removal HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 125 of 2189

Valve Seals

Replacement (Cylinder head removal not requiredl

NOTE: Cylinder head removal is not required in thisprocedure.

The procedure shown below applies when using the in-

car valve spring compressor (Snap-on YA884S withY48845 - 2 A7/8" attachment).

!@@ Alway wear approved eye protection whenusing ihe in-cai valve spring compressor.

1. Turn the crankshaft so that the No. I and the No. 4pistons are at top dead center (TDC).

2. Remove the cylinder head cover and the rocker arm

assembly.

NOTE:

. Refer to page 6-30 for rocker arm assembly

removat.

. When removing or installing the rocker armassembly, do not remove the camshaft holder

bolts. The bolts will keep the holders, springs

and rocker arms on the shaft.

. Refer to page 6-46 when installing the cylinder

head cover.

Remove the fuel injectors and the wire harness.

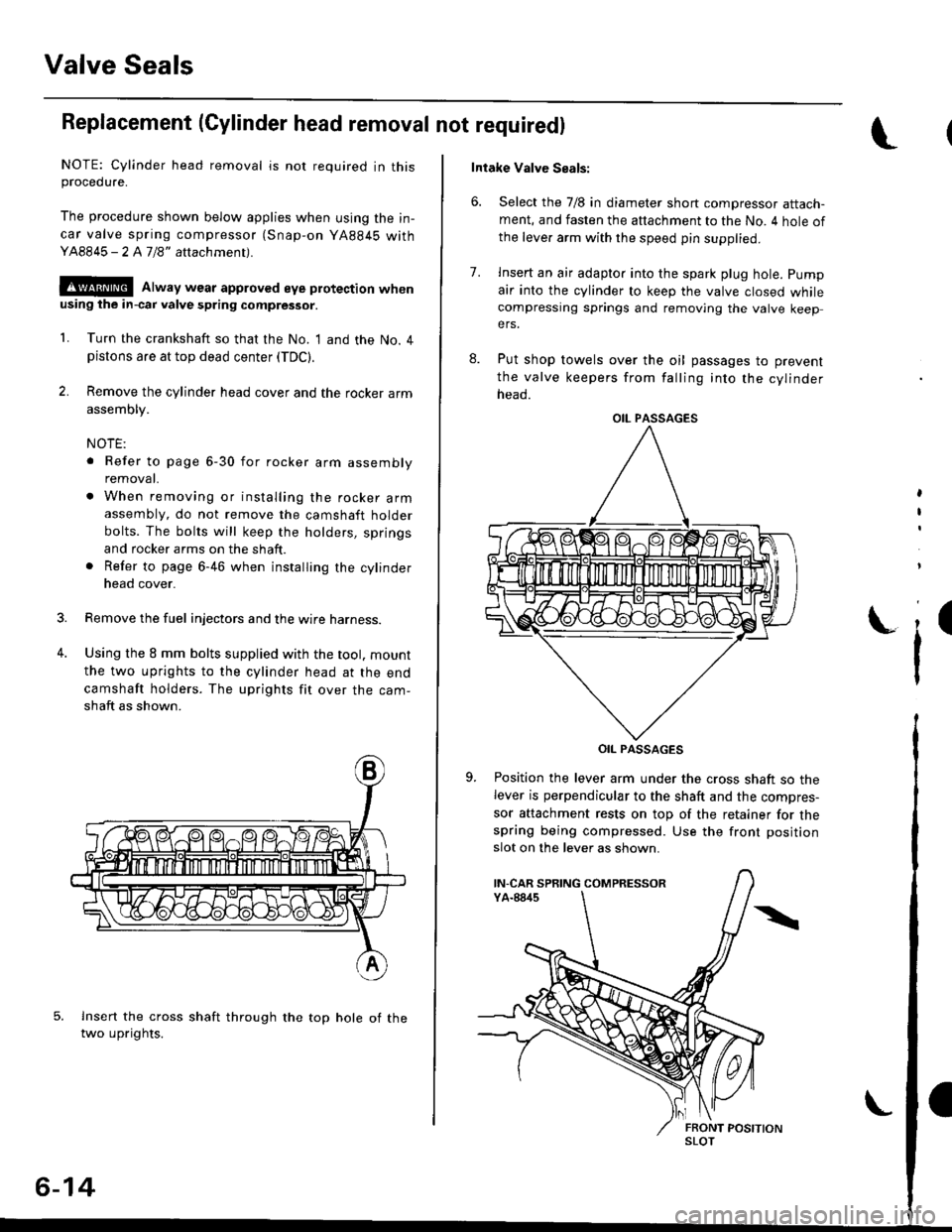

Using the 8 mm bolts supplied with the tool. mount

the two uprights to the cylinder head at the end

camshaft holders. The uprights fit over the cam-

shaft as shown.

lnsert the cross shaft through the top hole of thetwo uprights.

3.

4.

6-14

Intake Valve Seals:

6. Select the 7/8 in diameter short compressor attach-ment, and fasten the attachment to the No. 4 hole of

the leve. arm with the speed pin supplied.

8.

7.lnsert an air adapto. into the spark plug hole. pump

air into the cylinder to keep the valve closed whilecompressing springs and removing the valve keepers.

Put shop towels over the oil passages to prevent

the valve keepers from falling into the cylinder

neao.

OIL PASSAGES

Position the lever arm under the cross shaft so thelever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for thespring being compressed. Use the front position

slot on the lever as shown.

,

I

i'

OIL PASSAGES

IN-CAR SPRING COMPRESSOR

SLOT

Page 126 of 2189

10. Using a downward motion on the lever arm, com-

.press the valve spring and remove the keepers from

the valve stem. Slowly release pressure on the

spring.

11. Remove the valve seals (see page 6-38).

12. Install the valve seals {see page 6-43).

13. Install the springs, the retainers and the keepers in

reverse order of removal.

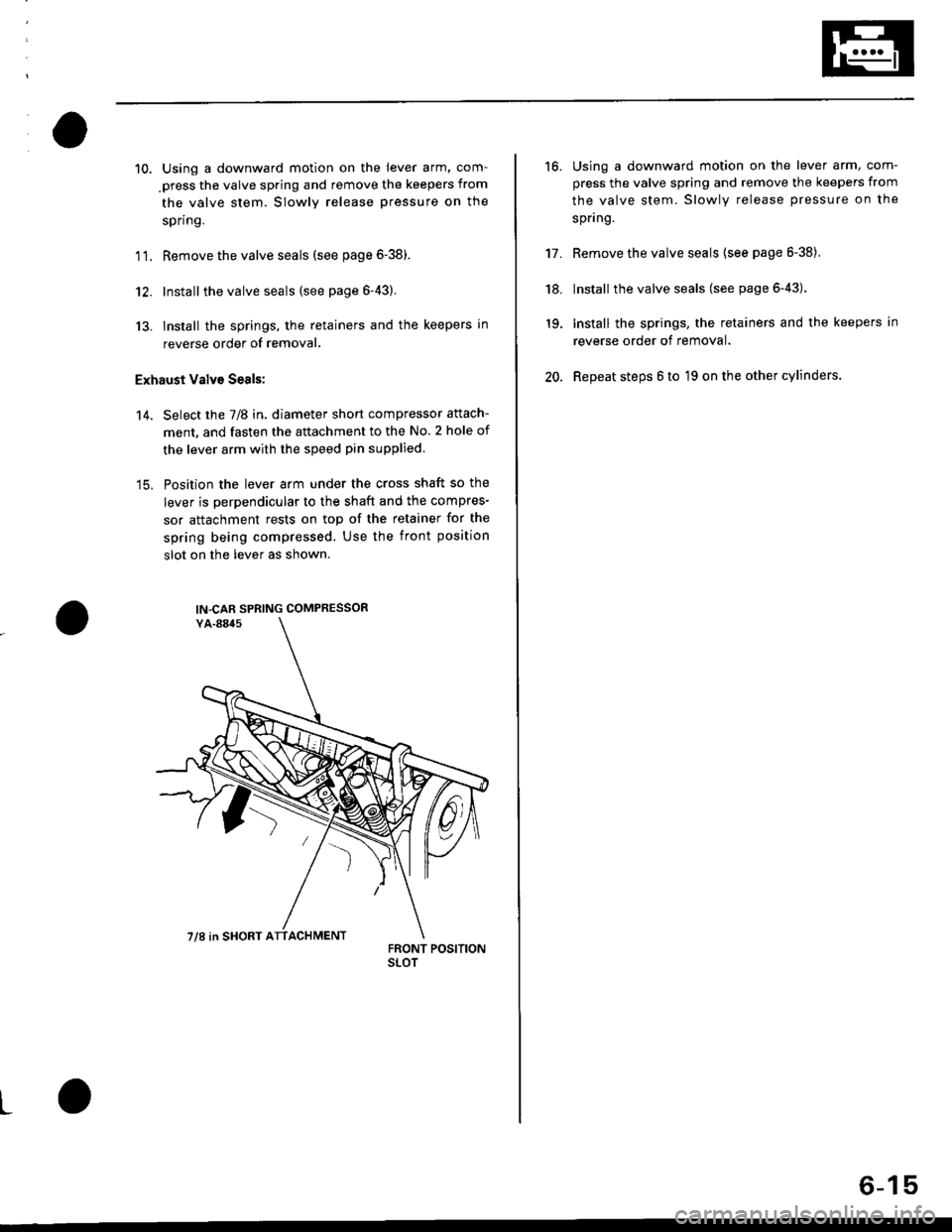

Exhaust Valvs Sesls:

Select the 7/8 in. diameter short compressor attach-

ment, and fasten the attachment to the No. 2 hole of

the lever arm with the speed pin supplied.

Position the lever arm under the cross shaft so the

lever is perpendicular to the shaft and the compres-

sor attachment rests on top of the retainer for the

spring being compressed. Use the front position

slot on the lever as shown.

'14.

IN-CAR SPRING COMPRESSOR

7/8 in SHORT ATTACHMENT

L

16.Using a downward motion on the lever arm, com-

press the valve spring and remove the keepers from

the valve stem. Slowly release pressure on the

spnng.

Remove the valve seals {see page 6-38),

Install the valve seals (see page 6-43).

Install the springs, the retainers and the keepers in

reverse order of removal.

Repeat steps 6 to 19 on the other cylinders.

't7.

'18.

19.

20.

6-15

Page 128 of 2189

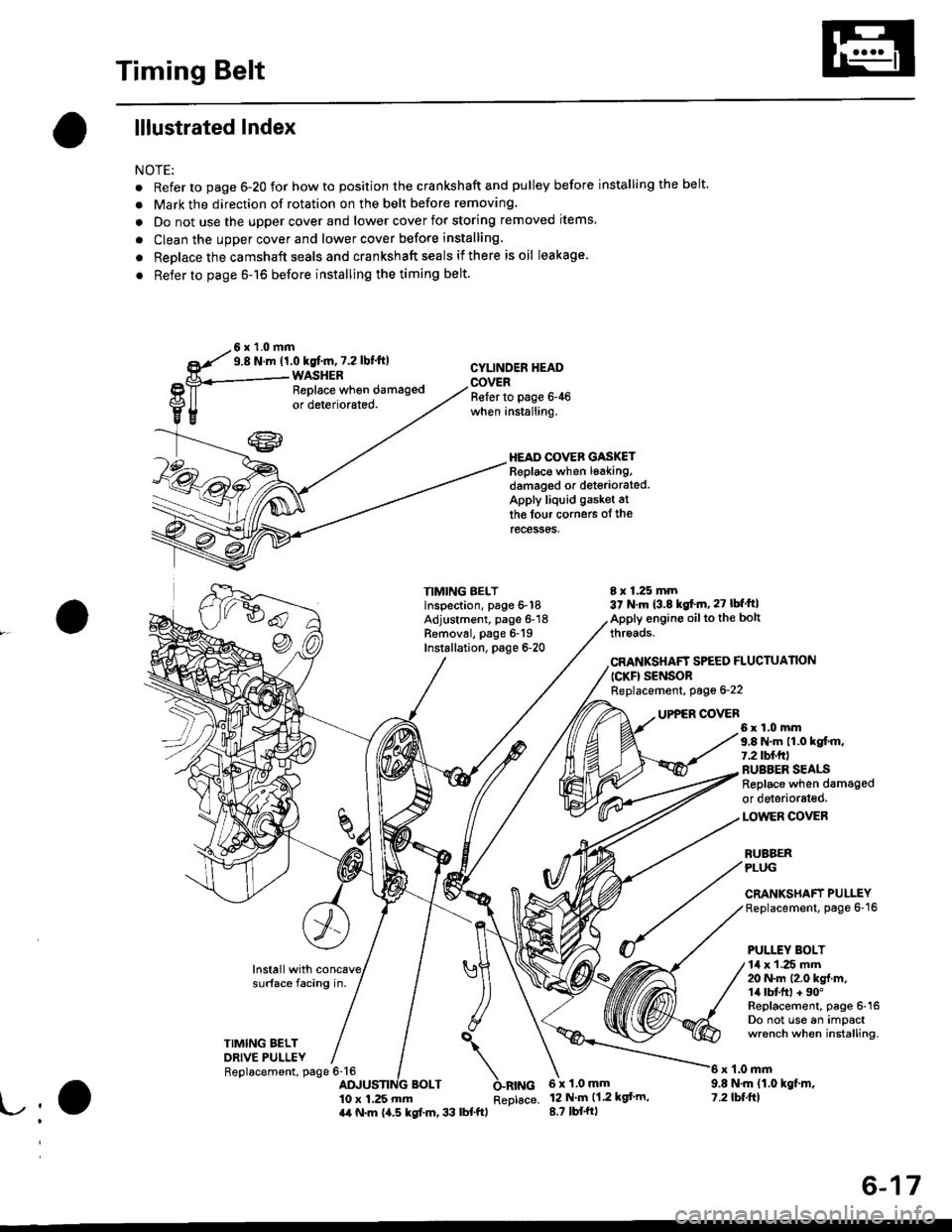

Timing Belt

Illustrated lndex

NOTE:

. Refer to page 6-20 for how to position the crankshaft and pulley before installing the belt.

. Mark the direction of rotation on the belt before removing.

a Do not use the upper cover and lower cover for storing removed items,

. Clean the upper cover and lower cover before installing.

. Replace the ca mshaft seals and cra n kshaft sea ls if there is oil leakage.

. Refer to page 6-16 before installing the timing belt.

CYLINDER HEADCOVERReler to page 6-46when installing.

HEAD COVEB GASKETReplaco when l6akin9,domaged or deteriorated.Apply liquid gasket at

th€ lour corners of thetecessos.

d

@

TIMING BELTInspection, page 6-18Adjustment, page 6-18Removal, page 6-19Installation. page 6-20

I x 1.25 mm3t N.m {3.8 kgf'm, 27 lbfftl

Apply engine oilto the bolt

thleads.

CRANKSHAFT SPEED FI.UCTUATION

lcr(Fl sENsoRReplacement, Page 6-22

UPPER COVEB

lnstallwithsurface facing in.

TIMING BELTDRIVE PULLEYReplacement, page 6_16

6x1.0mm9.8 N'm 11.0 kgt m,7.2 tbf.ft)NUBBER SEALSReplace when damagedor deledorated.

LOWER COVER

FUBBERPLUG

CRANKSHAFT PULLEYReplacement, page 6'16

PULLEY BOLTlil x 1.25 mm20 N.m 12.0 kgt.m,14 lbt'ft) + 90"Replacement, page 6'16Do not us6 an impactwrench when installing.

x 1.0 mmBOLT o-RING10 x 1,25 mm Reolace.14 N.m {,1.5 kgt m, 33 lbt ftl

6x1.0mmt2 N.m 11.2 kgf'm,8.7 tbt f0

9.E N'm (1.0 kgt.m,?.2 tbf.ftl\.-,o

6-17

Page 130 of 2189

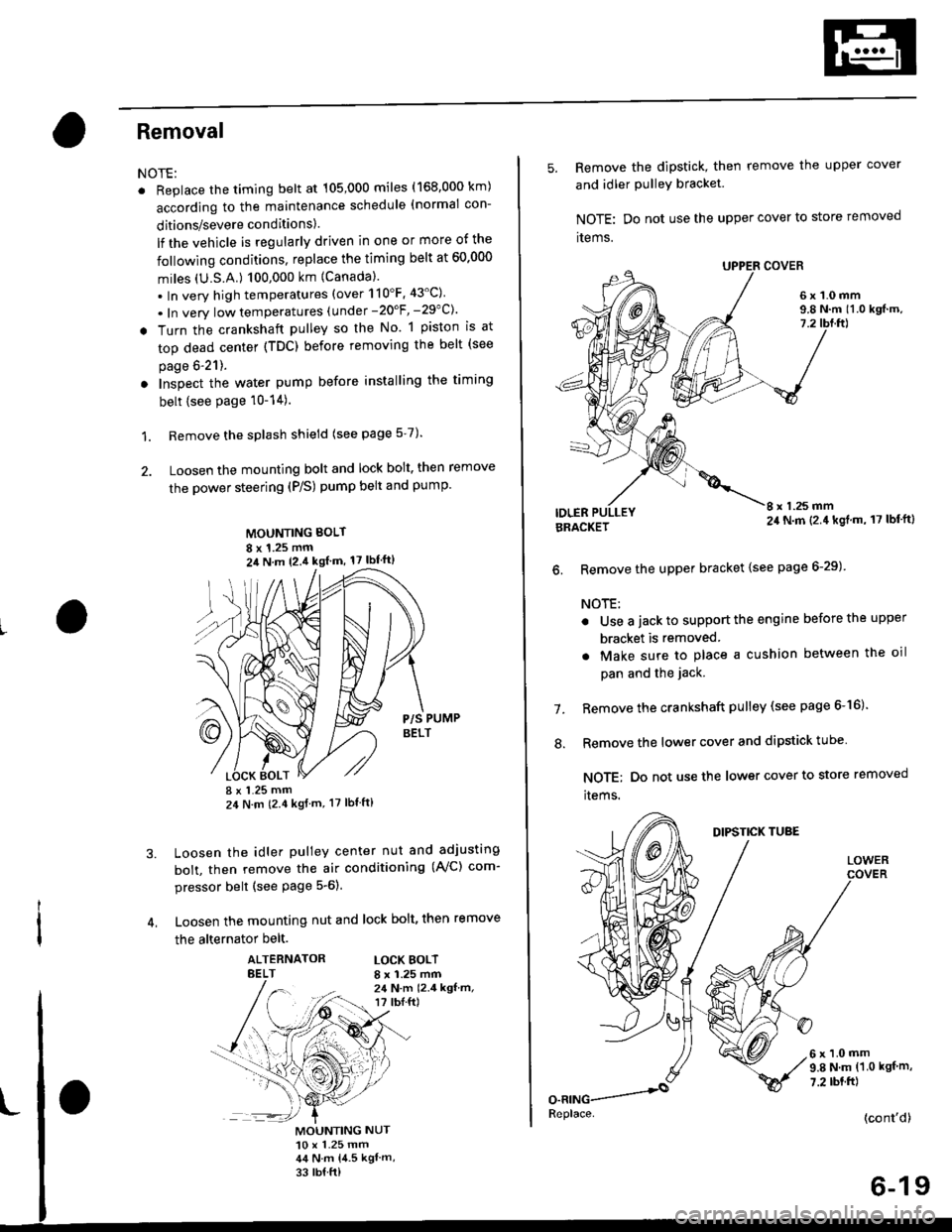

Removal

NOTE:

. Replace the timing belt at 105,000 miles (168.000 km)

according to the maintenance schedule (normal con-

ditions/severe conditions).

lf the vehicle is regularly driven in one or more of the

followlng conditions, replace the timing belt at 60.000

miles (U.S.A.) 100,000 km {Canada).

.In very high temperatures (over 110'F.43'C)

. In very low temperatures (under -20'F, -29"C)'

! Turn the crankshaft pulley so the No. 1 piston is at

top dead center (TDC) before removing the belt (see

page 6'21).

. Inspect the water pump before installing the timing

belt {see Page 10-14).

1. Remove the splash shield (see page 5-7).

2. Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt and pump

MOUNTING BOLT

8 x 1.25 mm2il N m 12.4 kgl m, 17 lbf'ft)

P/S PUMPBELT

I x 1.25 mm24 N m (2.4 kgf m, 17 lbt ft)

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (AVC) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt, then remove

the alternator belt.

ALTERNATORBELTLOCK BOLTI x 1.25 mm24 N.m 12.4 kgf.m,r? tbI.ft)

3.

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgl m,

33 rb{ ft)

5. Remove the dipstick, then remove the upper cover

and idler PulleY bracket

NOTE: Do not use the upper cover to store removed

items.

6x1.0mm9.8 N.m 11.0 kgf.m,7.2

IDLERI x 1.25 mm24 N.m (2.4 kgl.m, 17 lbf'ft)BRACKET

6. Remove the upper bracket {see page 6-29)

NOTE:

. Use a jack to support the engine before the upper

bracket is removed

. Make sure to place a cushion between the oil

pan and the jack.

Remove the crankshaft pulley (see page 6-16).

Remove the lower cover and dipstick tube

NOTE; Do not use the lower cover to store removed

items.

1.

.'.

DIPSTICK TUBE

LOWER

6x1.0mm9.8 N.m (1.0 kgf m,

7.2 rbt.ft)

(cont'd)

6-19

Replace.

Page 131 of 2189

Timing Belt

Removal (cont'd)

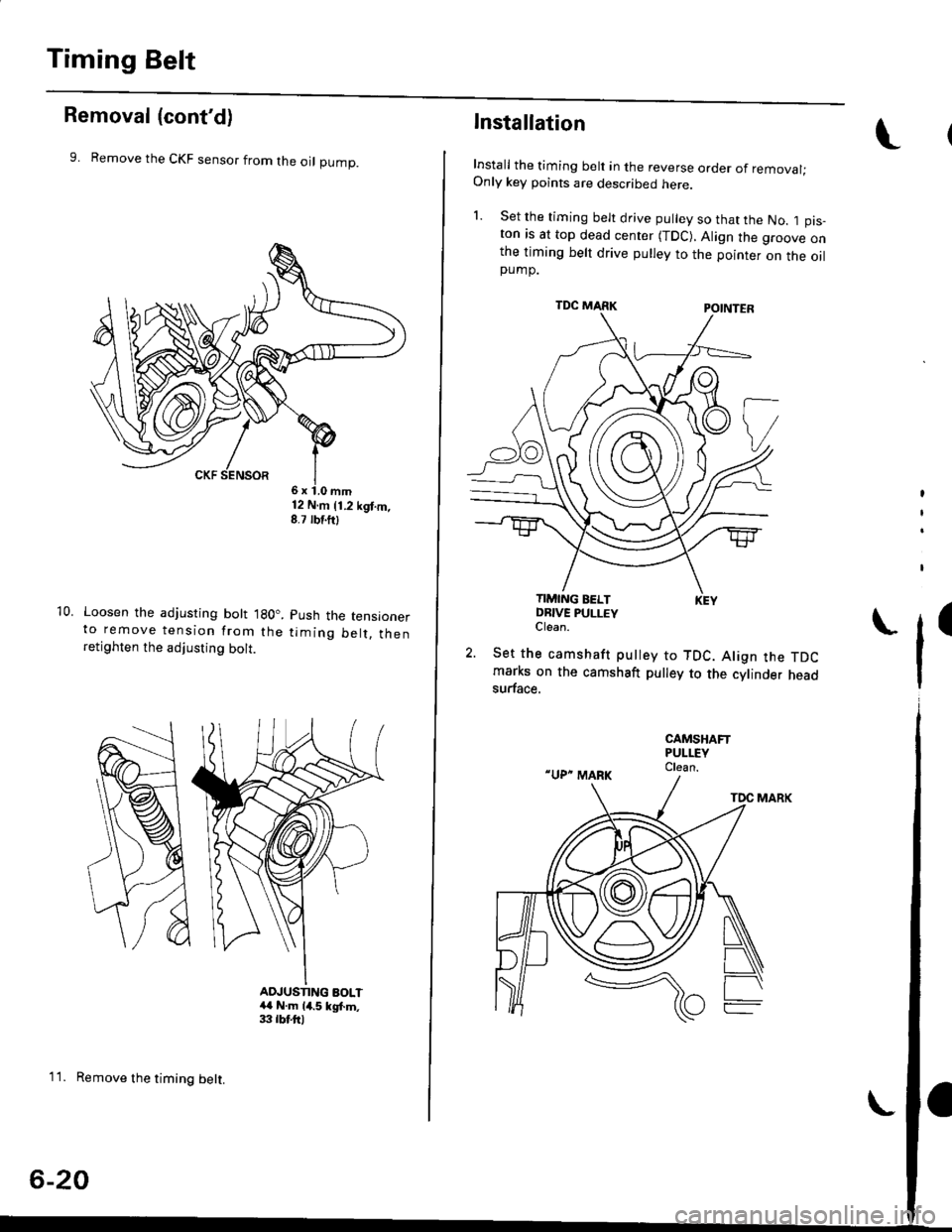

9. Remove the CKF sensor from the oI pump.

10. Loosen the adjusting bott lgO..to remove tension from theretighten the adjusting bolt.

12 N.m 11.2 kgt.m,8.7 rbf.ftl

Push the tensioner

timing be lt. then

AD.'USNNG BOLT4{ N.m 14.5 kgt m,33 tbtftl

1 1. Remove the timing belt.

6-20

lnstallation

Install the timing belt in the reverse order of removal;Only key points are described here.

l. set rhe timing belt drive pulley so that the No. 1 pis-ton as at top dead center (TDC), Align the groove onthe timing belt drive pulley to the pointer on the oilpump.

TDC MARKPOINTER

I

t

I

TIMING BELTDBIVE PULLEYClean.I

2. Set the camshaft pulley to TDC. Align the TDCmarks on the camshaft pulley to the cylinder headsurface.

Page 133 of 2189

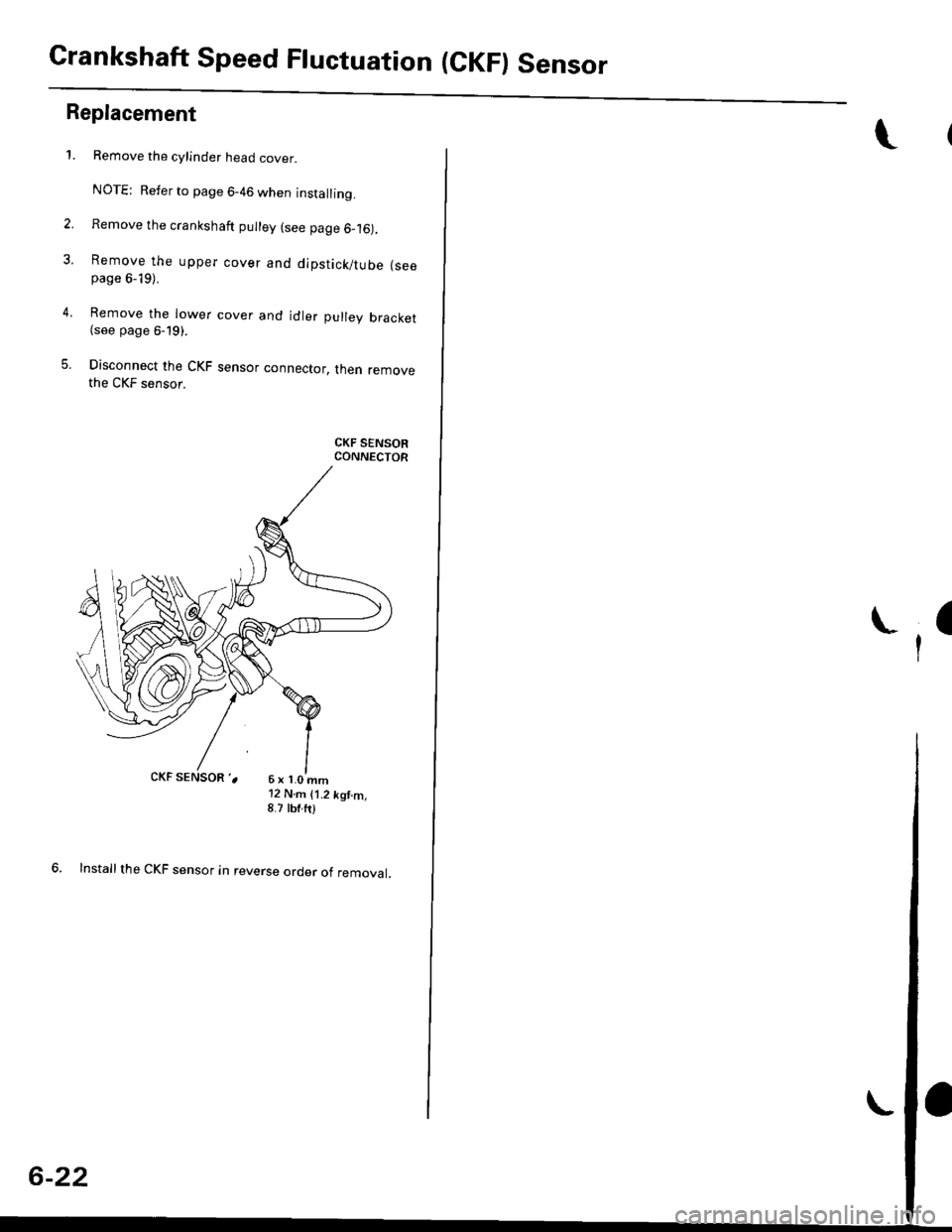

Crankshaft Speed Fluctuation (CKF) Sensor

2.

3.

5.

Replacement

4.

1.

6x1.0mm'12 N.m {1.2 kgt.m,8.7 tbf.ft)

6. Installthe CKF sensor in reverse order of removal.

Remove the cylinder head cover.

NOTE: Refer to page 6-46 when installing.

Remove the crankshaft pulley (see page 6_16),

Remove the upper cover and dipstick/tube {seepage 6-19).

Remove the lower cover and idler pulley bracket(see page 6-19).

Disconnect the CKF sensor connector, then removethe CKF sensor.

CKF SENSORCONNECTOR

6-22

:(

I

Page 135 of 2189

Cylinder Head

lllustrated Index (cont'dl

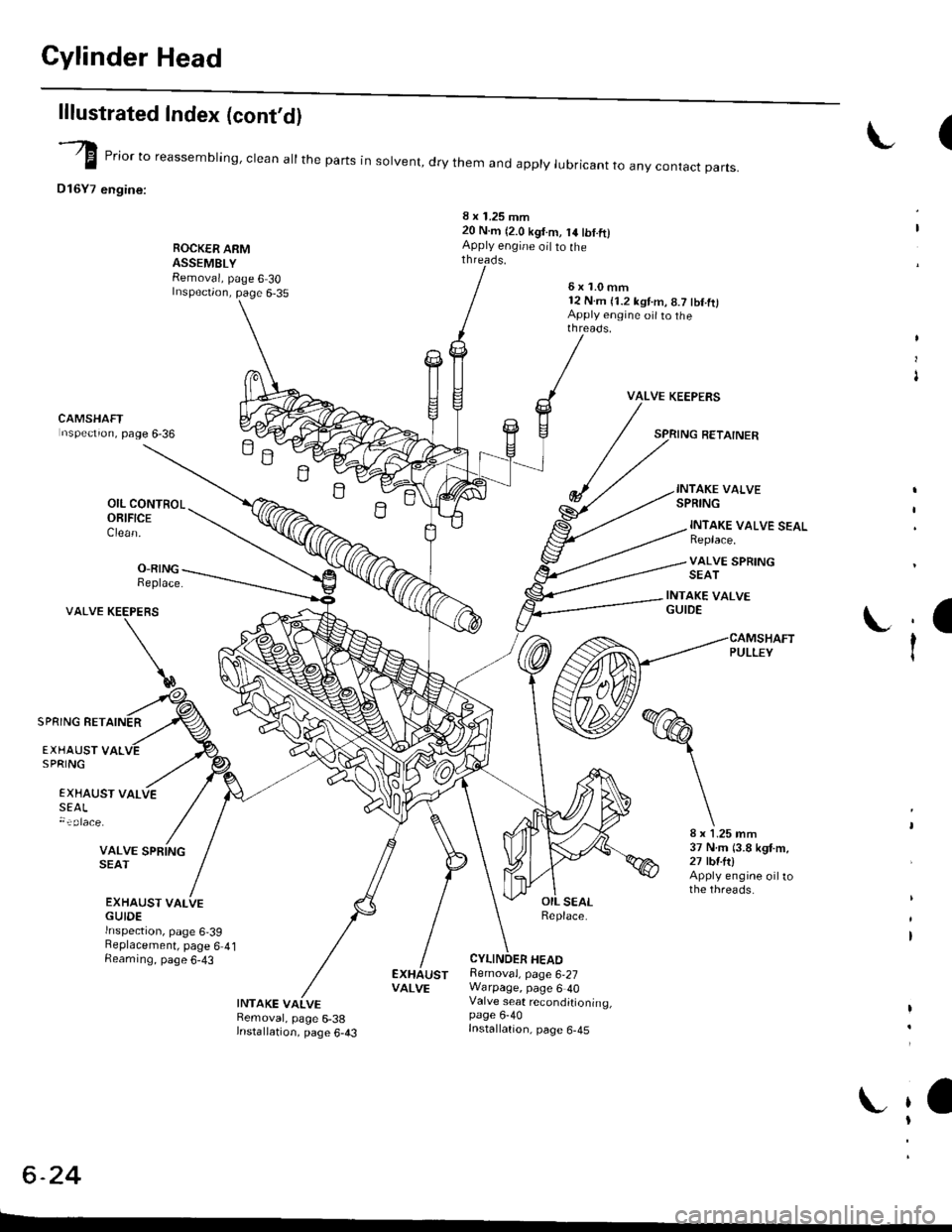

(-/) _.- E "or to reassembring, crean at the parts in sorvent, dry them and appry rubricant to anv contact oarts.

D16Y7 engine:

ROCK€R ARMASSEMBLYRemoval, page 6 30Inspection, page 6-35

8 x 1.25 mm20 N.m (2.0 kgt.m, 14 tbt.ftlApply engine oil to the

H

B

O-RINGReplace.

INTAKE VALVE SEALReplace.

VALVE SPRINGSEAT

INTAKE VALVEGUIDE

:a

ti

VALVE

SPRING RETAINER

EXHAUST VALVESEAL

VALVE SPRINGSEAT

EXHAUST VALVEGUIDErnspectron, page 6,39Beplacement, page 6 4lAeaming, page 6-43

8 x 1.25 mm37 N m (3.8 kgt m,27 tbtftlApply engine oiltothe threads.

INTAKE VALVERemoval, page 6-38lnstallation, page 6-43

Removal, page 6,27Warpage, page 6 40Valve seat reconditioning,page 6-40Installation, page 6-45

VALVE

t

t

t

CAMSHAFTnspectron, page 6-36

OIL CONTROLORIFICEClean.

KEEPERS

\

EXHAUST VALSPRING

c -A9-2.+

L

6x1.0mm12 N.m (1.2 kst.m, 8.7 tbf.ft)Apply engine oit to thethreads.

VALVE KEEPERS

SPRING RETAINER

INTAKE VALVESPRING

Page 136 of 2189

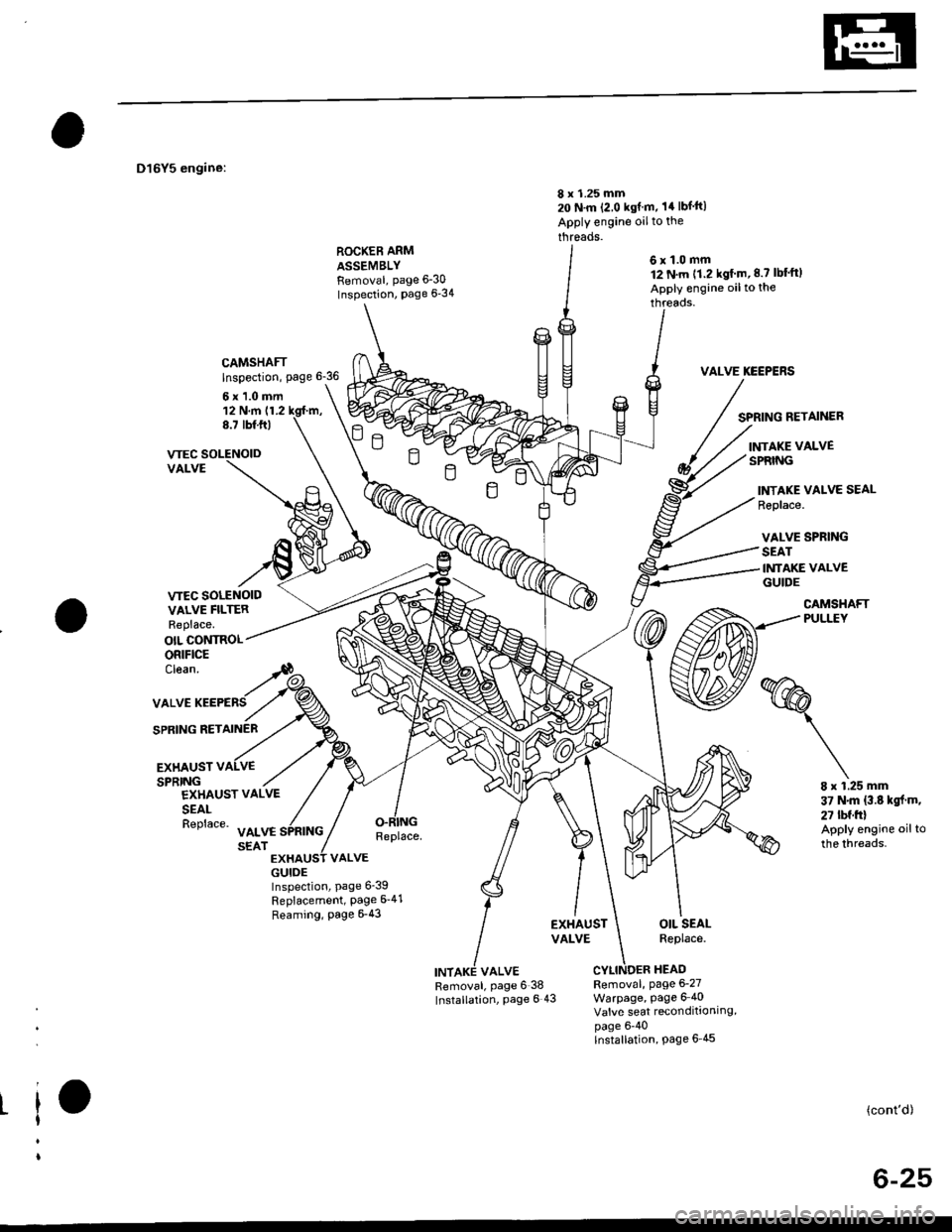

D16Y5 engine:

I x 1.25 mm20 N.m (2,0 kgf m, 14 lbf ft)

Apply engine oilto the

threads.ROCKEB ARMASSEMBLYFemoval, page 6-30

Inspection, Page 6-34

6x1.0mm12 N.m 11.2 kgf m, 8.7 lbf'ftl

Apply engine oilto the

threads.

VALVE KCEPERS

SPRING RETAINER

CAMSHAFTInspection, page 6-36

6x1.0mm12 N,m 11.28.7 tbf.ft)

WEC SOLENOIDVALVEBINTAKE VALVESPRING

INTAKE VALVE SEAL

Replace.

VALVE SPRINGSEAT

INTAKE VALVEGUIDE

CAMSHAFTPUL|'IY

VTEC SOLENOIDVALVE FILTERReplace.

OIL CONTROLORIFICEClean.

VALVE

SPRING RETAINEB

EXHAUST V

SPRING

VE

EXHAUST VALVE

SEALt"o'""".uoau,

SEATReplace.

GUIDEInspection, page 6-39Replacement, Page 6-41

Reaming, page 6-43EXHAUSTVALVEOIL SEALReplace.

HEAD

8 x 1.25 mm

37 N.m 13.8 kgf.m,

27 tbf.frlApply engine oiltothe lhreads.

(cont'd)

6-25

INTAKE VALVERemoval, page 6 38

Installalion, Page 6 43Removal, page 6-27Warpage, Page 6 40

Valve seat reconditioning'page 6-40lnstallation, page 6_45

Page 137 of 2189

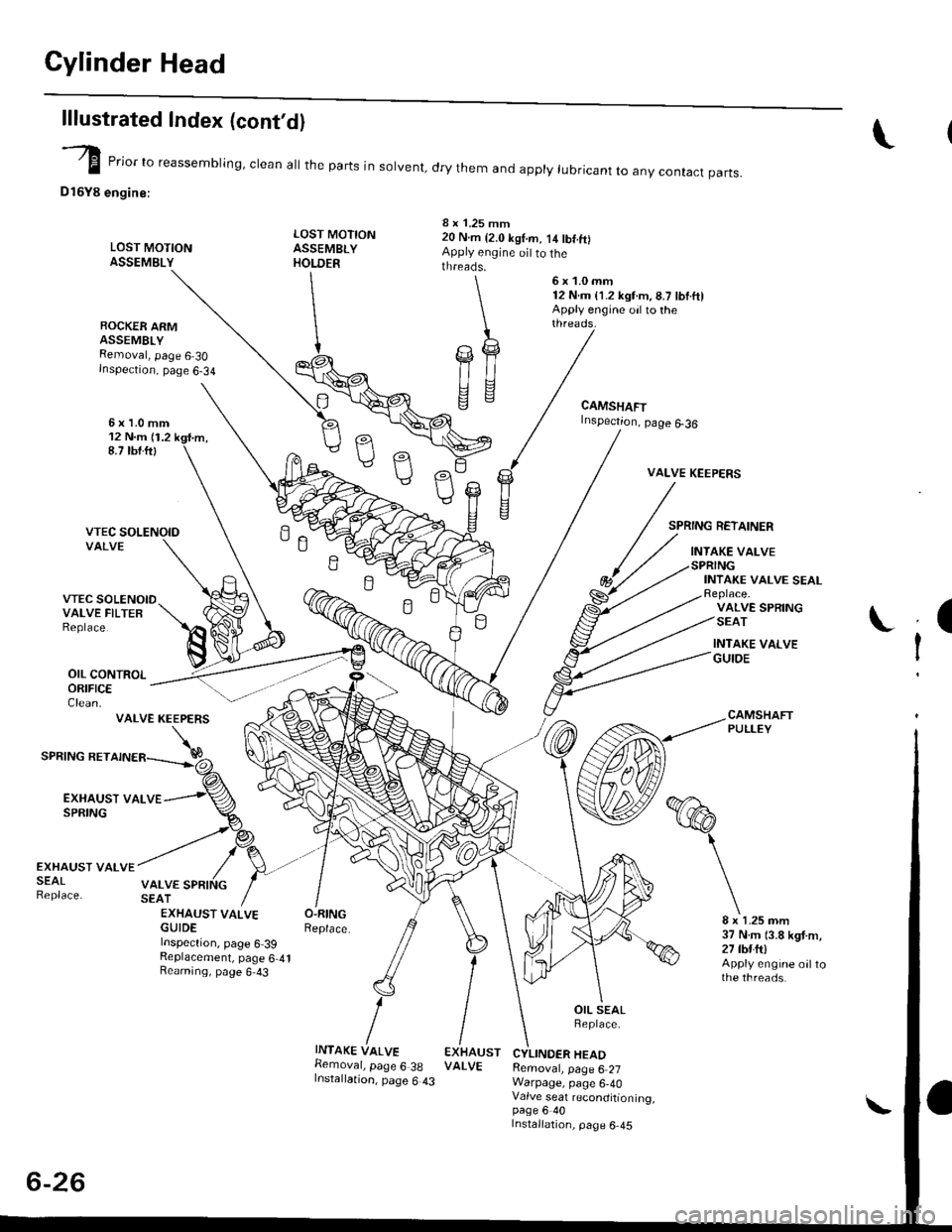

Cylinder Head

lllustrated Index (cont'dl

VALVE KEEPERS

SPRING RETAINER

INTAKE VALVE

VTEC SOLENOIDVALVE FILTEBReplace.

OIL CONTROLORIFICEClean.

INTAKE VALVE SEALReplace.VALVE SPRINGSEAT

INTAKE VAI.VEGUIOE

CAMSHAFTPULLEY

I

I

VALVE KEEPERS

SPRING RET

EXHAUST VALVESPRING

@

EXHAUST VALVESEALReplace.

8 x 1.25 mm37 N.m 13.8 kgt m,27 tbfitlApply engine oiltothe threads.

EXHAUSTVALVE

-vp

e,.io"o reassembring, crean at the parts in sorvent, dry them and appry rubricant to any contact parts.

D16Y8 engine:

LOST MOTIONASSEMgLY

ROCKER ARMASSEMBLYRemoval, page 6 30Inspection, page 6-34

5xl.0mm12 N.m {1.28.7 tbf.ft)

VALVE SPRINGSEATEXHAUSTVALVE O.RINGGUIDE Replace.Inspection, page 6 39Replacement, page 6 41Reaming, page 6 43

LOST MOTIONASSEMBLYHOLDER

INTAKE VALVEBemoval, page 6 38Installation, page 6 43

20 N.m 12.0 kgl.m, 14 tbf.ft)Apply engine oit to thethreads.

\

\

s9illl

CAMSHAFTInspection, page 6-36

OIL SEALBeplace.

CYLINDER HEADRemoval, page 6 27Warpage, page 6-40Valve seat reconditioning,page 6 40Installation, page 6-45

6x1.0mm12 N.m (1.2 kgt.m,8.7 lbf.ftlApply engine oil to thethreads,

Page 138 of 2189

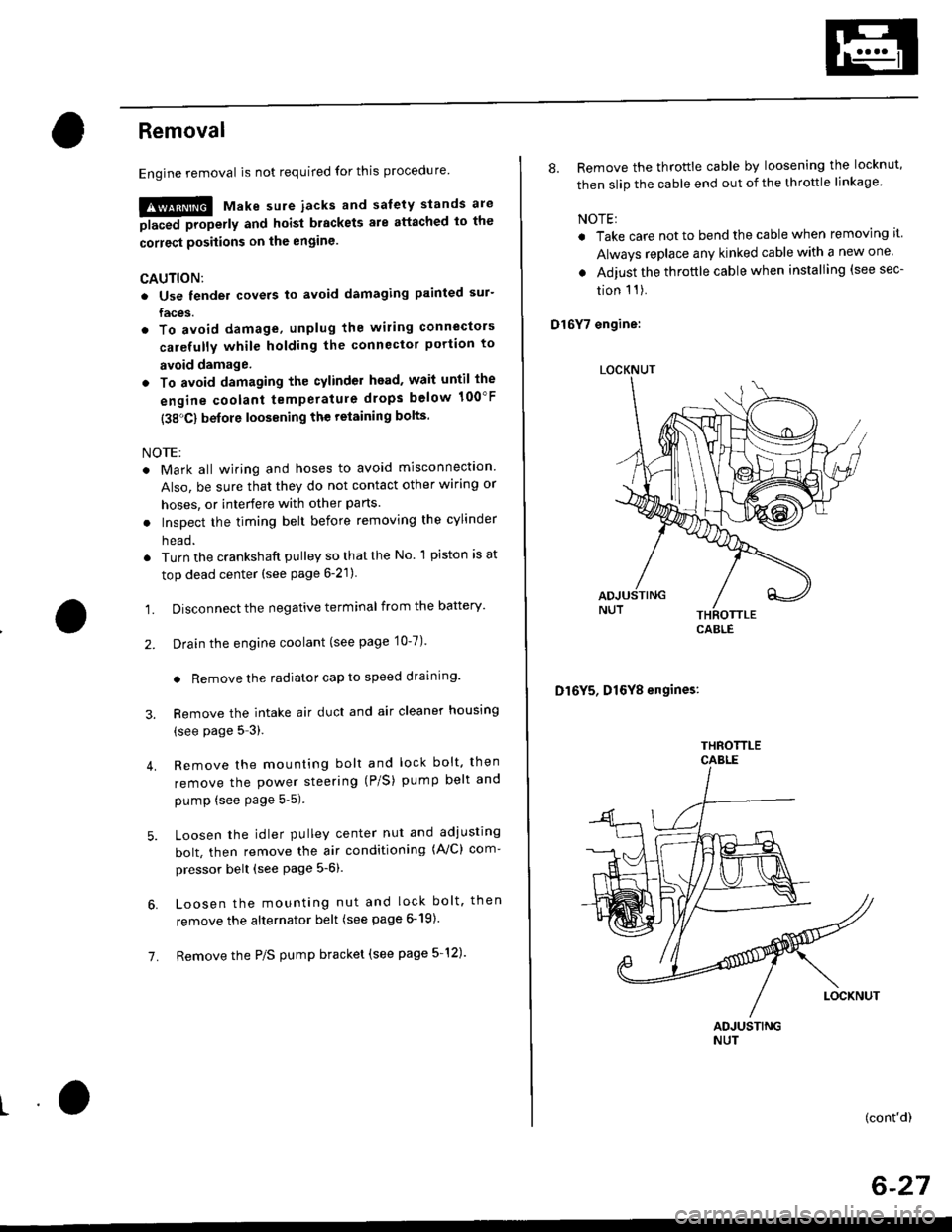

Removal

Engine removal is not required for this procedure

!!!s@ Make sure iacks and salety stands are

f ta"eata"ea propetty and hoist brackets are attached to the

correct positions on the engine.

CAUTION:

. Use tender covels to avoid damaging painted sul-

faces.

o To avoid damage, unplug the wiling connectors

carefully while holding the connector portion to

avoid damage.

. To avoid damaging the cylinder head, wait until the

engine coolant temperature drops below 100"F

{38"C} before loossning the tetaining bolts.

NOTE:

o Mark all wiring and hoses to avoid misconnectlon

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

. Inspect the timing belt before removing the cylinder

h ead.

. Turnthe crankshaft pu lley so that the No. lpistonisat

top dead center (see Page 6-21)

'1. Disconnect the negative terminal from the battery'

Drain the engine coolant (see page'10-7).

a Remove the radiator cap to speed draining.

Remove the intake air duct and air cleaner housing

(see page 5 3).

Remove the mounting bolt and lock bolt. then

remove the power steering (P/S) pump belt and

pump (see page 5'5).

Loosen the idler pulley center nut and adjusting

bolt' then remove the air conditioning (A'lc) com-

pressor belt (see Page 5-6).

Loosen the mounting nut and lock bolt. then

remove the alternator belt (see page 6-19).

Remove the P/S pump bracket (see page 5-12).

3.

4.

2.

6.

1.

8. Remove the throttle cable by loosening the locknut,

then slip the cable end out of the throttle linkage

NOTE:

. Take care not to bend the cable when removing it

Always replace any kinked cable with a new one

. Adjust the throttle cable when installing (see sec-

tion 1 1).

D16Y7 engine:

Dl6Y5, Dl6Y8 engines:

THFOTTLECABLE

(cont'd)

6-27

LOCKNUT

CABLE