Pgm fi HONDA CIVIC 1996 6.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 447 of 2189

PGM-FI System

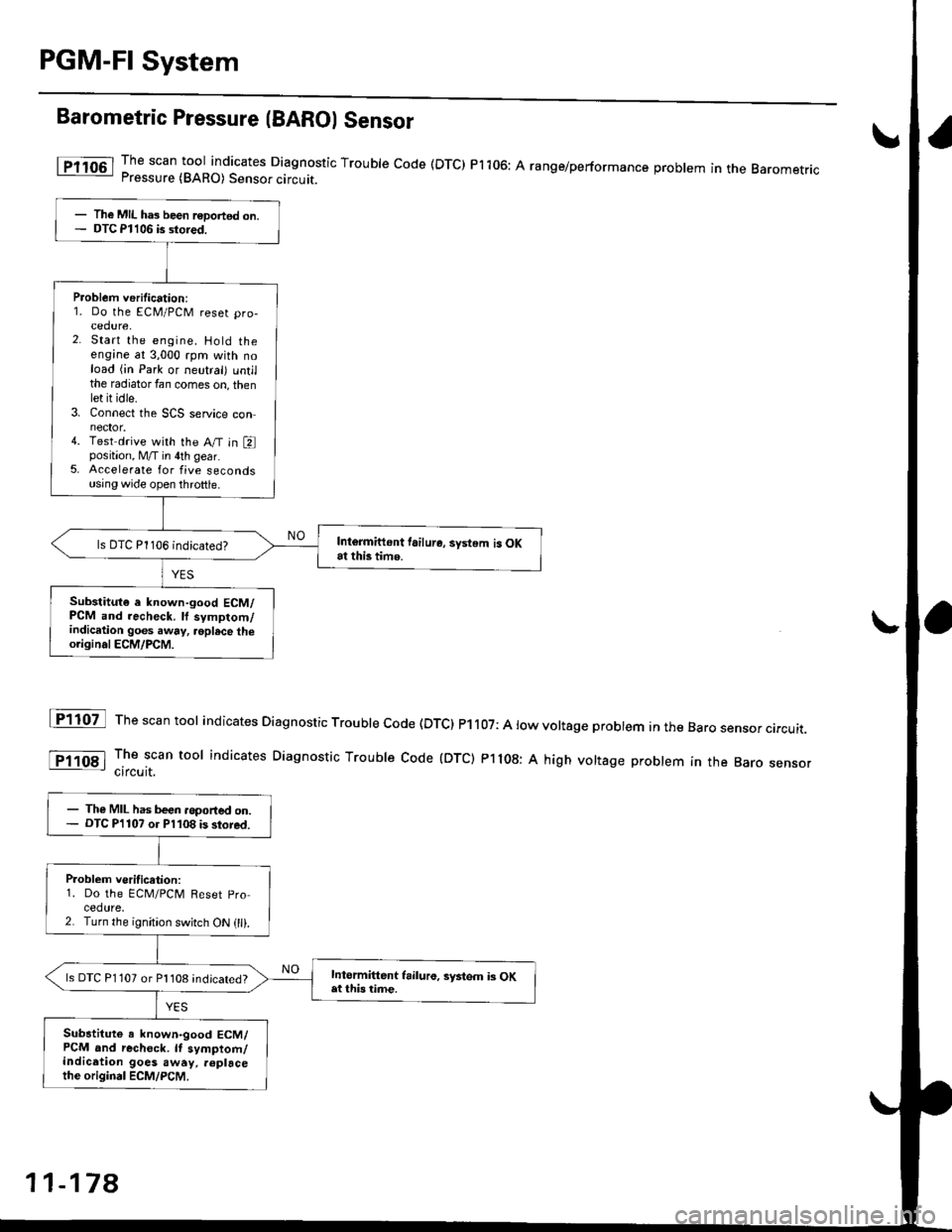

Barometric Pressure (BAROI Sensor

The scan tool indicates Diagnostic Trouble code (DTC) Pi106: A range/performance problem in the BaromerrrcPressure (BARO) Sensor circuit.

The scan tool indicates Diagnostic Trouble code (DTc) P1107: A low voltage probtem in the Baro sensor circurr.

The scan tool indicates Diagnostic Troubre code {DTC) p1108: A high vortage probrem in the Baro sensorcircuit.

fF1lot

tPlloal

The MIL ha3 been r€Dortsd on.DTC Pl106 is stored.

Problem verification:1. Do the ECM/PCM reset pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.3. Connect the SCS service connector.4. Test drive with the A/T in Eposition, M/T in 4th gear.5. Accelerate for five secondsusing wide open throttle.

Intormittont tailure, system is OKat this time.ls DTC P1106 indicated?

Substitut€ e known-good ECM/PCM and recheck. ll symptom/indication goes .way, .oplsce theo.iginal ECM/PCM.

The MIL has been .oported on.DTC P'l107 o. Pl108 is stored.

P.oblem veritication:1. Do the ECM/PClvl Reset pro

cedure,2. Turn the ignition switch ON (ll).

Intormittent frilure, syitem i3 OKat this time.ls DTC P1 107 or Pl108 indicated?

Substitute a known-good ECM/PCM and rechock. It symptom/indication goes away, .6placethe original ECM/PCM.

11-178

Page 449 of 2189

PGM-Fl System

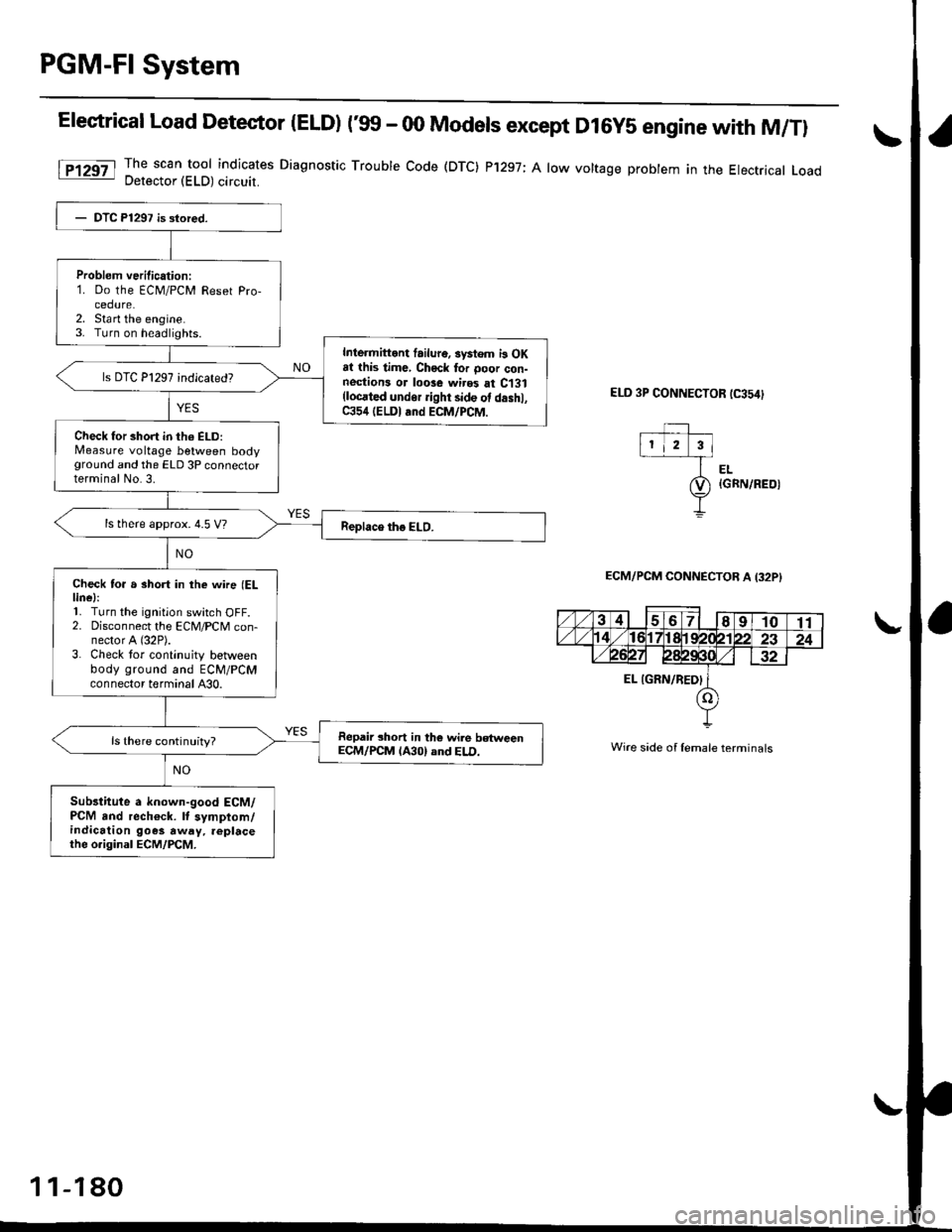

Elestrical Load Detector |ELD) t'glf - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P'1297; A low voltage probtem in the Electrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR tC354)

EL{GRN/REOI

ECM/PCM CONNECTOB A I32PI

Wire side of lemale terminals

Problem verilication:1. Do the ECM/PCM Reset Pro-cedure.2. Sta rt the engine.3. Turn on headlights.

Inlermittont failur6. systom i3 OKat this time, Chock tor ooor con-nestions or loose wires at C131(locrted undor ight side ot d.shl,C354 (ELDI and ECM/PCM.

Check for short in th6 ELD:Measure voltage between bodyground and the ELD 3P connectorterminal No.3.

ls there approx. 4.5 V?

Check to. a short in the wne (ELlinel:'L Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Check tor continuity betlveenbody ground and ECM/PCMconnector terminal A30.

Repair short in the wile betweenECM/PCM lA30) and ELD.ls there continuity?

Sub3titute a known-good ECM/PCM and rech€ck. It symptom/indication goes away. replacethe o.iginal ECM/PCM.

1 1-180

Page 451 of 2189

PGM-FI System

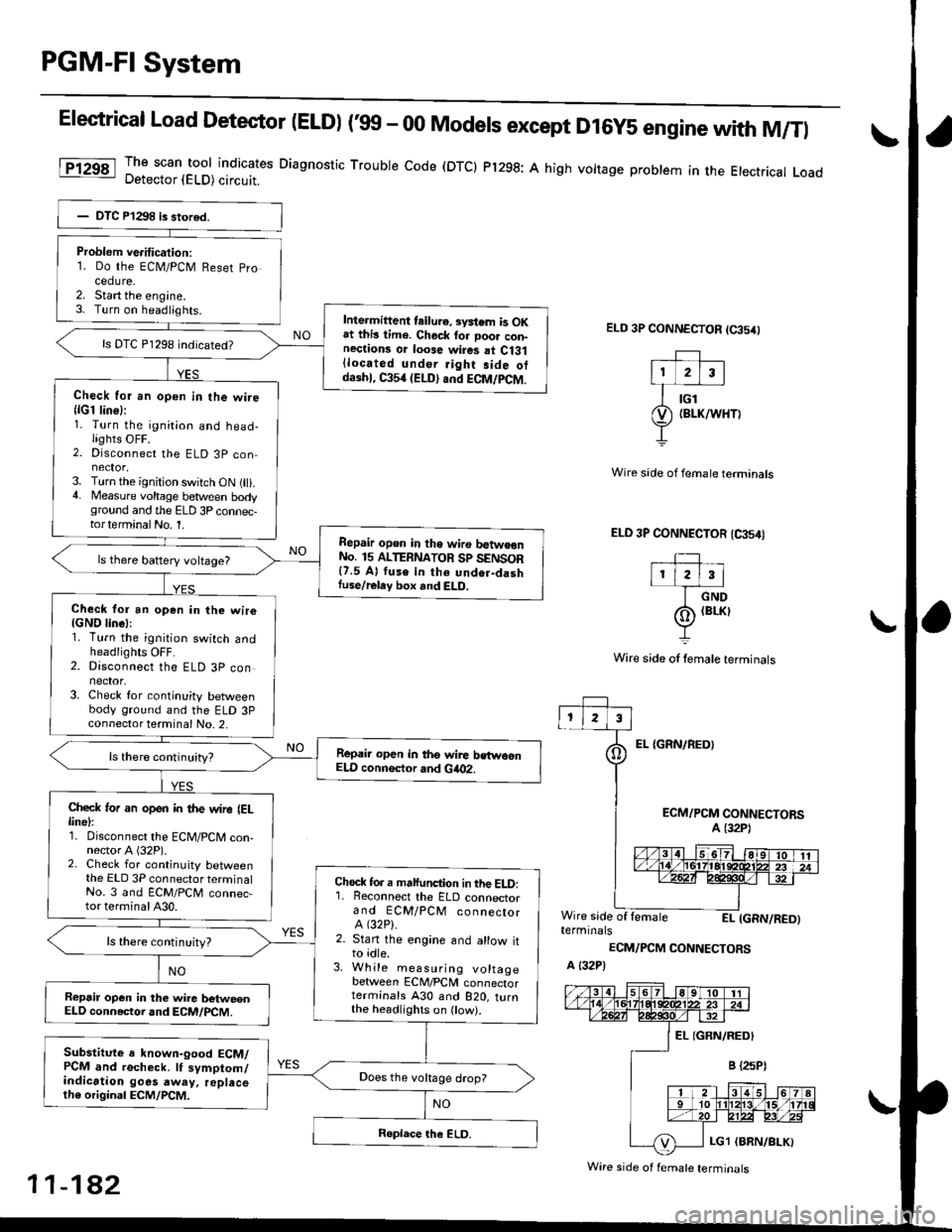

Elestrical Load Detector (ELDI ('99 - 00 Models except D16y5 engine with M/Tl

The scan tool indicates Diagnostic Trouble code (DTCI Pl298: A high vottage problem in the Etectrical LoadDetector (ELD) circuit.

ELD 3P CONNECTOR (65/0

EL {GRN/REOI

Wire side of fernale terminals

ELD 3P CONNECTOR (CA54I

TIr l2l3l

I crvo

(o) (BrKr

Y

Wire side of lemale terminals

ECM/PCM CONNECTORSA (32P1

Wire side of lemaleEI- IGRN/RED)terminals

ECM/PCM CONNECTORS

A {32P)

Problem ve.itication:1. Do the ECN4/PCM Reset pro

cedure.2. Start the engine.3- Turn on headiights.Inte.mittent teilu.e, svstem is OKat this lime. Chock for Door con-nections or loose wires at Ci31{located under Jight side otdaihl, C354 (ELD) and ECM/PCM.

ls DTC P1298 indicated?

Check for an open in the wire{lG1 line}:1. Turn the ignition and head-lights OFF.2. Disconnect the ELD 3P con

3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the ELD 3P connec-torterminalNo. 1.

Repair opon in tho wiro batwe€nNo. 15 ALTERNATOR Sp SENSOR{7.5 A} fuse in th6 undor-dashIuse/reley box and ELD.

ls there battery voltage?

Check for an open in the wiro{GND linel:1. Turn the ignition switch andheadlights OFF.2. Disconnect the ELD 3P connector.3. Check for continuity betweenbody ground and the ELD 3Pconnector terminal No. 2,

Repair open in the wire bstwoenELD connsctor and Gia02.

Check ,or an open in the wire IELlinel:1. Disconnect the ECM/PCM con-nector A (32P).2. Check for continuity betweenthe ELD 3P connector terminalNo. 3 and ECM/PCM connec-tor terminal A30.

Chock fo. a malfunction in the ELD:'1. Reconnect the ELD connectorand ECM/PCM connectorA (32P).

2. Stan the engine and allow itto idle.3. While measuring voltagebetween ECM/PCM connectorterminals A30 and B2O, turnthe headlighrs on ow).

ls there continuity?

Repsir op€n in the wire betweenELD connector and ECM/PCM.

Substitute a known-good ECM/PCM and recheck. lf symptom/indication goes away. replacelh6 original ECM/PCM.

Does the vokage drop?

Wire side of f€male terminals

11-182

Page 453 of 2189

PGM-FI System

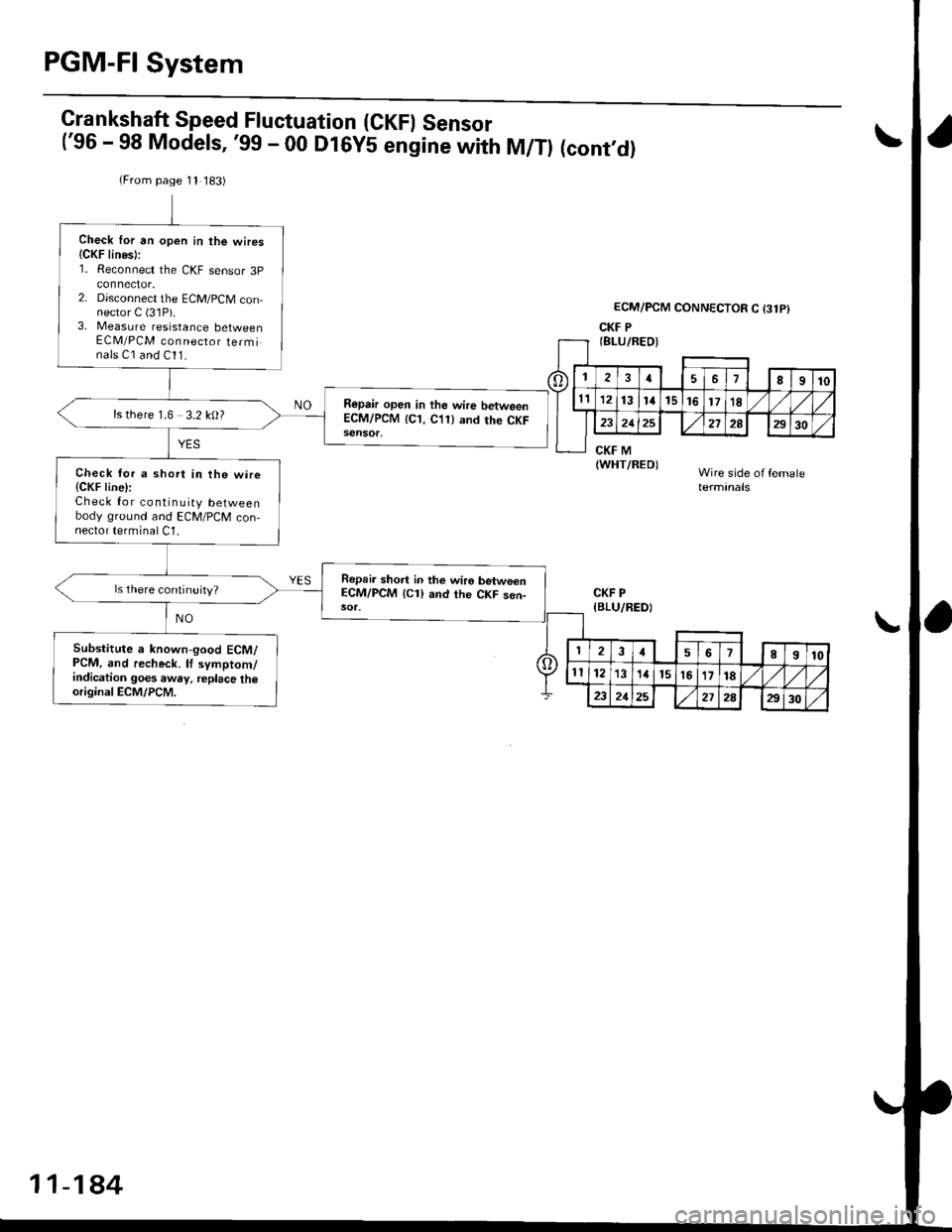

(From page 11 183)

Check lor an open in the wiresICKF lines):1. Reconnect the CKF sensor 3p

2. Dlsconnect the ECM/PCM con-nector C (31P).3, Measure resistance betweenECM/PCM connector terminals Cl and Cl1.

Repair open in the wire betweenECM/PCM {C1, C11} and the CKFls there 1.6 3.2 kO?

Check for a short in the wire{CKF line}:Check for continuity betweenbody ground and ECM/PCM con,nector terminal C1.

Repair short in the wiro bstwoenECM/PCM {Cl) and the CKF son-

Substitute a known-good ECM/PCM, and recheck. lf symptom/indication goes awry, replace theoriginal ECM/PCM.

Crankshaft Speed Fluctuation (GKFI Sensor('96 - 98 Models,'99 - 00 D16V5 engine with M/Tl (cont,d)a\

ECM/PCM CONN€CTOR C (31P}

CKF P(8LU/REO)

CKF M(WHT/REO)Wire side of femaletermtnats

CKF P(BLU/RED)

6r l-i

rF

tl

a678910

12131115t61718

21272A2930

11-184

Page 455 of 2189

PGM-FI System

Crankshaft Speed Fluctuation (GKFI Sensor('99 - 00 Models except D16YS engine with M/Tl (cont,d)I\

ECM/PCM CONNECTOR C 13lPI

Wire side of femaleterminals

aI

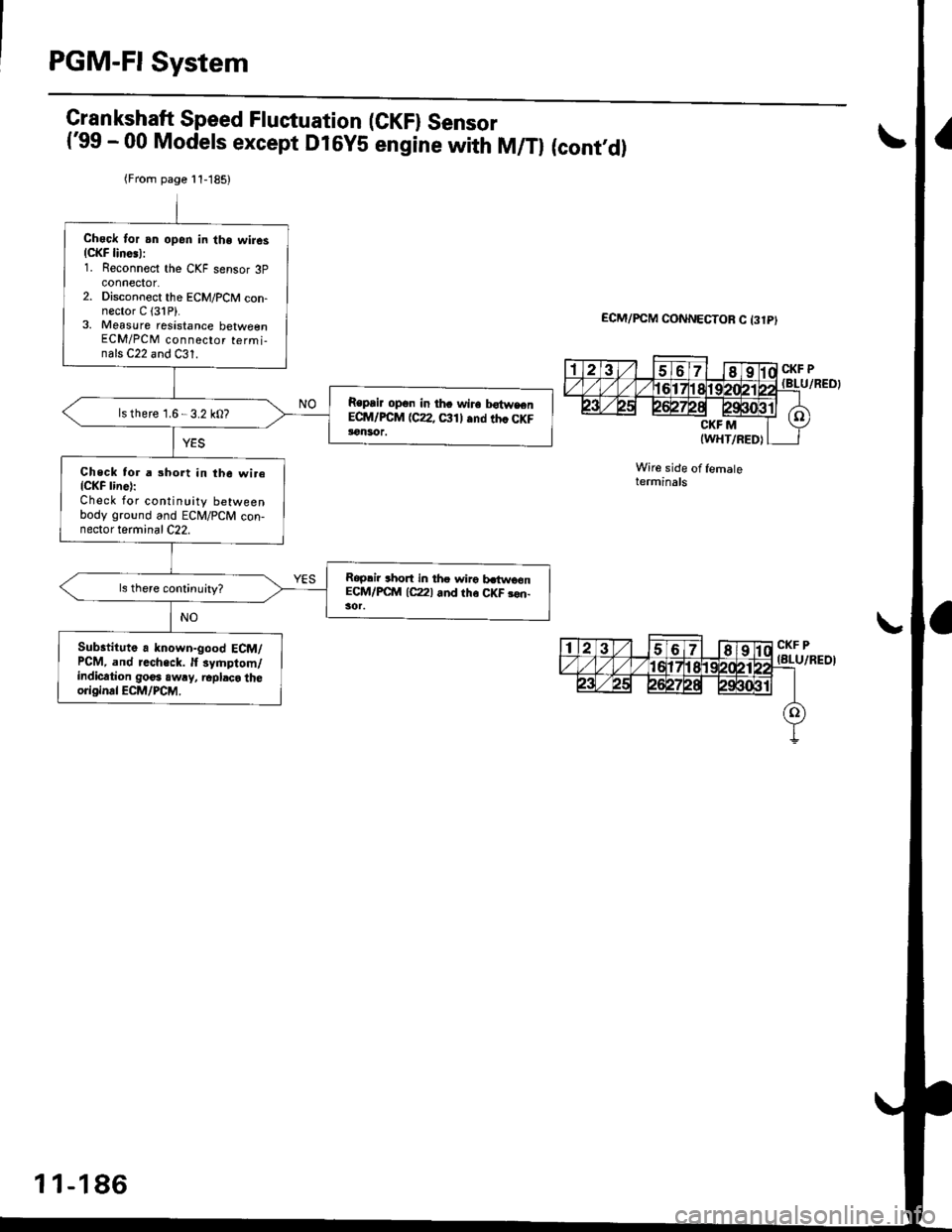

(Frorn page l1-185)

Check Ior an opsn in the wires(CKF lines):1. Reconnect the CKF sensor 3pconnector.2. Disconnect the ECM/PCM con-nector C {31P}.3. Measure resistance betw€enECM/PCM connector termi-nals C22 and C31.

Repair opqn in th. wire bo{weenECM/PCM (CZ, Ctll and th. CKFlon30r.

ls there 1.6-3.2 k0?

Check tor a short in the wireICKF line):Check for contin!ity betweenbody ground and ECM/PCM con-nector terminal C22.

Roplir thort in tho wirg b.iwoonECM/FC'ftl lc22l and tho CKF 3€n-

Substituto a known-good ECM/PCM, and r.ch.ck. It symptom/indication 90o. aw!y, 6pbco theoriginal ECM/PCM.

1 1-186

Page 457 of 2189

PGM-FI System

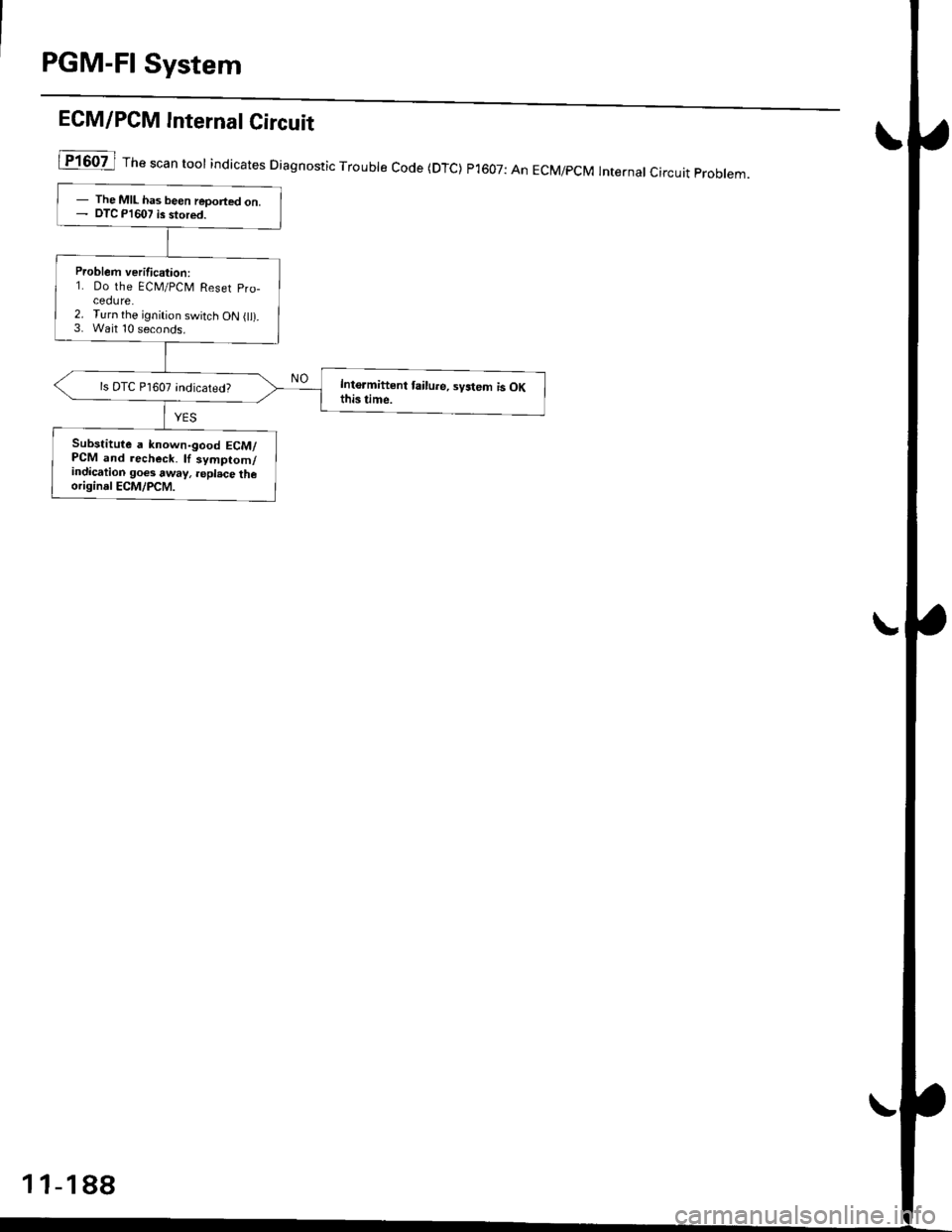

ECM/PCM lnternal Circuit

[Fi6oil th" """n tool indicates Diagnostic Trouble code (DTc) p1607: An EcM/pcM lnternal circuit probtem.

- The MIL has been reported on.- DTC P1607 is stored.

Problern verif ication:1. Do the ECN4/PCM Reset pro-

cedure.2. Turn the ignition switch ON t).3. Wait 10 seconds.

ls DTC P 1607 indicated?

Substitule a known-good ECM/PCM and recheck. lf symptom/indication goes away, .epl.ce theorigin.l ECM/PCM.

11-188

Page 463 of 2189

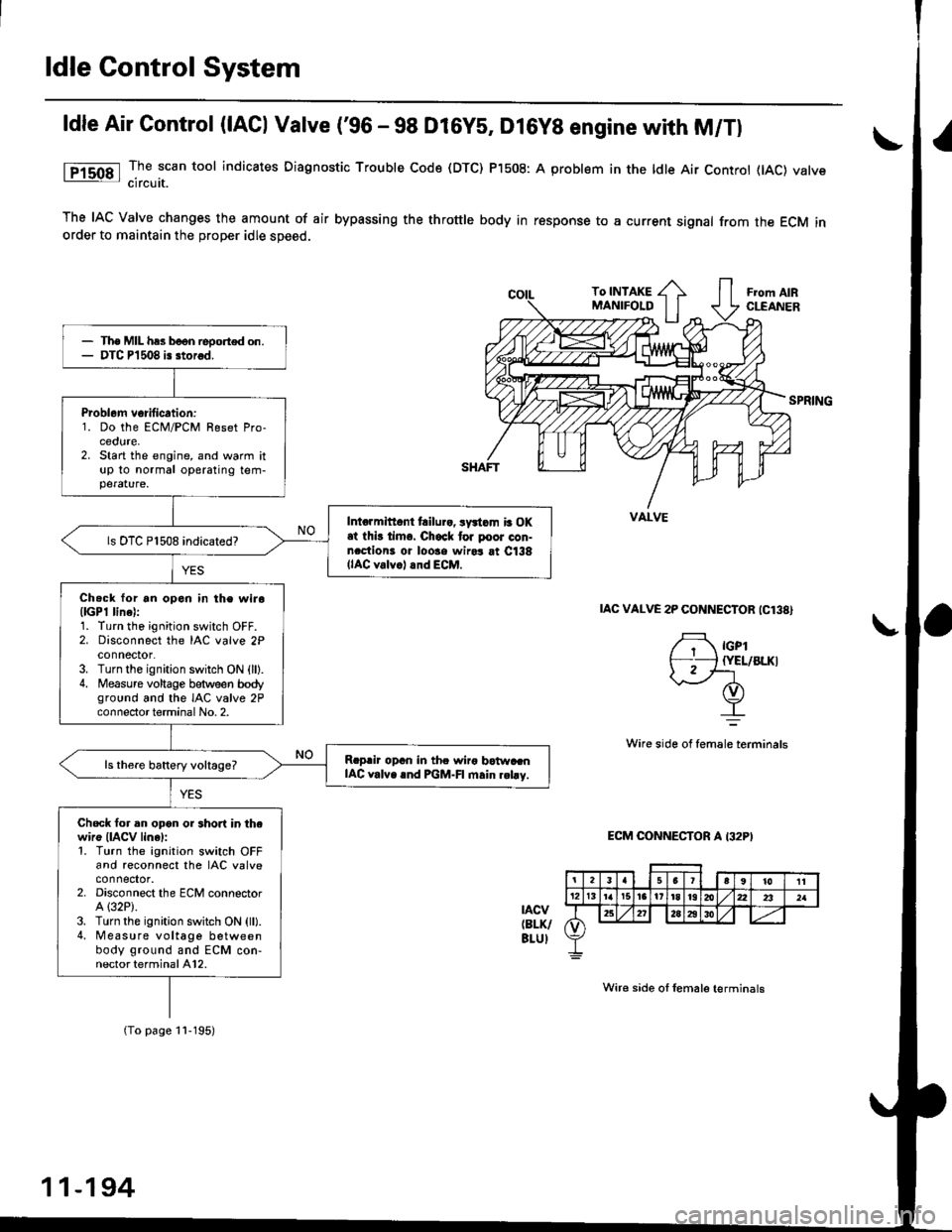

ldle Control System

ldle Air Control (lACl Vatve ('96 - 98 Dl6ys, Dl6yB engine with M/Tl

The scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt flAC) varvecircuit.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM inorder to maintain the proper idle speed.

IAC VALVE 2P CONNECTOR ICl3A)

,flrcerh-:J iYEL/BLKI

!.__-,/ -lt(v)

-T-=

Wire side of female terminals

tAcv(BLK/

ELUI

ECM CONNECTOR A I32PI

Wire side oI lemal€ terminals

VALVE

6a10ll12t3r5t6l7t8t920232a

t*25&a2A3o

The MIL hss b€on repo.ted on.DTC P'l508 i. itorod.

Problem vorification:1. Do the ECM/PCM Reset Pro-cedure,Start the engine, and warm ituP to normal operating tem-perature.

Intormittont t!llur., sy.tcm b OKat thb tim6. Chsck fol poor con-ncctionr or loo3e wirot at C138(lAC valv.l.nd ECM.

ls DTC P1508 indicated?

Check for an opcn in the wiro(lGPl line):1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON (ll).

4. Measure vohage between bodyground and the IAC valve 2Pconnectorterminal No. 2.

R.prir opan in the wiro botwa.nIAC valv..nd PGM-FI main r.l.y.

Chock for an opon or sho in thewire (IACV linal:1. Turn the ignition switch OFFand reconnect the IAC valveconnector.2. Disconnect the ECM connectorA (32P).

3. Turn the ignit;on switch ON (ll).4. Measure voltage betweenbody ground and ECM con-nector terminal A12.

(To page 1l-195)

11-194

Page 465 of 2189

![HONDA CIVIC 1996 6.G Repair Manual ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt HONDA CIVIC 1996 6.G Repair Manual ldle Gontrol System

ldle Air Control (lAG) Valve (99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt](/img/13/6068/w960_6068-464.png)

ldle Gontrol System

ldle Air Control (lAG) Valve ('99 - 00 Dl6Y8 engine with M/T, Bt6A2 enginel

[Fl50g l ]h" scan tool indicates Diagnostic Trouble Code (DTC) P1508: A problem in the ldle Air Controt AC) vatve- CtrCUtt.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM inorder to maintain the proper idle speed.

IAC VALVE 2P CONNECTOR IC138'

la rcprI - {YEL/8LKI 2t--d,

Y-=

Wire side ot female terminals

Wire side of lemale terminals

VALVE

The MIL has boon r€oorted on.DTC P1508 is srored.

Probl6m verification:1. Do the ECM/PCM Reset Pro-cedure.2. Start the engine, and warm itup to normal operating lem-perature.

Intermittent tailure, system is OKat this timg. Check to. poor con-noctions or loose wires at C138{lAC valvel and ECM.

ls DTC P1508 indicated?

Ch6ck for an open in the wir€{lGPl lino}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the IAC valve 2Pconneclor termina I No.2,

Repair opon in the wire bgtwoenIAC valve and PGM-Fl main relay.

Check tof an open or short in thewire {IACV line}l1. Turn the ignition switch OFFand reconnect the IAC valve

2. Disconnect the ECM connectorB {25P).3. Turn the ignition switch ON (ll).

4. Measure voltage betweenbody ground and ECM conn€ctor terminal 823.

(To page 11-197)

1 1-1 96

Page 468 of 2189

t

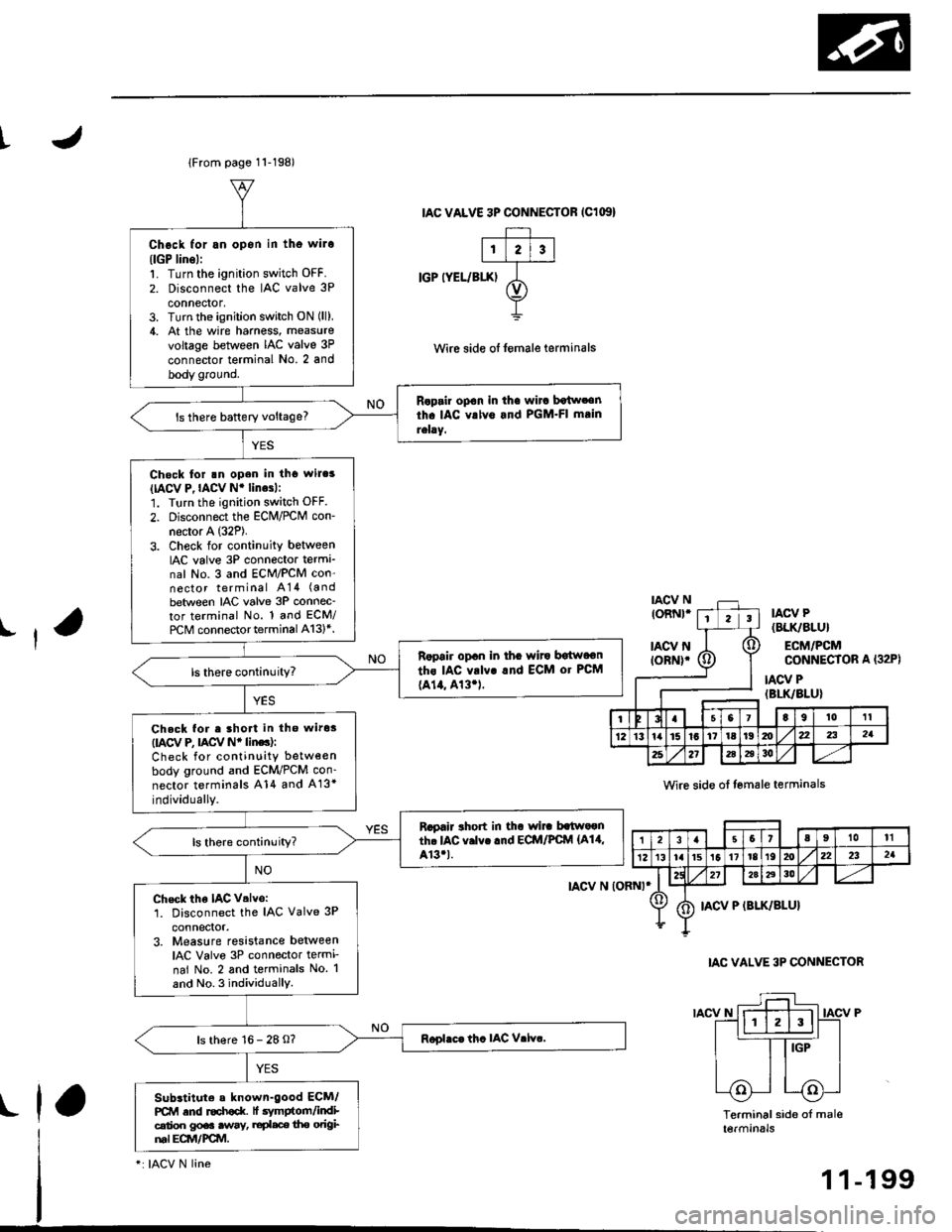

lFrom page 11-198)

Chock for an opon in tho wilo(lGP lins):'1. Turn the ignition switch OFF.

2. Disconnect the IAC valve 3P

connector,3. Turn the ignition switch ON (ll),

4. At the wire hamess, measure

voltage between IAC valve 3P

connector terminal No. 2 and

body ground.

Raprir op€n in th€ wirc botw.€nth. IAC vrlv6 and PGM.FI mtin

rehy.ls there baftery voltage?

Check for rn open in tho wil.s(IACV P,IACV Nr linesl:

1. Turn the ignition switch OFF.

2. Disconnect the ECM/rcM con-

necror A (32P).

3. Check for continuity betweenIAC valve 3P connecto. terma_nal No. 3 and ECM/PCM con-nector terminal A14 (a nd

between IAC valve 3P connec-tor terminal No. 1 and ECM/

rcM connector terminal A13l*.

Ropair opan in tha wito bgtwoon

ths IAC vrlv! rnd ECM or PCM

{A14, 413.1.

Check for e lhort in tho wiros(IACV e nCV Nr linc):

Check for continuity between

body ground and ECM/PCM con-

nector terminals A14 and A13*

individually.

Rapair rhort in thr wi]. batwaonth. IAC v.lvc .nd ECM/PCfvl {A14,Ar3.t.ls there continuity?

Check the IAC V.lvo:1. Disconnect the IAC Valve 3P

3. Measure resistance betweenIAC Valve 3P connector termi-

nai No. 2 and terminals No. 1

and No. 3 individuallY.

ls there 16 - 28 O?

Subrtituto a known-good ECM/PCM and r€ch€d( lt .vmptom/indicalioo gp€. .way, ruplace tho odgiml Eqvt/FCM.

IAC VALVE 3P CONNECTOR IClG'}

IGP IYEL/BIX)

tAcv N (oRNt*

IACV N

Wirc side of lemale teaminals

IAC VALVE 3P CONNECTOR

IACV P

Terminal side of mal6tetmtnats

(32P)

ll

toRNt*tIIACV P(BLK/8LU}

ECM/PCMCONNECIOR A

IACV P(BLK/BLU}

Io,tl0't1

1Z13ta15l617tal9mx22321

2521i6a3o

,|31.57aIl0tl

12t3r. lrst511r8t92022232a

272aA30

IACV P (BLK/SLU}

rla

-: IACV N line

1 1-199

Page 470 of 2189

I

I

L

IACV N(oRN)*IACV P{BLK/BLU'

ECM/PCMCONNECTON B (25PI

IACV N(oRNt.

Wire side of female terminals

IAC VALVE 3P CONNECTOR

IACV NIACV P

IACV P

IBLK/BLUI

IGP

Terminal side of male

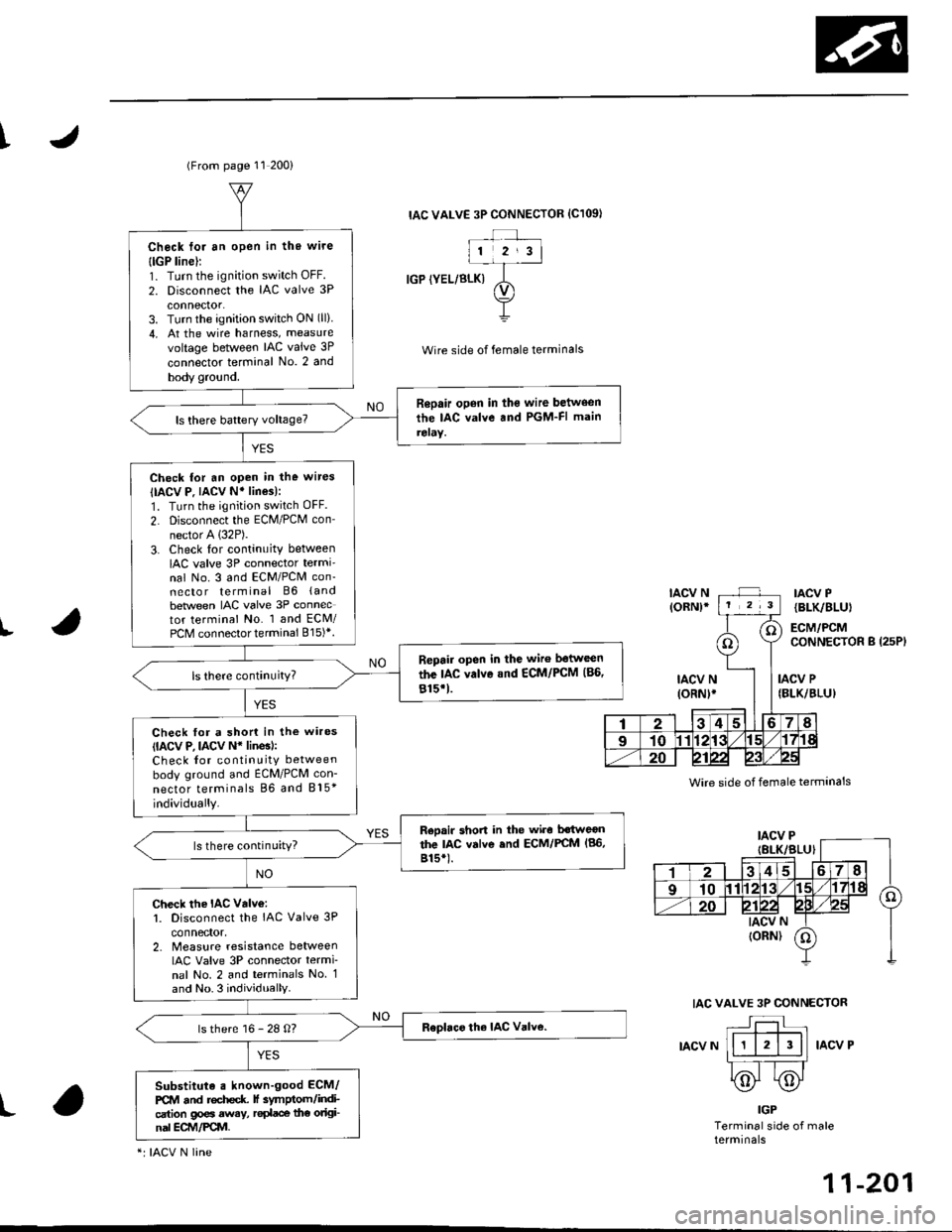

(From page 11 200)

IAC VALVE 3P CONNECTOR {C1O9I

IGP (YEL/BLK)

Wire side of female terminals

Check toi an open in thg wire

{lGP line):1. Turn the ignition switch OFF.

2. Disconnect the IAC valve 3P

connector.3. Turn the ignition switch ON (ll)

4, At the wire harness, measure

voltage between IAC valve 3P

connector terminal No. 2 and

body gro!nd.

Repair open in the wire between

the IAC valve and PGM-FI main

reraY.

Check for an open in the wires

IIACV P. IACV N' lines):

1. Turn the ignition switch OFF.

2. Disconnect the ECM/PCM con-

nector A (32P).

3. Check lor continuity between

IAC valve 3P connector termi'nal No. 3 and ECM/PCM con-necto r terminal B6 (and

beNveen IAC valve 3P connector terminal No. 1 and ECM/PCM connector terminal 815)*.

Repair open in the wiro ltstwcen

the IAC valvo and €CM/PCM (86,

815'1.

Check for a shon in the wires(IACV P, lACv N* linesl:Check for continuity between

body ground and ECM/PCM con-

nector terminals 86 and 815*

individually.

Reoair short in the wiro Mweonthe lac valve end ECM/FCM (86,

815*).ls there continuity?

Check the IAC valv€:l. Disconnect the IAC Valve 3P

connector,2. Measure resislance betweenIAC Valve 3P connector termi

nal No. 2 and terminals No 1and No.3 individually

ls there 16 - 28 O?

Substituta . known-good ECM/

PCM and rochcdc f 3ymptom/indication go€a away, r€dace the original ECM/Pqvl.

"r IACV N line

N

11-201