opening HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 973 of 2189

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator fan com6s on).

1. Apply the parking brake and block the wheels. Start the engine, then shift to the E position while depressing the

brake pedal. Depress the accelerator pedal and release it suddenly. The engine should not stall.

2. Test in E position

Park the vehicle in a slope (approx. 16'). apply the parking brake, and shift into E position. Release the brake; the

vehicle should not move.

3. Test-drive the vehicle on a flat road in the position shown in the table. Check that the engine speeds meet the approx-imate vehicle speeds shown in the table.

NOTE: Throttle position sensor voltage represents the throttle opening. To monitor the throttle position sensor volt-age, use one of the following methods:

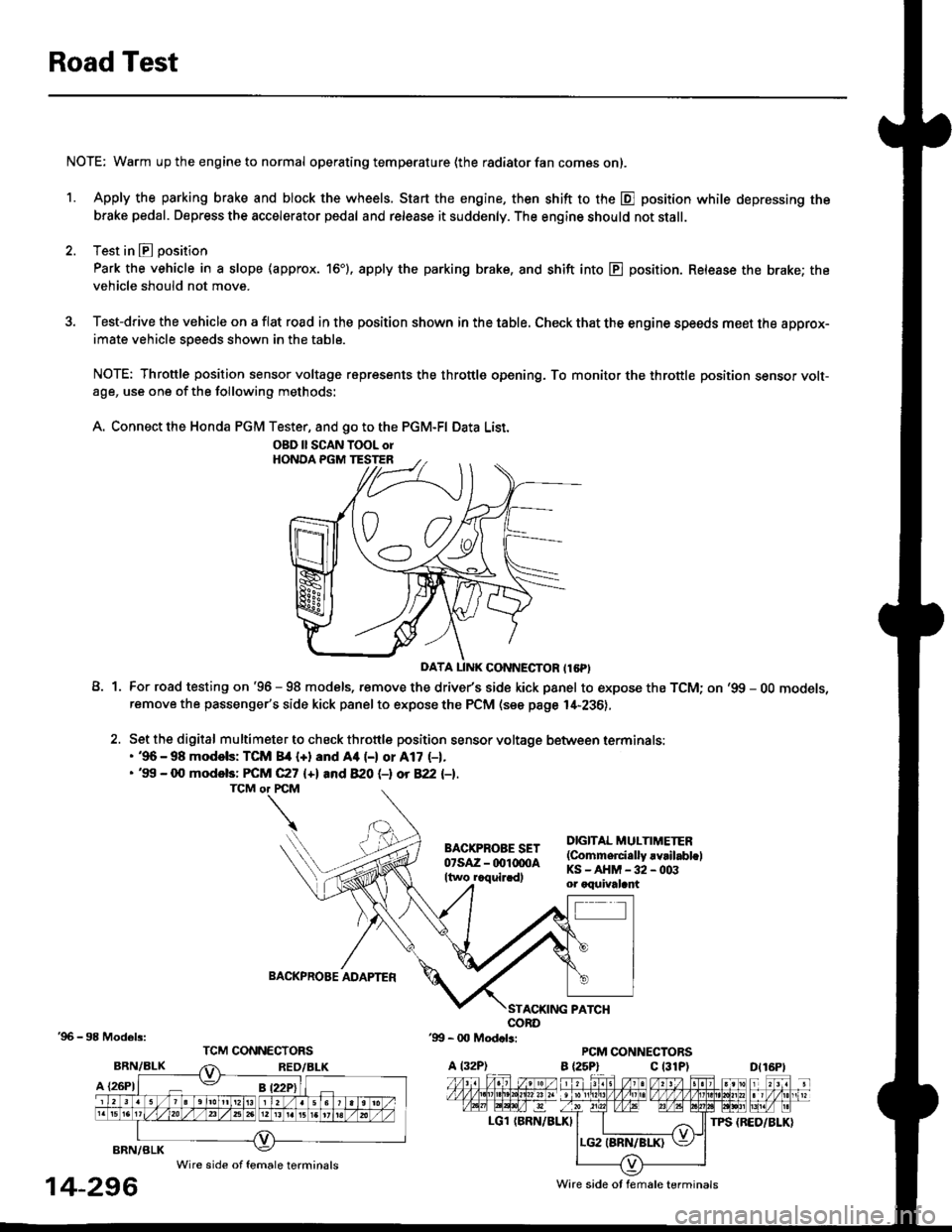

A. Connect the Honda PGM Tester, and go to the PGM-FI Data List.

A1For road testing on '96 - 98 models, remove the drive/s side kick panel to expose the TCM; on '99 - OO models,remove the passenger's side kick panel to expose the PCM (see page l,[-236),

Set the digital multimeter to check throttle position sensor voltage between terminals:. '96 - 98 modols: TCM 84 {+} and Aa (-) or A17 (-1.. '99 - 0O models: FCM C27 {+l and 820 (-l ot 822 l-1.

DIGITAL MULTIMETER(Commerci.lly rvrilabl.lKS-AHM-32-003or oquivalant

BACKPROBE ADAPTER

BRN/BLK

A {26P1

TPS {BED/BLK}

'96 - 98 Models:

BRN/BLK

14-296

OBD ll SCAN TOOL orHONOA PGM TESTER

D{16Pt

Ware side ot female terminals

Wire side of female terminals

Page 974 of 2189

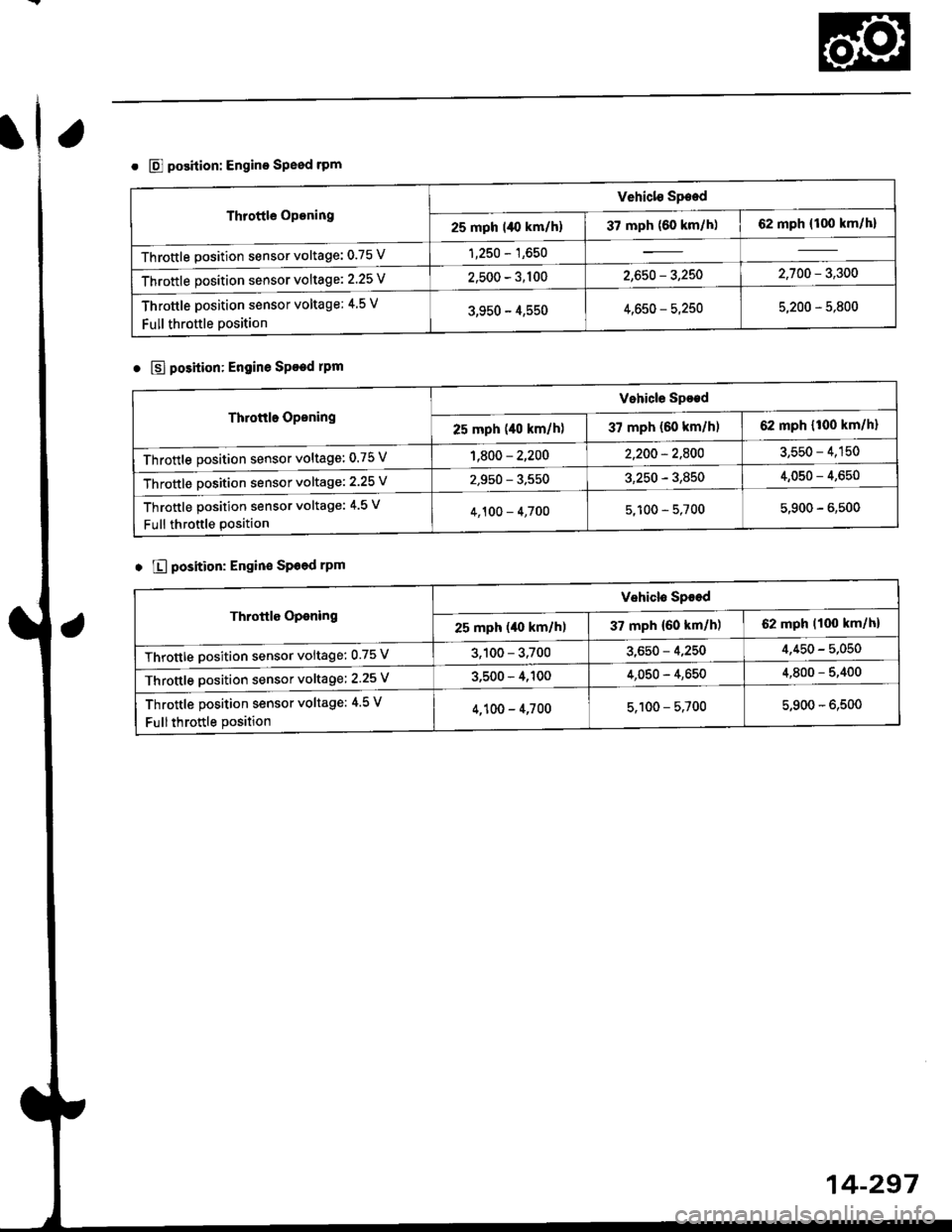

o @ position: Engino Speed rPm

Throttle Opening

Vehiclo Speed

-25 mph l/() km/h) | 37 mph {60 km/h) | 62 mph {100 km/h}

Throttle position sensor voltage: 0.75 V1,250 - 1,650

Throttle position sensor voltage: 2'25 V2,500 - 3,1002,650 - 3,2502,700 - 3,300

Throttle position sensor voltage; 4 5 V

Full throttle position3,950 - 4,5504,650 - 5,2505,200 - 5,800

o $l position: Engine Speed rPm

Throttle Oponing

Vehicle Spoed

2s mph (40 km/hl | 37 mph (60 km/hl | 62 mph {r00 km/h}

Throttle position sensor voltage: 0.75 V1,800 - 2,2002,200 - 2,8003,550 - 4,150

Throttle Dosition sensor voltage: 2.25 V2,950 - 3.5503,250 - 3,8504,050 - 4,650

Throftle position sensor voltage: 4.5 v

Full throftle position4,100 - 4,7005,100 - 5,7005,900 - 6,500

o E position: Engin€ Sp6ed rPm

Throttle Oponing

Vehiclo Spoed

25 mph (40 km/hl | 37mPh{60km/h) J 62 mph 1100 km/h}

Throttle Dosition sensor voltage: 0.75 V3,100 - 3,7003,650 - 4,2504,450 - 5,050

Throttle position sensor voltage; 2.25 V3,500 - 4,1004,050 - 4,6504,800 - 5,400

Throttle position sensor voltage: 4.5 V

Fullthrottle position4,100 - 4,7005,100 - 5.7005,900 - 6,500

14-297

Page 992 of 2189

l.

'1.

2.

5.

6.

7.

Remove the ATF cooler inlet iine bracket bolt'

Remove the ATF cooler outlet line

Remove the ATF pan (fourteen bolts).

Remove the ATF strainer {two bolts)

Remove the one bolt securing the solenoid harness

connector, then push the connector.

Remove the lower valve body (eight bolts)

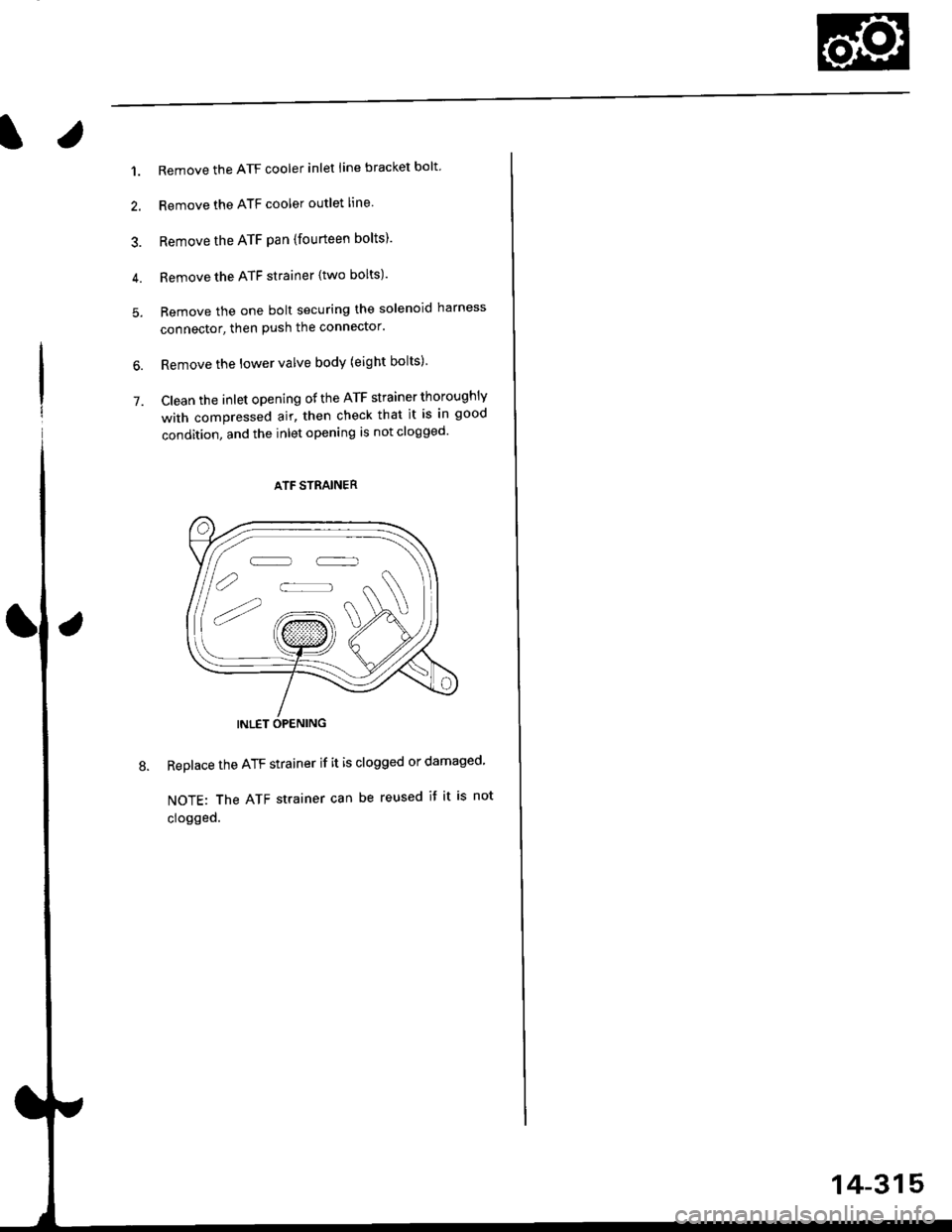

Clean the inlet opening of the ATF strainer thoroughly

with compressed air, then check that it is in good

condition, and the inlet opening is not clogged'

ATF STRAINER

INLET OPENING

Replace the ATF strainer if it is clogged or damaged

NOTE: The ATF strainer can be reused it it is not

clogged.

2c'

c;2 ar\

14-315

Page 1096 of 2189

Power Steering Pump

RemovaUlnstallation

NOTE: Eefore disconnecting the hoses from the pump,

Dlace a suitable container under the vehicle.

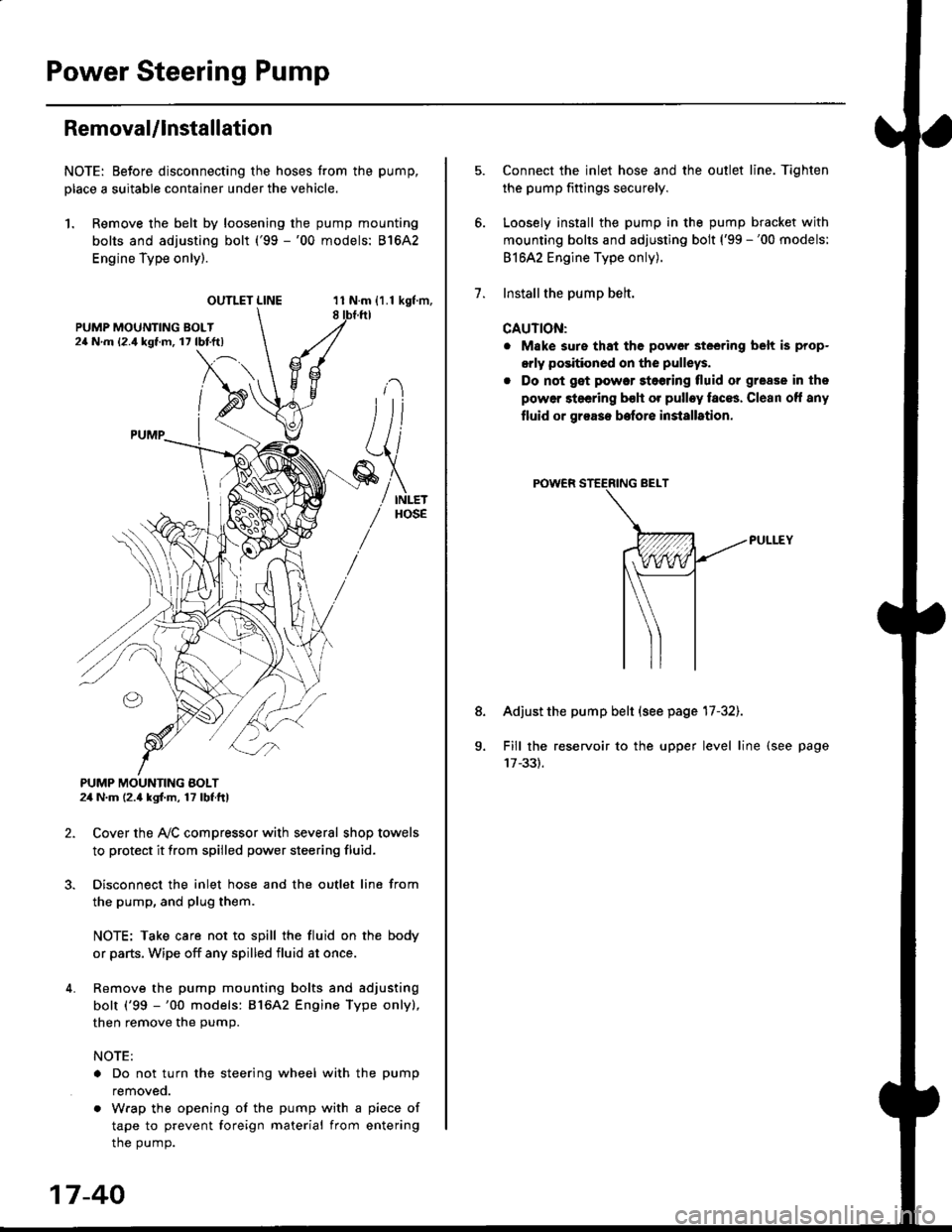

1. Remove the belt by loosening the pump mounting

bolts and adjusting bolt ('99 -'00 models: 81642

Engine Type only).

OUTLET LINE11 N.m {1.1 kgf'm,8

L

PUMP MOUNTING BOLT24 N.m (2.4 kgl.m, 17 lbf ft)

2. Cover the Ay'C compressor with several shop towels

to protect it from spilled power steering fluid.

3. Disconnect the inlet hose and the outlet line from

the pump, and plug them.

NOTE: Take care not to spill the fluid on the body

or parts, Wipe off any spilled fluid at once.

4. Remove the pump mounting bolts and adjusting

bolt ('99 -'00 models: 816A2 Engine Type only),

then remove the pump.

NOTE:

. Do not turn the steering wheel with the pump

removeo.

. Wrap the opening of the pump with a piece of

tape to prevent foreign material from entering

the pump.

17-40

1.

8.

Connect the inlet hose and the outlet line. Tiqhten

the pump fittings securely.

Loosely install the pump in the pump bracket with

mounting bolts and adjusting bolt ('99 -'00 models:

81642 Engine Type only).

Installthe pump belt.

CAUTION:

. Make sure that the power steering belt is prop-

orly positioned on the pulleys.

. Do not get power stoering tluid or grease in the

power steering bsh or pulley faces. Clean off any

fluid or grease before installrtion.

Adjust the pump belt (see page 17-32).

Fill the reservoir to the upper level line (see page

Page 1235 of 2189

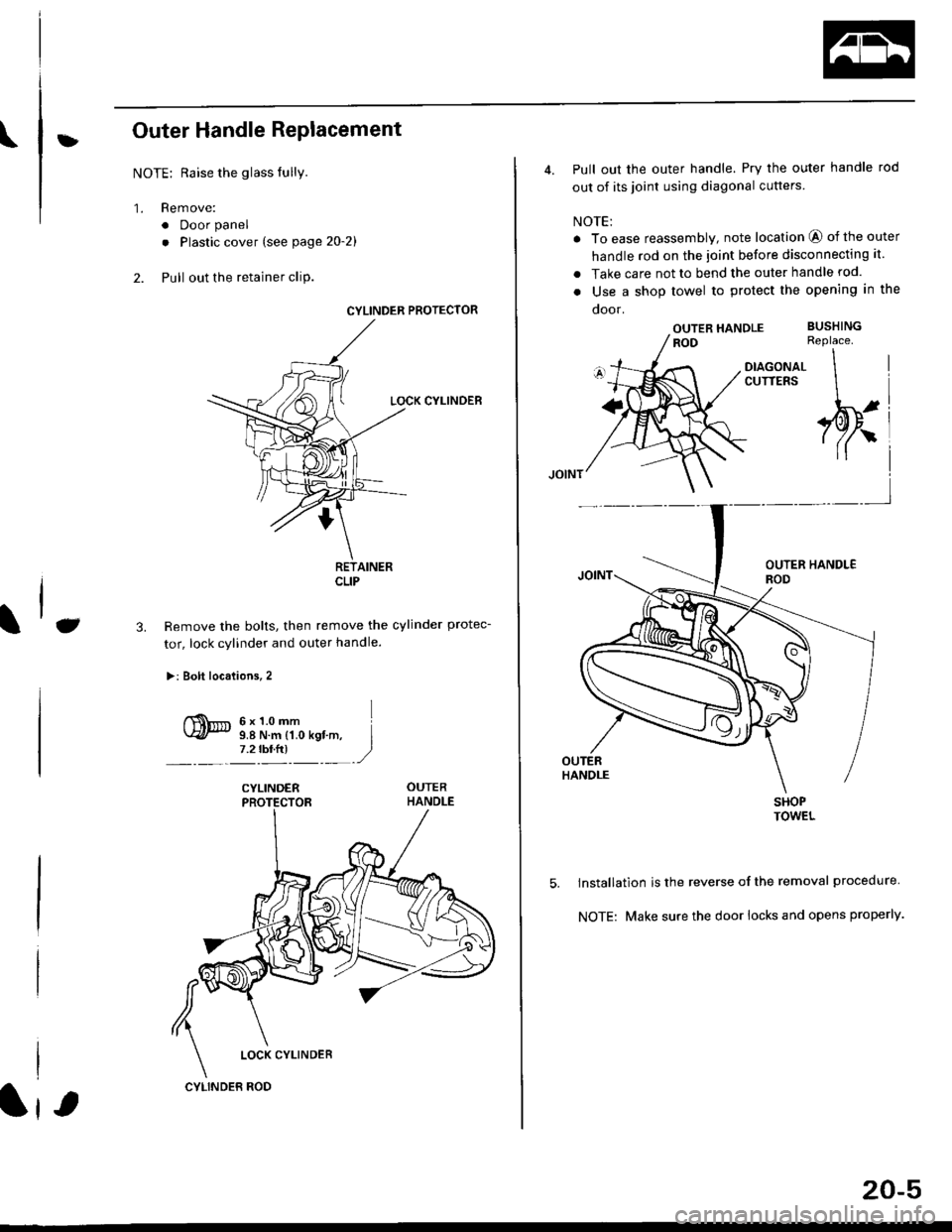

\:Outer Handle Replacement

NOTE: Raise the glass fully.

'1. Remove:

. Door panel

. Plastic cover (see page 2o-21

2. Pull out the retainer cliP.

6x1.omm Ii.e N.. tr.o rgf.-, I7.2 rbr.fi) ,2

C3.

CYLINDER PROTECTOR

LOCK CYLINDEB

RETAINERCLIP

Remove the bolts, then remove the cylinder protec-

tor, lock cylinder and outer handle.

>: Bolt locaiions,2

CYLINDER

LOCK CYLINDER

CYLINDER ROD

20-5

4. Pull out the outer handle. Pry the outer handle rod

out of its joint using diagonal cutters

NOTE:

a To ease reassembly, note location @ of the outer

handle rod on the joint before disconnecting it.

. Take care not to bend the outer handle rod.

o Use a shop towel to protect the opening in the

ooor.

OUTER HANDLEROD

DIAGONALCUTTERS

SHOPTOWEL

lnstallation is the reverse of the removal procedure

NOTE: Make sure the door locks and opens properly.

BUSHINGReplace.

\

,w.

5.

i4'

Page 1241 of 2189

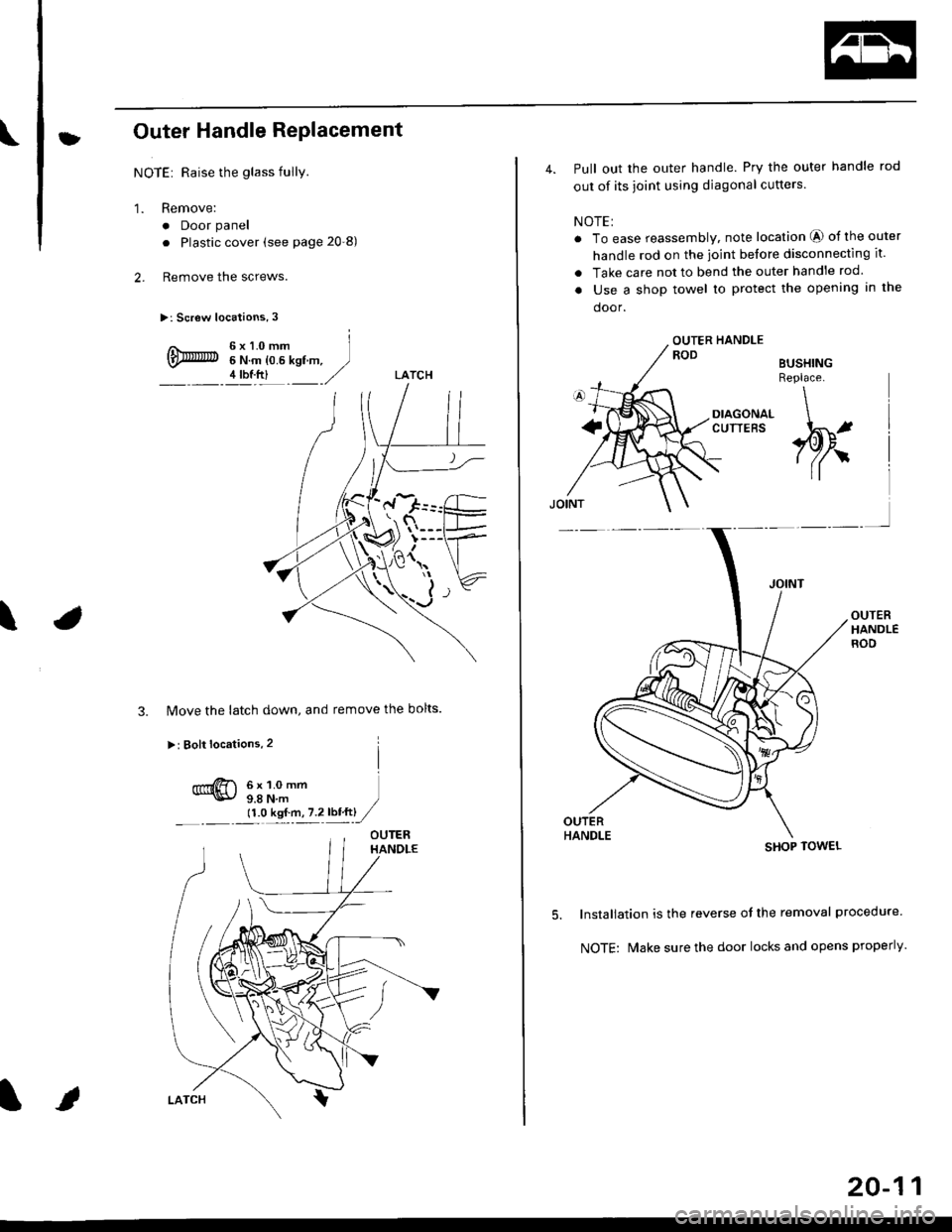

tOuter Handle Replacement

NOTE: Raise the glass fullY.

1. Remove:

. Door panel

. Plastic cover (see page 20-8)

2. Remove the screws.

>: Screw locations, 3

6x1.0mm6 N.m {0.6 kgf m,4 tbf.ftl

a\

3. Move the latch down, and remove the bolts.

>: Bolt locations,2

6x1.0mm9.8 N,m )11.O kst.n,7.2lbiftl //

4. Pull out the outer handle. Pry the outer handle rod

out of its joint using diagonal cutters.

NOTE:

. To ease reassembly, note location O of the outer

handle rod on the joint before disconnecting it.

. Take care not to bend the outer handle rod.

. Use a shop towel to protect the opening in the

door.

BUSHINGReplace.

OUTERHANDLEROD

5.

o

DIAGONAL \

:"'* ,w,

lnstallation is the reverse of the removal procedure

NOTE: N4ake sure the door locks and opens properly.

SHOP TOWEL

20-11

Page 1247 of 2189

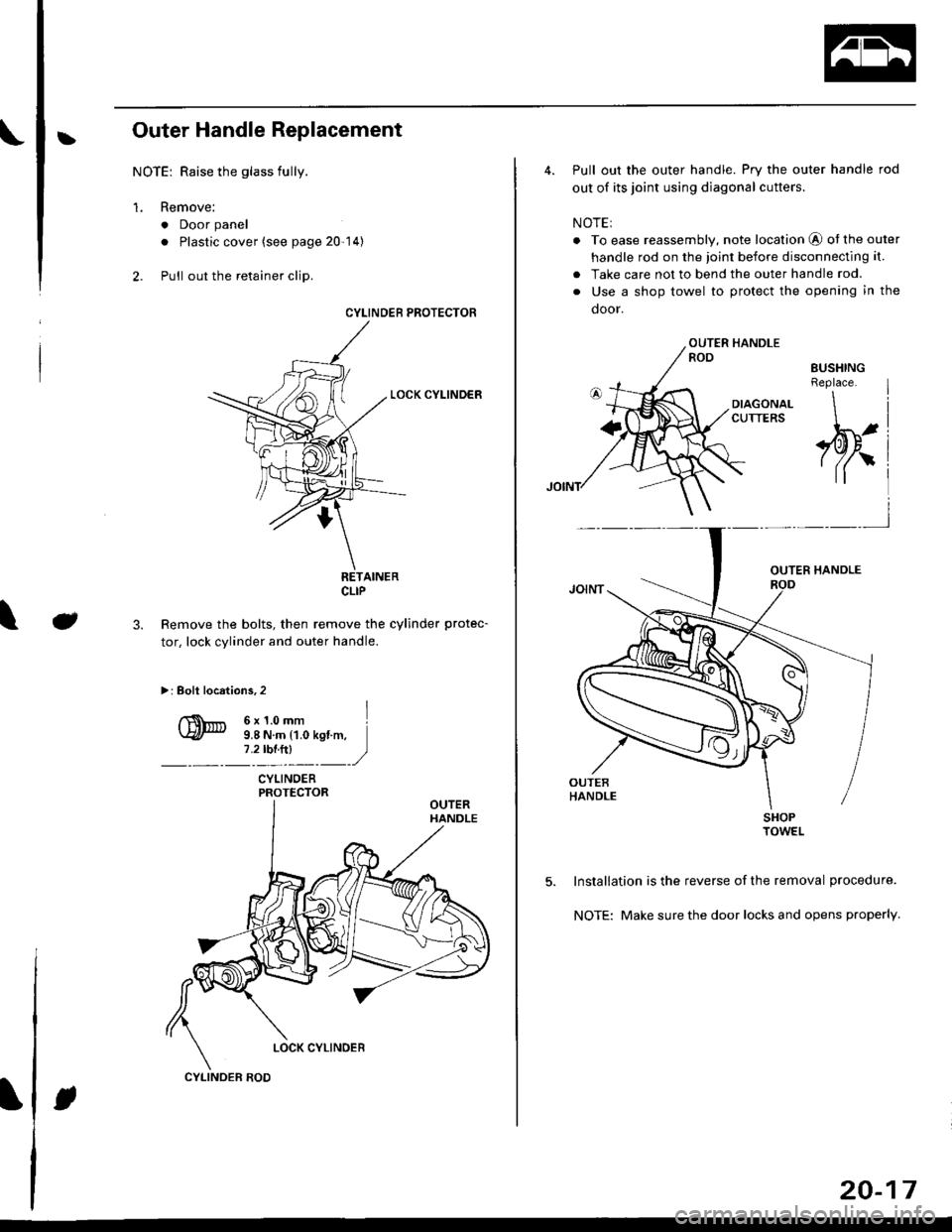

bOuter Handle Replacement

NOTE: Raise the glass fully.

1. Remove:

. Door panel

. Plastic cover (see page 20-14)

2. Pull out the retainer clip.

3.e\

CYLINOER PROTECTOR

LOCK CYLINDER

RETAINERCLIP

Remove the bolts, then remove the cylinder protec-

tor, lock cylinder and outer handle.

>: Bolt locations,2

6x1.omm ]9.8 N.m {1.0 kgf.m,1.2tbl,ttl )_, _-_-,/

CYLINDERPROTECTOR

LOCK CYLINOER

CYLINOER ROD

20-17

4. Pull out the outer handle. Pry the outer handle rod

out of its joint using diagonal cutters.

NOTE:

. To ease reassembly, note location @ ot the outer

handle rod on the joint before disconnecting it.

. Take care not to bend the outer handle rod.

. Use a shop towel to protect the opening in the

door.

DIAGONALCUTTERS

SHOPTOWEL

5. Installation is the reverse of the removal procedure.

NOTE: Make sure the door locks and opens properly.

EUSHINGReplace.

\

,pr,

Page 1259 of 2189

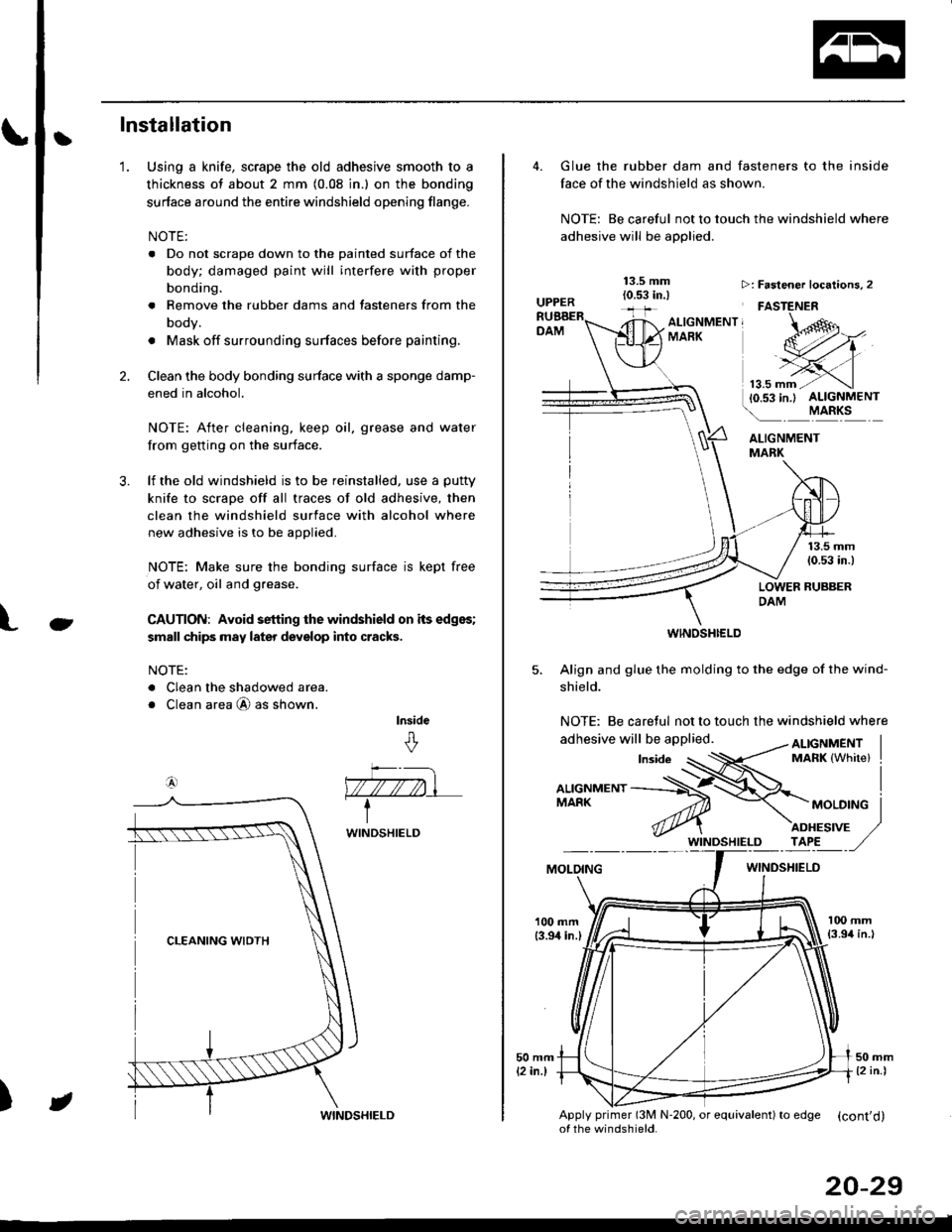

tInstallation

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire windshield opening flange.

NOTE:

. Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

. Remove the rubber dams and tasteners from the

body.

. Mask off surrounding surfaces before painting.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: After cleaning, keep oil, grease and water

from getting on the surface.

lf the old windshield is to be reinstalled, use a putty

knife to scrape off all traces of old adhesive, then

clean the windshield surface with alcohol where

new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the windshield on its edges;

small chips may later deyelop into cracks.

NOTE:

. Clean the shadowed area.

o Clean area @ as shown.

lnside

&

'1.

2.

3.

Ct

a4)

)

WINDSHIELD

JWINDSHIELD

20-29

Glue the rubber dam and fasteners to the inside

face of the windshield as shown.

NOTE: Be careful not to touch the windshield where

adhesive will be applied.

ALIGNMENTMABK

13.5 mm(0.53 in.)

LOWER RUBBERDAM

WINOSHI€LD

5. Align and glue the molding to the edge of the wind-

shield.

NOTE: Be caretul not to touch the windshield where

>: Faslener localions, 2

FASTENER

ALTGNMENT, -oMARK

MOLOINGWINDSHIELO

100 mm{3.94 in.l

Apply primer (3M N'200, or equivalent) to edSe (cont'd)of the windshield.

Page 1260 of 2189

Windshield

Installation (cont'd)

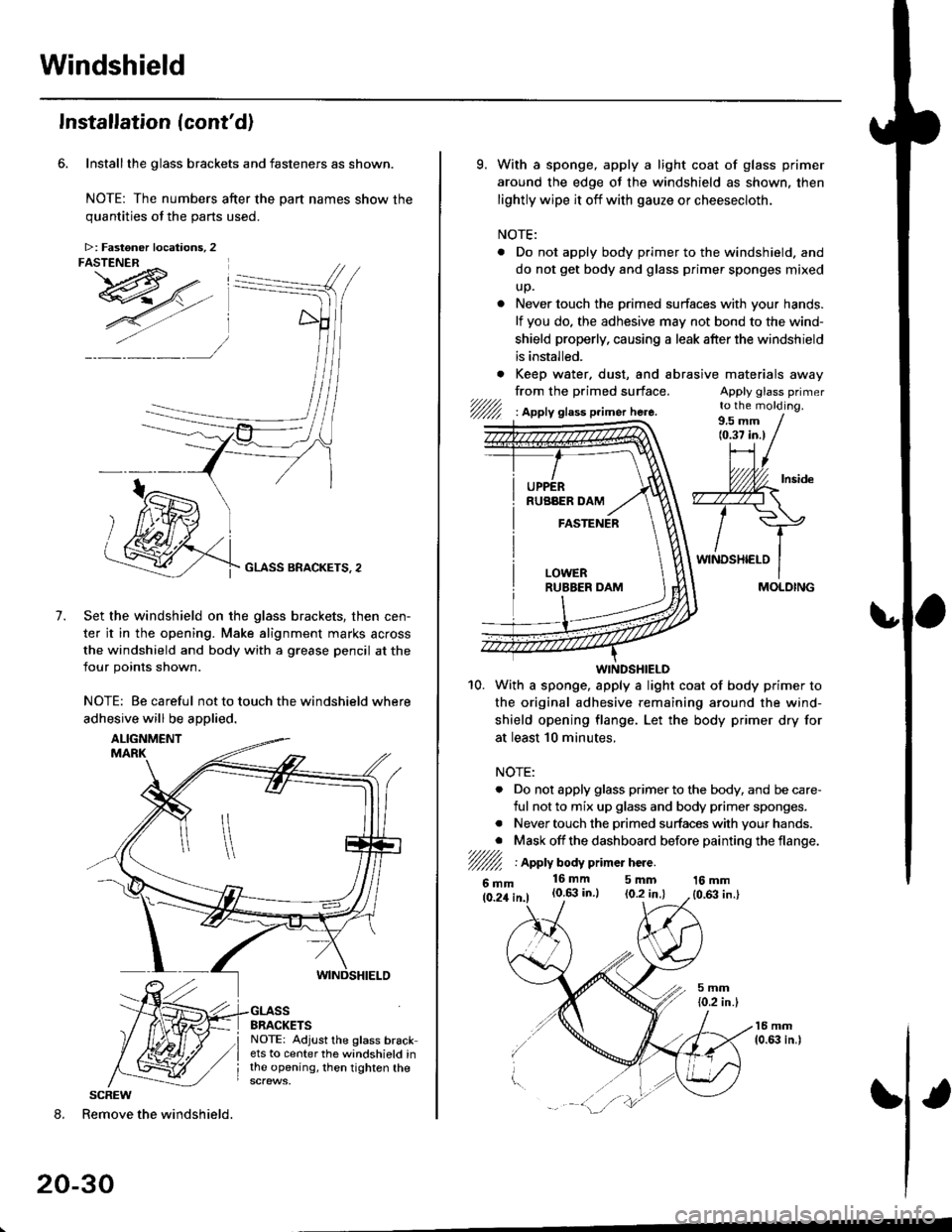

Installthe glass brackets and fasteners as shown.

NOTE: The numbers after the part names show thequantities of the oarts used.

GLASS BRACKETS, 2

Set the windshield on the glass brackets, then cen-

ter it in the opening. Make alignment marks across

the windshield and body with a grease pencil at the

four points shown.

NOTE: Be careful not to touch the windshield where

adhesive will be aDolied.

7.

8. Remove the windshield.

20-30

>: Fastoner locations, 2FASTENER ^ I

I

SCREW

9. With a sponge, apply a light coat of glass primer

around the edge of the windshield as shown. then

lightly wipe it off with gauze or cheesecloth.

NOTE:

. Do not apply body primer to the windshield. and

do not get body and glass primer sponges mixed

up.

. Never touch the primed surfaces with your hands.

lf you do. the adhesive may not bond to the wind-

shield properly, causing a leak after the windshield

is installed.

. Keep water. dust, and abrasrve

from the primed surface.t/////,'/////l I Apply glass p.imer here.

materaals away

Apply glass primerto the molding.

WINDSHIELD

10. With a sponge. apply a light coat of body primer to

the original adhesive remaining around the wind-

shield opening flange. Let the body primer dry for

at least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be care-

ful not to mix up glass and body primer sponges.

. Never touch the primed surfaces with your hands.

. Mask off the dashboard before painting the flange.7////l/////l I Apply body p mer hcre.

6mm16mm 5mm(0.6:| in.) (0.2 in.l16 mm

{0,63 in.}

/

MOLDING

Page 1261 of 2189

3

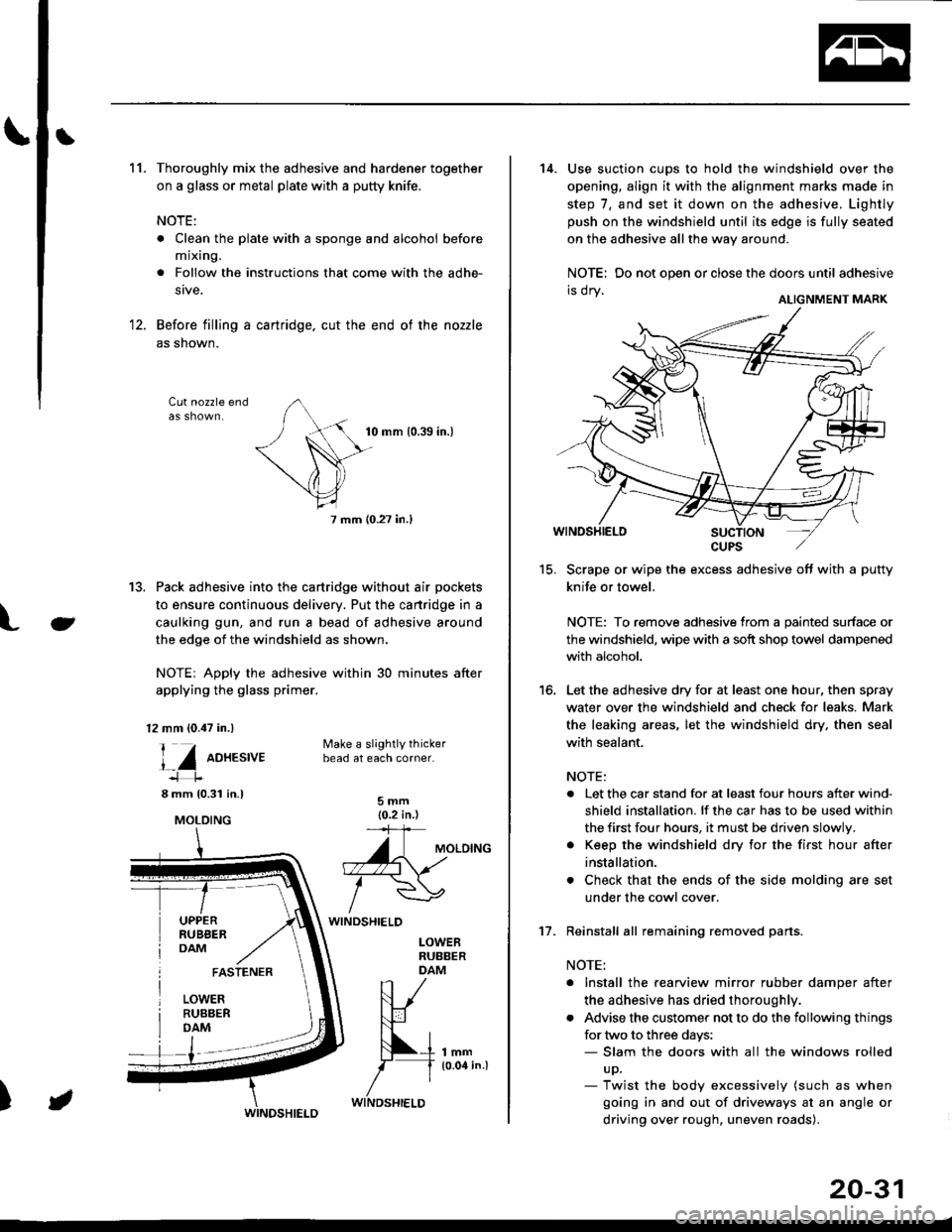

11.Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mixing.

. Follow the instructions that come with the adhe-

stve.

Before filling a cartridge. cut the end of the nozzle

as shown.

Cut nozzle end

tu

10 mm 10.39 in.)

7 mm (0.27 in.l

13. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (0.47 in.)

l_Z oo*.t,ut

8 mm 10.31 in.l

UPPERRUBBERDAM

Make a slightly thickerbead at each corner.

5mm(0.2 in )='+

A\uloto^o. -.\

/wWINDSHIELD

LOWEBRUBBERDAM

lmm10.04 in.l

FASTENER

LOWERRUBBERDAM

)

MOLDING

WINDSHIELD

20-31

15.

16.

14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTE: Do not open or close the doors until adhesive

ri vI Y ALTGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface or

the windshield, wipe with a soft shop towel dampened

with alcohol.

Let the adhesive dry for at least one hour, then spray

water over the windshield and check for leaks. Mark

the leaking areas, let the windshield dry, then seal

with sealant.

NOTE:

. Let the car stand for at least four hours after wind-

shield installation. lf the car has to be used within

the first four hours, it must be driven slowly.

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl',.

. Advise the customer not to do the following things

for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excessively (such as when

going in and out of driveways at an angle or

driving over rough, uneven roads).

't7.