Connectors HONDA CIVIC 1997 6.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 801 of 2189

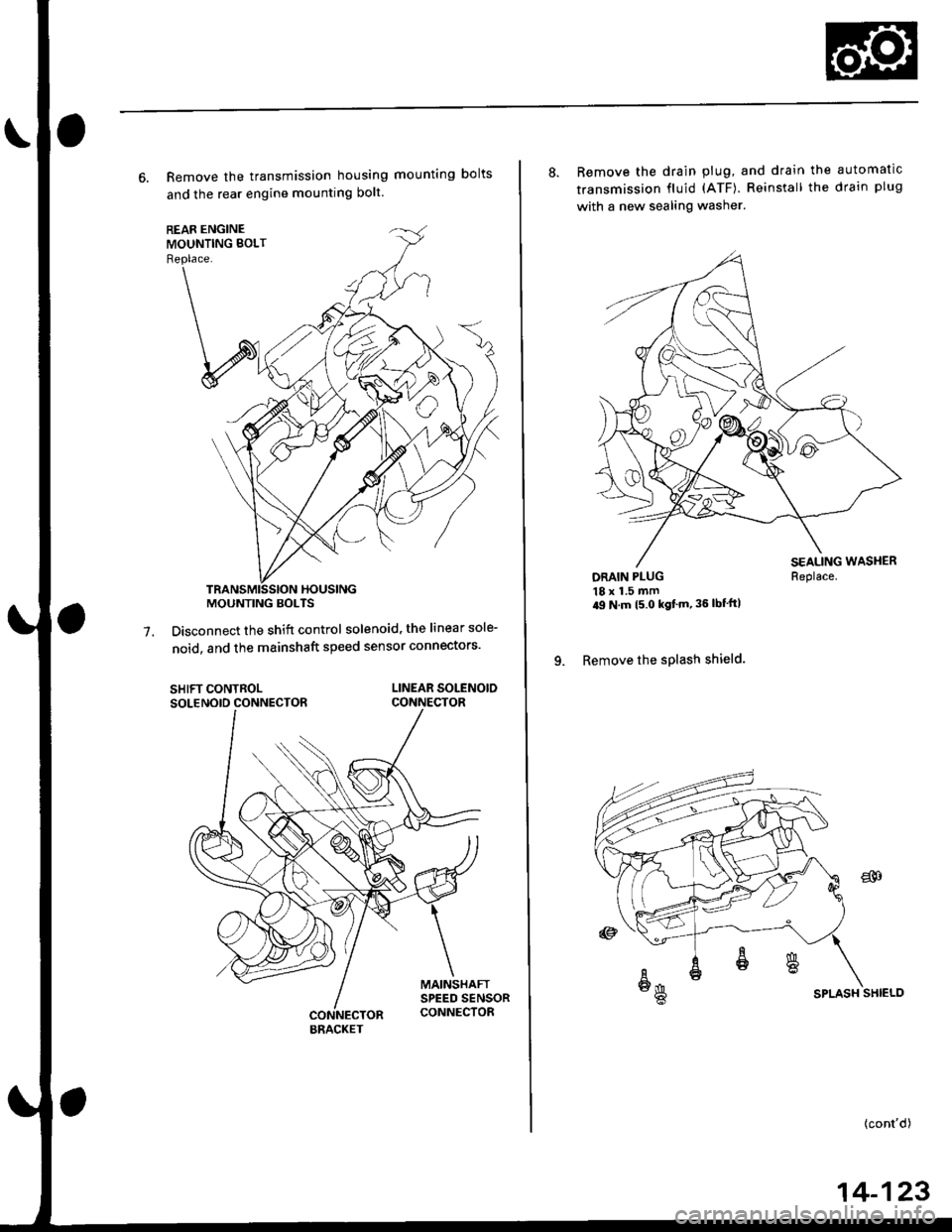

6. Remove the transmission housing mounting bolts

and the rear engine mounting bolt.

Disconnect the shift control solenoid, the linear sole-

noid, and the mainshaft speed sensor connectors'7.

SHIFT CONTROLSOLENOID CONNECTORLINEAR SOLENOIDCONNECTOR

MOUNTING BOLTS

BRACKET

8. Remove the drain plug, and drain the automatic

transmission fluid (ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN PLUG18 x 1.5 mm'9 N m t5 o kgf'm' 36 lbf'ft|

9. Remove the splash shield.

Replace.

SPLASH SHIELD

{cont'd)

14-123

Page 863 of 2189

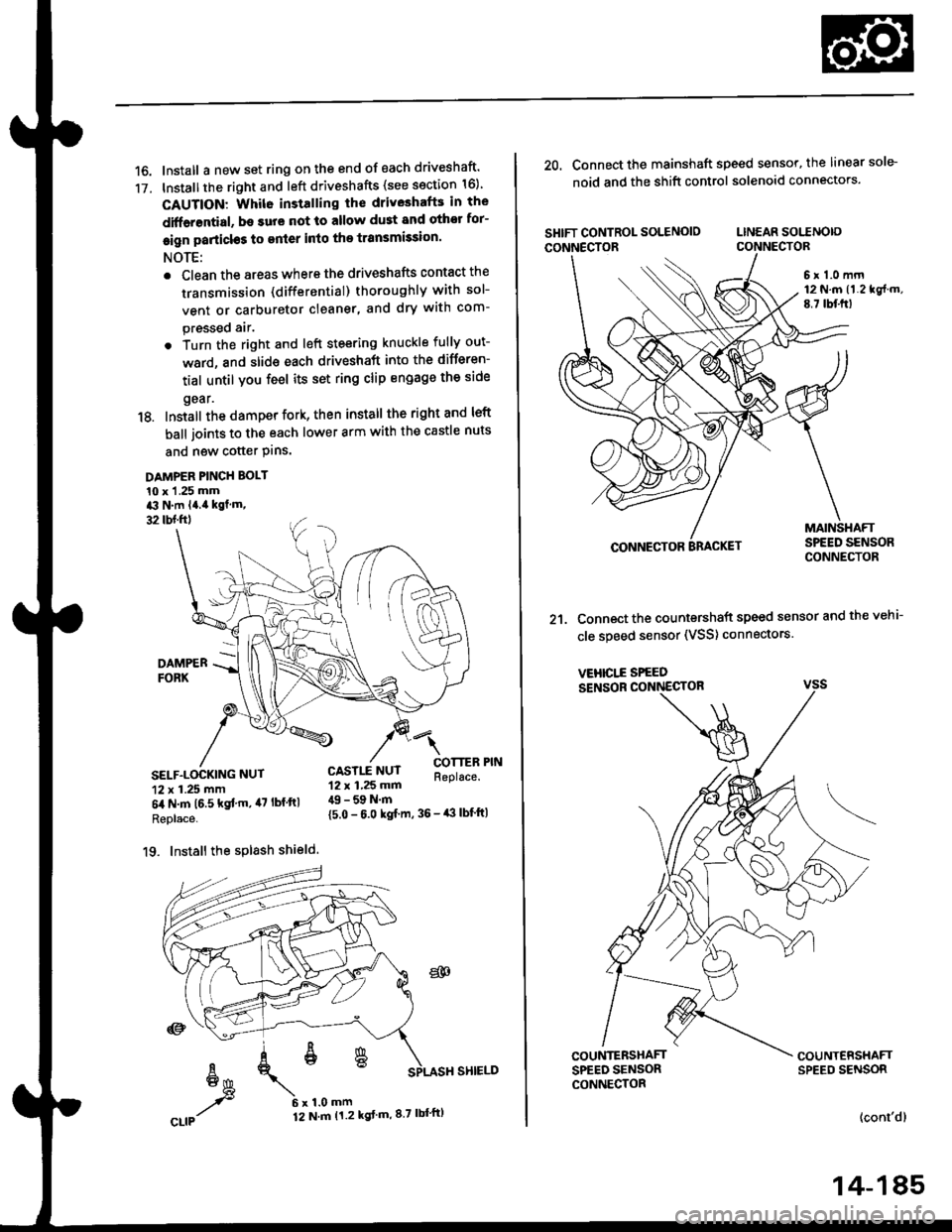

16. Install a new set ring on the end of each driveshaft'

17. Installthe right and left driveshafts (see ssction 16)

CAUTION: Whil6 installing the driveshafE in the

diffarential, be surs not lo allow du3t and othor for-

eign particl€s to enler into the transmission.

NOTE:

. Clean the areas where the driveshafts contact the

transmission (differential) thoroughly with sol-

vent or carburetor cleaner, and dry with com-

pressed air.

. Turn the right and left steering knuckle fully out-

ward, and slide each driveshaft into the differen-

tial until you feel its set ring clip engage the side

gear.

18. Install the damper fork, then install the rightand left

ball joints to the each lower arm with the castle nuts

and new cotter Plns.

DAMPER PINCH BOLT

10 x 1 .25 mma3 N.m l4.ia kgf.m,

32 tbl.ftl

4l

COTTERReplace.SELF.LOCKING NUT

12 x 1.25 mm

6il N.m t6.5 kgf'm, il7 lbf ftl

Replace.

19. Install the splash shield.

{5.0 - 6.0 kgf m, 36 - iB lbf'ft|

CASTLE NUT12 x 1,25 mm49 - 59 N.m

20. Connect the mainshaft speed sensor, the linear sole-

noid and the shift control solenoid connectors.

SHIFT CONTROL SOLENOIO LINEAR SOITNO|o

CONNECTOR CONNECTOR

6 r 1.0 mrn12 N.m (1.219f.m,

E.7 lbf.frl

CONNECTOR

21. Connect the countershaft speed sensor and the vehi-

cle speed sensor (VSS) connectors.

VEHICI..E SPEED

SENSOR CONNECTOR

COUNTERSHAFTSPEED SENSORCONNECTOR

(cont'dl

14-185

Page 913 of 2189

Troubleshooting Procedures

(cont'd)

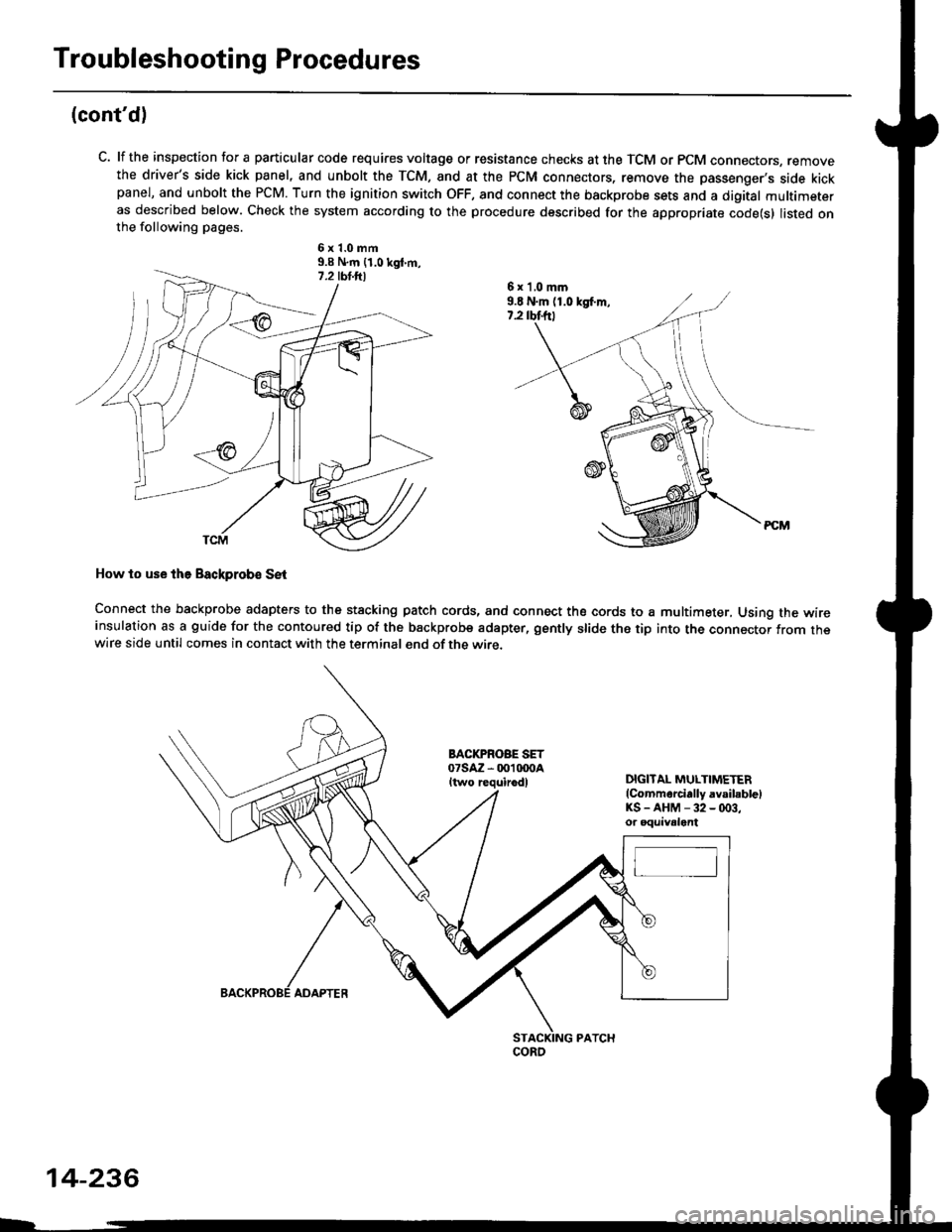

C. lf the inspection for a particular code requires voltage or resistance checks at the TCM or PCM connectors, removethe driver's side kick panel, and unbolt the TCM, and at the PCM connectors, remove the passenger's side kickpanel, and unbolt the PCM. Turn the ignition switch OFF, and connect the backprobe sets and a digital multimeteras described below. Check the system according to the procedure described for the appropriate code(s) listed onthe following pages.

6x1.0mm9.9 N.m {1.0 kgt m,

How to use lhe Backprob€ SE{

Connect the backprobe adapters to the stacking patch cords, and connect the cords to a multimeter, Using the wireinsulation as a guide for the contoured tip of the backprobe adapter, gently slide the tip into the connector from thewire side until comes in contact with the terminal end of the wire.

BACI(PROBE SET07saz - 001 txtoaItwo requirodlDIGITAL MULTIMETER(Commarcially avsibblelKS-AHM-32-(x)3,or oquivalent

6 x 'l,0 mm9.E N.m (1.0 kgf.m,7.2 rbtftt

coRo

14-236

ADAPTER

Page 919 of 2189

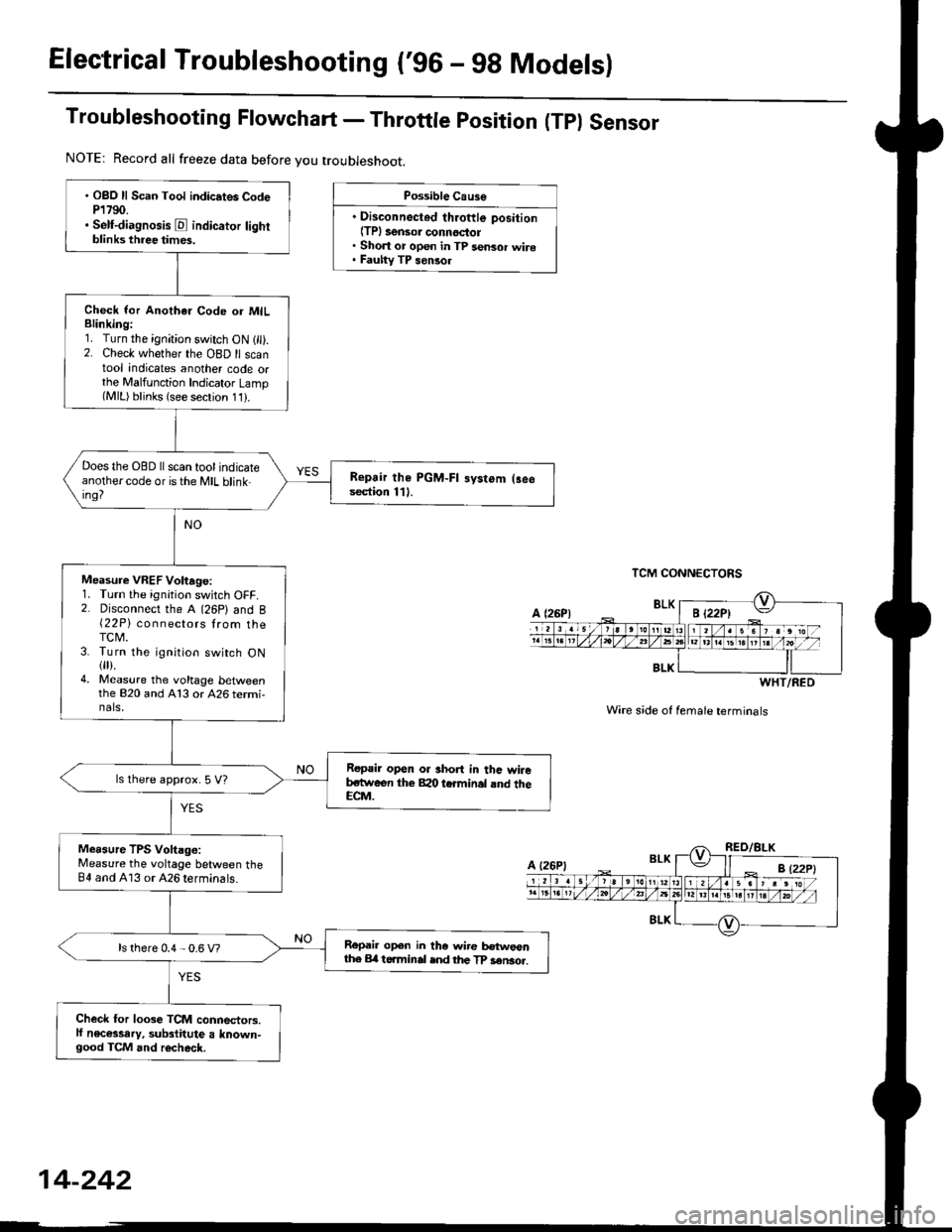

Electrical Troubleshooting ('96 - 98 Modelsl

Troubleshooting Flowchart - Throttle position (Tpl Sensor

Possible Cause

. Disconnected throftle position(TPl 3ensor connoctol. Short or open in TP sensor wire. Fauhy TP sensol

TCM CONNECTORS

Wire s;de of female terminals

. OBO ll Scan Tool indic.tes CodeP1790.. Self-diagnosis E indicator lightblinks three times.

Check lor Anothar Code or MILBlinking:1. Turn the ignition switch ON 1 ).2. Check whether the OBD ll scantool indicates another code orthe Malfunction Indicator Lamp(MlL) blinks (see secrion 11).

Does the OBD ll scan tool indicateanothercode oristhe MIL blink-ing?

Repair the PGM-FI systom (3eesection 111.

Measure VREF Voltage:1. Turn the ignition switch OFF.2. Disconnect the A (26P) and B{22P} connectors lrom theTCM.3. Turn the ignition switch ON{fl).4. Measure the voltage bet\iveenthe 820 and A13 or 426 termi-nals,

Repair open or short in thc wireb,stween the Bao tcrminal rnd theECM.

ls lhere approx. 5 V?

Measure TPS Voltago:Measure the voltage between theB4 and A13 or 426 terminals.

Repail open in the wire tr€tweonthe Erl t6.minal ind the TP sen3o..ls there 0.4 - 0.6 V?

Check for loose TCM connectors.lf necessary, substitute a known-good TCM and r6check.

NOTE: Record all freeze data before you troubleshoot.

BLK

WHT/RED

A {26P1

Page 920 of 2189

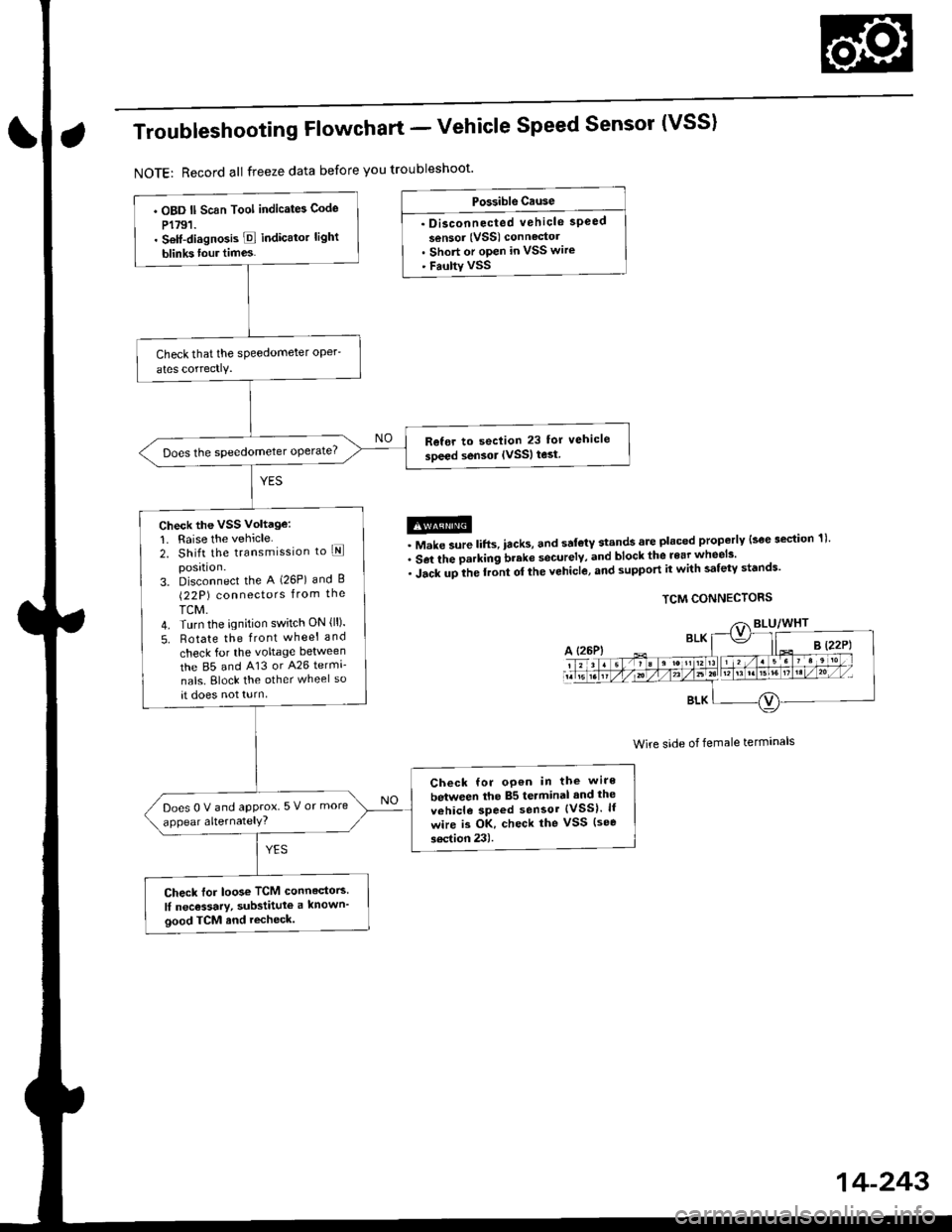

Troubleshooting Flowchart - Vehicle Speed Sensor (VSS)

NOTE: Record all freeze data before you troubleshoot'

Po$rible Ctuse

. Disconnected vehicle speed

sensor (VSS) connectol. Short or open in VSS wire' Faulty VSS

@. Make sure lifts, iacks, and sal€tY stands are placed properly lsoe section 1)'

. Set the parking brake securelv, and block the rear wheels'

. iacr upile rront or the vehicle, and support it with safety st'nds'

TCM CONNECTORS

Wire side of female terminals

. OBD ll Scan Tool indicates Code

P1791.. Setf-diagno3is E indicato. light

blinks tour times.

Refer to seclion 23 for vehicle

soeed sensor IVSSI test

Check the VSS Voltage:

1. Raise the vehicle2. Shift the transmission to lEposrtlon.3. Disconnect the A (26P) and B(22P) connectors from the

TCM.4. Turn the ignition switch ON {ll).

5. Rotate the front wheel and

check for the voltage between

the 85 and 413 or A26 termi-

nals. Block the other wheel so

at does not turn

Check for oP€n in the wire

between the 85 terminal and the

vehicle speed sensor {VSS}. lf

wire is OK, check the vSS (see

soction 23).

Does0Vandapprox 5 V or more

appear alternatelY?

Check for loos€ TCM connedors

lI nec€ssary, substitute a known'

good TCM and recheck.

14-243

Page 922 of 2189

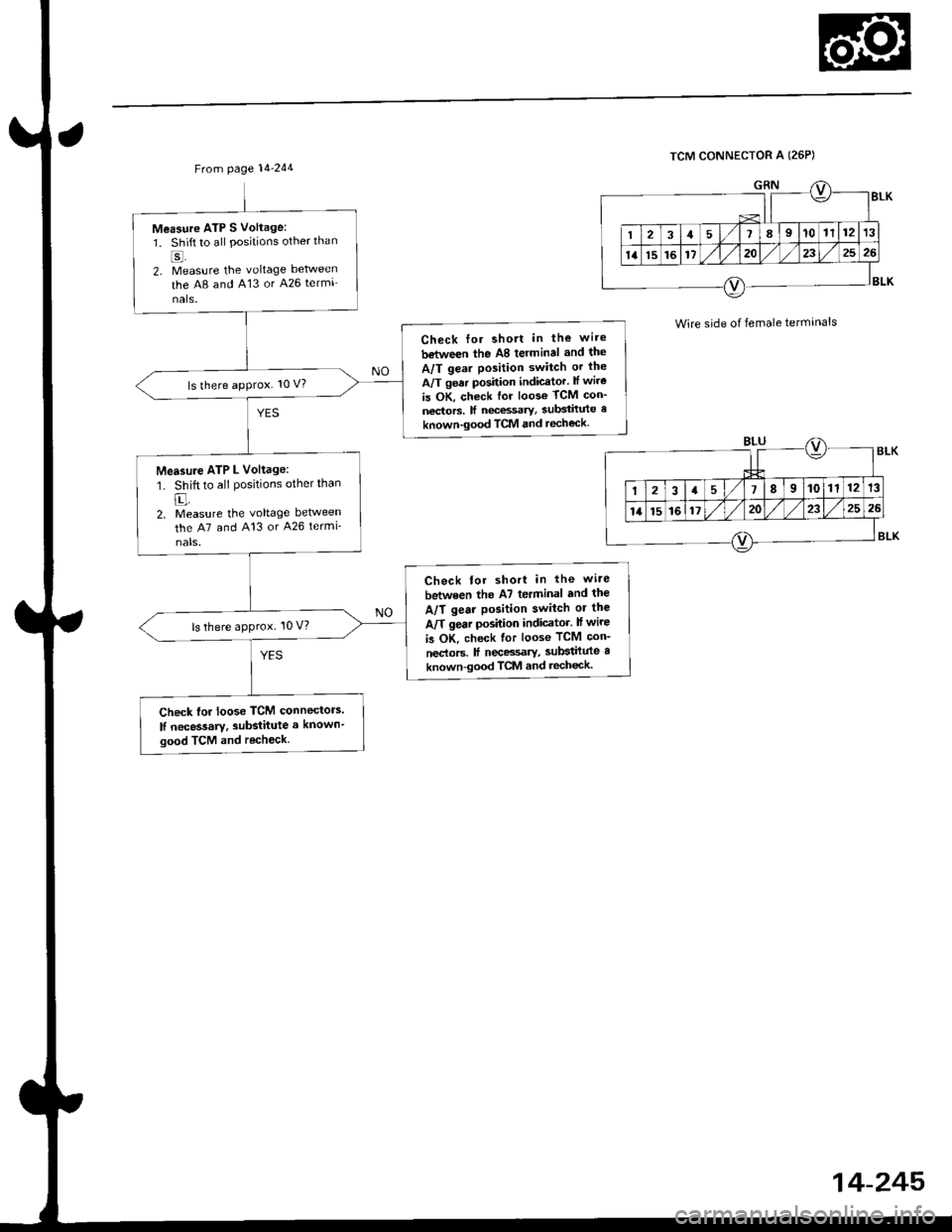

From page l4-244

Measure ATP S Vollage:

1. Shift to all Positions otherthan

2. Measure the voltage between

the A8 and A13 or A26 termi

nals.

Check lor shott in the wire

between the A8 terminal and the

A/T gea. Position switch or the

A/T gear position indicator. lf wire

is OK, check for loose TCM con_

nectors. lI necessary, substitute a

known-good TCM and recheck.

ls there approx. 10 V?

Measure ATP L Voltage:'1. Shift to all positions other than

E-2, Measure the voltage between

the A7 and A13 or A26 termi-

nals.

Check for short in the wi.e

between the A7 terminal and the

A/T gear position switch or the

A/T gear position indicator. lf wire

b OK. check for loose TCM con-

nectors. ff necessary, substilute a

known-good TCM and recheck.

ls there approx. 10 V?

Check lor loose TCM connectors.

lf necessary. substitute a known'

good TCM and recheck.

TCM CONNECTOR A (26P)

Wire side of female termanals

14-245

Page 924 of 2189

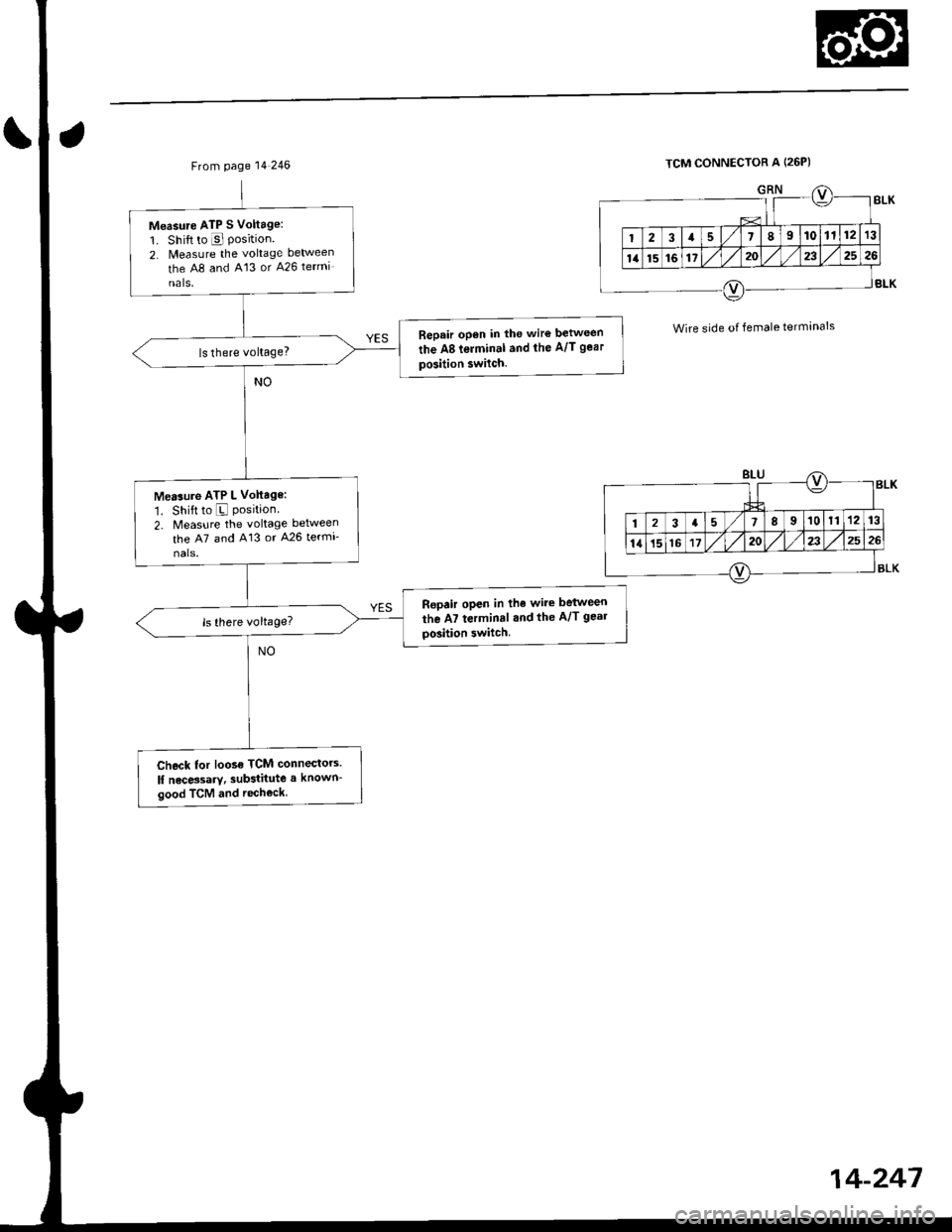

From page 14 246

Moasure ATP S Voltage:

1. Shift to E Position2. Measure the voltage between

the A8 and 413 or 426 termi

nals,

Bepair open in the wir€ between

the A8 t€rminal and the A/T gear

position switch.

Measure ATP L Vohage:

1. Shift to E Position2. Measure the voltage between

the A7 and A13 or 426 termi-

nals.

Repair open in the wire between

the A7 terminal and the A/T geal

Dosition switch

Chock tor loose TCM connectors.

lf necessary, substitute a l(nown-

good TCM and recheck,

TCM CONNECTOR A l26p)

Wire side of female terminals

14-247

Page 926 of 2189

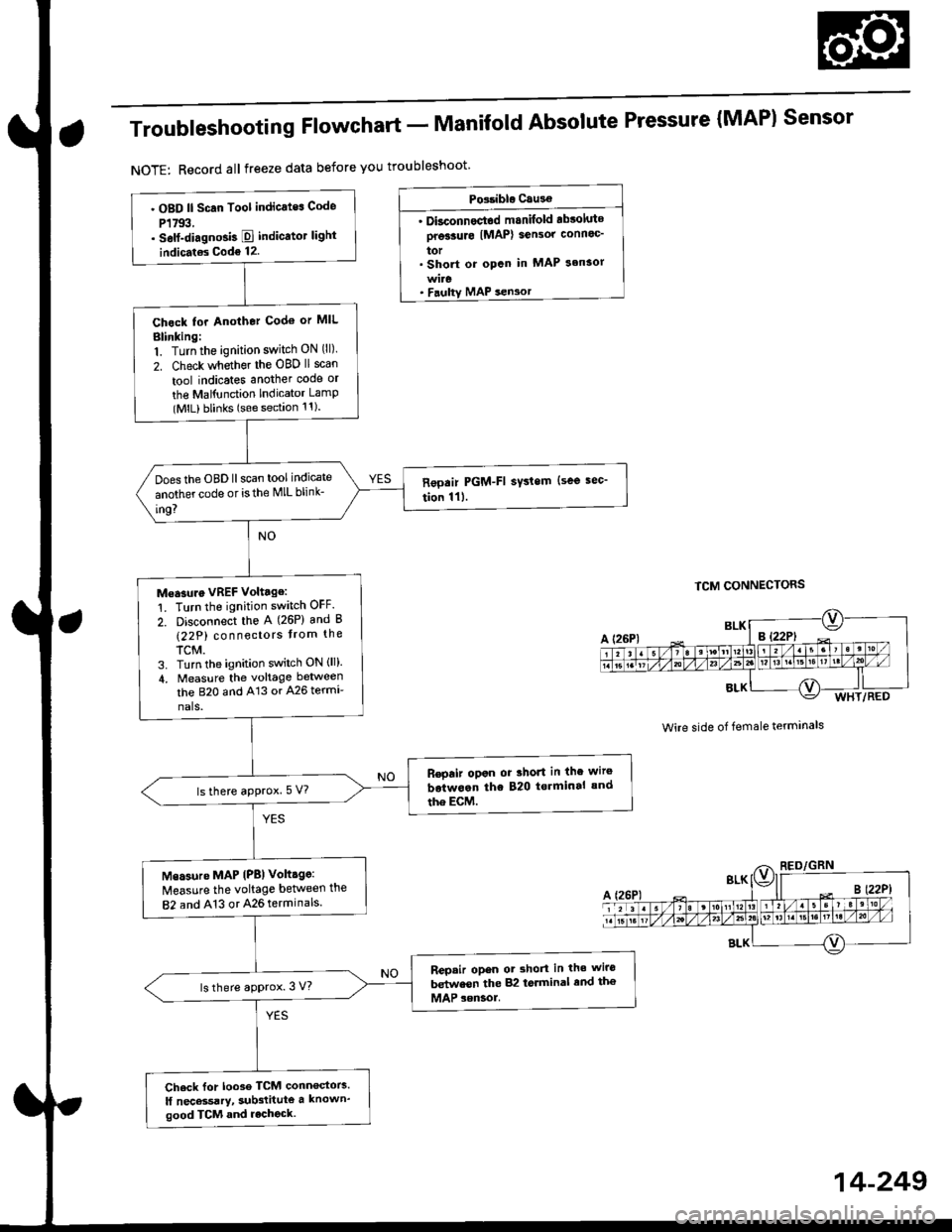

Troubleshooting Flowchart - Manifold

NOTE: Record all freeze data before you troubleshoot

Absolute Pressure {MAPI Sensor

TCM CONNECTORS

Wire side of female terminals

PG.iblo Cau3€

. Dkconnoctod manilold .bsoluto

ore33urc IMAP) sensor connoc'

lor. Short or opcn in MAP s.nsor

MAP sen3or

. OBD ll Scan Tool indicates Code

P1793,. self-diagno3b E indicato. light

indicat€s Code 12.

Chock tor Another Cod€ or MIL

Blinking:1. Turn the ignition switch ON (ll).

2. Check whether the OBD ll scan

tool indicates another code or

the Mal{unction Indicator LamP(MlL) blinks (sse section 11).

Does the OBD llscan tool indicate

another code or isthe lVlL blink-

in9?

Measure VREF voltage:

1. Turn the ignition switch OFF.

2. Disconnect the A (26P) and B

(22P) connectors trom the

TCM.3. Turn the ignition switch ON (ll).

4, Measure the voltage between

the B2O and A13 or A26 termr

nals.

R€pair opon or 3hort in the wire

botwoan the 820 t€.minal and

the EcM.lsthere aPprox.5 V?

Msasure MAP IPB) volt.ge:

Measure the voltage betlveen the

82 and A13 or 426 terminals.

Repair opon ot shorl in the wiro

betwesn the 82 torminal end th€

MAP sensol.ls there approx. 3 V?

Check for loo3e TCM conn€stors.

lf nec*sarY, sub3titute a known'

good TCM and rechock.

WHT/RED

14-249

Page 930 of 2189

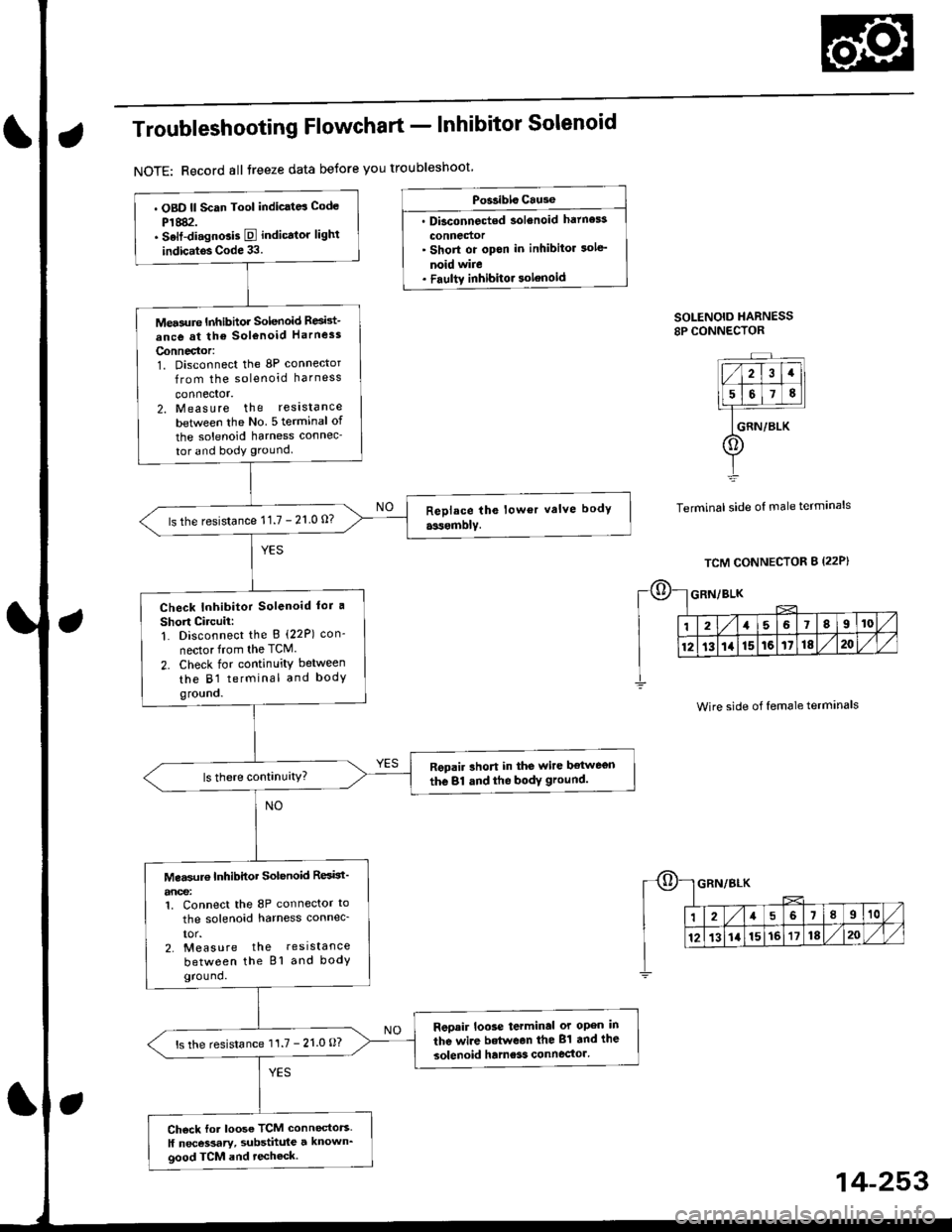

Troubleshooting Flowchart - Inhibitor Solenoid

NOTE: Record all treeze data betore you troubleshoot

Po$ibls Cause

. Dbconnected solenoid hatness

connedor' Short or opon in inhibitor sole'

noid wire. Faultv inhibitor solenoid

SOLENOID HARNESS8P CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indic.td Code

P1882.. Selt-di.gnGis E indicator lighl

indic.tos Code 33.

Mea3ure Inhibhor Solenoid Resid-

ance at the sol€noid Harness

Connector:1. Disconnect the 8P connector

from the solenoid harness

connector.2. Measure the reslstance

betlveen the No 5 terminal of

the solenoid harness connec-

tor and body ground.

ls the resistance 11.7 - 21 0 0?

Check Inhibitor Solenoid lor a

Short Circuii:1. Disconnect the B (22P) con-

nector from the TCM.

2. Check for continuity between

the B1 terminal and bodygro!no.

Repair rhort in the wire ltetwegn

the 81 dnd the bodY ground.

Mea$rr€ Inhibitor Solenoid ResBt'

anoe:1. Connect the 8P connector to

the solenoid harness connec_

IOr.2. Measure the resistance

between the Bl and bodyground.

Reoair loose terminal or open in

the wire betwean the 81 and the

solenoid hame3s connector'ls the resistance 11.7 - 21.0 O?

Ch6ck for loose TCM connectors.

ll necessary, substhule a known_good TCM and techeck.

Wire side of female terminals

14-253

Page 934 of 2189

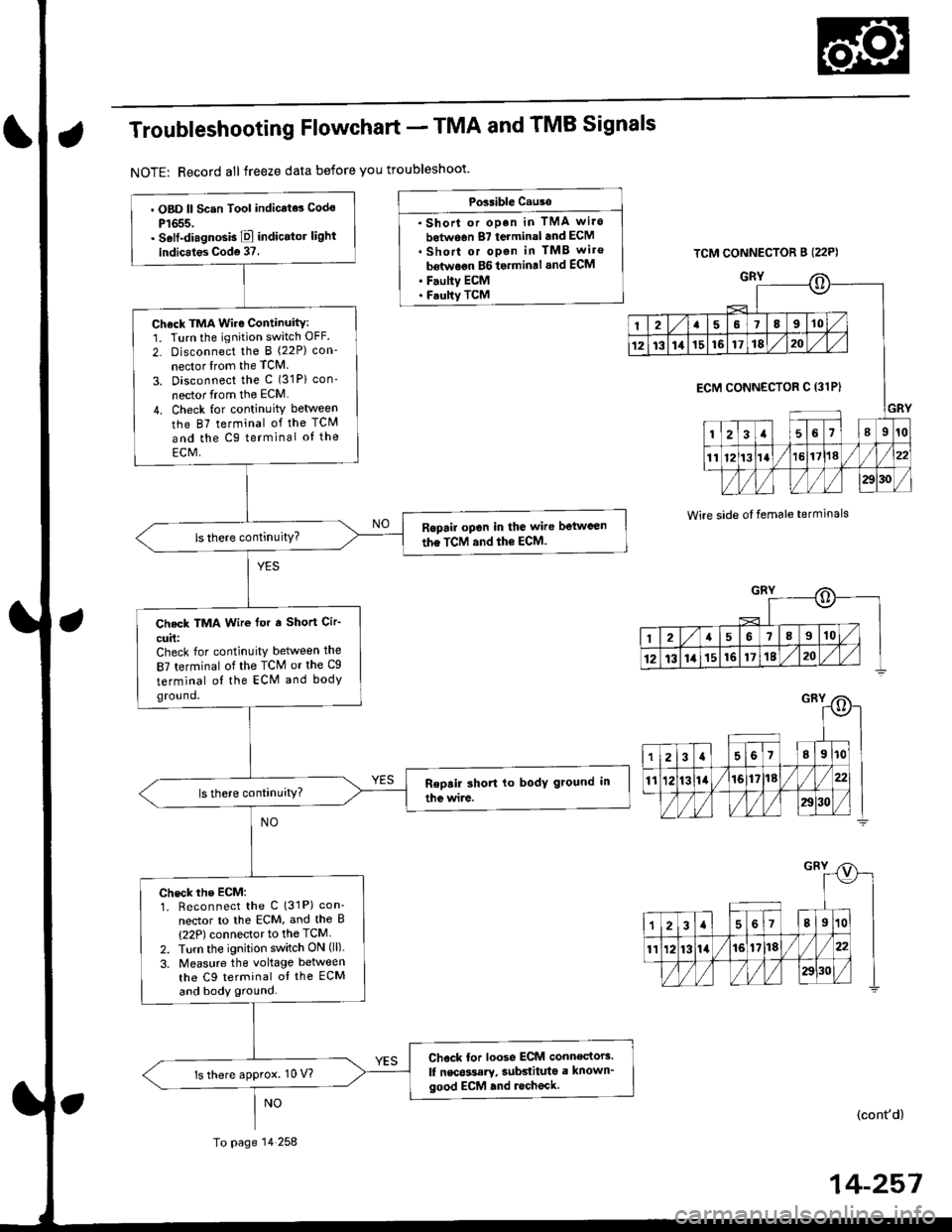

Troubleshooting Flowchart - TMA and TMB Signals

NOTE: Record all freeze data before you troubleshoot'

Possible Cause

. Shorl or op.n in TMA wi.o

botwo6n 87 terminal and ECM. Short or open in TMB wiro

bdtwoon BG to.min.l .nd ECM. F.ulty ECM. Faulty TCM

TCM CONNECTOR B (22P)

GRY

Wire side oI temale terminals

o

I2a58910

1213111516171820

GRY

ECM CONNECTOR C 13lPI

123a56l89r0

1112t3la1618//

29130 /

::)

I2a568910

12t3141516171820

. OBD ll Scsn Tool indicate3 Codo

P1655.. Self-diagnosb E indicator light

indicales Cod6 37.

Check TMA Wire Continuity:1. Turn the ignition switch OFF.

2- Disconnect the I (22P) con-

nector lrom the TCM

3. Disconnect the c (31P) con'

nector from the ECM

4. Check for continuity between

the 87 terminal of the TCM

and the Cg terminal oI the

ECM,

Ropail open in the wire betwcen

the TCM and the ECM.

Check TMA Wir€ for a Short Cir-

cuit:Check for continuity between the

87 terminal of the TCM or the Cg

terminal ol the ECM and bodyground.

check rhe EcM:1. Reconnect the C (31P) con'

nector to lhe ECM, and the B(22P) connector to the TCM

2. Turn the ignition switch ON (ll).

3. Measure the voltage between

the C9 terminal oI the ECM

and body ground.

Chock tor loose ECM connectors.

lf nscossary, subdituta a known'good ECM .nd lecheck.ls there approx. 10 V?

To page 14 258

(cont'd)

14-257