Driveshaft HONDA CIVIC 1997 6.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1053 of 2189

Intermediate Shaft

Removal

Drain the transmission oil or fluid {see section 13 or

r 4).

Remove the left driveshaft (see page 16-3).

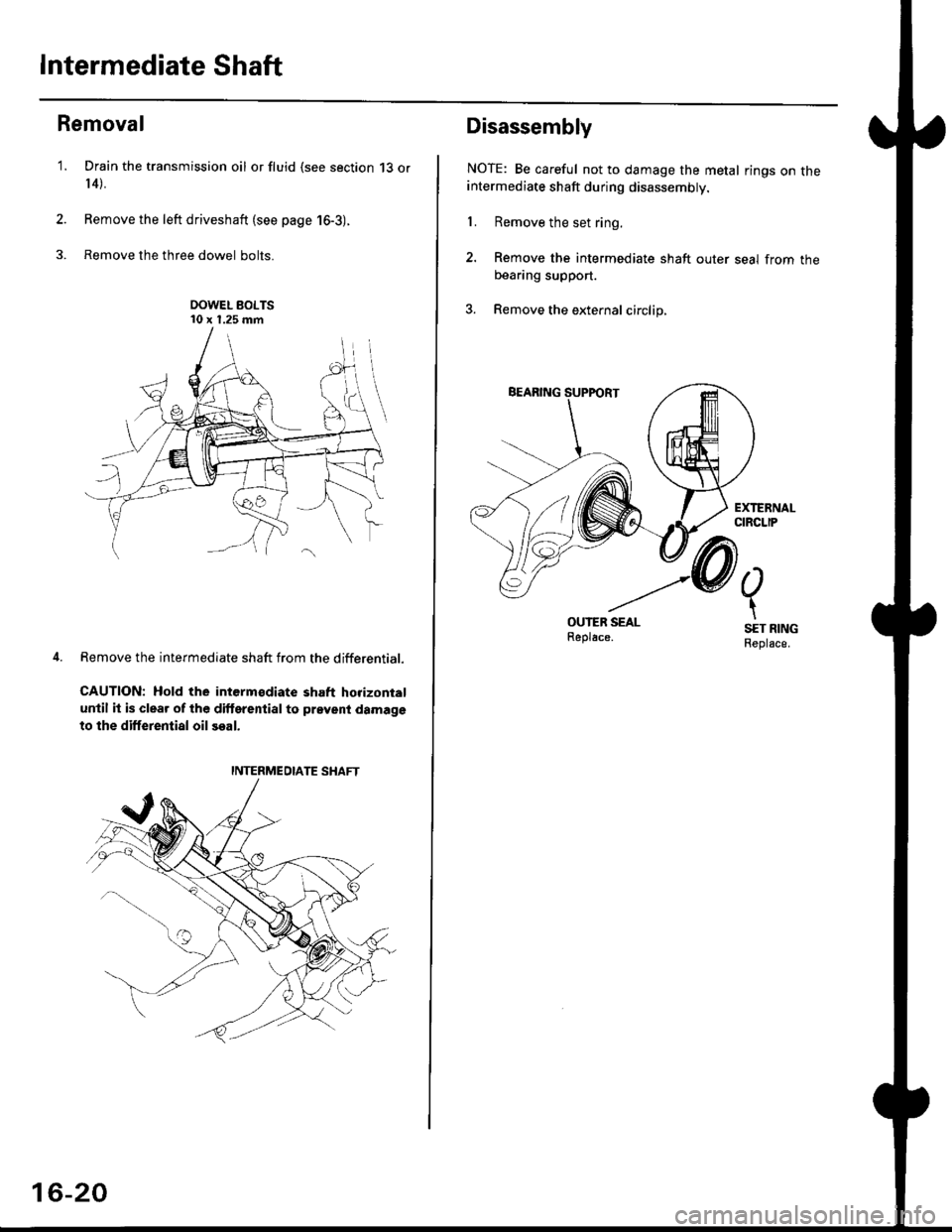

Remove the three dowel bolts.

OOWEL BOLTS'10 x 1.25 mm

Remove the intermediate shaft from the differential.

CAUTION: Hold the intermsdiate shaft horizontal

until it is clear of lhe dilterential to prevent damage

to the differential oil seal.

'1.

2.

3.

INTERMEDIATE SHAFT

16-20

Disassembly

NOTE: Be careful not to damage the metal rings on theintermediate shaft during disassembly.

1. Remove the set ring.

2. Remove the intermediate shaft outer seal from theDeaflng suppon.

3. Remove the external circlip,

Page 1134 of 2189

Front Suspension

Knuckle/Hub Replacement

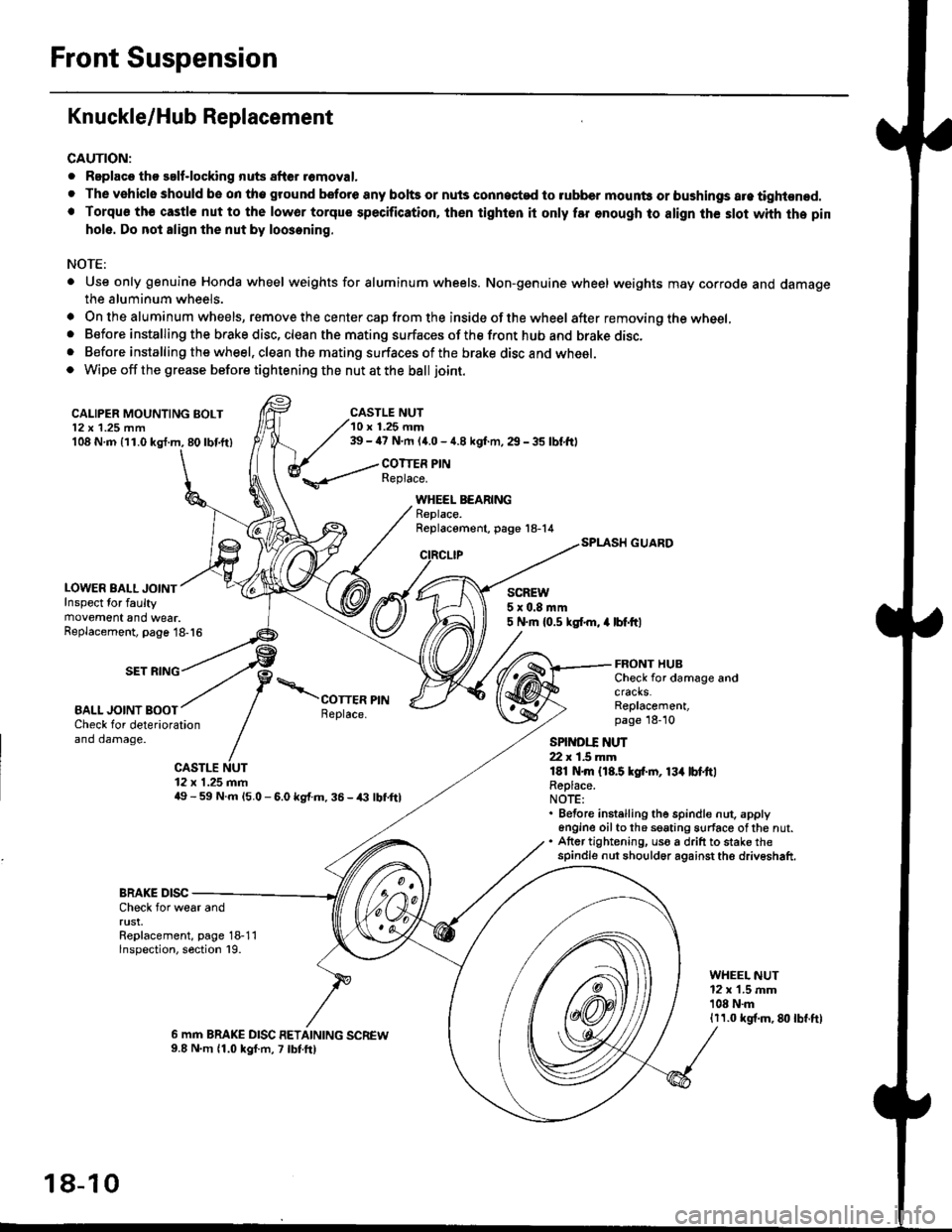

CAUTION:

. Replaco tho salf-locking nuts after romoval.

. The vehiclo should be on tho ground bsfore any bohs or nuls connected to rubber mounb or bushings are tightened.. Torqu€ th€ castle nut to the lowor torque specification, ihen tighton it only far enough to align th€ slot whh the pin

hole. Do not align the nut by loosening.

NOTE:

. Use only genuine Honda wheel weights for aluminum wheels. Non-genuine wheel weights may corrode and damagethe aluminum wheels.

. On the aluminum wheels, remove the center cap from the inside of the wheel after removing the wheel,. Before installing the brake disc, clean the mating surfaces of the front hub and brake disc,. Before installing the wheel, clean the mating surfaces of the brake disc and wheel.o Wipe off the grease before tightening the nut at the ball joint.

CALIPER MOUNTING BOLT12 x 1.25 mm108 N.m {11.0 kgl.m, 80lbf.ft)

LOWER BALL JOINTInspect for faultymovement and wear.

CASTLE NUT10 r 1.25 mm39 - ia7 N.m (4.0 - 4.8 kgf.m, 29 - 35 lbf,ftl

COTTER PINReplace.

WHEEL BEARINGReplace.Replacement, page 18-14

CIRCLIP

SCREW5x0.8mm5 N.m {0.5 ksl.m, 4 lbf.ftlReplacement, page 18-16

SET RING

BALL JOINT BOOT

FRONT HUBCheck for damage andcracks.Replacement,page 18-10Check for deteriorationand damage.

CASTLE NUT12 x 1.25 mm49 - 59 N.m l5.O - 6.0 kg{.m. 36 - /(} lbf,ftl

SPINDI.T ]{UT22 r 1.5 mmlEl N.m {18.5 kgf.rn, 13{ lbl.ttlReplace.NOTE:. Before instelling the spindle nut. apply6n9ine oilto th6 seating surface ofthe nut.. Atter tightening, uso a drift to stake thespindle nut should6r against the driveshaft.

BRAKE DISCCheck for wear andrust.Replacement, page 18-11lnspection, section 19.

WHEEL NUT12 x 1.5 mm'108 N.m1r1.0 kgf.m, 8lt lbf.ft)

6 mm BRAKE DISC RETAINING SCREW9.8 N.m 11.0 kgf.m, 7 lbtft)

18-10

Page 1135 of 2189

)

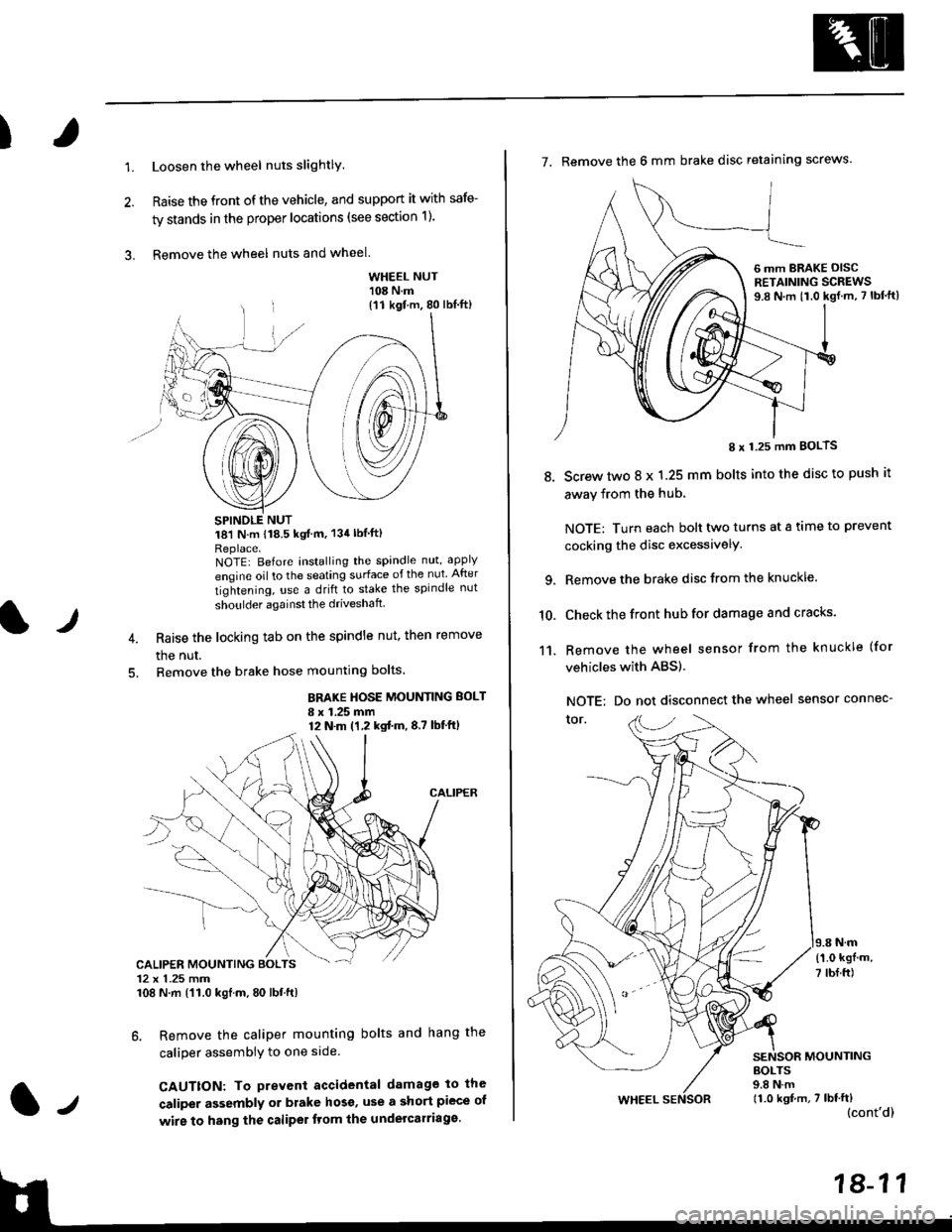

1.Loosen the wheel nuts slightlY.

Raise the front of the vehicle, and support it with safe-

ty stands in the proper locations (see section 1).

Remove the wheel nuts and wheel.3.

l)

WHEEL NUT'108 N.m

18'l N.m 118.5 kgf m, 134lblfti

Replace.NOTEI Before installing the spandle nut, apply

engine oil to the seating surface of the nut After

tightening, use a drift to stake the spindle nut

shoulder againsl the driveshaft

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT

I x 1.25 mm12 N.m (1,2 kgtm,8,7 lbf'ftl

6. Remove the caliper mounting bolts and hang the

caliper assembiy to one side

CAUTTON: To prevent accidental damage to the

caliper assembly or brake hoso' use a short piece of

wire to hang the caliPer tlom lhe undelcarriage.

{11 kgf m, 80 lbl.ft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m {'11.0 kgtm, 80 lbt.ft)

7. Remove the 6 mm brake disc retaining screws.

8.

I x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

away from the hub,

NOTE: Turn each bolt two turns at a tame to prevent

cocking the disc excessivelY.

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

Remove the wheel sensor from the knuckle (for

vehicles with ABS).

NOTE: Do not disconnect the wheel sensor connec-

tor.

N.m

6 mm BRAKE OISCRETAINING SCREWS9.8 N.m t1.0 kgf.m, 7 lbf'ft)

{'1.0 kgf m,

7 tbf.ft)

10.

11.

MOUNTING

WHEEL

BOLTS9.8 N.m11.0 kgf,m, 7 lbf'ft)(cont'd)

Page 1137 of 2189

)

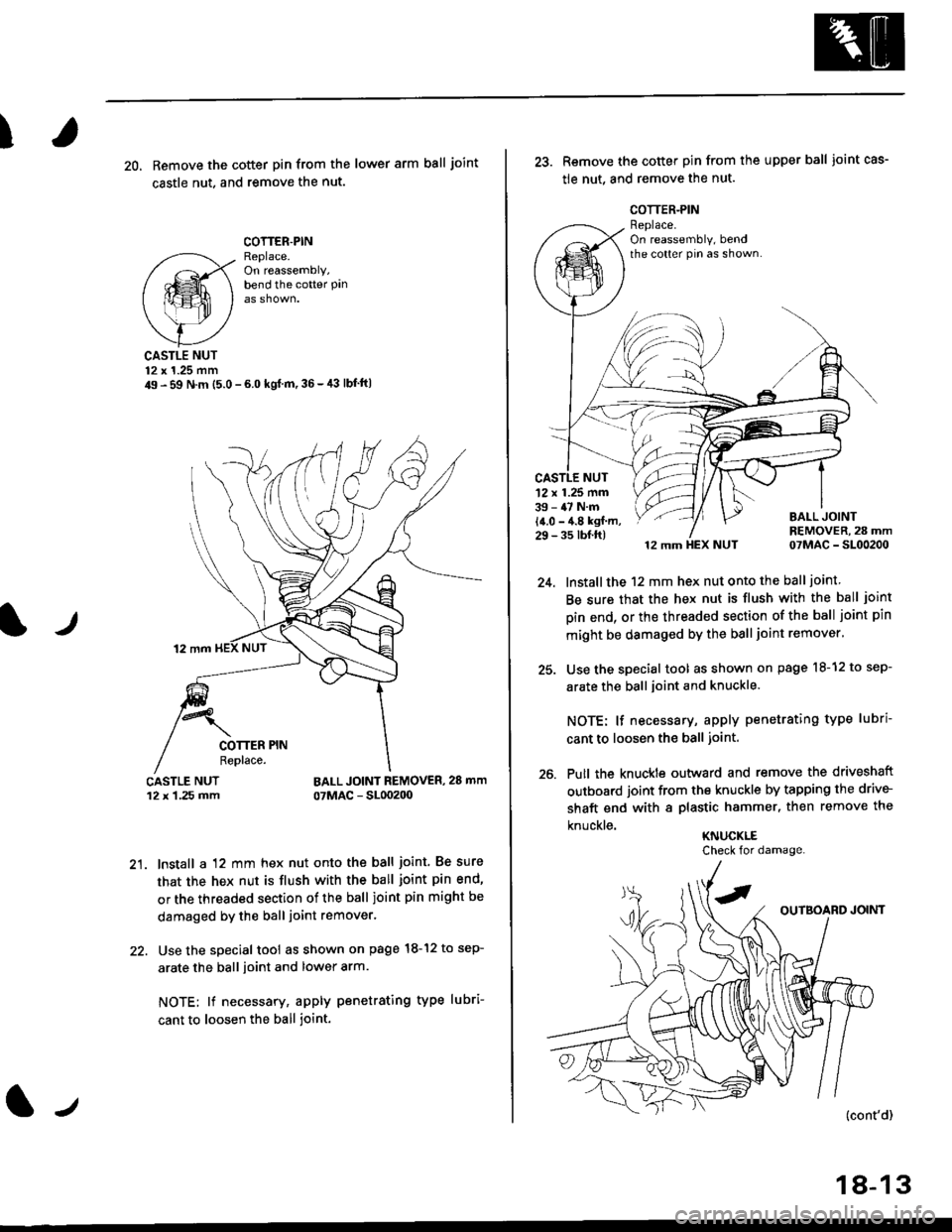

20, Remove the cotter pin from the lower arm ball joint

castle nut. and remove the nut.

COTTER.PINReplace.On reassembly,bend the cotter Pan

lr

CASTLE NUT12 x 1.25 mm49 - 59 N.m (5.0 - 6.0 kgl m,36-,13 lbf'ft|

BALL JOINT REMOVER, 28 mm

07MAC - SL00200

21. lnstall a 12 mm hex nut onto the ball joint. Be sure

that the hex nut is flush with the ball joint pin end'

or the threaded section of the ball joint pin might be

damaged by the ball joint remover.

22. Use the special tool as shown on page l8-12 to sep-

arate the ball ioint and lower arm.

NOTE; lf necessary, apply penetrating type lubri-

cant to loosen the ball joint.

lJ

18-13

25.

26.

Remove the cotter pin from the upper ball joint cas-

tle nut, and remove the nut.

12 mm HEX NUT 07MAC - SL00200

lnstall the 12 mm hex nut onto the ball joint

Be sure that the hex nut is flush with the ball joint

pin end, or the threaded section of the ball joint pin

mlght be damaged by the ball joint remover'

Use the special tool as shown on page l8-12 to sep-

arate the ball joint and knuckle.

NOTE: lf necessary, apply penetrating type lubri

cant to loosen the ball joint.

Putl the knuckte outward and remove the driveshaft

outboard joint from the knuckle by tapping the drive-

shaft end with a plastic hammer, then remove the

knuckle.KNUCKLE

'12 x 1.25 mm39 - 47 N.m

14.0 - 4.8 kgf m,29 - 35 tbf.ft)

Check for damage.

Page 1144 of 2189

Front Damper

Installation (cont'd)

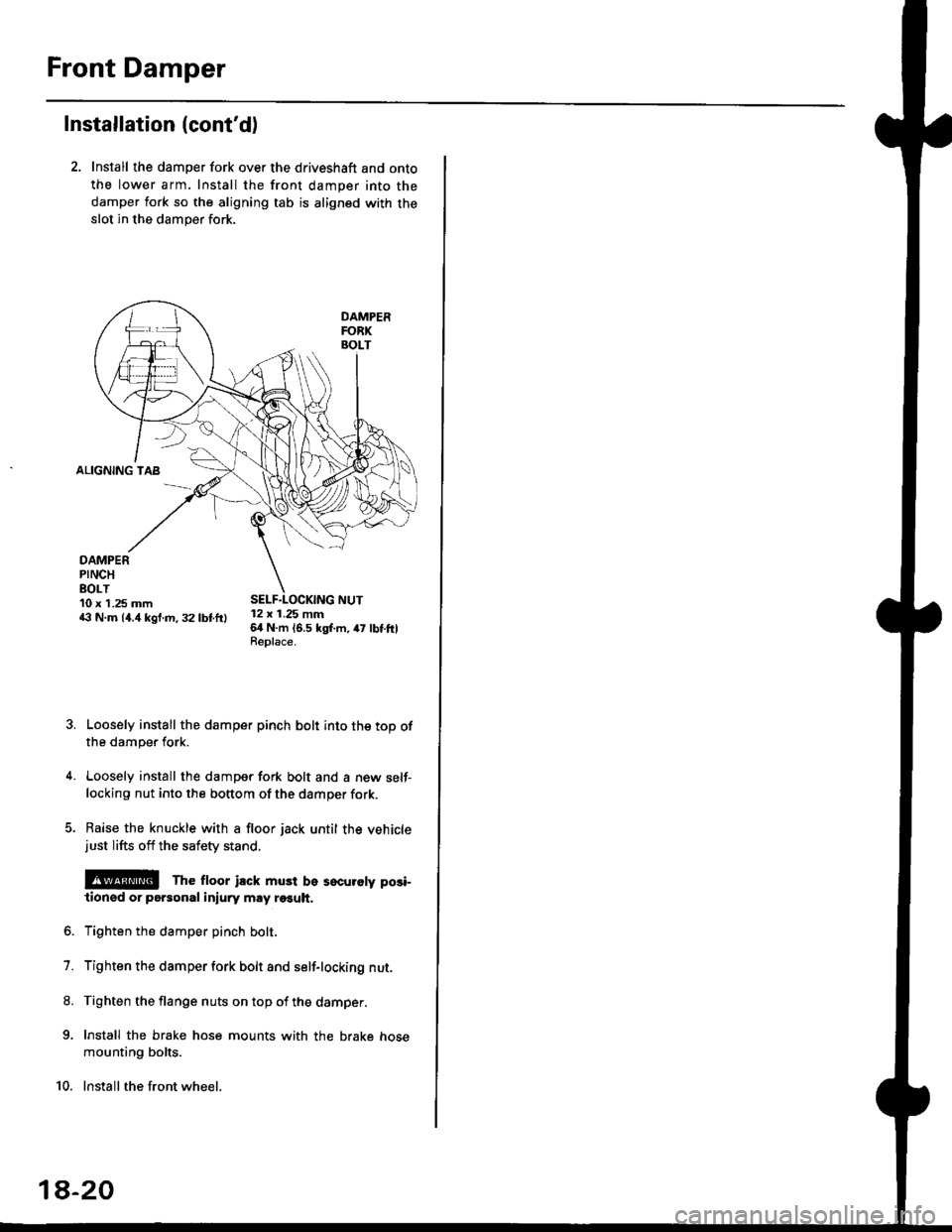

2. Install the damper fork over the driveshaft and onto

the lower arm. Install the front damper into the

damper fork so the aligning tab is aligned with the

slot in the damper fork.

ALIGNING TAB

DAMPERPINCHEOLT10 x 1.25 mm43 N.m 14.4 kgf.m, 32 lbtftl12 x 1.25 mm64 N.m 16.5 kgl.m, 47 lbtftlReplace.

Loosely install the damper pinch bolt into the top ofthe damper fork.

Loosely install the damper fork bolt and a new self-locking nut into the bottom of the damper fork.

Raise the knuckle with a floor jack until the vehiclejust lifts off the safety stand.

@E The ftoor ilck must be sscuroty posi-

lionsd or personal iniury may r€€uh.

Tighten the damper pinch bolt.

Tighten the damper fork bolt and self-locking nut.

Tighten the flange nuts on top of the damper.

Install the brake hose mounts with the brake hose

mounting bolts.

Install the front wheel.

7.

8.

9.

10.

1a-20