head sequence HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 141 of 2189

Cylinder HeadRocker Arms

18.

19.

21.

22.

Removal (cont'd)

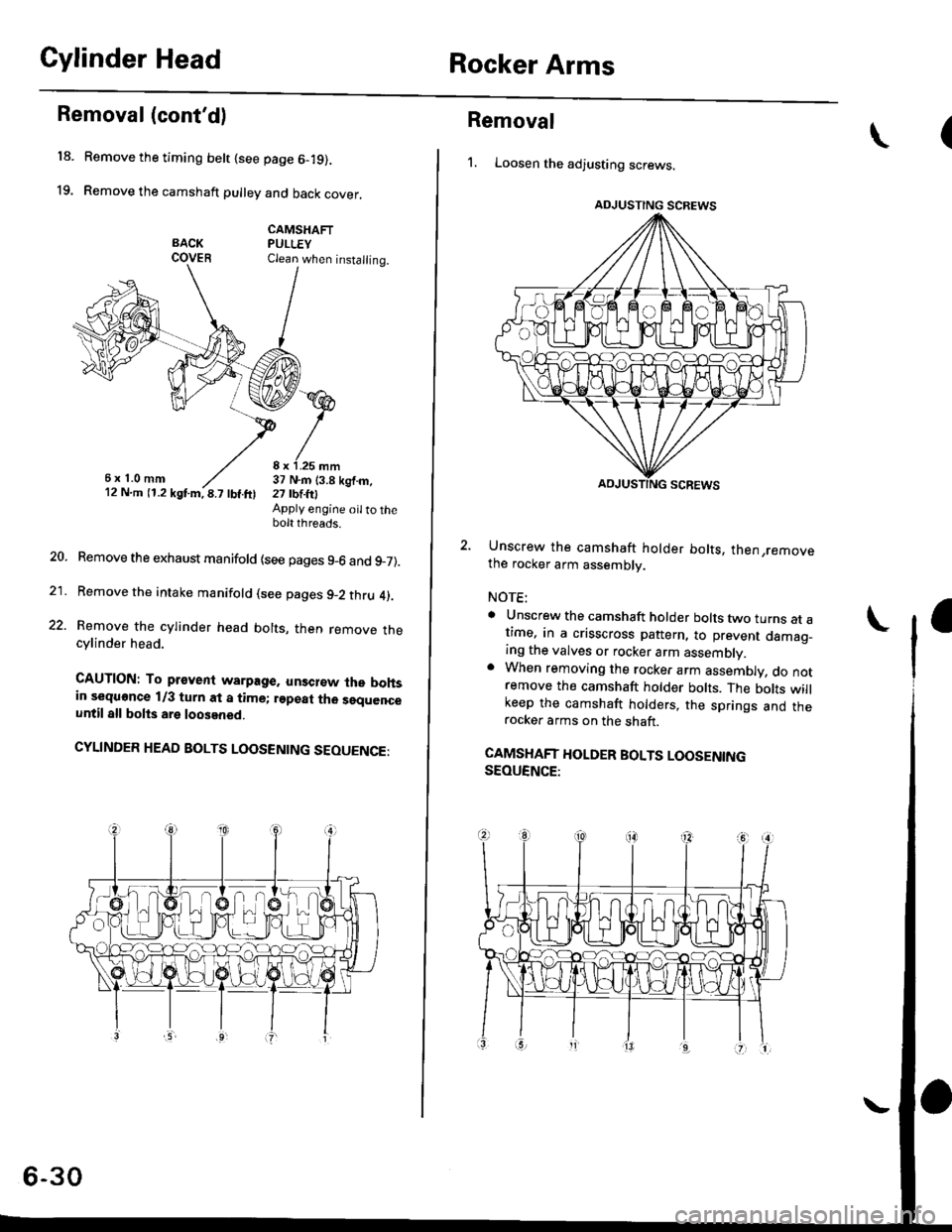

Remove the timing belt {see page 6-19).

Remove the camshaft pulley and back cover,

CAMSHAFTPULLEYClean when installing.

6x1.0mm8 x 1.25 mm37 N.m (3.8 kgf.m,21 tbtlrlApply engine oilto thebolt threads.

Remove the exhaust manifold {see pages 9-6 and 9_7).

Remove the intake manifold (see pages 9-2 thru 4).

Remove the cylinder head bolts, then remove thecylinder head.

CAUTION: To pr€vent warpage, unsclew lhe bohsin sequonce 1/3 turn at a time; rgpeat tho sequenceuntil all bolts are loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENGE:

6-30

Removal

1. Loosen the adjusting screws.

2. Unscrew the camshaft holder bolts, then,removethe rocker arm assembly.

NOTE:

a Unscrew the camshaft holder bolts two turns at at,me, in a crisscross pattern, to prevent damao_ing the valves or rocker arm assembly.. When removing the rocker arm assembly, do notremove the camshaft holder bolts. The bolts willkeep the camshaft holders, the springs and therocker arms on the shaft.

CAMSHAFT HOLDER BOLTS LOOSENINGSEOUENCE:

\(

ADJUSTING SCREWS

Page 156 of 2189

Cylinder Head

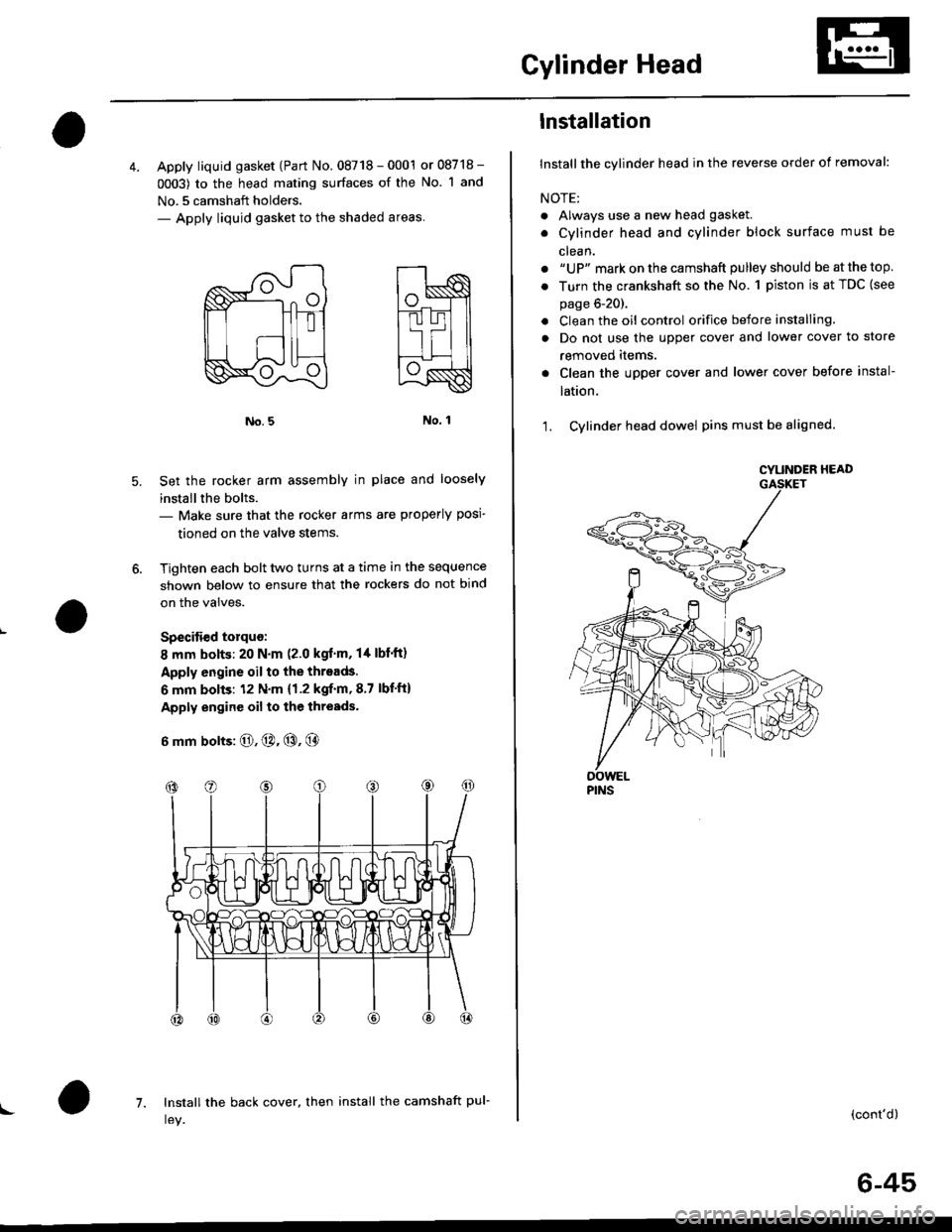

4. Apply liquid gasket (Part No. 08718 - 0001 or 08718 -

0003) to the head mating surfaces of the No. 1 and

No.5 camshaft holders.- Apply liquid gasket to the shaded areas

Set the rocker arm assemblY in place and loosely

installthe bolts.- Make sure that the rocker arms are properly posi-

tioned on the valve stems.

Tighten each bolt two turns at a time in the sequence

shown below to ensure that the rockers do not bind

on the valves.

Specitied torquo:

8 mm bolts: 20 N.m (2.0 kgt'm, l/t lbf'ft)

Apply engine oil to the threads.

6 mm bolts: 12 N.m {1.2 kgif'm, 8.7 lbf'ft)

Apply engine oil to the thresds.

6 mm bolts: O, @. @, @

7. Install the back cover. then install the camshaft pul-!

6-45

lnstallation

lnstallthe cylinder head in the reverse order of removal:

NOTE:

. Always use a new head gasket.

. Cylinder head and cylinder block surface must be

clean.

. "UP" mark on the camshaft pulley should be at the top

. Turn the crankshaft so the No. 1 piston is at TDC (see

page 6-20).

. Clean the oil control orifice before installing.

a Do not use the upper cover and lower cover to store

removeo rlems.

Clean the upper cover and lower cover before instal-

taUon.

Cylinder head dowel pins must be aligned.1.

CYUNOER HEAD

PINS

(cont'd)

Page 158 of 2189

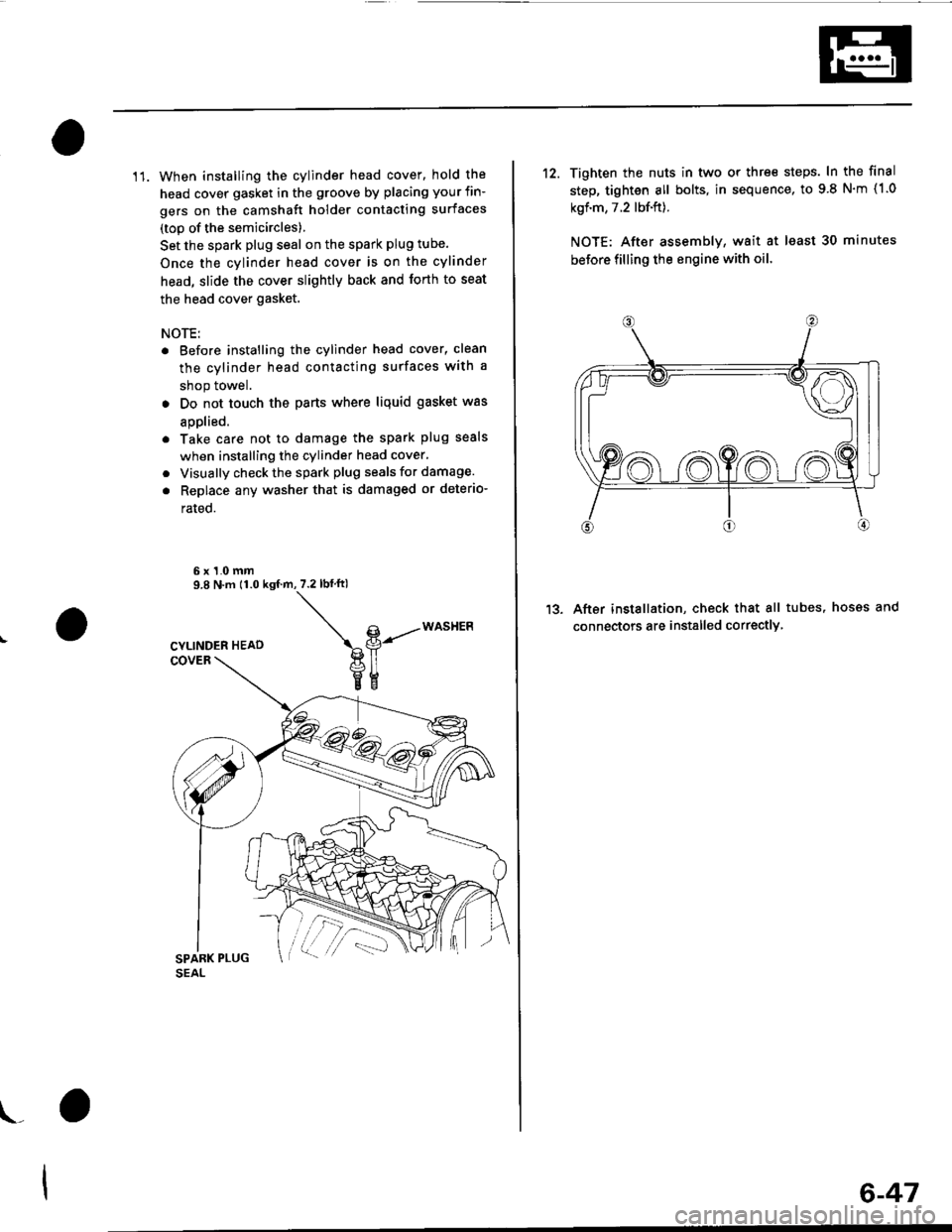

11. When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft holder contacting surfaces

(top of the semicircles)

Set the spark plug seal on the spark plug tube.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

. Before installing the cylinder head cover, clean

the cylinder head contacting surfaces with a

shop towel.

. Do not touch the parts where liquid gasket was

aDolied.

. Take care not to damage the spark plug seals

when installing the cylinder head cover,

. Visually check the spark plug seals for damage.

. Replace any washer that is damaged or deterio-

rated.

6x1.0mm9.8 N.m 11.0 ksf.m,7.2lbf ftl

\g-----*o""t'Ptl

veEE

\_

6-47

12. Tighten the nuts in two or thre€ steps. In the final

step, tighten all bolts, in sequence, to 9 8 N'm (1.0

kgf.m, 7.2 lbf.ft).

NOTE: After assemblv, wait at least 30 minutes

before filling the engine with oil

After installation, check that all tubes, hosss and

connectors are installed correctlY

1?

Page 180 of 2189

Cylinder Head

19.

20.

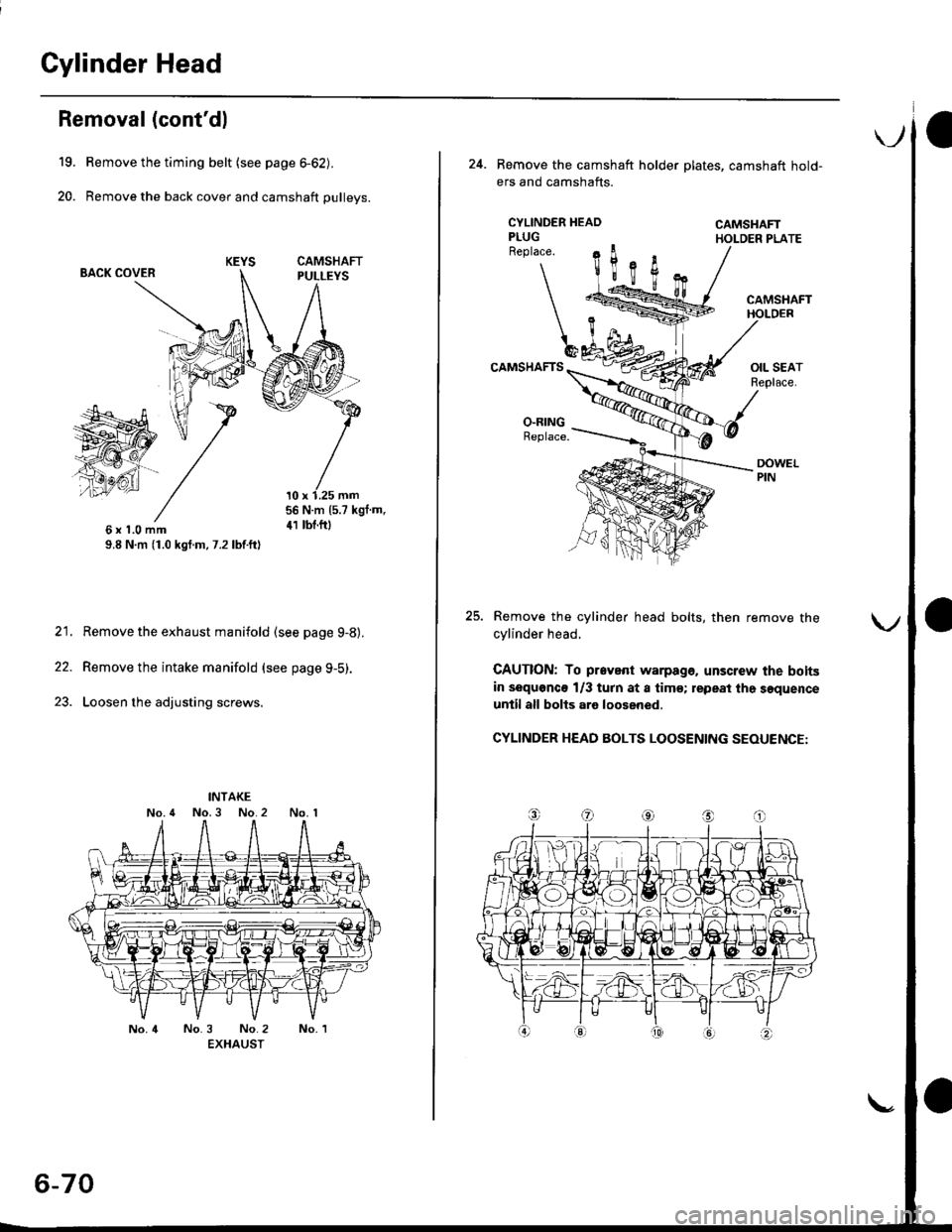

Removal (cont'dl

Remove the timing belt {see page 6-62).

Remove the back cover and camshaft pulleys.

BACK COVER

56 N.m (5.7 kgf m,

41 tbt.f06xl.0mm9.8 N,m (1.0 kgf.m, 7.2 lbf.ft)

21, Remove the exhaust manifold (see page 9-8).

22. Remove the intake manifold (see page g-5).

23. Loosen the adjusting screws.

INTAKE

No.4 No.3 No.2 No. 1

6-70

24. Remove the camshaft holder plates, camshaft hold-ers and camshafts.

CAMSHAFTHOLDER PLATE

Remove the cylinder head bolts, then remove the

cylinder head.

CAUTION: To prevsnt warpage. unscrew the bolts

in sequonc€ 1/3 turn at a tim€; lepeat lh6 sequence

until all bolts aro loosened.

CYLINDER HEAD BOLTS LOOSENING SEOUENCE:

CYLINDER HEADPLUGReplace. t

\1

\€\i

b4CAMSIIAFTS -

Page 194 of 2189

I

Cylinder Head

Installation

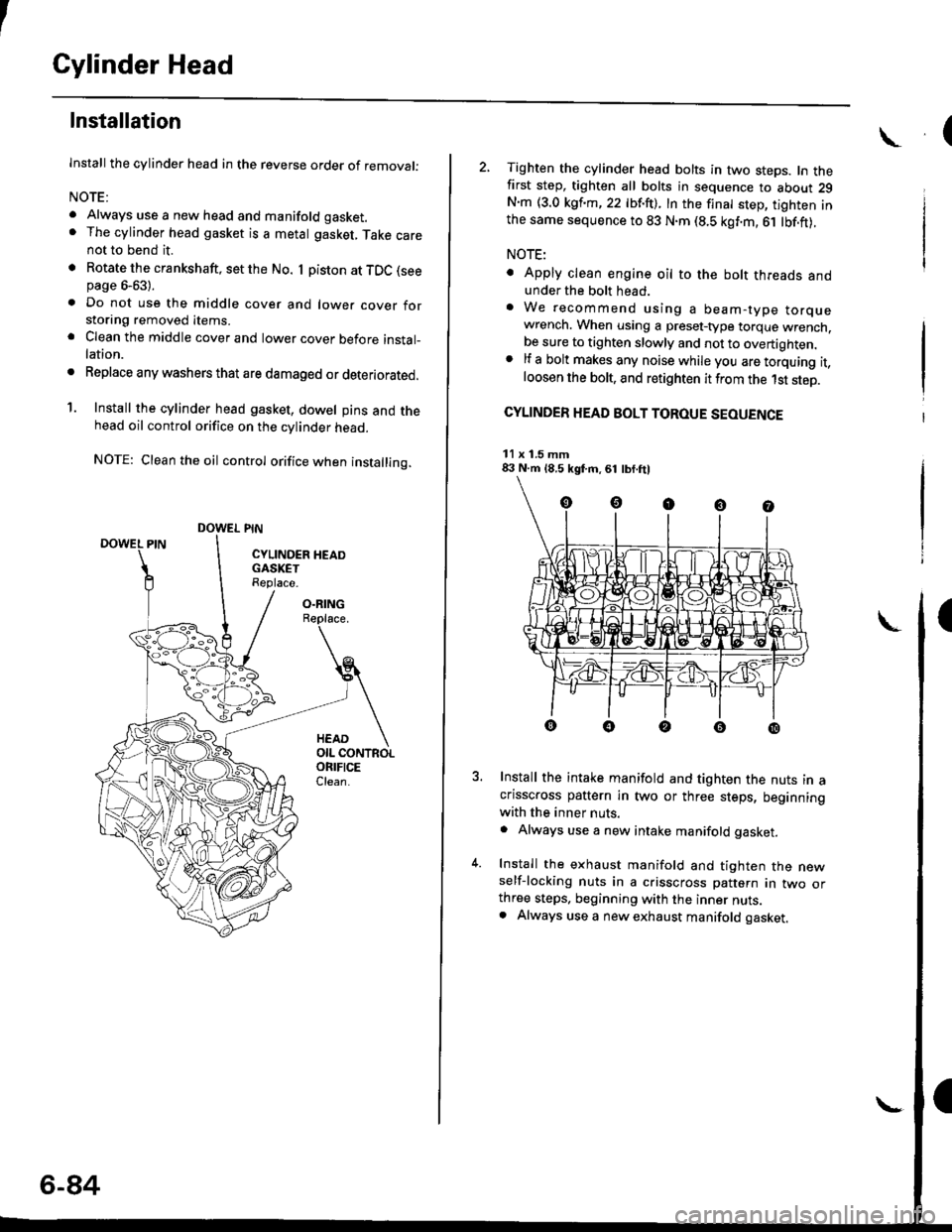

lnstall the cylinder head in the reverse order of removal:

NOTE:

. Always use a new head and manifold gasket.. The cylinder head gasket is a metal gasket, Take carenot to bend it.

. Rotate the crankshaft, set the No. 1 piston at TDC (seepage 6-63).

. Do not use the middle cover and lower cover forstorang removed items.. Clean the middle cover and lower cover before instal_lation.

o Replace any washers that are damaged or deteriorated.

1. Install the cylinder head gasket, dowel pins and thehead oil control orifice on the cylinder head.

NOTE: Clean the oil control orifice when installing.

DOWEL PIN

6-84

2, Tighten the cylinder head bolts in two steps. In thefirst step, tighten all bolts in sequence to about 29N.m (3.0 kgf.m, 22 tbf.ftl. ln the final step, tighten inthe same sequence to 83 N.m (8.S kgf.m,6t lbf.ft).

NOTE:

. Apply clean engine oil to the bolt threads andunder the bolt head.. We recommend using a beam-type torquewrench. When using a preset-type torque wrench,be sure to tighten slowly and not to overtighten.. lf a bolt makes any noise while you are torquing it,loosen the bolt, and retighten it from the 1st step.

CYLINDER HEAD BOLT TOROUE SEOUENCE

11x 1.5 mm83 N.m 18.5 kgf.m, 61 tbf.ftl

Install the intake manifold and tighten the nuts in acflsscross pattern in two or three steps, beginningwith the inner nuts.. Always use a new intake manifold gasket.

Install the exhaust manifold and tighten the newself-locking nuts in a crisscross pattern in two orthree steps. beginning with the inner nuts.. Always use a new exhaust manifold gasket.

4.

Page 195 of 2189

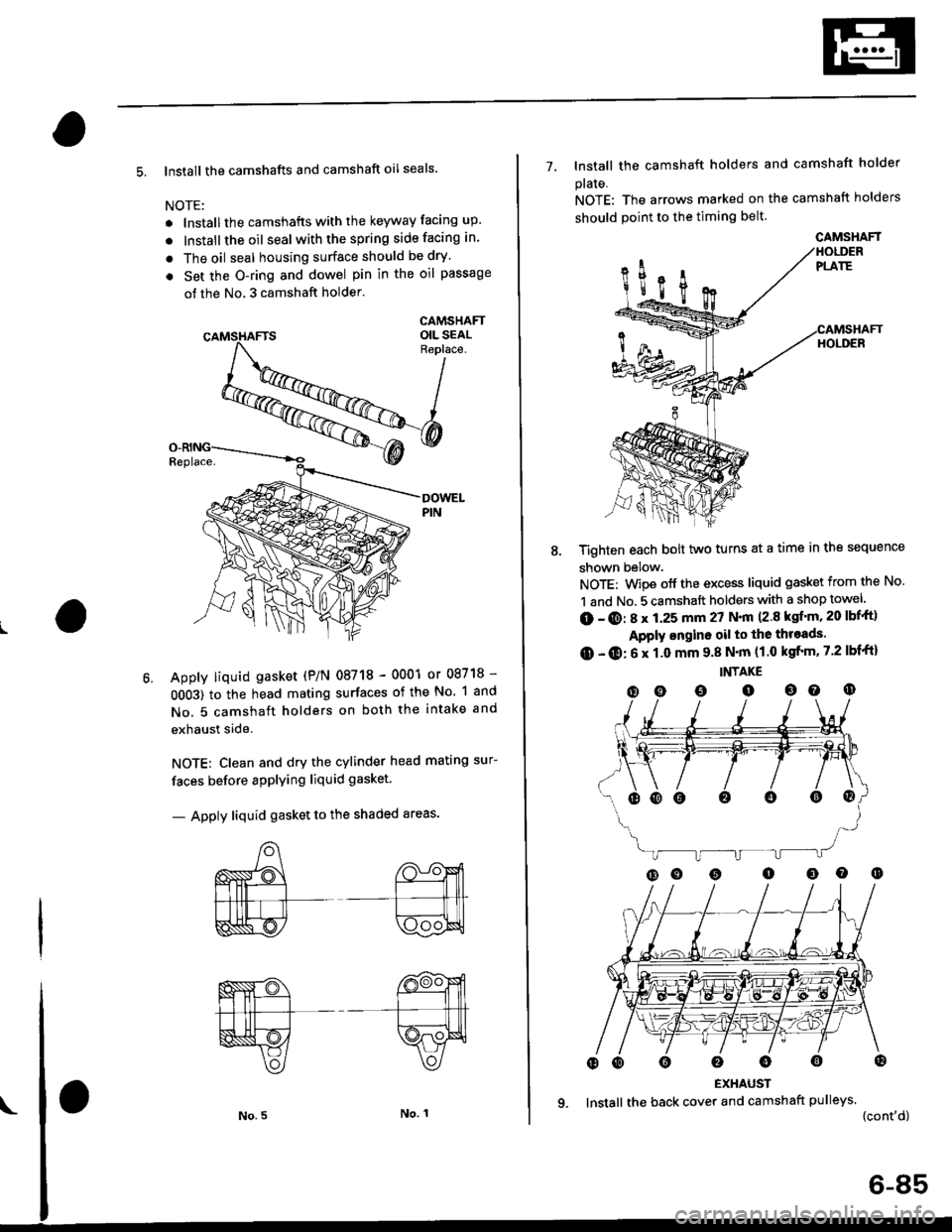

5. lnstall the camshafts and camshaft oil seals.

NOTE:

. lnstallthe camshafts with the keyway facing up.

. lnstall the oil seal withthespring side facing in.

. The oil seal housing surface should be dry'

. Set the O-ring and dowel pin in the oil passage

of the No, 3 camshaft holder'

CAMSHAFTOIL SEALReplace.

Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0OO3) to the head mating surfaces of the No. 1 and

No. 5 camshaft holders on both the intake and

exhaust side.

NOTE: Clean and dry the cylinder head mating sur-

faces before applying liquid gasket.

- Apply liquid gasket to the shaded areas'

7- lnstall the camshaft holders and camshaft holder

plaIe.

NOTE: The arrows marked on the camshaft holders

should point to the timing belt.

Tighten each bolt two turns at a time in the sequence

shown below.

NOTE: Wipe off the excess liquid gasket from the No.

1 and No. 5 camshaft holders with a shop towel

(D - @: 8 x 1.25 mm 27 N.|n (2.8 ksf'm, 20 lbf'ft)

Apply ongine oil to the throads.

O - O: 6 x 1.0 mm 9.8 N'm (1.0 kgfrm, 7.2 lbf'ft)

INTAKE

(D o o o oo o

EXHAUST

lnstall the back cover and camshaft pulleys.

{cont'd)

oooo0o@

CAMSHAFT

6-85

Page 197 of 2189

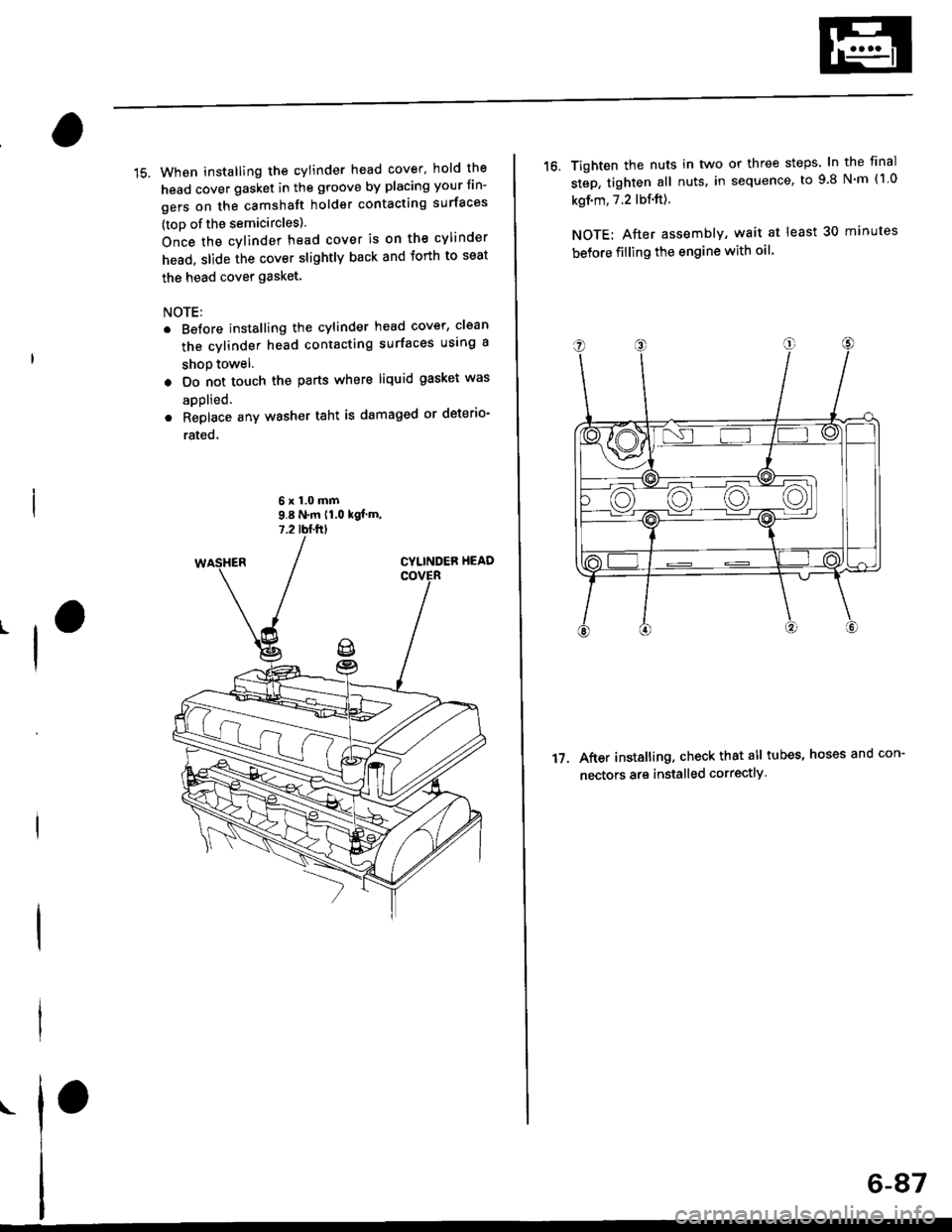

15. When installing the cylinder head cover, hold the

head cover gasket in the groove by placing your fin-

gers on the camshaft holder contacting surfaces

(toD of the semicircles).

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

NOTE:

. Be{ore installing the cylinder head cover, clean

the cvlinder head contacting surfaces using a

shoP towel.

. Oo not touch the parts where liquid gasket was

applied.

. Replace any washer taht is damaged or deter'o-

rated.

t

\

6-A7

16. Tighten the nuts in two or three steps. In the final

step, tighten all nuts, in sequence, to 9 8 N'm {1 0

kgf.m, 7.2 lbf.ft).

NOTE: After assembly, wait at least 30 minutes

before filling the engine with oil.

After installing, check that all tubes' hoses and con-

nectors are installed correctly.17.

Page 857 of 2189

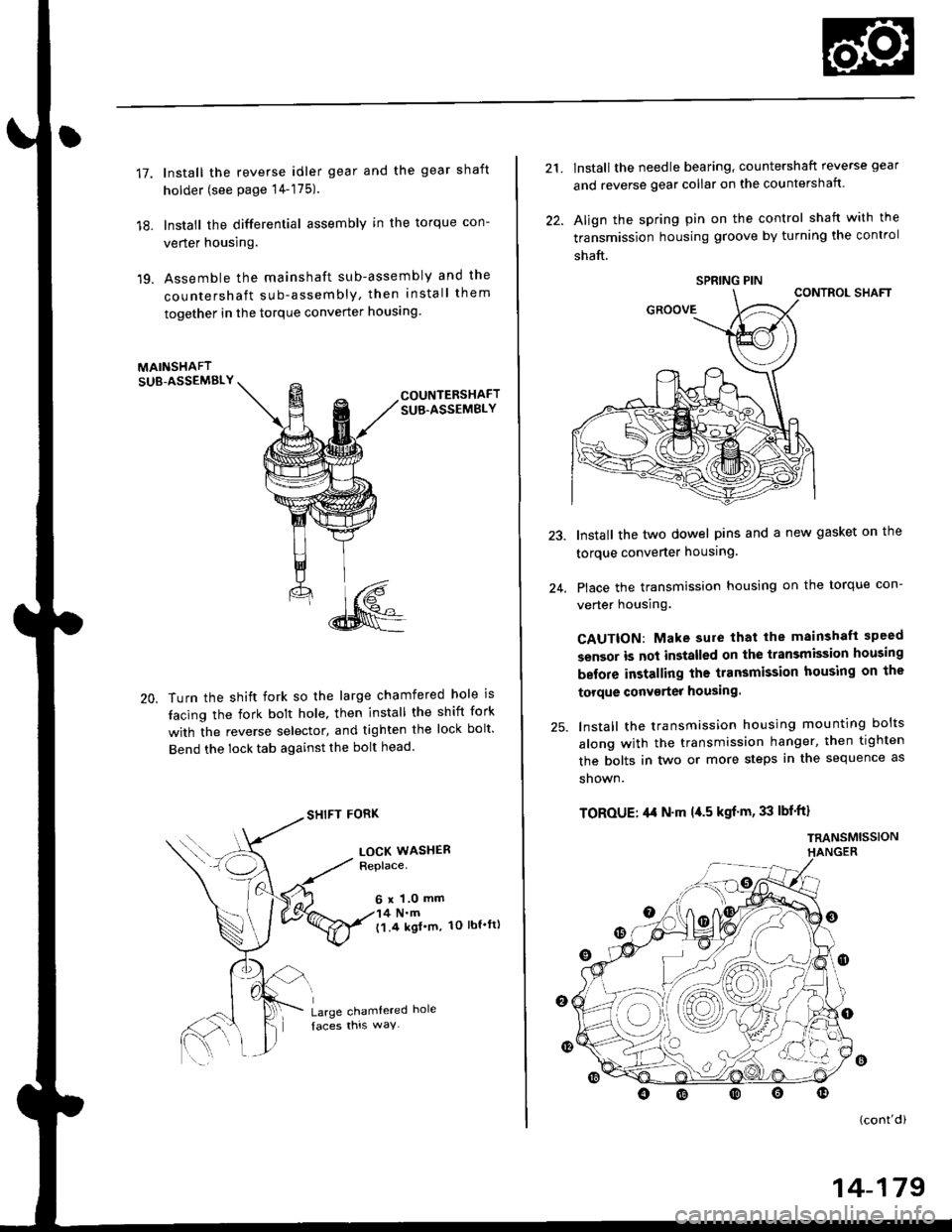

17.

18.

19.

lnstall the reverse idler gear and the gear shaft

holder (see page 14-175).

lnstall the differential assembly in the torque con-

verter housing.

Assemble the mainshaft sub-assembly and the

countershaft sub-assembly, then install them

together in the torque converter houslng

MAINSHAFTSUB-ASSEMBLY

20,

COUNTERSHAFTSUB.ASSEMBLY

Turn the shift fork so the large chamfered hole is

tacing the fork bolt hole, then install the shift fork

with the reverse selector, and tighten the lock bolt'

Bend the lock tab against the bolt head

SHIFT FORK

LOCK WASHERReplace.

6 x 1.0 mm4 N.m('l.4 kgl'm, 1O lbt'ft)

Large chamtered hole

21.

22.

lnstall the needle bearing, countershaft reverse gear

and reverse gear collar on the countershaft.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

CONTROL SHAFT

Install the two dowel pins and a new gasket on the

torque converter housing.

Place the transmission housing on the torque con-

verter housing.

CAUTION: Make sure that lhe mainshaft speed

sensor is not installed on the transmission housing

before installing the transmission housing on the

torque conv€rter housing.

lnstall the transmission housing mounting bolts

along with the transmission hanger, then tighten

the bolts in two or more steps in the sequence as

shown.

TOROUE: ,l,t N'm l{.5 kgf'm, 33 lbf'ft}

TRANSMISSIONHANGER

24.

o

(cont'di

SPRING PIN

14-179

Page 1819 of 2189

How To Use This Manual

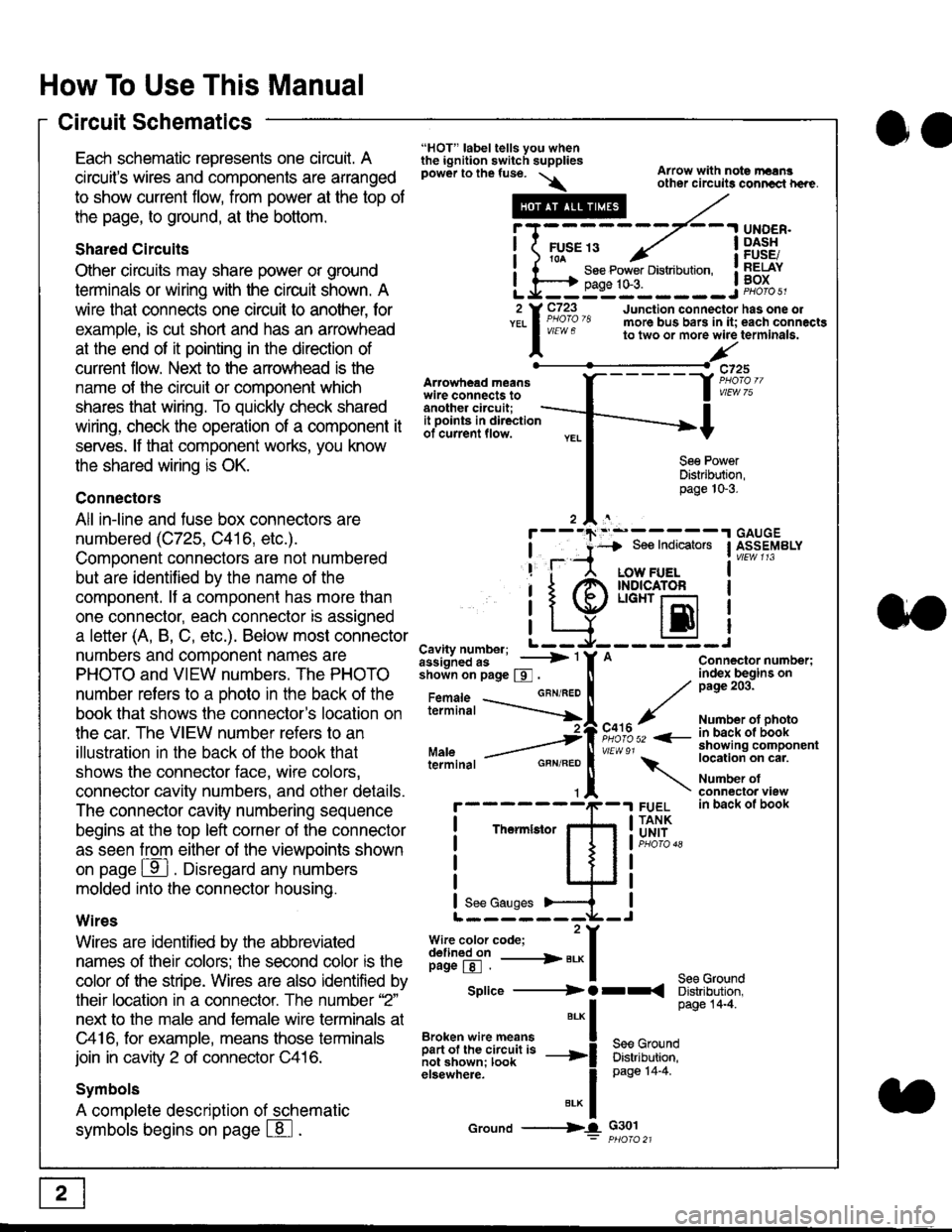

Circuit Schematics

oa

Each schematic represents one circult. A

circuit's wires and components are arranged

to show current flow, from power at the top of

the page, to ground, at the bottom.

Shared Circuits

Other circuits may share power or ground

terminals or wiring with the circuit shown. A

wire that connects one circuit to another, for

example, is cut short and has an arrowhead

at the end of it pointing in the direction of

current flow. Nelit to the anowhead is the

name o{ the circuil or comoonent which

shares that wiring. To quickly check shared

wiring, check the operation of a component it

serves. lf that component works, you know

the shared wiring is OK.

Connectors

All in-line and fuse box connectors are

numbered (C725, C416, etc.).

Component connectors are not numbered

but are identiJied by the name of the

component. lf a componenl has more than

one connector, each connector is assigned

a letter (A, B, C, etc.). Below most connector

numbers and comDonent names are

PHOTO and VIEW numbers. The PHOTO

number refers to a Dhoto in the back of the

book that shows lhe conneclor's location on

the car. The VIEW number refers to an

illustration in the back of the book that

shows the connector face, wire colors,

connector cavity numbers, and other details.

The connector cavity numbering sequence

begins at the top left corner oJ the connector

as seen from either of the viewooints shown

on page ffl . Disregard any numbers

molded into the connector housino.

Wires

Wires are identilied by the abbreviated

names of their colors; the second color rs the

color of the stripe. Wires are also identified by

their location in a connector. The number '2"

next to the male and female wire terminals at

C416, for example, means those terminals

join in cavity 2 of connector C416.

Symbols

A complete description of schematic

symbols begins on page | 8

"HOT" label tells you whenthe ignition switch suppliespower to the fuse. \

Artowhead meanswire connects toanother circuit;

Arrow with note rErngother circuils conncct h€re.

it .a

llu":: ^,{ ii t See Power Distribution, .I t----t oaqe tO-3. IL*--:--------J2 Y C723 Junction connectorYEL I Pao'o'8 more bus bars in it;

I - " " to two or more wire

l,/

-t>?

See PowerDistribution,page 10-3.

UNDER.DASHFUSE/RELAYBOX

has one oleach connactgterminala.

it ooints in directionof current flow.

TheImletor

t_I

Cavity number; L ---

Jiili'iJi!--' -----> '

shoin on page S .

Maleterminal

L?*?l?,-

"'"'I

c725

vlEUt/ 75

Connector number;index begins onpage 203.

Number ot photoin back ol bookshowing componentlocation on cat.

Number ofconneclor viewin back of book

7

GBN/FEO

See Ground

Soe Indicators I ASSEMBLY

:-------J

LOW FUELINDICATOFLIGHT r-l

EI

A

"o'r"/PHOTO 52 <-

\

FUELTANKUNIT

Splice ---------) O rr

".* I Page 14'4'

IBroken wire means | --^ -

iar";J.'It,;,rJ;ii; -----i Bffi,Bili*l

elsewhere. I 0a0e tn-a

IBrK Icround --->lL c301: ptioro 21