bracket HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1311 of 2189

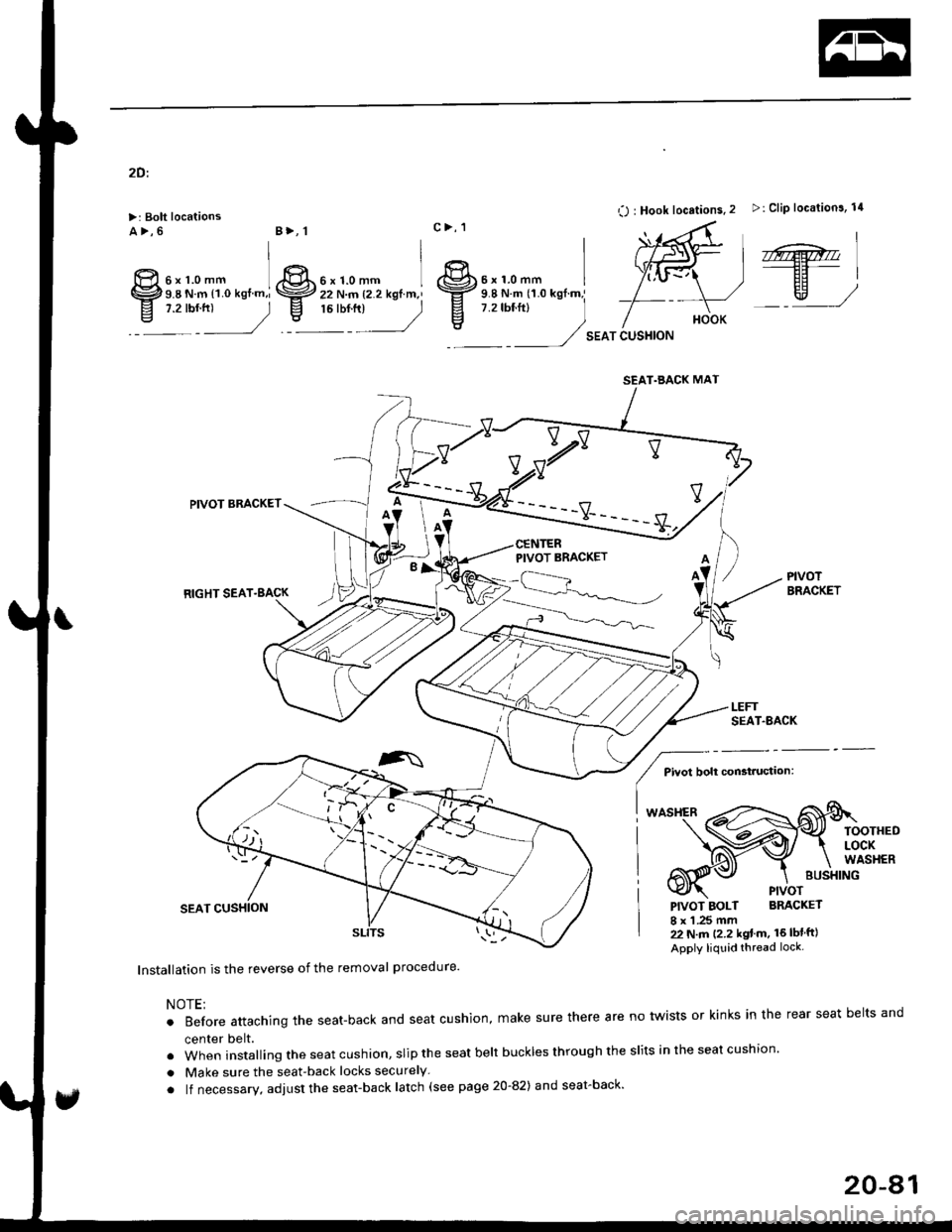

2Dt

>: Bolt locationsa>,6

O : Hook locations. 2 >: Clip location3, 14

SEAT CUSHION

,r@.''----EF-|

EH)w,/

PIVOTBRACKET

BUSXING

PIVOT

PIVOT BOLT BRACKET

I x 1 .25 mm22 N.m (2.2 kgt m. 16lblft)

Apply liquid thread lock.

lnstallation is the reverse of the removal procedure'

NOTE;

.Beforeattachingtheseat-backandseatcushion,makesuretherearenotwistsorkinksintherearseatbe|tsand

center belt.

.wheninsta||ingtheseatcushion,sliptheseatbe|tbucklesthroughthes|itsintheseatcushion.

. Make sure the seat-back locks securely

. lf necessary, adjust the seat-back latch (see page 20-82) and seat-back'

6xr.omm ]9.8 N.m l1.O kgf.m,i,:r:2

B>, 1

ffi

IgIt

c>, 1

6xr.omm I 8r.'r.o-- r22 N.m {2.2 kgtm,' \ffz s.e N.m tr.o *gf.m,'

,r:r",

_) E

7.2rbf.ftl

)

vv

PIVOT BRACKET

RIGHT SEAT.BACK

PIVOT BRACKET

Pivot bolt constauctaon:

TOOTHEDLOCKWASHER

SEAT.BACK MAT

,^

20-41

Page 1317 of 2189

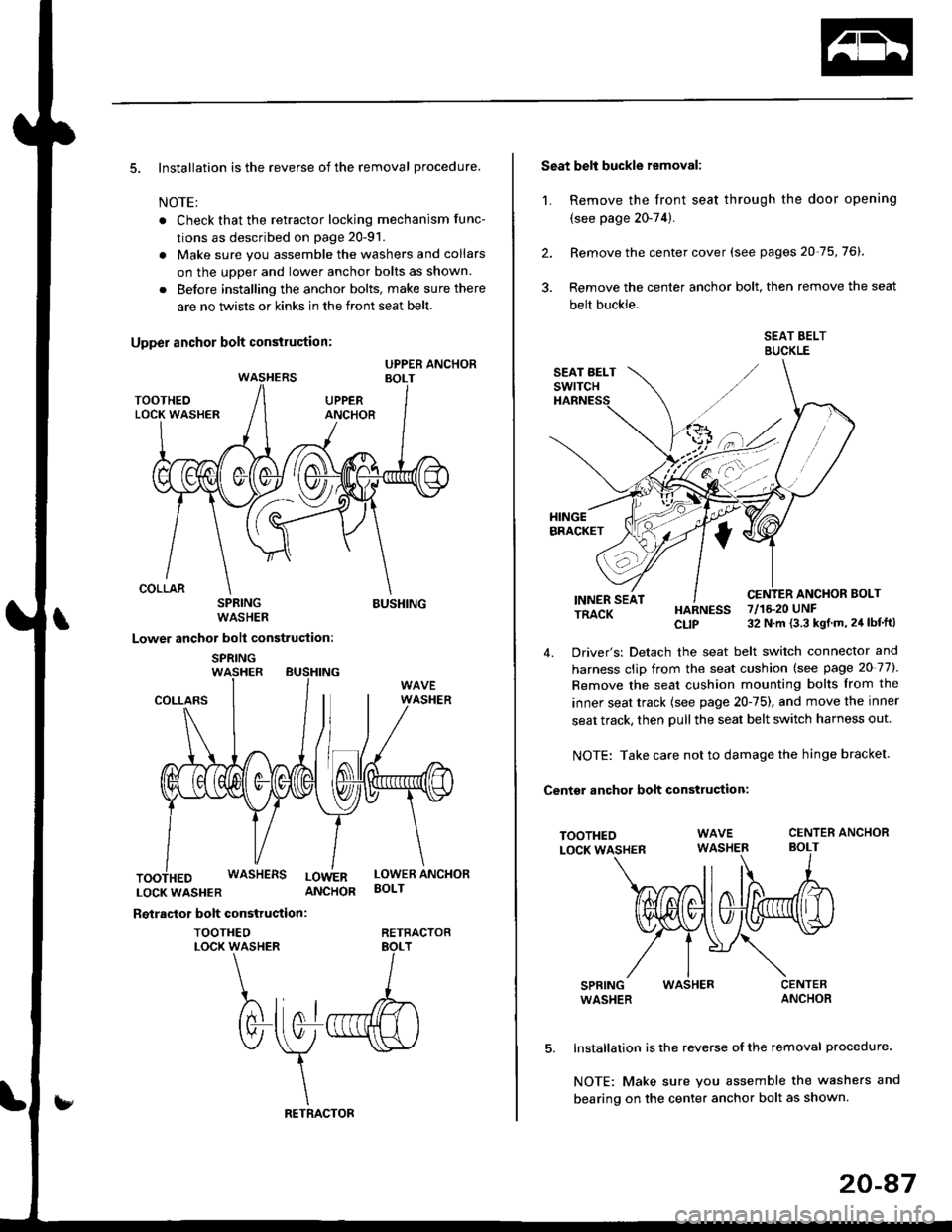

5. Installation is the reverse of the removal procedure.

NOTE:

. Check that the retractor locking mechanism func-

tions as described on page 20-91.

. Make sure you assemble the washers and collars

on the uoDer and lower anchor bolts as shown.

. Before installing the anchor bolts, make sure there

are no twists or kinks in the front seat belt.

SPRINGWASHER

Lower anchor bolt construction:

SPRINGWASHER BUSHING

BUSHING

COLLARS

LOCKWASHER ANCHOR

Reiractor bolt construction:

TOOTHEOLOCK WASHER

WASHERS LowERLOWER ANCHORBOLT

RETRACTOB

Seat belt buckle removal:

1. Remove the front seat through the door opening

{see page 20-74).

2. Remove the center cover (see pages 20-75,76).

3. Remove the center anchor bolt, then remove the seat

belt buckle.

SEAT BELTBUCKLE

ANCHOR BOLTINNER SEATTRACK

TOOTHEOLOCK WASHER

SPRINGWASHER

HARNESS 7/16.20 UNF

CLIP 32 N m (3.3 kgt m, 24 lbf'ft)

4. Driver's: Detach the seat belt switch connector and

harness clip from the seat cushion (see page 20 77).

Remove the seat cushion mounting bolts from the

inner seat track {see page 20-75), and move the inner

seat track, then pull the seat belt switch harness out.

NOTE: Take care not to damage the hinge bracket.

Centsr anchor bolt construction:

CENTER ANCHORBOLT

WASHER

Installation is the reverse of the removal procedure.

NOTE: Make sure you assemble the washers and

bearing on the center anchor bolt as shown.

20-47

Page 1355 of 2189

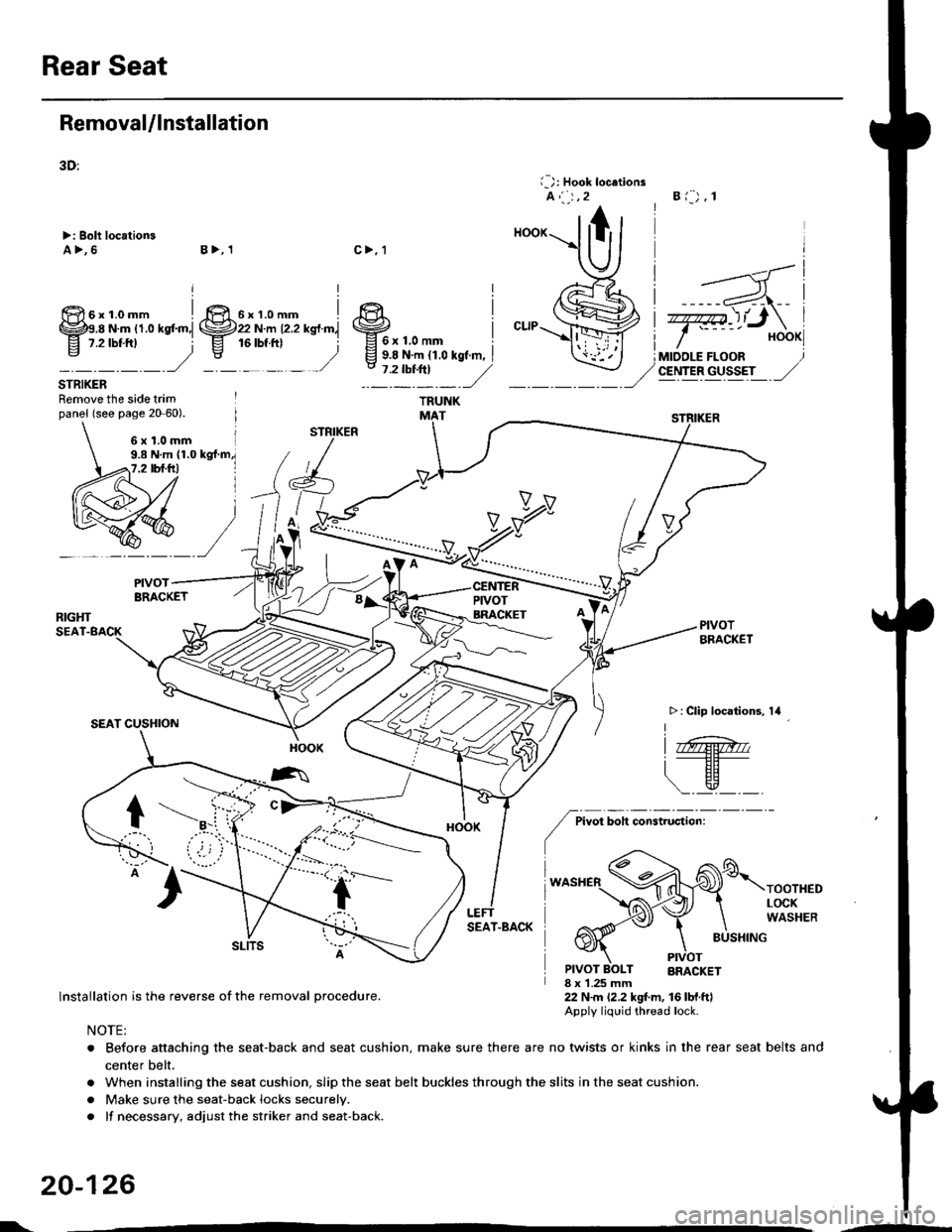

Rear Seat

RemovaUlnstallation

3D:

>: Bolt locationsa>,6

i_): Hook locations4i.,,2

c>, 1

Bt-;,1

T=ttJX,.)MIOOLE FLOORCENTER GUSSET

6x1.Omm9.8 N.m {1.07.2 tbt.trl

STRIKERRemove the side trimpanel (see page 20 60).

.2 tb,f.ft)

--::.........VV

STNIKER

>: Clip locations, 14

l@nIFF(EE

\qt

;*... 1PIVOTBRACKET

SEAT CUSHION

HOOK

A

c

Pivot boft con3truction:

TOOTXEDLOCKWASHERSEAT.BACK

A

Instailation is the reverse of the removal procedure.

NOTE:

. Before attaching the seat-back and seat cushion, make sure there are

center belt.

. When installing the seat cushion, slip the seat belt buckles through the

. Make sure the seat-back locks securely.

. lf necessary, adjust the striker and seat-back.

20-126

PIVOT BOLT BRACKET8 x 1.25 mm22 N.m 12,2 kgf,m, 16 lbl.ftlApply liquid thread lock.

no twists or kinks in the rear seat belts and

slits in the seat cushion.

iI

*nt.]

j

6x1.0mm9.8 N.m {1.0

B>,'t

I

-@e ' t.o.- |S=222 N.m 12.2 kg{.m,Ig 16 tbf.ft) j

:,/

I

I

Ifgf..,i

l

)

l---

Page 1356 of 2189

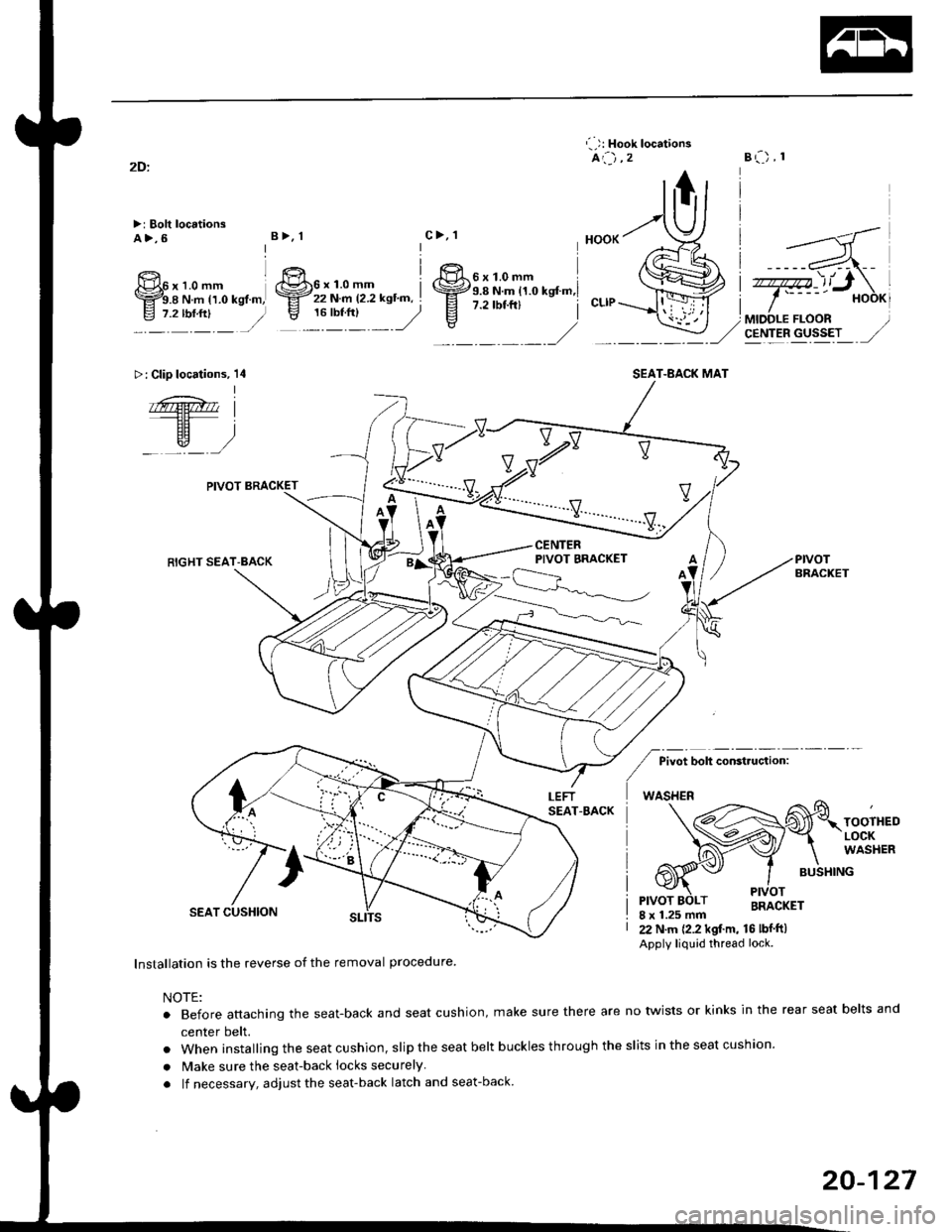

,-. ): Hook locations^(:).zB() ' t2D:

>: Bolt locationsA>,6c>,1B>. 1

6le

9rJ*'Ll-",-, i VH 16 rbr'frl ) g

,/v

6x1.omm i9.8 N.m 11.0 ksf.m,l7.2 rbf.ft) i

>: Clio locations, 14

PIVOT BRACKET

V

CENTER

RIGHT SEAT-BACK

LEFTSEAT-BACK

SEAT CUSHION

lnstallation is the reverse of the removal procedure.

NOTE:

. Before attaching the seat-back and seat cushion, make sure there are

center belt.

. When installing the seat cushion, slip the seat belt buckles through the

. Make sure the seat-back locks securely

. lf necessary, adjust the seat-back latch and seat-back

BUSHING

PIVOT BOLTBRACKET8 x 1.25 mm22 N.m {2.2 kgf.m, 16 lbIft)Apply liquid thread lock.

no twists or kinks in the rear seat belts and

slits in the seat cushion.

SEAT-AACK MAT

VV

TOOIHEDLOCKWASHER

PIVOT BRACKET

20-127

Page 1358 of 2189

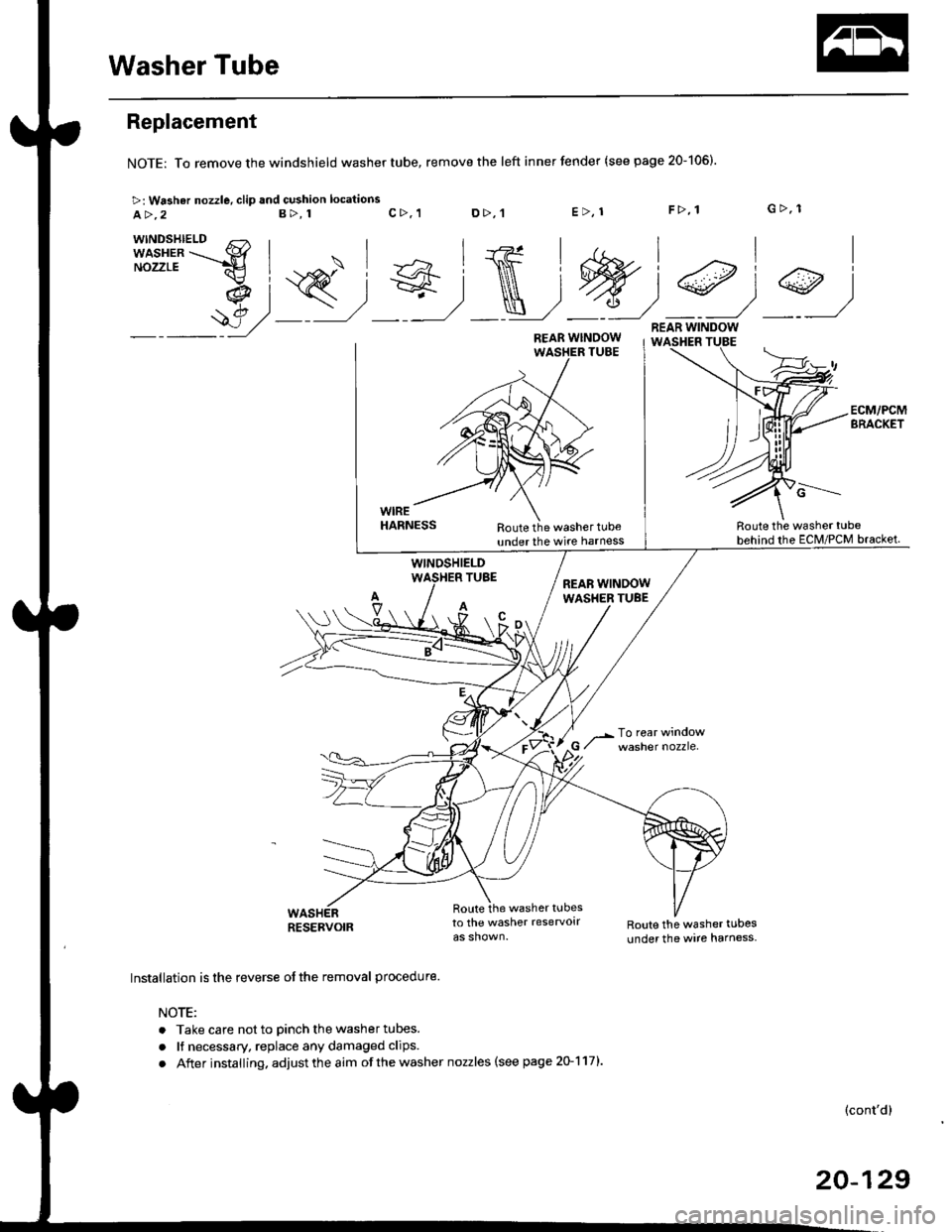

Washer Tube

Replacement

NOTE: To remove the windshield washer tube,

>: Washar nozzle, clip and cushion locations

a>,2B>, 1

remove the left inner fender (see page 20-106).

c>, 1 D>,'tE>, 1F>, 1 G>, 1

n,i#,T

I

9)

ECM/PCMBRACKET

WIREHARNESS

WINOSHIELDTUBE

A

Route the washer tubeunder the wire harnessRoute the washer tube

behind the EcM/PcM bracket.

(cont'd)

RESERVOIR

\/

Route the washer tubesto the washer reservolrRoute the washer tubes

under the wire harness.

Installation is the reverse of the removal procedure.

NOTE:

. Take care not to Dinch the washer tubes.

. lf necessary, replace any damaged clips.

. After installing, adjust the aim of the washer nozzles (see page 20-117l'

c-------.-

REAR WINDOWWASHER TUBE

20-129

Page 1447 of 2189

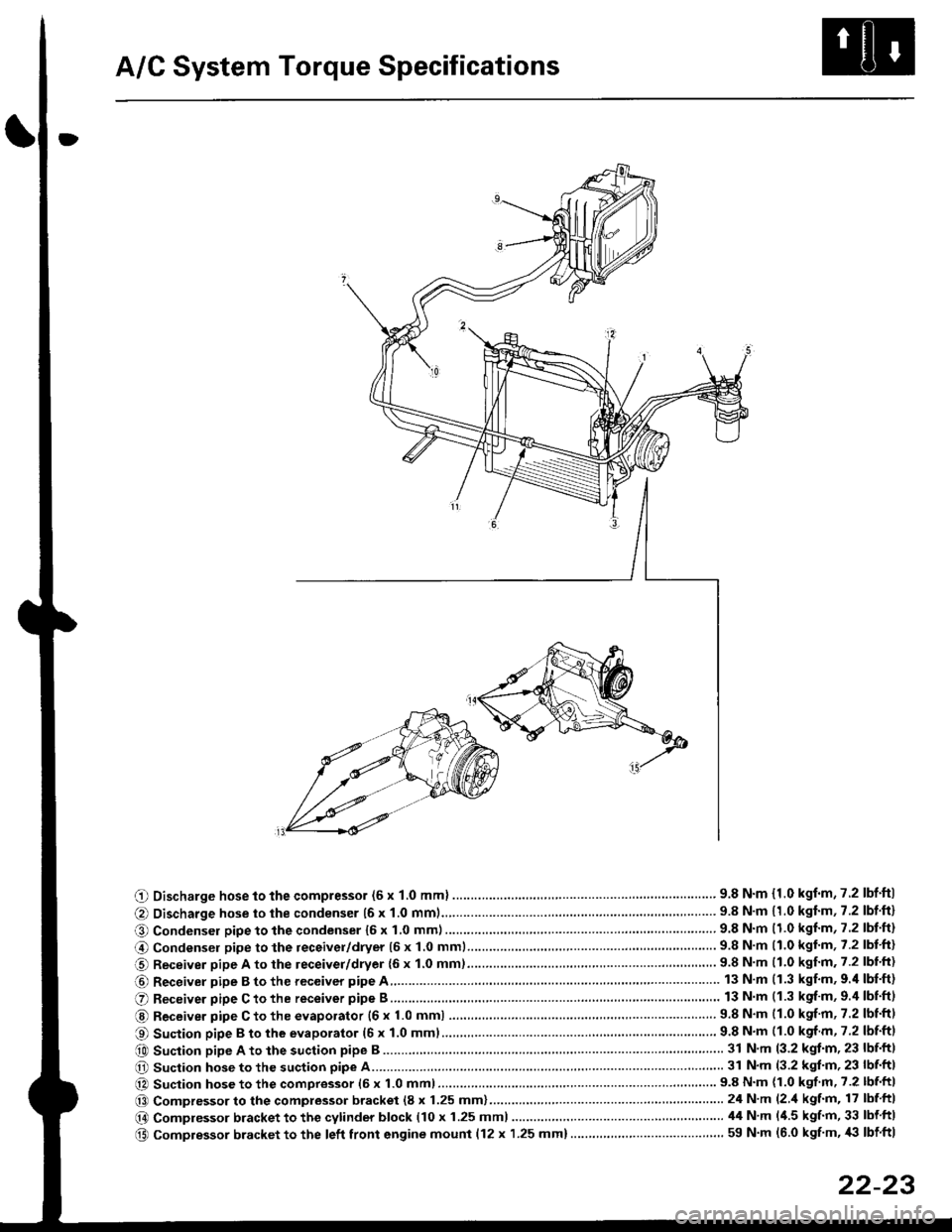

A/C System Torque Specifications

O Discharge hose to the compressor (6 x 1.0 mml ............... .. .... ...............' 9.8 N'm {1.0 kgf'm,7.2 lbf'ftl

@ Discharge hose to the condenser {6 x 1.0 mm1................... '... ...... . ......... 9.8 N'm 11.0 kgf'm, 7.2 lbf'ft}

O Condenser pipe to the condenser 16 x 1,0 mm)...............'. . . . ...........'..... 9.8 N'm (1.0 kgl'm, 7.2 lbt'ft)

@ Condensel pipe to the receivel/dryer (5 x 1.0 mml......... ..... . ... . '.......... 9.8 N'm (1.0 kgl'm, 7.2 lbt'ft)

O Receiver pipe A to the leceiver/dryer {6 x 1.0 mm)......... ... .......... .. . . .... 9.8 N'm 11.0 kgf'm. 7.2 lbl'ft)

@ Receiver pipe B to the receiver pipe A 13 N m (1.3 kgf'm, 9.'l lbf'ft)

O Receiver pipe C to the receiver pipe B 13 N m (1.3 kgf'm, 9.4 lbnftl

@ Receiver pipe C to the evaporator {6 x 1.0 mm) ....... 9.8 N'm (1.0 kgf'm, 7.2 lbtftl

O Suction pipe B to the evaporator (6 x 1.0 mml................ . .........'......'....... 9.8 N'm (1.0 kgf m, 7.2 lbf'ftl

e0 Suction pipe A to the suction pipe B ...'. . ...... . ... ...... 31 N'm (3.2 kgt'm, 23 lbf'ftl

O Suction hose to the suction pipe A... ............ . . '......... 31 N'm (3.2 kgl'm, 23 lbf'ft|

@ Suction hose to the compressor (6 x 1.0 mm)................... .. . ... .. ............ 9.8 N'm (1.0 kgf'm' 7.2 lbf'ft|

@@ Compressor to the compressor bracket (8 x 1.25 mm)... ..-........'.'......-.......24 N'm (2 'l kgf'm, 17 lbf ftl

@ Compressor bracket to the cytinder block (10 x 1.25 mml 44 N'm l'1.5 kgf'm, 33 lbf ftl

@ Compressor bracket to the left front engine mounl {12 x 1.25 mm}..... . . . . .. ................. ... ... 59 N'm (6.0 kgf'm, '|i} lbf ftl

22-23

Page 1455 of 2189

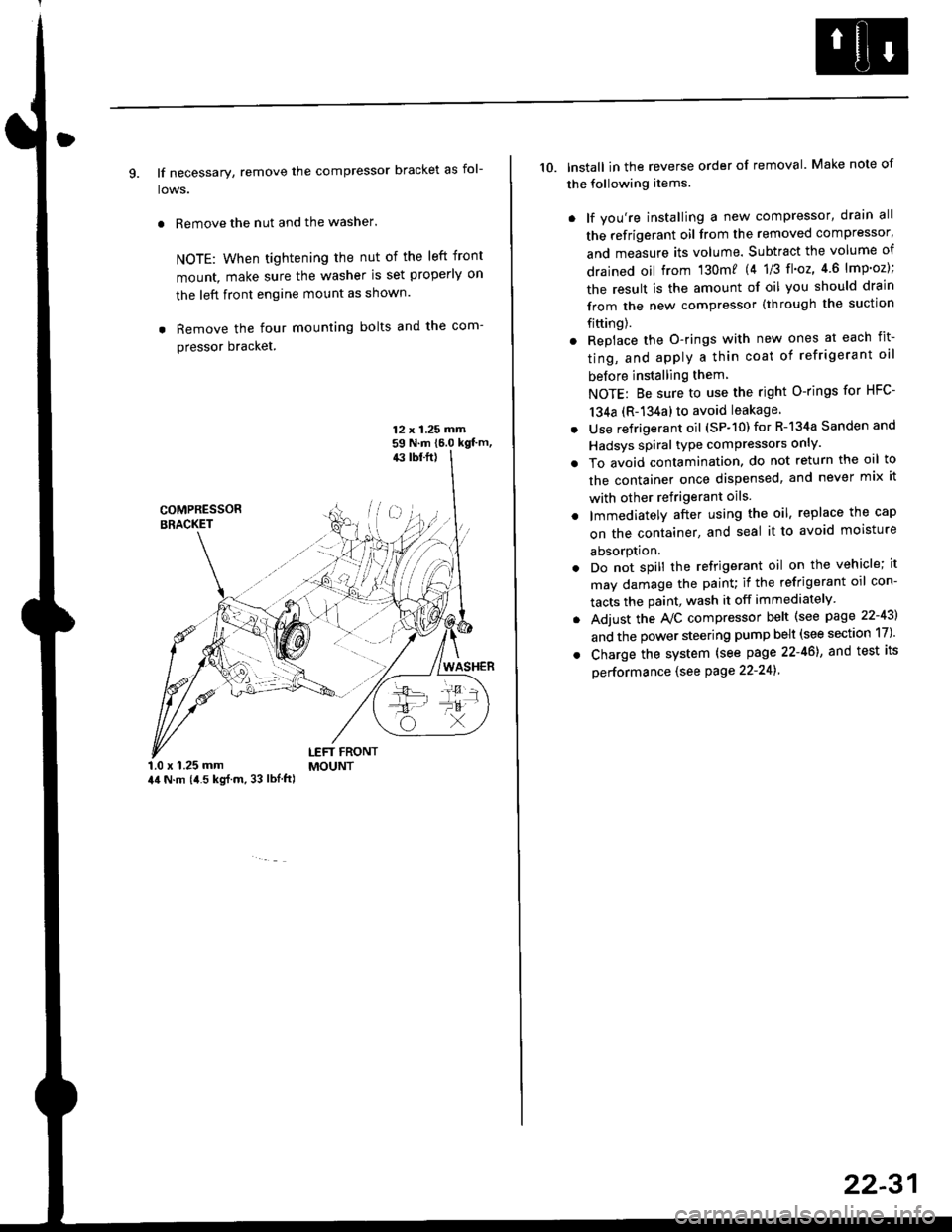

9. lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer.

NOTE: When tightening the nut of the left front

mount, make sure the washer is set properly on

the left front engine mount as shown.

. Remove the four mounting bolts and the com-

pressor bracket.

12 x 1.25 rrirn59 N.m 16.0 kgt'm,43 tbf.ft)

COMPRESSORBRACKET

WASHER

1.0 x 1.25 mm44 N.m (i1.5 kg{.m, 33 lbl.ft)

LEFT FRONTMOUNT

10. lnstall in the reverse order of removal. Make note of

the following items.

. lf you're installing a new compressor, drain all

the refrigerant oil from the removed compressor,

and measure its volume. Subtract the volume of

drained oil from '130m? 14 1/3 tl'o2,4 6 lmp'oz);

the result is the amount of oil you should drain

from the new compressor (through the suction

fifting).

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them

NOTE: Be sure to use the right O-rings for HFC-

134a (R-134a) to avoid leakage

. Use refrigerant oil (SP-10) for R-134a Sanden and

Hadsys spiral type compressors only'

o To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediatelY after using the oil, replace the cap

on the container, and seal it to avoid moisture

absorption.

. Do not spill the refrigerant oil on the vehicle; it

may damage the painu if the refrigerant oil con-

tacts the paint, wash it off immediately

. Adjust the Ay'C compressor belt (see page 22-43)

and the power steering pump belt (see section 17)'

. Charge the system (see page 22-46), and test its

oerformance (see Page 22-241

22-31

Page 1461 of 2189

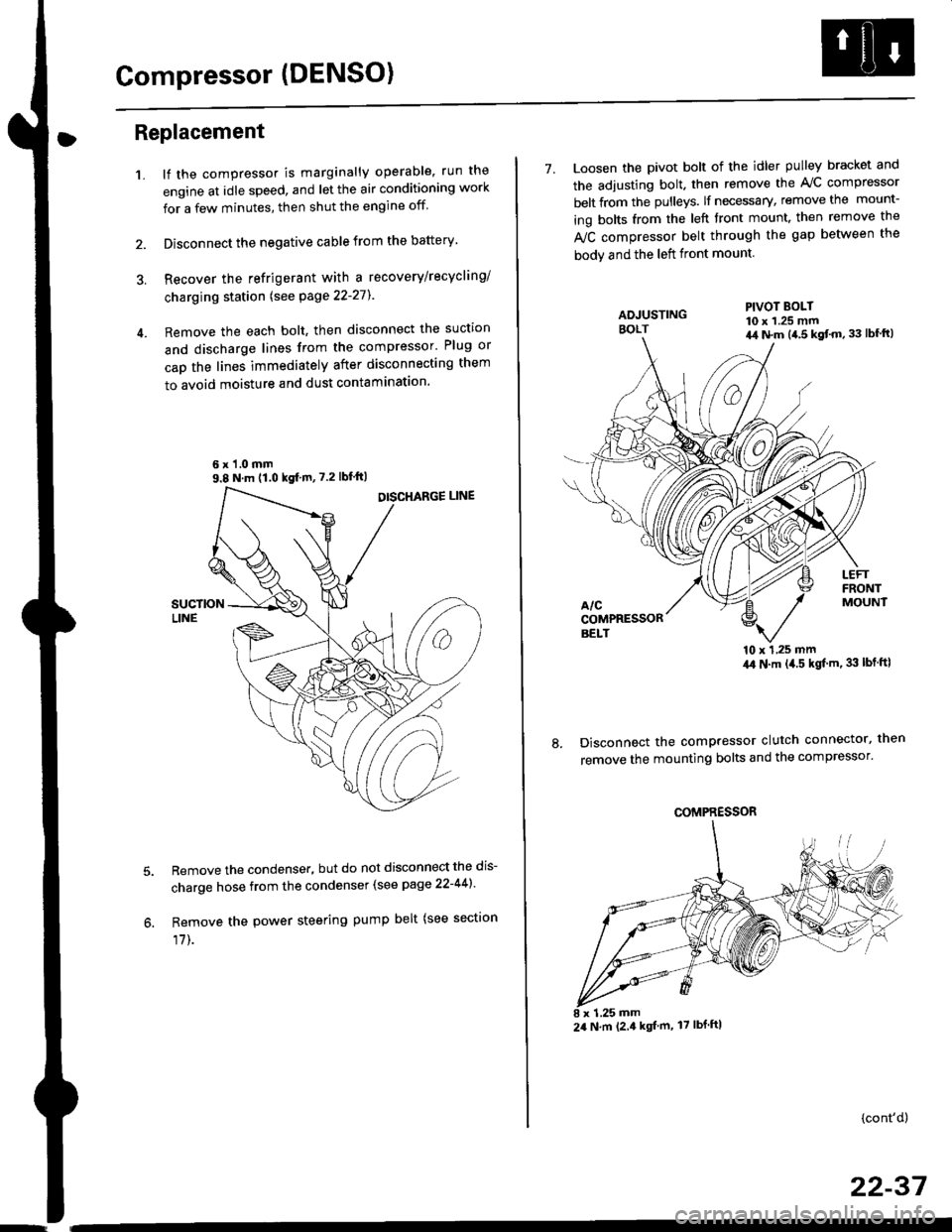

Compressor (DENSO)

Replacement

1.lf the compressor is marginally operable, run the

engine at idle speed, and let the air conditioning work

for a few minutes, then shut the engine off

Disconnect the negative cable from the battery'

Recover the refrigerant with a recovery/recycling/

charging station lsee page 22-271

Remove the each bolt, then disconnect the suction

and discharge lines from the compressor' Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contaminatlon.

6 x '1.0 mm9.8 N.m (1.0 kgf m,7.2 lbfft)

Remove the condenser, but do not disconnect the dis-

charge hose from the condenser (see page 22-441'

Remove the power steering pump belt (see sectron

17]-.

7. Loosen the pivot bolt of the idler pulley bracket and

the adjusting bolt. then remove the A,/C compressor

belt from the pulleys. lf necessary, remove the mount-

ing bolts from the left front mount. then remove the

fuC compressor belt through the gap between the

bodv and the left front mount.

'10 x 1,25 mm4,0 N.m (,1.5 kgf'm. 33 lbt ftl

Disconnect the compressor clutch connector, then

remove the mounting bolts and the compressor'

PIVOT BOLT10 x 1.25 mm4,1 N.m (4.5 kgt'm,33 lbfft)

COMPRESSOR

24 N.m (2.4 kgf m, 17 lbf ftl

(cont'd)

22-37

Page 1462 of 2189

Compressor (DENSOI

Replacement (cont'd)

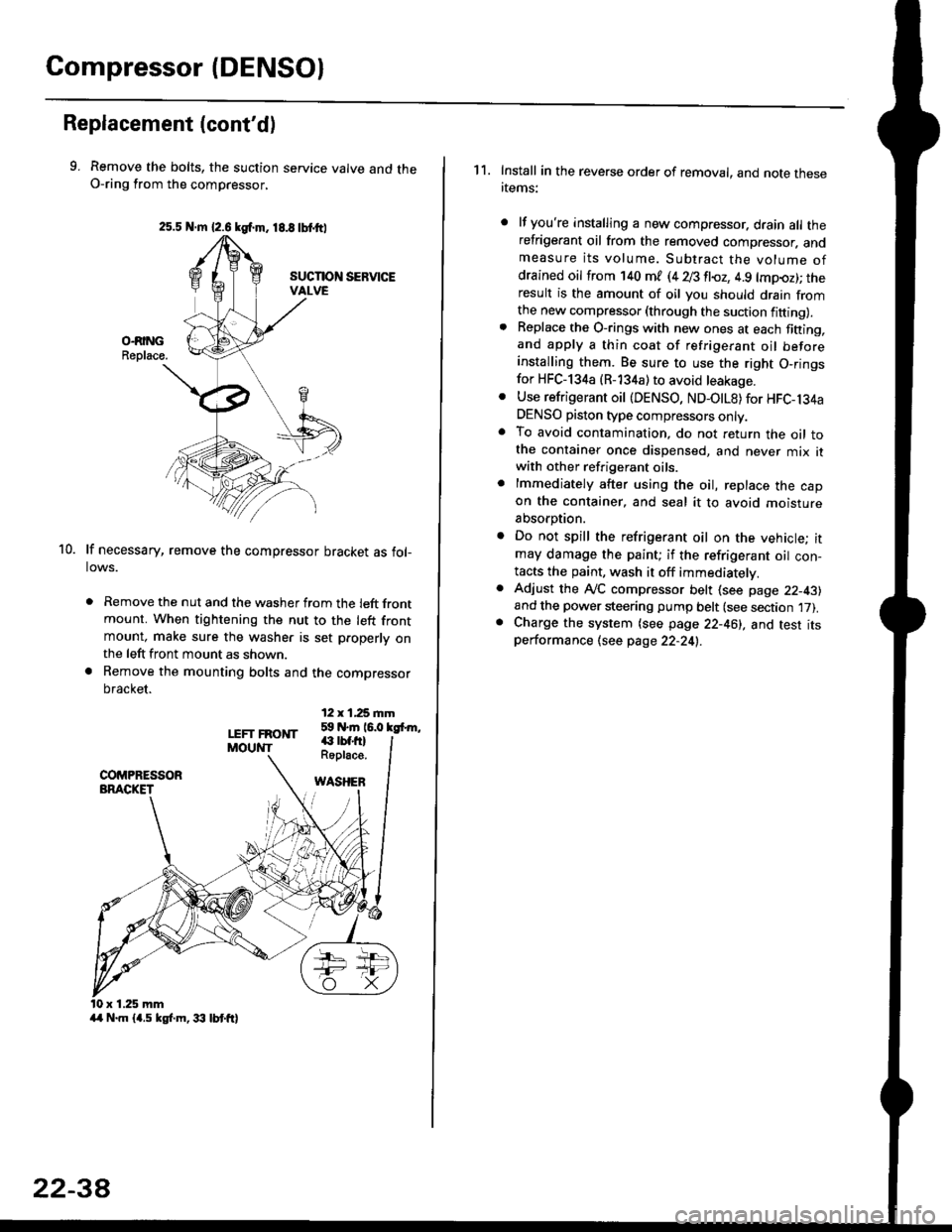

9. Remove the bolts, the suction service valve and theO-ring from the compressor,

lf necessary, remove the compressor bracket as fol-lows.

. Remove the nut and the washer from the left frontmount. When tightening the nut to the left frontmount, make sure the washer is set p.operly onthe left front mount as shown.

a Remove the mounting bolts and the compressor

bracket.

12 x 1,25 rnm59 N.m 16.0 kgfrm,

10.

LEFT FRONTMOUNT€ rbf.fi)Roplace.

WASHEB

x 1.25 mm

2s.5 N.m {2.6 kgf.m. 18.8 tbtttl

4/r N.m {4.5 kgf.m, 33 lbt ft}

22-3A

1 1. Install in the reverse order of removal, and note thesertems:

lf you're installing a new compressor. drain all therefrigerant oil from the removed compressor. andmeasure its volume. Subtract the volume ofdrained oil from '140 ml (4 28 fl{,z, 4.9 lmpoz); theresult is the amount of oil you should drain fromthe new compressor (through the suction fifting).Replace the O-rings with new ones at each fining,and apply a thin coat of refrigerant oil beforeinstalling them. Be sure to use the right O,ringsfor HFC-134a (R-134a) to avoid leakage.

Use refrigerant oil {DENSO, ND-OtL8) for HFC-134aDENSO piston type compressors only.To avoid contamination, do not return the oil tothe container once dispensed, and never mix itwith other refrigerant oils.

lmmediately after using the oil, replace the capon the container, and seal it to avoid moisture

absorption.

Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediatelv.

Adjust the ly'C compressor belt (see page 22-43)and the power steering pump belt (see section 17).Charge the system (see page 22-46), and test itsperformance (see page 22-24!..

Page 1467 of 2189

A/G GomPressor Belt

Adjustment

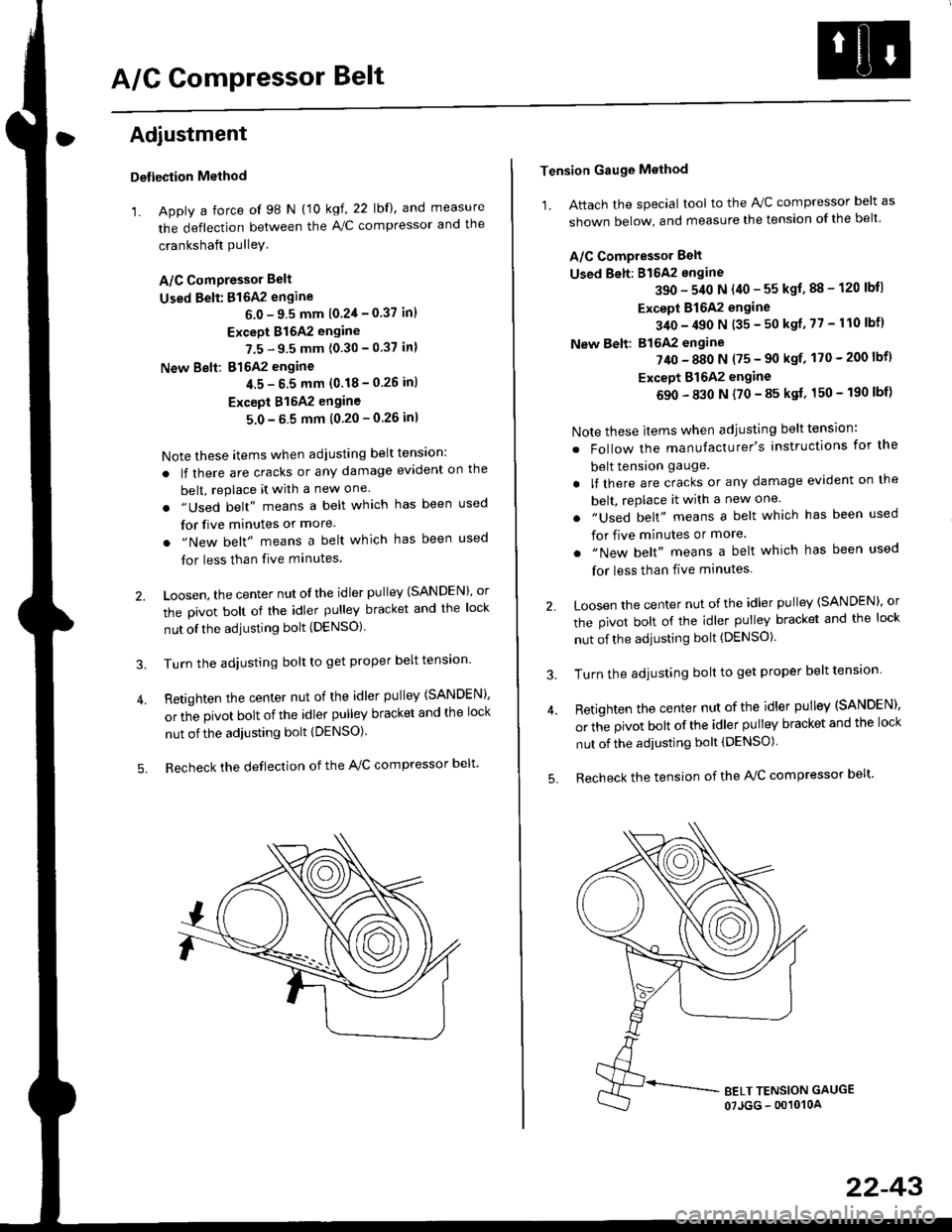

Detlection Method

'1. Apply a force of 98 N (10 kgf, 22 lbf), and measure

the deflection between the A,/C compressor and the

crankshaft PulleY

A/C ComPressor Belt

Used Belt: 816A2 engine

6.0 - 9.5 mm 10 2'l - 0.37 inl

Except 816A2 engine

7.5 - 9.5 mm (0.30 - 0.37 in)

New Belt: 816A2 engine

4.5- 6 5 mm (0.18-0.26 in)

Except 815A2 engine

5.0-5 5 mm (0.20-0.26 inl

Note these items when adjusting belt tens'on:

. lf there are cracks or any damage evident on the

belt, replace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

tor less than five minutes.

2. Loosen, the center nut ofthe idler pulley (SANDEN), or

the pivot bolt of the idler pulley bracket and the lock

nut ofthe adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension'

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

5. Recheck the deflection of the A,/C compressor belt'

Tension Gauge Method

1. Attach the special tool to the IVC compressor belt as

shown below, and measure the tension of the belt

A/C Compressor Belt

Used Belt: 816A2 engine

390 - 540 N (40 - 55 kgf, 88 - 120 lbll

Except 816A2 engine

340 - 490 N (35 - 50 ksf, 77 - 110 lbfl

New Belt: B16A2 engine

?40 - 880 N {75 - 90 ksf' 170 - 200 lbf)

Except Bl642 engine

690 - 830 N (70 - 85 ksf, 150 - 190 lbf)

Note these items when adjusting belt tension:

. Follow the manufacturer's instructions for the

belt tension gauge.

. lf there are cracks or any damage evident on the

belt, rePlace it with a new one.

. "Used belt" means a belt which has been used

for five minutes or more.

. "New belt" means a belt which has been used

for less than five minutes

2 Loosen the center nut of the idler pulley (SANDEN)' or

the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO).

3. Turn the adjusting bolt to get proper belt tension

4. Retighten the center nut of the idler pulley (SANDEN),

or the pivot bolt of the idler pulley bracket and the lock

nut of the adjusting bolt (DENSO)

5. Recheck the tension of the A/C compressor belt'

22-43