for HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 690 of 2189

Description

Power Flow (cont'd)

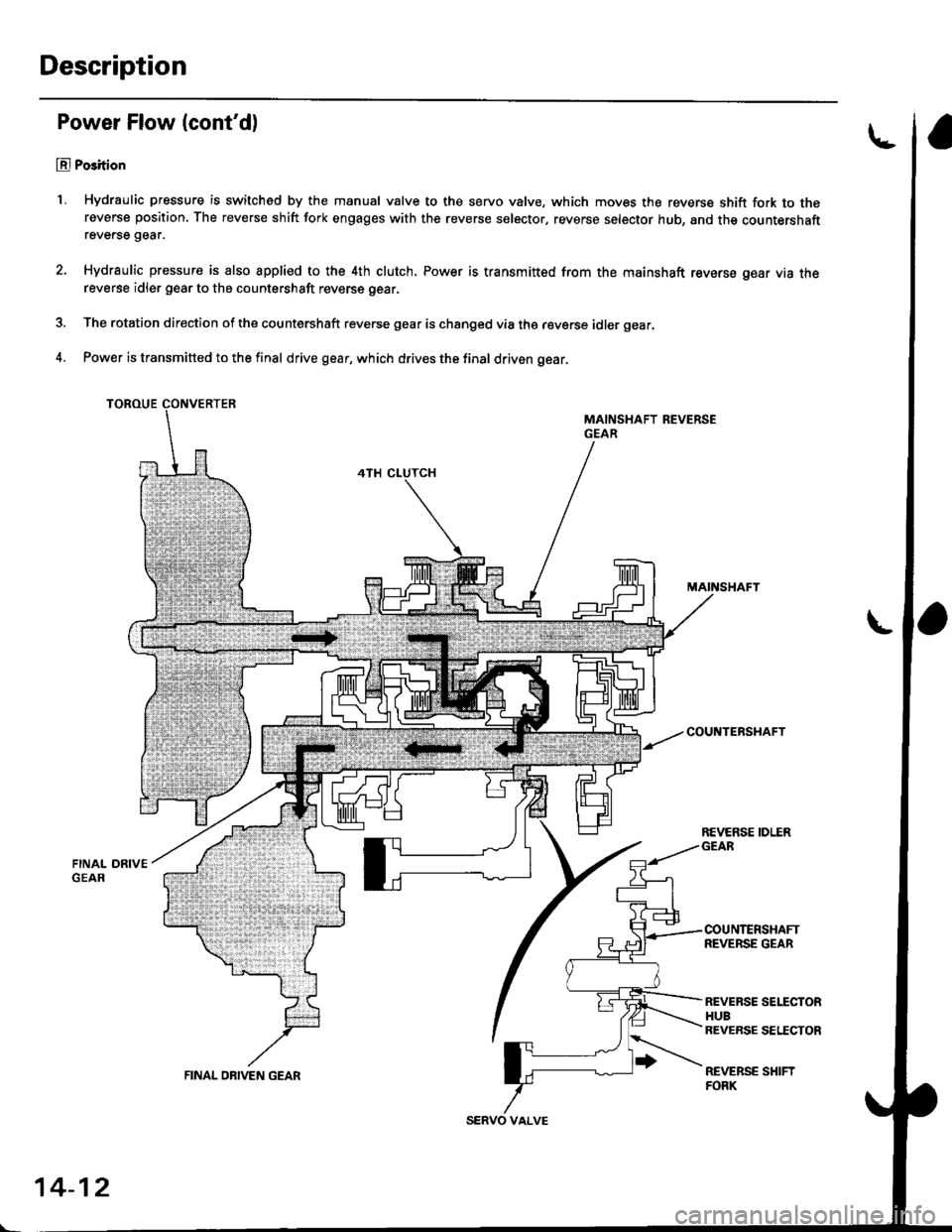

El Po3ition

1, Hydraulic pressure is switched by the manual valve to the servo valve, which moves the reverse shift fork to thereverse position. The reverse shift fork engages with the reverse selector, reverse selector hub, and the countershaftreverse gear.

Hydraulic pressure is also applied to the 4th clutch. Power is transmitt€d from the mainshaft reverse gear via thereverse idler gear to the countershaft reverse gear.

The rotation direction of the countershaft reverse gear is changed via the reverse idler gear,

Power is transmitted to the final drive gear, which drives the final driven gear.

TOROUE

MAINSHAFT

COU TERSHAFT

REVERSE SELECTORHUBREVERSE SETICTOR

REVERSE SHIFTFORK

REVERSE IDLER

14-12

FINAL ON|VEN GEAR

Page 691 of 2189

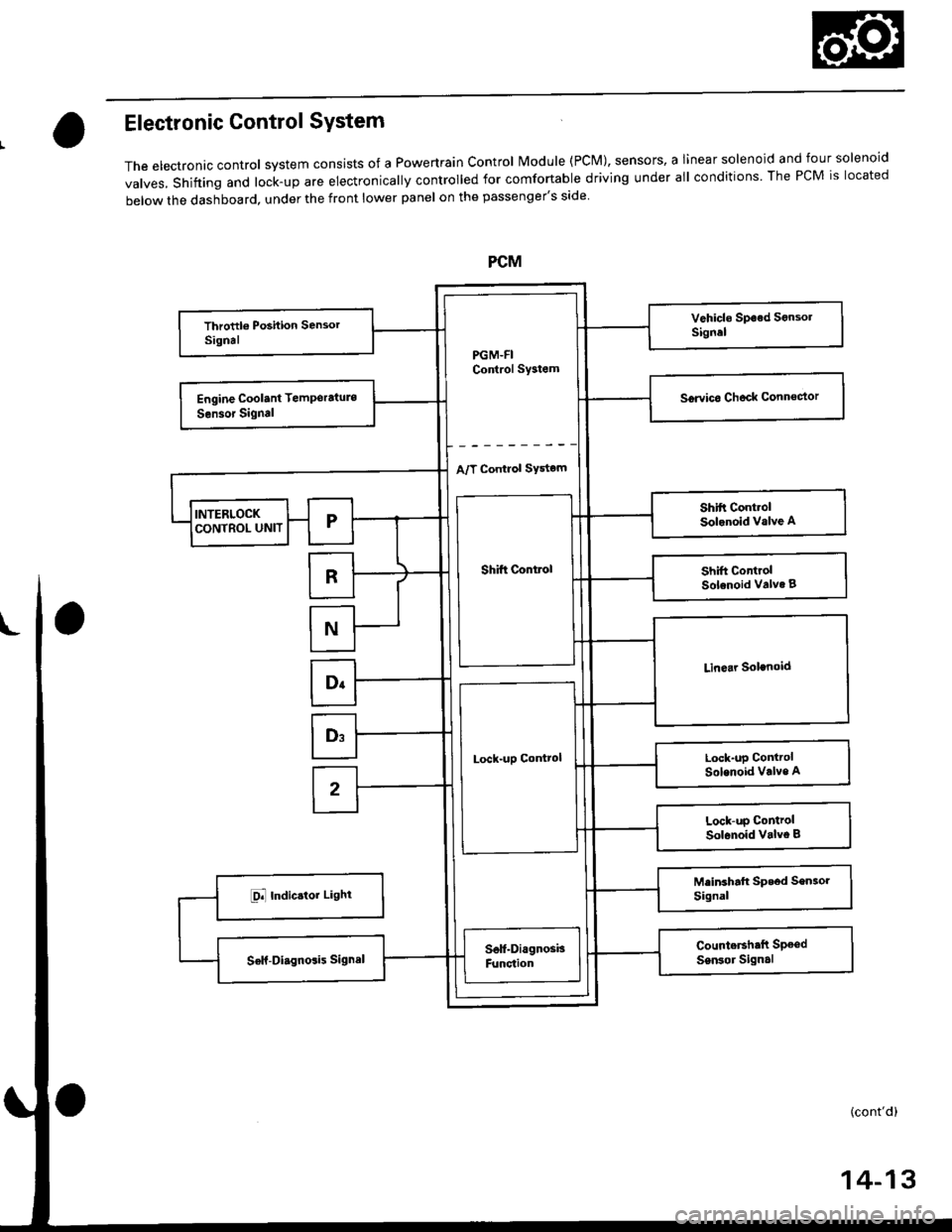

Electronic Control SYstem

The electronac controt system consrsts of a Powertrain control Module (PcM), sensors, a Iinear solenoid and four solenoid

valves, shifting and lock-up are electronically controlled for comfortable driving under all conditions The PCM is located

below the dashboard, under the front lower panel on the passenger's side

PGM-FIControl Sy3tem

A/T Control SYstom

Shift Control

Lock-uD Control

14-13

Page 692 of 2189

Description

Electronic Control System (cont'd)

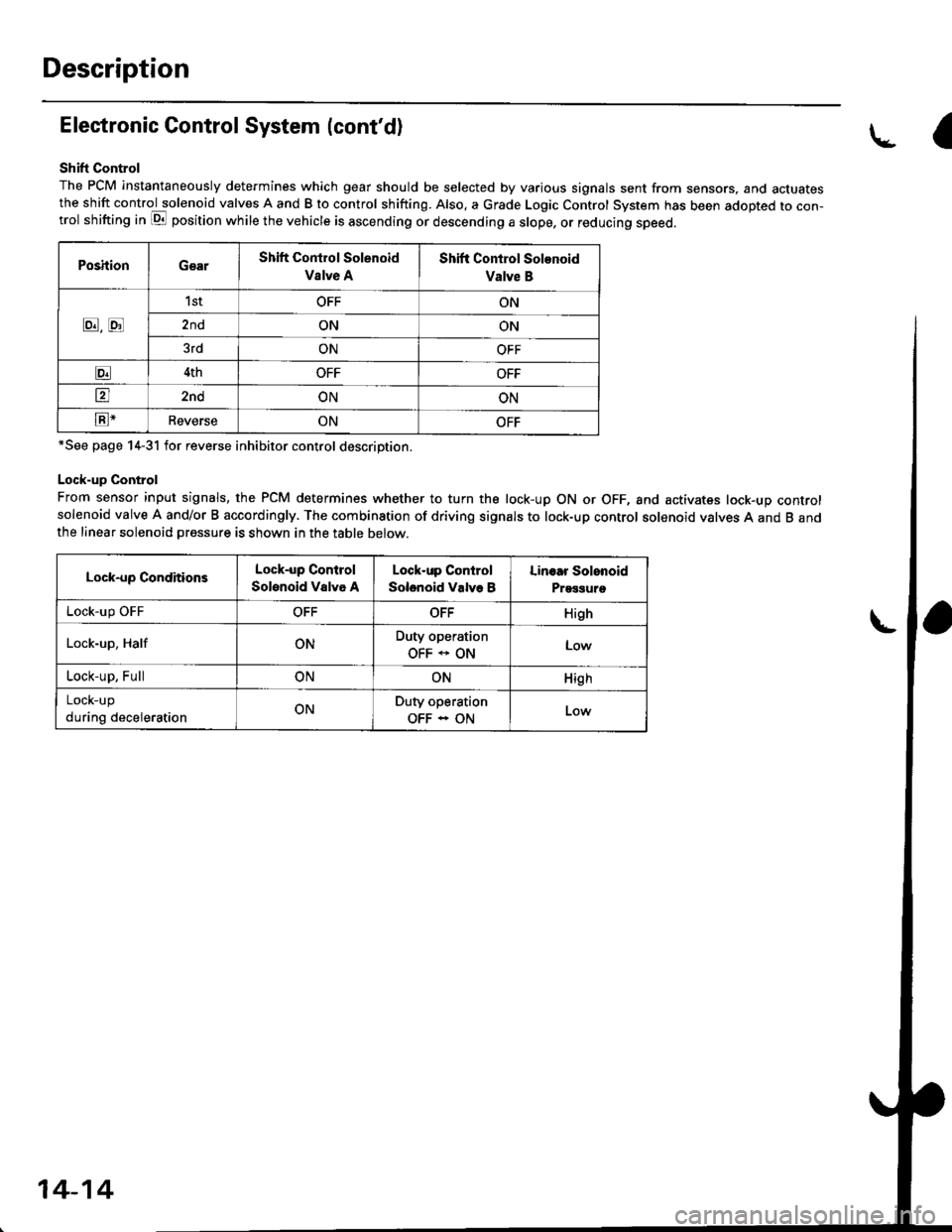

Shift Control

The PCM instantaneously determines which gear should be selected by various signals sent from sensors, and actuatesthe shift control solenoid valves A and B to control shifting. Also. a Grade Logic Control System has been adopted to con-trol shifting in E position while the vehicle is ascending or descending a slope, or reducing speed.

PoshionGearShift Control Solenoid

Vslve A

Shift Control Solenoid

Valve B

8,tr

1stOFFON

2ndONON

3rdONOFF

E4thOFFOFF

tr2ndONON

E-ReverseONOFF

*See page 14-31 for reverse inhibitor control description.

Lock-up Control

From sensor input signals, the PCM determines whether to turn the lock-up ON or OFF, and activates lock-up controlsolenoid valve A and/or B accordingly. The combination of driving signals to lock-up control solenoid valves A and B andthe linear solenoid pressure is shown in the table below.

Lock-up ConditionsLock-up Control

Solenoid Valvo A

Lock-up Control

Solenoid Valve B

Linoar Solonoid

Prggguro

Lock-up OFFOFFOFFHigh

Lock-up, HalfONDuty operation

OFF * ONLow

Lock-up, FullONONHigh

LOCK-Up

during decelerationONDuty operation

OFF - ON

a

14-14

Page 694 of 2189

Description

Electronic Control System {cont'dl

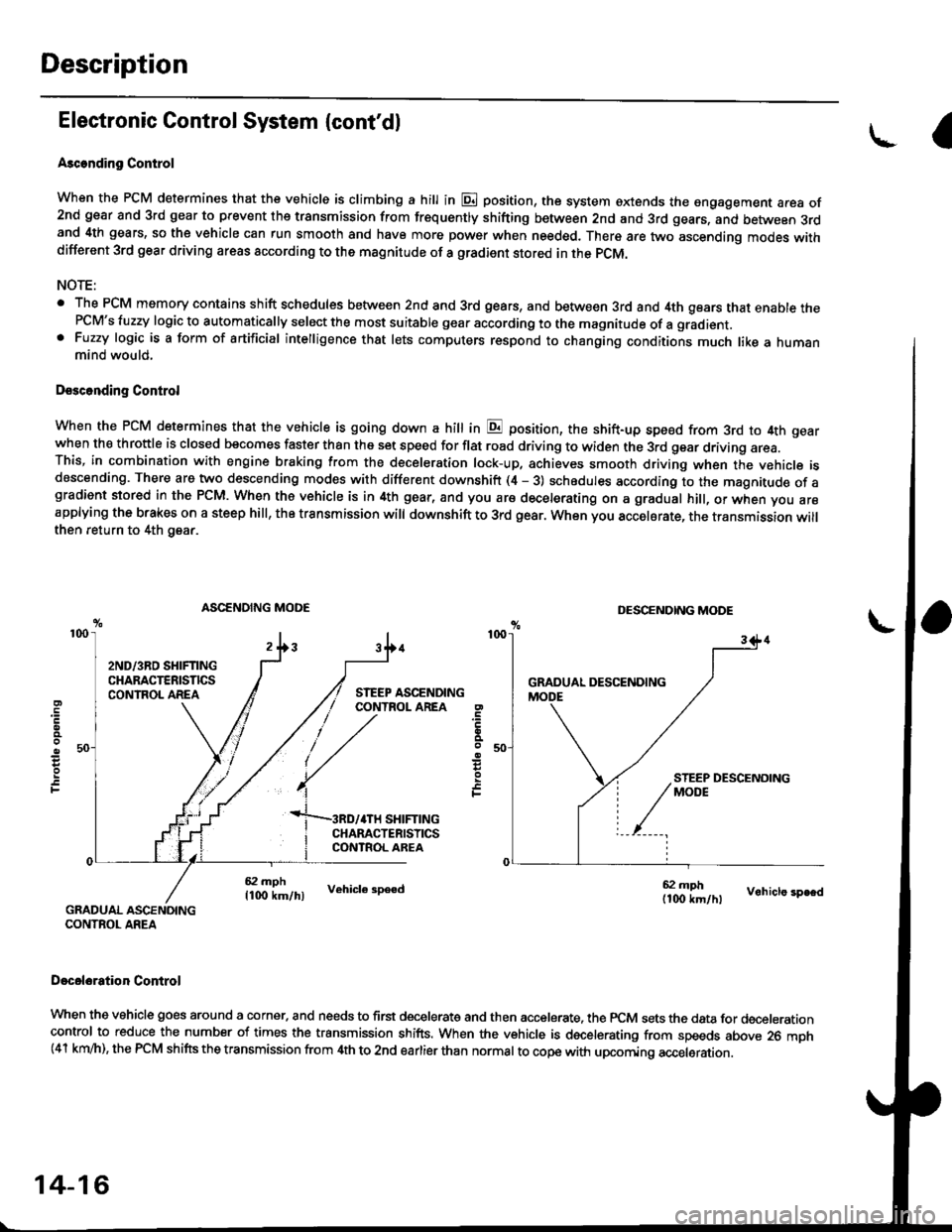

Ascending Control

When the PCM determines that the vehicle is climbing a hill in E position, the system oxtends the sngagement area of2nd gear and 3rd gear to prevent ths transmission from fr€quently shifting between 2nd and 3rd gears, and between 3rdand 4th gears, so the vehicle can run smooth and have more power when needed. There are two ascending modes withdifferent 3rd gear driving areas according to the magnitude of a gradient stored in the pCM.

NOTE:

. The PCM memory contains shift schedules between 2nd and 3rd gears, and between 3rd and 4th gears that enable thePCM's fuzzy logic to automatically select the most suitable gear according to the magnitude of a gradient. Fuzzy logic is a form of artificial intelligence that lets computers respond to changing conditions much like a humanmind would,

Dssconding Control

When the PCM determines that the vehicle is going down a hilt in E position, the shift-up speed from 3rd to 4th gearwhen th€ throftle is closed becomes faster than the set speed for flat road driving to widen the 3rd gear driving area.This, in combination with engine braking from the deceleration lock-up, achieves smooth driving when the vehicle isdescending. There are two descending modes with different downshift (4 - 3) schedules according to the magnitude of agradient stored in the PCM. When the vehicle is in 4th gear, and you are decelerating on a gradual hill, or when you areapplying the brakes on a steep hill, the transmission will downshift to 3rd gear. When you accel6rate, the transmission willthen return to 4th gear.

ASCENDING MODEDESCENDING MODE

4TH SHIFTING

L.

F

CHARACTERISIICSCONTROL AREA

ff.1"11", vehicr. 3pe€dff;Tlr., vohicre speed

GRADUAL ASCENOINGCONTROL AREA

Docel6ration Control

When the vehicle goes around a corner. and needs to first decelerate and then accelerate. the rcM sets the data for decelerationcontrol to reduce the number of times the transmission shifts. When the vehicle is decelerating from speeds above 26 mph(41 km/h), the rcM shifts the transmission from 4th to 2nd earlier than normal to cope with upcoming acceleration.

14-16

Page 700 of 2189

Description

Hydraulic Control (cont'dl

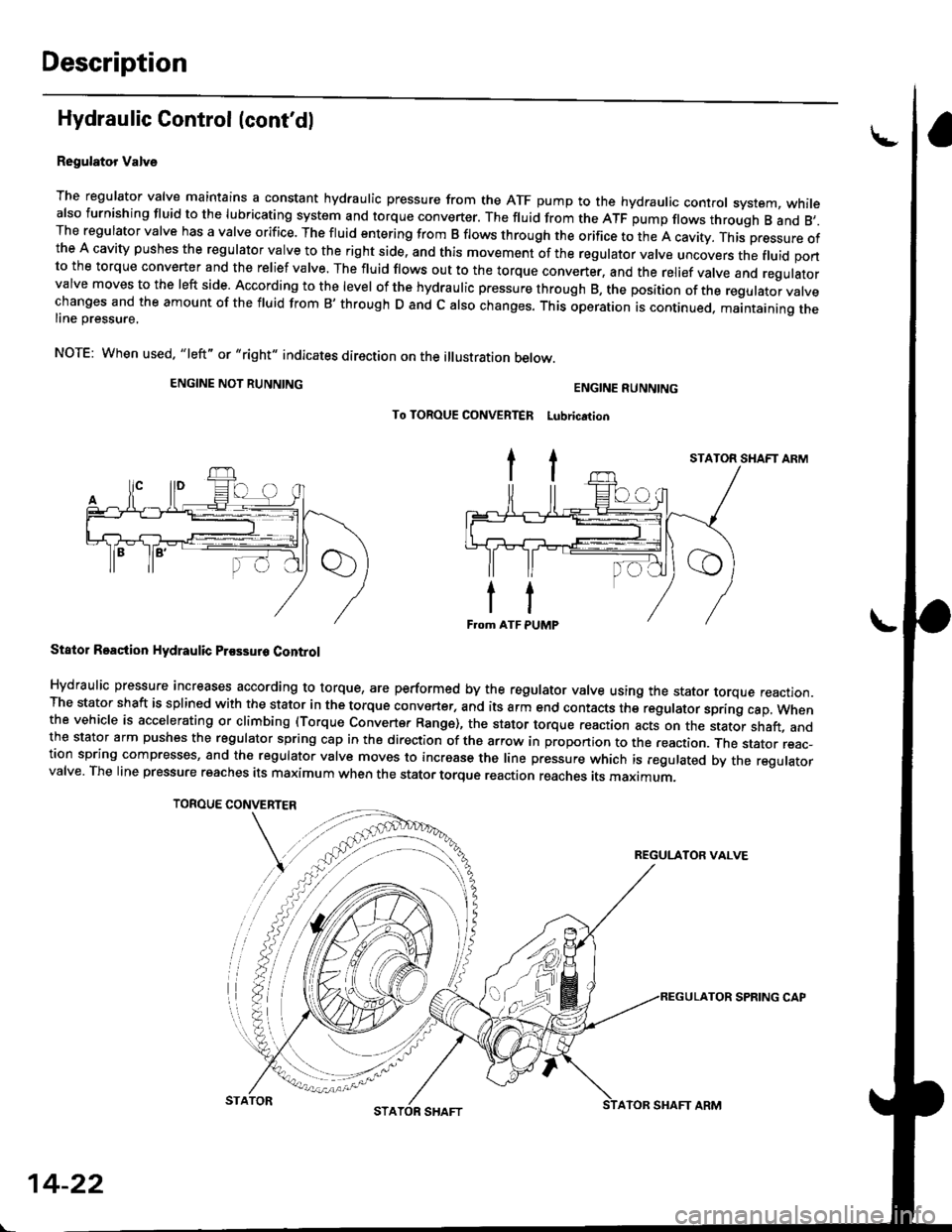

Regulator Valve

The regulator valve maintains a constant hydraulic pressure from the ATF pump to the hydraulic control system, whitealso furnishing fluid to the lubricating system and torque converter. The fluid from the ATF pump flows through B and 8,.The regulator valve has a valve orifice. The fluid entering from B flows through the orifice to the A cavity. This pressure ofthe A cavity pushes the regulator valve to the right side, and this movement of the regulator valve uncovers the fluid portto the torque converter and the relief valve. The fluid flows out to the torque converter, and the relief valve and regulatorvalve moves to the left side. According to the level of the hydraulic pressure through B, the position of the regutator vatvechanges and the amount of the fluid from B' through D and c also changes. This operation is continued. maantaining theline pressure,

NOTE: When used. "|eft" or "right" indicates direction on the illustration betow.

ENGINE NOT RUNNING

TOROUE CONVERTER

ENGINE RUNNING

To TOROUE CONVERTER Lubrication

Stator Roaction Hydraulic Prossur6 Control

Hydraulic pressure increases according to torque, are performed by the regulator valve using the stator torque reaction.The stator shaft is splined with the stator in the torque converter, and its arm end contacts the regulator sprang cap. whenthe vehicle is accelerating or climbing (Torque Convert€r Range), the stator torque reaction acts on the stator shaft, andthe stator arm pushes the regulator spring cap in the direction of the arrow in proponion to the reaction. Jne stator reac-tion spring compresses, and th€ reoulator valve moves to increase the line pressure which is regulated by the regulatorvalve. The line pressure reaches its maximum when the stator torque reaction reaches its maximum.

STATOR SHAFT ARM

REGULATOR VALVE

14-22

STATORATOR SHAFT ARM

SPRING CAP

Page 701 of 2189

\

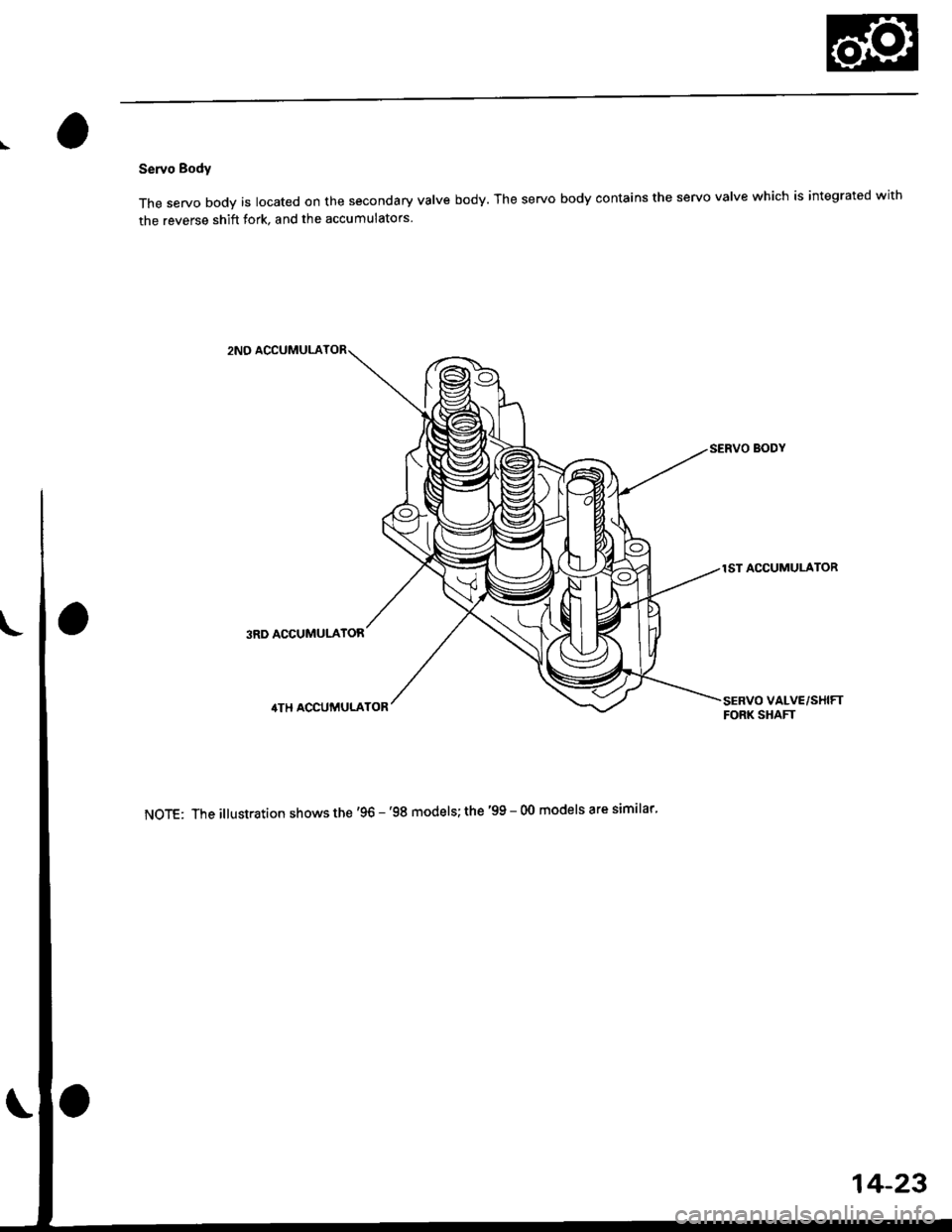

Servo Body

The servo body is located on the secondary valve body. The servo body contains the servo valve which is integrated with

the reverse shift fork, and the accumulators

2NO ACCUMULA

SERVO BODY

1ST ACCUMULATOR

3RD ACCUMULATOR

SERVO VALVE/SHIFTFORK SHAFT

NoTE: The illustration shows the'96 - '98 models; the '99 - 00 models are similar'

14-23

Page 709 of 2189

L

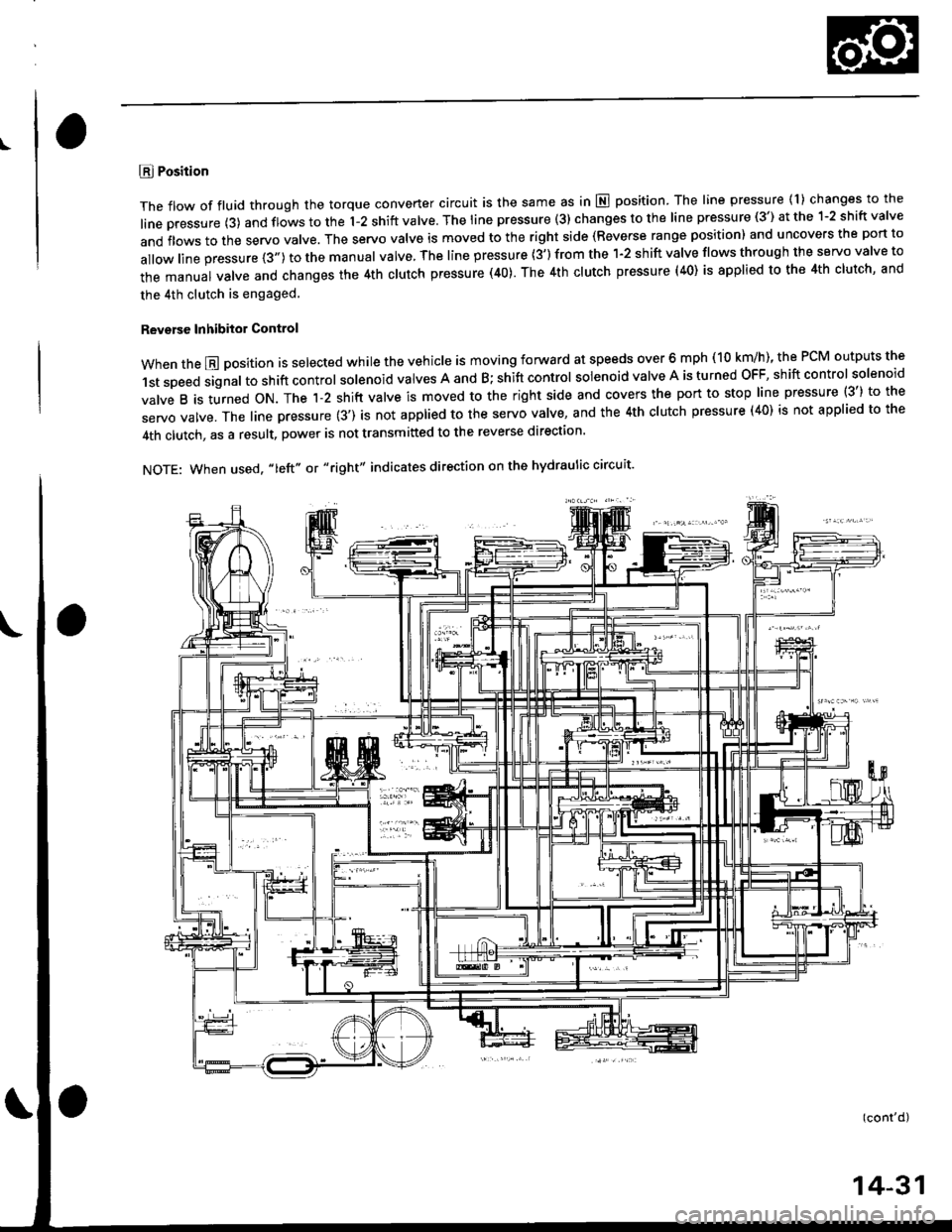

E Position

The flow of fluid through the torque convefter circuit is the same as in E position The line pressure (1) changes to the

line pressure (3) and flows to the l-2 shift valve. The iine pressure (3) changes to the line pressure (3') at the 'l-2 shift valve

and flows to the servo valve. The servo valve is moved to the right side (Reverse range position) and uncovers the port to

allow line pressure {3") to the manual valve, The line pressure {3') from the 1-2 shift valve flows through the servo valve to

the manual valve and changes the 4th clutch pressure (40). The 4th clutch pressure (40) is applied to the 4th clutch, and

the 4th clutch is engaged,

Reverse Inhibitor Control

When the E position is selected while the vehicle is moving forward at spe€ds over 6 mph (10 km/h)' the PCM outputs the

1st speed signal to shift control solenoid valves A and B; shift control solenoid valve A is turned oFF, shift control solenoid

valve B is turned ON. The 1-2 shift valve is moved to the right side and covers the port to stop line pressure (3') to the

servo valve. The line pressure (3'�) is not applied to the servo valve, and the 4th clutch pressure (40) is not applied to the

4th clutch, as a result, power is not transmitted to the reverse direction'

When used. 'left" or "right" indicates direction on the hydraulic circuit'

14-31

Page 714 of 2189

Description

Lock-up System (cont'dl

TOROUE CONVERTER

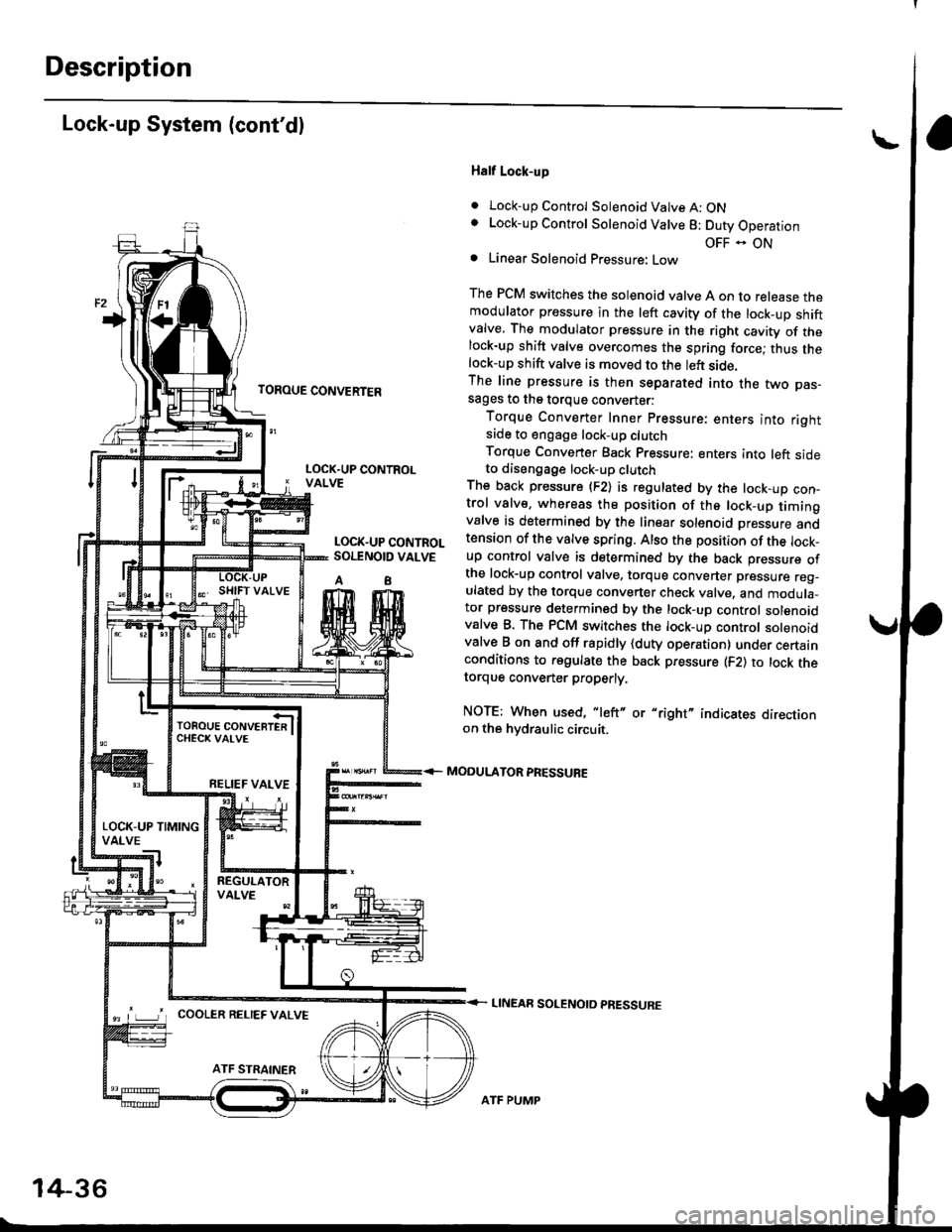

Half Lock-up

. Lock-up Control Solenoid Valve A: ONLock-up Control Solenoid Valve 8: Duty Operation

OFF - ONLinear Solenoid Pressure: Low

The PCM switches the solenoid valve A on to release themodulator pressure in the left cavity of the lock_up shiftvalve. The modulator pressure in the right cavity of thelock-up shift valve overcomes the spring force; thus thelock-up shift valve is moved to the left side.The line pressure is then separated into the two pas-sages to the torque converter:

Torque Converter Inner pressure: enters into rightsade to engage lock-up clutch

Torque Converter Back pressure: enters into left sideto diseogage lock-up clutchThe back pressure (F2) is regulated by the lock-up con-trol valve, whereas the position of the lock-up timingvalve is determined by the linear solenoid Dressure andtension of the valve spring. Also the position of the lock_up control valve is determined by the back pressure ofthe lock-up control valve, torque converter pressure reg_ulated by the torque converter check valve, and modula_tor pressure determined by the lock-up control solenoidvalve B. The PCM switches the lock-up control solenoidvalve B on and off rapidly {duty operation} under certainconditions to regulate the back pressure (F2) to lock thetorque convener properly.

NOTE: When used, "left" or "right" indicates directionon the hvdraulic circuit.

MODULATOR PRESSURE

LINEAR SOLENOTD PRESSURE

LOCK.UP CONTROLVALVE

LOCK.UP CONTROLSOI.TNOID VALVE

A8

TOROUE CONVERTERCHECK VAI-VE

RELIEF VALVE

LOCK-UP TIMINGVALVE

^ L____J'r cooLER RELTEF valvE

14-36

ATF PUMP

Page 715 of 2189

TOROUE CONVERTER

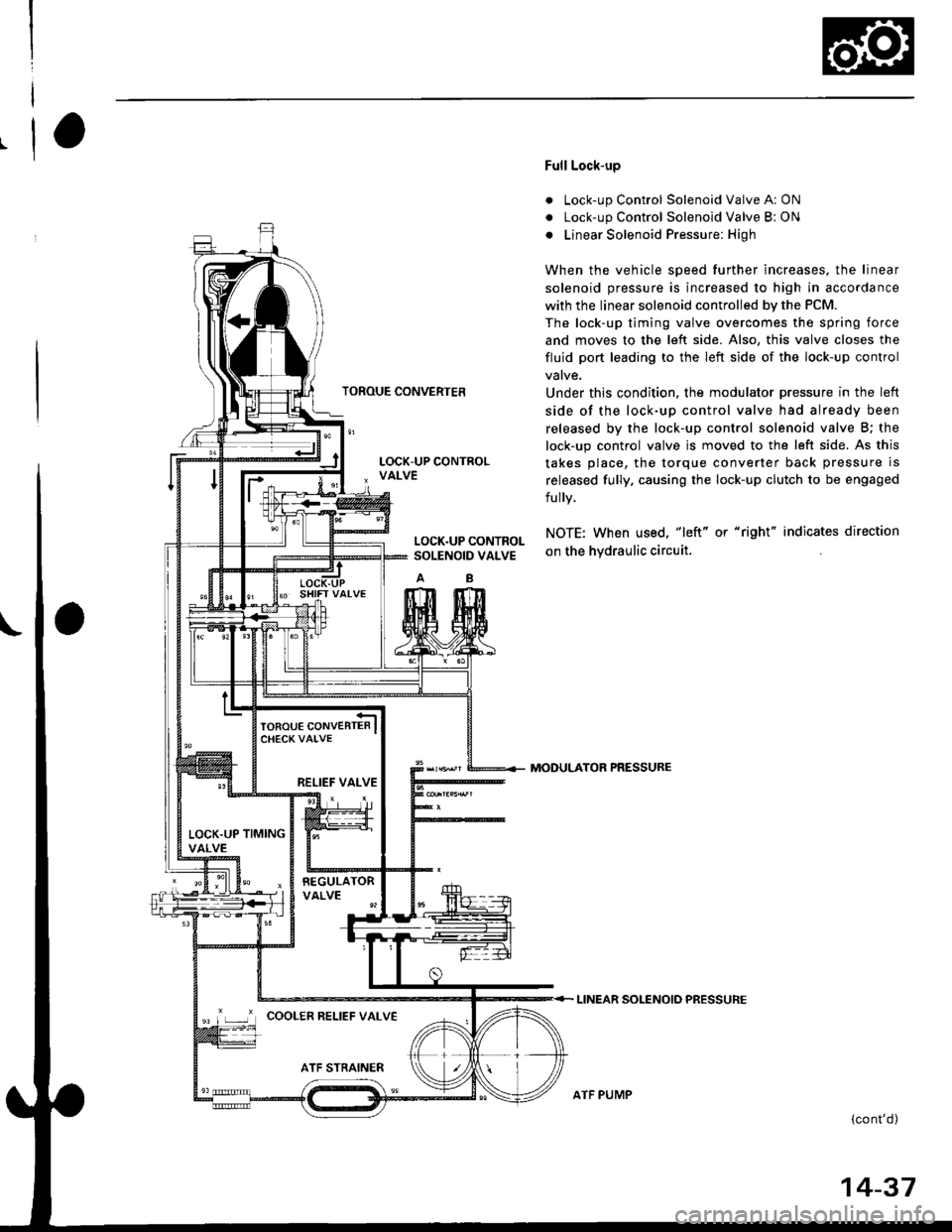

Full Lock-up

. Lock-up Control Solenoid Valve A: ON

. Lock-up Control Solenoid Valve B: ON

o Linear Solenoid Pressure: High

When the vehicle speed further increases. the linear

solenoid pressure is increased to high in accordance

with the linear solenoid controlled bv the PCM.

The lock-up timing valve overcomes the spring force

and moves to the left side. Also, this valve closes the

fluid port leading to the left side of the lock-up control

Under this condition. the modulator pressure in the left

side of the lock-up control valve had already been

released by the lock-up control solenoid valve B; the

lock-up control valve js moved to the left side. As this

takes place, the torque converter back pressure is

released fully. causing the lock-up clutch to be engaged

fully.

NOTE: When used, "|eft" or "right" indicates direction

on the hvdraulic circuit.

MODULATOR PRESSURE

LINEAR SOLENOIO PRESSURE

{cont'd)

LOCK.UP CONTROLSOLENOID VALVE

RELIEF VALVE

LOCK.UP TIMINGVALVE

'r ,-.r' cooLER RELTEF vALvE

ATF PUMP

14-37

Page 720 of 2189

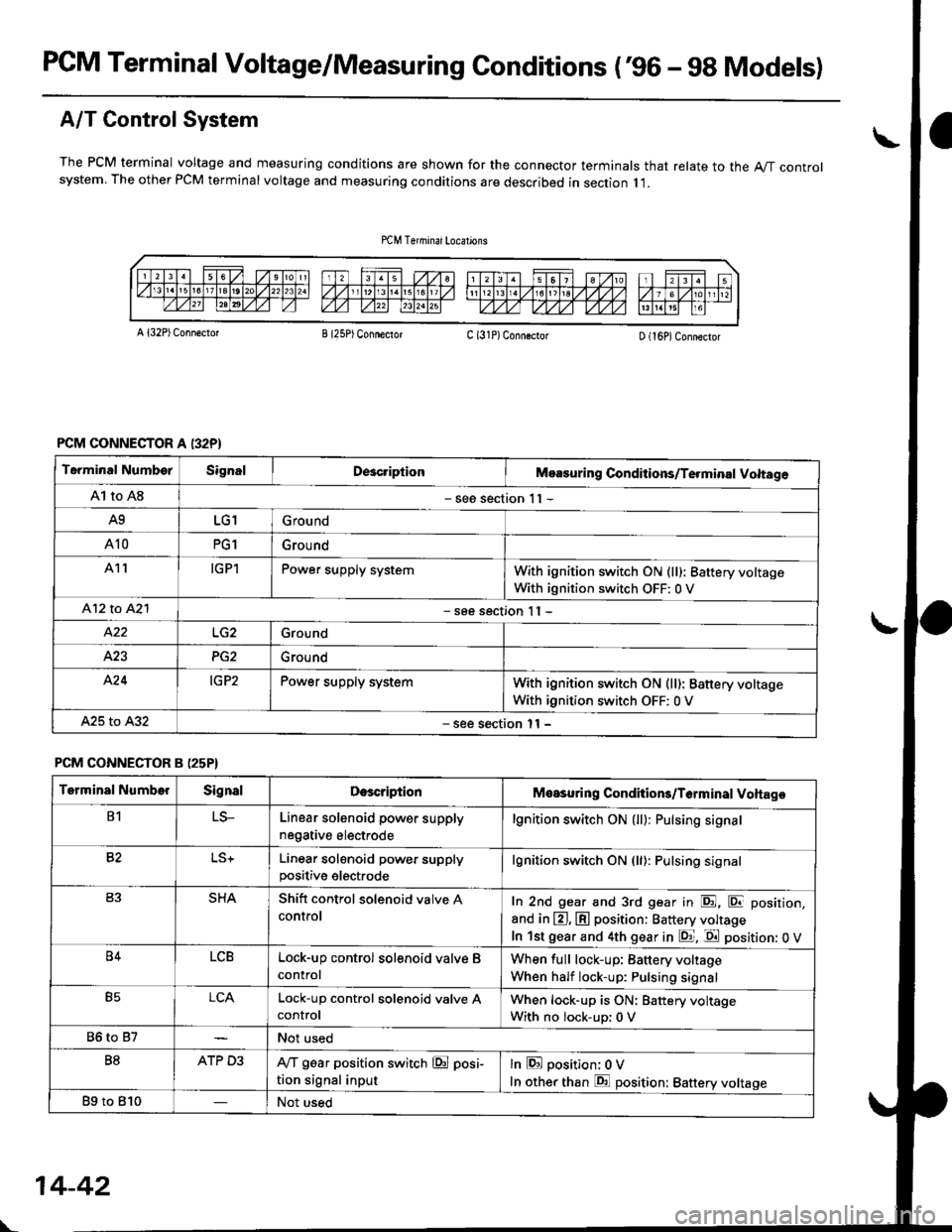

PCM Terminal Voltage/Measuring Gonditions ('96 - 9g Models)

A/T Control System

The PCM terminal voltage and measuring conditions are shown for the connector terminals that relate to the A"/T controlsystem. The other PCM terminal voltage and measuring conditions are described in section I l.

A l32P) Conn€ctotB I25P) ConnectorC (31P)ConngctorD (16P)Connector

PCM CONNECTOR A I32P}

Terminal NumborSignalDcacriptionMoasuring Conditions/Te.minal Voltage

A1 to A8- see section 1 I -

A9LG1Ground

A10PG1Grou nd

A11IGPlPower supply systemWith ignition switch ON (ll): 8attery voltage

With ignition switch OFF: 0 V

412 to A2l- see section I I -

Ground

423PG2Ground

A'24IG P2Power supply systemWith ignition switch ON (ll): Battery voltage

With ignition switch OFF: 0 V

A25 to A32- see section l1 -

PCM CONNECTOR B (25P}

Terminal NumberSignalDescriptionMeasuring Conditions/T6rminal Voltage

B1LS-Linear solenoid power supply

negative electrode

lgnition switch ON (ll): Pulsing signa.

82Linear solenoid power supplypositive electrode

lgnition switch ON (ll): Pulsing signal

SHAShitt control solenoid valve A

controlIn 2nd gear and 3rd gear in E, E position,

and in @, @ position: Battery voltage

In lst gear and 4th gear in E. E position: 0 V

B4LCBLock-up control solenoid valve B

control

When full lock-up: Battery voltage

When half lock-up: Pulsing signal

B5LCALock-up control sol€noid valve AcontrolWhen lock-up is ON: Battery voltage

With no lock-up: 0 V

86 to 87Not used

B8ATP D3IVT g6ar position switch @ posi-

tion signal input

lnEposition; OV

In other than E position: Battery voltage

Bg to 810Not used

\-

14-42