steering boot HONDA CIVIC 1997 6.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1087 of 2189

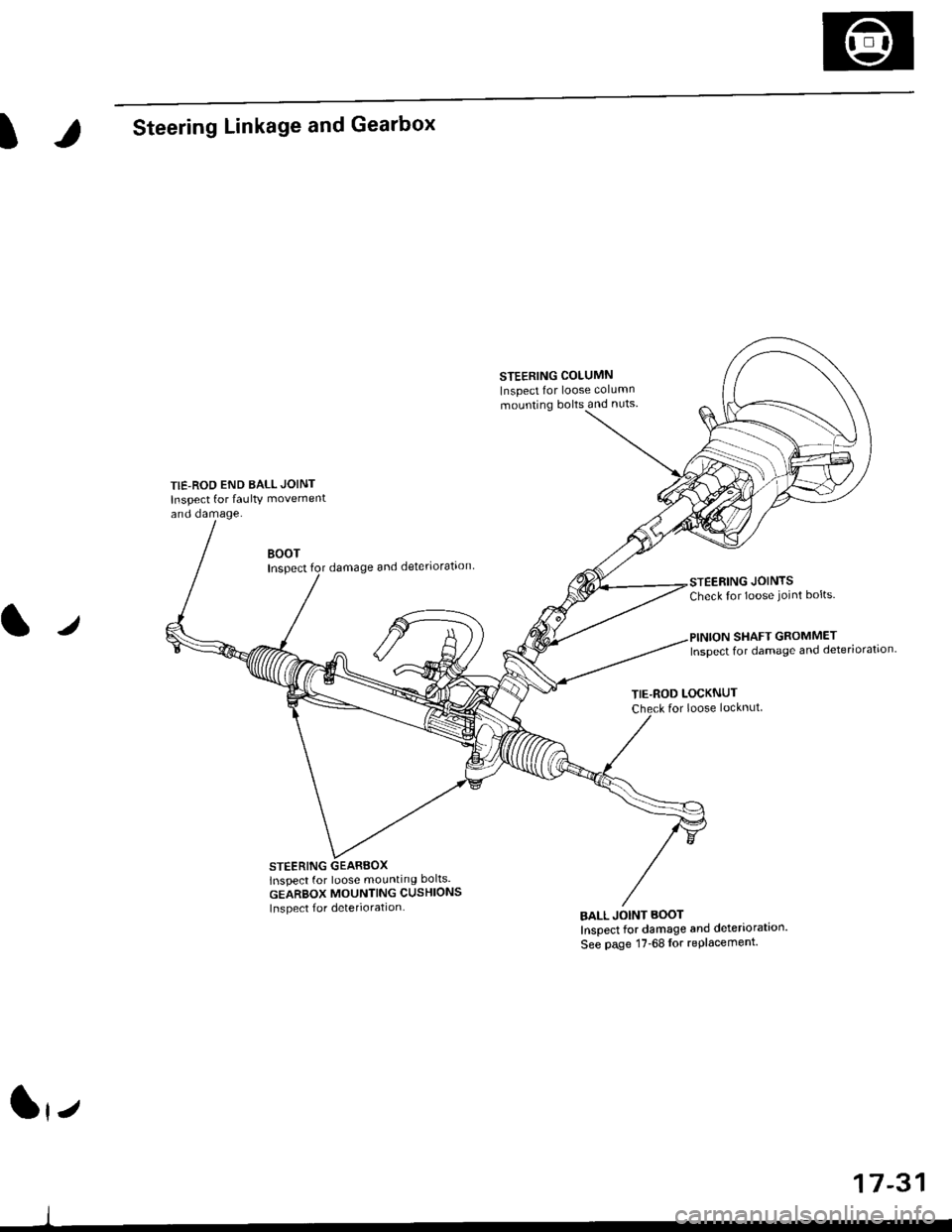

ISteering Linkage and Gearbox

TIE-ROD END BALL JOINT

Inspect for faulty movement

and damage.

STEERING COLUMN

Inspect for loose column

mounting bolts and nuts

BOOTInspectdamage and deteriorataon

STEERING GEARBOXlnspect for loose mounting bolts.

GEARBOX MOUNTING CUSHIONS

Inspect f or deterioration

STEERING JOINTSCheck for loose joint bolts.

l./

TIE-ROD LOCKNUTfor loose locknut

BALL JOINT BOOT

Inspect for damage and deteriorataon'

See page 17-68lor replacement.

SHAFT GROMMETInspect for damage and deteriorataon.

lrz

17-31

Page 1103 of 2189

Steering Gearbox

)

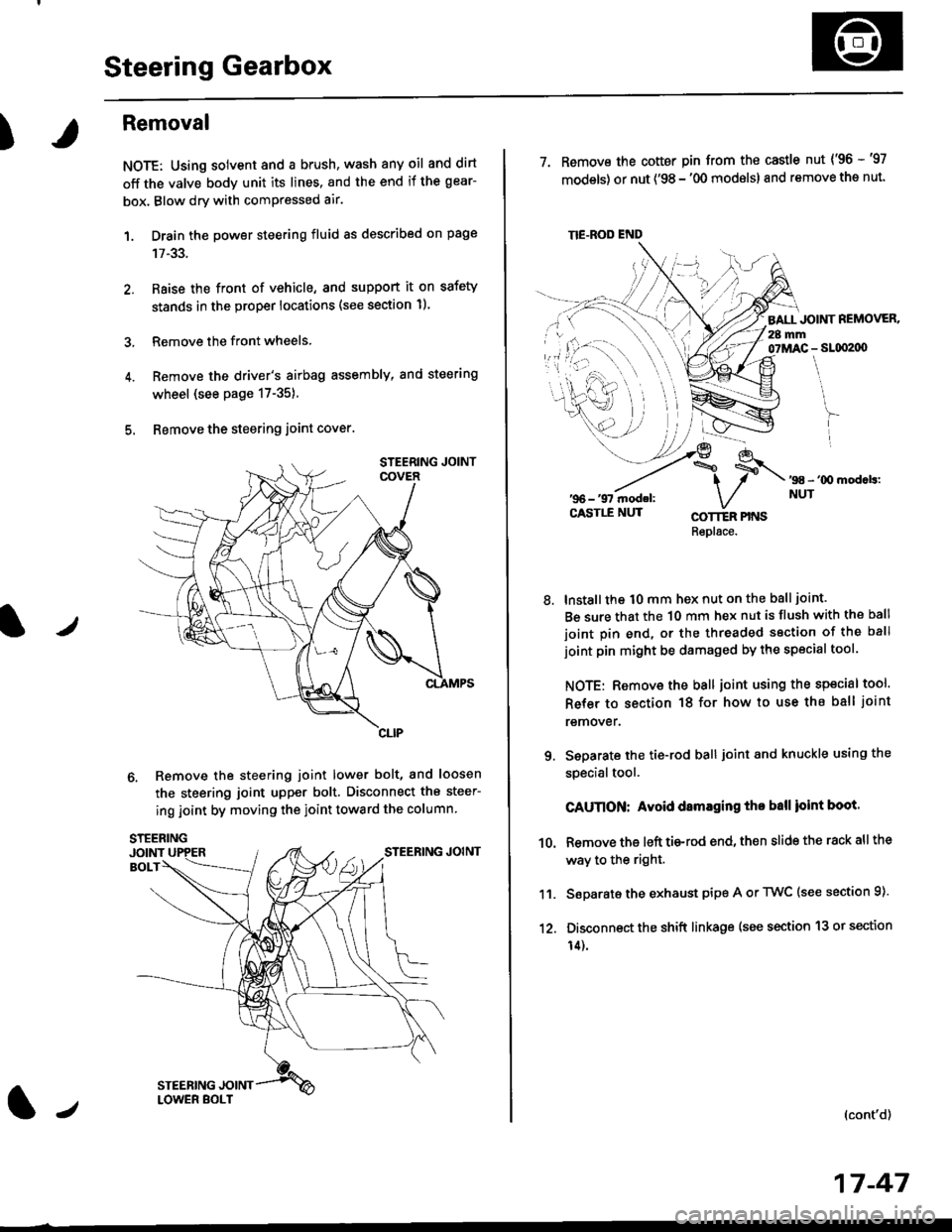

Removal

NOTE: Using solvent and a brush, wash any oil and dirt

off the valve body unit its lines. and the end if the gear-

box. Blow dry with comPressed air.

1. Drain the power steering fluid as described on page

2. Raise the front of vehicle, and support it on safety

stands in the proper locations (see section 11.

3, Remove the front wheels.

4. Remove the driver's airbag assembly, and steering

wheel (see page 17-35)

5. Bemove the steering joint cover.

6. Remove the steering joint lower bolt, and loosen

the steering joint upper bolt. Disconnect the steer-

ing joint by moving the ioint toward the column

tJ

17-47

TIE.ROD END

7. Remove the cotter pin from the castle nut {'96 -'97

models) or nut ('98 - '00 modslsl and remove the nut.

BALL JOINT REMOVER.28 mm07MAC - SLqI2|X)

'98 - '00 mod.b:NUT

8.

COTTER PINSRepl6ce.

lnstall the t0 mm hex nut on the ball joint.

Be sure that the 10 mm hex nut is flush with the ball

joint pin end, or the threaded section of the ball

joint pin might be damaged by the special tool.

NOTE: Remove the ball joint using the special tool.

Refer to section 18 for how to use ths ball joint

remover.

Seoarate the tie-rod ball joint and knuckle using the

specialtool.

CAUnON: Avoid damaging tho ball ioint boot.

Remove the left tie-rod end, then slide the rack all the

way to the right.

Separate the exhaust pipe A or TWC (see section 9).

Disconnect the shift linkage (see section 13 or section

14).

(cont'd)

9.

10.

11.

12.

Page 1105 of 2189

)

Disassembly

t)

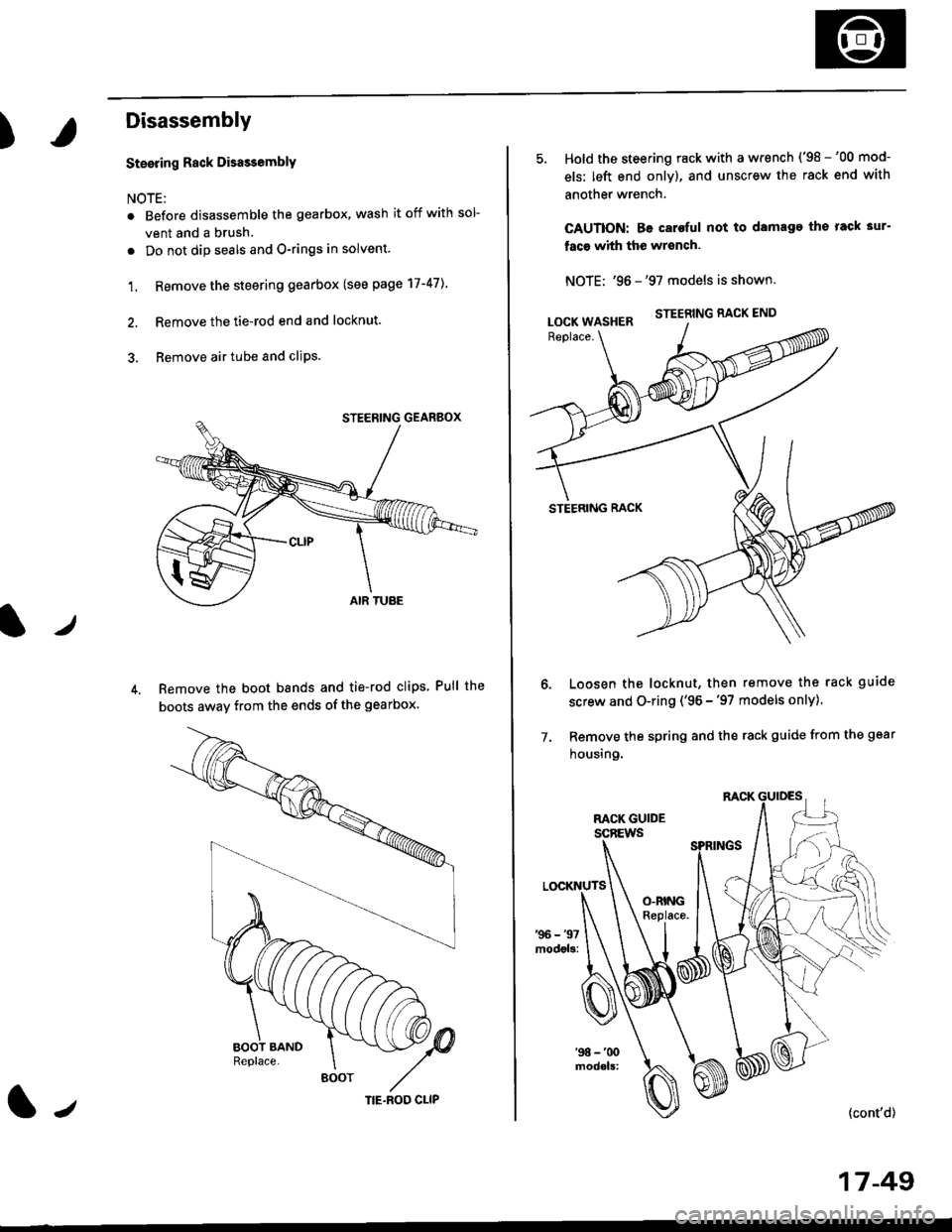

Steering Rack DisassemblY

NOTE:

r Before disassemble the gearbox, wash it off with sol

vent and a brush.

. Do not dip seals and O-rings in solvent.

1. Remove the steering gearbox (see page 17-47]..

2. Remove the tie-rod end and locknut.

3. Remove air tube and cliPs.

Remove the boot bands and tie-rod clips Pull the

boots away from the ends of the gearbox.

BOOT

(|-,TIE.ROD CLIP

Hold the steering rack with a wrench ('98 -'00 mod-

els: left end only), and unscrew the rack end with

another wrench.

CAUTION: Be caroful not to damage the rack 3ur-

faco whh the wrench.

NOTE: '96 -'97 models is shown.

STEERING RACK END

STEERING RACK

Loosen the locknut, then remove the rack guide

screw and O-ring ('96 -'97 models only)

Remove the spring and the rack guide from the gear

housing.

7.

{cont'd}

17 -49

LOCK WASHER

Page 1120 of 2189

Steering Gearbox

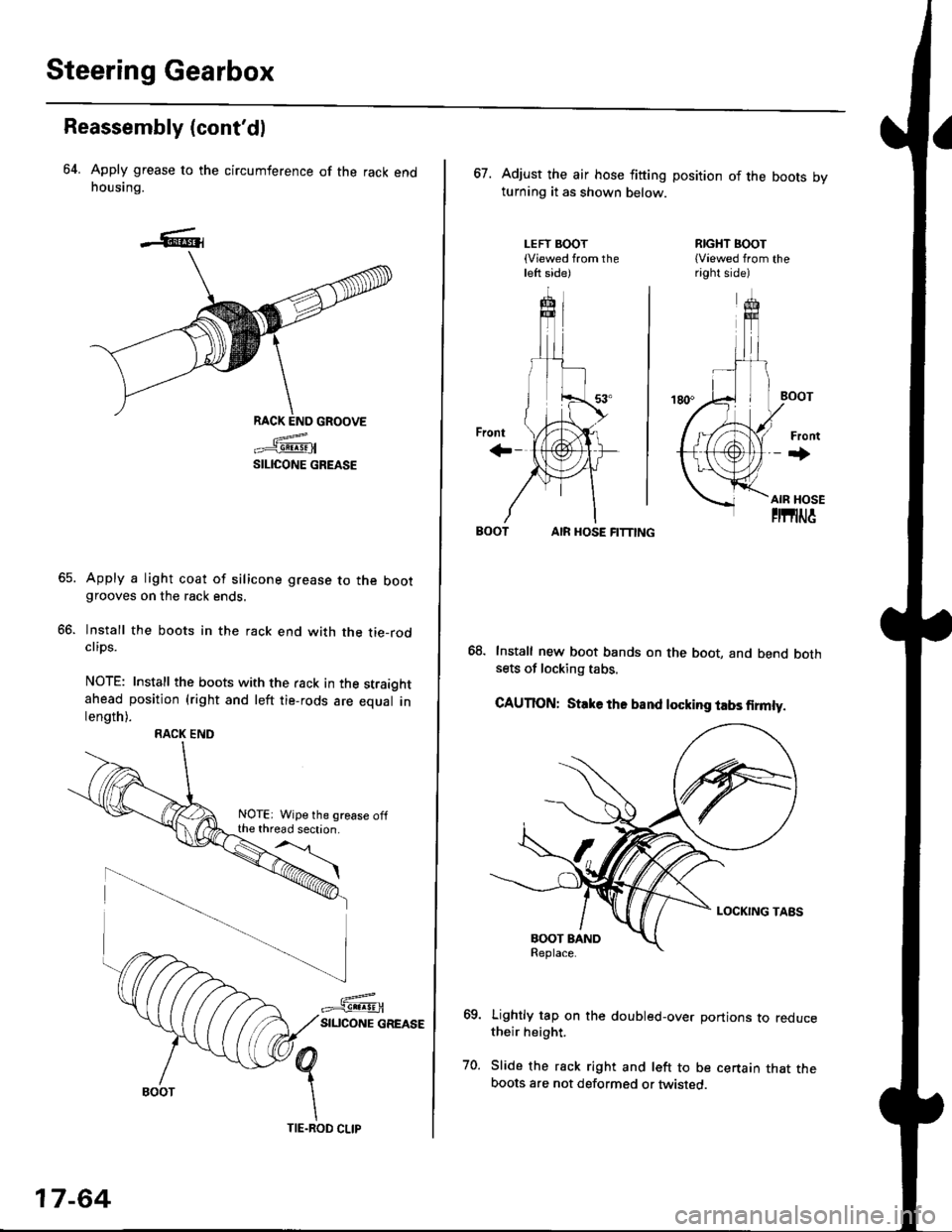

Reassembly (cont'dl

64. Apply grease to the circumference of the rack endhousing.

RACK END GROOVE

=^.#-q!:s!!H

SILICONE GREASE

Apply a light coat of silicone grease to the bootgrooves on the rack ends.

lnstall the boots in the rack end with the tie-rodclips.

NOTE: Install the boots with the rack in the straightahead position (right and left tie-rods are equal inlength).

66.

RACK END

NOTE: Wipe the grease offthe thread section.

17-64

TIE.ROD CLIP

67. Adjust the air hose fitting position of the boots bvturning it as shown below.

LEFT BOOT(Viewed from theleft side)

RIGHT BOOT{Viewed from theright side)

AIR HOSE FITTING

Install new boot bands on the boot, and bend bothsets of locking tabs.

CAUTION: Stlke ths band locking tabs firmly.

Lightly tap on the doubled-over portions to reducetheir height.

Slide the rack right and left to be certain that theboots are not deformed or twisted.

Page 1121 of 2189

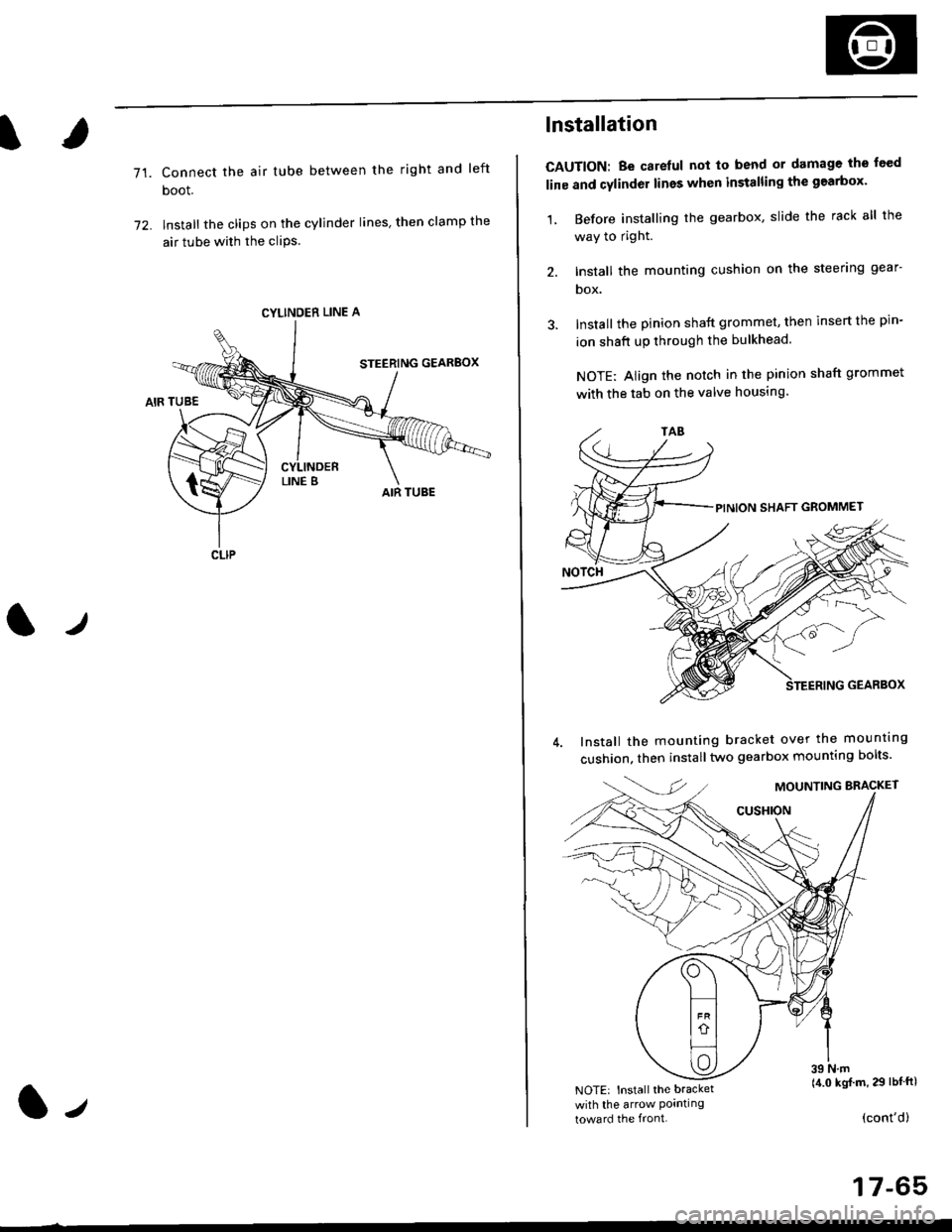

71.Connect the air tube between the right and left

boot.

lnstall the clips on the cylinder lines' then clamp the

air tube with the cliPs.

l./

CYLINDER LINE A

CLIP

l-,

lnstallation

CAUTION: Be carelul not to bend or damage the feed

line and cylinder lines when installing the gearbox'

1, Before installing the gearbox, slide the rack all the

way to right.

2. Install the mounting cushion on the steering gear-

DOX.

Install the pinion shaft grommet, then insert the pin-

ion shaft up through the bulkhead.

NOTE: Align the notch in the pinion shaft grommet

with the tab on the valve housing.

Install the mounting bracket over the mounttng

cushion, then installtwo gearbox mounting bolts'

MOUNTING BRACKET

cusHroN

39 N.m(4.0 kgj m, 29 lbtftlNOTE: Install the bracket

with the arrow Pornllngtoward the front.(cont'd)

17-65

Page 1129 of 2189

?

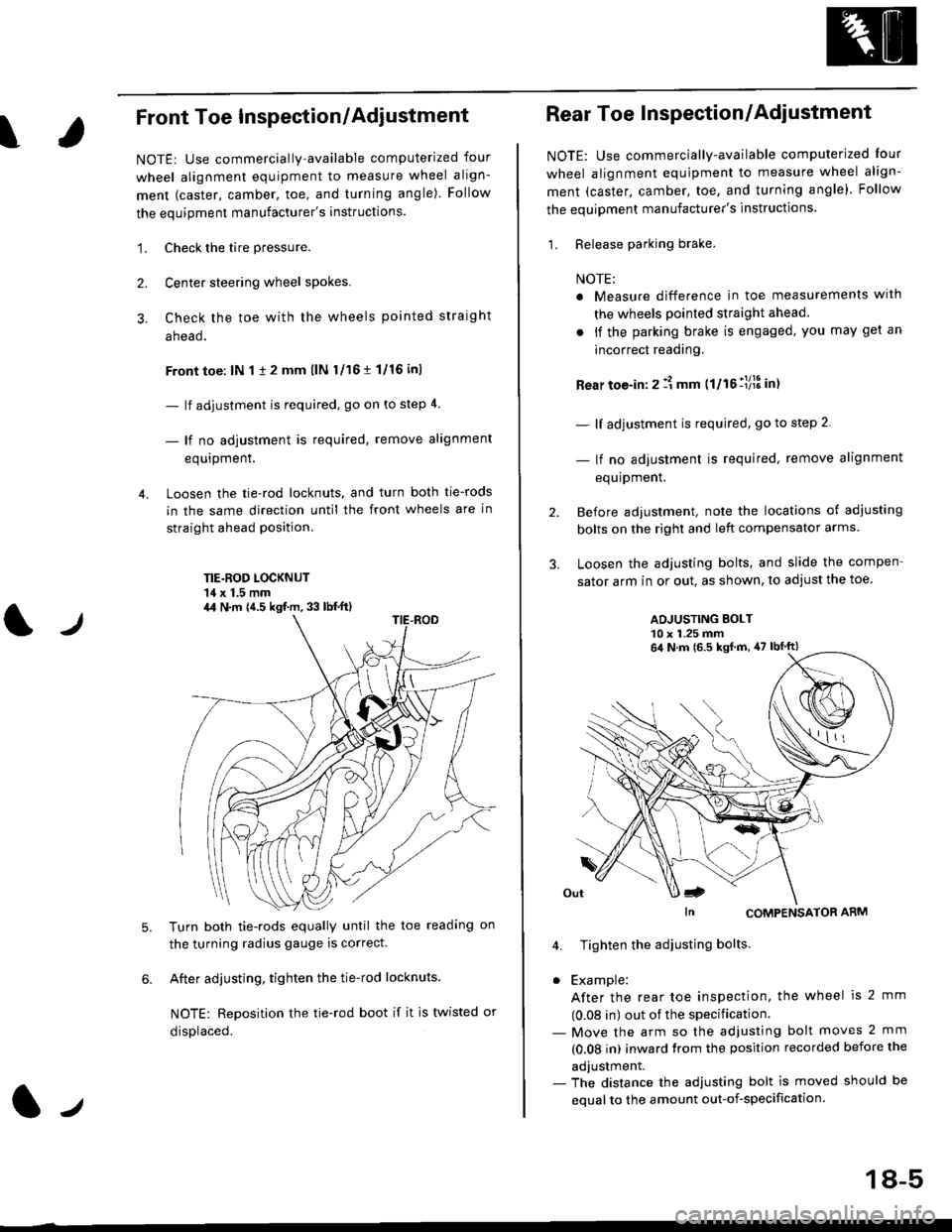

Front Toe Inspection/Adiustment

NOTE: Use commercially-available computerized four

wheel alignment equipment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Check the tire pressure.

Center steering wheel spokes.

Check the toe with the wheels pointed straight

a head.

Front toe: lN 1 1 2 mm llN l/16 r 1/16 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equrpmenr.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are in

straight ahead position.

TIE.ROD LOCKNUT'14 x 1.5 mm

4.

tJ

6.

Turn both tie-rods equally until the toe readang on

the turning radius gauge is correct.

After adjusting, tighten the tie-rod locknuts.

NOTE: Reposition the tie-rod boot if it is twisted or

displaced.

4,1 N.m {4.5 kgf.m, 33 lb{.ft)

2.

Rear Toe Inspection/Adiustment

NOTE: Use commercially-available computerjzed Iour

wheel alignment equjpment to measure wheel align-

ment (caster, camber, toe, and turning angle). Follow

the equipment manufacturer's instructions.

1. Release parking brake.

NOTE:

a Measure difference in toe measurements wlth

the wheels pointed straight ahead.

. if the parking brake is engaged, you may get an

incorrect readang,

Rear toe-in: 2 11 mm ttltollllS int

- lf adjustment is required, go to step 2.

- lf no adjustment is required, remove alignment

equipment.

Before adjustment, note the locations of adiusting

bolts on the right and left compensator arms

Loosen the adjusting bolts, and slide the compen

sator arm in or out. as shown, to adjust the toe

ADJUSTING BOLT10 x 1.25 mm

In CoMPENSAToR ARM

4. Tighten the adiusting bolts

. Example:

After the rear toe inspection, the wheel is 2 mm

(0.08 in) out of the specification.- Move the arm so the adjusfing bolt moves 2 mm

(0.08 in) inward trom the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

64 N.m 16.5 ksf m, 47 lbtft)

18-5

Page 1136 of 2189

Front Suspension

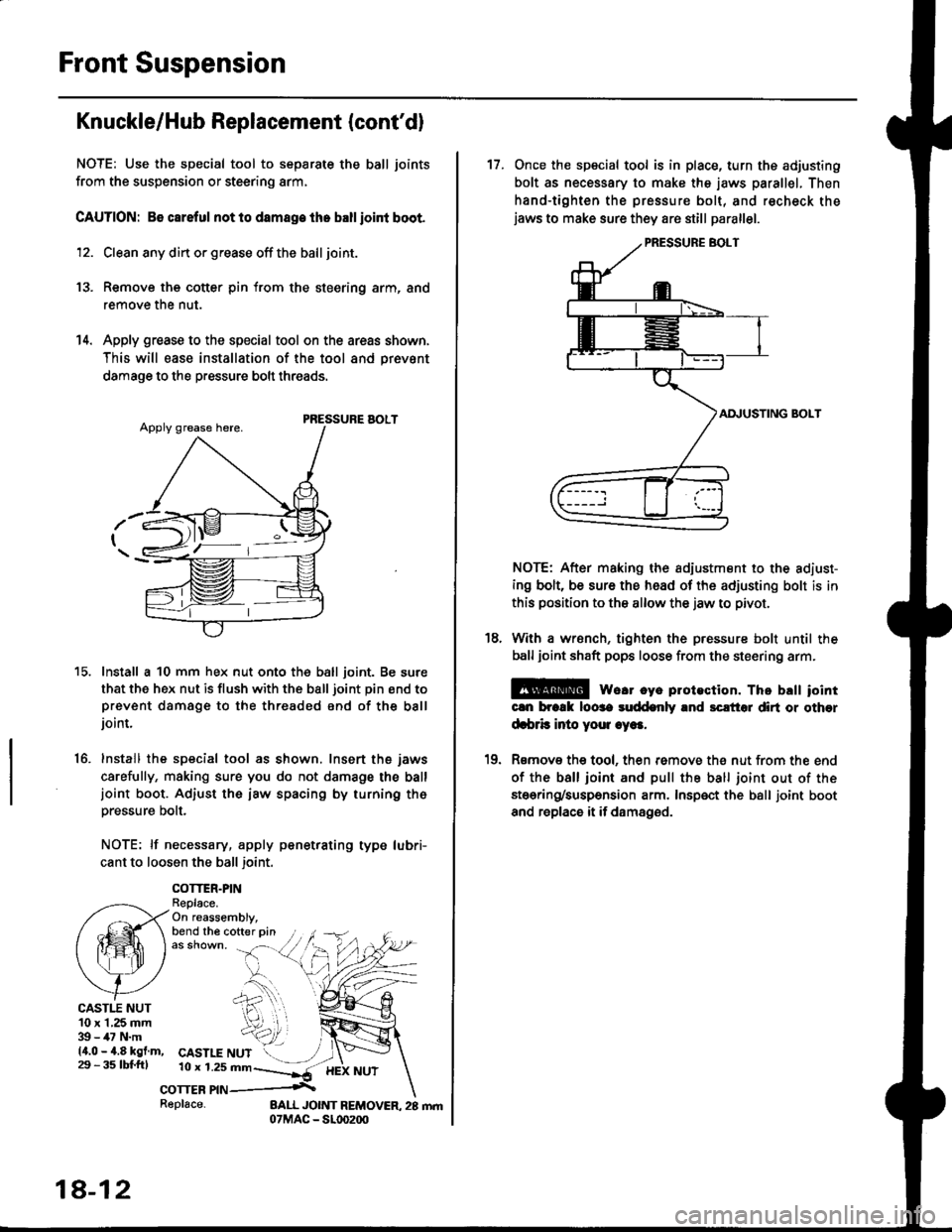

Knuckle/Hub Replacement (cont'dl

NOTE: Use the special tool to separate the ball joints

from the suspension or steering arm,

CAUTION: 86 careful not lo damage the ballioint boot.

12. Clean any din or grease off the ball joint.

13. Remove the cotter pin from the steering arm, and

remove the nut.

14. Apply grease to the special tool on the areas shown,

This will ease installation of the tool and prevsnt

damage to the pressure bolt threads.

PRESSURE AOLT

Install a 10 mm hex nut onto the ball joint. Be sure

that the hex nut is flush with the ball joint pin end toprevent damage to the threaded end of the balljoint.

Install the special tool as shown. Insert the jaws

carefully, making sure you do not damage the balljoint boot. Adiust the iaw spacing by turning th6pressure bolt.

NOTE: lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

COTTER.PINReplace.On reassembly,bend the cofter pin

15.

16.

CASTI.T NUT10 x 1,25 mm39 - 47 N.m14.0 - 4.8 kgf.m,29 - 3s tbl.fttCASTLE NUT10 r 1.2s mn--]*-

corrcn nn .\

18-12

Replace-

17. Once the special tool is in place, turn ths adjusting

bolt as necessary to make the jaws parallel. Then

hand-tighten the pressure bolt, and recheck thejaws to make sure they are still parallel.

AI\IUSTING BOLT

NOTE: After making the adiustment to the adiust-

ing bolt, be sure the head of the adjusting bolt is in

this position to the allow the jaw to pivot.

With a wrsnch, tighten the pressure bolt until the

ball joint shaft pops loose from the steering arm.

E@ we.r cye plotection. Thc brtt iointcln brcrk loose suddenly and sclt'tol dirt or other

d.brb inio youl .ye..

Rsmov€ the tool, then remove th€ nut from the end

of the ball ioint and pull the ball joint out of the

stoering/suspension arm. Insp€ct the ball joint boot

and replace it if damaged.

18.

10

Page 2163 of 2189

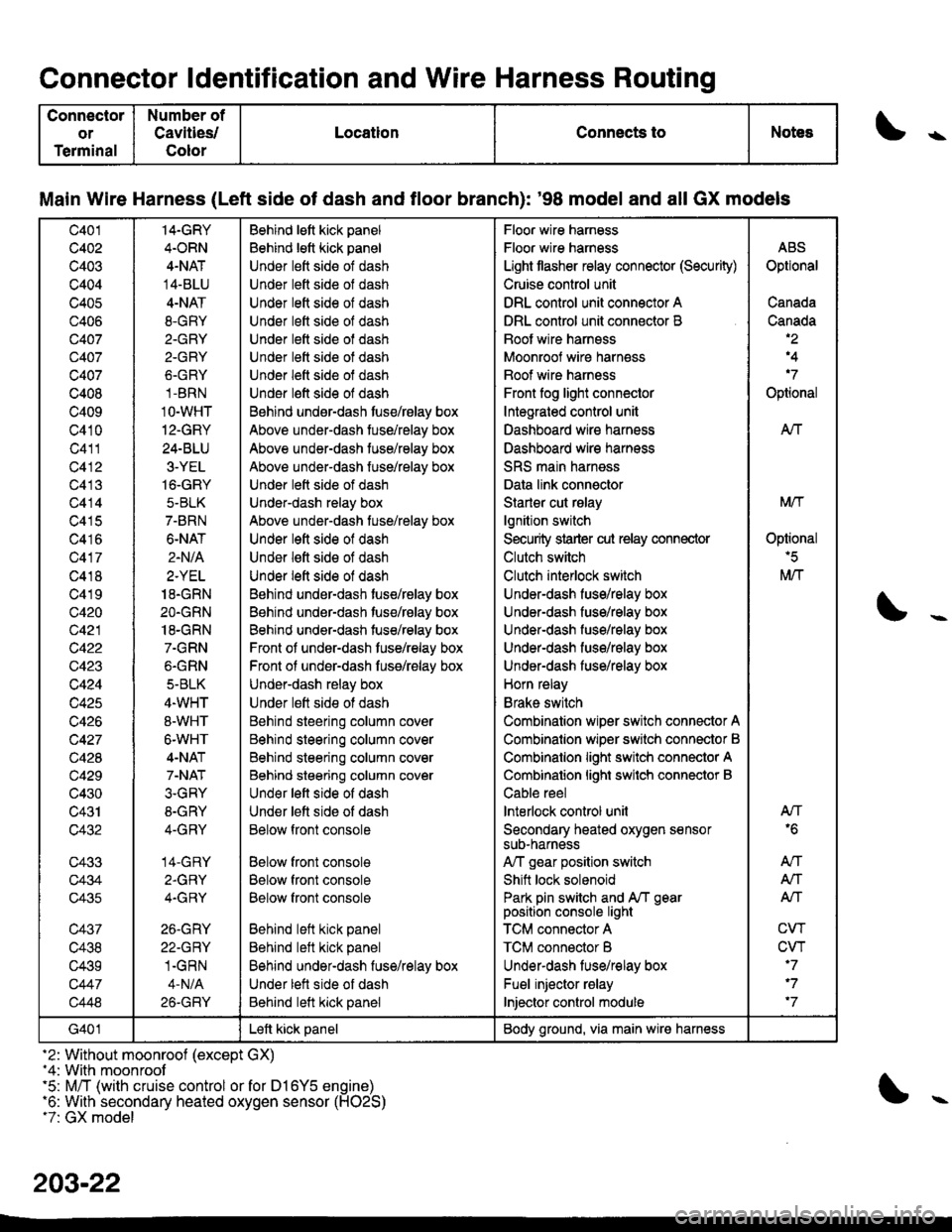

Connector ldentification and Wire Harness Routing

Connector

or

Terminal

Number of

Cavities/

Color

LocationConnects toNotess

Main Wire Harness (Left side of dash and tloor branch): '98 model and all GX models

c401

c402

c403

c404

c405

c406

Q407

c407

c407

c408

c409

c410

c411

c412

c413

c414

c415

c416

c417

c418

c419

c420

c421

c422

c423

c424

c425

c426

c427

c428

c429

c430

c431

c432

c433

c434

c435

c437

c438

c439

c447

c448

14-GRY

4.ORN

4-NAT

14-BLU

4-NAT

8.GRY

2.GRY

2-GRY

6.GRY

1-BRN

1O-WHT

12-GRY

24-BLU

3-YEL

16-GRY

5-BLK

7-BRN

6-NAT

2.N/A

2.YEL

18.GRN

2O.GRN

18-GRN

7.GRN

6.GRN

5-BLK

4.WHT

8-WHT

6-WHT

4-NAT

7-NAT

3.GRY

8-GRY

4-GRY

14-GRY

2.GRY

4.GRY

26.GRY

22-GRY

1.GRN

4-N/A

26-GRY

Behind lett kick panel

Behind lett kick panel

Under lett side of dash

Under lett side ol dash

Under lett side of dash

Under left side of dash

Under lett side of dash

Under lett side ot dash

Under left side of dash

Under l€ft side of dash

Behind undsr-dash tuse/rBlay box

Above under-dash tuse/relay box

Above under-dash tuse/relay box

Above under-dash fuse/relay box

Under lett side of dash

Under-dash relay box

Above under-dash tuse/relay box

Under left side of dash

Under lett side of dash

Under left side of dash

Behind under-dash tuse/relay box

Behind under-dash tuse/relay box

Behind under-dash tuse/relay box

Front of under-dash tuse/relay box

Front ol under-dash fuss/relay box

Under-dash relay box

Under lett side ot dash

Behind steering column cover

Behind steering column cover

Behind steering column cover

Behind steering column cover

Und€r left side of dash

Under lett side of dash

Below front console

Below front console

Below front console

Below front console

Behind left kick panel

Behind left kick panel

Behind under-dash fuse/relay box

Under lett side of dash

Behind left kick panel

Floor wire harness

Floor wire harness

Light tlasher relay connector (Security)

Cruise control unit

DRL control unit connector A

DRL control unit connector B

Boot wire harnsss

Moonroof wire harness

Boof wire harness

Front fog light connector

Integrated control unit

Dashboard wire harness

Dashboard wire harness

SRS main harness

Data link connector

Starler cut rslay

lgnition switch

Security strarter cut relay connector

Clutch switch

Clutch interlock switch

Under-dash fuse/relay box

Under-dash fuse/relay box

Under-dash fuso/rolay box

UndeFdash fuse/relay box

Under-dash fuse/relay box

Horn relay

Brake switch

Combination wiper switch connector A

Combinalion wiper srvitch connector B

Combinalion light switch connector A

Combinalion lighi swilch connector B

Cable reel

lnterlock control unil

Secondary heated oxygen sensorsuD-narness

A,/T gear position switch

Shift lock solenoid

Park pin switch and A/T gearposition console light

TCM connector A

TCM connector B

Underdash lus€/relay box

Fuel injector relay

Injector control module

ABS

Optional

Canada

Canada,2

,4

'7

Optional

AIf

Mtf

Oplional'5

M/T

AN'6

An

A,/T

Alf

CW

CVT'7

'7

'7

G401Left kick panelBody ground, via main wire harness

-2: Without moonroof (except GX)-4: With moonroof'5: M/T (with cruise control or for D16Y5 engine)'6: With secondary heated oxygen sensor (H02S)t7: GX model

203-22