oil leak HONDA CIVIC 1996 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1996, Model line: CIVIC, Model: HONDA CIVIC 1996 6.GPages: 2189, PDF Size: 69.39 MB

Page 110 of 2189

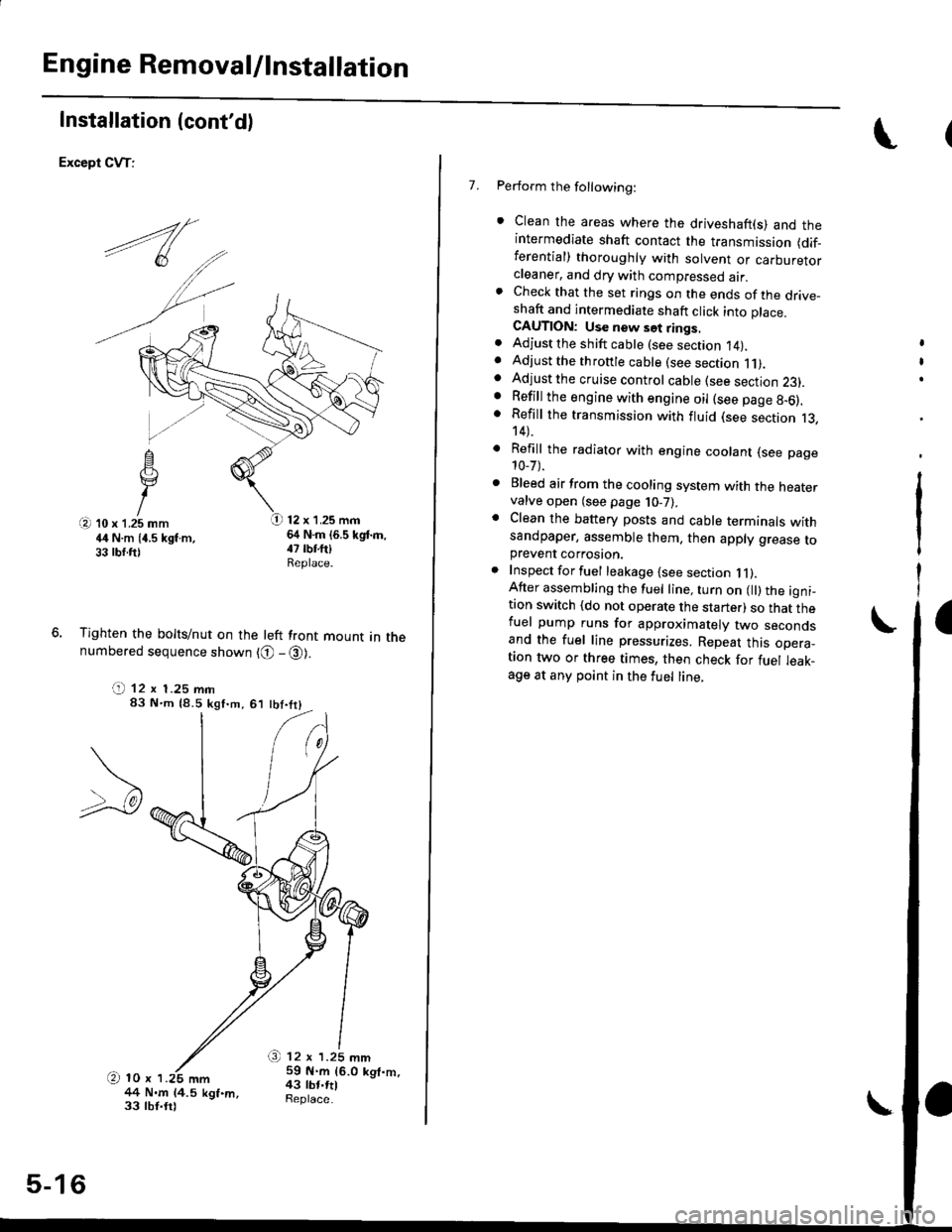

Engine Removal/lnstallation

Installation (cont'd)

Except CVT:

12 x 1.25 mm64 N.m (6.5 kgd.m,

Tighten the bolts/nut on the left front mount in thenumbered sequence shown {O - @).

(t 12 x 1.25 mm83 N'm (8.5 kgf.m,61 tbt.trl

/+4 N.m 14.5 kgf.m,33 lbt.trl

O 12 r 1.25 mm59 N.m 16.0 kgt.m,43 tbt.rtlSeplace.

5-16

\

7. Perform the following:

. Clean the areas where the driveshaft(s) and theintermediate shaft contact the transmission (dif_ferential) thoroughly with solvent or carburetorcteaner, and dry with compressed air.. Check that the set rings on the ends of the drive_shaft and intermediate shaft click into place.CAUTION: Use new set rings,. Adjust the shift cable (see section 14).. Adjust the throttle cable (see section 11).. Adjust the cruise control cable (see section 23).. Refill the engine with engine oil (see page 8-6).. Refill the transmission with fluid (see section 13,14).

. Refill the radiator with engine coolant (see page10-7).

. Bleed air from the cooling system with the heatervalve open (see page j0-7).

. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toprevent corrosaon.. Inspect for fuel leakage (see section j l).After assembling the fuel line, turn on l) the igni_tion switch (do not operate the starter) so that thefuel pump runs for approximately two secondsand the fuel line pressurizes. Repeat this opera_taon two or three times, then check for fuel leak_age at any point in the fuel line,

Page 128 of 2189

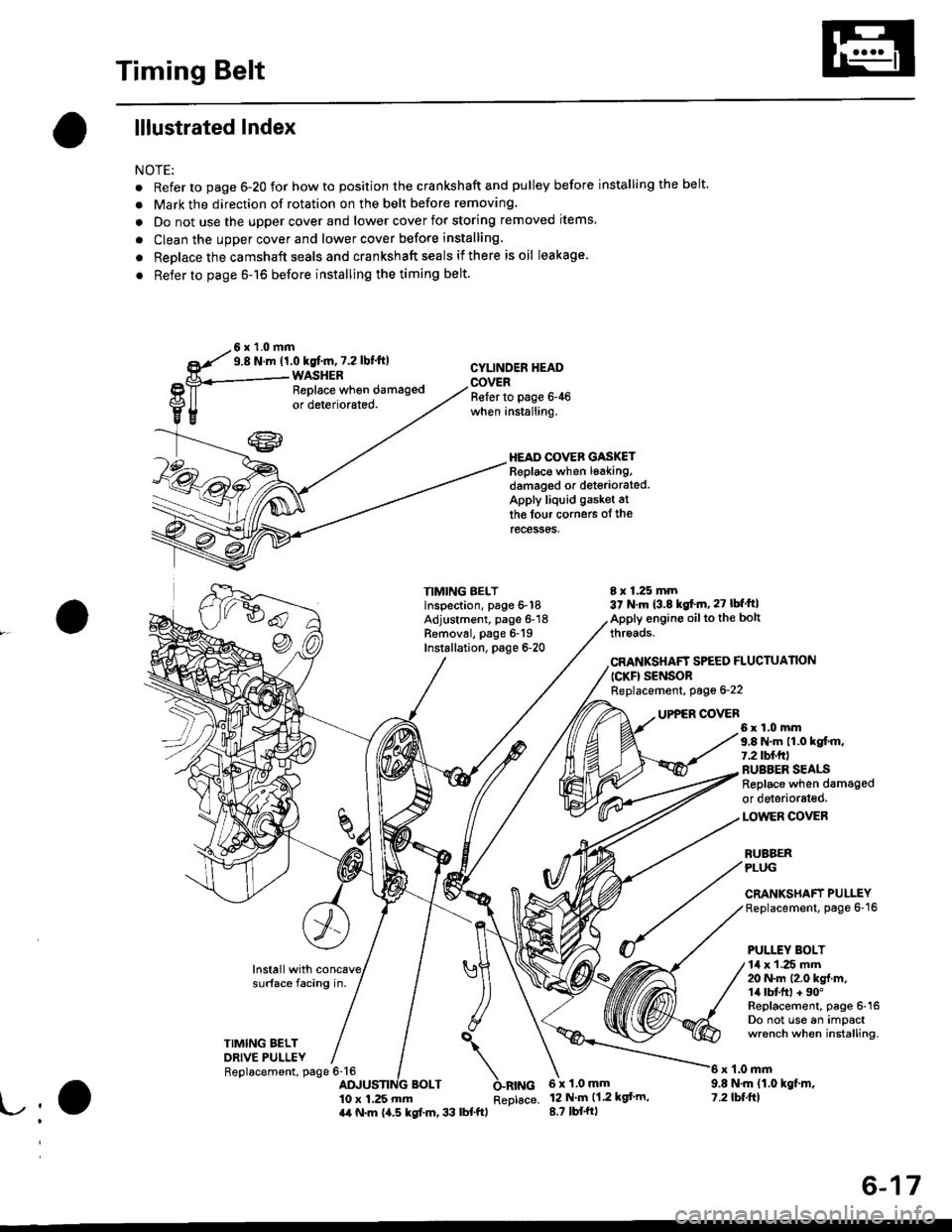

Timing Belt

Illustrated lndex

NOTE:

. Refer to page 6-20 for how to position the crankshaft and pulley before installing the belt.

. Mark the direction of rotation on the belt before removing.

a Do not use the upper cover and lower cover for storing removed items,

. Clean the upper cover and lower cover before installing.

. Replace the ca mshaft seals and cra n kshaft sea ls if there is oil leakage.

. Refer to page 6-16 before installing the timing belt.

CYLINDER HEADCOVERReler to page 6-46when installing.

HEAD COVEB GASKETReplaco when l6akin9,domaged or deteriorated.Apply liquid gasket at

th€ lour corners of thetecessos.

d

@

TIMING BELTInspection, page 6-18Adjustment, page 6-18Removal, page 6-19Installation. page 6-20

I x 1.25 mm3t N.m {3.8 kgf'm, 27 lbfftl

Apply engine oilto the bolt

thleads.

CRANKSHAFT SPEED FI.UCTUATION

lcr(Fl sENsoRReplacement, Page 6-22

UPPER COVEB

lnstallwithsurface facing in.

TIMING BELTDRIVE PULLEYReplacement, page 6_16

6x1.0mm9.8 N'm 11.0 kgt m,7.2 tbf.ft)NUBBER SEALSReplace when damagedor deledorated.

LOWER COVER

FUBBERPLUG

CRANKSHAFT PULLEYReplacement, page 6'16

PULLEY BOLTlil x 1.25 mm20 N.m 12.0 kgt.m,14 lbt'ft) + 90"Replacement, page 6'16Do not us6 an impactwrench when installing.

x 1.0 mmBOLT o-RING10 x 1,25 mm Reolace.14 N.m {,1.5 kgt m, 33 lbt ftl

6x1.0mmt2 N.m 11.2 kgf'm,8.7 tbt f0

9.E N'm (1.0 kgt.m,?.2 tbf.ftl\.-,o

6-17

Page 134 of 2189

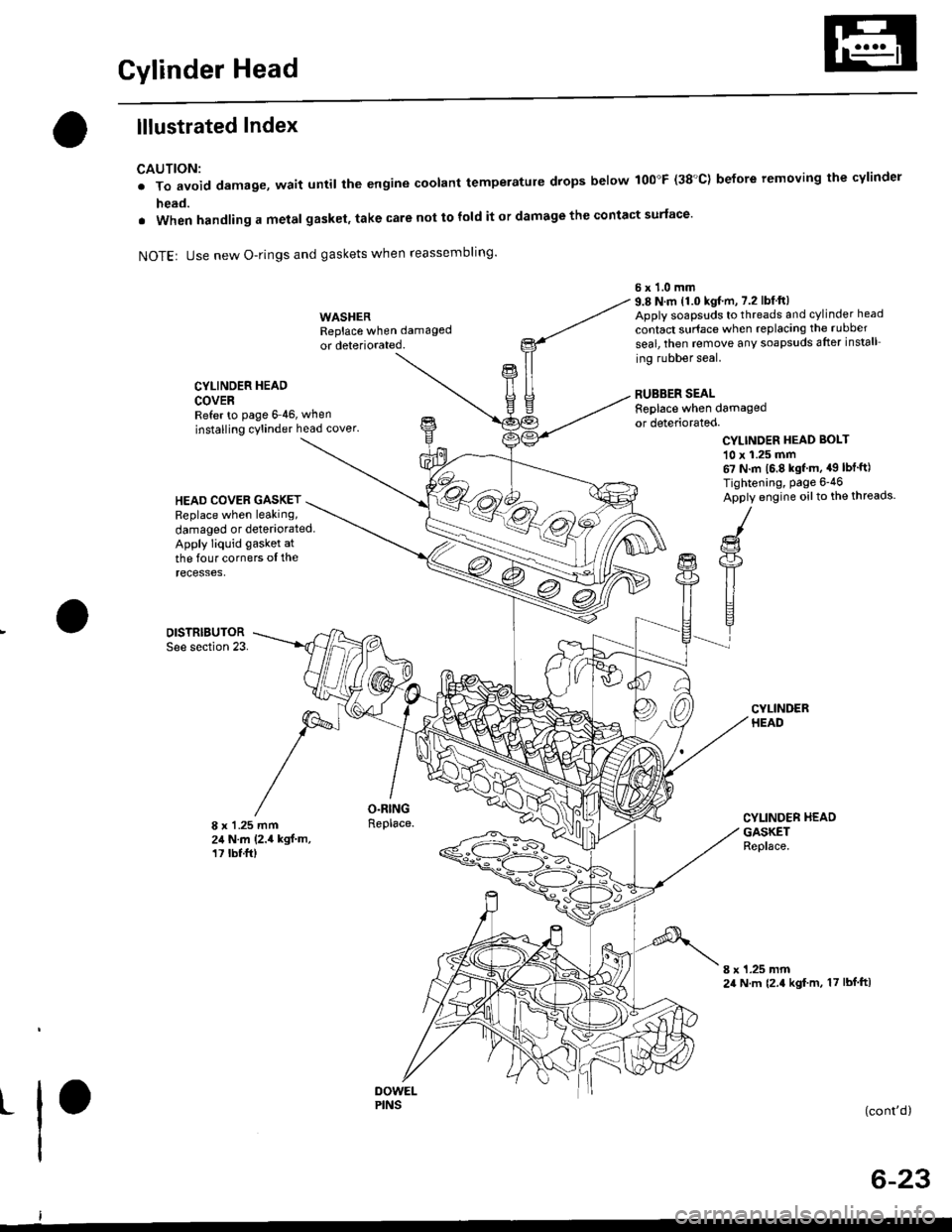

Gylinder Head

lllustrated Index

CAUTION:

. To avoid damage, wait until the engine coolant temperatule drops below 100"F (38'C) before removing the cylinder

head.

. When handling a metal gasket, take care not to fold it or damage the contact surface'

NOTEr Use new O-rings and gaskets when reassembling'

CYLINDER HEAD

COVERRefer to page 6 46, when

installing cylinder head cover.

WASHERReplace when damaged

or deteriorated.

O.RINGReplace.

6x1.0mm9.8 N.m 11.0 kgf.m, 7.2 lbfft)Apply soapsuds to threads and cylinder head

contact surface when replacing the rubber

seal, then temove any soapsuds after install

ing rubber seal.

RUBBER SEALReplace when damagedor deteriorated.

CYLINDER HEAD BOI-T

10 x 1.25 mm67 N.m 16.8 kgf m, a9 lbt'ft)

Tightening, Page 6-46

Apply engine oilto the threads.HEAD COVEB GASKETReplace when leaking,

damaged or deteriorated.Apply liquid gasket at

the four corners ol therecesses,

DISTRIBUTORSee section 23.

8 x 1 .25 mm24 N.m (2.4 kgf.m,17 tbt.ft)

CYLINDER HEADGASKETReplace.

8 x 1.25 mm24 N.m {2.4 kgf m, 17 lbf ftl

t(cont'd)

6-23

PINS

Page 170 of 2189

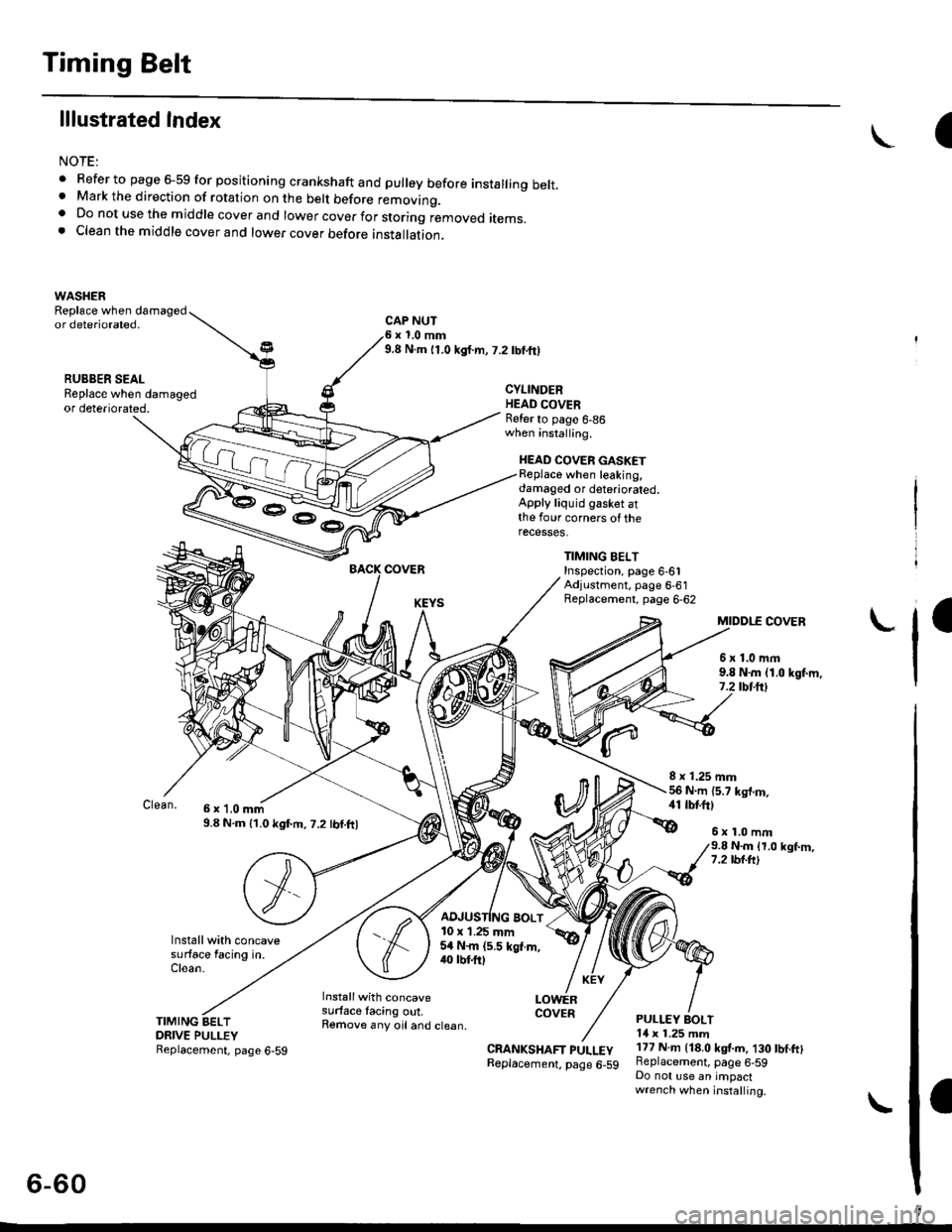

Timing Belt

lllustrated Index

NOTE:

. Refer to page 6-59 for positioning crankshaft and pulley before installing belt.. Mark the direction of rotation on the belt before removino.a Do not use the middle cover and lower cover for storing r'emoved items.. Clean the middle cover and lower cover before installation.

WASHER

I

Replace when damagedor deteriorated.CAP NUTx 1,0 mm9.8 N.m lr.0 kgf.m, 7.2lbtftl

CYLINDERHEAD COVERRefer to page 6-86when installing.

HEAD COVER GASKETReplace when leaking,damaged or deteriorated.Apply liquid gasket atthe four corners ol therecesses,

TIMING BELTInspection, page 6-61Adjustment, page 6-61Replacement, page 6-62

I

6 x '1.0 mm9.8 N.m {1.0 kgf.m, 7.2 lbt.ftl

l0 x 1.25 mm5a N.m {5.5 kgl.m,40 tbt ftt

MIDDTE COVER

6 x 1.0 mrn9.8 N.m {1.0 kgf.m,7.2 tbt-ltl

8 x 1.25 mmN.m {5.7 kgt.m,41 tbt fr)

6x1.0mmN.m 11.0 kgf.m,7.2 tbt.ft'l

PULLEY BOLT14 x 1.25 mm177 N.m {18.0 kgf.m. 130 tbt.ft}Beplacement, page 6-59Do not use an impactwrench when installing.

TIMING BELTDRIVE PULLEY

Installwith concavesurtace facing out.Remove any oil and clean.

LOWERCOVER

CRANKSHAFT PULLEYReplacement, page 6-59

- -o

6-60

Replacement, page 6-59

Page 175 of 2189

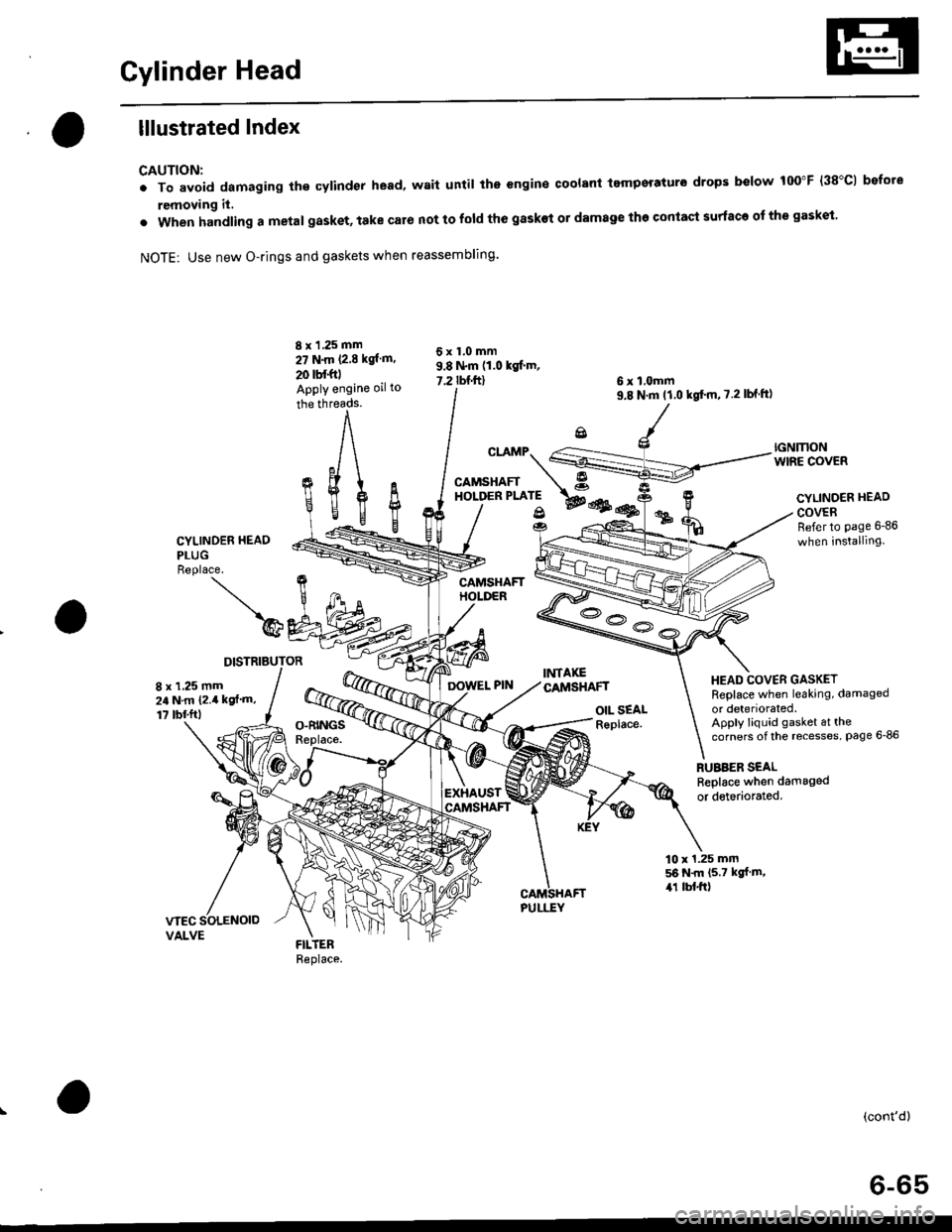

Cylinder Head

lllustrated Index

CAUTION:

. To avoid damaging the cylinder head, wait until the engine coolant tempsraturo drops below 100"F (38"C1 bofote

removing it,

. when handling a metal gasket, take caro not to fold the gaskot or damage the contact surface of the gasket.

NOTE: Use new O-rings and gaskets when reassembling.

CYLINDER HEAO

PLUGReplace.

)@

DISTRIBUTOR

8 x 1 ,25 mm

27 N.m P.E kgl m.

20 tbf.foApply engine oil to

the threads.

cr.rMp.S

CAMSHAFT A"o''*t*'; wes@

OIL SEALReplace.

6 x l,omm9.8 N'm tl.0 kgt'm,7.2lbf ft)

RUBBER SEALReplace when damaged

or detedorated.

6x1.0mm9.8 N.m (1.0 kgf'm,

7.2 rbnftl

fi%

IGNMONWIRE COVER

CYLINOER HEAD

COVERRefer to page 6-86

when installing

HEAD COVER GASKETReplace when leaking, damaged

or deteriorated.Apply liquid gasket at thecorners of the recesses, Page 6-86

8 x 1,25 mm24 N.m {2.4 kgf'm,

1? tbf.ftl

EXHAUST

10 x 1.25 mm56 N.m (5.7 kgf m,,r1 lbl.ft)

(cont'd)

6-65

Page 221 of 2189

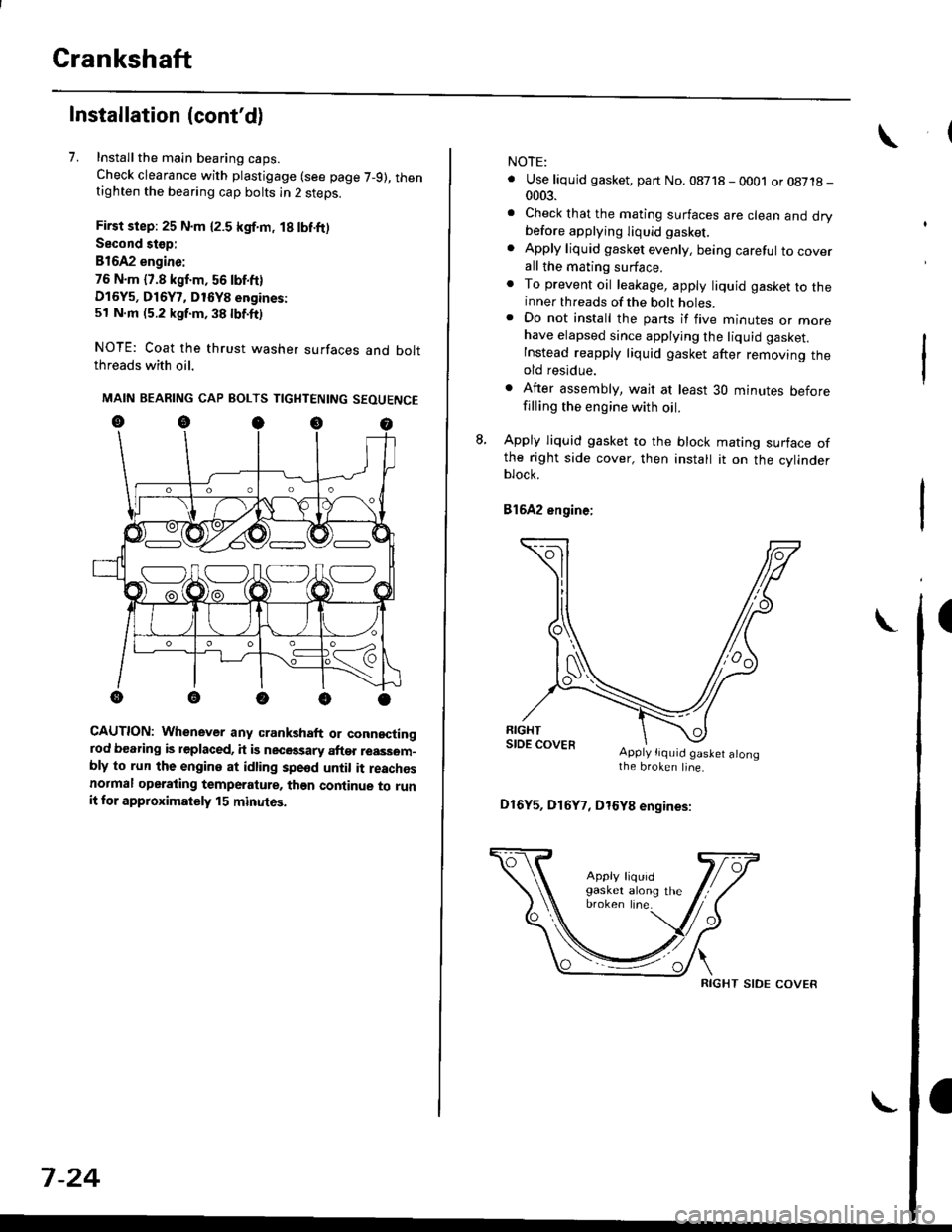

Crankshaft

Installation (cont'd)

7. Installthe main bearing caps.

Check clearance with plastigage (see page 7-9), thentighten the bearing cap bolts in 2 steps.

First step: 25 N.m {2.5 kgf.m, 18 lbf.ft)

Second stop:

B1642 engine:

76 N.m {7.8 kgf.m, 56 lbf.ft)

D16Y5, D16Y7, D16Y8 engines:

51 N.m (5.2 kgf.m, 38 lbf.ft)

NOTE: Coat the thrust washer surfaces and boltthreads with oil.

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

oocoo

CAUTION: Whenever any crankshaft or connectingrod bearing is replaced, it is necGssary after reassom-bly to run the engine at idling spe6d until it reachesnormal operating temperature, than continue to runit for approximately 15 minutos.

:V fr\-/.---\-/.-

7-24

NOTE:

. Use liquid gasket, part No. 08718 - 0001 or08718-0003.

. Check that the mating surfaces are clean and drybefore apptying liquid gasket.

. Apply liquid gasket evenly, being careful to coverall the mating surface.. To prevent oil leakage, apply liquid gasket to theinner threads of the bolt holes.. Do not install the parts if five minutes or morehave elapsed since applying the liquid gasket.

Instead reapply liquid gasket after removing theold residue.

. After assembly, wait at least 30 minutes beforefilling the engine with oil.

L Apply liquid gasket to the block mating surface ofthe right side cover, then install it on the cylinderblock.

Bl6A2 engine;

Apply tiquid gaslet alongthe broken line.

D16Y5, D16Y7, D16Y8 engines:

RIGHT SIDE COVER

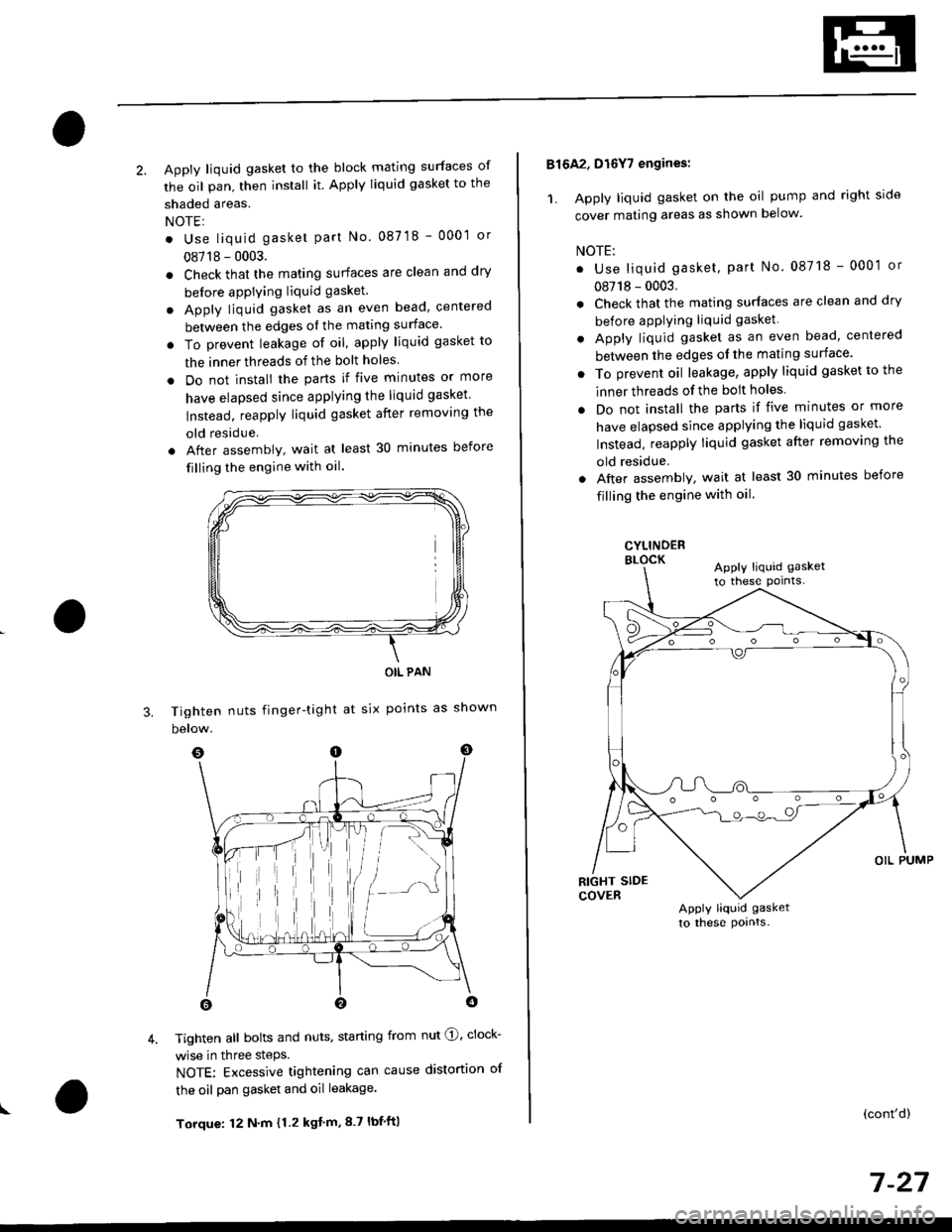

Page 224 of 2189

2. Apply liquid gasket to the block mating surfaces of

the oil pan, then install it. Apply liquid gasket to the

shaded areas.

NOTEI

. Use liquid gasket part No. 087 18 - 0001 or

08718 - 0003.

. Check that the mating surfaces are clean and dry

before apPlying liquid gasket.

. Apply liquid gasket as an even bead, centered

between the edges ol the mating surface'

. To prevent leakage of oil, apply liquid gasket to

the inner threads of the bolt holes

. Do not install the parts if five minutes or more

have elapsed since applying the liquid gasket

lnstead, reapply liquid gasket after removing the

old residue

. After assembly, wait at least 30 minutes before

filling the engine with oil.

Tighten nuts finger-tight

below.

OIL PAN

at six points as shown

I

3.

4. Tighten all bolts and nuts, starting from nut @, clock-

wise in three steps.

NOTE: Excessive tightening can cause distortion of

the oil pan gasket and oil leakage.

Torque: 12 N'm {1.2 kgt'm,8.7 lbf'ft|

816A2, D16Y7 engines:

1. Apply liquid gasket on the oil pump and right side

cover mating areas as shown below.

NOTE:

. Use liquid gasket, part No. 08718 - 0001 or

08718 - 0003.

. Check that the mating surfaces are clean and dry

before applying liquid gasket

. Apply liquid gasket as an even bead, centered

between the edges ol the mating surface'

. To prevent oil leakage, apply liquid gasket to the

inner threads of the bolt holes

. Do not install the parts if five minutes or more

have elapsed since applying the liquid gasket

Instead, reapply liquid gasket after removing the

old residue.

. Aftel assembly, wait at least 30 minutes before

filling the engine with oil.

CYLINDERELOCKApply liquid gasket

to these pornts-

Apply liquid gasket

to these pornts.

(cont'd)

7 -27

Page 225 of 2189

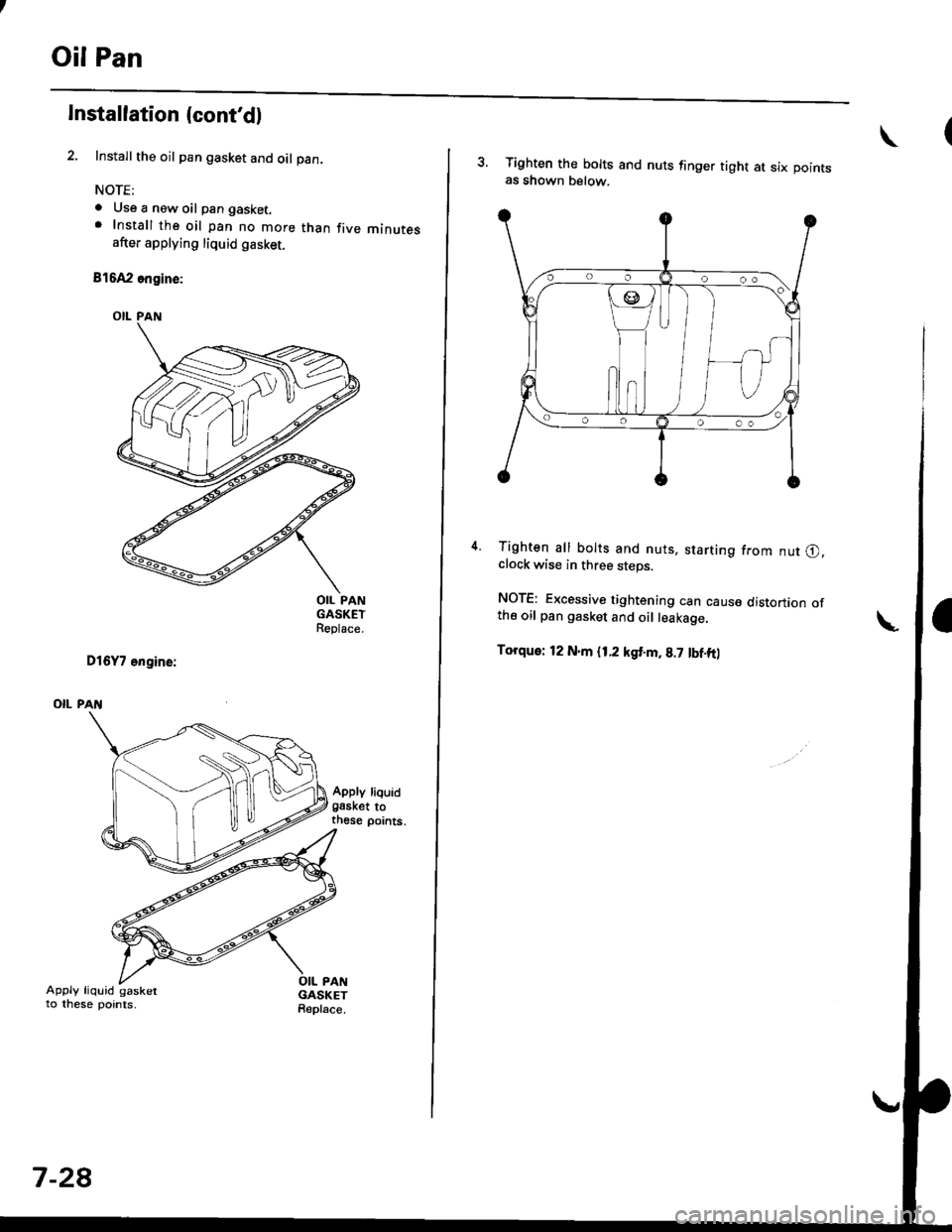

Oil Pan

lnstallation (cont'dl

Install the oil pan gasket and oil pan

NOTE:

a Use a new oil pan gasket.. Install the oil pan no more than five minutesafter applying liquid gasket.

816A2 engine:

OIL PANGASKETR€place.

Apply liquidgasKet tothese points.

Apply liquid gaskerto these points.

OIL PANGASKETBeplace.

7-28

\

3, Tighten the bolts and nuts finger tight at six pointsas shown below.

Tighten all bolts and nuts, starting from nut O.clock wise in three steps.

NOTE: Excessive tightening can cause distortion ofthe oil pan gasket and oil leakage.

Torque: 12 N.m {1.2 kgf.m, 8.7 lbf.ft)

4.

Page 233 of 2189

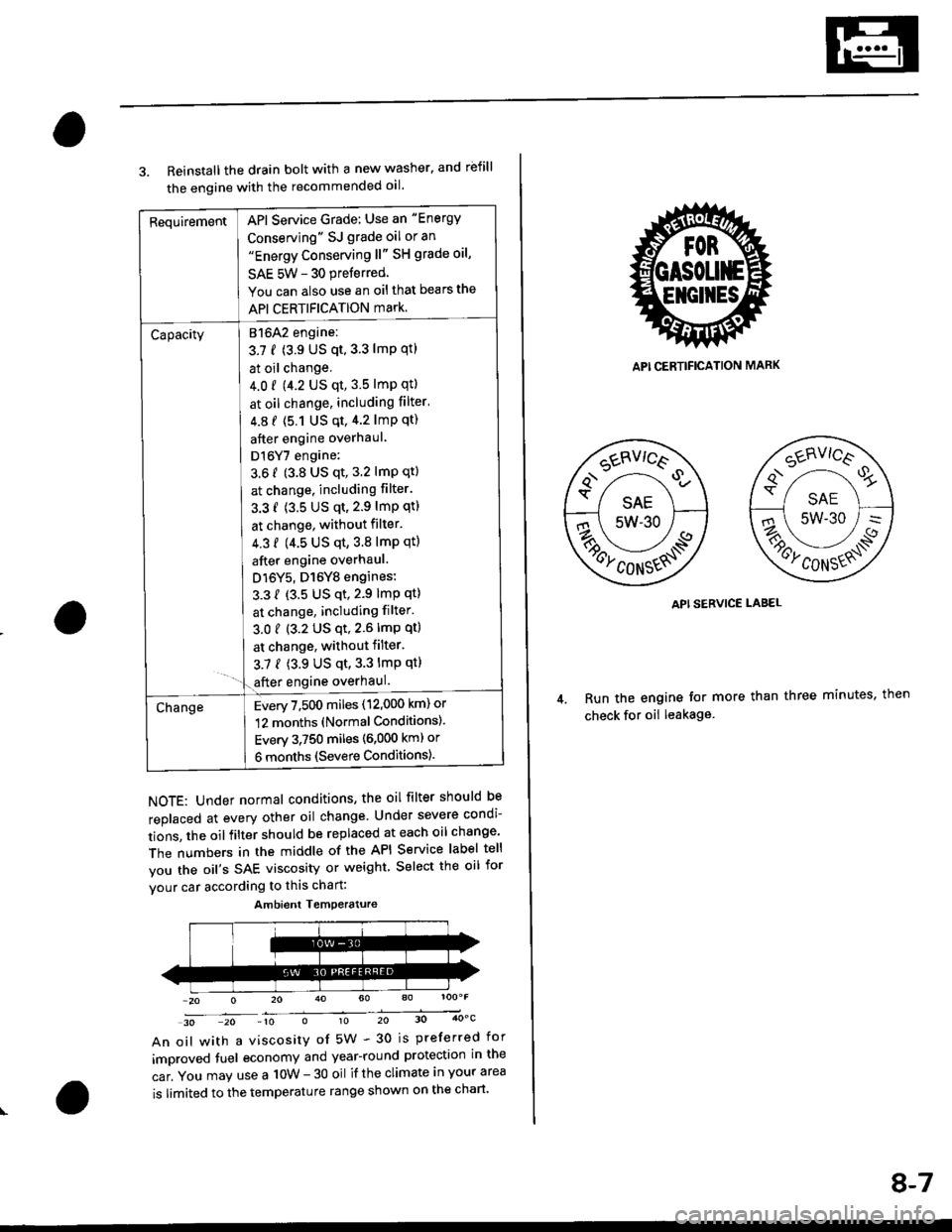

RequirementAPI Service Grade: Use an "Energy

Conserving" SJ grade oil or an"Energy Conserving ll" SH grade oil,

SAE 5W - 30 preferred

You can also use an oil that bears the

API CERTIFICATION mark.

Capacity[atolz engine:

3.7 f (3.9 US qt,3.3 lmp qtl

I at oil change.

J 4.0 r 9.2 US qt, 3.5 lmp qtl

I at oil change, including filter'

| 4.8 f (5.1 Us qt,4.2 lmp qt)

I after engine overhaul

I Dl6Y7 engine:

3.6 f (3.8 US qt, 3.2 lmP qt)

I at change. including filter.

I 3.3 f (3.5 US qt,2.9 lmP qtl

I at change, without filter.

I 4.3 f (4.5 us qt,3.8 lmp qtl

I after engine overhaul.

J D16Y5, D16Y8 engines:

L 3.3 { {3.5 US qt,2.9 lmp qt}

I at change, including filter.

3.01 (3.2 US qt,2.6lmp qt)

I at change, withoutfilter.

3.7 { (3.9 US qt,3.3 lmp qt}- '1.€fter engine overhaul.

ChangeEvery 7,500 miles (12,000 km) or

12 months (Normal Conditions).

Every 3,750 miles (6,000 kml or

6 months (Severe Conditions).

3. Reinstall the drain bolt with a new washer. and rbfill

the engine with the recommended oil.

NOTE: Under normal conditions, the oil filter should be

replaced at every other oil change Under severe condi-

tions, the oilfilter should be replaced at each oil change'

The numbers in the middle of the API Service label tell

you the oil's SAE viscosity or weight Select the oil for

vour car according to this chart:

30 20 -10 010 20 30 4OoC

An oil with a viscosity of 5W - 30 is preferred for

improved tuel economy and year-round protection in the

car. You may use a 10W - 30 oil if the climate in your area

is limited to the temperature range shown on the chart'

Ambient Temoerature

API CERTIFICATION MARK

API SERVICE LABEL

Run the engine tor more than three minutes, then

check for oii leakage

8-7

Page 235 of 2189

Oil Pressure

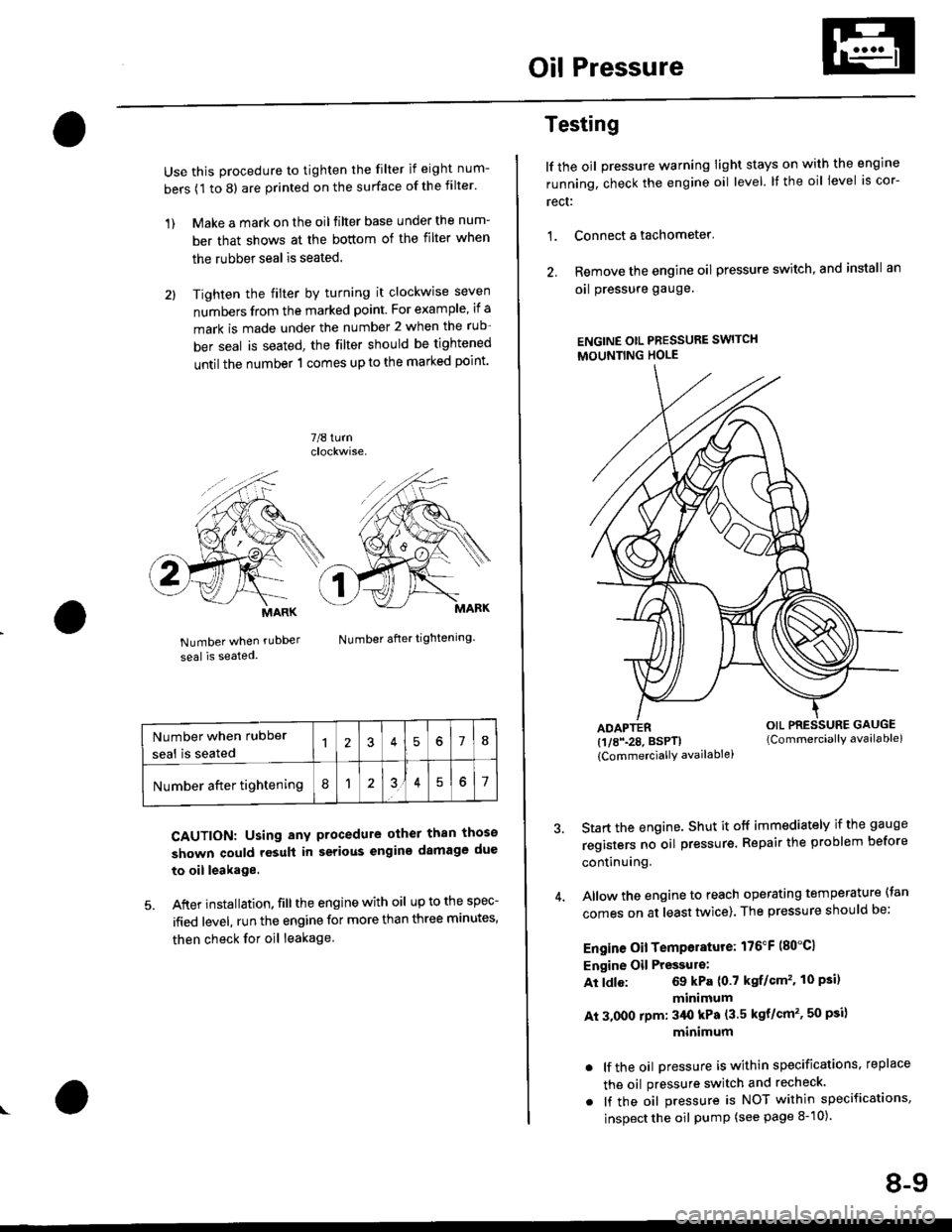

Use this procedure to tighten the filter if eight num-

bers (1 to 8) are printed on the surface of the filter.

1) Make a mark on the oil filter base under the num-

ber that shows at the bottom of the filter when

the rubber seal is seated.

2l Tighten the filter by turning it clockwise seven

numbers from the marked point. For example, if a

mark is made under the number 2 when the rub

ber seal is seated, the filter should be tightened

until the number 1 comes up to the marked point'

7/8 turn

Number when rubDer

seal is seated

Number after tightening.

CAUTION: Using any procedure other than those

shown could rosult in serious engins damage due

to oil leakage

5. After installation. fill the engine with oil up to the spec-

ified level, run the engine for more than three minutes,

then check for oil leakage

MARK

Number when rubber

seal is seated578

Number after tightening8151

Testing

lf the oil pressure warning Iight stays on with the engine

running, check the engine oil level. It the oil level is cor-

rect:

1. Connect a tachometer'

2. Remove the engine oil pressure switch, and install an

oal pressure gauge.

ENGINE OtL PRESSURE SWITCH

MOUNTING HOLE

ADAPTER(1/8\28. BSPTI

{CommerciallY availablei

Start the engine. Shut it off immediately if the gauge

registers no oil pr€ssure. Repair the problem before

continuing.

Allow the engine to reach operating temperature (tan

comes on at least tlivice). The pressure should be;

Engine Oil Temperature: 176"F (80"C1

Engine Oil Pressulo:

At ldle: 69 kPa (0.7 kgf/Gm'�. 10 Psi)

minimum

At 3.000 rpm: 3/Ut kPa (3.5 kgt/cm'�, 50 psi)

minimum

. lf the oil Dressure is within specifications, replace

the oil pressure switch and recheck.

. lf the oil pressure is NOT within specifications,

inspect the oil pump (see page 8-10).

OIL PRESSURE GAUGE(Commerciallv available)

8-9