Oil HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 988 of 2189

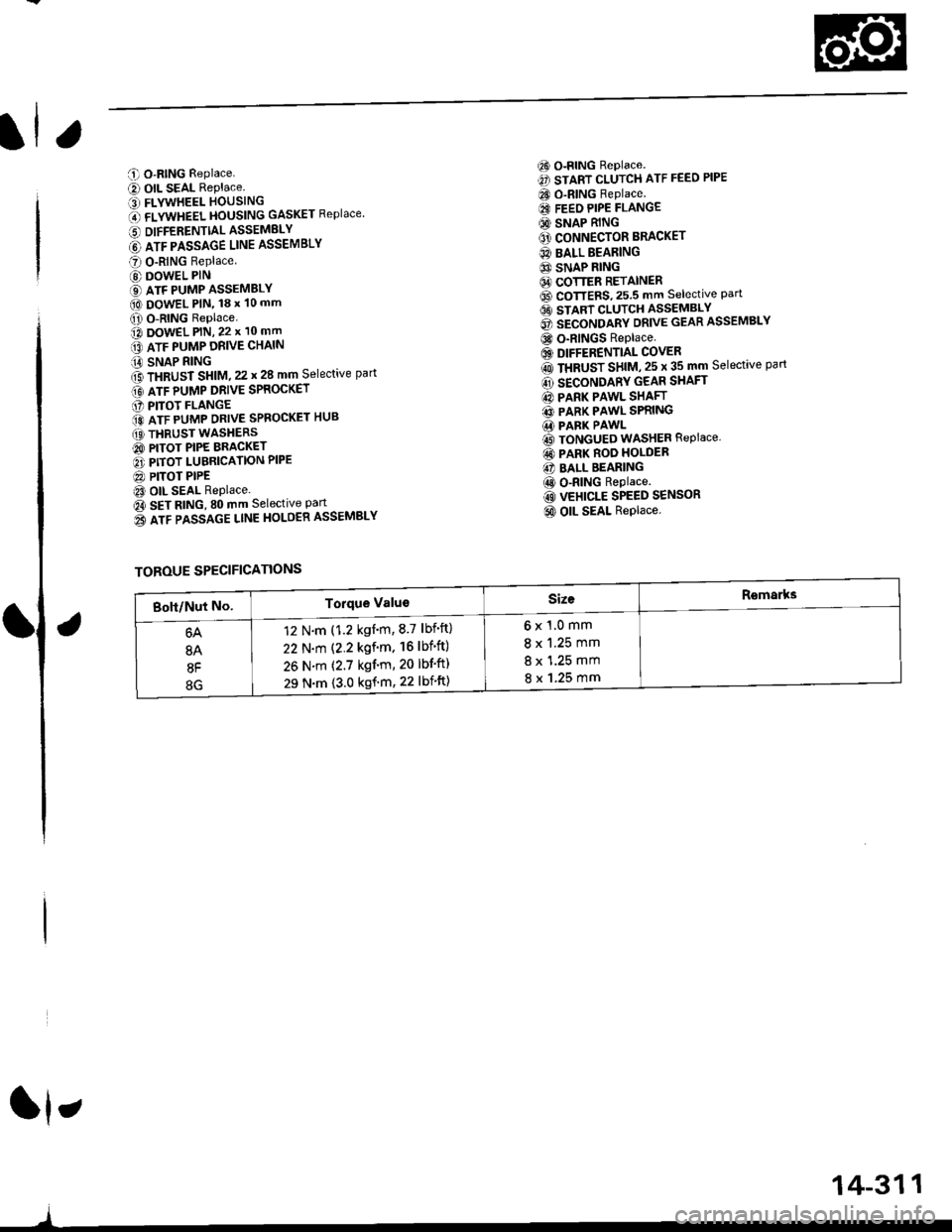

C O-RING Replace.

e) OIL SEAL RePlace.' FLYWHEEL HOUSING

O flVWneel }|OUSttttG GASKET Replace

6 DIFFERENTTALASSEMELY

@ lrr plsslce uruE ASSEMBLY

O O-RING Replace

@ DOWEL PIN

€) ATF PUMP ASSEMBLY(O DowEL PlN, 18 x 10 mm

O O-RING Replace.o DowEL PlN, 22 x 10 mm

lrr puup oRve cxltttt

iA SNAP RING

f3 fxaUst St|t|l, zz t 28 mm Selective part

Gt lrr punp ontve spaocxer

O PITOT FLANGE

ito nTF purrap ontve SPRoGKET HUB

(O THRUST WASHERS

@ PITOT PIPE BRACKET

O PITOT LUBRICATION PIPE

@ PITOT PIPEt3 OIL SEAL Replace.

Oa SEt AtitC, SO mm Selective Part

o3 lrr passlce ltnE HoLOER ASSEMBLY

6) o-RING Replace.

€) START CLUTCH ATF FEED PIPE

CO O-RING Replace.

€I FEEO PIPE FLANGE

@ SNAP RING

O' CONNECTOR BRACKET

@ BALL BEARING

6} SNAP RING64 COTTER RETAINER6D CoTTERS,25.5 mm selective Part6t stlnt cLutcH asseMsLv

@ secoruomv ontvE GEAR ASSEMBLY

@ o-RINGS Replace

6) DIFFERENTIAL COVER

rO ttaUSr SntU, zs t 35 mm Selective part

@ SECONDARY GEAR SHAFT

@ PARK PAWL SHAFT

@ PARK PAWL SPRING.1i PARK PAWL

@ TONGUED WASHER REPIACE,

@ PARK ROO HOLDER

@ BALL BEARING

@ o-RING Replace.

@ VEHICLE SPEED SENSOR

@ OIL SEAL Replace.

ft,

)

TOROUE SPECIFICATIONS

6x1.0mm

8 x 1.25 mm

8 x 1.25 mm

8 x 1.25 mm

12 N.m (1.2 kgnm,8.7 lbf'ft)

22 N.m (2.2 kgf'm. 16lbf'ft)

26 N.m (2.7 kgf'm, 20 lbf'ft)

29 N.m {3.0 kgf'm, 22 lbift)

14-311

Page 1008 of 2189

l.

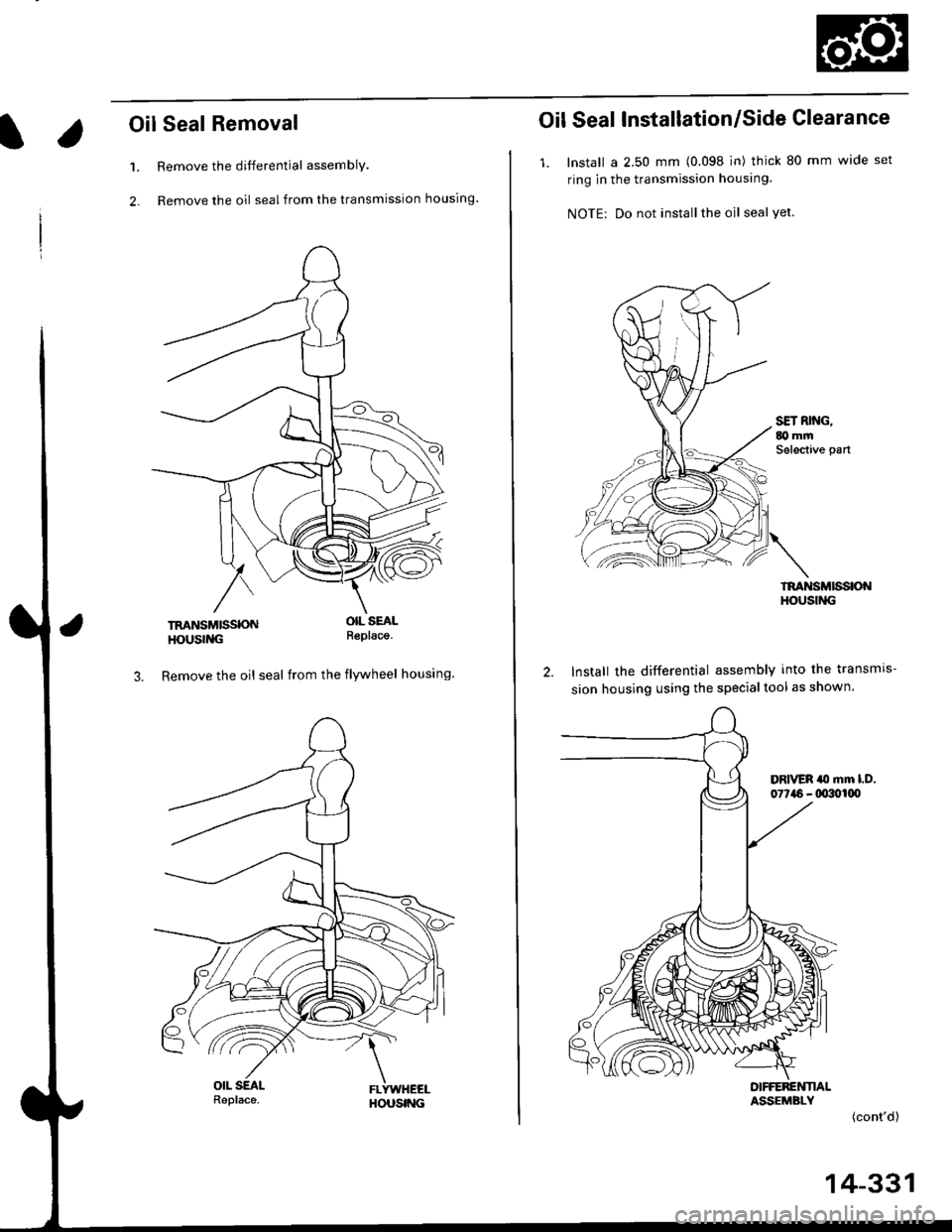

Oil Seal Removal

Remove the differential assembly.

Remove the oil seal from the transmission housing.

1.

2.

TRANSMISSONHOUSING

OIL SEALR€placa.

3. Remove the oil seal from the flywheel housing.

Oil Seal Installation/Side Clearance

1. lnstall a 2.50 mm (0.098 in) thick 80 mm wide set

ring in the transmission housing.

NOTE: Do not installthe oil seal yet.

TRANSMISSIONHOUStl{G

lnstall the differential assembly into the transmrs-

sion housing using the specialtool as shown

DIFFEREI{NALASSEMBLY(cont'd)

14-331

Page 1009 of 2189

Differential

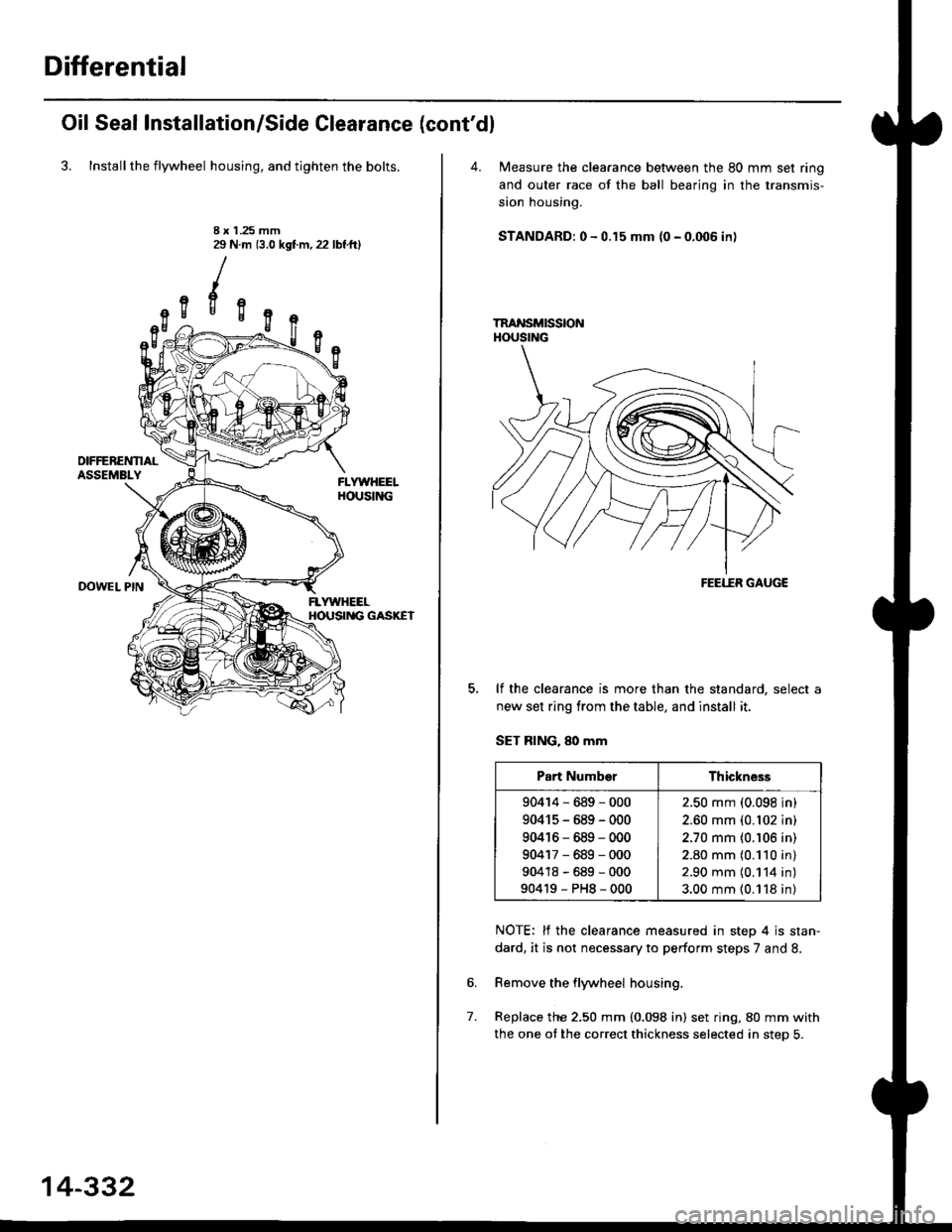

Oil Seal Installation/Side Clearance (cont'dl

3. Installthe flywheel housing, and tighten the bolts.

DOWEL PIN

1 .25 mmN m (3.0 kgt m,22 lbf.ttl8x29

uigE

14-332

4. Measure the clea.ance between the 80 mm set ring

and outer race of the ball bearing in the transmis-

sion housing.

STANDARD: 0 - 0.15 mm (0 - 0.006 in)

lf the clearance is more than the standard, select a

new set ring from the table, and install it.

SET RING, 80 mm

NOTE: lf the clearance measured in steD 4 is stan-

dard, it is not necessary to perform steps 7 and 8.

Remove the flywheel housing.

Replace ttle 2.50 mm (0.098 in) set ring, 80 mm with

the one ot the correct thickness selected in steD 5.

6.

7.

Part NumberThickness

904'�r4-689-000

90415-689-000

90416-689-000

90417-689-000

90418-689-000

90419-PH8-000

2.50 mm (0.098 in)

2.60 mm (0.102 in)

2.70 mm (0.106 in)

2.80 mm (0.110 in)

2.90 mm (0.114 in)

3.00 mm (0.118 in)

Page 1010 of 2189

Flywheel Housing

Input Shaft Oil Seal

l.

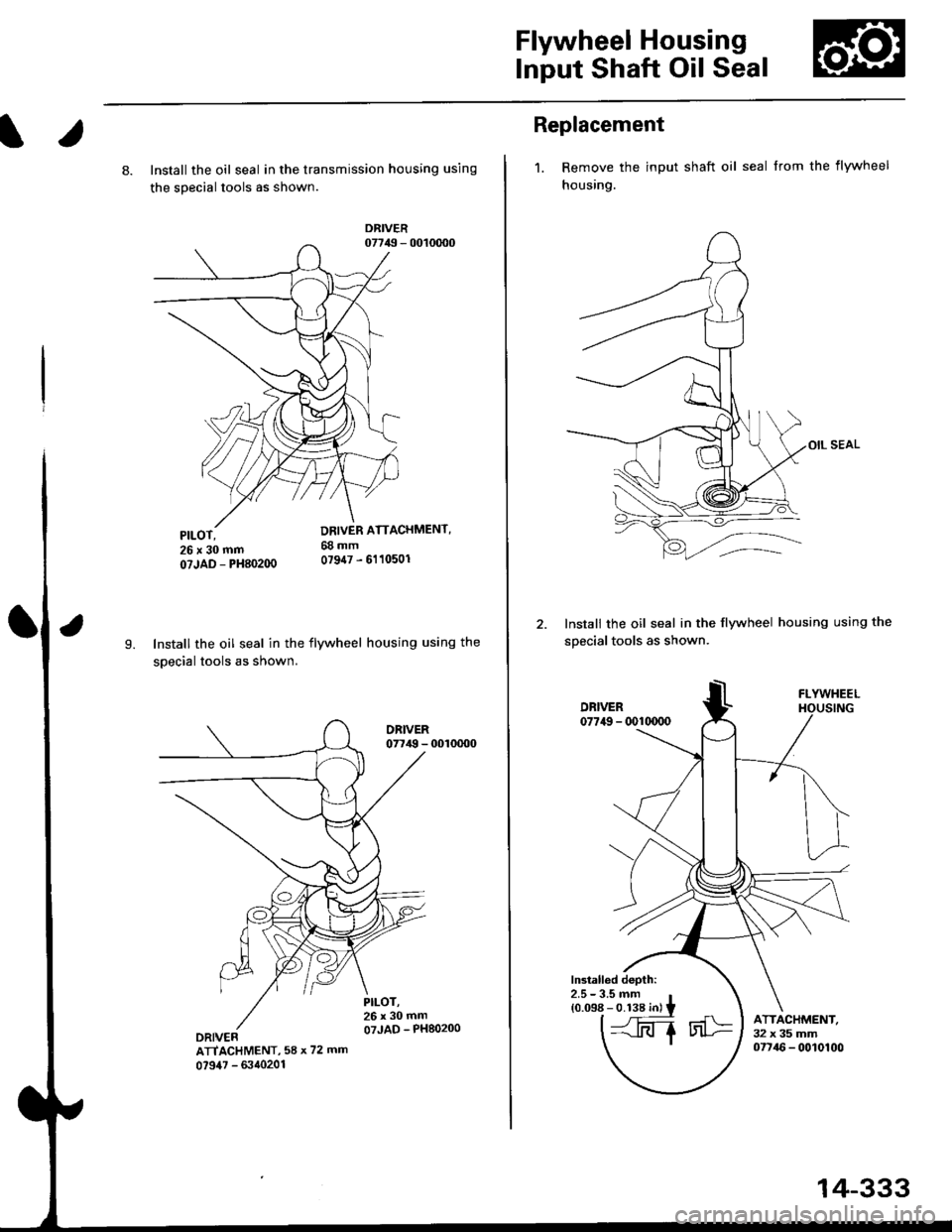

8. Install the oil seal in the transmission housing using

the sDecial tools as shown.

DRIVER07749 - 0010d)0

9.Install the oil seal in the flywheel housing using the

soecial tools as shown.

PILOT,26x30mmoTJAD - PH80200DRIVERATIACHMENT, 58 x 72 rnin

0?947 - d'40201

Replacement

1. Remove the input shaft oil seal from the flywheel

housing.

OIL SEAL

Instali the oil seal in the flywheel housing using the

soecialtools as shown.

FLYWHEEL

lmtalled depth:2.5- 3.5 mmro"nri':,ilii.rl

t@

14-333

Page 1037 of 2189

Driveshafts

Removal (cont'd)

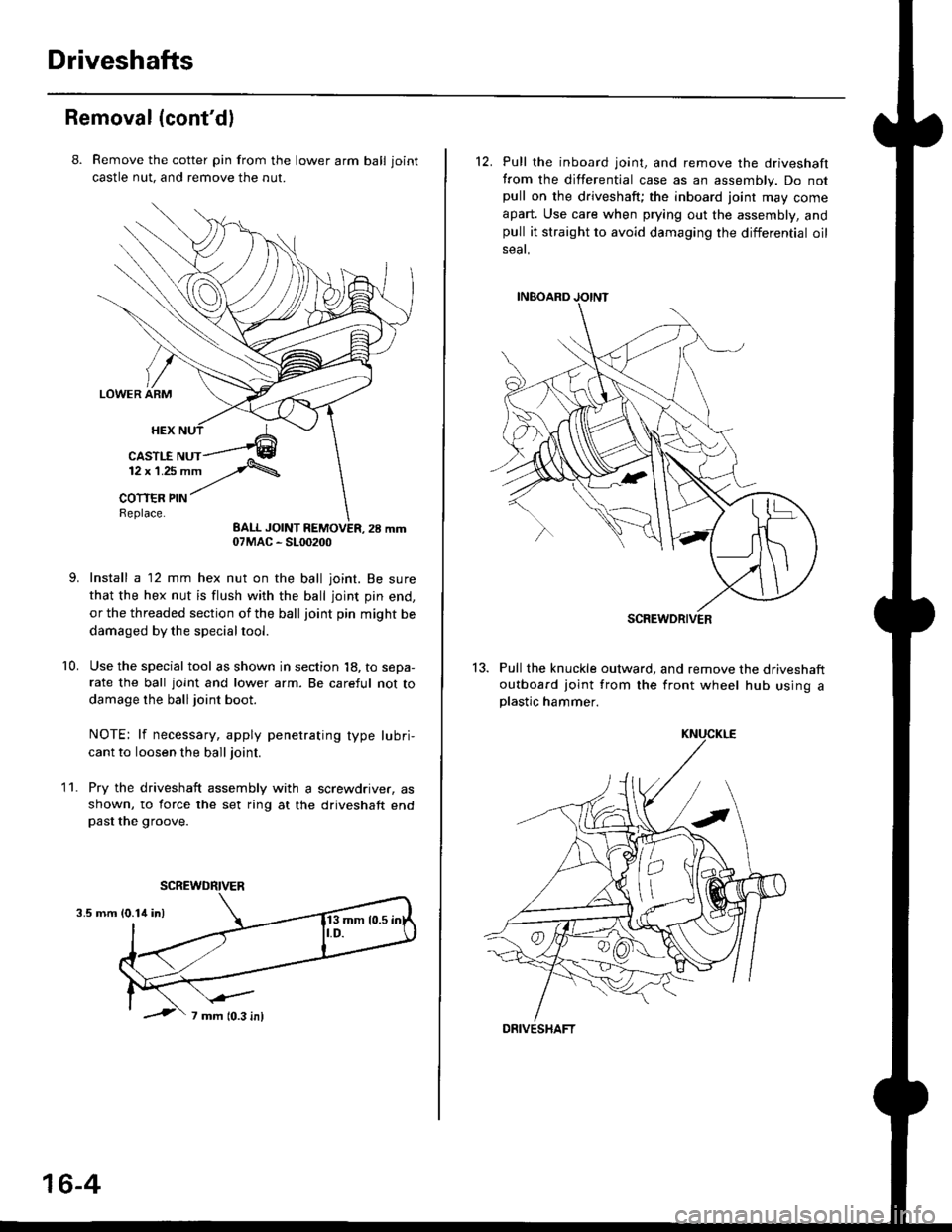

8. Remove the cotter pin from the lawer arm ball joint

castle nut. and remove the nut.

Install a 12 mm hex nut on the ball joint. Be sure

that the hex nut is flush with the ball joint pin end,

or the threaded section of the ball joint pin might be

damaged by the special tool.

Use the special tool as shown in section 18, to sepa-

rate the ball joint and lower arm. Be careful not to

damage the ball joint boot.

NOTE: lf necessary, apply penetrating type lubri,

cant to loosen the ball joint.

Pry the driveshaft assembly with a screwdriver, as

shown, to force the set ring at the driveshaft endpast the groove.

10.

11.

3.5 mm

07MAC - SL00200

SCREWDRIVER

16-4

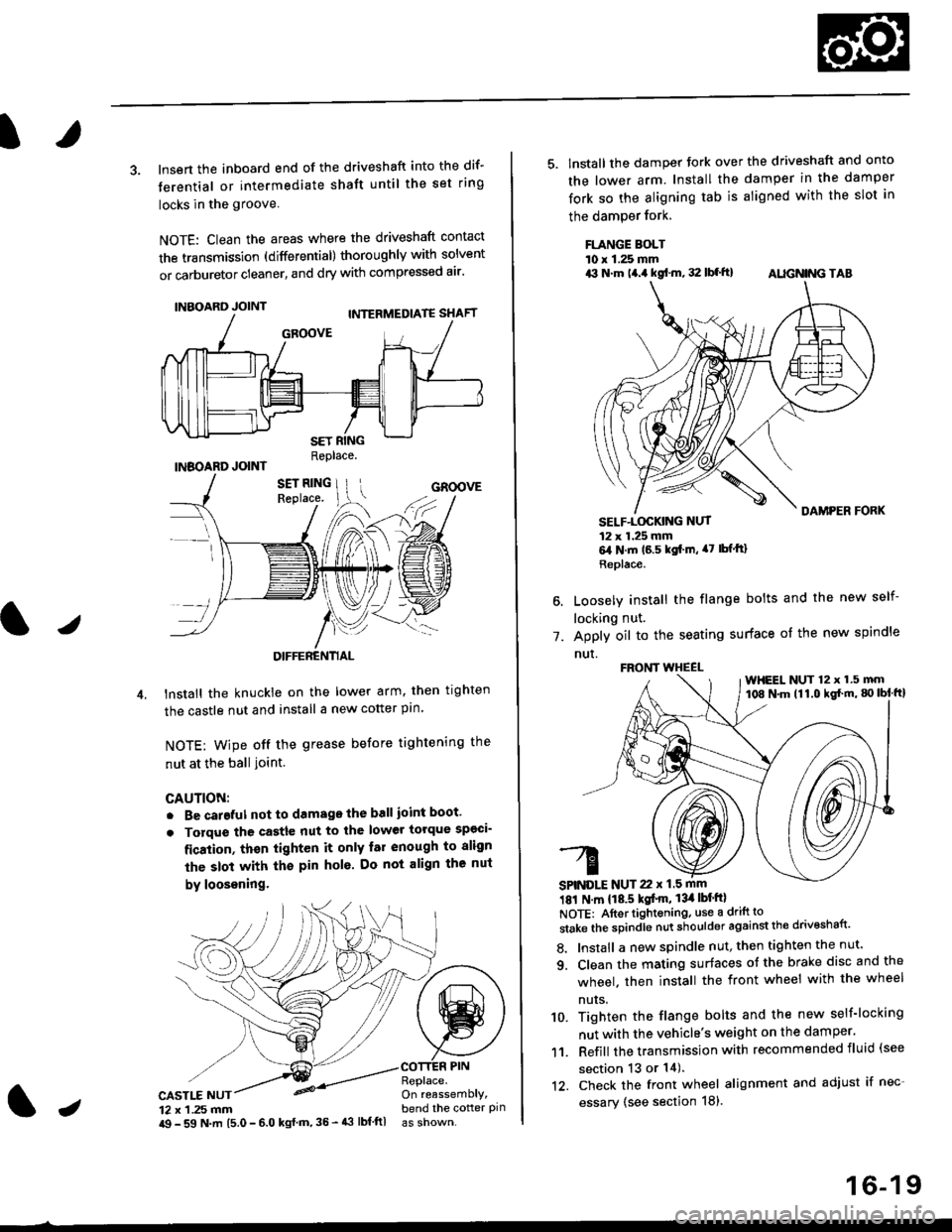

12. Pull the inboard joint, and remove the driveshaft

from the differential case as an assembly. Do notpull on the driveshaft; the inboard joint may come

apart. Use care when prying out the assembly, andpull it straight to avoid damaging the differential oil

seat.

13. Pull the knuckle outward, and remove the driveshaft

outboard joint from the front wheel hub using aplastic hammer.

SCREWDRIVER

DRIVESHAFT

Page 1052 of 2189

3. lnsert the inboard end of the driveshaft into the dif-

terential or intermediate shaft until the set ring

locks in the groove

NOTE: Clean the areas where the driveshaft contact

the transmission (differential) thoroughly with solvent

or carburetor cleaner, and dry with compressed air'

INBOARD JOINT

INBOARD JOINTReplace.

GROOVE

an

DIFFERENTIAL

lnstall the knuckie on the lower arm. then trghten

the castle nut and install a new cotter pin

NOTE: wipe off the grease before tightening the

nut at the ball ioint.

CAUTION:

. Be careful not to damago the ball ioint boot'

. Torque the castle nut to the lower torque sp€ci-

fication, thsn tighten it only far enough to align

the slot with th€ pin hol6. Do not align the nut

by loosening.

CASTLE NUT12 x 1 .25 mm

COTTER PINReplace.On reassemblY,bend the cotter pinJi$ - 59 N.m 15.0 - 6.0 kgl m,35 - 43 lbf ftl

16-19

5. lnstall the damper tork over the driveshaft and onto

the lower arm. Install the damper in the damper

fork so the aligning tab is aligned with the slot in

the damPer fork.

FLANGE BOLTl0 r 1.25 mmrit N.m t4.a kgf.m, 32 lbf.ft) AIIGN|NG TAB

1.

SELF-LOGKING NUT12 x 1.25 mm6,1N.m 16.5 kgi.m, a7 lbfftl

Replace.

Loosely install the flange bolts and the new self-

locking nut.

Apply oil to the seating surface of the new spindle

nut.

181 N m 118.5 kgt'm, 13il lbt'ftl

NOTE: Aftortightening, use a drift to

stake the spindle nut shoulder against the drivoshaft'

8. Install a new spindle nut, then tighten the nut'

9. Clean the mating surfaces ot the brake disc and the

wheel. then install the front wheel with the wheel

nuts.

10. Tighten the flange bolts and the new self-locking

nut with the vehicle's weight on the damper.

11. Refill the transmission with recommended fluid (see

section 13 or 14).'t2. Check the front wheel alignment and adjust if nec-

essary (see section 18),

FRONT WHEEL

SPINDLE NUT 22 x 1.5 mm

WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgl'm, g) lbl ftl

Page 1053 of 2189

Intermediate Shaft

Removal

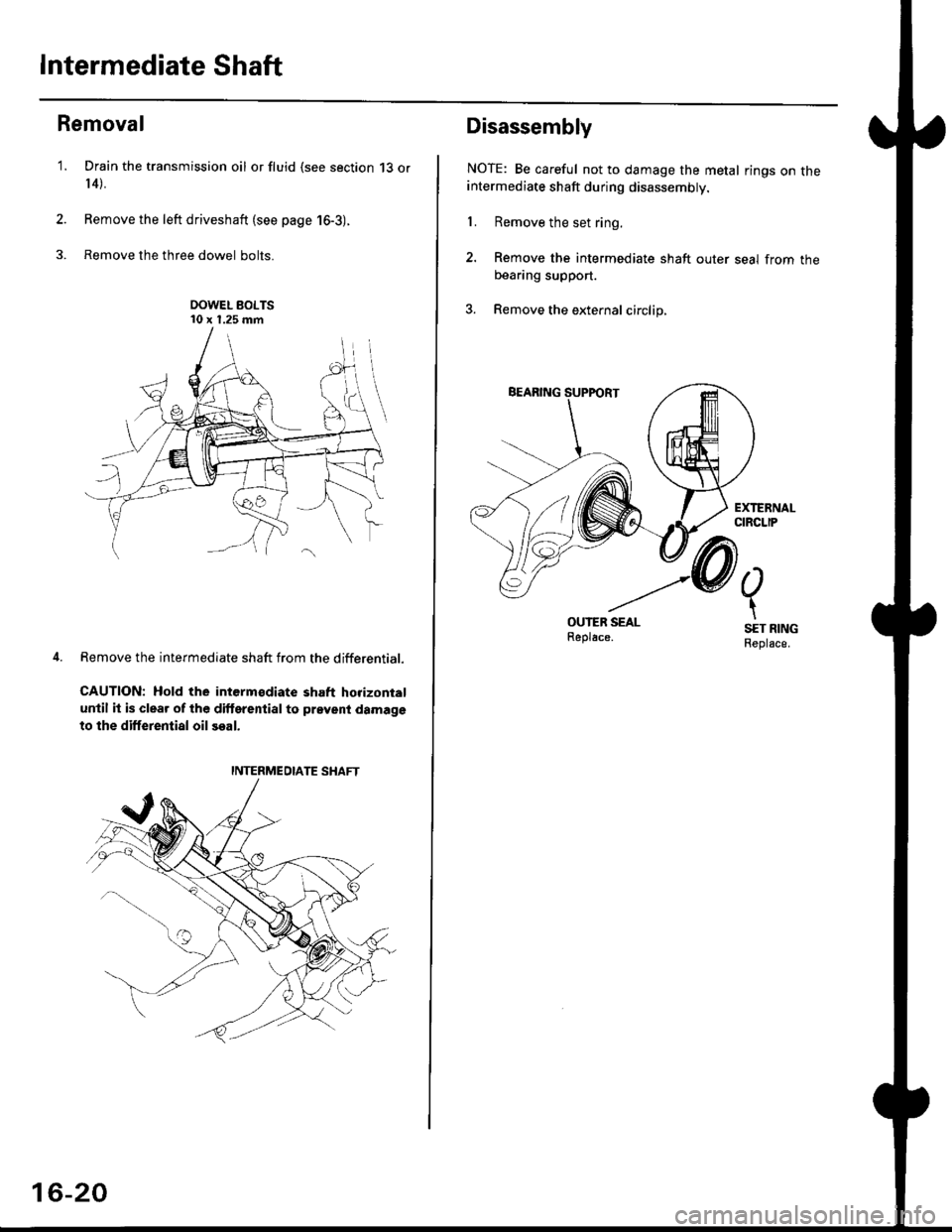

Drain the transmission oil or fluid {see section 13 or

r 4).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

OOWEL BOLTS'10 x 1.25 mm

Remove the intermediate shaft from the differential.

CAUTION: Hold the intermsdiate shaft horizontal

until it is clear of lhe dilterential to prevent damage

to the differential oil seal.

'1.

2.

3.

INTERMEDIATE SHAFT

16-20

Disassembly

NOTE: Be careful not to damage the metal rings on theintermediate shaft during disassembly.

1. Remove the set ring.

2. Remove the intermediate shaft outer seal from theDeaflng suppon.

3. Remove the external circlip,

Page 1056 of 2189

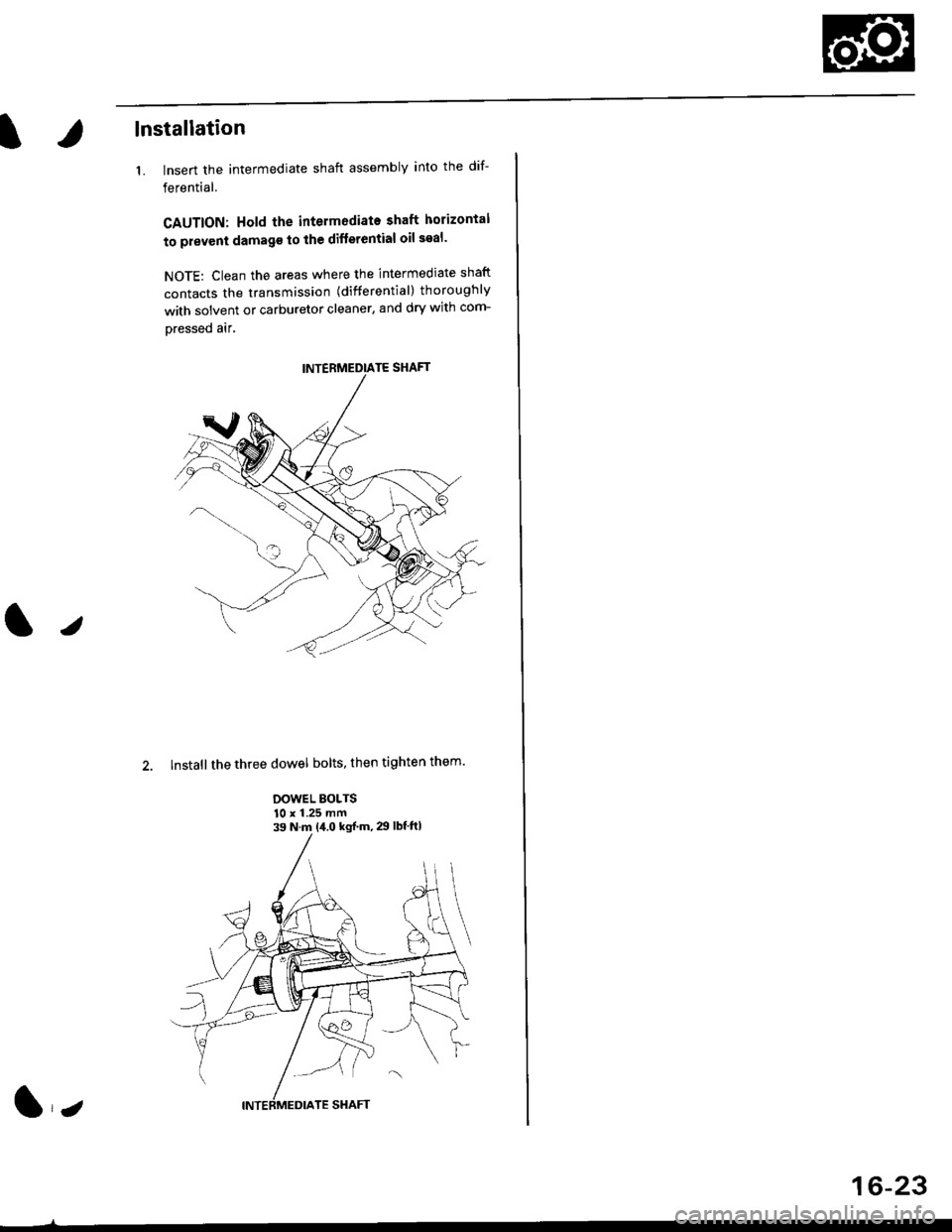

lnstallation

1. lnsert the intermediate shaft assembly into the dif-

ferential.

CAUTION: Hold the intermodiate shaft horizontal

to prevent damag€ to the difterential oil seal'

NOTE: Clean the areas where the intermediate shaft

contacts the transmission (differential) thoroughly

with solvent or carburetor cleaner, and dry with com-

Dressed air,

2. Install the three dowel bolts, then tighten them'

DOWEL BOLTS10 x 1.25 mm39 N.m {i1.0 kgf'm, 29 lbf'ftl

lz

16-23

Page 1061 of 2189

Steering Gearbox

l.r

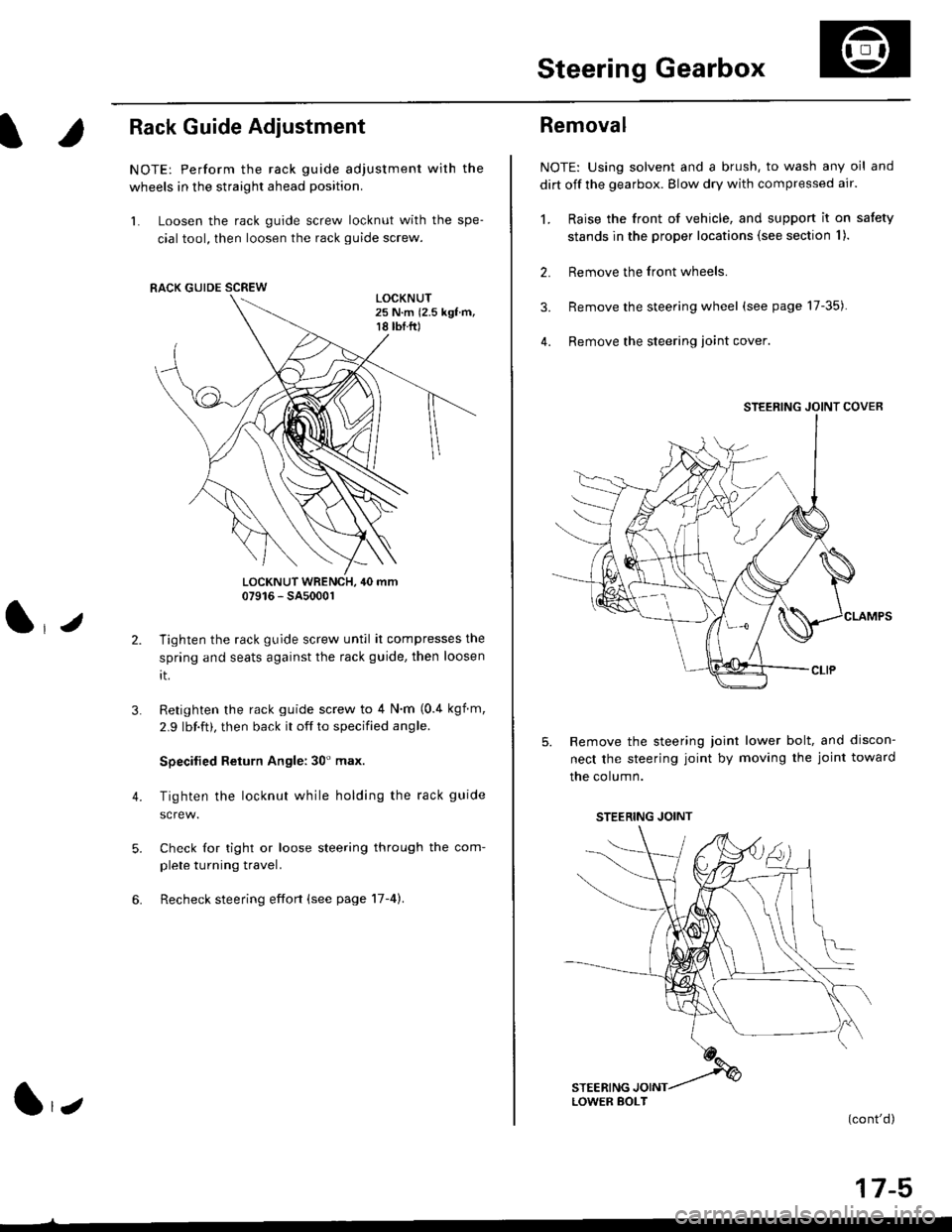

Rack Guide Adjustment

NOTE: Perform the rack guide adjustment with the

wheels in the straight ahead position.

1. Loosen the rack guide screw locknut with the spe-

cial tool, then loosen the rack guide screw.

LOCKNUT WRENCH, 40 mm07916 - SA5000r

Tighten the rack guide screw until it compresses the

spring and seats against the rack guide, then loosen

rt.

Retighten the rack guide screw to 4 N'm (0.4 kgf m,

2.9 lbf.ft), then back it off to specified angle.

Specilied Return Angle: 30' max.

Tighten the locknut while holding the rack guide

Check for tight or loose steering through the com-

plete turning travel.

Recheck steering effort (see page 17-4).

4.

RACK GUIDE SCREW

l,z

Removal

NOTE: Using solvent and a brush, to wash any oil and

dirt off the gearbox. Blow dry with compressed air.

1. Raise the front of vehicle, and support it on satety

stands in the proper locations (see section I ).

2. Remove the front wheels.

3. Remove the steering wheel (see page 17-35).

4. Remove the steering loint cover

Remove the steering joint lower bolt, and discon-

nect the steering joint by moving the joint toward

the column.

(cont'd)

17-5

STEERING JOINT COVER

LOWER BOLT

STEERING JOINT

Page 1074 of 2189

System Description

Steering Pump (cont'dl

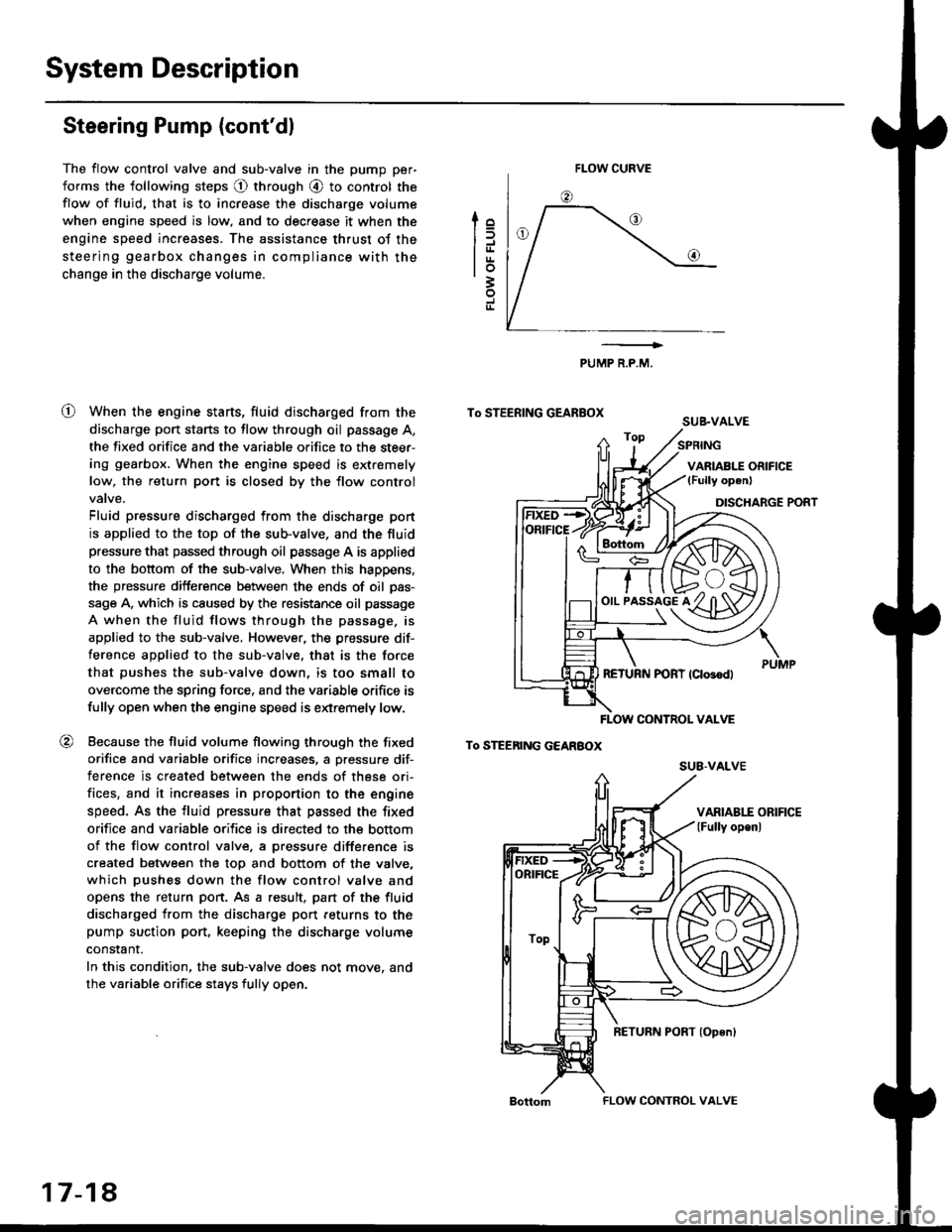

The flow control valve and sub-valve in the pump per-

forms the following steps @ through @ to control the

flow of fluid, that is to increase the discharge volume

when engine speed is low, and to decrease it when the

engine speed increases. The assistance thrust of the

steering gearbox changes in compliance with the

change in the discharge volume.

When the engine starts, fluid discharged from the

discharge port starts to flow through oil passage A,

the fixed orifice and the variable orifice to the steer-

ing gearbox. When the engine speed is extremely

low, the return port is closed by the flow control

Fluid pressure discharged from the discharge port

is applied to the top of the sub-valve, and the fluid

pressure that passed through oil passage A is applied

to the bottom of the sub-valve. When this happens,

the pressure difference between the ends of oil pas-

sage A, which is caused by the resistance oil passage

A when the fluid flows through the passage. is

applied to the sub-valve, However, the pressure dif-

ference applied to the sub-valve. that is the force

that pushes the sub-valve down, is too small to

overcome the spring force, and the variable orifice is

fully open when the engine speed is extremely low.

Because the fluid volume flowing through the fixed

orifice and variable orifice increases, a pressure dif-

terence is created between the ends of these ori-

fices, and it increases in proportion to the engine

speed. As the fluid pressure that passed the fixed

orifice and variable orifice is directed to the bottom

of the flow control valve. a pressure difference is

created between the top and bottom of the valve,

which pushes down the flow control valve and

opens the return port. As a result, pan of the fluid

discharged from the discharge port feturns to the

pump suction port, keeping the discharge volume

constant.

In this condition, the sub-valve does not move. and

the variable orifice stays fully open.

lo

trrtrrlo3

J

o

PUMP R.P.M.

To STEERING GEARBOXSUB.VALVE

To STEEnING GEARBOX

FLOW CURVE

!rs+/f/ffih\

o,,-i^"l^tKzYt)91y ul3Yl

FLOW CONTNOL VALVE

su8-vALvE

ORIFICE

ToP

17-18

FLOW CONTROL VALVE