Gear HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1620 of 2189

![HONDA CIVIC 1997 6.G Workshop Manual A/T Gear Position Indicator

UNDER.DASHFI.JSE/FELAY BOXIGNITIONswrrcH

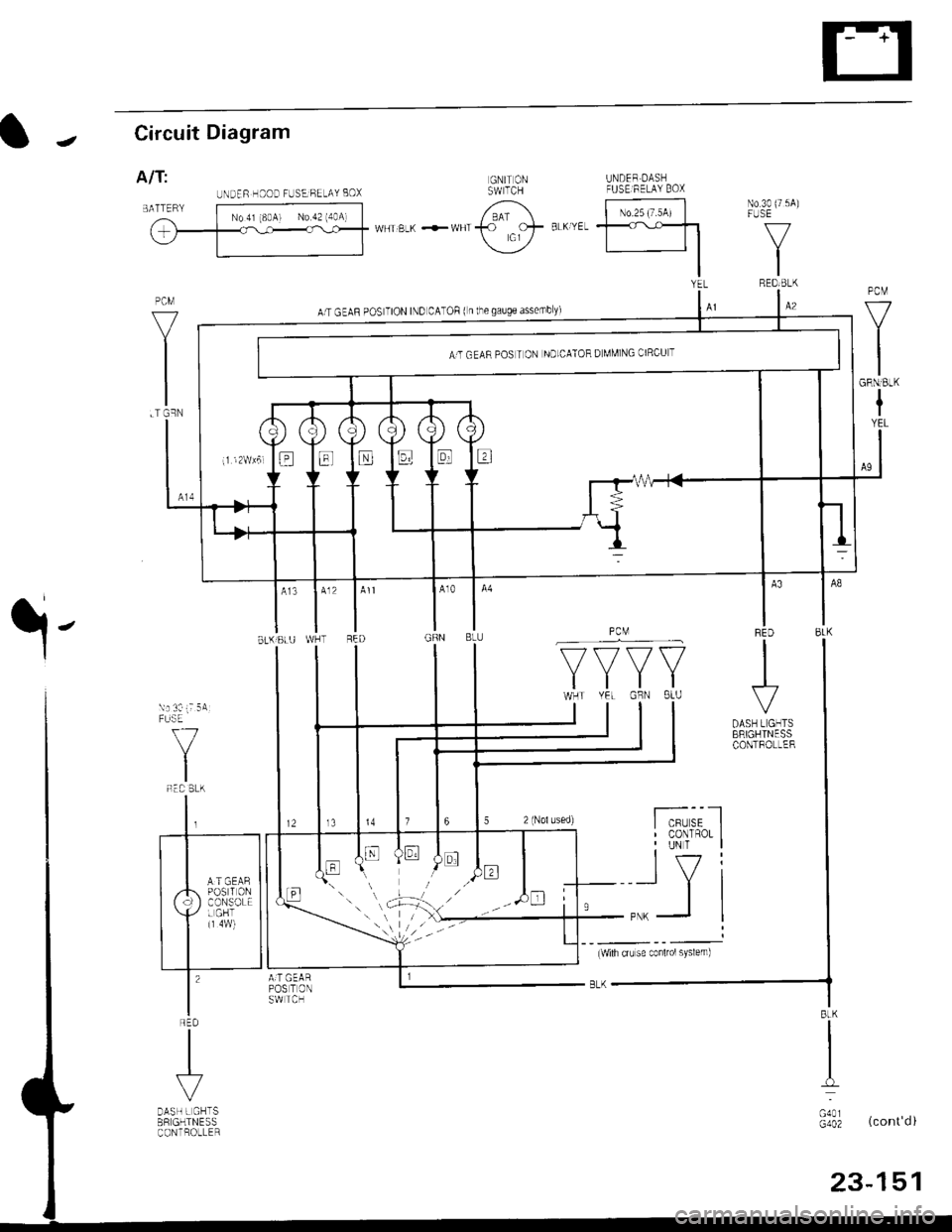

Circuit Diagram

CW:

UNDER HOOD FUSE/RELAY BOX

6; |-;,,r&l \o3o75A

rr,/-TPLK+r,,rirac coJ-aL("E1.<\c-t]

---

IY. PCM"

:i3M)

V

I HONDA CIVIC 1997 6.G Workshop Manual A/T Gear Position Indicator

UNDER.DASHFI.JSE/FELAY BOXIGNITIONswrrcH

Circuit Diagram

CW:

UNDER HOOD FUSE/RELAY BOX

6; |-;,,r&l \o3o75A

rr,/-TPLK+r,,rirac coJ-aL("E1.<\c-t]

---

IY. PCM"

:i3M)

V

I](/img/13/6068/w960_6068-1619.png)

A/T Gear Position Indicator

UNDER.DASHFI.JSE/FELAY BOXIGNITIONswrrcH

Circuit Diagram

CW:

UNDER HOOD FUSE/RELAY BOX

6; |-;,,'r&l \o3o'75A

rr,/-TPLK+r,,'rirac coJ-aL("E1.<\c-t]

---

IY. PCM"

:i3M)''

V

ILT GRN

TqM 'l

f7v

tlYEL GFN

8LK

G401G442

*1 : 96'98 modeis+2 i '99t0 models

No 30 {7.5A)

V

IRED/BLK

t,

||l

| ,k sfi0f, |Itg)coNsotEl

I Y i1?ri I

tll

t'RED

I

I

vDASI| L GHTSERIGHTNESSCONTNOLLER

l./TGEAR POSITION INDICAToR (h lhe gauge assembty)

YYYY

A/TGEARPostTtoNswrTcH

A'/T GEAB POSITION NDICATOR OIMMING C]RCUIT

23-150

Page 1621 of 2189

JCircuit Diagram

A/TUNDER HCCD FUSE BELAY BOX

PCi\4

V

I

I.T Gq

GNIT ONSW TCHTJNDEF OASH

'^a" fr-.-r^ """- *

-l

6l\

U__t- -t ir_i ;_P _+irh-

\:f

; h,:_

ArT GEAR POS TION IND CATOF (n lhegauge assembyl

A13412

YEL

f333{'*)

f7

IRED,ELKPCM

V

IGRNlBLK

I

l-

6LK 8LU

12

f7 f7 fl

ItlWHT YEL GFN

rl\4 l765 2 (Nol used)

{'}'}'1,

I

A._. --An i

t.--it-

Lrl9_PNK-

A'T GEARBLK

AIT GEAR POSTON NDLCA1ORD MM]NG CIRCUT

II

I

DASH L GHTSBRIGHTNESSCONTFOLLER

f7

ISLU\. -Ti i:5AFL]SE

V

IF:I BLK

I

l',

ll^,.,^,1L,-N pos r oN II(d].ONSCLEI

lYi:il |

Il--f'-

IRED

I

I

DASH L GHTSBB GHTNESSCONTFOLLER

BLK

I

oio,G402

23-151

Page 1622 of 2189

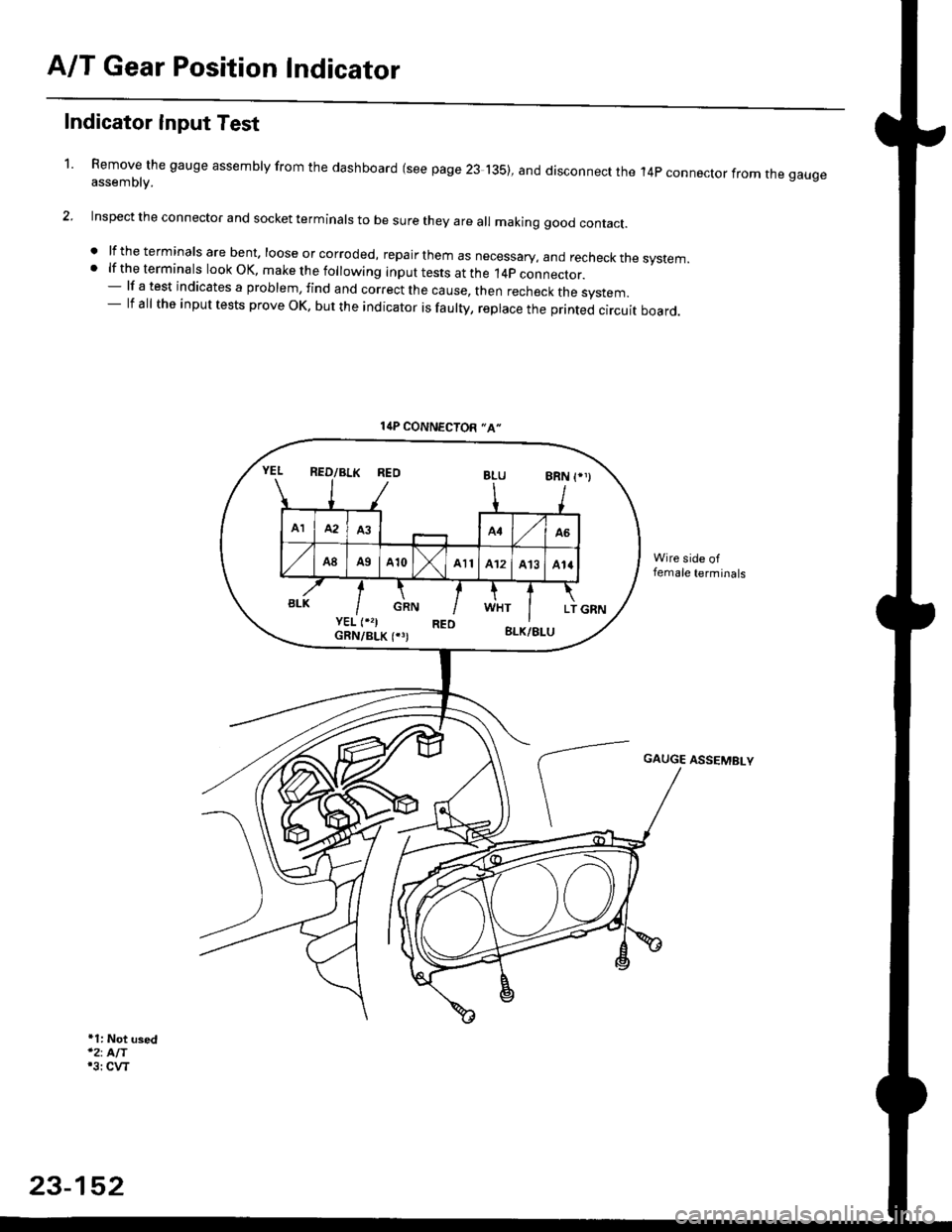

A/T Gear Position Indicator

1.

Indicator Input Test

Remove the gauge assembly from the dashboard (see page 23 135), and disconnect the 14p connector from rne gaugeassemblv.

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent. loose or corroded, repa ir them as necessary, and recheck the system.. lf the terminals look OK, make the following input tests at the 14p connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty, replace the printed circuit board.

+1: Not used'2: AIT'3i CVT

l{P CONNECTOR "A"

REOBLU8RN

AIMA3A4A6

A8A9A10All412A13414

GRNLTBLK

GAUGE ASSEMBLY

23-152

Page 1623 of 2189

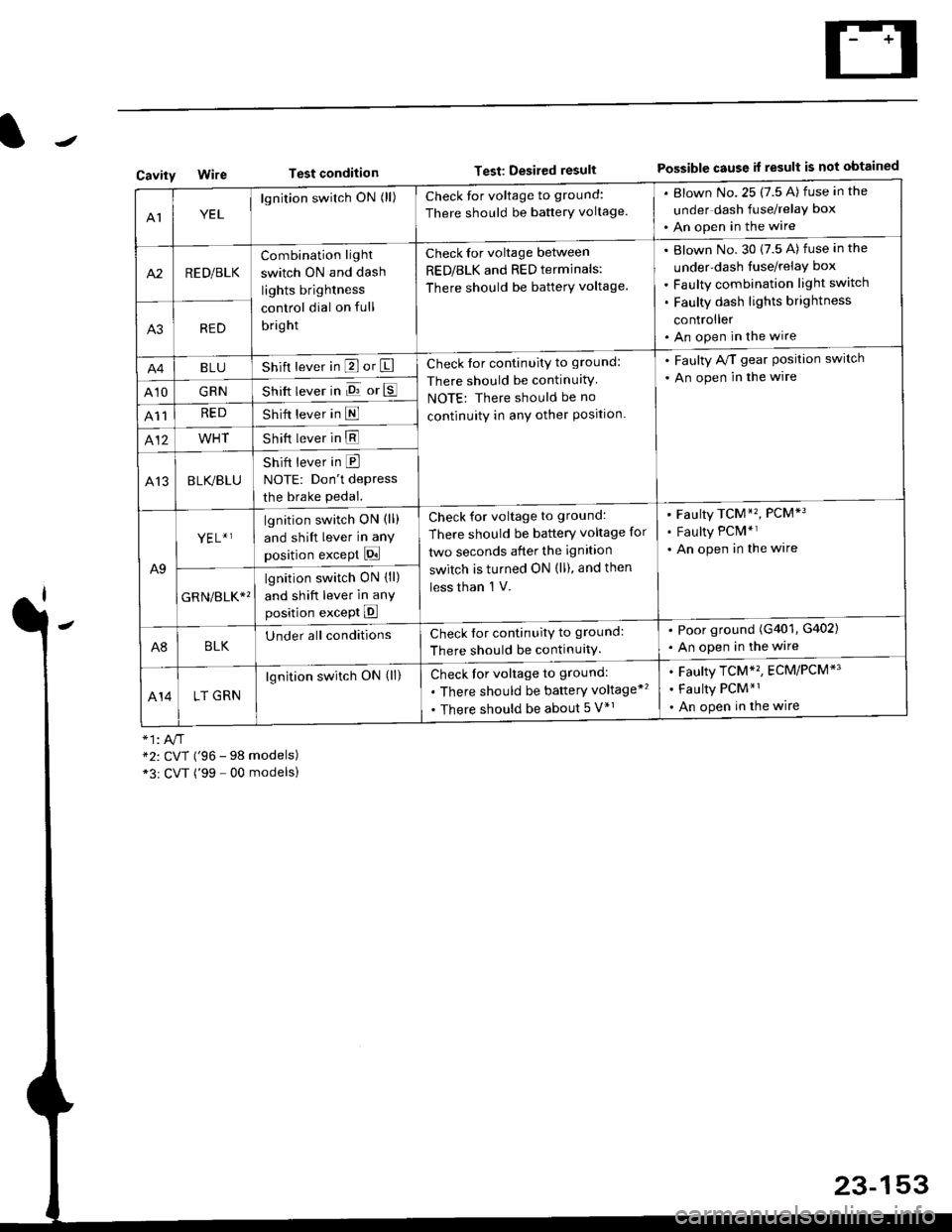

Test conditionTest: Desired resultPossible cause it result is not obtainedCavity

AIYEL

lgnition switch ON (ll)Check for voltage to ground:

There should be banerY voltage.

. Blown No.25 (7.5 A) fuse in the

under dash fuse/relay box

. An open in the wire

A2RED/BLK

Combination light

switch ON and dash

lights brightness

control dial on full

bright

Check for voltage between

RED/BLK and RED terminals:

There should be batterY voltage.

Blown No. 30 {7.5 A) fuse in the

under-dash tuse/relay box

Faulty combination light switch

Faulty dash lights brightness

controller

An open in the wireA3RED

BLUShift lever in P or ICheck for continuity to ground:

There should be continuitY

NOTE: There should be no

continuity in anY other Position.

. Faulty A/T gear Position switch

. An open in the wire

A10GRNShift lever in E or E

A11REDShift lever in E

412WHTShift lever in E

A13BLK/BLU

Shift lever in E

NOTE: Don't depress

the brake pedal.

A9

YEL+ ]lgnition switch ON (ll)

and shift lever in any

position except Pi

Check for voltage to ground:

There should be battery voltage for

two seconds after the ignition

switch is turned ON (ll), and then

less than 'l V.

Faulty TCM*'�, PCM*3

Faulty PCM*r

An open in the wire

GRN/err*'

lgnition switch ON {ll)

and shift lever in anY

position except E

A8BLKUnder all conditionsCheck for continuitv to ground:

There should be continuitY.

. Poor ground (G401, G402)

. An open in the wire

414LT GRN

lgnition switch ON (ll)Check for voltage to ground:

. There should be baftery voltage*'�

. There should be about 5 V*r

Faulty TCM*'�, ECM/PCM*'

Faulty PCM*1

An open in the wire

*2: CVT ('96 - 98 models)*3r CVT ('99 - 00 modelsl

23-153

Page 1624 of 2189

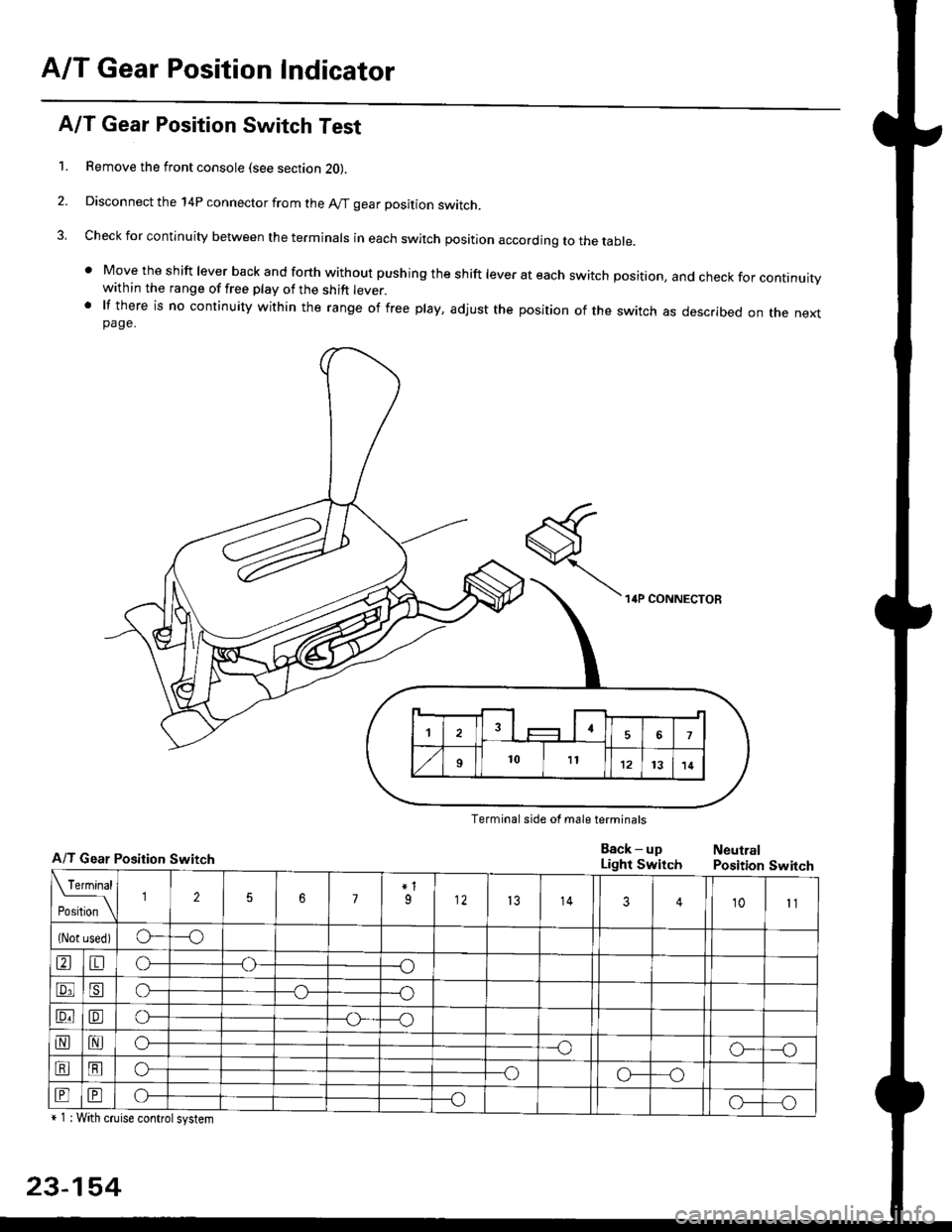

A/T Gear Position Indicator

A/T Gear Position Switch Test

1. Remove the front console (see section 2O).

2. Disconnect the 14P connector from the A/T gear position switch.

3. Check for continuity between the terminals in each switch position according to the table.

' Move the shift lever back and forth without pushing the shift lever at each switch position, and check for continuitywithin the range of free play of the shift lever.' lf there is no continuity within the range of free play, adjust the position of the switch as described on the nextpage.

Terminal side of male terminals

A/T Gear Position Switch

+ 1 : With cruise controlsystem

23-154

Eack - upLight SwitchNeutralPosition Switch

Page 1625 of 2189

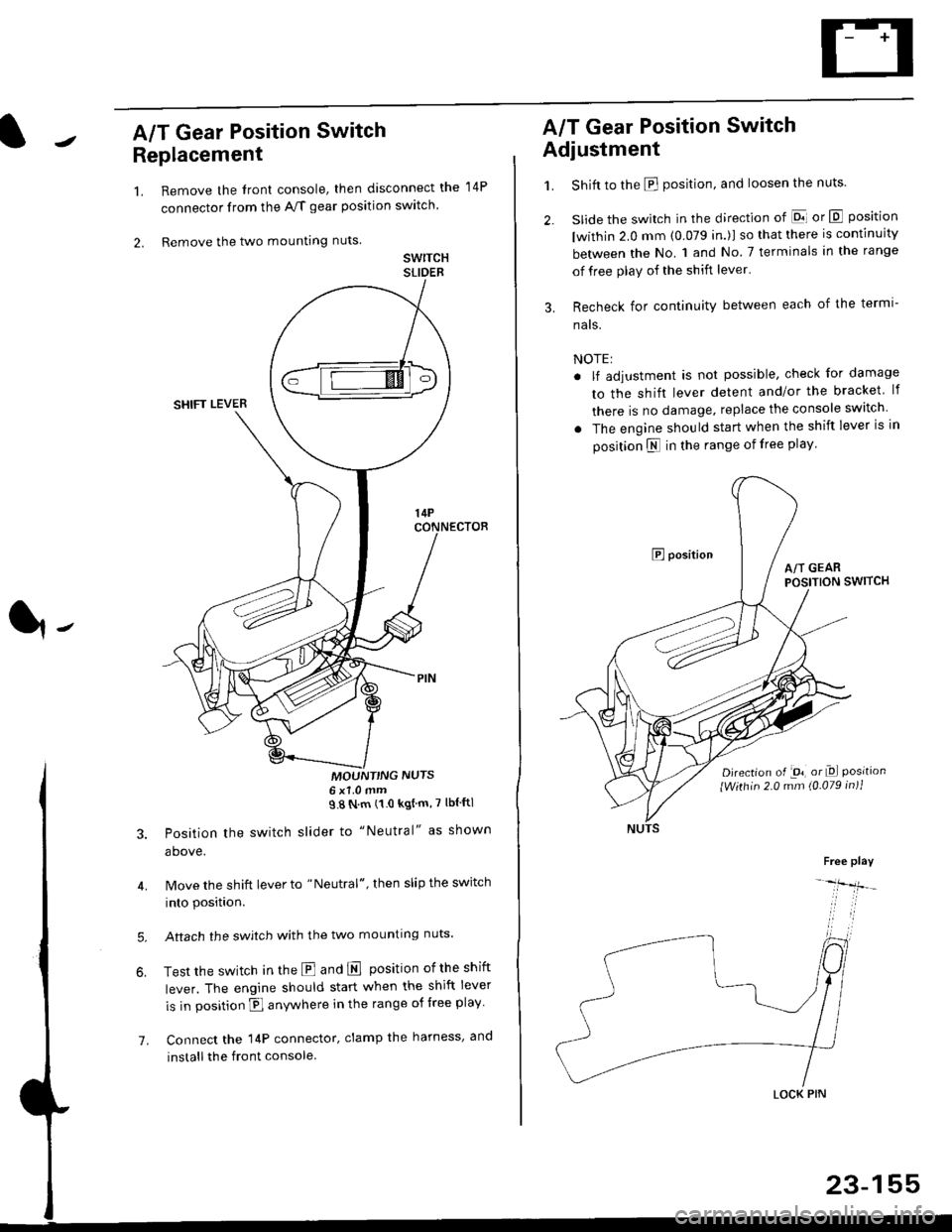

A/T Gear Position Switch

Replacement

1.

2.

7.

Remove the front console, then disconnect the

connector from the A/f gear position swltch

Remove the two mounting nuts

swrTcHSLIDEB

MOUNT'NG NUTS6x1 0mm98Nm(10kgtm'7lblftl

Position the switch slider to "Neutral" as shown

above.

Move the shift lever to "Neutral", then slip the switch

into position.

Aftach the swjtch with the two mounting nuts.

Test the switch in the E and E position ofthe shift

lever. The engine should start when the shift lever

is in position fl anywhere in the range of free play

Connect the 14P connector, clamp the harness, and

install the front console

14P

A/T Gear Position Switch

Adjustment

1.

3.

Shift to the E position, and loosen the nuts.

slide the switch in the direction of El or E position

lwithin 2.0 mm (0.079 in.)l so that there is continuity

between the No. 1 and No 7 terminals in the range

of free play of the shift lever'

Recheck for continuity between each of the termi-

nats.

NOTE:

. lf adjustment is not possible, check for damage

to the shift lever detent and/or the bracket lf

there is no damage. replace the console switch

. The engine should start when the shift lever is in

position N in the range of free play

E positionA/T GEARPOSITION SWITCH

Djrection of -on, or Dl Positionlwithin 2.0 mm (0.079 in)1

Free play

-lfr-

LOCK PIN

23-155

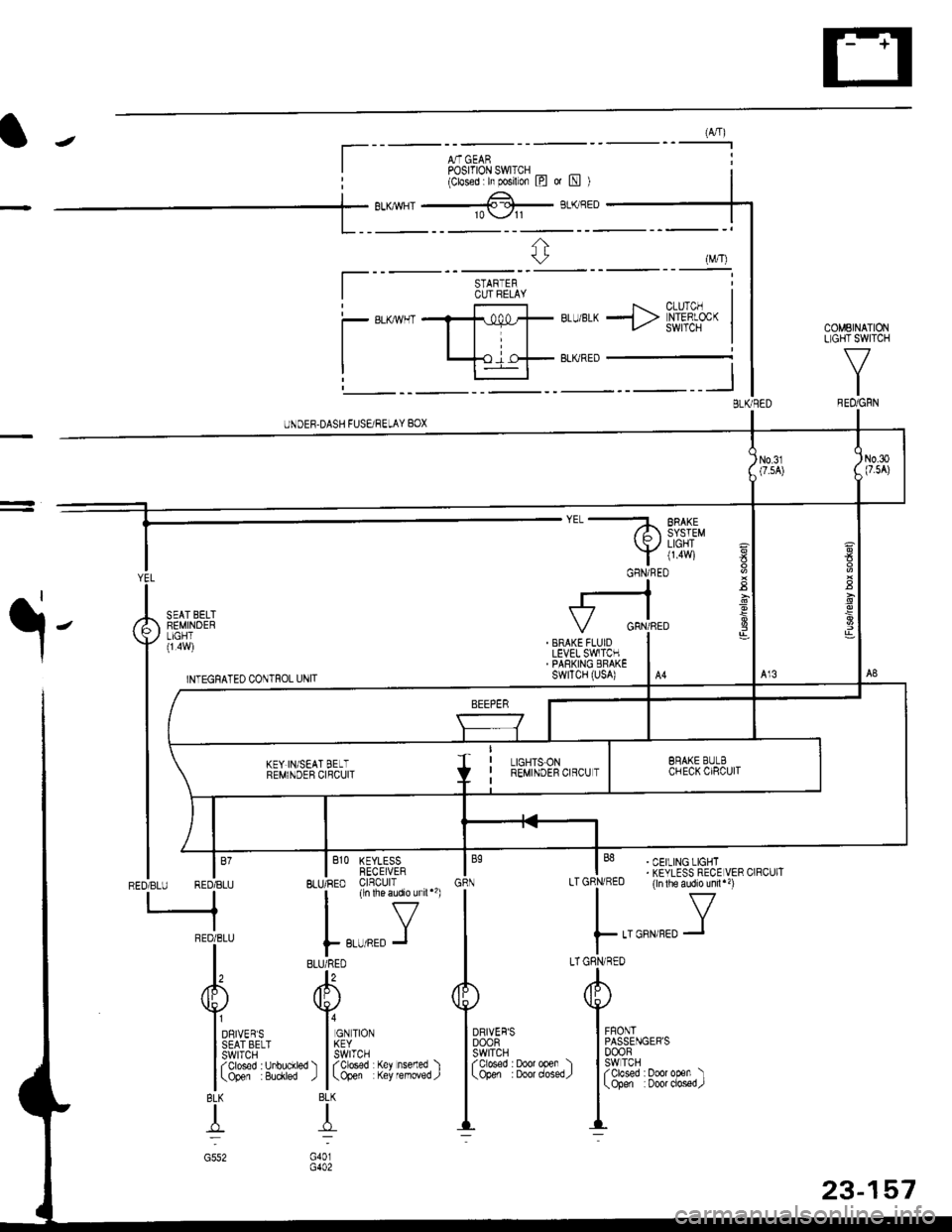

Page 1627 of 2189

(A,4)

A,T GEARPosrfloN swlrcH _ _(Closed h posilon l?l ot [!l )

BLU/BLK -> [h'#f- |COMEINATIONLIGHT SWITCH

V

IREO/GRN

UNDEF.DASH FUSEi RELAY BOX

a

E

YEL

I

A iEi,I,B"'T

vll".i,l

| ,rr.nrorro .orrro, ,*,,

tt-

t(

rffi

|

BEMI\DEB crqcurl

lm

| /t I

tffinEoTsru REDTBLU BLIJ/RED clnculr

-neoieru | ,,-,r.0 J

l, "ulTo

/fP /Itr\

YVI onrveqs I or rtor

l3fifl&''' l5frl'.'

l (3'&T' 8iytr") l

(3&Y fiti'fJ"fl )

BLK BLK

TT

c552 G401

I

. BRAKE FLUIDLEVEL SWITCH. PARKING ERAKEswrTcH (usA)

' CEILING LIGHT. KEYLESS RECE VER CIRCUIT(ln lhe audio unil")

..aorr,rro Y

A

Iu$ut,""'

I3fif'�3#3trr,)-::

DRIVER'SDOOFswtTcHfolosed : Door open )(Open :Doordosed/

STARTERCUT FELAY

a

-

GFNi RED

23-157

Page 1638 of 2189

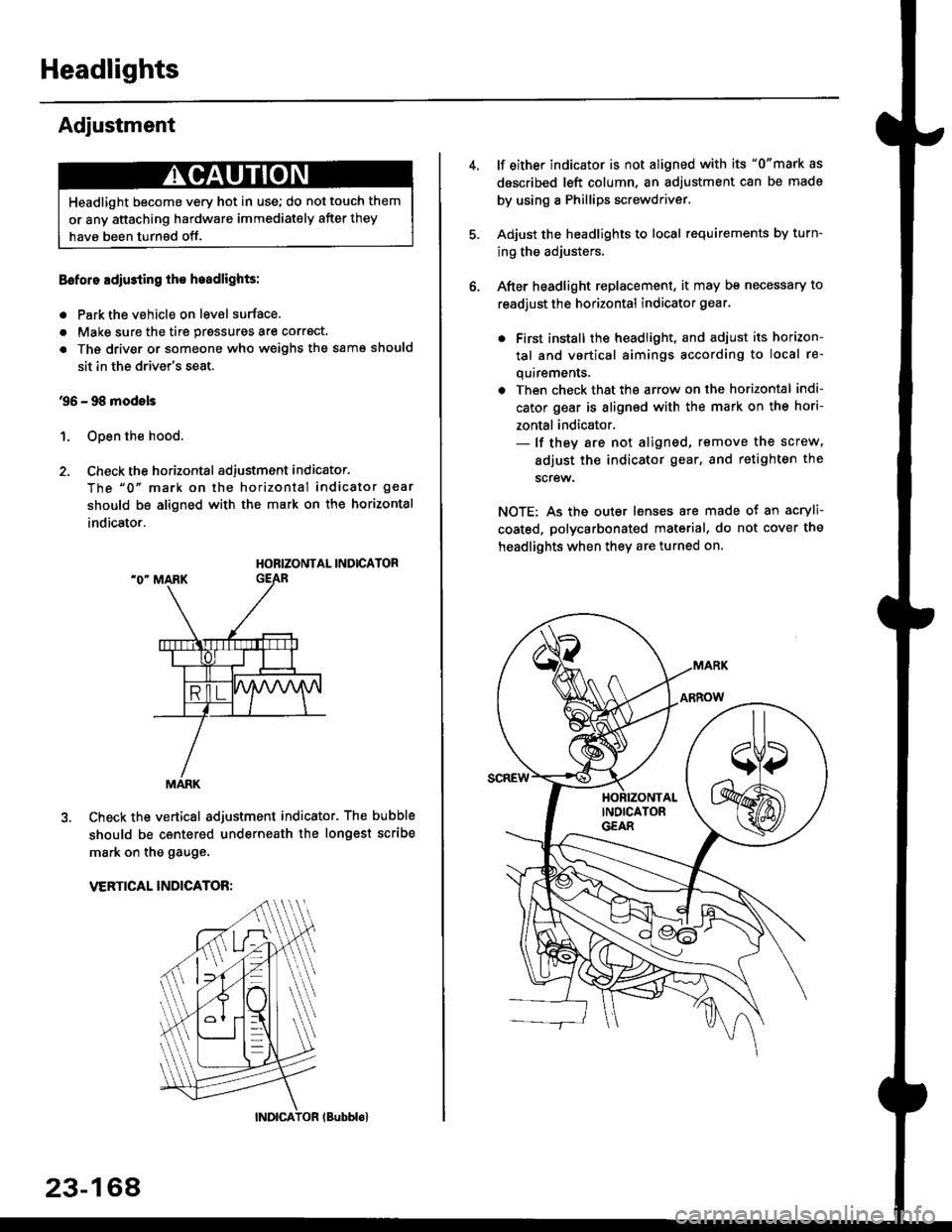

Headlights

Adjustment

Eoforo adiu3ting th€ h.adlights:

. Park the vehicle on level surface.

. Make sure the tire prgssures are correct.

a The driver or someone who weighs the same should

sit in the driver's seat.

96 - 98 modols

1. Open the hood.

2. Check the horizontal adjustment indicator.

The "0" mark on the horizontal indicator gear

should be aligned with the mark on the horizontal

indicator.

HORIZONTAL INDICATOR

Check the vertical adjustment indicator. The bubble

should be centered underneath the longest scribe

mark on the gauge.

VERTICAL INDICATOR:

Headlight become very hot in use; do not touch them

or any attaching hardware immediately after they

have been turnsd off.

MARK

23-164

(Bubblol

lf either indicator is not aligned with its "0"mark as

described left column, an adjustment can be made

by using a Phillips screwdriver.

Adjust the headlights to local requirements by turn-

ing the adjusters.

After headlight replacement, it may bs necessary to

readjust the horizontal indicator gear.

. First install the headlioht, and adjust its horizon-

tal and vertical aimings according to local re-

quirements.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator.- lf they are not aligned, remove the screw,

adiust the indicator gear, and retighten the

screw.

NOTE: As the outer lenses are made ot an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.

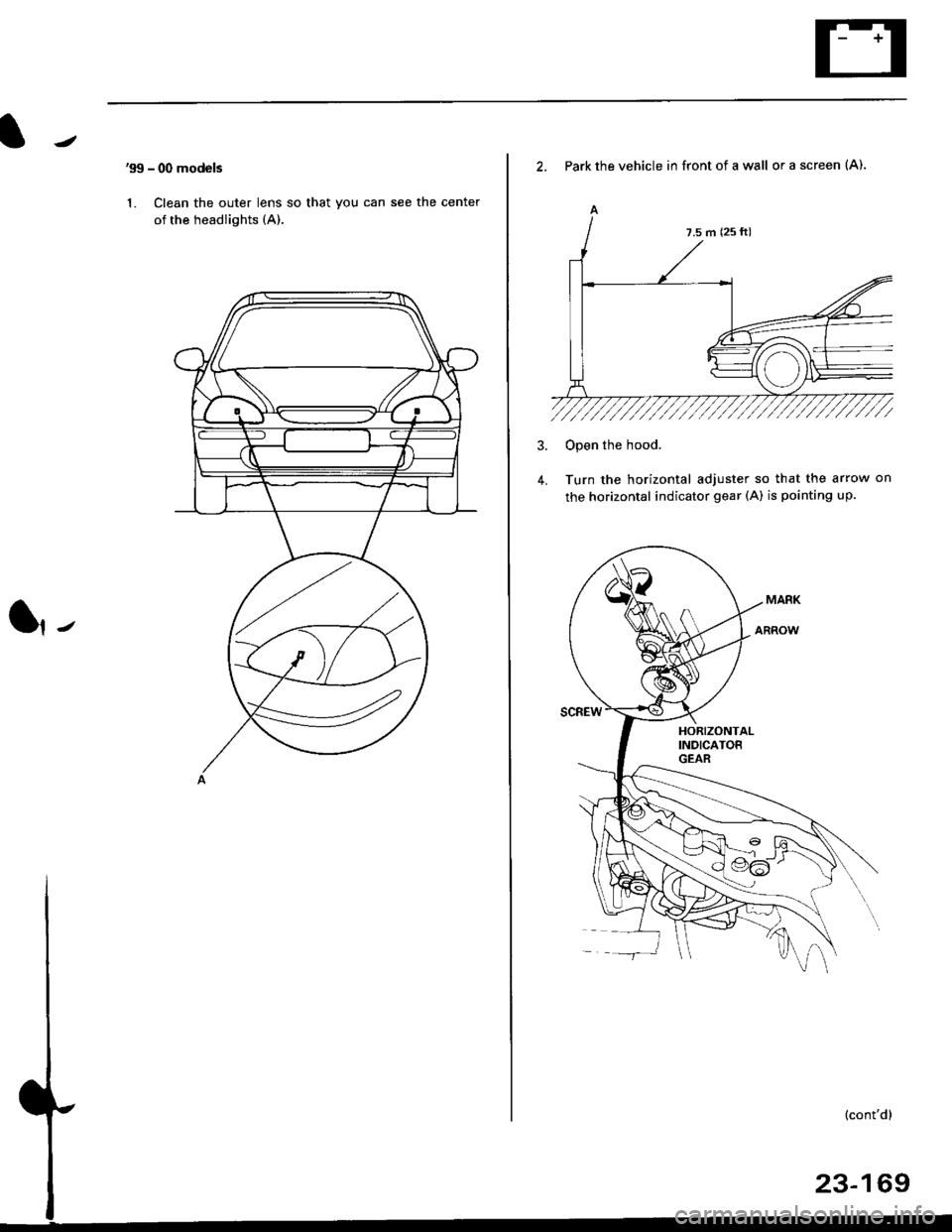

Page 1639 of 2189

'99 - 00 models

1. Clean the outer lens so that you can see the center

of the headlights (A).

l,-

2. Park the vehicle in front of a wall or a screen (A).

A

4.

Open the hood.

Turn the horizontal adjuster so that the arrow on

the horizontal indicator gear (A) is pointing up.

7.5 m (25 ft)

Page 1640 of 2189

Headlights

Adjustment (cont'dl

Turn the low beams on.

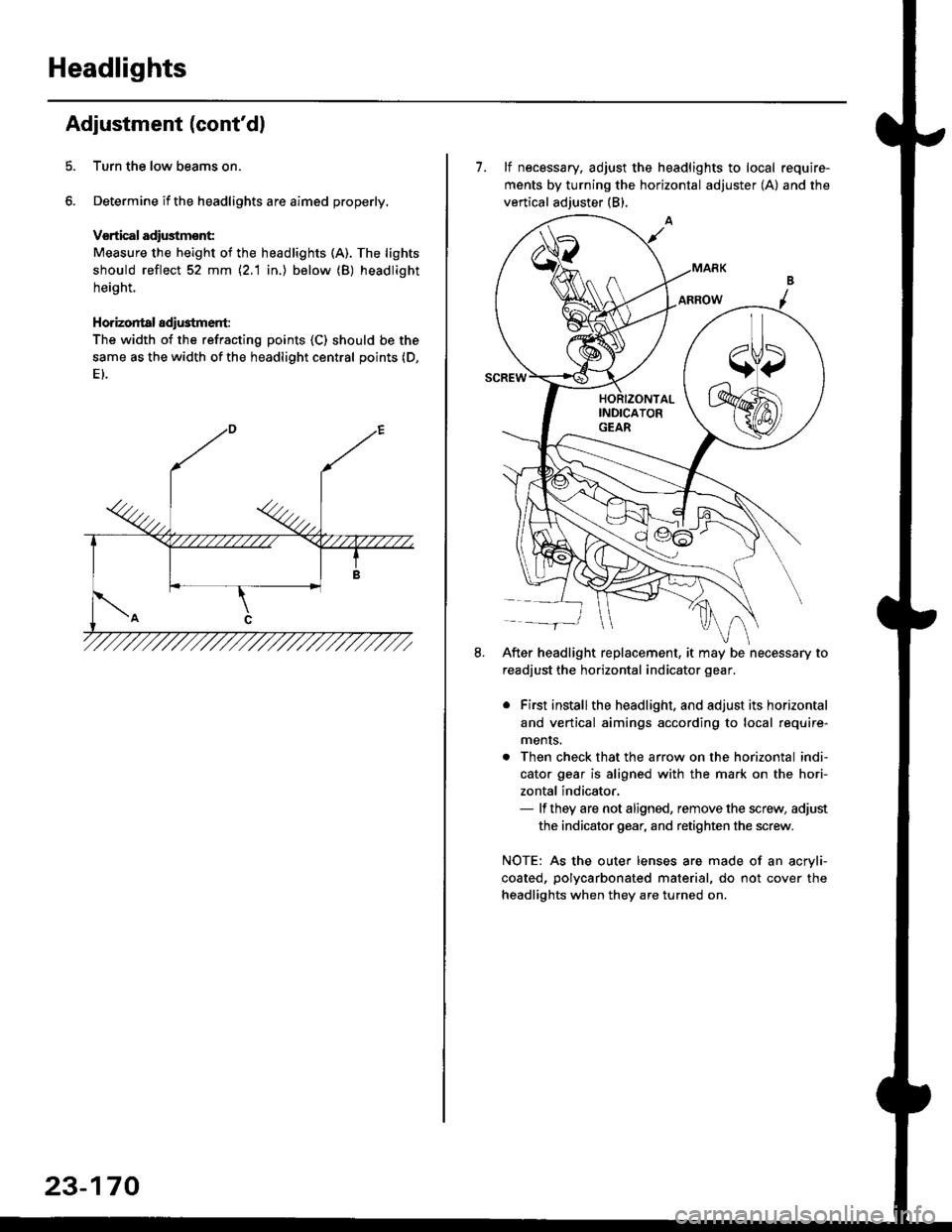

Determine if the headlights are aimed properly.

Vsrtical adiustmsnt:

Measure the height of the headlights (A). The lights

should reflect 52 mm \2.1 in.) below (B) headlight

height.

Horizontal adi$tment:

The width of the refracting points (C) should be the

same as the width of the headlight central points (D,

23-170

7. lf necessary, adjust the headlights to local require-

ments by turning the horizontal adjuster (A) and the

vertical adjuster (B).

After headlight replacement, it may be necessary to

readjust the horizontal indicator gear.

. First installthe headlight, and adjust its horizontal

and vertical aimings according to local require-

ments.

. Then check that the arrow on the horizontal indi-

cator gear is aligned with the mark on the hori-

zontal indicator,- lf they are not aligned, remove the screw, adjust

the indicator gear, and retighten the screw.

NOTE: As the outer lenses are made of an acryli-

coated, polycarbonated material, do not cover the

headlights when they are turned on.