Face HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1334 of 2189

Door and Side Moldings

Replacement (cont'dl

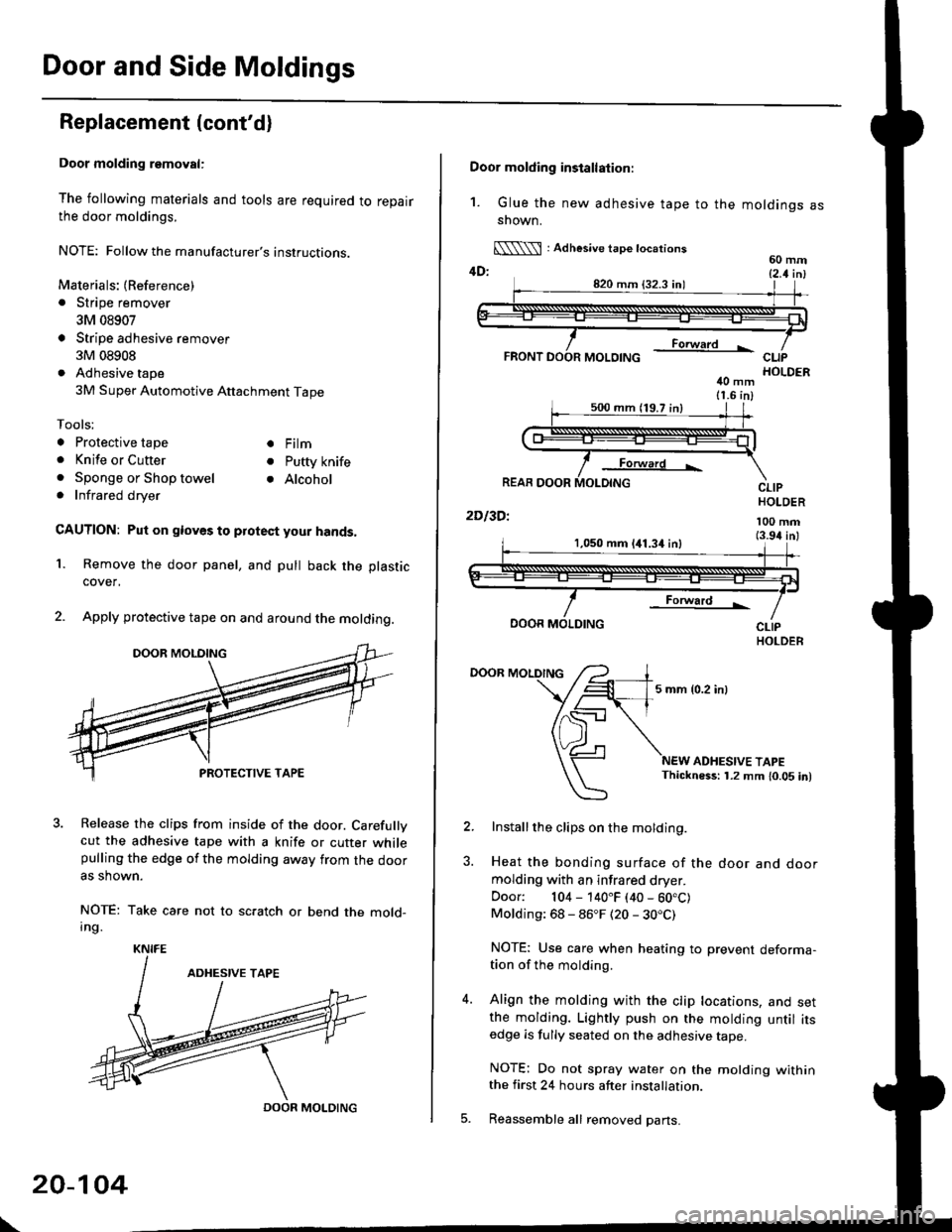

Door molding removal:

The following materials and tools are required to repairthe door moldings.

NOTE: Followthe manufacturer's instructions.

Materials: (Reference)

. Stripe remover

3M 08907

Stripe adhesive remover

3M 08908

Adhesive tape

3M Super Automotive Attachment Tape

Tools;

a Protective tape

. Knife or Cutter

. Sponge or Shop towel. Infrared dryer

. Film

. Putty knife

. Alcohol

CAUTION: Put on gloves to protect your hands,

Remove the door panel, and pull back the plastic

cover,

Apply protective tape on and around the molding.

3. Release the clips from inside of the door. Carefullvcut the adhesive tape with a knife or cutter whilepulling the edge of the molding away trom the dooras shown.

NOTE: Take care not to scratch or bend the mold-Ing.

1.

KNIFE

DOOR MOLDING

\

20-104

Door molding installation:

1. Glue the new adhesive tape to the moldings assnown.

[\\\l : Adhesive tape tocations60 mm4D: t2 t i^l

40 mm11.6 in)

Forward L

REAR DOOR

2Dl3Dl

CLIPHOLDER

100 mm(3.94 inl1,050 mm 141.34 inl

Forward !

DOOR MOLDING

DOOR MOLDING

5 mm {0.2 inl

ADHESIVE TAPEThickness: 1.2 mm 10.05 in)

Installthe clips on the molding.

Heat the bonding surface of the door and doormolding with an infrared dryer.

Door: 104 - 140"F (40 - 60.C)Molding: 68 - 86"F (20 - 30.C)

NOTE: Use care when heating to prevent deforma-tion of the molding.

Align the molding with the clip locations, and setthe molding. Lightly push on the molding until itsedge is fully seated on the adhesive tape.

NOTE: Do not spray water on the motding withinthe first 24 hours after installation.

Reassemble all removed pans.

Page 1336 of 2189

Inner Fender, Fenderwell rrim, Fuel Pipe protector and Rear

Air Outlet

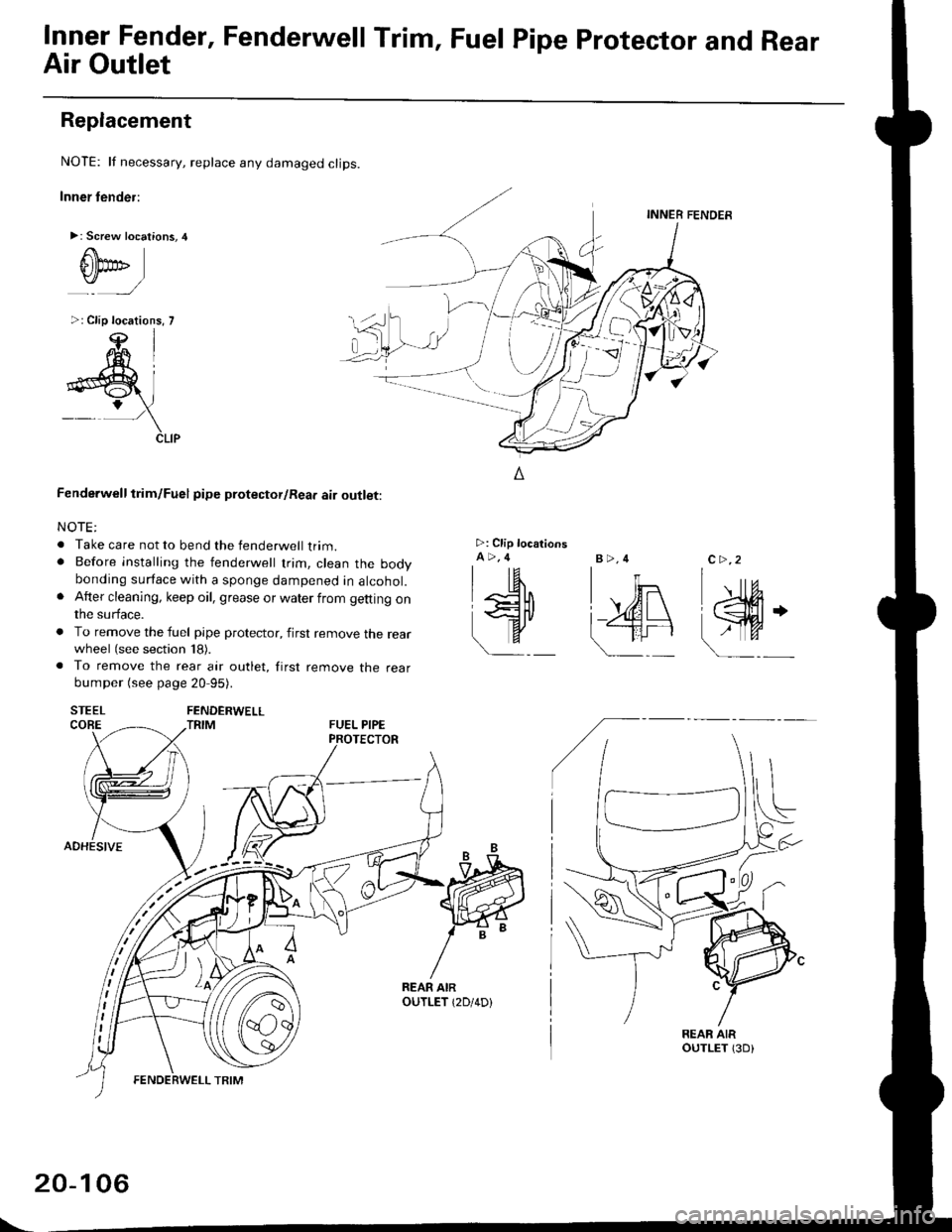

Replacement

NOTE: lf necessary, replace any damaged clips.

Inner tender:

>: Screw locations,4

r\

tllpo" l:,/

>: Clip locations, 7

Fenderwell trim/Fuel pipe protector/Rea. air outlet:

NOTE:

. Take care not to bend the fenderwell trim.. Before lnstalling the fenderwell trim, clean the bodybonding surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease or water from getting onthe surface.

. To remove the fuel pipe protector, first remove the rearwheel (see section 18).. To remove the rear air outlet, first remove the rearbumper (see page 20 95).

STEEL FENDERWELL

>: Clip locationsA>,4B>,4

l;1A

!--l1!

c >,2

I

tAh'frv

\:

+

\-

20-106

Page 1348 of 2189

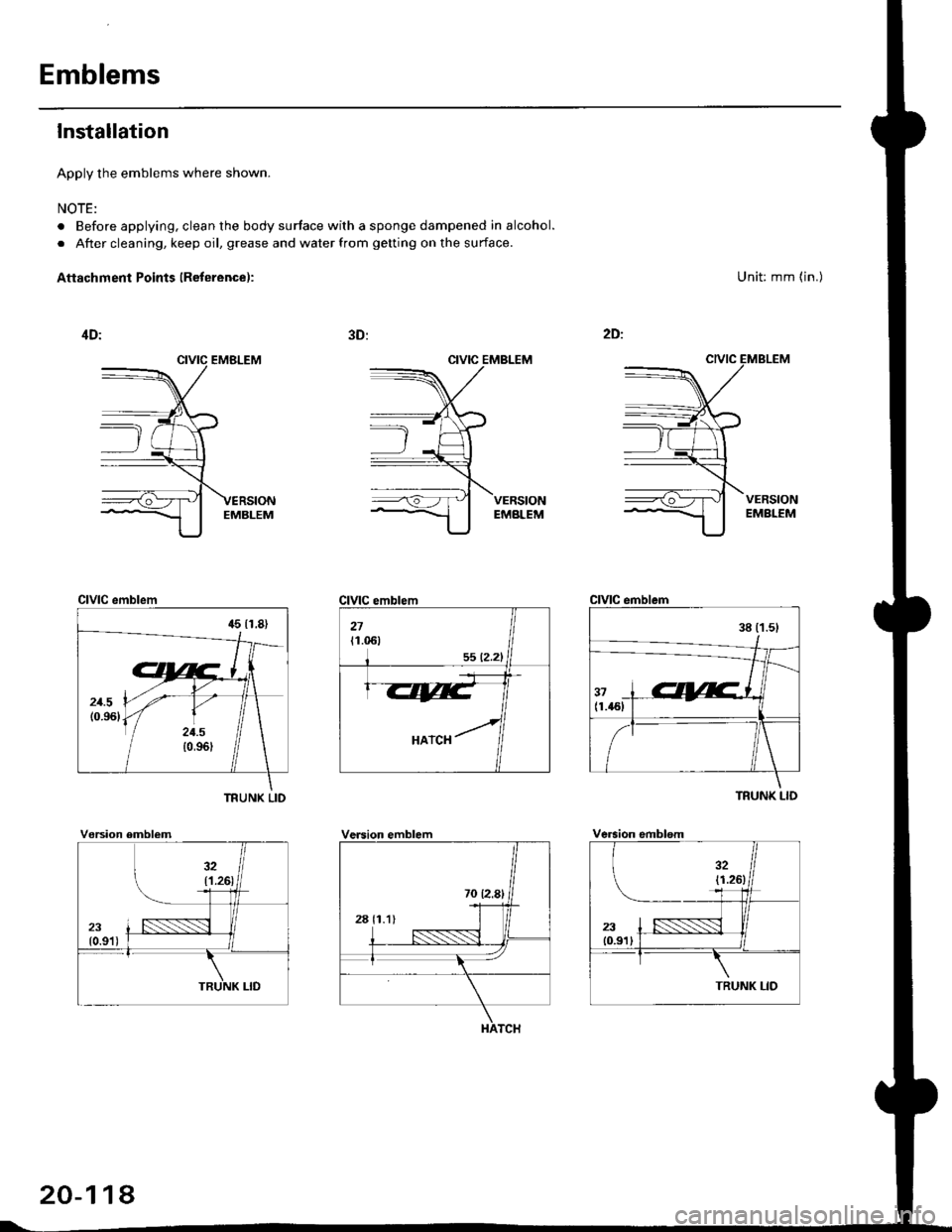

Emblems

Installation

Apply the emblems where shown.

NOTE:

. Before applying, clean the body surface with a sponge dampened in alcohol.

. After cleaning, keep oil, grease and water from getting on the surface.

Aftachment Points (Reterence):

CIVIC EMBLEM

Unit: mm (in.)

CIVIC emblem

TFUNK LID

CIVIC emblem

TRUNK LID

Vorsion emblemVersion emblemVersion emblsm

20-114

Page 1369 of 2189

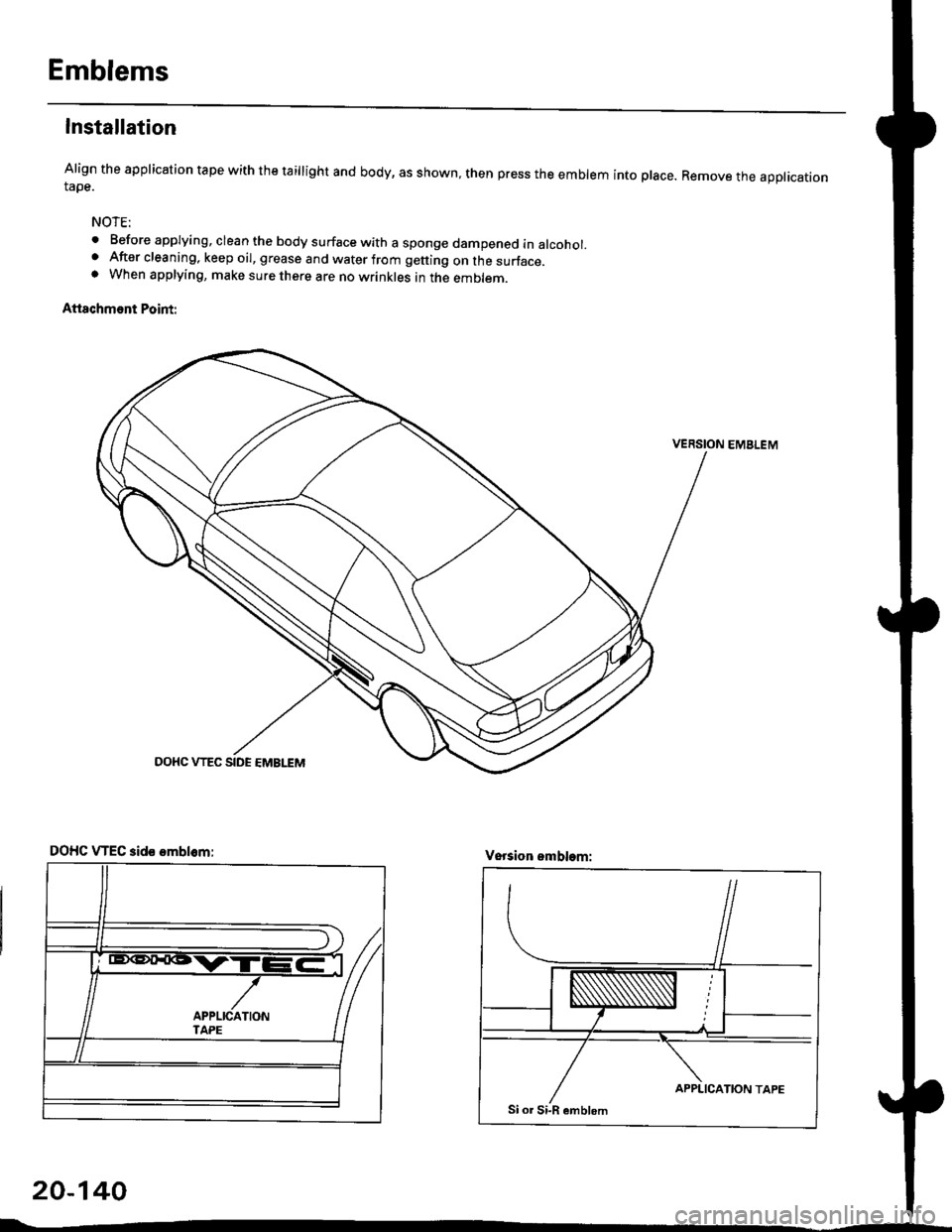

Emblems

Installation

Align the application tape with the taillight and body, as shown, then press the emblem into place. Remove the appticationtape.

NOTE:

o Before applying, clean the body surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease and water from getting on the surface.. When applying, make sure there are no wrinkles in the emblem.

Attschment Point:

VERSION EMBLEM

20-140

DOHC VTEC aid€ omblom:Vsrsion emblem:

Page 1373 of 2189

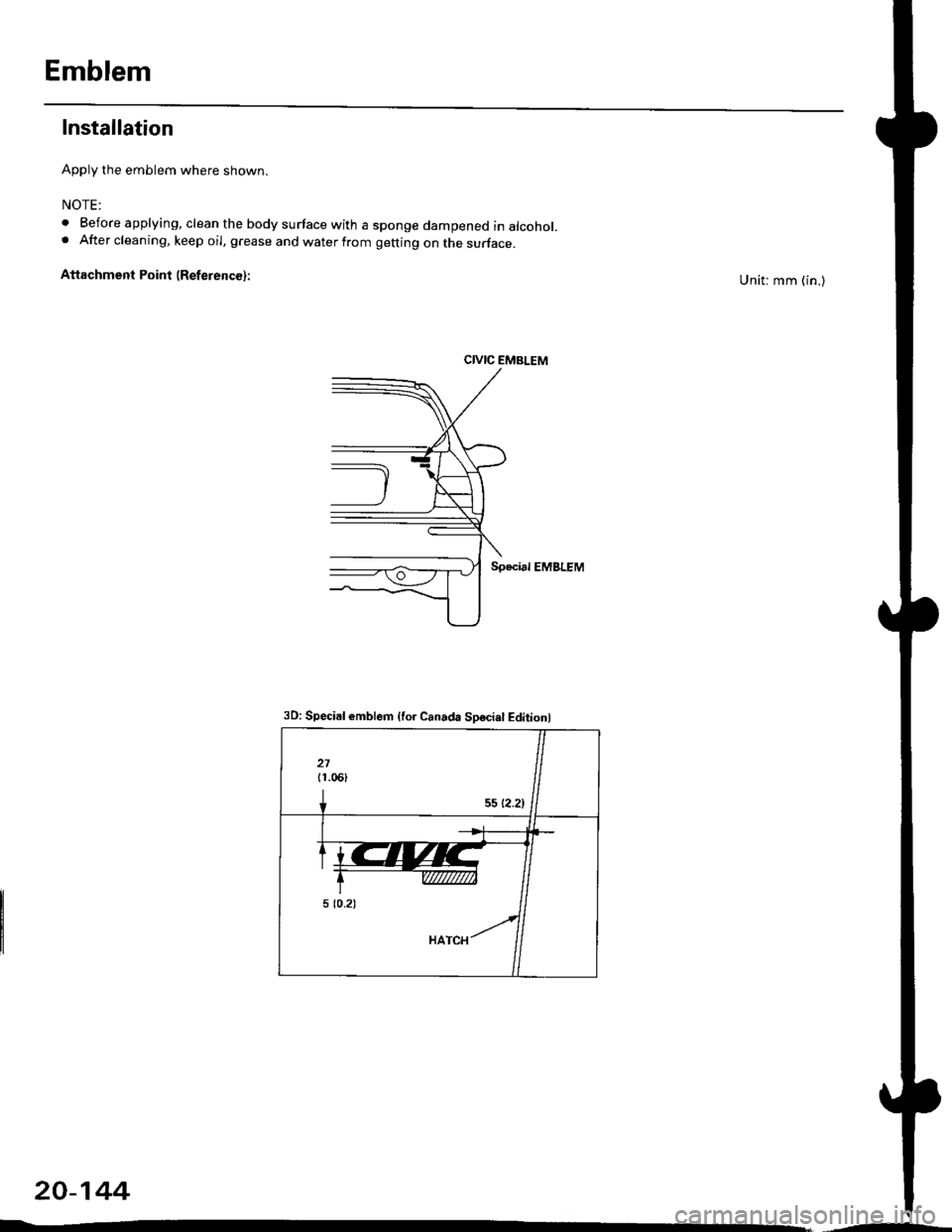

Emblem

Installation

Apply the emblem where shown.

NOTE:

. Before applying, clean the body surface with a sponge dampened in alcohol.. After cleaning, keep oil, grease and water from getting on the surface.

Attachment Point (ReferencG):Unit: mm (in,)

CIVIC EMBLEM

Special EMBLEM

20-144

3D: Special emblem {for Canada Sosciel Editionl

Page 1375 of 2189

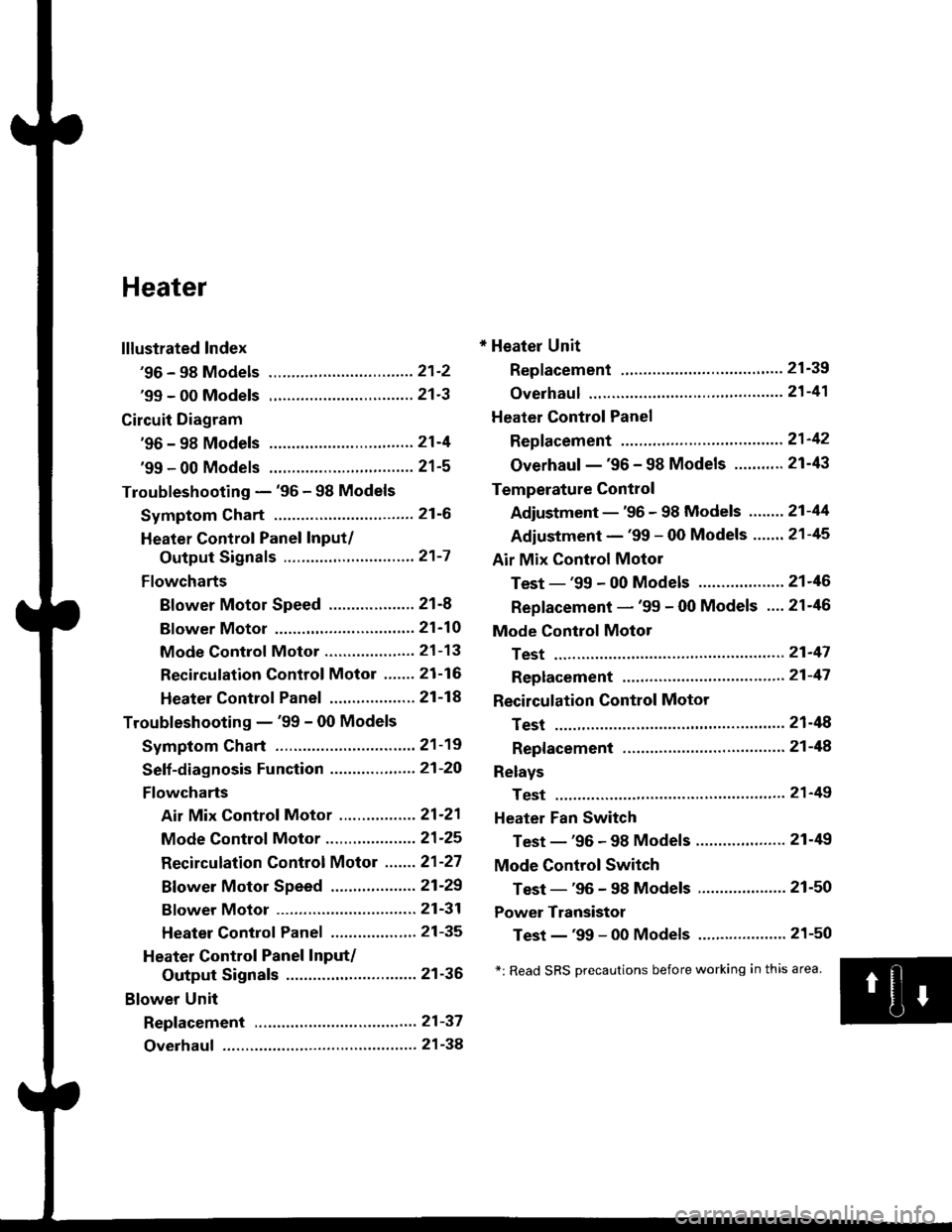

Heater

lllustrated Index

'96 - 98 Models ................................ 21'2

'99 - 00 Models ................................ 21'3

Circuit Diagram

'96 - 98 Models .....21-4

'99 - 00 Models ................................ 21-5

Troubleshooting - '96 - 98 Models

Symptom Chart ............................... 21-6

Heater Control Panel Input/

Output Signals ..............,.............. 21-7

Flowcharts

Blower Motor Speed ................... 21-8

Bf ower Motor ,...21'10

Mode Control Motor ............... ,.'.' 21-13

Recirculation control Motor ....... 21-16

Heater Control Panel ................ ... 21 -14

Troubleshooting - '99 - 00 Models

Symptom Chart ............................... 21-19

Seff-diagnosis Function ............,,,.... 21-20

Flowcharts

Air Mix Control Motor ......,.......... 21-21

Mode Control Motor ............... ..... 21 -25

Recirculation Control Motor ....... 21-27

Bf ower Motor Speed .............. .....21'29

Bf ower Motor ....21-31

Heater Control Panel ................,.. 21-35

Heater Control Panel Input/

Output Signals ............................. 21-36

Blower Unit

Repf acement .........21-37

Overhaul ................ 21-38

* Heater Unit

Replacement ....'....21-39

overhaul """" """' 21-4'l

Heater Control Panel

Repfacement .........21'42

Overhaul -'96 - 98 Models ........... 21-43

Temperature Control

Adjustment - '96 - 98 Models """" 21-44

Adiustment - '99 - 00 Models .......21-45

Air Mix Control Motor

Test - '99 - 00 Models ...........' .......21'46

Replacement - '99 - 00 Models ....21'46

Mode Control Motol

Test ................, .,...'.21'47

Replacement '.'."...21-47

Recirculation Control Motor

Test ................. .......21-48

Repf acement ......." 21-48

Relays

Test ................. .......2'l-49

Heater Fan Switch

Test - '96 - 98 Models ............. .......21-49

Mode Control Switch

Test -'96 - 98 Models ..........."....... 21-50

Power Transistor

Test - '99 - 00 Models ....'........ ....".21-50

*: Read SRS Drecautions before working in this area.

Page 1425 of 2189

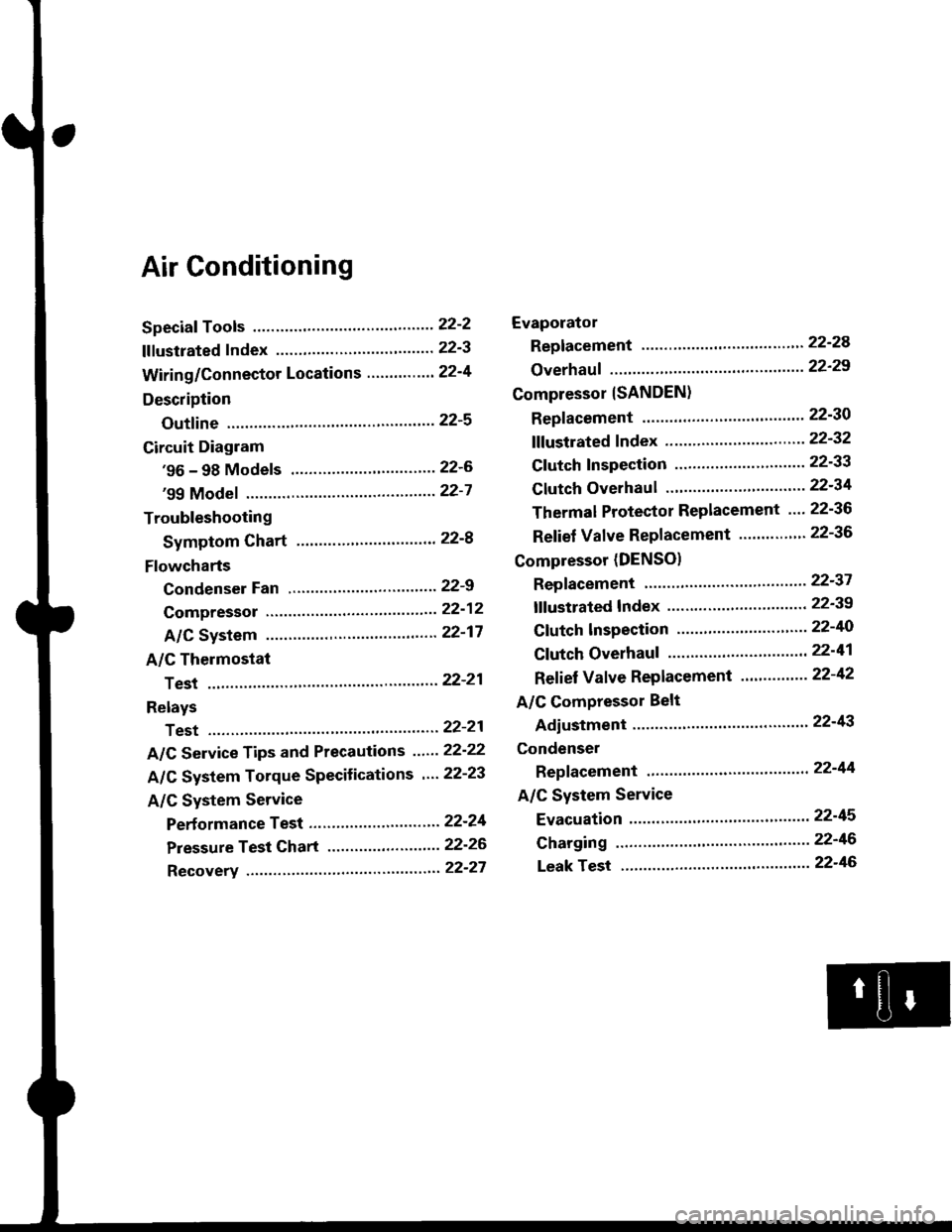

Air Conditioning

Speciaf Tools ......'.....' 22-2

f f f ustrated f ndex ......................... ".......' 22-3

Wiring/Connector Locations'.........'.... 22'4

Description

Outfine ............ .......22-s

Circuit Diagram

'96 - 98 Models ......"..........".......'.... 22-6

'99 Modef """""""' 22-7

Troubleshooting

Symptom Chart ".'......""................. 22-8

Flowcharts

Condenser Fan .........".................,..'. 22-9

Compressor .....""" 22-12

A/C System .........'.22'17

A/C Thermostat

Test ........'.......' """'22'21

Relays

Test ....."'......... ..""'22-21

A/C Service Tips and Precautions ......22-22

A/C System Torque Specifications '...22-23

A/C System Service

Performance Test ... '."......... ".... ....'..22-24

Pressure Test Chart .................. .... "' 22-26

Recovery ...".........," 22-27

Evaporator

Replacement .....",' 22'24

Overhauf .....-.....""' 22'29

Compressor {SANDEN}

Repf acement ......'.' 22-30

fffustrated fndex ......"..................'.... 22'32

Cf utch Inspection ......... "............ ...... 22-33

Clutch Overhau I ........................ ....... 22-34

Thermal Protector Replacement .... 22-36

Relief Valve Replacement ......'..."". 22-36

Compressor (DENSO)

Repfacement ..""',' 22-37

lf lustrated Index ............................... 22-39

Clutch lnspection ............."'...... "'.... 22-40

Cf utch Overhaul .....................'......... 22-41

Ref ief Valve Replacement'..'......"'.. 22-42

A/C Compressor Belt

Adiustment ............22'43

Condenser

Repfacement .......,,22'44

A/C System Service

Evacuation ...,,,.......22-45

Charging '..........--'..22'46

Leak rest """""""'22-46

Page 1459 of 2189

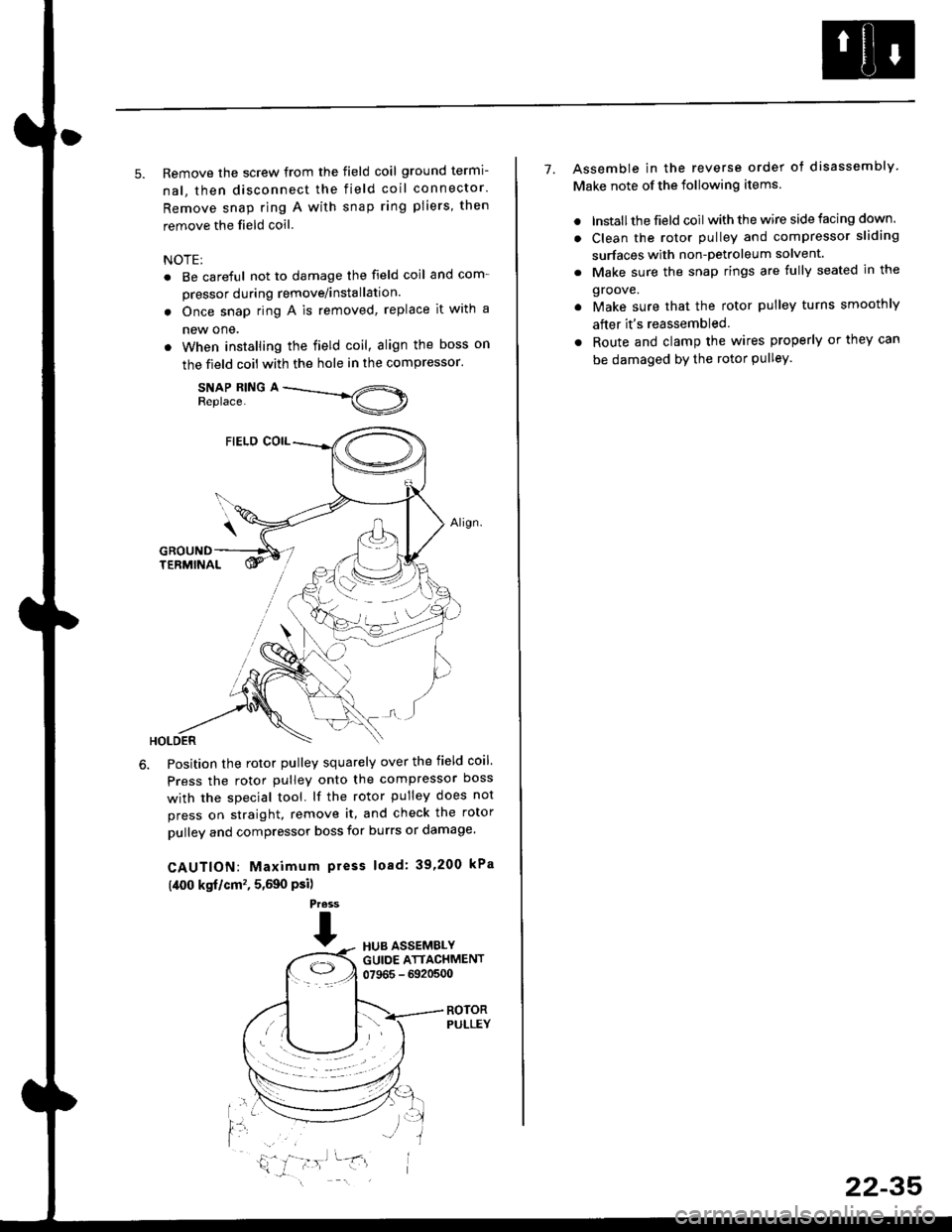

5. Remove the screw from the field coil ground termi-

nal, then disconnect the field coil connector.

Remove snap ring A with snap ring pliers, then

remove the field coil

NOTE:

. Be careful not to damage the field coil and com-

pressor during remove/installation.

. Once snap ring A is removed, replace it with a

new one.

. When installing the field coil, align the boss on

the field coil with the hole in the compressor.

SNAP RING AReplace.

Position the rotor pulley squarely over the field coil.

Press the rotor pulley onto the compressor boss

with the special tool. lf the rotor pulley does not

press on straight, remove it, and check the rotor

pulley and compressor boss for burrs or damage.

CAUTION: Maximum press load: 39,200 kPa

(,[00 kgf/cm'�, 5,590 Psi)

Press

THUB ASSEMBLYGUIDE ATTACHMENT07965 - 6920500

ROTORPULLEY

t'l

i,'

7. Assemble in the reverse order of disassembly

Make note of the following items.

. lnstall the field coil with the wire side facing down.

. Clean the rotor pulley and compressor sliding

surfaces with non-petroleum solvent.

. Make sure the snap rings are fully seated in the

groove.

. Make sure that the rotor pulley turns smoothly

after it's reassembled

. Route and clamp the wires properly or they can

be damaged bY the rotor Pulley.

22-35

Page 1460 of 2189

Compressor (SANDENI

Thermal Protestor Replacement

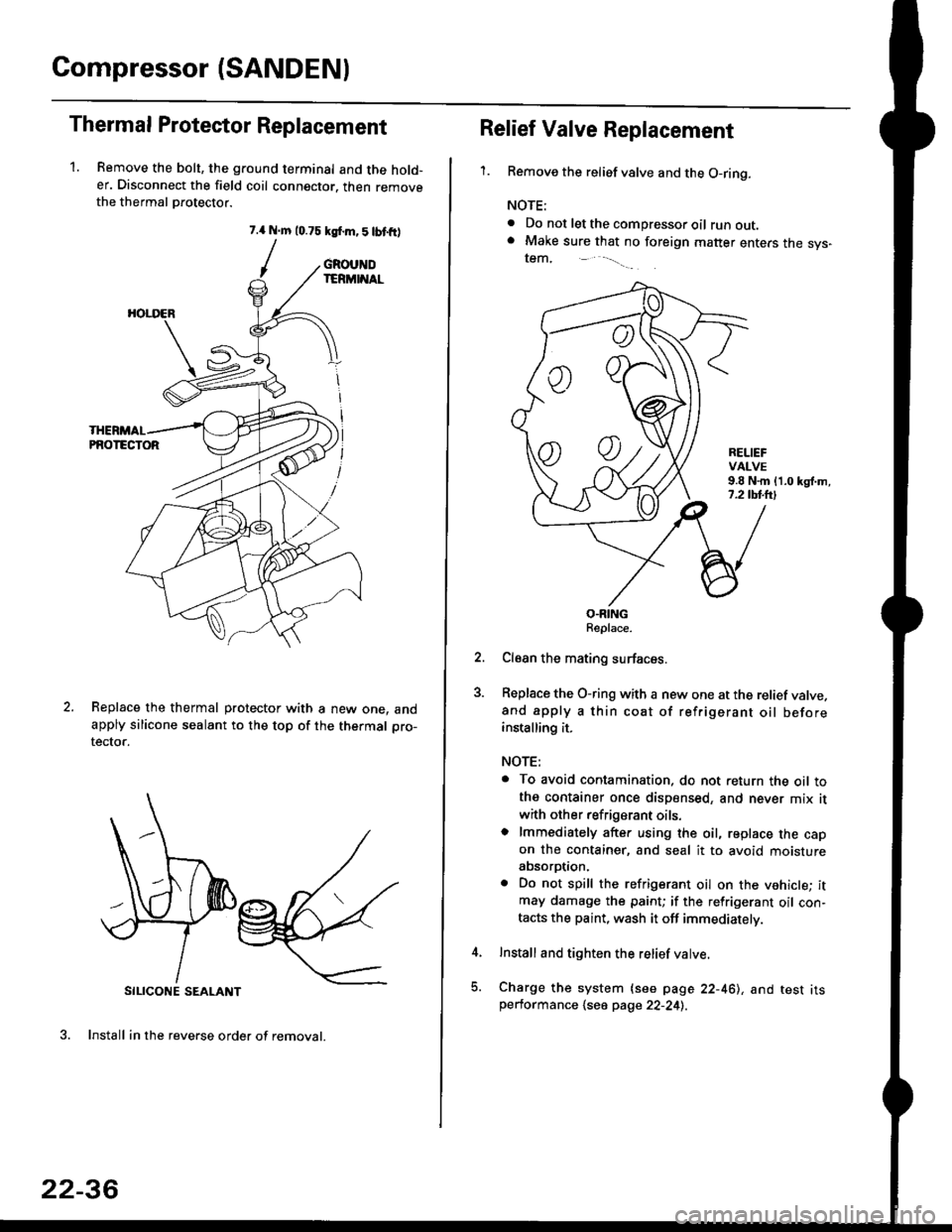

1. Remove the bolt, the ground terminal and the hold-er. Disconnect the field coil connector. then removethe thermal Drotector.

7.{ N.m 10.75 ksf.m,5lbtfr)

/

SILICONE SEALANT

3. Install in the reverse order of removal.

GROUNDIERMINAL

HOI.I'ER

PNOTECTOR

Replace the thermal protector with a new one. andapply silicone sealant to the top of the thermal pro-

tector.

22-36

oo

Relief Valve Replacement

'1.Remove the relief valve and the O-ring.

NOTE:

. Do not let the compressor oil runout.. Make sure that no foreign matter enters the sys-tem,

RELIEFVALVE9.8 N.m {1.0 kgl.m,7.2 tbl.lrl

O.RINGReplace.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil beforeinstalling it.

NOTE:

. To avoid contamination. do not return the oil tothe container once dispensed, and never mix it

with other refrigerant oils.o lmmediately after using the oil, replace the capon the container, and seal it to avoid moistureabsorption.

. Do not spill the refrigerant oil on the vehicle; itmay damage the paint; if the refrigerant oil con-tacts the paint, wash it off immediately.

Install and tighten the relief valve.

Charge the system {see page 22-461, and test itsperformance 1se6 page 22-241.

Page 1466 of 2189

Compressor (DENSO)

Clutch Overhaul (cont'd)

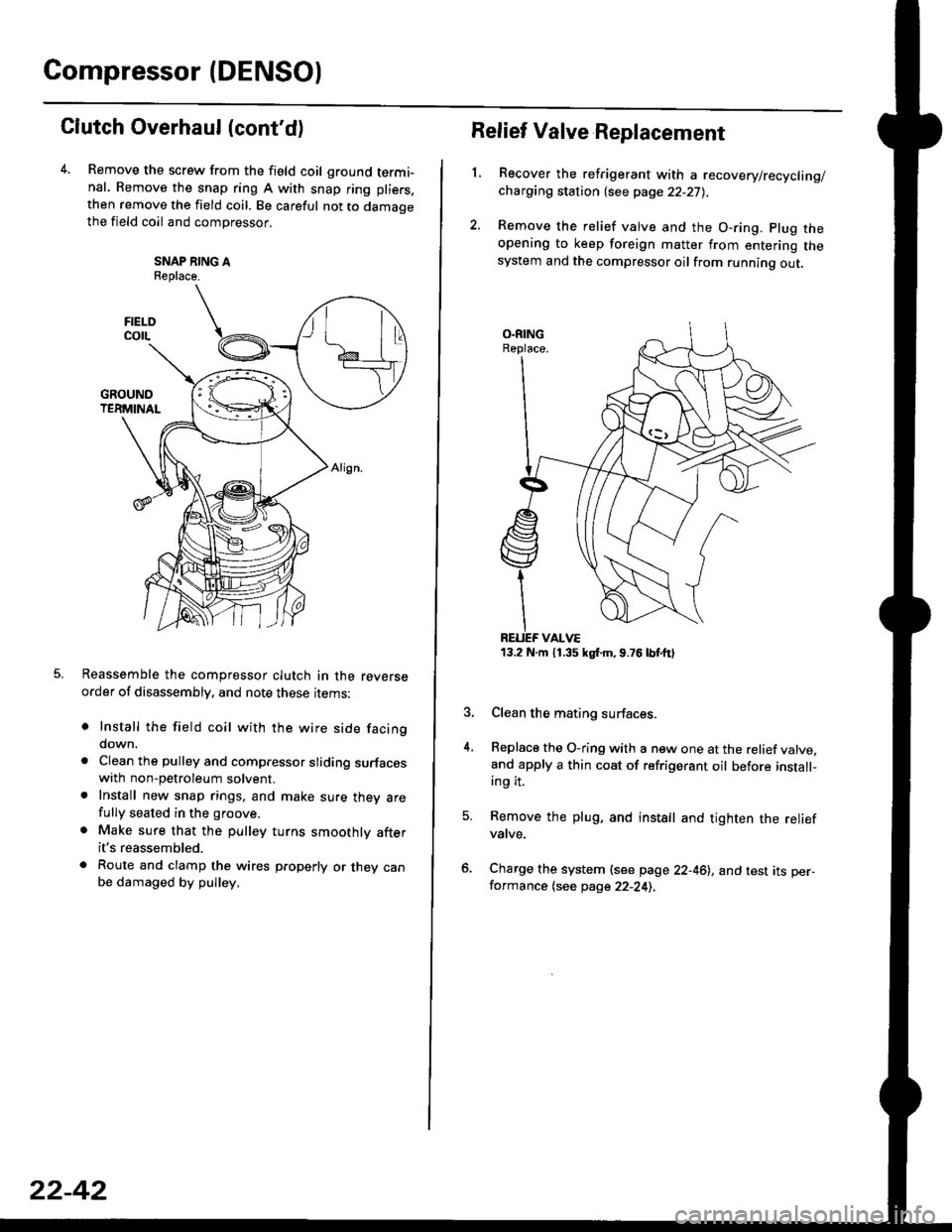

Remove the screw from the field coil ground termi-nal. Remove the snap ring A with snap ring pliers.

then remove the field coil. Be careful not to damaoethe field coil and compressor.

SNAP NING AReplace.

Reassemble the compressor clutch in the reverseorder of disassembly, and note these rrems:

o Install the field coil with the wire side facingdown.

a Clean the pulley and compressor sliding surfaceswith non-petroleum solvent.. Install new snap rings, and make sure thev arefully seated in the groove.

. Make sure that the pulley turns smoothly afterit's reassembled.

. Route and clamp the wires p.operly or they canbe damaged by pulley.

FIELOcorL

22-42

13.2 N.m 11.35 kgt m,9.76lbtttl

Relief Valve Replacement

L

4.

Recover the refrigerant with a recovery/recycling/charging station {see page 22-27),

Remove the relief valve and the O-ring. plug theopening to keep foreign matter from entering thesystem and the compressor oilfrom running out.

Clean the mating surfaces.

Replace the O-ring with a new one at the relief valve.and apply a thin coat of refrigerant oil before install-ing it.

Remove the plug, and install and tighten the reliefvatve.

Charge the system (see page 22-46), and test its per-formance (see page 22-24),