Sensors HONDA CIVIC 1997 6.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 883 of 2189

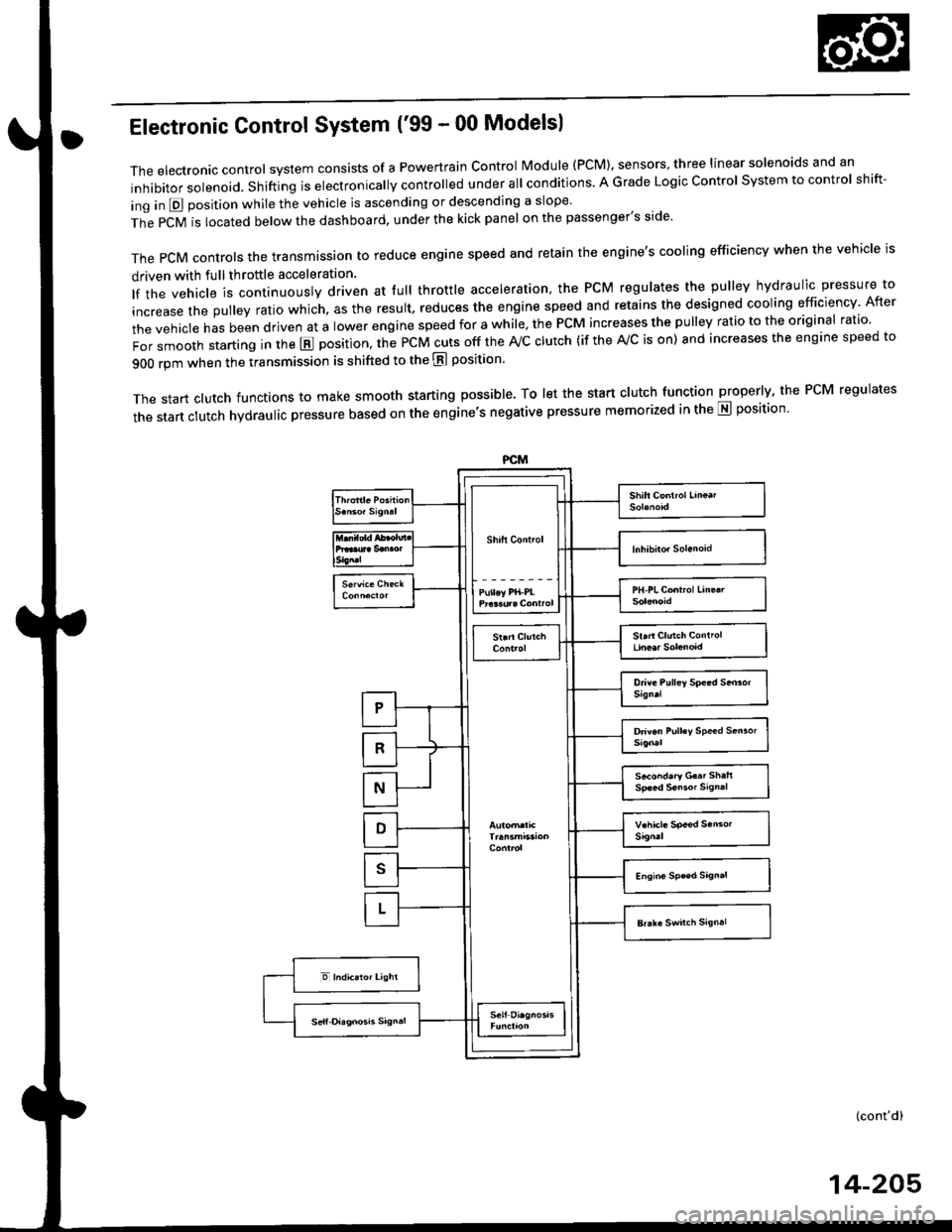

Electronic Gontrol System ('99 - 00 Modelsl

The electronic controt system conststs of a Powertrain control Module (PCM). sensors, three linear solenoids and an

inhibitor solenoid. shifting is electronically controlled under all conditions A Grade Logic control system to control shift-

ing in E position while the vehicle is ascending or descending a slope'

fn"pCVirlocatedbelowthedashboard,underthekickpanelonthepassenger'sside'

The pCM controls the transmassion to reduce engine speed and retain the engine's cooling efficiency when the vehicle is

driven with full throftle acceleration

lf the vehicle is continuously driven at lull throttle acceleration, the PCM regulates the pulley hydraulic pressure to

increase the pulley ratio which. as the result, reduces the engine speed and retains the designed cooling efficiency After

the vehicle has been driven at a lower engine speed for a while, the PCM increases the pulley ratio to the original ratio'

i"i ".nl",rr starting in the E position, the PcM cuts off the ,Vc clutch (if the A/c is on) and increases the engine speed to

900 rpm when the transmission is shifted to the E position'

The start clutch functions to make smooth starting possible. To let the start clutch function properly, the PcM regulates

the start clutch hydraulic pressure based on the engine's negative pressure memorized in the E position'

FCM

s*o.d.ry G..t Sh.h

(cont'd)

14-205

Page 898 of 2189

Description

Hydraulic Flow (cont'd)

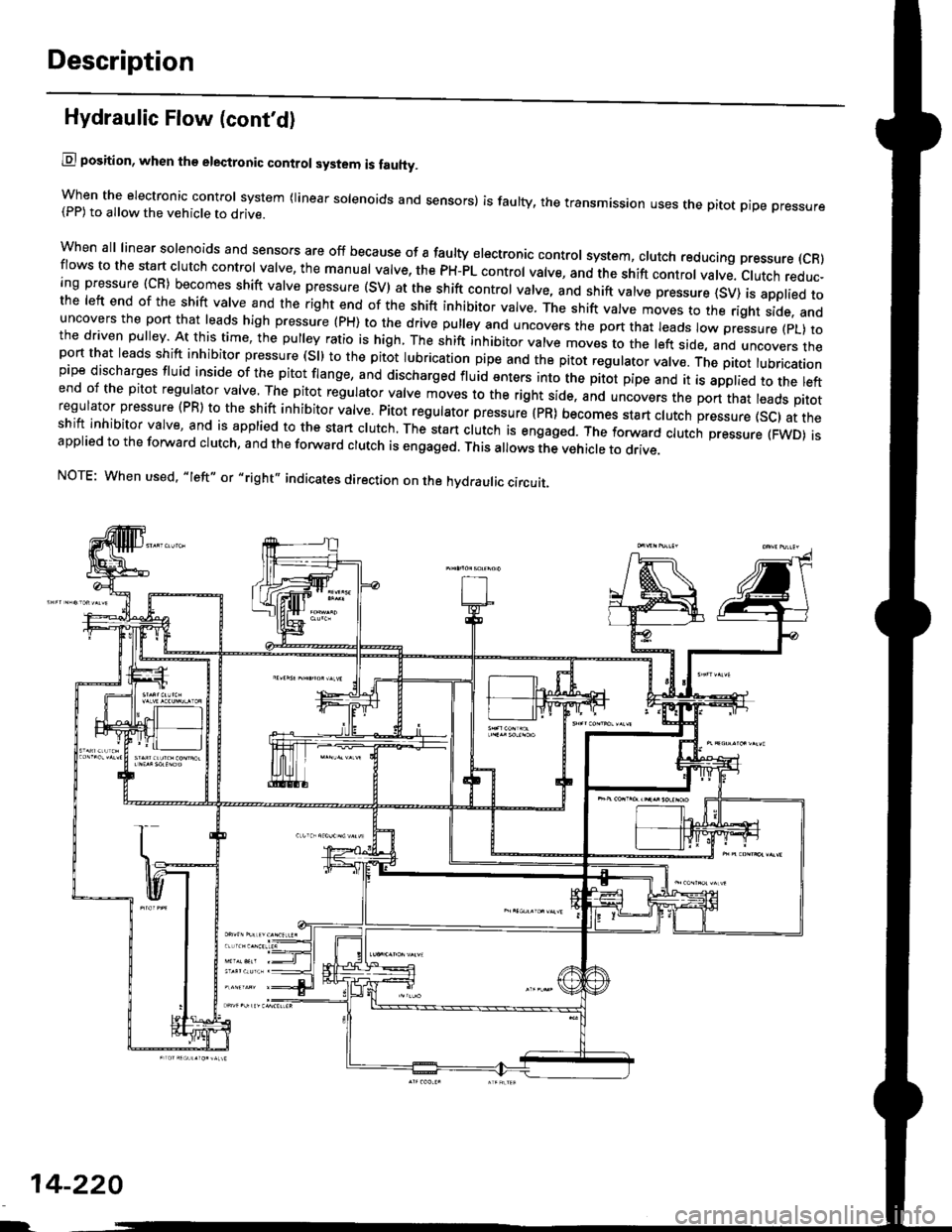

lll position, when th€ electronic control system is fauhy.

when the electronic control svstem (linear solenoids and sensors) is faulty, the transmission uses the pitot pipe pressure(PP) to 311o- rh" u"hicle to drive.

when all linear solenoids and sensors are off because of a faulty electronrc control system, clutch reducing pressure (cR)flows to the start clutch control valve, the manual valve, the PH-PL control valve, and the shift control valve. clutch reduc-ing pressure (cR) becomes shift varve pressure (sV) at the shift contror varve, and shift varve pressure {sv) is appried tothe left end of the shift valve and the right end of the shift inhibitor valve. The shift valve moves to the right side. anduncovers the pon that leads high pressure (PH) to the drive pulley and uncovers the po.t tlr"t r""1" ro,,"-pressure (pL) tothe driven pulley At this time, the pulley ratio is high, The shift inhibitor valve moves to the left side, and uncovers theport that leads shift inhibitor pressure (Sll to the pitot lubrication pipe and the pitot regulator valve. tne prtot lubricationpipe discharges fluid inside of the pitot flange, and discharged fluid enters into the pitot pipe and it is applied to the leftend of the pitot regulator valve. The pitot regulator valve moves lo the right side, and uncovers the port that leads pitotregulator pressure (PR) to the shift inhibitor valve. Pitot regulator pressure {pR) becomes start clutch pressure {sc1 at theshift inhibitor valve, and is applied to the stan clutch. The stan clutch rs engaged. The forward clutch pressure (FWD) isapplied to the forward crutch, and the forward crutch is engaged. This alows the vehicre to drive.

NOTE: When used. "|eft" or ,,right', indicates direction on the hydraulic circuit.

14-220

I.

Page 969 of 2189

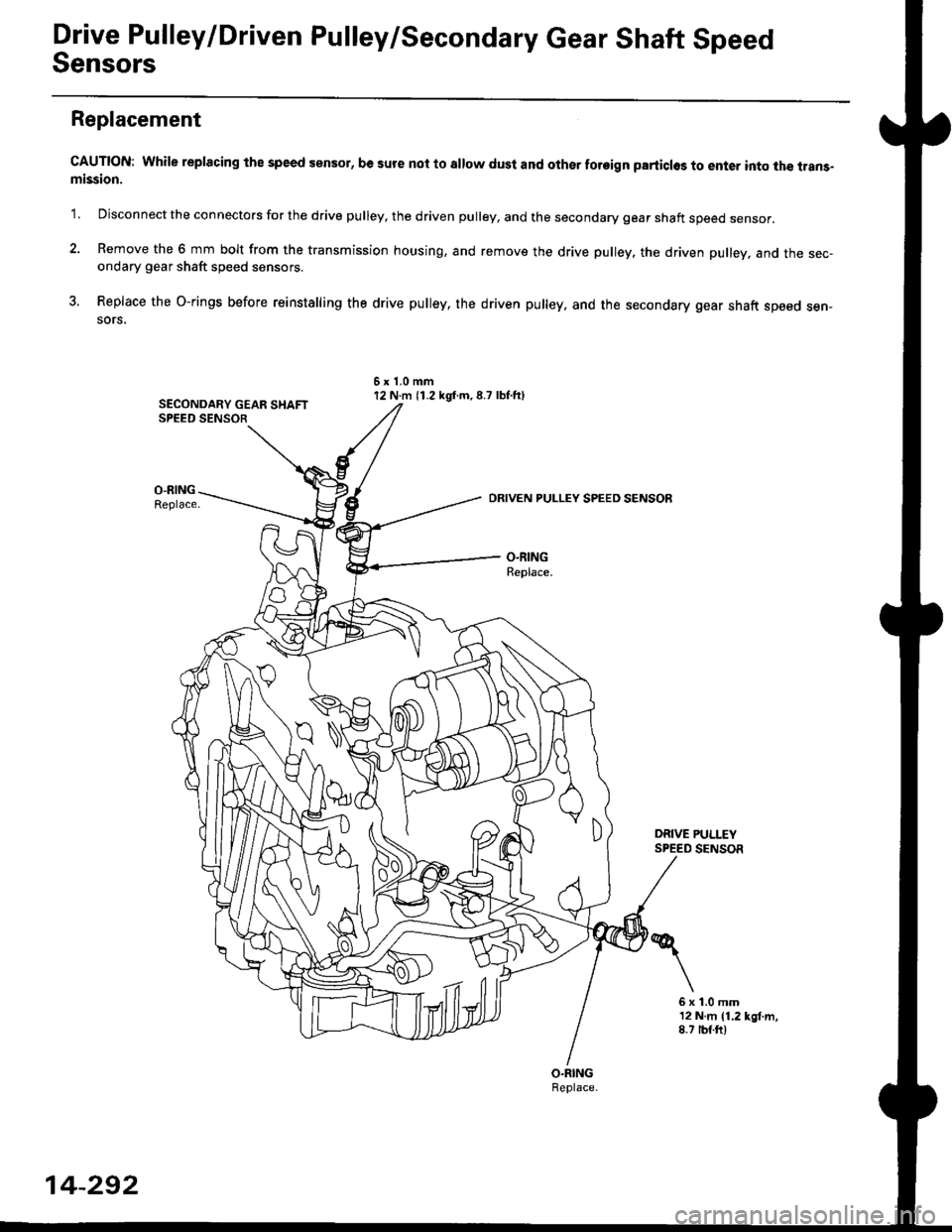

Drive Pulley/Driven Pulley/Secondary Gear Shaft Speed

Sensors

Replacement

CAUTION: While replacing the speed sensor, be sure not to allow dust and other foreign parliclos to enter into the trans-mission.

'1. Disconnect the connectors for the drive pulley, the driven pulley, and the secondary gear shaft speed sensor.

2. Remove the 6 mm bolt from the transmission housing, and remove the drive pulley. the driven pulley, and the sec-ondary gear shaft speed sensors.

3. Replace the O-rings before reinstalling the drive pulley, the driven pulley, and the secondary gear shaft sp€ed sen-sors.

6x1.0mm12 N.m (1.2 kgf.m,8.7 lbf.ft)

6x1.0mm12 N.m (1.2 kgt.m,8.7 tbf.ft)

DRIVEN PULLEY SPEED SENSOB

14-292

Page 1196 of 2189

L-

t

Anti-lock Brake System (ABSI

Special Tools ............. 19-44

Component Locations ......................... 19-45

Anti-lock Brake System (ABS)

Features/Construction ..................., 19-46

Operation ............... 19-47

Circuit Diagram ......... 19-50

ABS Control Unit Terminal

Arrangement ......... 19-52

Troubleshooting Precautions ............. 19-54

Diagnostic Trouble Code (DTCI

Diagnostic Trouble Gode (DTCI

Indication ........... 19-56

DTC Erasure ........... 19-57

Symptom-to System Chart ............. 19-58

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-60

ABS Indicator Light Does Not

Go Off ............................................ 19-62

Wheel Sensor ........ 19-64

Solenoid ................. 19-60

ABS Pump Motor ............................. 19-68

Main Relay ............. 19-71

lgnition Voltage .... 19-73

Central Processing Unit {CPU} ........ 19-74

Modulator Unit

Removal/lnstallation ....................... 19-75

ABS Control Unit

Replacement ......... 19-76

Pulsers/Wheel Sensors

Inspection .............. 19-76

Wheel Sensor Replacement ............ 19-77

t/

Page 1202 of 2189

L

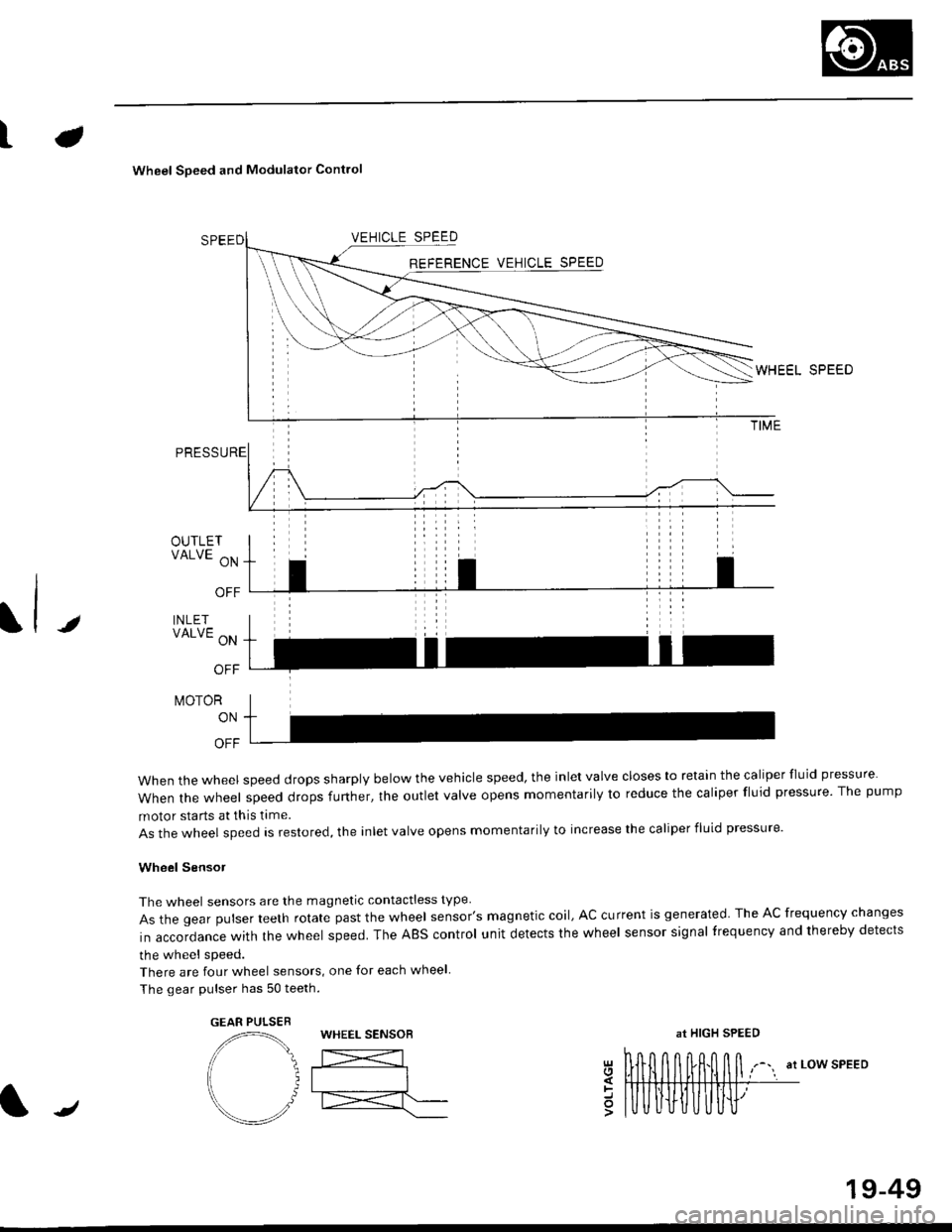

Wheel Soeed and Modulator Contlo

t

OUTLETVALVE ON

OFF

INLETVALVE ON

OFF

t\,40ToR

ON

OFF

when the wheel speed drops sharply below the vehicle speed, the inlet valve closes to retain the caliper fluid pressure

When the wheel speed drops further, the outlet valve opens momentarily to reduce the caliper fluid pressure. The pump

motor starts at this time.

As the wheel speed is restored, the inlet valve opens momentarily to increase the caliper fluid pressure.

Wheel SensoJ

The wheel sensors are the magnetic contactless type

As the gear pulser teeth rotate past the wheel sensor's magnetic coil, AC current is generated The AC frequency changes

in accordance with the wheel speed. The ABS control unit detects the wheel sensor signal frequency and thereby detects

the wheel speed.

There are four wheel sensors, one for each wheel

The gear pulser has 50 teeth.

EEL SPEED

at LOW SPEEDgl

=o

GEAR PULSEBWHEEL SENSOBat HIGH SPEED

/

19-49

Page 1205 of 2189

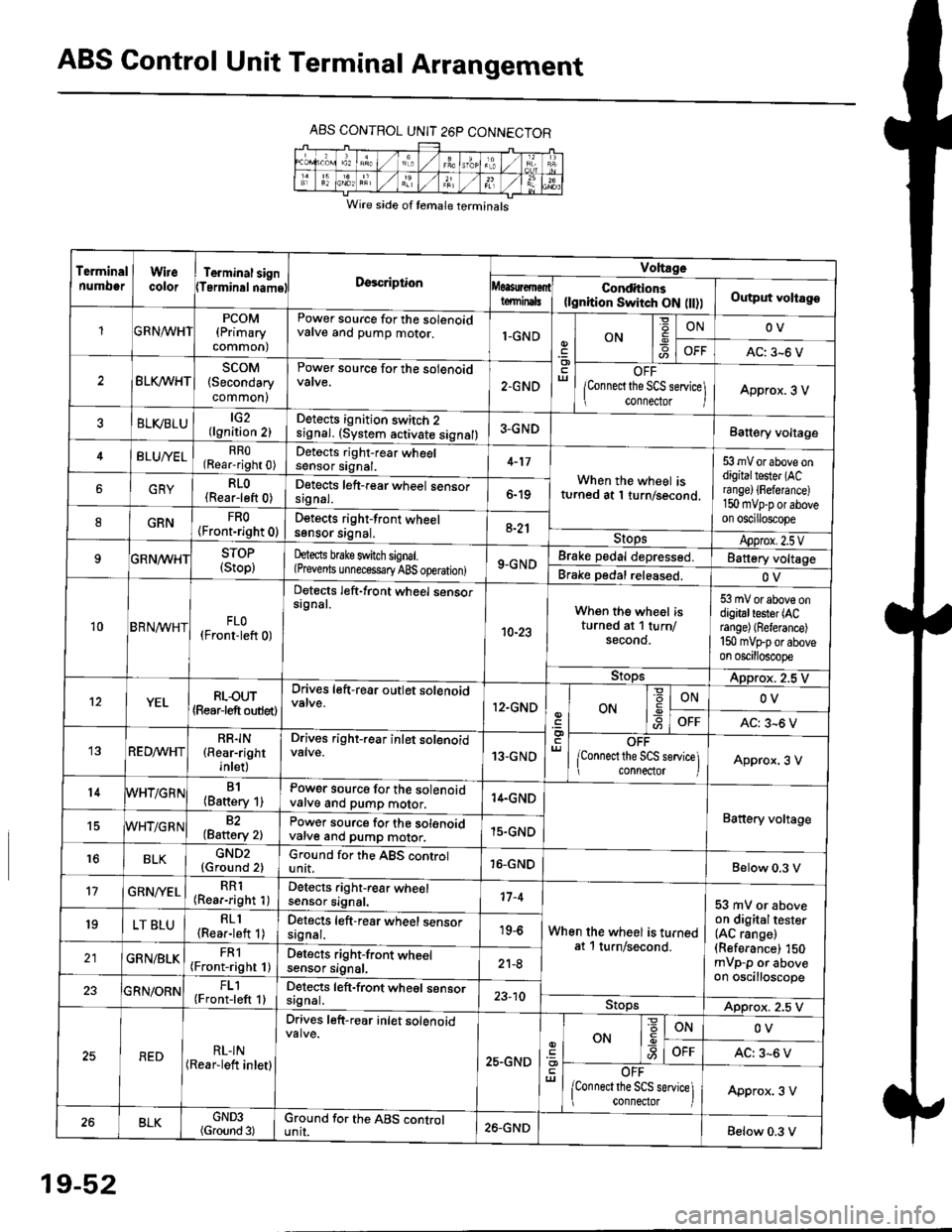

ABS Control Unit Terminal Arrangement

ABS CONTROL UNIT 26P CONNECTOR

Wire side of temale terminals

Terminalnumo0rWirecolorTerminal signTerminalnamoDgscriptionVoltage

Conditions(lgnition Switch ON flt))Output voltagoteminals

PCOM(Primary

common)

Power source for the solenoidvalve and pump motor.1-GNDON

=ONOV

AC: 3-6 V

BLK/WHTscoM(Secondary

common)

Power source for the solenoid

2.GNDOFF

lConnect the SCS service\

conneclor lApprox. 3 V

ELVBLUtG2(lgnition 2)Detects ignition switch 2

!9nal. (system activate signal)3-GNDBatt€ry voltage

BLU/YELRRO(Rear-right 0)Detects right-rear wheelsensor signal.4-17

When the wheel isturned at 1 turn/second.

53 mV or above ondigitaltester (ACra nge) {Fefera nce)150 mvp-p or aboveon oscilloscope

6GRYRLO(Rear-left 0)Detects left-rear wheel sensorsrgnal.6-19

8GRNFRO(Front-right 0)D€tects right-front wheelsgnsor srgnal,a-21StopsApprox.2.5VSTOP(Stop)hects brake switch signal.(Prevents unnecess€ry ABS operation)9-GNDBrake pedal depressed.Battery voltage

Brake pedal released.OV

10BRN^/vHTFLO(Front-left 0)

Detects left-front wheel sensorsignal.

10-23

When the wheel isturned at 1 turn/secono.

53 mV or above ondigitaltester (ACrange) (Referance)

150 mVFporaboveon oscilloscope

9!opsApprox. 2.5 V

12YELRLOUT(Rearjeft outlet)

Drives left-rear outlet solenoid

12.GNDON-9ONOV

OFFAC: 3^6 V

REDMHTRR]N(Rear-right

inlet)

Drives right-rear inlet solenoidvalve.13-GNDOFF

lconnect the SCS service]i connector IApprox. 3 V

14B1(Battery 1)Power source for the solenoidvatve and pump motor.14.GND

Battery voltage15WHT/G R N82(Baftery 2)Power source for the solenoidvarve ano pump motor.15.GND

r6BLKGND2{Ground 2)Ground for the ABS controlunit.16-GNDBelow 0.3 V

17GRN/'/ELRR1(Rear-right 1)Detects right-rear wheelsensor signal.17-4

When the wheel is turnedat 1 turn/second.

53 mV or aboveon digitaltester(AC range)(Referance) 150mVp-p or aboveon oscilloscope

19LT BLURLl(Rea.-left 1)Detects left-rear wheel sensorsagnal.19-6

GRN/BLKFRl(Front-right 1)Detects right-front wheelsensor signal.21-8

FL1(Front-left 1)Detects left-front wheel sensorsignal.23-10StopsApprox. 2.5 V

REDRL-IN(Rear-lett inletl

Drives left-r€ar inlet solenoid

25.GND

ut

ON

'6

-9ONOV

OFFAC: 3-6 V

OFF

lconnect the SCS service] connector lApprox. 3 V

BLKGND3(Ground 3)Ground for the ABS cgntrolunit.26.GNDBelow 0.3 V

19-52

Page 1229 of 2189

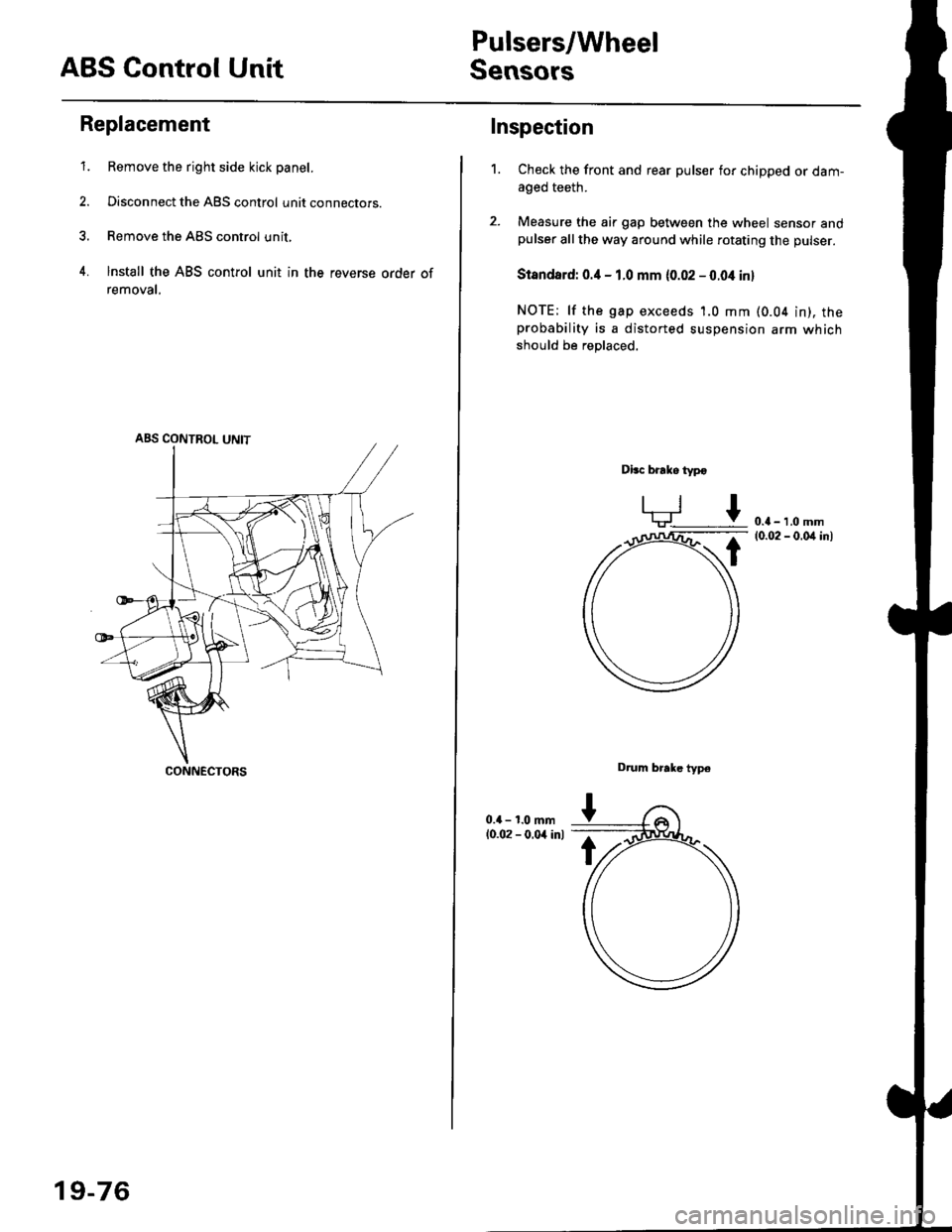

ABS Control Unit

Pulsers/Wheel

Sensors

Replacement

1. Remove the right side kick panel.

2. Disconnect the ABS control unit connecrors.

3. Remove the ABS control unit,

4. lnstall the ABS control unit in the reverse order of

removal,

CONNECTORS

19-76

Inspection

Check the front and rear pulser for chipped or dam-aged teeth.

Measure the air gap between the wheel sensor andpulser all the way around while rotating the pulser.

Slandard: 0.4 - 1.0 mm (0.02 - 0.04 in,

NOTE; lf the gap exceeds 1.0 mm (0.04 in), theprobability is a distorted suspension arm which

should be replaced.

Dbc brake typo

0.{ - 1.0 mm(0.02 - 0.04 in)

Drum brake typ6

1.

Page 1230 of 2189

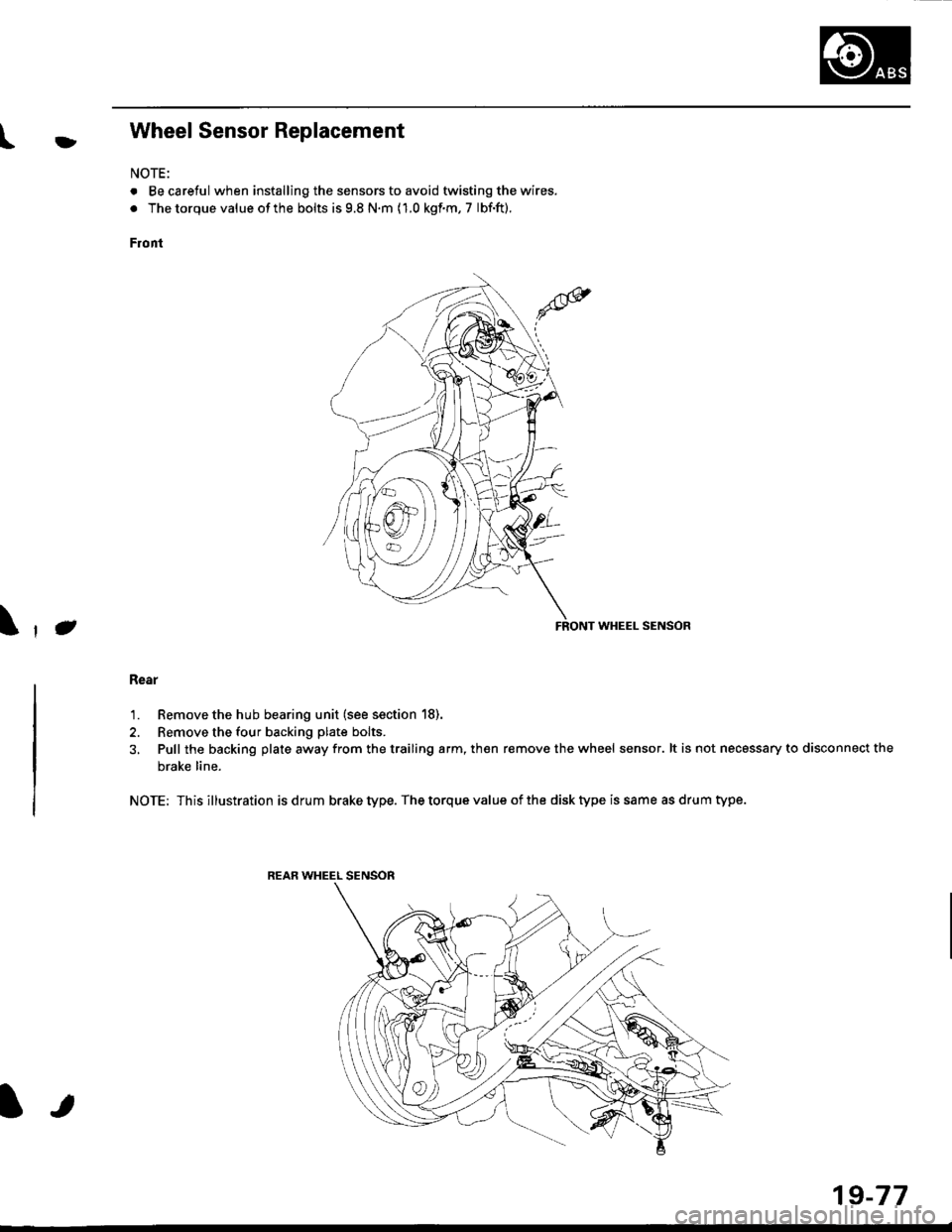

l}tWheel Sensor Replacement

NOTE:

. Becareful when installingthe sensors to avoid twisting the wires.

. The torque value of the bolts is 9.8 N.m (1.0 kgf.m, 7 lbf.ft).

Front

FRONT WHEEL SENSOR

Rear

1. Remove the hub bearing unit (see section 18).

2. Remove the four backing plate bolts.

3, Pull the backing plate away from the trailing arm, then remove the wheel sensor. lt is not necessary to disconnect the

brake line.

NOTE: This illustration is drum brake type. The torque value of the disk type is same as drum type.

REAR WHEEL SENSOR

J\

It

19-77

Page 1486 of 2189

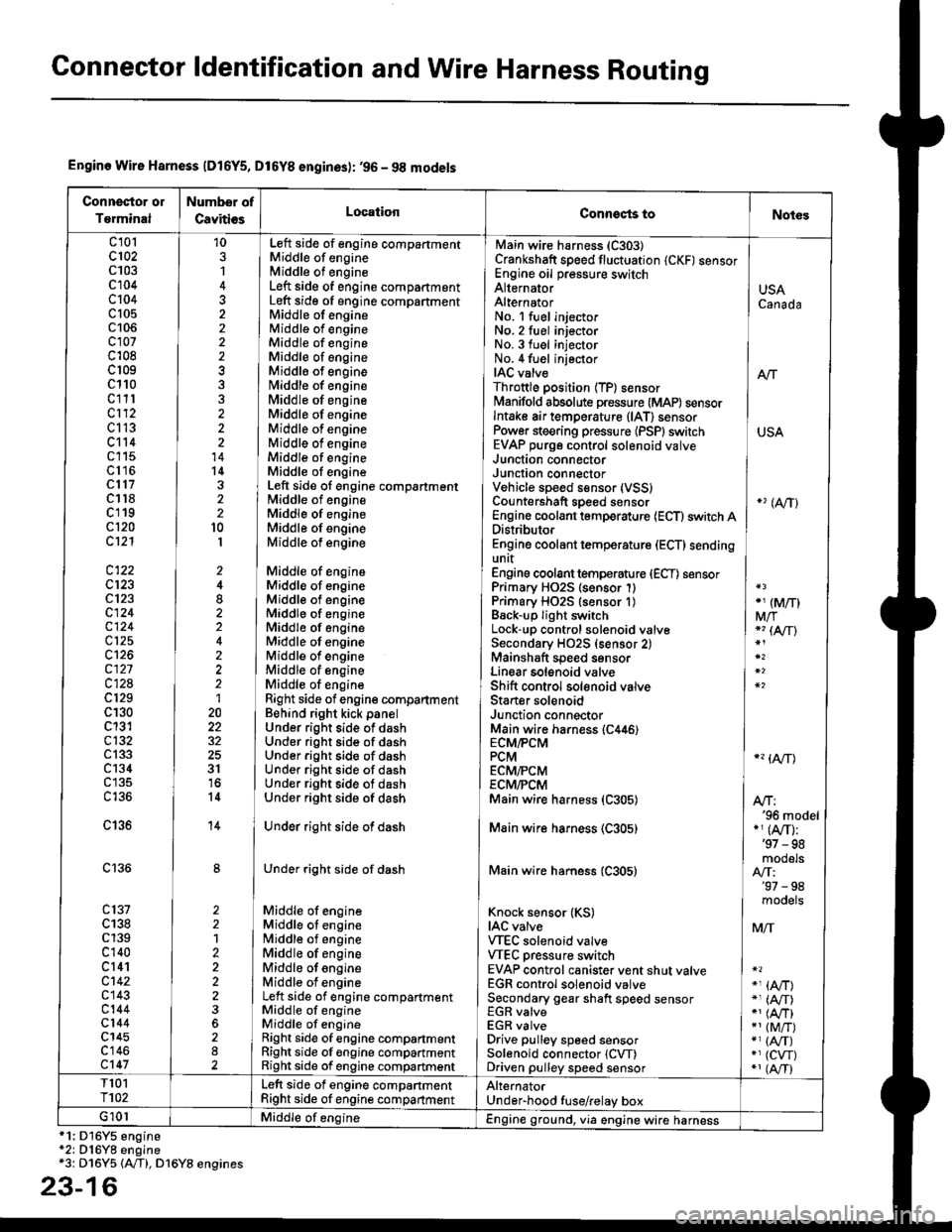

Connector ldentification and Wire Harness Routing

Engine Wire Harness lD16Y5, D16Y8 enginss): '96 - 98 models

Connector or

Torminal

Numbsr of

CavitissLocationConnects toNot€s

c 101c102c103c104c104c105c106c107c108c 109c110c111c112c113c114c115c116cl17c118c119c120cl21

c122c123cl23c124

c125

c127c12Ac129c130c131c132c 133c134c135

c136

c138c139c140c 141c142c 143c144cl44c145c'146cl47

10

1

22

14l4322l0I

2

2

2

2120

3l

14

14

1222

2

2

22

Left side of engine compartmentMiddle of engineMiddle of engineLeft side of engine companmentLeft side of engine compartmentMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of enginefvliddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineLeft side of engine compartmentMiddle of engineMiddle of engineMiddle of engineMiddle of engine

Middle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineRight side of engine companmentBehind right kick panelUnder right side of dashUnder riOht side of dashUnder right side of dashUnder right side of dashUnder right side of dashUnder right side of dash

Under right side of dash

Under right side of dash

Middle of engineMiddle ot enginel iddle of engineMiddle of engineMiddle of ongineMiddle of engineLeft side of engine compartmentMiddle of engineMiddle of engineRight side of engine compartmentRight side of engine compartmentRight side of engine compartment

USACanada

Afi

USA

-' (A/r)

Main wire harness (C303)Crankshaft speed fluctuation (CKF) sensorEngine oil pressure switchAlternatorAlternatorNo. 'l fuel injectorNo. 2 fuel injectorNo.3 fuel injectorNo. 4 fuel injectorIAC valveThrottle position (TP) sensorl\4anifold absolute pressure (MAP) sensorIntake air temperature (lAT) sensorPower steering pressure {PSPI switchEVAP purge control solenoid valveJunction connectorJunction conn€ctorVehicle speed sensor {VSS}Countershaft speed sensorEngine coolant temp€rature (ECT) switch ADistributorEngine coolant temperature (ECT) sendingunrtEngine coolant temperature (ECT) sensorPrimary HO2S (sensor'l)Primary HO2S (sensor 1)Back-up light switchLock-up control solenoid valveSecondary HO2S (sensor 2)Mainshaft speed sensorLinear solgnoid valveShift control solsnoid valveStarter solenoidJunction connectorMain wire harnesE (C446)ECM/PCMPCMECMiPCMECM/PCMMain wire harness (C305)

Main wire harness (C305)

Main wire harness (C305)

Knock sensor (KS)IAC valveVTEC solenoid valveVTEC pressure switchEVAP control canister vent shut valveEGR control solenoid valveSecondary gear shaft speed sensorEGR valveEGR valveDrive pulley speed sensorSolenoid connector {CVT)Driven pulley speed sensor

*, (M/T)M/T*" INT\

*, tAtf)

NT:'96 model*,(A,/T):'97 - 98mooets

moqets

M/T

-1 (l,/T)*, (A,/T)-,(4,/T)*1 {M/T)*, (A,/T)*1 (CW)*, (A,T)

T101r102Left side of engine companmentRight side of engine companmentAlternatorUnder-hood fuse/relay boxG 101Middle of engineEngine ground, via engine wire harness

2

*1: Dl6Y5 engine*2: D16Y8 engine*3: D16Y5 (Ay'T), D16Y8 engines

3-16

Page 1488 of 2189

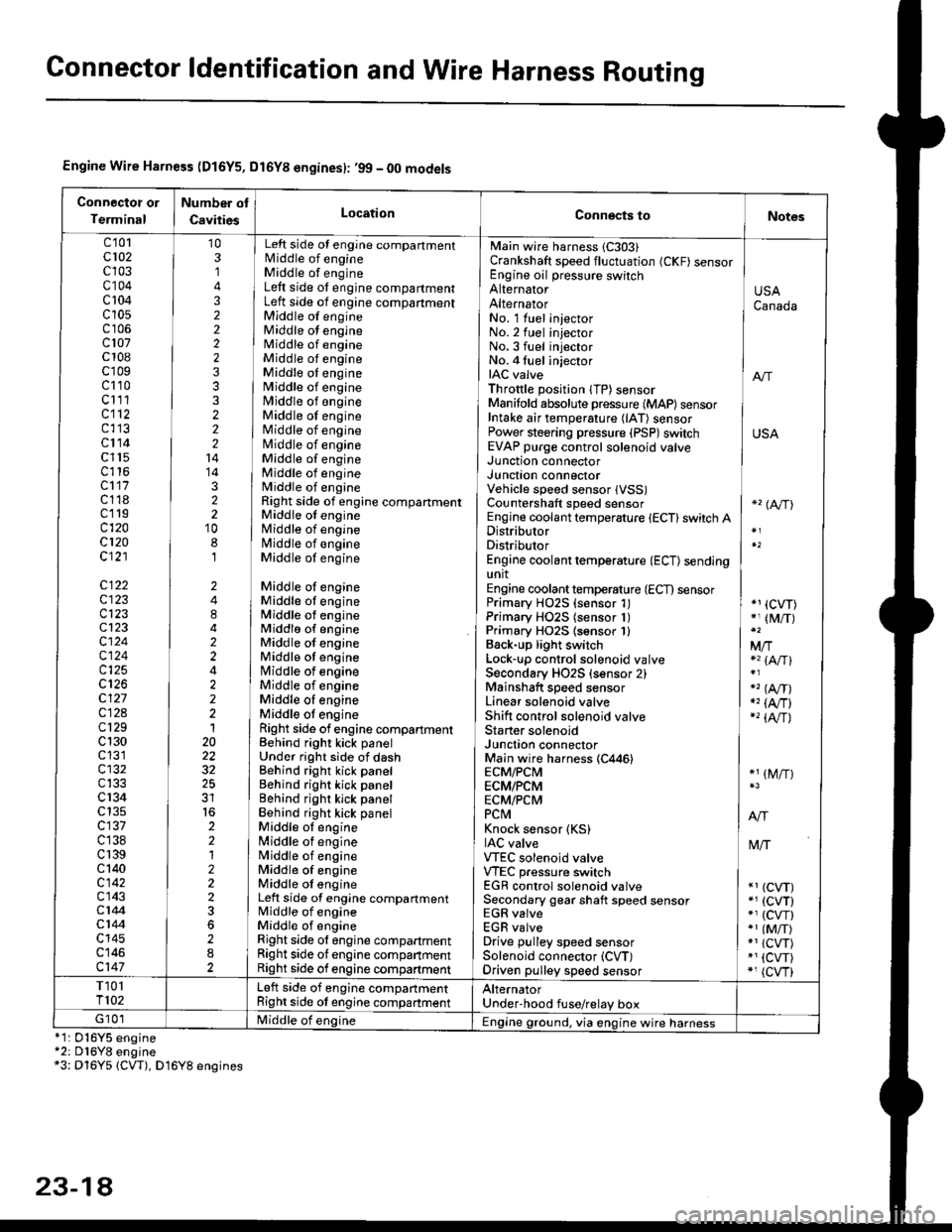

Gonnector ldentification and Wire Harness Routing

Engine Wire Harness (D16Y5, Dl6Yg engines): ,99 - 00 models

Connectot or

Terminal

Number ot

CavitiesLocationConn€cts toNotes

c'101cl02c103c104c 104c10s

c107c 108c'r09c110c111cl12c113cl14c l15c116cl17c118c119c120cl20c121

c122c123c123cl23cl24c124c125

c127c12Ac129c 130c131cl32c133c 134c135c137c138c 139c 140c142c143c144cl44c145c146c147

103,]

322223332221414322'10

8,l

2484224222120

32

2212223

282

No. 1 luel injector INo.2 fuel injectorNo.3 fuel injector ]No. 4 fuel injector iIAC valve I anThrottle position lTP) sensorManifold absolute pressure {MAP) sensor IIntake air temperature (lAT) sensor IPower steering pressure (PSP)switch USAEVAP purge control solenoid valve ]

Main wire harness 1C303)Crankshaft speed fluctuation (CKF) sensorEngine oil pressure switchAlternatorAlternator

Left side ot engine compartmentlvliddle of engineMiddle of engineLeft side ot engine compartmentLeft side of engine compartmentMiddle of engineMiddle ot engineMiddle of engineMiddle of engineMiddle oI engineMiddle of engineMiddle of engineMiddle of engineMiddle of engineNliddle of engineMiddle of engineMiddle of engineMiddle of engineRight side of engine compartmentMiddle of engineMiddle of engineN4iddle of engineMiddle of engine

Middle of engineMiddle ot engineMiddle ot engineMiddlo of engineMiddle of engineMiddle ot enginelrliddle of engineMiddle of engineMiddle oI engineMiddle ot engineRight side of engine compartmenlBehind right kick panelUnder right side of dashBehind right kick panelBehind right kick panelBehind righr kick panelBehind right kick panelMiddle ot engine[,liddle of engineN4iddle of engineMiddle of engineMiddle oI engineLeft side of engine compartmentMiddle of engineMiddle of engineRight side ol engine compartmentRight side of engine companmentRight side of engine compartment

USACanada

Junction connectorJUnct|On COnnectorVehicle speed sensor lVSS)Countershaft speed sensorEngine coolant temperature {ECT} switch ADistributorDistributorEngine coolant temperature (ECT) sendingunitEngine coolant temperature (ECT) sensorPrimary H02S (sensor 1)Primary HO2S (sensor 1)Primary HO2S lsensor 1)Back-up light switchLock'!p control solenoid valveSecondary HO2S (sensor 2)Mainshaft speed sensorLinear solenoid valveShift control solenoid valveStarter solenoidJunction connectorMain wire harness (C446)ECM/PCMECM/PCMECM/PCMPCtvtKnock sensor (KS)IAC valveVTEC solenoid valveVTEC pressure switchEGR control solenoid valveSecondary gear shaft speed sensorEGR valveEGR valveDrive pulley speed sensorSolenoid connector (CVT)Driven pulley speed sensor

*'� (A/TI

*1 (CVT)*, (M/T)

Mfia (A/Tl

" (A,/T)., (4,/r)-'� {AlrJ

*1 (M/T)

tvliT

*1 (CVT)*, (cvT)*' (cw)*1 (MiT)*1 {CVT)*1 {CVT)*, (cvr)

T101T102Left side of engine companmentRight side ot engine companmentAlternatorUnder'hood fuse/relay boxG 101Middle of englne IEngine ground, via engine wire harness*1: 016Y5*2: D16Y8*3: Dl6Y5

engineengine(CW), D16Y8 engines

23-14