Dash harness HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 546 of 2189

\

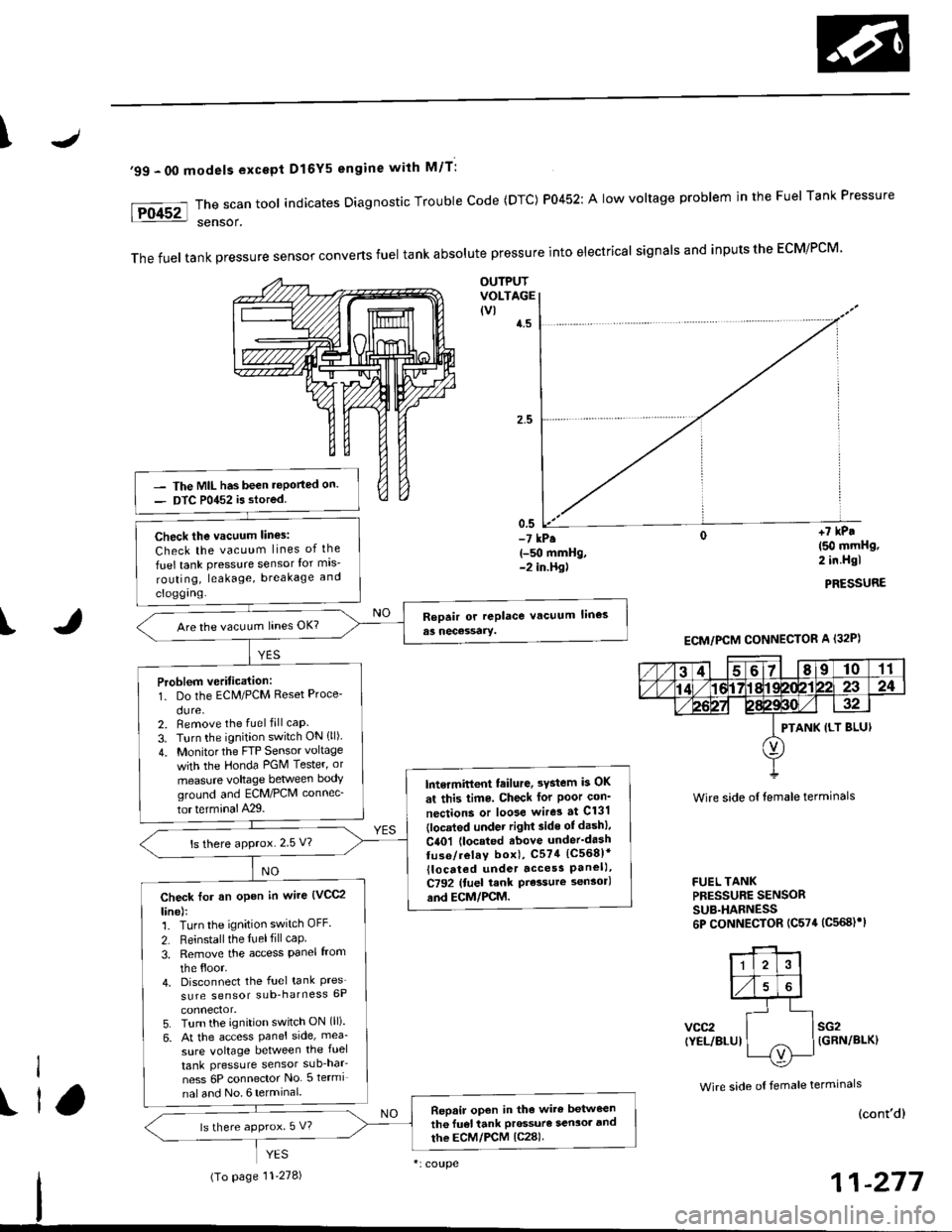

'99 - 00 models excepi Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM

OUTPUTVOLTAGE(vlt.5

0.5-7 kP.(-g) mmHg,-2 in.Hgl

+7 kP.

150 mmHg,2 in.Hgl

PRESSURE

I

Wire side of lemale terminals

FUEL TANKPRESSURE SENSORSUB.HARNESS6P CONNECTOR (C574 (C568)rl

vcc2(YEL/BLUIsG2{GRN/BLK}

Wire side o{ temale terminals

The MIL has been .eported on.

DTC P0452 is stored

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum hnes OK?

Problem veritication:1. Do the ECM/PCM Reset Proce-

du re,2. Bemove the fuel fill caP.

3. Turn the ignition switch ON {ll)

4. Monitorthe FTP Sensor voltage

with the Honda PGM Tester' or

measure voltage between body

groLrnd and ECM/PCM connec_

tor terminalA29.

lntermitlent tailure, 3Ystem b OK

at this time. Check for Poor con'

nections or loose wire3 at C131

{located under right side of dash},

C401 {located above under'dash

tuse/relay box), C574 (C568)*

llocdted under access Panel),C792 (tuel rank Prcssure sensorl

and ECM/PCM.

ls there approx.2 5 V?

Check for an open in wire {VCC2

line):1. Turn the ignition switch OFF.

2. Reinstall the ltrel fill caP

3, Remove the access Panel from

the floor.4. Disconnect the fuel tank Pres'sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll).

6. At the access Panel side, mea_

sure voltage between the fuel

tank Pressure sensor sub-nar-

ness 6P connector No 5termi

nal and No. 6 termlnal.

Repair open in tho wire between

th6 fu€l tank Prossuro sen3oa and

the ECM/PCM lc28).ls there approx 5 V?

ECM/PCM CONNECTOR A (32P)

PTANK {LT BLUI

I

ll

(To page '11-278)

(cont'd)

Page 550 of 2189

\

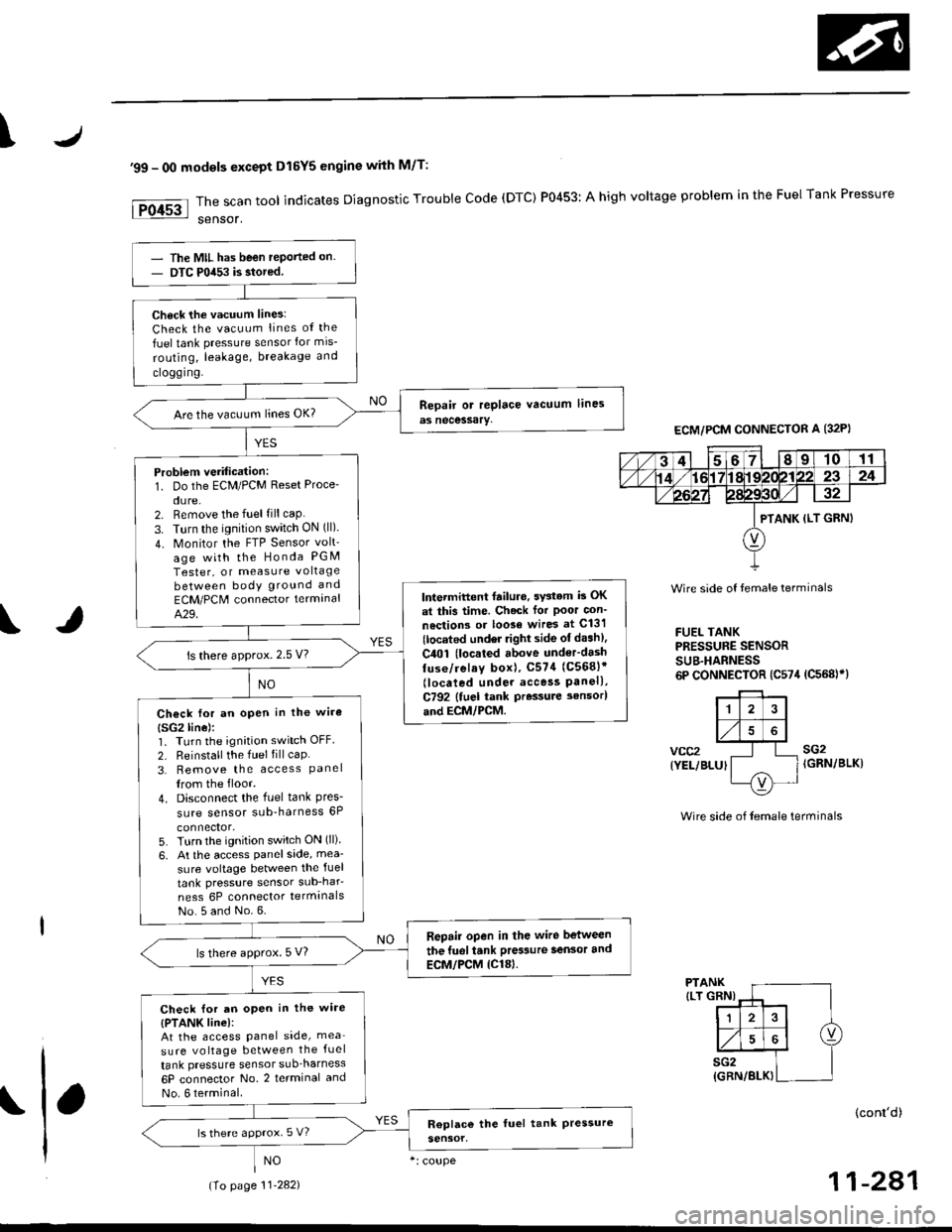

'99 - 0O modols except Dl5Y5 engine with M/T:

rFo45'::n":"tooIindicatesDiagnosticTroub|ecode(DTc)P0453:Ahighvo|tageprob|emintheFUelTankPressure

Wire side of temale terminals

FUEL TANKPRESSUNE SENSOR

SUB.HARNESS6P CONNECTOR {C574 (C568)}}

vcc2{YEL/BLUI

sG2IGRN/BLK)

Wire side of female terminals

PTANK{LT GRNI

(cont'd)

11-281

ECM/PCM CONNECTOR A {32P)

PTANK {LT GRN)

The MIL has been reported on.

DTC P0453 is stored.

Check the vacuum lines:

Check the vacuum lines ot the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verilication:1. Do the ECM/PCM Reset Proce-

du re,2. Remove the fuel fill caP

3. Turn the ignition switch ON (ll).

4. Monitor the FTP Sensor volt'

age with the Honda PGM

Tester, or measure voltage

between body ground and

ECM/PCM connector terminalA.29.

lntermittent failuro. svstem b OK

at this time. Check for Poor con_

noctions or loo3€ wire3 at C131

{located under tight side of dash),

C4Ol {located above underdash

fuse/relay boxl, C57{ (C5681'

llocaled unde. access Panell,C792 {fuel tank Pressure sensorl

aod ECM/PCM.

ls there approx.2.5 V?

Ch€ck for an open in the wira

{SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuel fill caP

3. Remove the access Panellrom the floor.

4. Disconnect the fuel tank Pres-sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll)

6, At the access Panelside, mea-

sure voltage between the fuel

tank pressure sensor sub_har-

ness 6P connector termlnals

No.5 and No.6.

Repair open in the wire between

the fueliank Pres3ure 3ensor and

ECM/PCM {Cl8).ls there approx.5 V?

Check lor an oPen in the wire

{PTANK linel:At the access Panel side, mea

sure voltage between the fuel

tank pressure sensor suo_harness

6P connector No. 2 terminal and

No. 6 terminal.

ls there approx. 5 V?

(To page 11.282)

Page 1093 of 2189

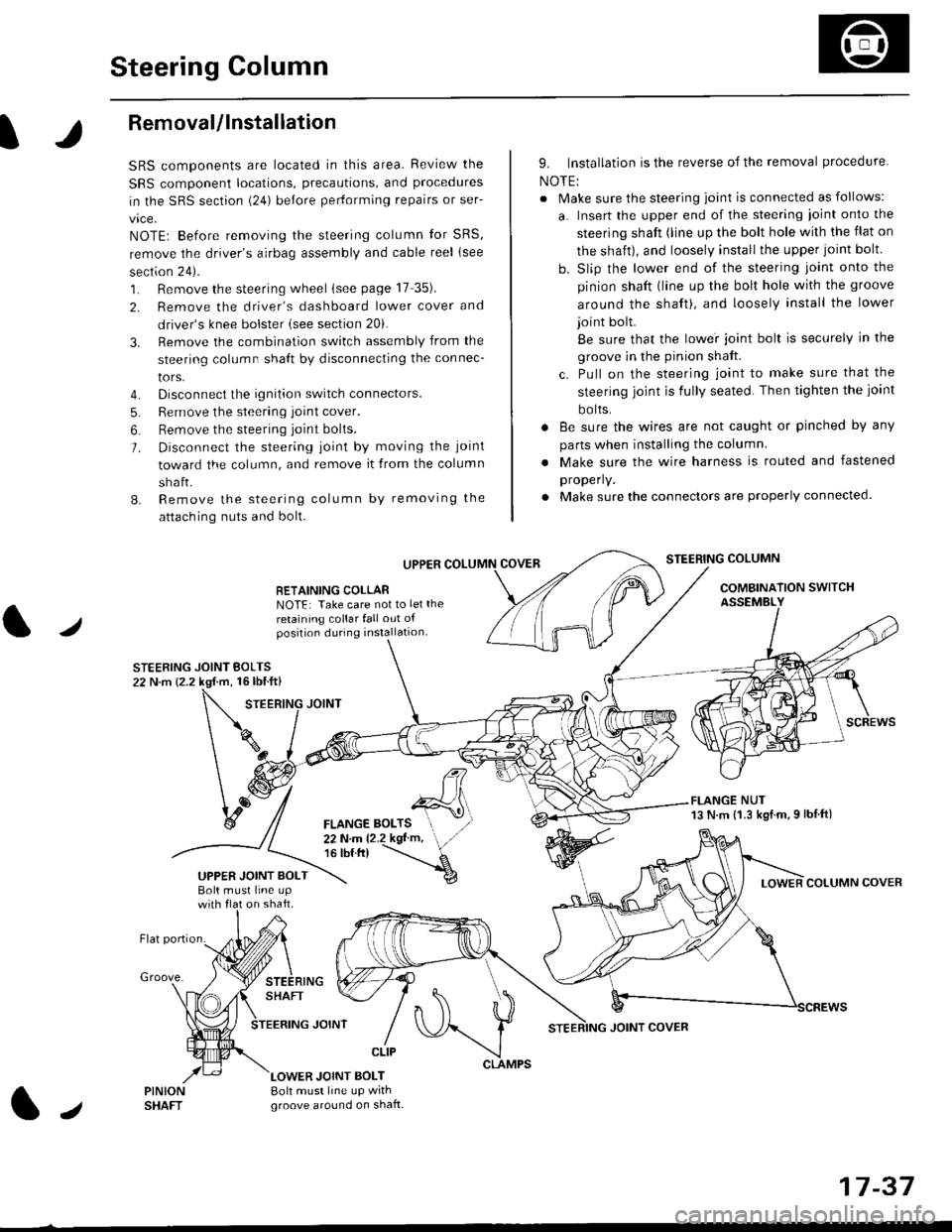

Steering Column

I

Removal/lnstallation

SRS components are located in this area. Review the

SRS component locations, precautions, and proceclures

in the SRS sectron (24) before pertorming repairs or ser-

vice.

NOTE: Before removing the steering column for SRS,

remove the driver's airbag assembly and cable reel lsee

section 24).

1. Remove the steering wheel (see page 17 35).

2. Remove the driver's dashboard lower cover and

driver's knee bolster (see section 20).

3. Remove the combination switch assembly from the

steering column sha{t by disconnecting the connec-

tors.

4. Disconnect the ignition switch connectors.

5. Remove the steering joint cover.

6. Bemove the steering joint bolls.

7. Disconnect the steering ioint by moving the joint

toward the column, and remove it from the column

shaft.

8. Remove the steering column by removing the

attaching nuts and bolt.

UPPER

RETAINING COLLABNOTE: Take care not to let the

retaining collar fall out ofposition during installation.

STEERING JOINT BOLTS22 N.m {2.2 kgf.m, 16lbtft}

9. Installation is the reverse of the removal procedure

NOTE:

. Make sure the steering joint is connected as follows:

a. Insert the upper end of the steering ioint onto the

steering shaft (line up the bolt hole with the flat on

the shait), and loosely install the upper joint bolt.

b. Slip the lower end of the steering joint onto the

pinion shaft (line up the bolt hole with the groove

around the shaft), and loosely install the lower

joint bolt.

Be sure that the lowei joint bolt is securely in the

groove in the pinion shaft.

c. Pull on the steering joint to make sure that the

steering joint js fully seated. Then tighten the ioint

bolts.

. 8e sure the wires are not caught or pinched by any

parts when installing the column

. Make sure the wire harness is routed and fastened

properly.

. Make sure the connectors are properly connected.

STEERING COLUMN

COMBINATION SWITCHASSEMBLY

FLANGE NUT13 N.m {1.3 kgl.m.9 lbf ft)

COLUMN COVER

FLANGE BOLTS22Nm12.2kgl'm,16 tbt.tr)

UPPER JOINT BOLTBolt musl line upon shaft.

Groove.

LOWER JOINT BOLT8oh must line up wrthgroove around on shaft.

CLIP

J

JOINT COVER

17-37

Page 1284 of 2189

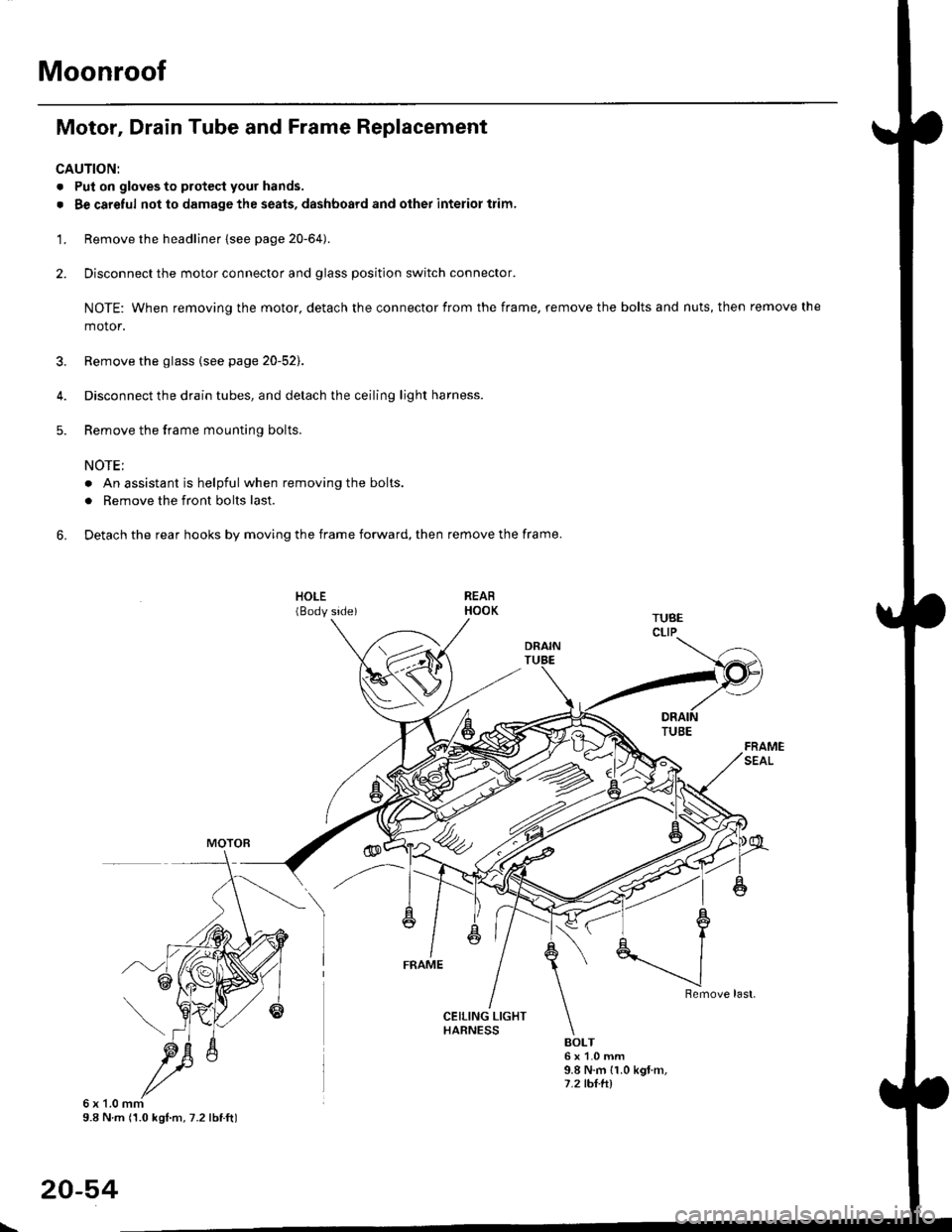

Moonroof

Motor, Drain Tube and Frame Replacement

CAUTION:

. Put on gloves to protecl your hands.

. Be careful not to damage the seats, dashboard and other interior trim.

'1. Remove the headliner {see page 20-64).

2. Disconnect the motor connector and glass position switch connector.

NOTE: When removing the motor, detach the connector from the frame, remove the bolts and nuts, then remove the

motor.

3. Remove the glass {see page 20-52).

4. Disconnect the drain tubes, and detach the ceiling light harness.

5. Remove the frame mounting bolts.

NOTE;

. An assistant is helpful when removing the bolts.

. Remove the front bolts last.

6. Detach the rear hooks by moving the frame forward, then remove the frame.

BOLT6x1.0mm9.8 N.m {1.0 kgt m,7.2 tht.hl

6x1.0mm9.8 N m (1.0 kgl.m, 7.2 lbtft)

20-54

\

Page 1300 of 2189

Dashboard

Gomponent Removal/lnstallation

(cont'd)

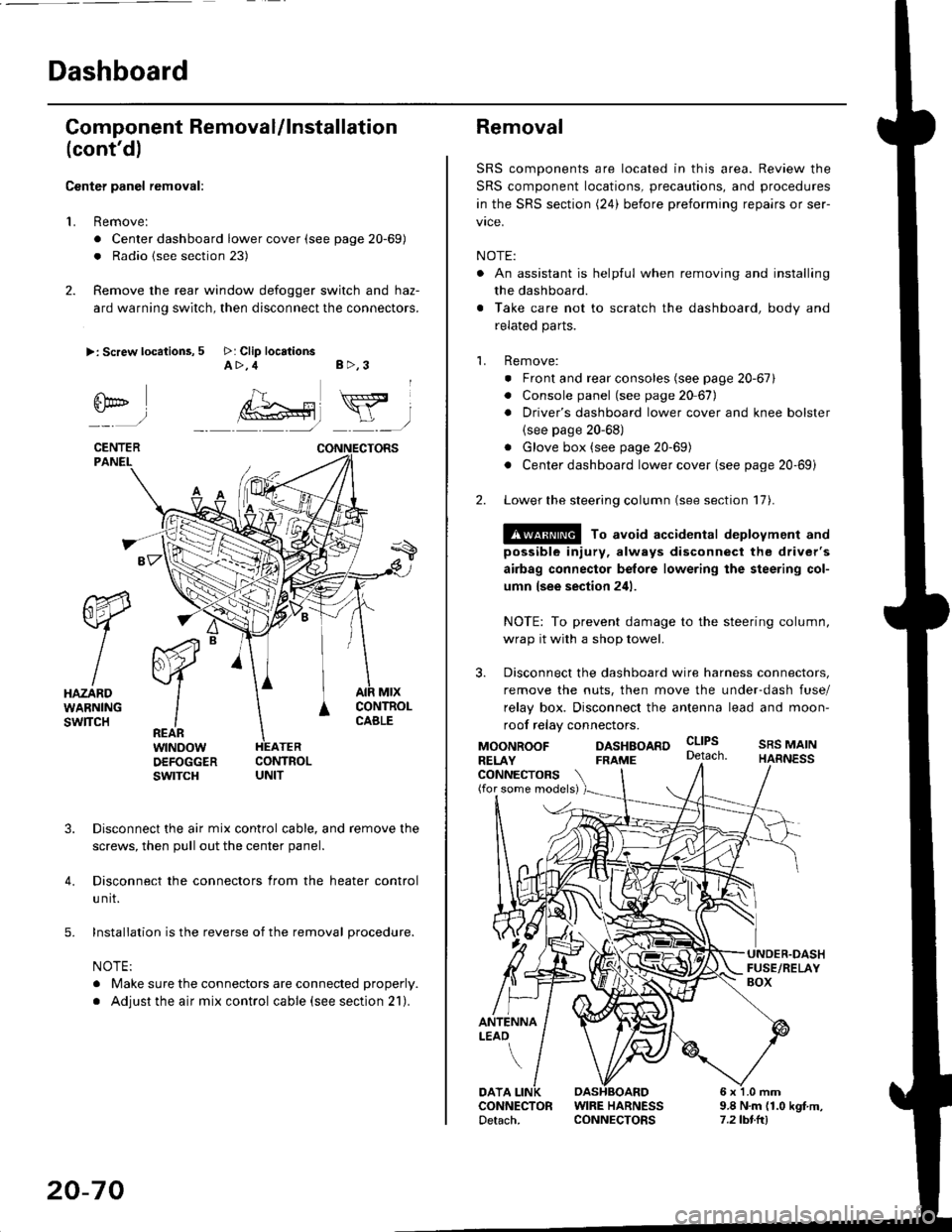

Center panel removal:

1. Remove:

. Center dashboard lower cover (see page 20-69)

. Radio {see section 23)

2. Remove the rear window defogger switch and haz-

ard warning switch, then disconnect the connectors.

>: Screw locations, 5 >: Clip locationsA>,4 B>,3

fii*-)

CENTERPANEI.

rt-xR.

W

IHAZARDWARNINGswlTcH

r44 "

F.IZvl

IIREARwtNoowOEFOGGERswtrcH

MtxCONTNOLCABLE

3. Disconnect the air mix control cable, and remove the

screws, then pull out the center panel.

4. Disconnect the connectors from the heater control

u nit.

5. Installation is the reverse of the removal procedure.

NOTE:

. Make sure the connectors are connected properly.

. Adjust the air mix control cable (see section 21).

20-70

Removal

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section (24) before preforming repairs or ser-

vice.

NOTE:

. An assistant is helpful when removing and installing

the dashboard.

. Take care not to scratch the dashboard, body and

related parts.

1. Remove:

o Front and rear consoles (see page 20-67)

. Console panel (see page 2O 67),

. Driver's dashboard lower cover and knee bolster(see page 20-68)

. Glove box (see page 20-69)

. Center dashboard lower cover (see page 20-69i

2. Lower the steering column (see section 17).

@ To avoid accidental deplovment and

possible injury, always disconnect the driver's

airbag connector belore lowering the steering col-

umn lsee section 241.

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

3. Disconnect the dashboard wire harness connectors,

remove the nuts, then move the under-dash fuse/

relay box. Disconnect the antenna lead and moon-

roof relay connectors.

DASHBOARD cltPs

CONNECTORS(for some models)

MOONROOFRELAY

ANTENNALEAO

FRAME

SRS MAINHARNESS

9.8 N.m (1.0 kgf m,7.2lbt.ltl

DATACONNECTOR WIRE HARNESSDetach. CONNECTORS

Page 1302 of 2189

![HONDA CIVIC 1996 6.G Workshop Manual Dashboard

Removal (contd)

7. lf necessary, remove the dashboard frame from the dashboard.

>: Screw localionsa>,21 B>,4a: Nut locations, 3

>: Clip locations

l^1./\

I Shl: OlbtvY/l\-]1

ra 6 x 1.0 m HONDA CIVIC 1996 6.G Workshop Manual Dashboard

Removal (contd)

7. lf necessary, remove the dashboard frame from the dashboard.

>: Screw localionsa>,21 B>,4a: Nut locations, 3

>: Clip locations

l^1./\

I Shl: OlbtvY/l\-]1

ra 6 x 1.0 m](/img/13/6068/w960_6068-1301.png)

Dashboard

Removal (cont'd)

7. lf necessary, remove the dashboard frame from the dashboard.

>: Screw localionsa>,21 B>,4a: Nut locations, 3

>: Clip locations

l^1./'\

I Shl:' Olb'tvY/l\-]1

ra 6 x '1.0 mm

Yi.!i[11"-"'".

DASHBOARD BRACKETSIDE COVER

Installation is the reverse of the removal orocedure.

NOTE:

. Before tightening the bolts, make sure the dashboard wire harnesses are not pinched.a Make sure the connectors, antenna lead and air mix control cable are connected properly.

FRONT PASSENGER'S

OASHBOARD

20-72

Page 1411 of 2189

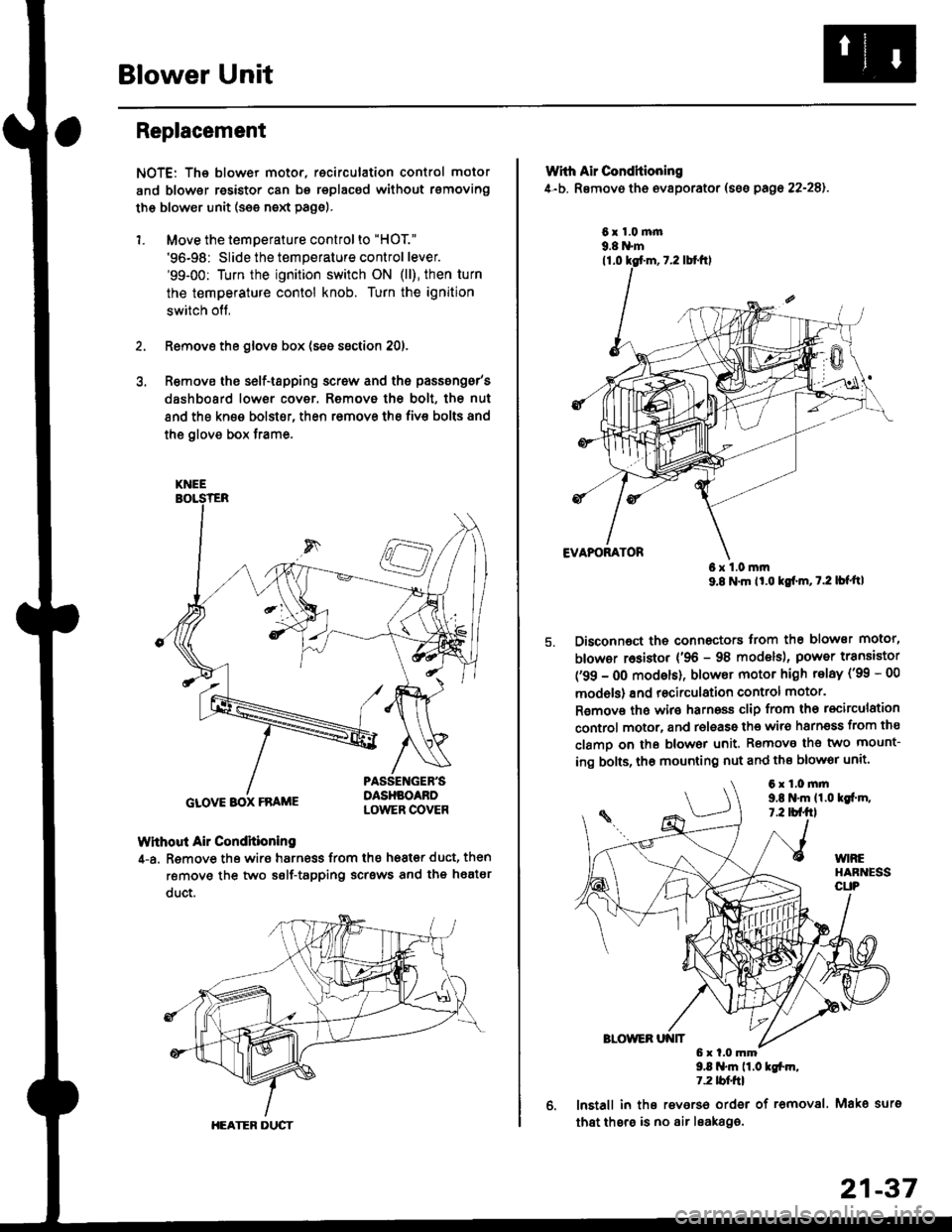

Blower Unit

Replacement

NOTE: The blower motor, recirculation control motor

and blower resistor can bs replacsd without rsmoving

th€ blower unit (see neld Page).

1. Move the temperature control to "HOT."

'96-98: Slide the temperature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off,

Remove the glovs box (ses ssction 20),

R€move ths s6lf-tapping screw and ths passsng6r's

dashboard low€r cover. Removo the bolt, the nut

and the kn€e bolst€r, then remove the fiv€ bolts and

the glove box trame,

Without Air Condhioning

4-a. Remove the wiro harness from the h68t€r duct, then

remove the two self-tapping scrsws and the heatsr

duct.

KNEE

GLOVE BOX FRAME

HEATER DUCT

21-37

Wrth Air Conditioning

4-b. Removo th6 ev8porator (sss pago 22-28).

6x1.0m|n9.8 N'm

6x1.0mm9.8 N'm lt'o tgf'm, t.2 lb{'ttl

Disconnoct the connectors trom th€ blower motor,

blowor r6sistor {'96 - 98 models), power transiator

('99 - 0O modsls), blowor motor high telay ('99 - 00

models) and recirculation control motor.

R€mov€ ths wiro harnoss clip from tho recirculation

control motor, and release the wir6 harnsss from ths

clamo on the blowor unit. Remove the two mount-

ing bolts, tho mounting nut and ths blowor unit'

9.8 .m 11.0 tgfm,1.2 tblfrl

lnstall in ths reverso order of removal. Mako surs

that thsre is no air leaka96.

6x1.0mm9,t N'm 11.0lgi.m,7.2 tbf.fil

Page 1414 of 2189

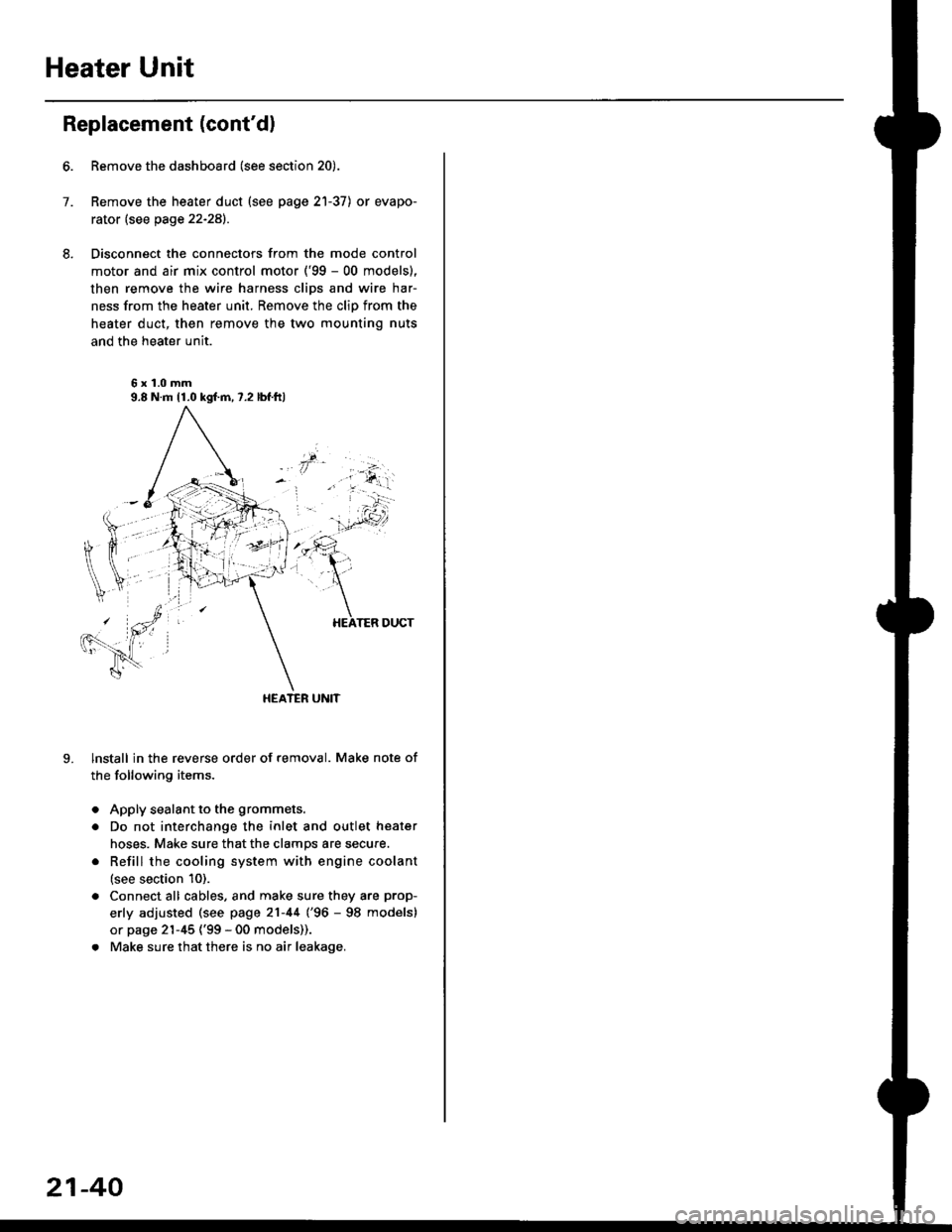

Heater Unit

Replacement (cont'dl

6.

7.

8.

9.

Remove the dashboard (see section 20).

Remove the heater duct (see page 21-37) or evapo-

rator (see page 22-28).

Disconnect the connectors from the mode control

motor and air mix control motor ('99 - 00 models),

then remove the wire harness clips and wire har-

ness from the heater unit. Remove the clip from the

heater duct, then remove the two mounting nuts

and the heater unit.

6x1.0mm9.8 N.m 11.0 kgl.m,7.2 lbf.ftl

HEATER UNIT

lnstall in the reverse order of removal. Make note of

the following items.

Apply sealant to the grommets.

Do not interchange the inlet and outlet heater

hoses. Make sure that the clamps are secure.

Refill the cooling system with engine coolant

(see section 10).

Connect all cables, and make sure they are prop-

erly adjusted (see page 21-44 (96 - 98 models)

or page 21-45 ('99 - 00 models)).

Make sure that there is no air leakage.

21-40

Page 1452 of 2189

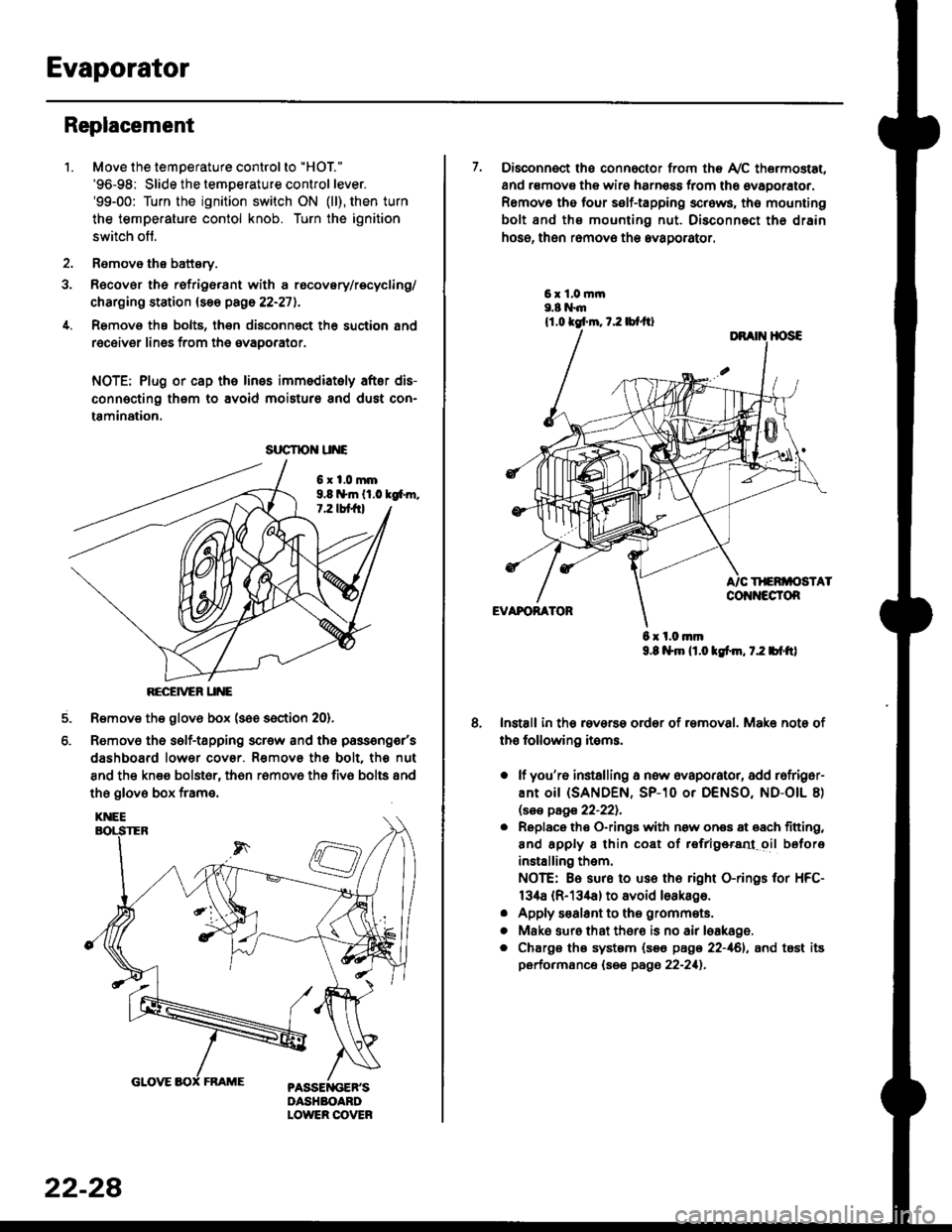

Evaporator

1.

Replacement

4.

Move the temperature control to "HOl"

'96-98: Slide the temoerature control lever.'99-00: Turn the ignition switch ON (ll), then turn

the temperature contol knob. Turn the ignition

switch off.

Remove the battsry.

Rgcover the refrigerant with a rocovery/recycling/

charging station (see page 22-271.

Remove the bolts, then disconnect th6 suction 8nd

receiver lines from th6 evaoorator.

NOTE: Plug or cap the lines imm€diatoly after dis-

connecting them to avoid moisture and dust con-

tamination.

6xl.0mm9.8 n*ln ll.0 tg6m.7.2 lbt frl

RECEiVER UNE

Remove the glov6 box (see section 20).

Removo the self-tapping scr€w and the passeng€r's

dashboard lower cover. Removs the bolt. the nut

8nd the kn€e bolst6r, th6n r6mov6 th6 fiv6 bolts and

the glove box frame.

6.

srrcrrc u E

22-28

7. Disconnect the connector from th€ Ay'C thermostat,

and r€movs the wire harness from the ovaporator.

Remov6 tho four self-tapping screws, tho mounting

bolt and ths mounting nut. Disconnect th€ drain

hose, then remov€ th6 avagorator.

6 x l.0.nm9.8 l$m lt.o ldm, 7.2 bl.tt)

Install in the reverse order of removal. Make note of

th€ following items.

o lf you'r6 installing a new evaporator, add rofriger-

ANt OiI {SANDEN, SP-10 Or DENSO, ND-OIL 8)

lsas page 22-221.

. Replace the O-rings with now ones 8t 68ch titting,

and apply 8 thin coat of r€frlgersd oil before

installing them.

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid loakago.

. Apply s€alant to tha grommets.

. Mske sure that ther€ is no air leakage.

. Chargs ths system {s€€ page 22-161, and tost its

performance (see pags 22-211.

Page 1471 of 2189

l'f .

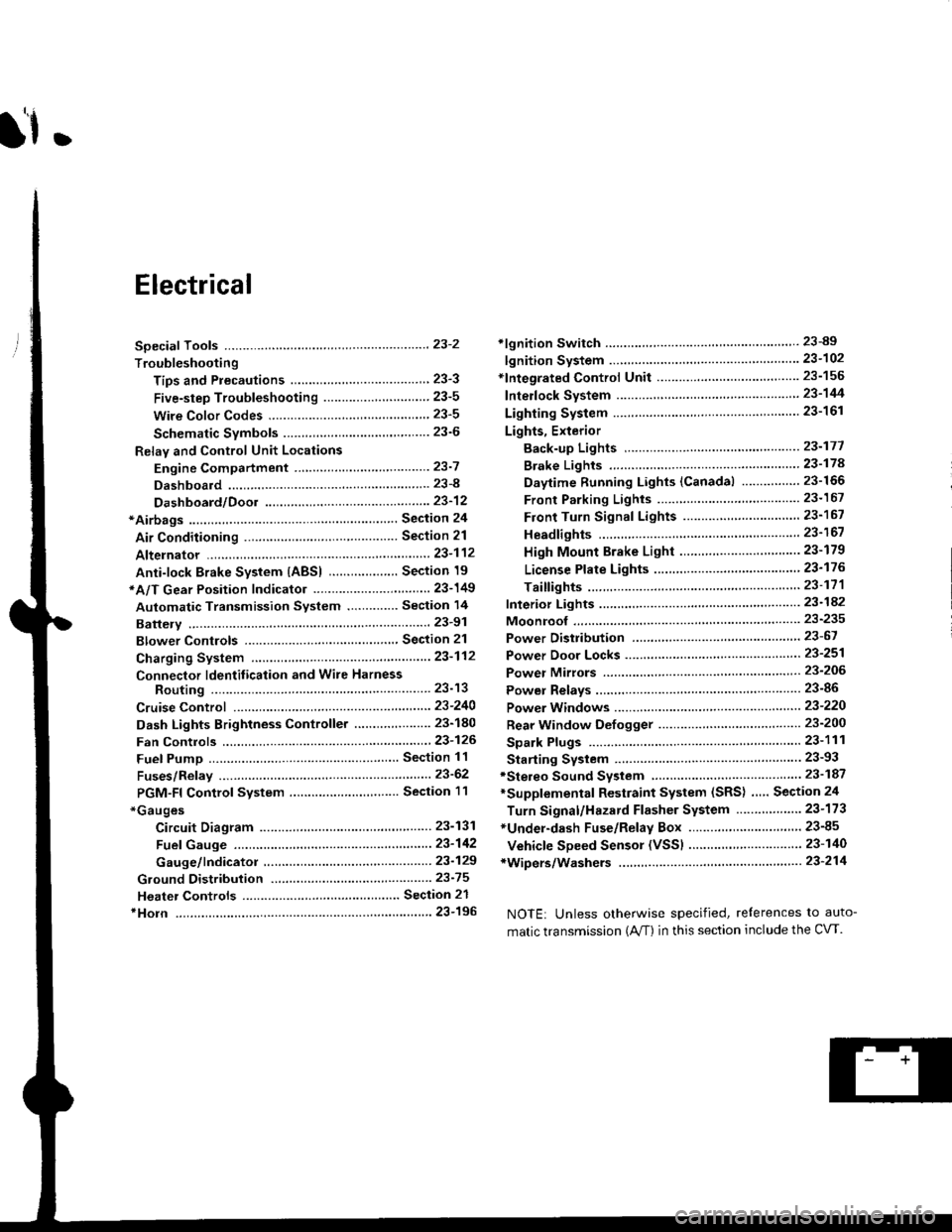

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.