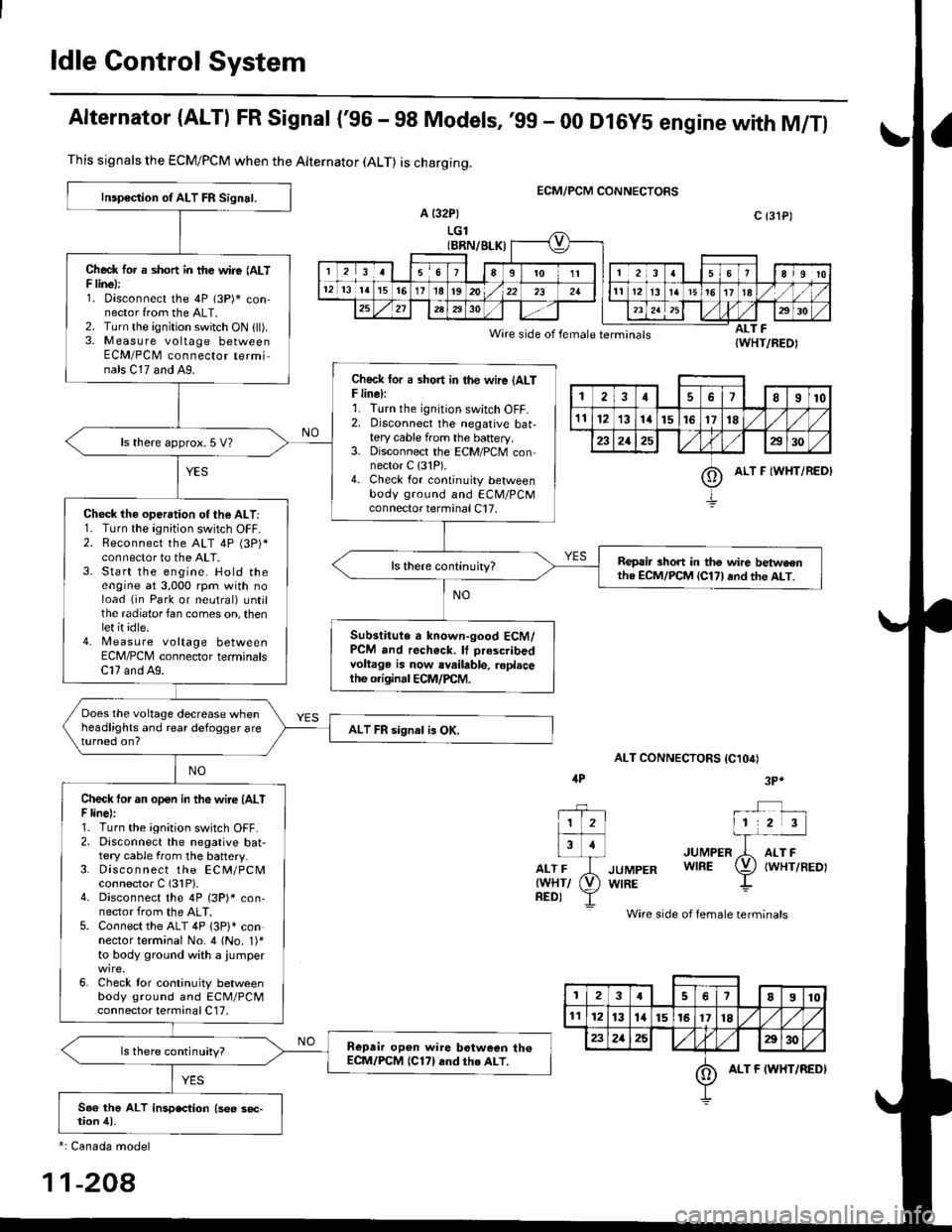

ldle Control System

Alternator (ALTI FR Signal {'96 - 98 Models,'99 - 00 Dl6y5 engine with M/Tl

ECM/PCM CONNECTORS

a {32P)

LGl(BRN/BLK)

Wire side of female terminals

ALT CONNECTORS IC1O4I

JUMPER

JUMPER WIRE

WIRE

Wire side of female terminals

ALT F{WHT/REO)

This signals the ECM/PCM when the Alternator (ALT) is charging.

Inspoction of ALT FR Signal.

Check tor a short in tfte wire (ALTF linel:1. oisconnect the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON (ll).3. M easu re voltage betweenECM/PCM connector terminals C17 and A9.Check lor a sho.t in the wire {ALTF line):r. I urn rne tgn|lton swtlch ul-f,2. Disconnect the negative bat-tery cable from the baftery.3. Disconnect the ECM/PCM connector C {31P).4. Check for continuity betweenbody ground and ECM/PCMconnector terminal C17.

ls there approx. 5 V?

Check th€ operation of the ALT:1. Turn the ignition switch OFF.2. Reconnect the ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untjlthe radiator fan comes on, thenlet it idle.4. [,4easu re voltage betweenECM/PCM connector terminalsC17 and A9.

Repair short in the wire betwe€nthe ECM/PCM {Cl71and th€ ALT.

Substitute a known-good ECM/PCM and recheck. It prescribedvoltage is now available, roplacethe originrl ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR signal is OK.

Check tor an open in the wire (AlTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disco n nect the ECM/PCMconnector C (31P).4. Disconnect the 4P (3P)* con,nector from the ALT.5. Connect the ALT 4P 13P)l connector terminal No. 4 (No. 1)'to body ground with a iumper

6. Check lor continuity betweenbody ground and ECM/PCMconnector terminal C17,

Repair op6n wire botween th€ECM/PCM (C171rnd th€ ALT.ls there continuity?

c {31P)

1178I10

1112131415161718

232125a30

oALT F IWHT/REDI

4P3P*

1 2l

Flr

rr-ri-frwHr/ (V)

neor Y

*: Canada model

11-208

3I78910

1l1213l415161718/l

232125E30

oALT F IWHT/REDI

Page 478 of 2189

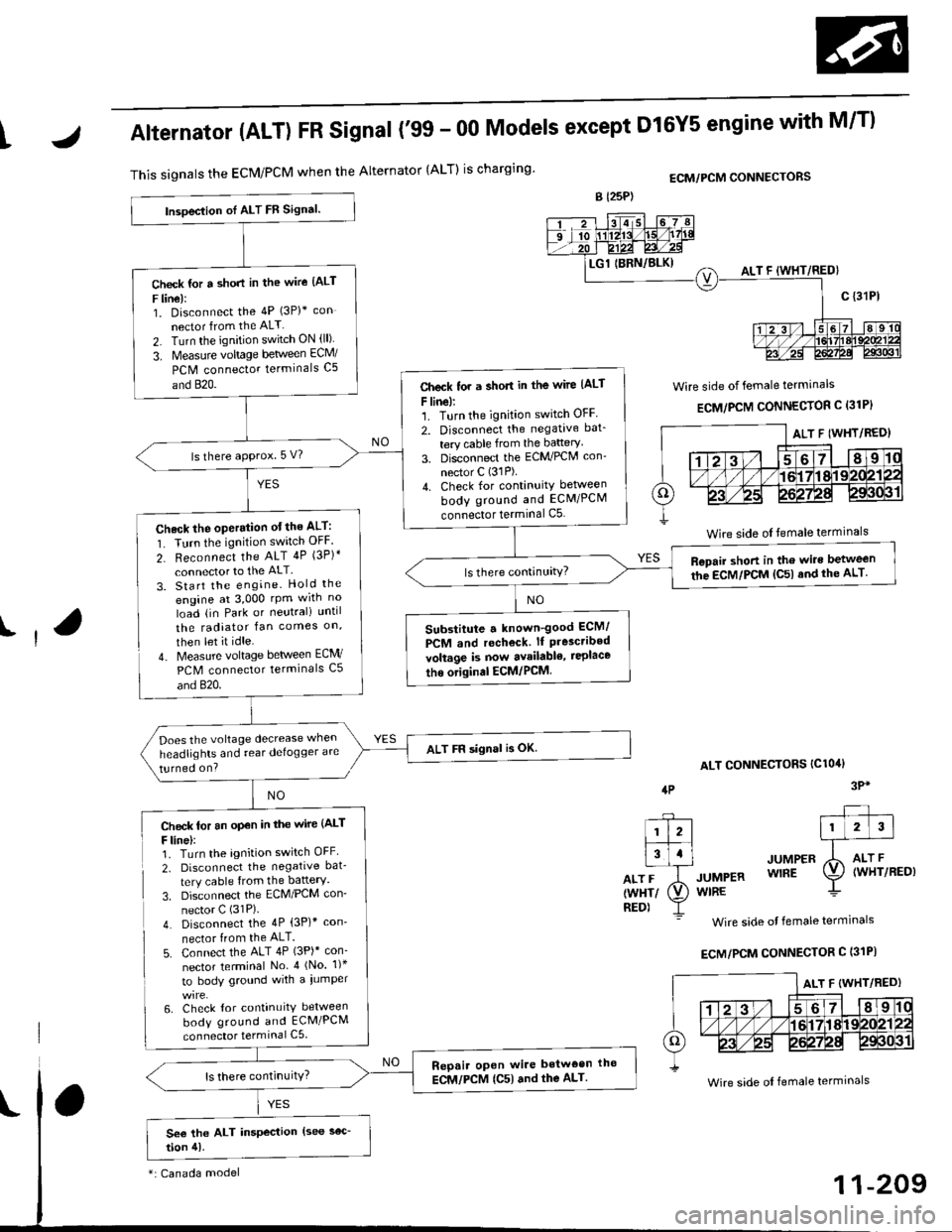

tAlternator (ALT) FR Signal ('99 - 00 Models except Dl6Y5 engine with M/T)

This signals the ECM/PCM when the Alternator {ALT) is chargingECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C (31P}

lt

lP

ALT CONNECTORS IClO4I

JUMPER

JUMpER WlnE

WIRE

Wire side of female termlnals

ECM/PCM CONNECTOR C (31PI

3P*NO

Check lor an op€n in the wire (ALT

F line,:1. Turn the agnition switch OFF

2. Disconnect the negative bat-

tery cable {rom the battery.

3. Disconnect the ECM/PCM con'

nector C (31P).

4. Disconnect the 4P (3P)* con'

nector from the ALT.

5. Connect the ALT 4P (3P)* con-

nector terminal No 4 (No. 1)*

to bodY ground with a iumper

6. Check lor continuity between

body ground and ECM/PCM

connector terminal C5

--?--1l2l|�#i3l.l

otriJrwxrr (V)

neor Y

lnsoeclion oI ALT FB Signal.

Check {or a short in the wire {ALT

F line):1. Disconnect the 4P (3P)+ con

nector from the ALT

2. Turn the ignition switch ON (ll)

3. Measurc voltage between EcM/

PCM connector terminals C5

and 820.Check tor a short in the wirc (ALt

F line):1. Turn the ignition switch OFF

2. Disconnect the negative bat_

tery cable from the baRery'

3. Disconnect the ECM/PCM con'

nector C (31P).

4. Check for continuity between

body ground and ECM/PCM

connector terminal C5

ls there aPProx. 5 V?

Check the operation otthe ALT:

1. Turn the ignition switch OFF.

2- Reconnect the ALT 4P (3P)*

connector to the ALT

3. Start the engine. Hold the

engine at 3,000 rpm wrth no

load {in Park or neutrali until

the radiator fan comes on,

then let it idle.

4- Measure voltage between ECM/

PCM connector terminals C5

and 820.

Repair short in the wire between

the EcM/PCM {C5l and the ALT.

Substitute a known-good ECM/

PCM and rechock. lf P.esc.ibedvoltage is now availabl€, ieplace

tho original ECM/PCM

Does the voltage decrease when

headlights and rear delogger are

turned on?

ALT FF signal is OK.

Repair oPen wire betwoen t|lo

ECM,/PCM {C5) and the ALT.

ALT F (WHT/RED)

Wire side of temale terminals

*: Canada model

Wire side of female termrnals

Page 495 of 2189

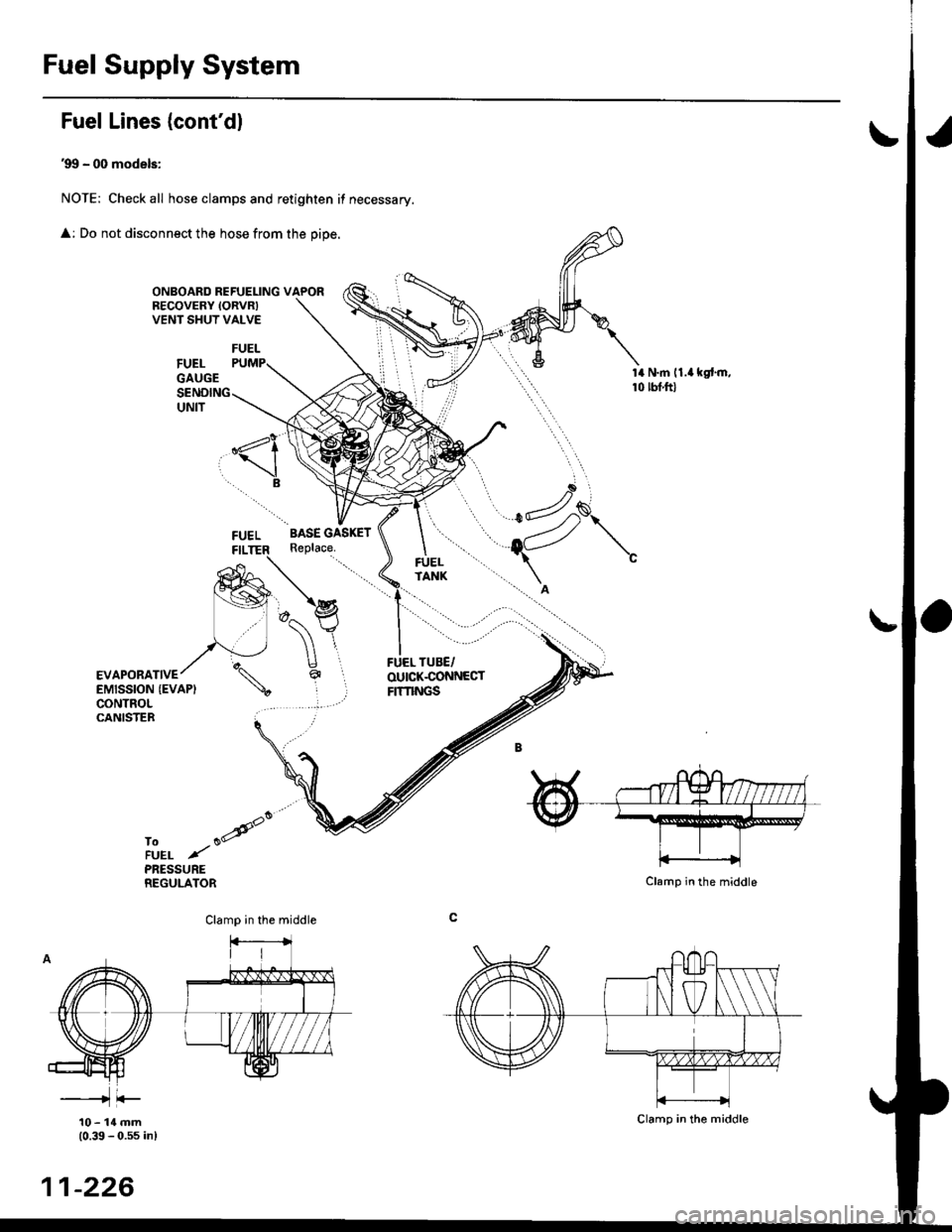

Fuel Supply System

Fuel Lines (cont'dl

.99 - 00 models:

NOTE: Check all hose clamps and retighten if necessary.

: Do not disconnect the hose from the pipe.

ONBOARD REFUELING VAPORBECOVERY IORVRIVENT SHUT VALVE

B

FUELGAUGElt N.rn l1.a kgt.m,r0 lbt ftl

ftr, n'fo'PRESSUREREGULATOR

Clamp in the middle

Clamp in the middle

11-226

Page 499 of 2189

Fuel Supply System

System Description

The fuel supply system consists of a fuel tank, in-tank

high pressure fuel pump, PGM-FI main relay, fuelfilter,

fuel pressure regulator, fuel injectors. and fuel delivery

and return lines. This system delivers pressure-regu-

lated fuel to the fuel injectors and cuts the fuel delivery

when the engine is not running.

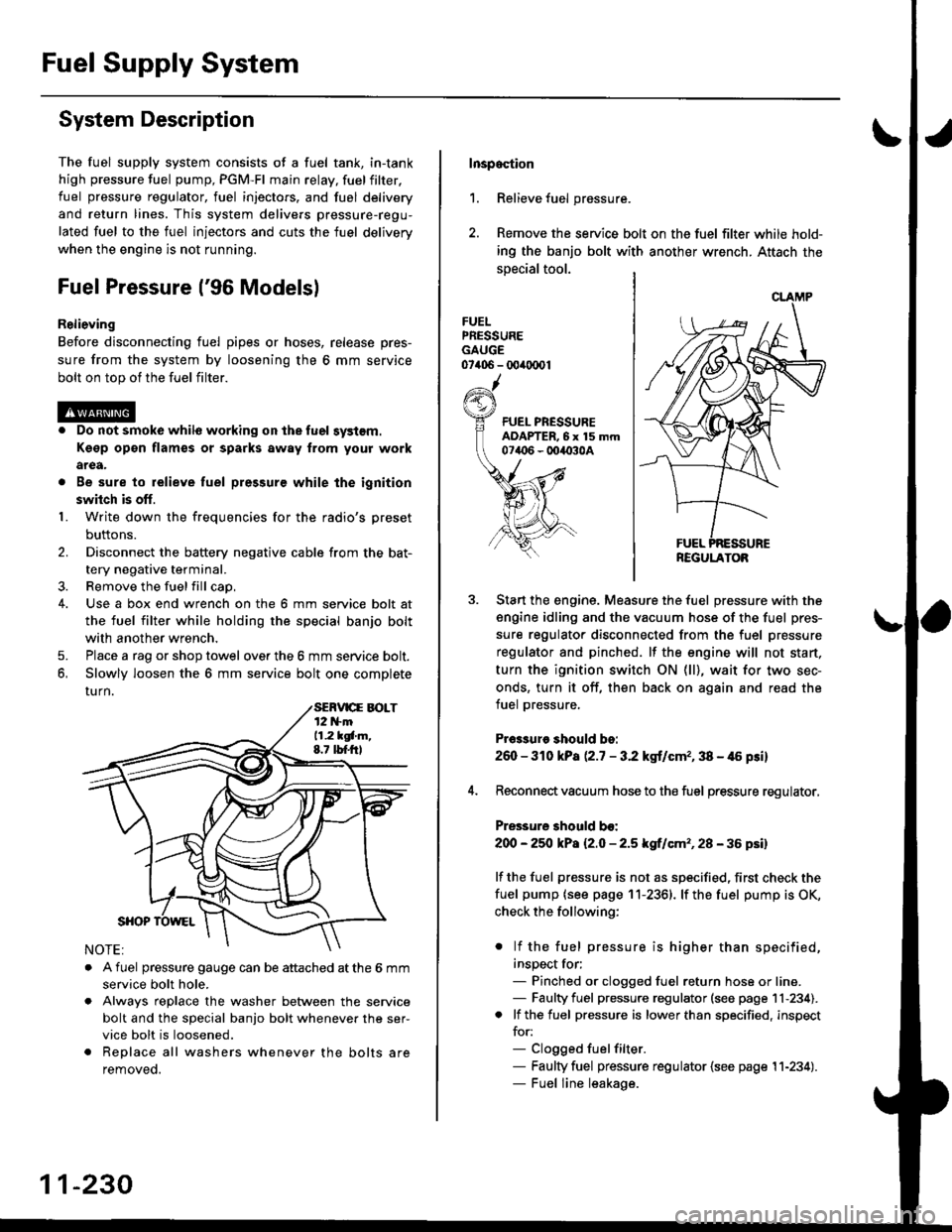

Fuel Pressure l'96 Modelsl

Relieving

Before disconnecting fuel pipes or hoses, release pres-

sure from the system by loosening the 6 mm service

bolt on top of the fuel filter.

. Do not smoke whil6 working on the fuel system.

Kgsp opon flames or sparks away from youl work

area.

. Be sure to relieve fuel pressure while the ignition

switch is off.

1. Write down the frequencies for the radio's preset

buttons.

2. Disconnect the battery negative cable from the bat-

tery negative terminal.

3. Remove the fuelfill cap,

4. Use a box end wrench on the 6 mm service bolt at

the fuel filter while holding the special banjo bolt

with another wrench,

5. Place a rag or shop towel over the 6 mm service bolt.

6, Slowly loosen the 6 mm service bolt one complete

rurn.

. A fuel pressure gauge can be attached at the 6 mm

service bolt hole.

. Always reDlace the washer between the service

bolt and the special banjo bolt whenever the ser-

vice bolt is loosened.

. Replace all washers whenever the bolts are

removeo.

11-230

Inspoction

1. Relieve fuel pressure.

2. Remove the service bolt on the fuel filter while hold-

ing the banjo bolt with another wrench. Attach the

special tool.

FUELPRESSUREGAUGE07406 - 00ir0(x)1

Start the engine. Measure the fuel pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched. lf the engine will not start,

turn the ignition switch ON (ll), wait for two sec-

onds, turn it off, then back on again and read the

fuel pressure.

Pr€3sure should bo:

260 - 310 kPa (2.7 - 3.2 kgt/cmr, 38 - 46 psi)

Reconnect vacuum hose to the fuel pressure regulator,

Pressure should bo:

200 - 25O kPa l2.O - 2.5 kgf/cm'�, 28 - 36 psil

lf the fuel pressure is not as specified, first check the

fuel pump {see page 11-2361. lf the fuel pump is OK,

check the following:

. lf the fuel pressure is higher than specified,

inspect for;- Pinched or clogged fuel return hose or line.- Faulty fuel pressure regulator (see page 11-234).. lf the fuel pressure is lower than specified, inspect

for:- Clogged fuelfilter.- Faulty fuel pressure regulator {see page 11-234).- Fuel line leakage.

REGULATOB

Page 500 of 2189

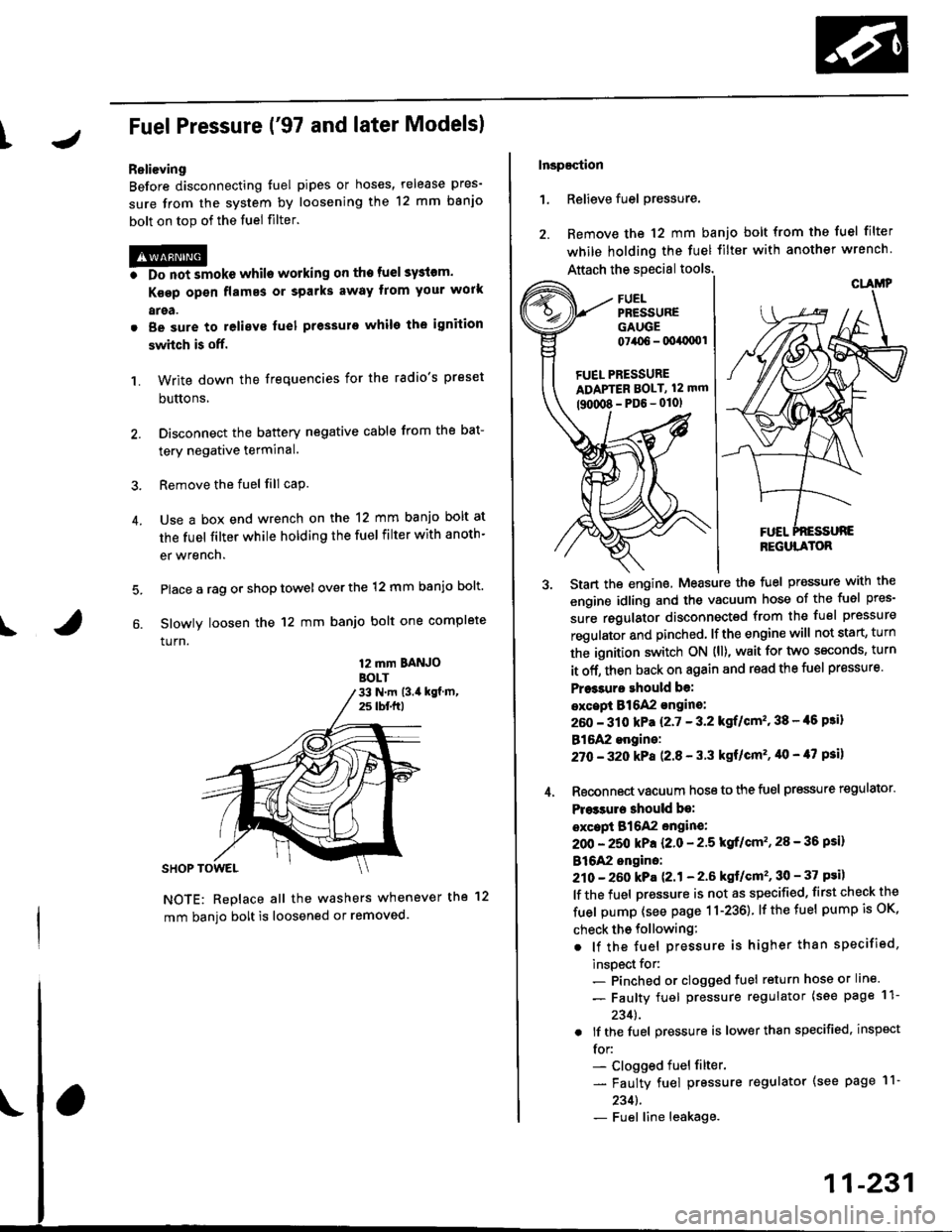

tJFuel Pressure {'97 and later Models)

ReliGving

Before disconnecting tuel pipes or hoses, release pres-

sure from the system by loosening the 12 mm banjo

bolt on top of the fuel filter.

@o Do not smoke whilo working on the fuel sy3lom.

Ksgp op€n flames or sparks away tlom Your work

arga.

. Be sure to relieve fuel pressule while the ignition

swhch is off.

1. Write down the frequencies for the radio's preset

buttons,

2. Disconnect the battery negative cable from the bat-

tery negative terminal.

3. Remove the fuel fill cap.

Use a box end wrench on the 12 mm banjo bolt at

the fuel filter while holding the fuel filter with anoth-

er wrench.

Place a rag or shop towel over the 12 mm banio bolt.

Slowly loosen the 12 mm banjo bolt one complete

turn.

4.

I

12 mm BAtt OBOLT33 N.m (3.i1 kgf m,25 tbf.f0

NOTE: Replace all the washers whenever the 12

mm banio bolt is loosened or removed.

Inspaqtion

1. Relieve fuel pressure.

2. Remove the 12 mm banjo bolt from the fuel filter

while holding the fuel Jilter with another wrench

Attach the special tools.

3. Start the enginethe fuel Pressure with the

engine idling and the vacuum hose of the fuel pres-

sure regulator disconnected from the fuel pressure

regulator and pinched lfthe engine will not start, turn

the ignition switch ON {ll), wait for two seconds, turn

it off, then back on again and read the fuel pressure'

Pr$3uro ehould be:

excepi 816A2 sngine:

260 - 310 kPa {2'7 - 3.2 kgf/cm" 38 - {6 Fi}

B16A2 engine:

27O -32O kPa P.8 - 3'3 kgf/cm'�, '10 - 47 psi)

4. Reconnect vacuum hoso to the fuel pressure regulator'

Pre33ure 3hould be:

except B16A2 engin€:

2OO - 250 kPa {2.0 - 2'5 kgf/cm'�, 28 - 36 psi)

B16A2 engino:

210 - 260 kPa 121 - 2.6 ksf/cm'�, 30 - 37 psi)

lf the fuel pressure is not as specified, first check the

fuel pump (see page 11-236) lfthetuel pumpisoK,

check tho following:

. lf the fuel pressure is higher than specified,

inspect for:- Pinched or clogged fuel return hose or line.

- Faulty fuel pressure regulator (see page 11-

2341.

. lf the fuel pressure is lower than specified, inspect

for:- Clogged fuel filter.

- Faulty fuel pressure regulator (see page l1-

2341.- Fuel line leakage.

FUEL PRESSUREADAPTER BOLT, 12 mm

tguxt8-PD6-0101

CLAMP

REGULATOR

11-231

Page 504 of 2189

I

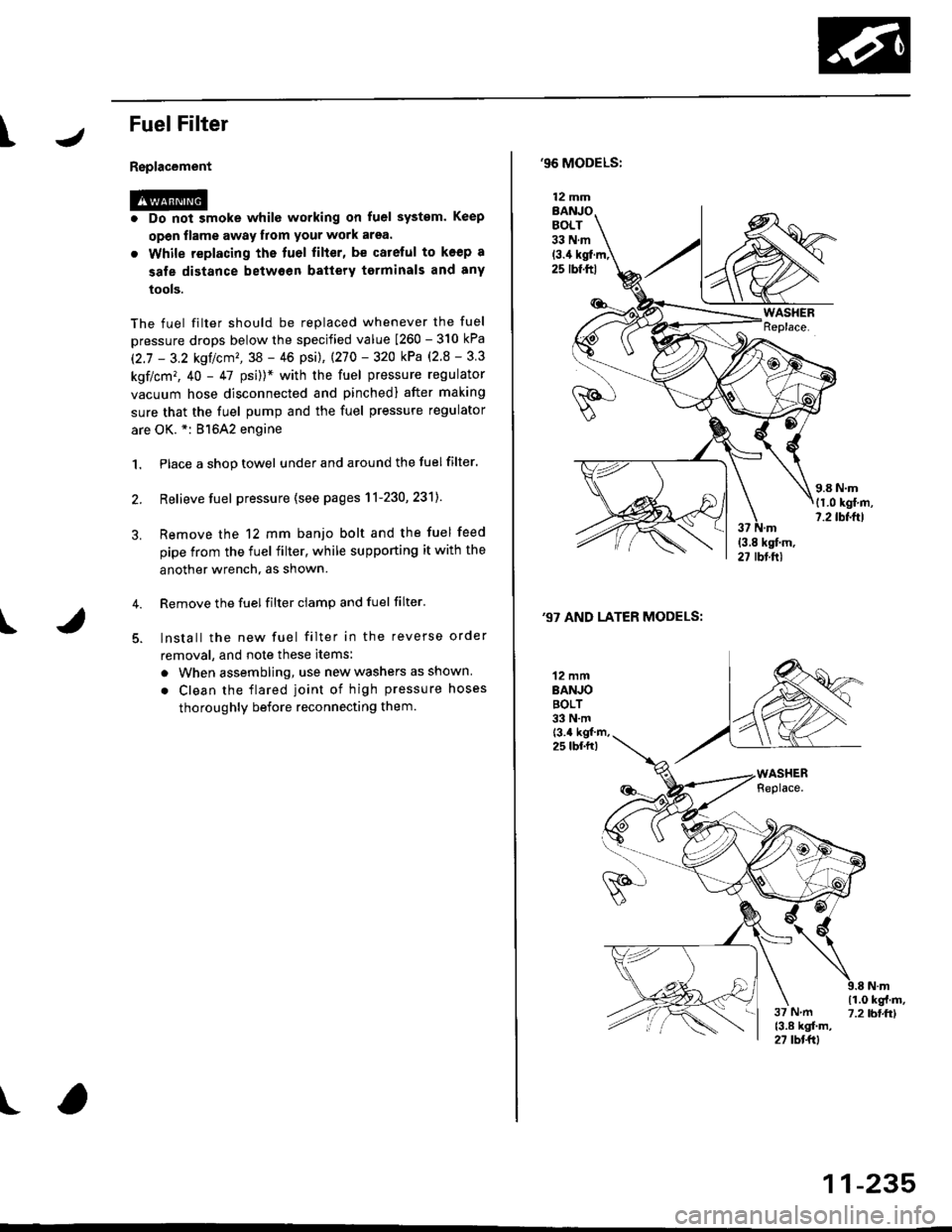

FuelFilter

Replacement

r@. Do not smoke whilc working on fuel system. Keep

open flame away from your work arsa.

. While replacing the tuel filter, be catelul to koep a

sale distance betwoen battery torminals and any

tools.

The fuel filter should be replaced whenever the fuel

pressure drops below the specified value [260 - 310 kPa

12.7 - 3.2 ksl/cm'�,38 - 46 psi), |270 - 320 kPa (2.8 - 3 3

kgf/cm,, 40 - 47 psi))* with the fuel pressure regulator

vacuum hose disconnected and pinchedl after making

sure that the fuel pump and the fuel pressure regulator

are OK. *: 81642 engine

1. Place a shop towel under and around the fuelfilter.

2. Relieve fuel pressure (see pages 11-230,231]-

Remove the 12 mm banjo bolt and the fuel feed

pipe from the fuel filter, while supporting it with the

another wrench, as shown.

Remove the fuel filter ciamp and fuel filter'

lnstall the new fuel filter in the reverse order

removal, and note these items:

a When assembling, use new washers as shown

. Clean the flared joint of high pressure hoses

thoroughly before reconnecting them.

I

,96 MODELS:

(3.4 kgl.m,25 rbf.ftl

,97 AND LATER MODELS:

12 mmBANJOBOLT33 N.m

12 mmBANJOBOLT33 N.mt3.4 kgf m,25 lbf.fr)

\i(o-r

)

11-235

Page 506 of 2189

I

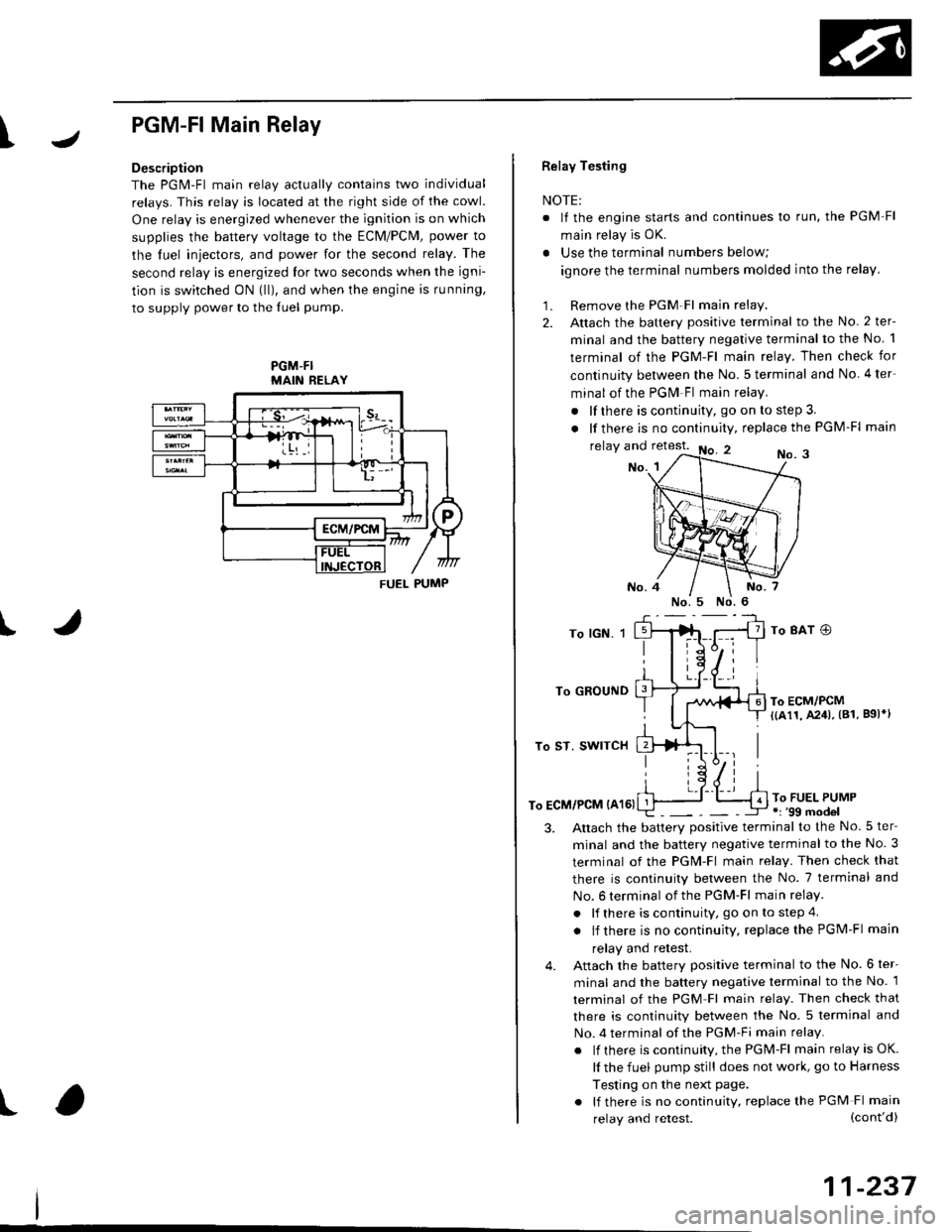

PGM-FlMain Relay

Description

The PGM-Fl main relav actuallv contains two individual

relays. This relay is located at the right side of the cowl.

One relay is energized whenever the ignition is on which

supplies the battery voltage to the ECM/PCM, power to

the luel iniectors, and power for the second relay. The

second relay is energized lor two seconds when the igni-

tion is switched ON (lll, and when the engine is running,

to supply power to the luel pump.

PGM-FIMAIN RELAY

J

I

t

FUEL PUMP

Relay Testing

NOTE:

. It the engine starts and continues lo run. the PGM Fl

main relay is OK.

. Use the terminal numbers below;

ignore the terminal numbers molded into the relay,

1. Remove the PGM Fl main relay.

2. Attach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No.5 terminal and No 4ter-

minal of the PGM Fl main relay.

. lf there is continuity, go on to step 3.

. lf there is nocontinuity, replacethe PGM-Fl main

relay and retest.No. 3No. 1

To lGN. 1

To GROUND

To ST. SWITCH

To ECM/PCM {A161

To 8AT O

To ECM/PCM{(a11, A241, (81. B9l*l

To FUEL PUMP.r '99 model

3.Altach the batterv positive terminal to the No.5 ter-

minal and the battery negative terminal to the No. 3

terminal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-Fl main relay.

. lf there is continuity, go on to step 4

. lf there is nocontinuity, replacethePGM-Fl main

relay and retest.

Attach the battery positive terminal to the No. 6 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM Fl main relay. Then check that

there is continuity between the No. 5 terminal and

No. 4 terminal of the PGM-Fi main relay.

. lf there is continuity, the PGM-Fl main relay is OK.

lf the fuel pump still does not work, go to Harness

Testing on the next page.

. lf there is no continuity, replace the PGM Fl main

4.

(cont'd)

11-237

relay and retest.

Page 508 of 2189

JI

I

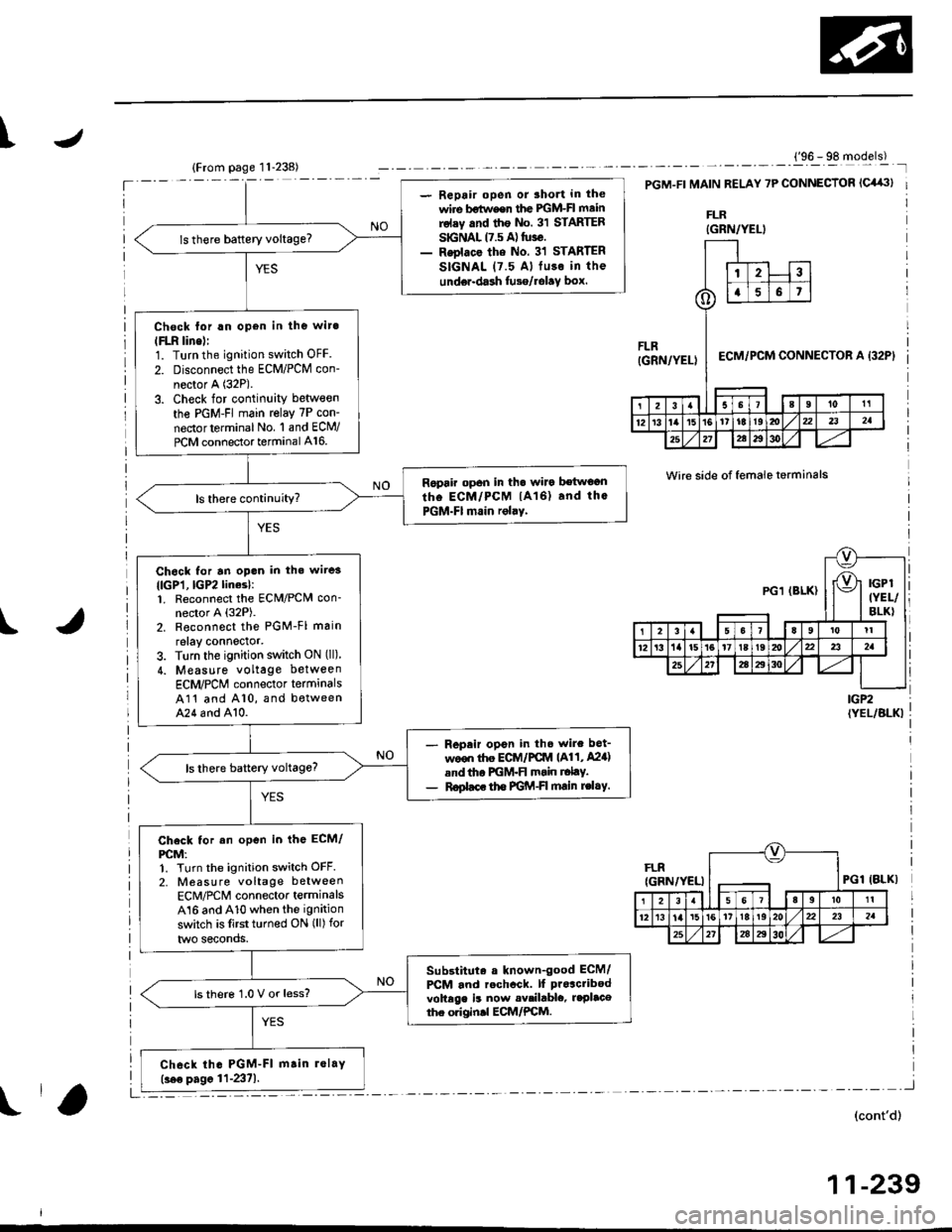

- Repair open or 3hort in the

wire bstw€er the lGM-Fl mainrolsy .nd the No. 31 STARTERSGNAL 17.5 A) tuse.- Reolace the No. 31 STARTER

SIGNAL (7.5 Al fu3o in the

unde.-dash tusg/rolav box.

ls there baftery voltage?

Chock lor !n open in the wit.

lFLn line)l1. Turn the ignition switch OFF

2. Disconnect the ECM/PCM con-

nector A (32P).

3. Check for continuity between

the PGM-FI main relay 7P con-

nectorterminal No. 1 and ECM/

PCM connector terminal A16.

Ropair op6n in th. walo betwoanthe ECM/PCM lA16) and thc

PGM-FI main rolaY.

Ch6ck for an opon in th. wi.e3

llcPl,lGP2linesl:1. Reconnect the ECM/PCN4 con-nector A (32P).

2. Reconnoct the PGM-Fl main

relay connector,3. Turn the ignition switch ON (ll)

4. Measure voltage between

ECM/PCM connector termanals

A11 and A10, and betweenA24 6nd A10.

Repeir opon in th6 wire bet-

ween ttre ECiA /PCM (A11, A24)

and tho PGM-FI msin r.lty.

R€plac. tho FGM-FI main rc|.Y.

Check tor an open in the ECM/

PCM:1. Turn the ignition switch OFF.

2, Measure voltage between

ECM/PCM connector terminalsA16 and A10 when the ignition

switch is lirst turned ON (ll) for

two seconds.

Substituta a known-good ECM/

PCM and rechcck. lf proacribod

voltege is now availablc, r.Placethe originll ECM/PCM.

ls thero 1.0 V or less?

Ch6ck th. PGM-FI m.in lolay(.ee pagc 11-2371.

('96 - 98 models)

t32Pt

Wire side of female terminals

IGP2{YEL/BLKI

FLRIGRN/YELIPGl

3l5 6 7l lslel tl1l

1213'tal5t6't7t8t920221 232a

2527284t

(cont'd)

1 1-239

IBLK)

{GRN/YELI

FLR(GRN/YELI

23

()a6t

ECM/PCM CONNECTOR A

21Il0t1

12r31'al5't61'tti9ml,/x2232a

25212e293ol./

PGl (BLK)

1I

12't/t15t617t8t9zi

25272A4t304l

Page 536 of 2189

1\

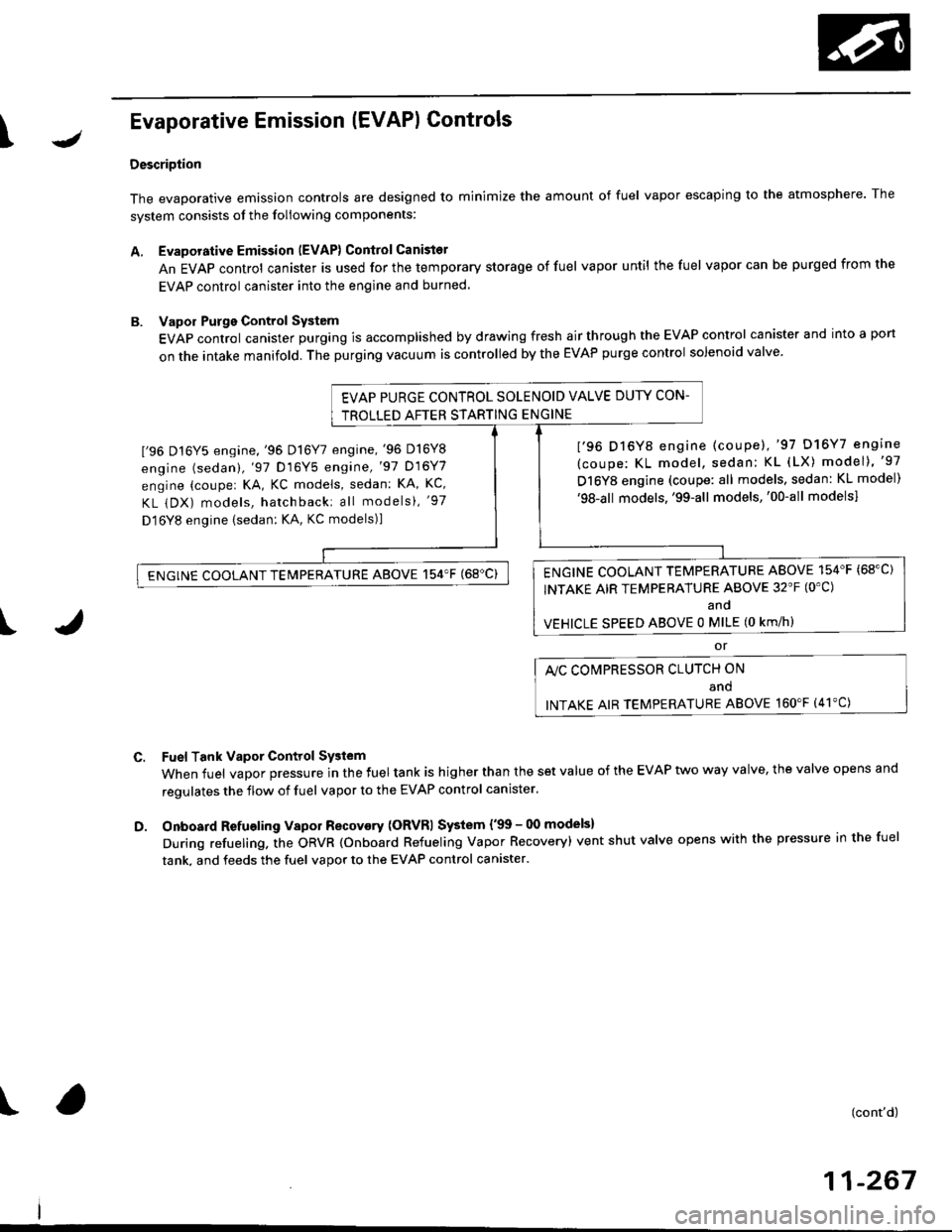

Evaporative Emission (EVAPI Controls

Description

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the foliowing components:

A. Evaporative Emission (EVAP) Control Canisto]

An EVAP control canister is used for the temporary storage of fuel vapor until the fuel vapor can be purged from the

EVAP control canister into the engine and burned.

B. Vapor Purge Control System

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a port

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

I'96 D16Y5 engine,'96 Dl6Y7 engine,'96 D16Y8

engine (sedan),'97 D16Y5 engine,'97 D16Y7

engine (couper KA, KC models, sedan: KA, Kc'

KL iDX) models, hatchback: all models), '97

D 16Y8 engine (sedan: KA, KC models)l

I'96 D16Y8 engine (coupe),'97 D16Y7 engine

(coupe: KL model, sedan: KL (LX) model)"97

D16Y8 engine (coupe: all models, sedan: KL model)'98-all models,'99-all models,'00-all modelsl

I

c.

D.

or

l'lc COMPRESSOR CLUTCH ON

and

INTAKE AIR TEMPERATURE ABOVE 160"F (41'C)

Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow of fuel vapor to the EVAP control canister.

Onboard Refueling Vapor Recovery (ORVRI System {'99 - 00 models}

During refueling. the oRVR {onboard Refueling Vapor Recovery) vent shut valve opens with the pressure in the fuel

tank. and feeds the fuel vapor to the EVAP control canister.

t(cont'd)

11-267

EVAP PURGE CONTROL SOLENOID VALVE DUTY CON-

TROLLED AFTER STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154'F {68"C)

INTAKE AIR TEMPERATURE ABOVE 32'F (O'C)

and

VEHICLE SPEED ABOVE O MILE (O KM/h}

ENGINE COOLANT TEMPERATURE ABOVE 154'F (68'C)