Wire harness HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 470 of 2189

I

I

L

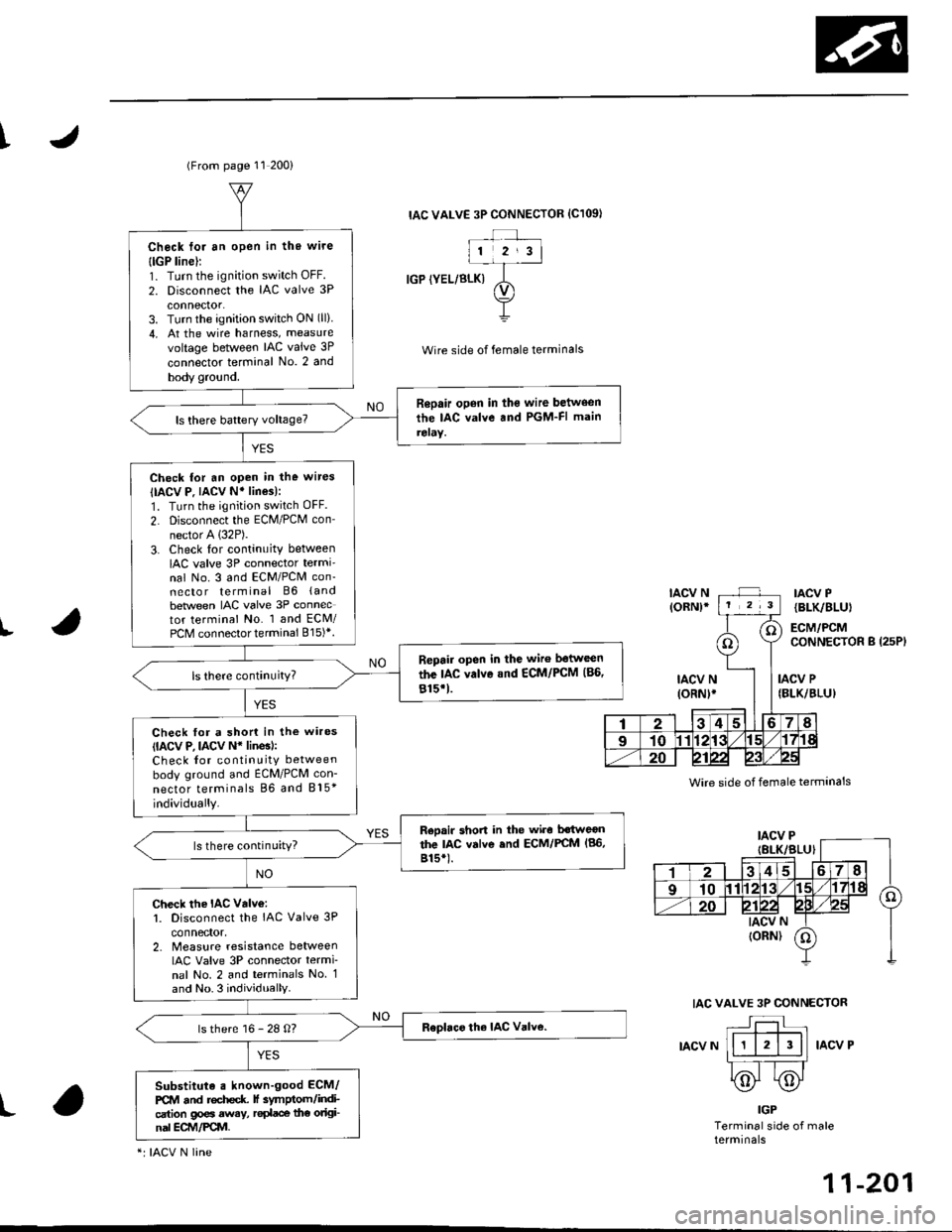

IACV N(oRN)*IACV P{BLK/BLU'

ECM/PCMCONNECTON B (25PI

IACV N(oRNt.

Wire side of female terminals

IAC VALVE 3P CONNECTOR

IACV NIACV P

IACV P

IBLK/BLUI

IGP

Terminal side of male

(From page 11 200)

IAC VALVE 3P CONNECTOR {C1O9I

IGP (YEL/BLK)

Wire side of female terminals

Check toi an open in thg wire

{lGP line):1. Turn the ignition switch OFF.

2. Disconnect the IAC valve 3P

connector.3. Turn the ignition switch ON (ll)

4, At the wire harness, measure

voltage between IAC valve 3P

connector terminal No. 2 and

body gro!nd.

Repair open in the wire between

the IAC valve and PGM-FI main

reraY.

Check for an open in the wires

IIACV P. IACV N' lines):

1. Turn the ignition switch OFF.

2. Disconnect the ECM/PCM con-

nector A (32P).

3. Check lor continuity between

IAC valve 3P connector termi'nal No. 3 and ECM/PCM con-necto r terminal B6 (and

beNveen IAC valve 3P connector terminal No. 1 and ECM/PCM connector terminal 815)*.

Repair open in the wiro ltstwcen

the IAC valvo and €CM/PCM (86,

815'1.

Check for a shon in the wires(IACV P, lACv N* linesl:Check for continuity between

body ground and ECM/PCM con-

nector terminals 86 and 815*

individually.

Reoair short in the wiro Mweonthe lac valve end ECM/FCM (86,

815*).ls there continuity?

Check the IAC valv€:l. Disconnect the IAC Valve 3P

connector,2. Measure resislance betweenIAC Valve 3P connector termi

nal No. 2 and terminals No 1and No.3 individually

ls there 16 - 28 O?

Substituta . known-good ECM/

PCM and rochcdc f 3ymptom/indication go€a away, r€dace the original ECM/Pqvl.

"r IACV N line

N

11-201

Page 481 of 2189

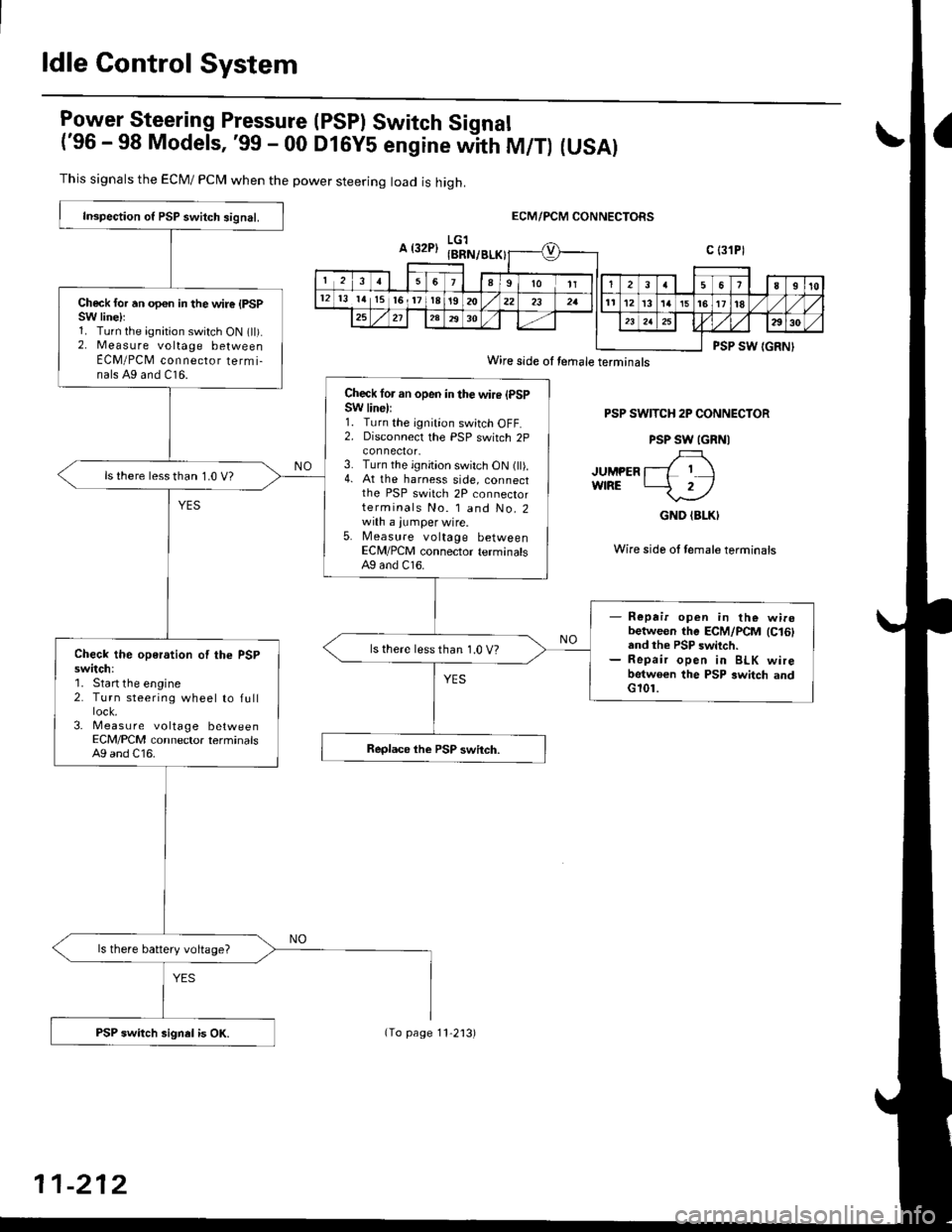

ldle Control System

lgy"t9!"_"ring Pressure (PSPI Switch Signal

('96 - 98 Models, '99 - 00 DlGy5 engine witn fU/f) (USAI

This signals the ECM/ PCN4 when the power steering load is high.

ECM/PCM CONNECTORS

PSP SWITCH 2P CONNECTOR

PSP SW IGRNI

JUMPER l--L I IwfRE -2/

GND (BLKI

Wire side ol female terminais

Inspection o{ PSP switch signal.

Check for an opon in the wire {PSPSW linelr1. Turn the ignition switch ON (ll).2. Measure voltage betweenECM/PCM connecror termi-nals A9 and C16.

Check lor an open in the wire (PSPSW line):1. Turn the ignition switch OFF.2. Disconnecl the PSP switch 2p

3. Turn the ignition switch ON (ll).4. At the harness side, connectthe PSP switch 2P connectorterminals No. l and No.2with a jumper wire.5. Measure voltage betweenECM/PCM connector terminalsAg and C16.

ls there lessthan 1.0 V?

- Repair open in the wirobetween the ECM/PCM lc16land the PSP switch.- Repair open in BLK wirebetwoen the PSP switch andG101.

ls there less than 1.0 V?Check the operation of the PSPswitch:'1. Start the engine2. Turn steering wheel to full

3- Measu re voltage betweenECM/PCM connector terminalsA9 and C16.

ls there battery voltage?

PSP switch signel is OK.

Wire side oI temale terminals

11-212

(To page 11'2'13)

Page 505 of 2189

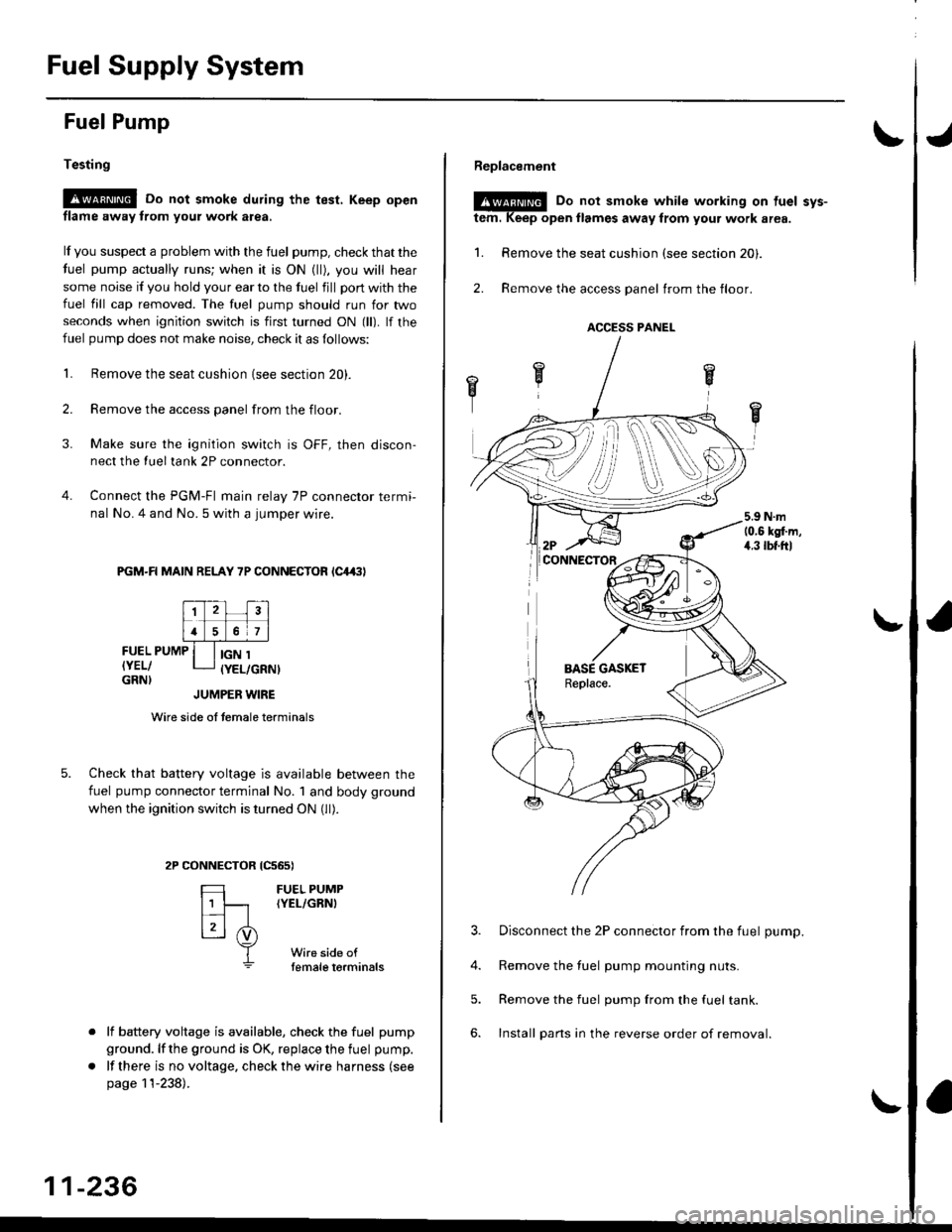

Fuel Supply System

Fuel Pump

Testing

!@ Do not smoke during the test, Keep open

flame away from your work atea,

lf you suspect a problem with the fuel pump, check that the

fuel pump actually runs; when it is ON (ll), you will hear

some noise if you hold your ear to the fuel fill port with the

fuel fill cap removed. The fuel pump should run for two

seconds when ignition switch is first turned ON (ll). lf the

fuel pump does not make noise, check it as follows:

L Remove the seat cushion {see section 20).

2. Remove the access panel from the floor.

3. Make sure the ignition switch is OFF, then discon-

nect the Iueltank 2P connector.

4. Connect the PGM-FI main relay 7P connector termi-

nal No. 4 and No. 5 with a jumper wire.

PGM-R MAIN RELAY 7P CONNECTOR lC4,(|l

FUEL PUMP

IYEL/GRN}

IGN 1(YEL/GRNI

tcs6s)

FUEL PUMP(YEL/GRNI

Wire side oftemale torminals

JUMPER WIRE

Wire side of temale terminals

Check that battery voltage is available between the

fuel pump connector terminal No. 1 and body ground

when the ignition switch is turned ON (ll).

CONNECTOR

=

[t

L3l .i)

T

lf battery voltage is available, check the fuel pump

ground. lf the ground is OK, replace the fuel pump.

lf there is no voltage, check the wire harness (see

page 11-238).

11-236

Replacement

@E Do not smoke while working on tuel svs-

tem. Keep open llames away from your work area.

1. Remove the seat cushion (see section 20).

2. Remove the access panel trom the floor.

3. Disconnect the 2P connector from the fuel pump.

4. Remove the fuel pump mounting nuts.

5. Remove the fuel pump from the fuel tank.

6. Install pans in the reverse order of removal.

ACCESS PANEL

i

Page 543 of 2189

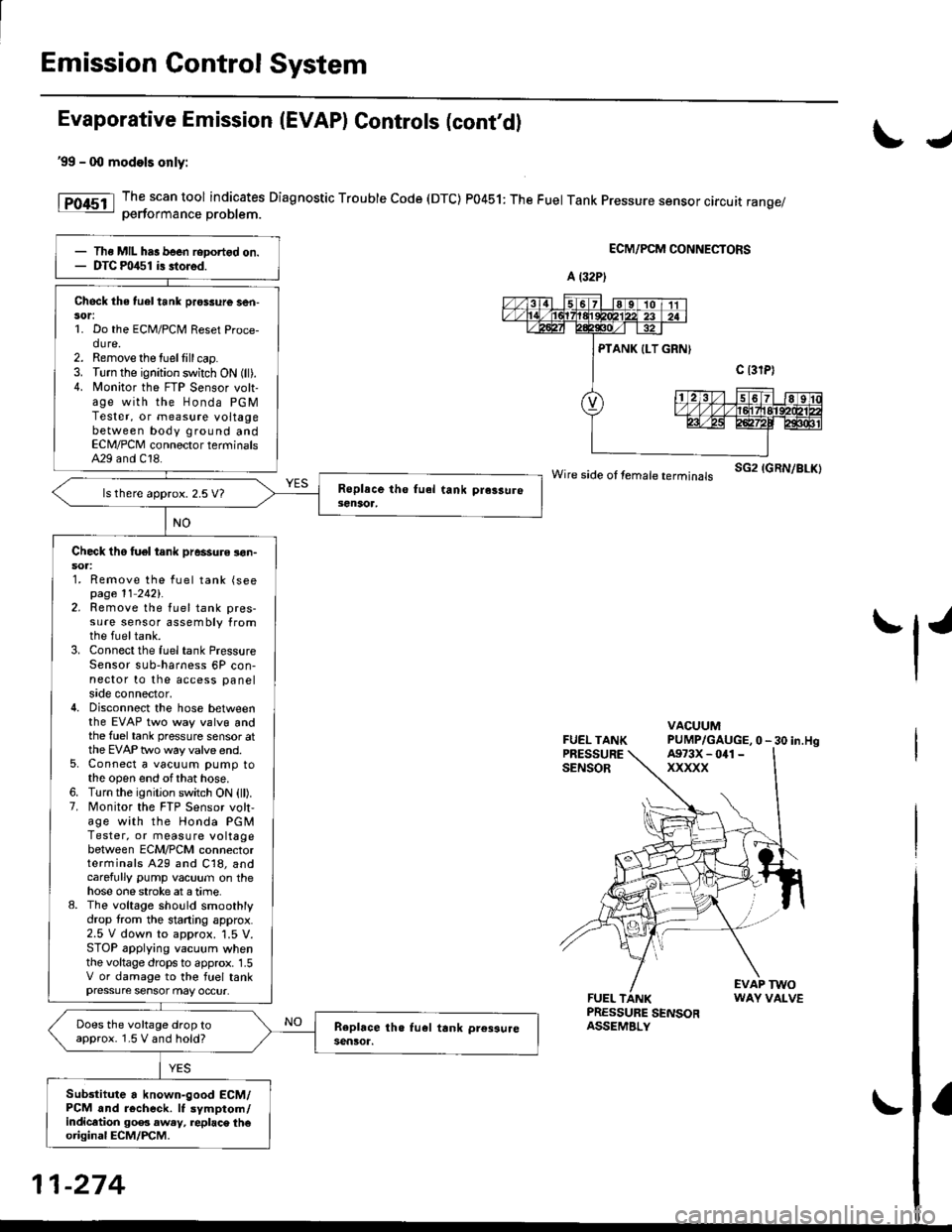

Emission Control System

Evaporative Emission (EVAP) Gontrols (cont'd)

'99 - 0O models only:

The scan tool indicates Diagnostic Trouble Code (DTC) P0451: The Fuel Tank Pressure sensor circuit range/oerformance Droblem.

ECM/PCM CONNECTORS

wire side ot femare terminars sG2 IGRN/BLK)

FUEL TANKPRESSURESENSOR

VACUUMPUMP/GAUGE,0 - 30 in.Hg

FUEL TANKPRESSURE SENSORASSEMBLY

EVAP TWOWAY VALVE

IJ

tl'

Ths MIL has been reDortgd on.DTC m/$1 i3 stored.

Check the tuel tank pros3ure ser|-sor:1. Do the ECM/PCM Reset Proce-dure.2. Remove the tuellill cap.3. Turn the ignition switch ON (ll).4. N4onitor the FTP Sensor volt-age with the Honda PGMTester, or measure voltagebetween body ground andECN4/PCM connector terminalsA29 and C18.

ls there approx. 2.5 V7

Check tho tuel tank pressure !on-soa:1. Remove the fuel tank (seepage 11 2421.2. Remove the fuel tank pres-sure sensor assembly fromthe fueltank.3. Connect the fuel tank PressureSensor sub-harness 6P con-nector to the access panelside connector,4. Disconnect the hose betweenthe EVAP two way valvg andthe fuel tank pressure sensor atthe EVAP two way valve end.5. Connect a vacuum pump tothe open end ofthat hose.6. Turn the ignition switch ON (ll).7. Monitor the FTP Sensor volt,age with the Honda PGMTester, or measure voltagebetween ECM/PCM connectorterminals A29 and C18, andcarefully pump vacuum on thehose one stroke at a time.8. The voltage sho!ld smoothlydrop from the stading approx.2.5 V down to approx. '1.5 V.STOP applying vacuum whenthe voltage drops to approx. 1.5V or damage to the fuel tankpressure sensor may occur.

Does the voltage drop toapprox. 1.5 V and hold?

Sub3titute a known-good ECM/PCM and r6check. It symptom/indicltion 90e3 aw.y, replac\. th€original ECM/PCM.

A (32P)

A973X - 041 -

xxxxx

11-274

Page 546 of 2189

\

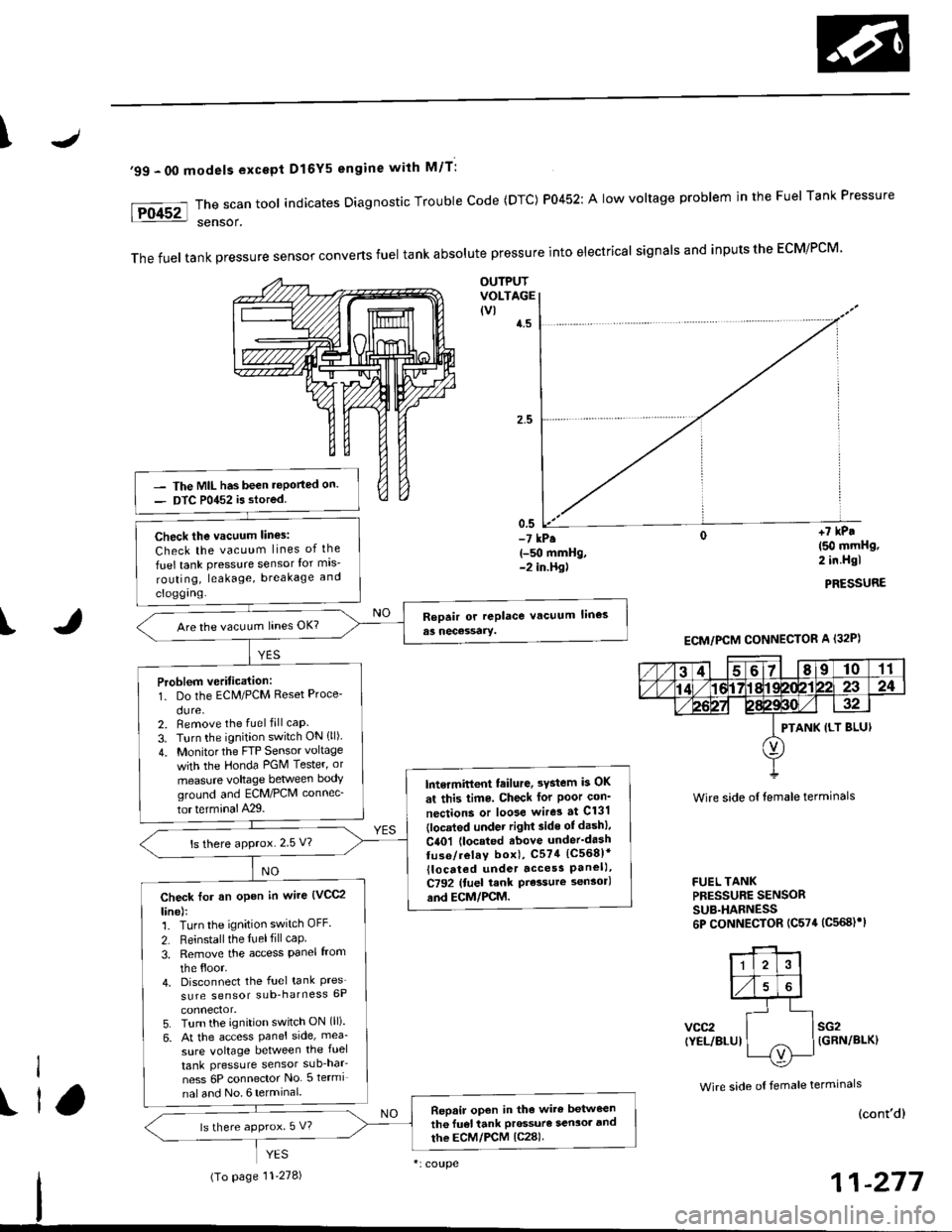

'99 - 00 models excepi Dl6Y5 engine with M/T:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensor.

The fuel tank pressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM

OUTPUTVOLTAGE(vlt.5

0.5-7 kP.(-g) mmHg,-2 in.Hgl

+7 kP.

150 mmHg,2 in.Hgl

PRESSURE

I

Wire side of lemale terminals

FUEL TANKPRESSURE SENSORSUB.HARNESS6P CONNECTOR (C574 (C568)rl

vcc2(YEL/BLUIsG2{GRN/BLK}

Wire side o{ temale terminals

The MIL has been .eported on.

DTC P0452 is stored

Check the vacuum lines:

Check the vacuum lines of the

fuel tank pressure sensor lor mis-

routing, leakage, breakage and

cloggrng.

Are the vacuum hnes OK?

Problem veritication:1. Do the ECM/PCM Reset Proce-

du re,2. Bemove the fuel fill caP.

3. Turn the ignition switch ON {ll)

4. Monitorthe FTP Sensor voltage

with the Honda PGM Tester' or

measure voltage between body

groLrnd and ECM/PCM connec_

tor terminalA29.

lntermitlent tailure, 3Ystem b OK

at this time. Check for Poor con'

nections or loose wire3 at C131

{located under right side of dash},

C401 {located above under'dash

tuse/relay box), C574 (C568)*

llocdted under access Panel),C792 (tuel rank Prcssure sensorl

and ECM/PCM.

ls there approx.2 5 V?

Check for an open in wire {VCC2

line):1. Turn the ignition switch OFF.

2. Reinstall the ltrel fill caP

3, Remove the access Panel from

the floor.4. Disconnect the fuel tank Pres'sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll).

6. At the access Panel side, mea_

sure voltage between the fuel

tank Pressure sensor sub-nar-

ness 6P connector No 5termi

nal and No. 6 termlnal.

Repair open in tho wire between

th6 fu€l tank Prossuro sen3oa and

the ECM/PCM lc28).ls there approx 5 V?

ECM/PCM CONNECTOR A (32P)

PTANK {LT BLUI

I

ll

(To page '11-278)

(cont'd)

Page 547 of 2189

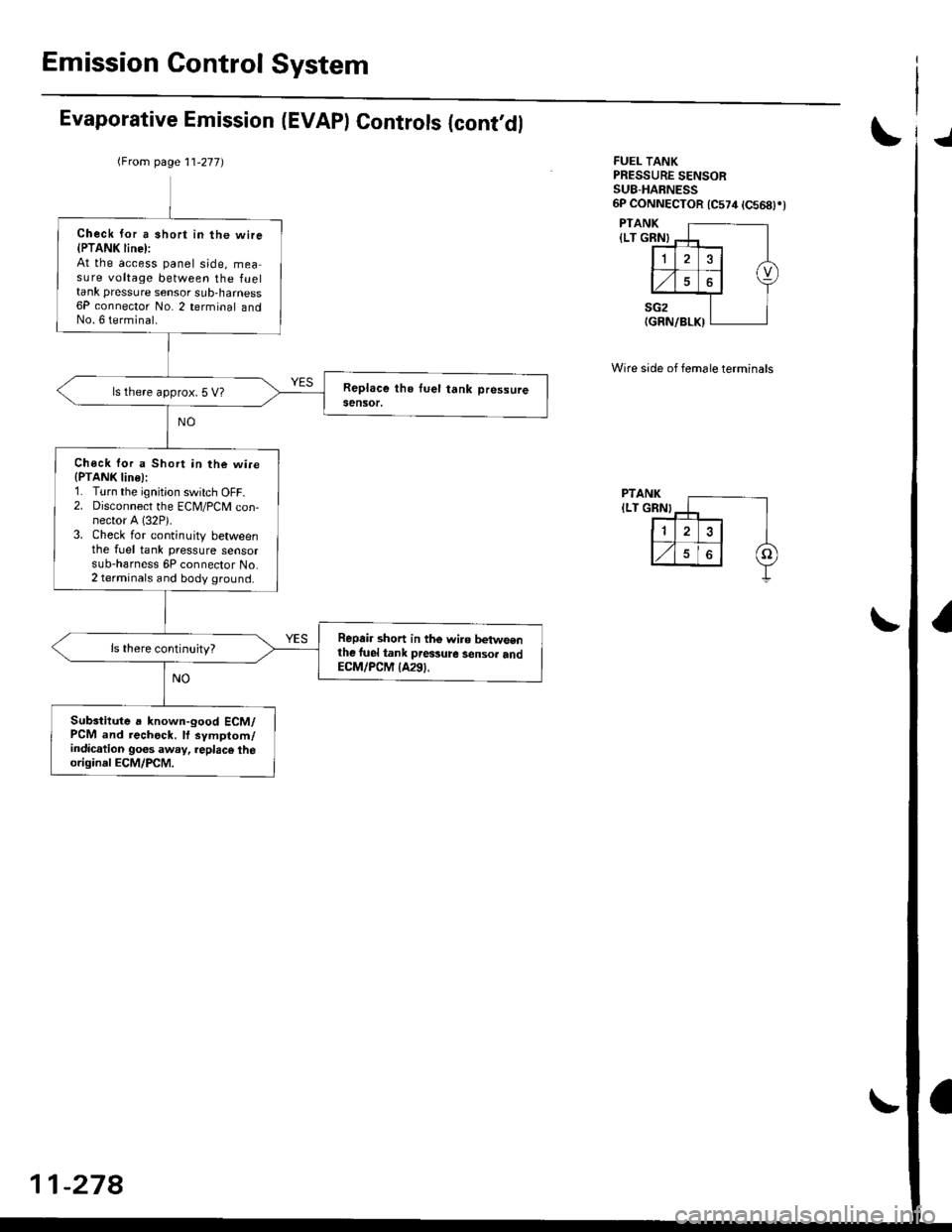

Emission Control System

Evaporative Emission (EVAPI Controls {cont,dlJ

FUEL TANKPRESSURE SENSORSU8-HABNESS6P CONNECTOR 1C574 tC568)rt

PTANK

{LT GRN}

PTANK

ILT GRN}

Wire side of female terminals

(From page 11-277)

Check for a short in the wire{PTANK line):At the access panel side, measure voltage between the fueltank pressure sensor sub-harness6P connector No. 2 terminal andNo. 6 terminal.

ls there approx. 5 V?

Chock lor a Short in the wi.e(PTANK line):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector A (32P).

3. Check for continuity betweenthe fuel tank pressure sensorsub-harness 6P connector No.2 terminals and body ground.

Repair short in the wi.e betwsenthe luel tank pressure sensor andECM/PCM {A291.

Subsiitute a known-good ECM/PCM and rechock. lf symptom/indication goes away, replac€ theoriginal ECM/PCM.

11-278

Page 550 of 2189

\

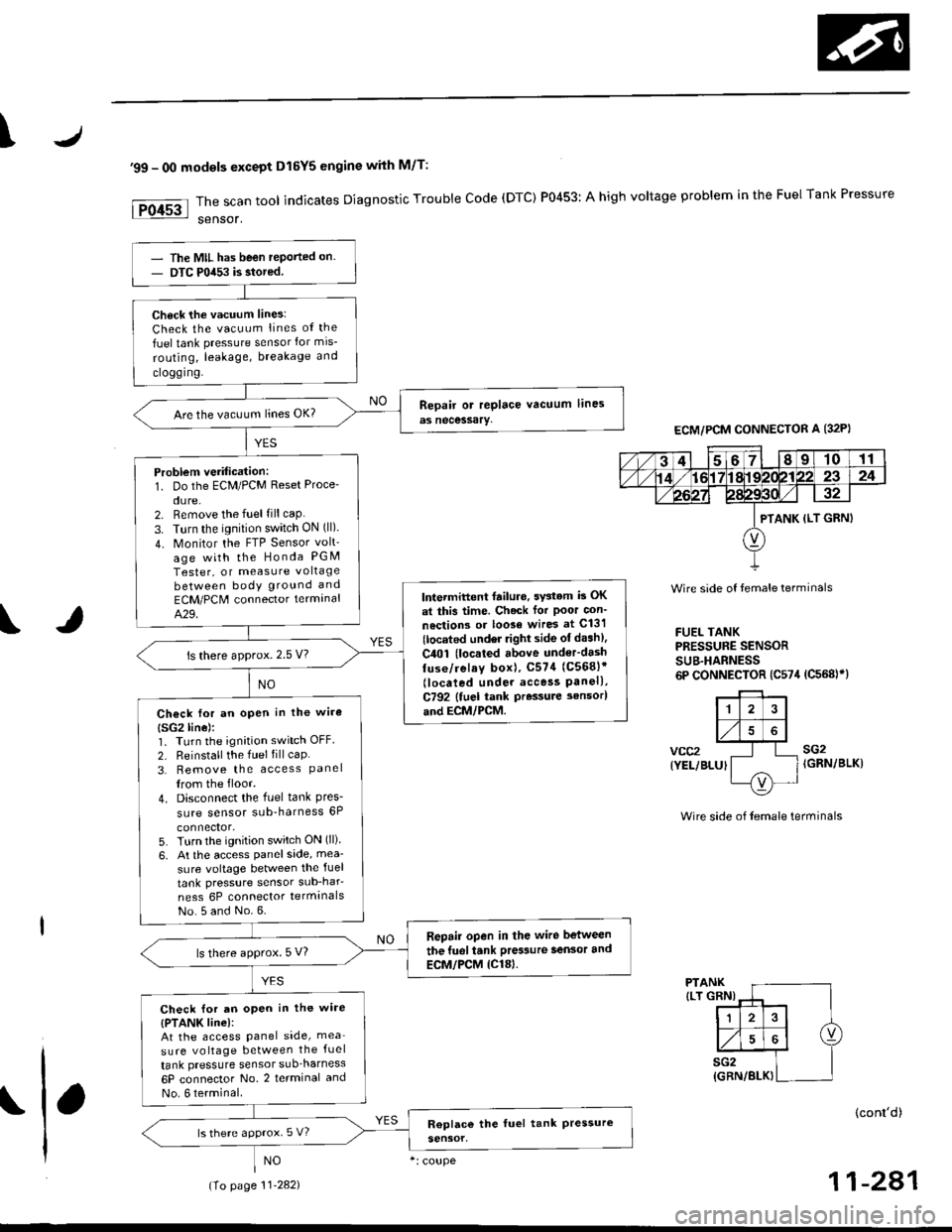

'99 - 0O modols except Dl5Y5 engine with M/T:

rFo45'::n":"tooIindicatesDiagnosticTroub|ecode(DTc)P0453:Ahighvo|tageprob|emintheFUelTankPressure

Wire side of temale terminals

FUEL TANKPRESSUNE SENSOR

SUB.HARNESS6P CONNECTOR {C574 (C568)}}

vcc2{YEL/BLUI

sG2IGRN/BLK)

Wire side of female terminals

PTANK{LT GRNI

(cont'd)

11-281

ECM/PCM CONNECTOR A {32P)

PTANK {LT GRN)

The MIL has been reported on.

DTC P0453 is stored.

Check the vacuum lines:

Check the vacuum lines ot the

fuel tank pressure sensor for mis-

routing, leakage, breakage and

clogging.

Are the vacuum lines OK?

Problem verilication:1. Do the ECM/PCM Reset Proce-

du re,2. Remove the fuel fill caP

3. Turn the ignition switch ON (ll).

4. Monitor the FTP Sensor volt'

age with the Honda PGM

Tester, or measure voltage

between body ground and

ECM/PCM connector terminalA.29.

lntermittent failuro. svstem b OK

at this time. Check for Poor con_

noctions or loo3€ wire3 at C131

{located under tight side of dash),

C4Ol {located above underdash

fuse/relay boxl, C57{ (C5681'

llocaled unde. access Panell,C792 {fuel tank Pressure sensorl

aod ECM/PCM.

ls there approx.2.5 V?

Ch€ck for an open in the wira

{SG2line):1. Turn the ignition switch OFF.

2. Reinstall the fuel fill caP

3. Remove the access Panellrom the floor.

4. Disconnect the fuel tank Pres-sure sensor sub-harness 6P

5. Turn the ignition switch ON (ll)

6, At the access Panelside, mea-

sure voltage between the fuel

tank pressure sensor sub_har-

ness 6P connector termlnals

No.5 and No.6.

Repair open in the wire between

the fueliank Pres3ure 3ensor and

ECM/PCM {Cl8).ls there approx.5 V?

Check lor an oPen in the wire

{PTANK linel:At the access Panel side, mea

sure voltage between the fuel

tank pressure sensor suo_harness

6P connector No. 2 terminal and

No. 6 terminal.

ls there approx. 5 V?

(To page 11.282)

Page 554 of 2189

\

\

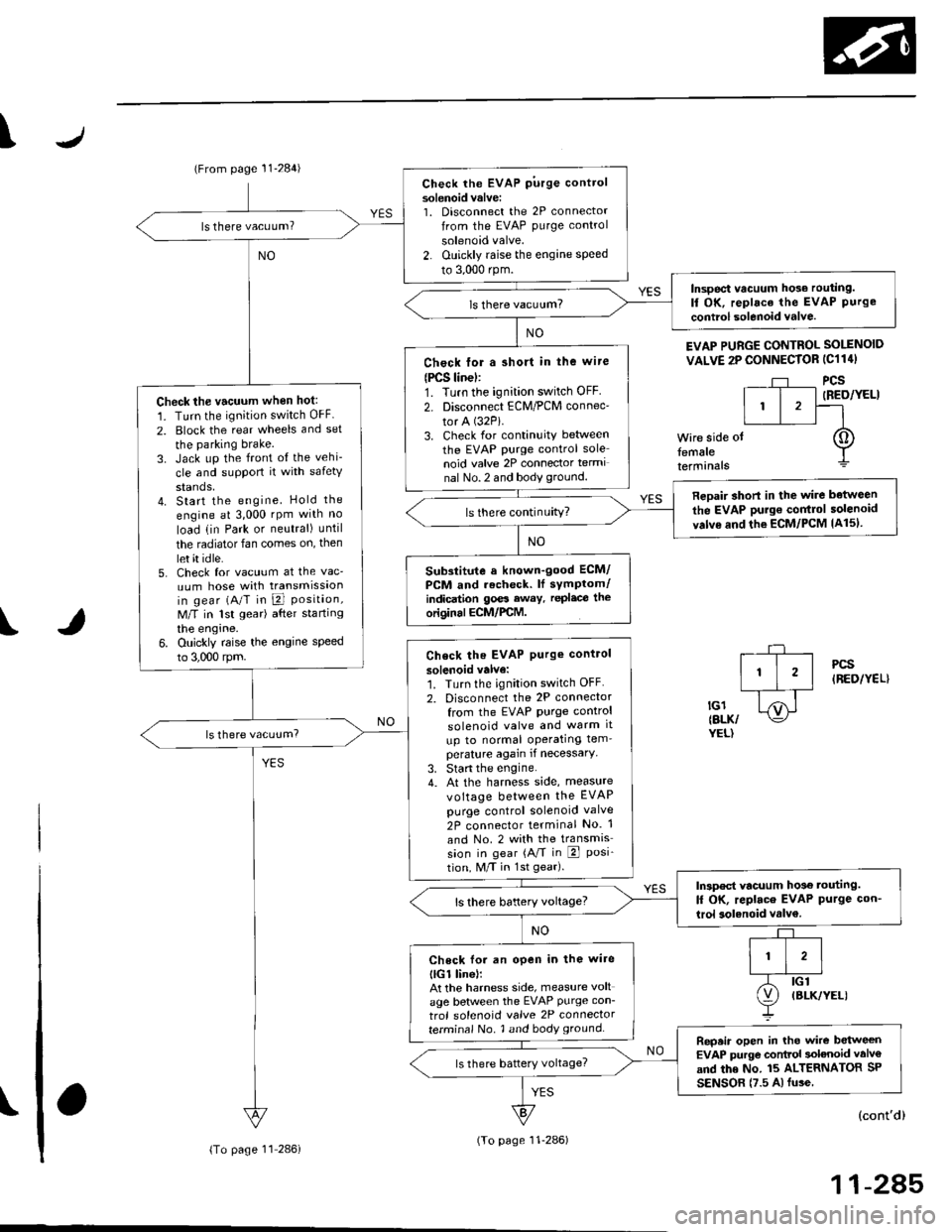

(From page 11-284)

\(cont'd)

11-285

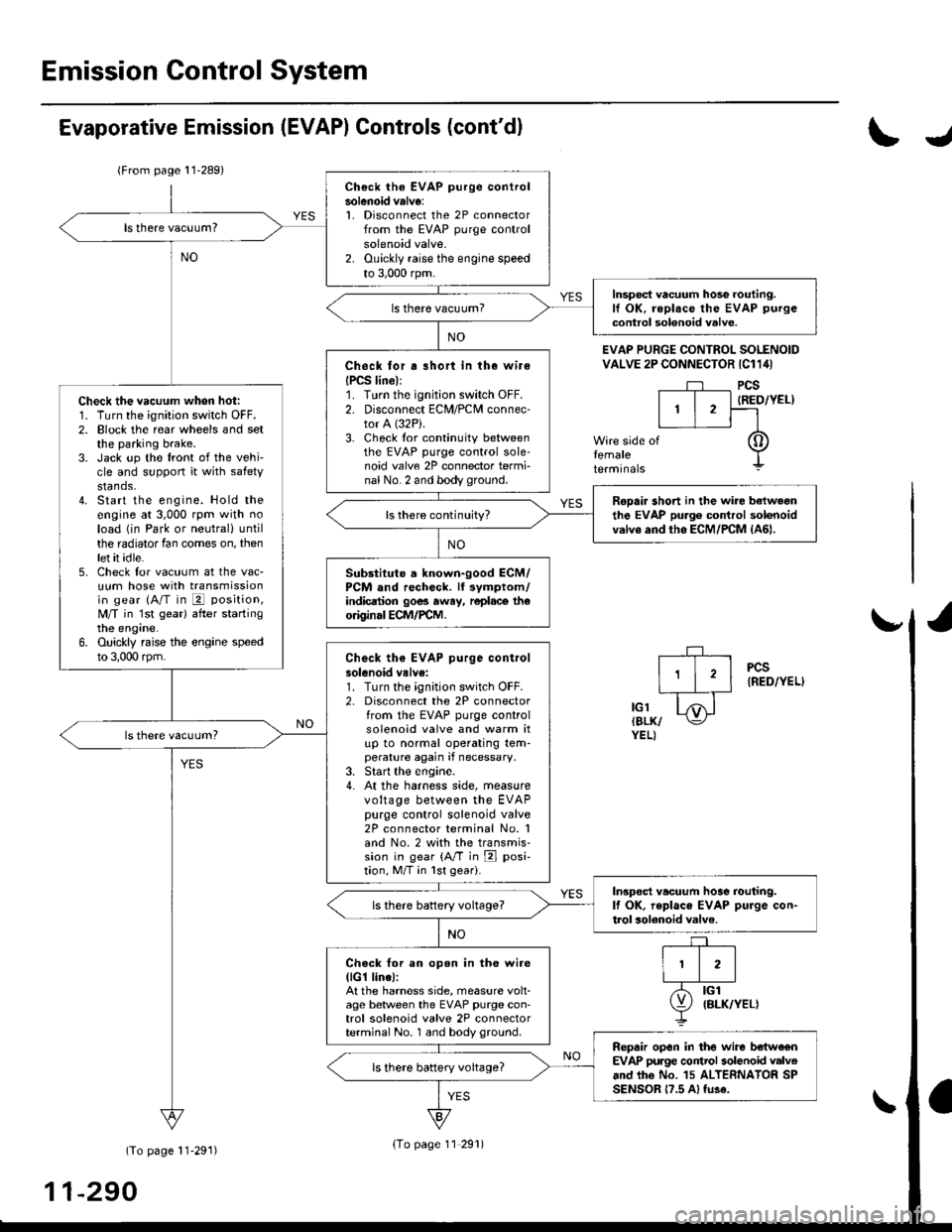

EVAP PURGE CONTROL SOI.INOID

VALVE 2P CONNECTOR IC114I

Wire side otfemaleterminals

?,

I,l,lil?"",,,u

EL,TWYEL)

Check the EVAP pirrge controlsolenoid valvei1. Disconnect the 2P connector

lrom the EVAP purge control

solenoid valve.

2. Ouickly raise the engine speed

to 3,000 rpm.

ls there vacuum?

InsDect vacuum ho56 routing.ll OK, replace the EVAP Purgecontrol solenoid valve.

Chock for a short in the wire(PCS linel:1. Turn the ignition switch OFF

2. Disconnect ECM/PCM connec'

tor A (32Pi.

3. Check for continuity between

the EVAP PUrge control sole

noid valve 2P connector termi

nal No.2 and body ground.

Check the vacuum when hot:

1. Turn the ignition switch OFF

2. Block the rear wheels and set

the parking brake.3. Jack up the front o{ the vehi-

cle and support it with safety

stands,4. Start the engine. Hold the

engine al 3,000 rpm wlth no

load (in Park or neutral) until

the radiator fan comes on, then

let it idle.5, Check for vacuum at the vac-

uum hose with transmissaonin gear (A/T in B Position,M/T in lst gear) after starting

the engrne.6. Ouickly raise the engine speed

to 3,000 rpm.

Reoair short in the wire botween

the EVAP purg€ cor|t]ol solenoid

valve and the ECM/pcM lA15l.ls there continuity?

Substitute a known-good ECM/

PCM and recheck. lf sYmPtom/indication goes eway. repl.c€ the

original ECM/PCM.

Check the EVAP Purg€ control

solenoid valve:1. Turn the ignition switch OFF

2. Disconnect the 2P connector

from the EVAP Purge control

solenoid valve and warm lt

up to normal operating tem_perature again if necessary

3. Stan the engine.4. At the harness side, measure

voltage between the EVAP

Purge control solenoid valve

2P connector terminal No. 1

and No. 2 with the transmission in gear (A,/T in E Posi-tion, M/T in 1st gear).

In3pect vacuum ho3€ touting.

ll OK, replace EVAP Purge con-

lrol aolenoid vtlv€.

Check lo. an open in the wire

llGl linel:At the harness side, measure volt

age between the EVAP Purge con-

trol solenoid valve 2P connectorterminal No. 1 and body groundRepeir open in tho wire between

EVAP purge conttol solenoid valv€

and the No. 15 ALTERNATOR SP

SENSOR (7.5 A fu3e

IBLK/YELI

lTo page 11 286i(To page 11-286)

Page 559 of 2189

Emission Control System

Ch€ck the EVAP purge controlsolenoid valv6:1. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve.2. Ouickly raise the engine speedto 3,000 rpm.

Insped vacuum hose routing.lf OK. roplace the EVAP purge

control solonoid valve.

Chock tor r short in the wir€

{PCS line):1. Turn the ignition switch OFF.2. Disconnect ECM/PCM connec-tor A (32P).

3- Check tor continuity betweenthe EVAP purge control sole-noid valve 2P connector termi-nal No. 2 and body ground.

Check the vacuum when hot:1. Turn the ignition switch OFF.2. Block the rear wheels and setthe parking brake.3. Jack up the lront of the vehi-cle and support it with safetystands.4. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutrali until

the radiator fan comes on, thenlet it idle.5. Check for vacuum at the vac-uum hose with transmissionin gear (A/T in E position,

lvl/T in 1st gear) after startingthe engine.6. Ouickly raise the engine speedto 3,000 rpm.

Rooair shoft in the wire belwegnthe EVAP pulg6 control solenoidvalvs and tho ECM/PCM {A61.ls there continuity?

Substitute a known-good ECM/PCM and rech6ck. lt 3ymptom/indicrtion 90e3 rway, r6plac6 th€o.iginal ECM/FCM.

Check th€ EVAP purge controlsolenoid valve:1. Turn the;gnition switch OFF.2. Disconnect the 2P connectorfrom the EVAP purge controlsolenoid valve and warm itup to normal operating tem-perature again if necessary.3. Start the engine.4- At the harness side, measurevoltage between the EVAPpurge control solenoid valve2P connector terminal No. 1and No.2 with the transmis-sion in gear {A/T in E posi-tion, M/T in lst geari.

In3pect vacuum hoae routing.lf OK, repl.ce EVAP purge con-trol solonoid valve.ls there battery voltage?

Chock for an open in the wire(lG1 lina):At the harnoss side, measure volt-age beNveen the EVAP purge con-trol solenoid valve 2P connectorterminal No. 1 and body ground.

Repair open in the wire b€lwe€nEVAP purge contrl 3olenoid valv6and lhe No. 15 ALTERNATOR SPSENSOR 17.5 A, fu3e.

ls there battery voltage?

Evaporative Emission (EVAPI Controls (cont'dl

(From page 11-289)

(To page 11-291)

11-290

IJ

EVAP PURGE CONTROL SOLENOIDVALVE 2P CONNECTOR IC114I

PCS

IRED/YEL)

temaletermrnars

of

PCS(RED/YEL)

tGlIBLK/YEL)

{To page 11 291)

Page 560 of 2189

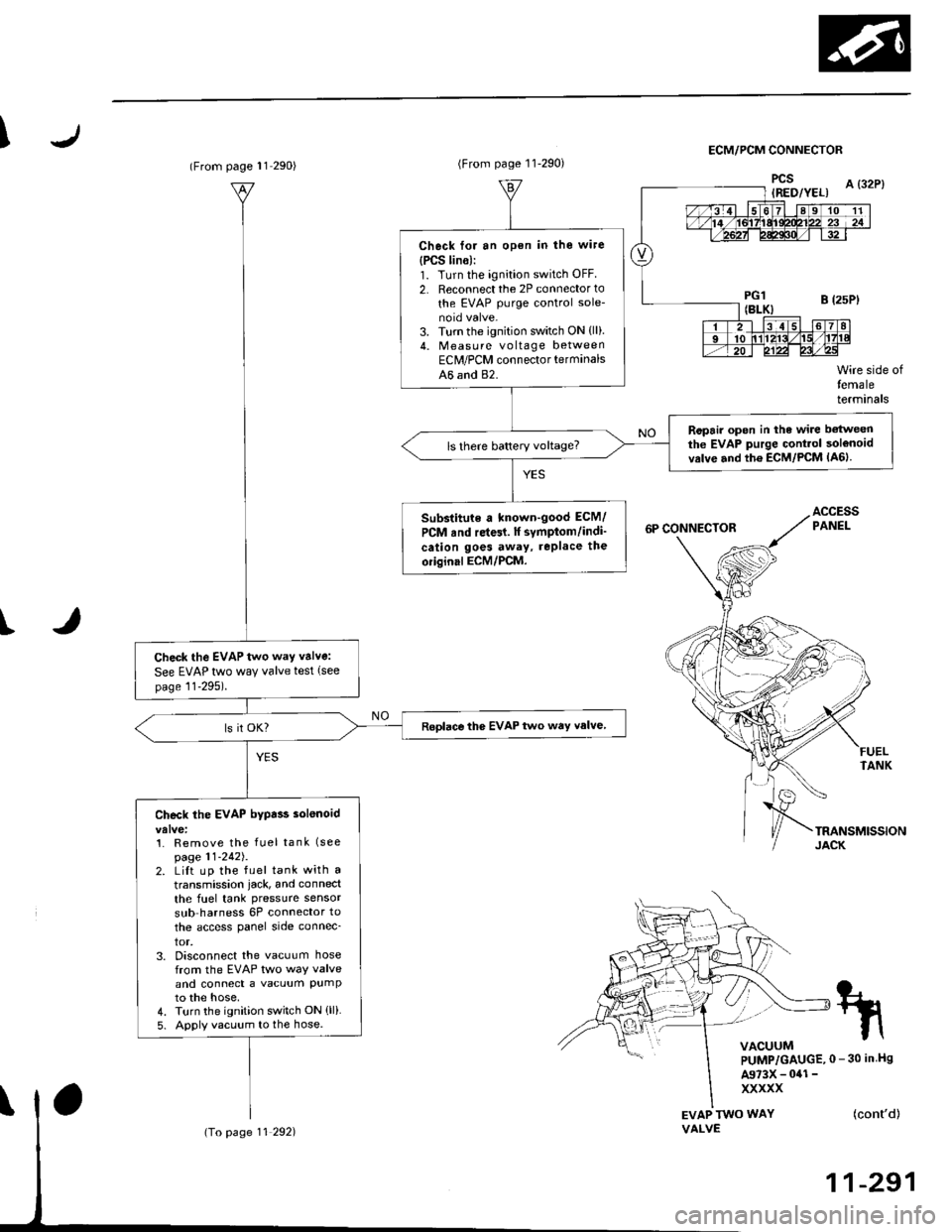

IECM/PCM CONNECTOR

I

EVAP TWO WAYVALVE

Wire side oftemaleterminals

FUELTANK

(cont'd)

11-291

tn

VACUUMPUMP/GAUGE,0 - 30 in Hs

A973X - 041 -

xxxxx

(From page l1 290)

Check the EVAP two way valve:

See EVAP two way valve test (see

page 11-295).

Roplace the EVAP two way valve

Check the EVAP bypa$ solenoid

1. Remove the fuel tank (see

page 11-242J.2. LiIt up the fuel tank with a

transmission iack, and connect

the fuel tank pressure sensor

sub harness 6P connector to

the access panel side connec_

tor,3. Disconnect the vacuum hosefrom the EVAP two way valveand connect a vacuum PumPto the hose,4. Turn the ignition switch ON (ll)

5. Apply vacuum to the hose.

(To page 11 292)

(From page 11-290)

Check for an open in the wire

{PCS lin6):1. Turn the ignition switch OFF

2. Reconnect the 2P connector to

the EVAP purge control sole-

3. Turn the ignition switch ON {ll).4. Measu re voltage betweenEClr/PCM connector terminals

A6 and 82.

Ropair open in the wire betweenthe EVAP purge Gontrol solenoidvrlve and th6 ECM/PCM lA6lls there battery voltage?

Substitute a known-good ECM/

PCM rnd re{61. lf symptom/indi'

cation goes away, rePlace the

oiiginal ECM/PCM.