plastic HONDA CIVIC 1997 6.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1250 of 2189

Doors

Glass/Regulator Replacement (cont'dl

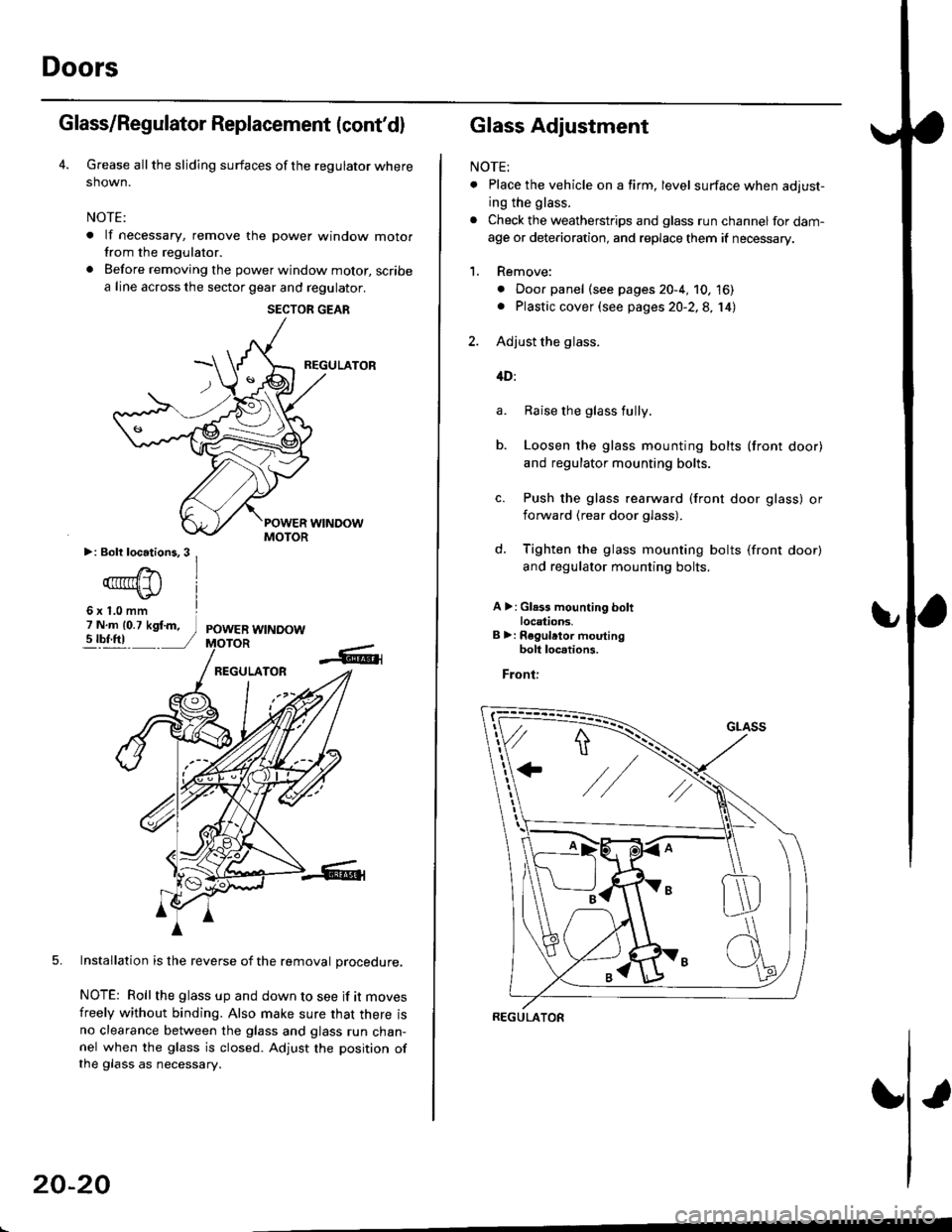

Grease all the sliding surfaces of the regulator where

shown.

NOTE:

. lf necessary, remove the power window motorfrom the regulator.

. Before removing the power window motor, scribe

a line across the sector gear and regulator.

REGULATOR

5. Installation is the reverse of the removal orocedure.

NOTE: Roll the glass up and down to see if it moves

freely without binding. Also make sure that there isno clearance between the glass and glass run chan-nel when the glass is closed. Adjust the position ofthe glass as necessary.

SECTOR GEAR

20-20

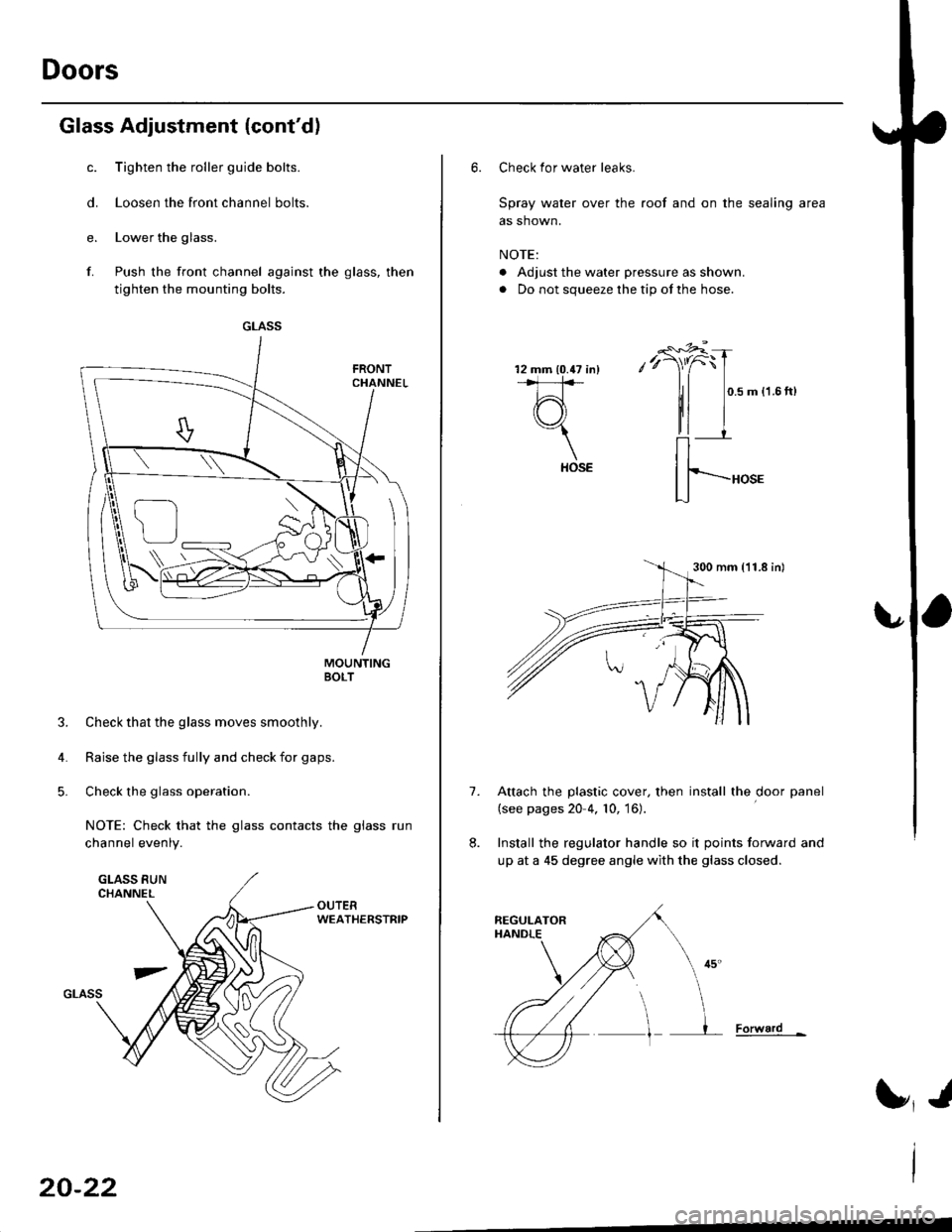

Glass Adjustment

NOTE:

. Place the vehicle on a firm, level surface when adjust-

ing the glass.

. Check the weatherstrips and glass run channel for dam-

age or deterioration, and replace them if necessary.

1. Remove:

. Door panel (see pages 20-4, 10, 16). Plastic cover (see pages 20-2,8, 14)

2. Adjust the glass.

4D:

Raise the glass fully.

Loosen the glass mounting bolts (front door)

and regulator mounting bolts.

Push the glass rearward (front door glass) or

iorward (rear door glass).

Tighten the glass mounting bolts (front door)

and regulator mounting bolts.

A >: Gl.3s mounting boltlocations.B >: Regulrtor moutingbolt loc.tions.

Front:

a.

b.

d.

REGULATOR

Page 1252 of 2189

Doors

Glass Adjustment {cont'd)

c. Tighten the roller guide bolts.

d. Loosen the front channel bolts.

e. Lower the glass.

f. Push the front channel against the glass, then

tighten the mounting bolts.

MOUNTINGBOLT

3. Check that the glass moves smoothly.

4. Raise the glass fully and check for gaps.

5. Check the glass operation.

NOTE: Check that the glass contacts the glass run

channel evenly.

WEATHERSTRIP

GLASS

U

-\,

20-22

6. Check for water leaks.

Spray water over the roof and on the sealing area

as shown.

NOTE:

. Adjust the water pressure as shown.

. Do not squeeze the tip of the hose.

0.5 m {1.6ft)

HOSE

Attach the plastic cover, then install the door panel

(see pages 20 4, 10, 16).

Install the regulator handle so it points forward and

up at a 45 degree angle with the glass closed.

Forward -

1.

HOSE

300 mm {11.8 in)

Page 1253 of 2189

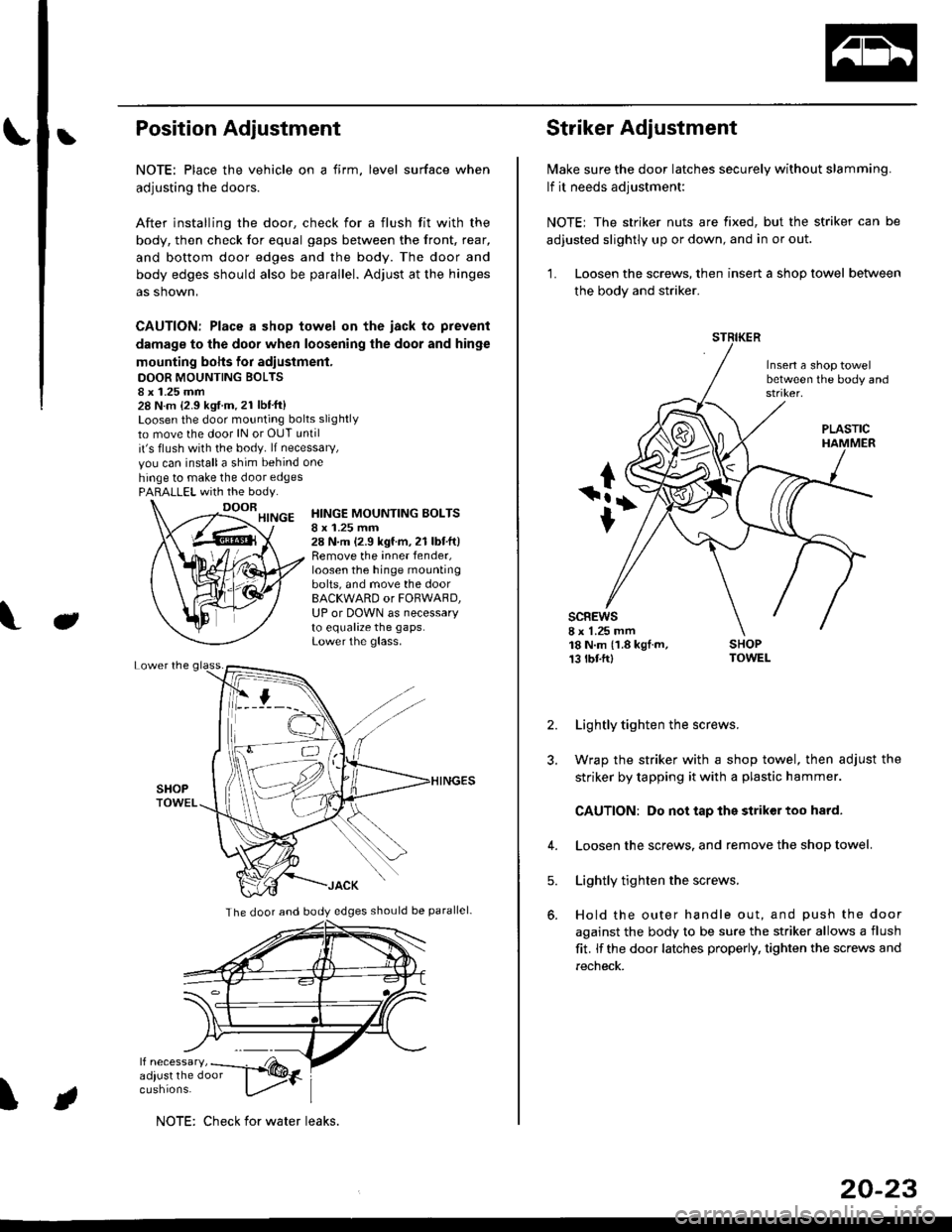

bPosition Adjustment

NOTE: Place the vehicle on a firm, level surface when

adjusting the doors.

After installing the door, check for a flush fit with the

body, then check for equal gaps between the front, rear,

and bottom door edges and the body. The door and

body edges should also be parallel. Adjust at the hinges

as shown,

CAUTION: Place a shop towel on the iack to prevent

damage to the door when loosening the door and hinge

mounting bohs for adiustment.

DOOR MOUNTING BOLTS8 x 1.25 mm28 N.m {2.9 kgf.m.21 lbt'ft}Loosen the door mounting bolts slightly

to move the door lN or OUT until

it's flush with the body. lf necessary,

vou can installa shim behind one

hinge to make the door edgesPARALLEL with the body.

J

HINGE MOUNTING BOLTSI x 1.25 mm28 N.m (2.9 kgf.m,21 lbtft)Remove the inner fender,loosen the hinge mountingbolts, and move the doorBACKWARD or FORWARD,UP or DOWN as necessaryto equalize the gaps.Lower the glass.

\

The door and body edges should be parallel-

ifF t

NOTE: Check for water leaks.

20-23

Striker Adjustment

lvlake sure the door latches securely without slamming.

lf it needs adjustment:

NOTE; The striker nuts are fixed, but the striker can be

adjusted slightly up or down, and in or out.

'L Loosen the screws, then insert a shop towel between

the body and striker.

Insert a shop towelbetween the body and

sc8Ews8 x 1.25 mm18 N.m (1.8 kgf.m,13 tbtftl

PLASTIC

2. Lightly tighten the screws.

3. Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striker too hard.

4. Loosen the screws. and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door

against the body to be sure the striker allows a flush

fit. lf the door latches properly, tighten the screws and

recheck.

5.

Page 1333 of 2189

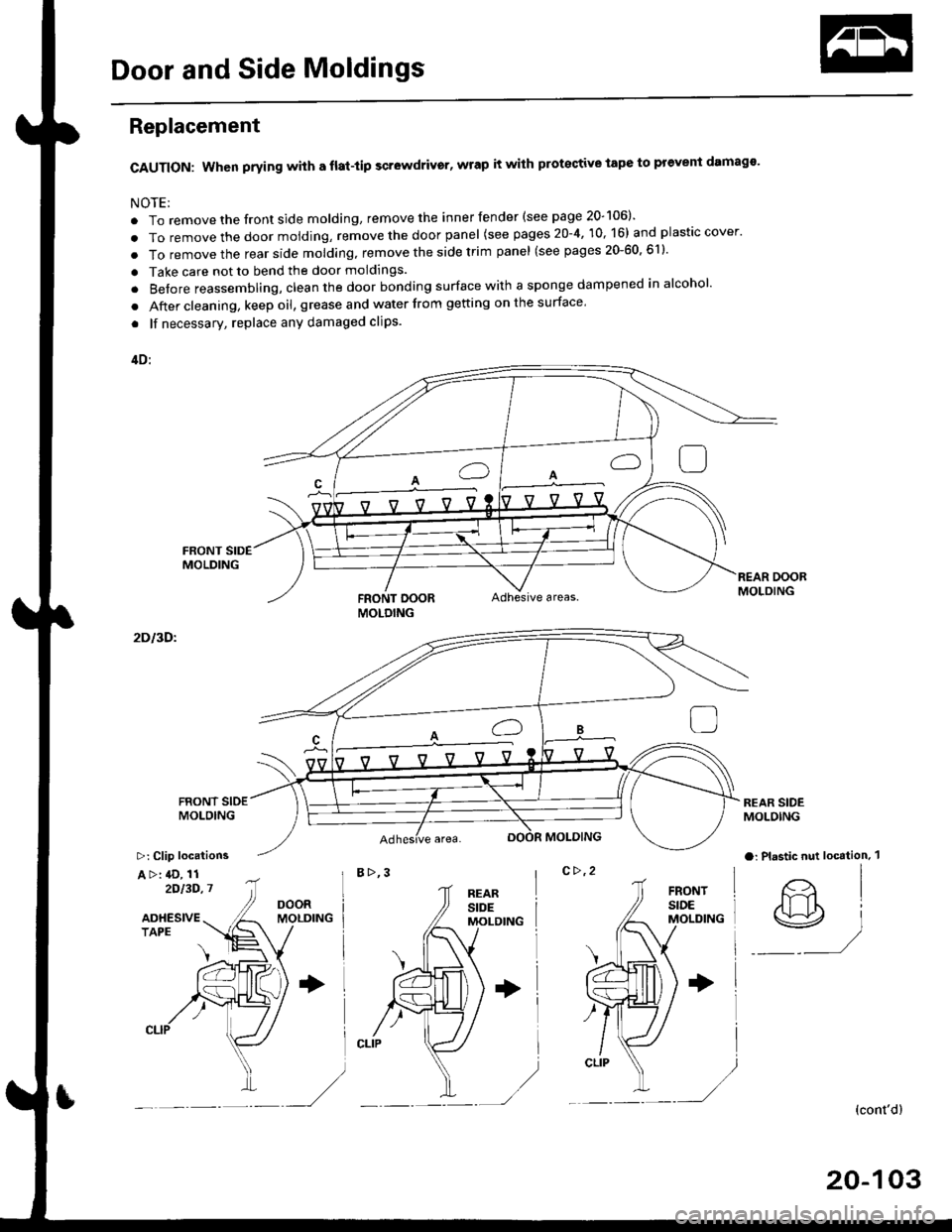

Door and Side Moldings

Replacement

CAUTION: When prying with a flat-tip scr6wdrivgr, wrap it with protective tape to prevent damags'

NOTE;

. To remove the front side molding, remove the inner fender (see page 20-106)'

. To remove the door moiding, remove the door panel (see pages 20-4, 10, 16) and plastic cover.

. To removethe rearside molding, remove the side trim panel (see pages 20-60,611'

. Take care not to bend the door moldings.

. Before reassembling, clean the door bonding surface with a sponge dampened in alcohol'

. After cleaning, keep oil, grease and water from getting on the surface'

. lf necessary, replace any damaged clips.

4D:

FRONT DOORAdhesive areas.

2Dl3Dl

B>,3c>,2

REAR SIDEMOLOING

a: Plastic nut loc€tion. 1

@)

(cont'dl

20-103

MOLDING

>: Clip locations

A >: 4D, 112')13D,7

Page 1334 of 2189

Door and Side Moldings

Replacement (cont'dl

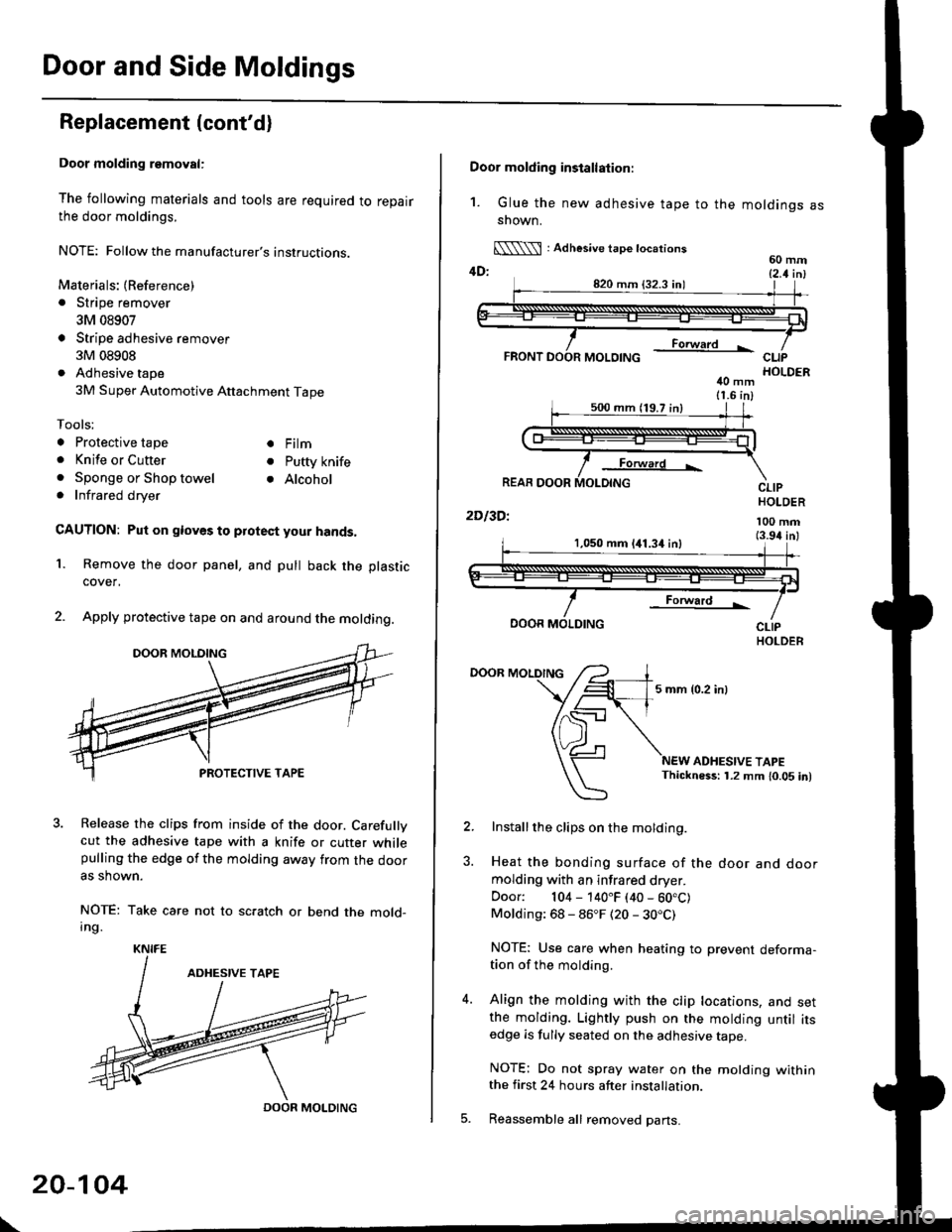

Door molding removal:

The following materials and tools are required to repairthe door moldings.

NOTE: Followthe manufacturer's instructions.

Materials: (Reference)

. Stripe remover

3M 08907

Stripe adhesive remover

3M 08908

Adhesive tape

3M Super Automotive Attachment Tape

Tools;

a Protective tape

. Knife or Cutter

. Sponge or Shop towel. Infrared dryer

. Film

. Putty knife

. Alcohol

CAUTION: Put on gloves to protect your hands,

Remove the door panel, and pull back the plastic

cover,

Apply protective tape on and around the molding.

3. Release the clips from inside of the door. Carefullvcut the adhesive tape with a knife or cutter whilepulling the edge of the molding away trom the dooras shown.

NOTE: Take care not to scratch or bend the mold-Ing.

1.

KNIFE

DOOR MOLDING

\

20-104

Door molding installation:

1. Glue the new adhesive tape to the moldings assnown.

[\\\l : Adhesive tape tocations60 mm4D: t2 t i^l

40 mm11.6 in)

Forward L

REAR DOOR

2Dl3Dl

CLIPHOLDER

100 mm(3.94 inl1,050 mm 141.34 inl

Forward !

DOOR MOLDING

DOOR MOLDING

5 mm {0.2 inl

ADHESIVE TAPEThickness: 1.2 mm 10.05 in)

Installthe clips on the molding.

Heat the bonding surface of the door and doormolding with an infrared dryer.

Door: 104 - 140"F (40 - 60.C)Molding: 68 - 86"F (20 - 30.C)

NOTE: Use care when heating to prevent deforma-tion of the molding.

Align the molding with the clip locations, and setthe molding. Lightly push on the molding until itsedge is fully seated on the adhesive tape.

NOTE: Do not spray water on the motding withinthe first 24 hours after installation.

Reassemble all removed pans.

Page 1473 of 2189

Troubleshooting

ll.

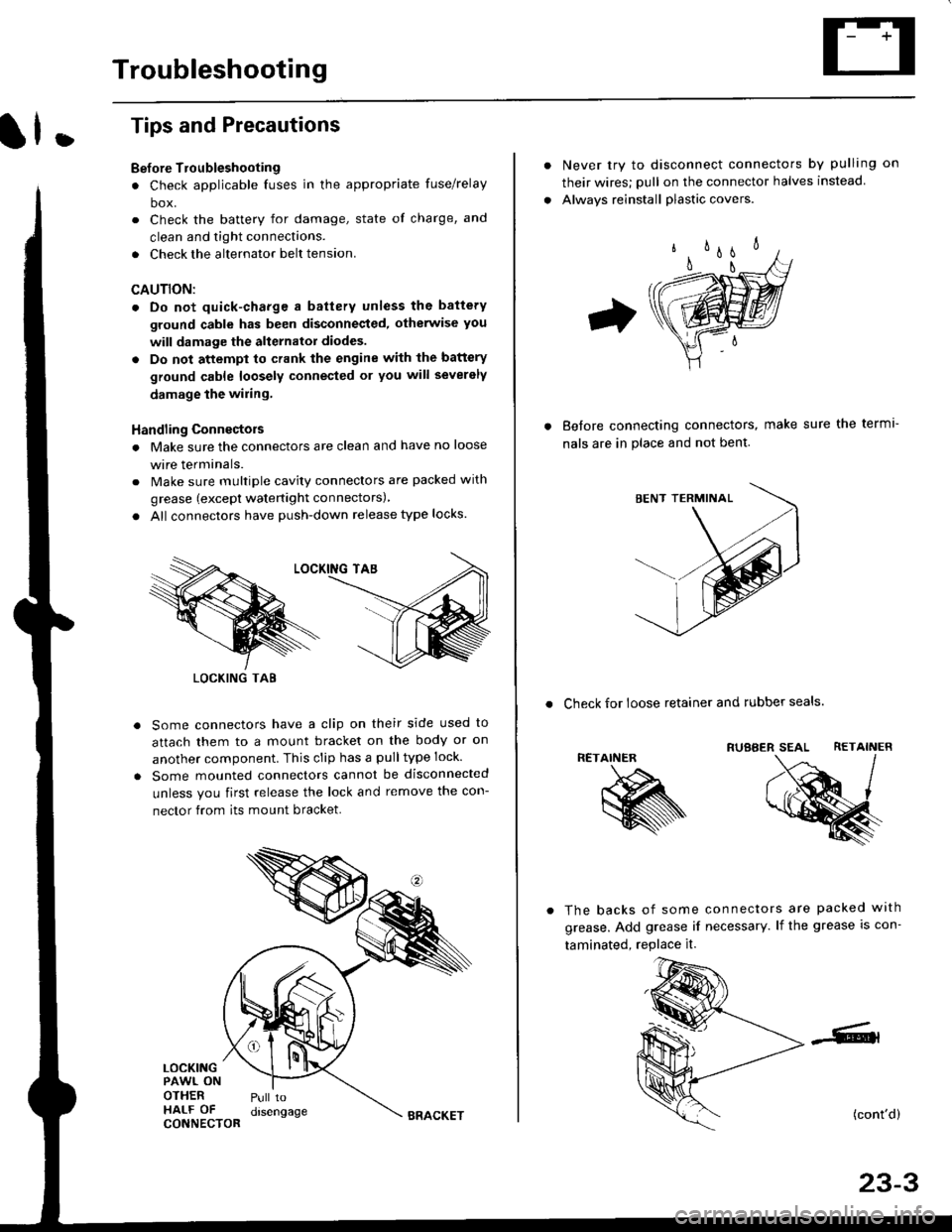

Tips and Precautions

Bef ore Troubleshooting

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconneqted, otherwise you

will damage the alternator diodes.

. Do not attempt to crank the engine with the battery

ground cable loosely connecled or you will severely

damage the wiling,

Handling Connectois

. Make sure the connectors are clean and have no loose

wire terminals.

. Make sure multiple cavity connectors are packed with

grease (except watertight connectors)

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pulltype lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFCONNECTOR

Pull todrsengage

LOCKING TAB

BRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead

Alwavs reinstall plastic covers.

Before connectang connectors,

nals are in place and not bent.

make sure the terml-

. Check for loose retainer and rubber seals.

RETAINER

The backs of some connectors are packed with

grease. Add grease if necessary. lf the grease is con-

taminated, replace it.

(cont'd)

23-3

Page 1809 of 2189

E-

)I

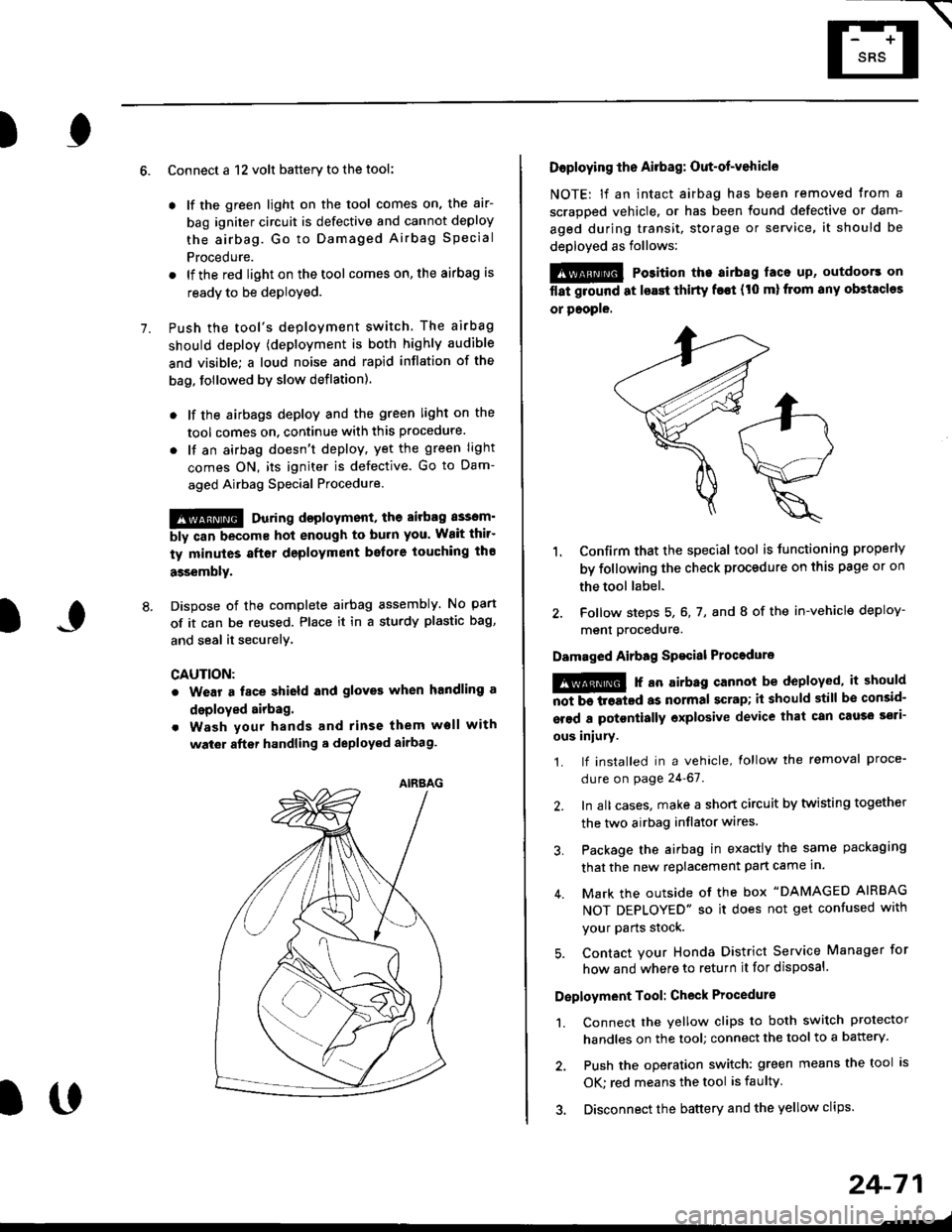

Connect a 12 volt battery to the tool:

. lf the green light on the tool comes on, the aar-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

. lf the red light on the tool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploY (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on. continue with this procedure.

. l{ an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

!!@ During doployment, the airbag sssom'

bly can become hot enough to buln you. Wait thir'

ty minutes aftsr deployment belore touching tho

assembly.

Dispose of the complete airbag assembly. No part

of it can be reused. Place it in a sturdy plastic bag,

and seal it securelY,

CAUTION:

. Wear a fsce shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

wat6r after handling. deployed airbag.

t('

24-71

7.

AIRAAG

Doploying th6 Airbag: Out-of-vehicle

NOTE: lf an intact airbag has been removed from a

scrapped vehicle. or has been found defective or dam-

aged during transit, storage or service, it should be

deployed as follows:

@ Po3ition the airbag laca up, outdoors on

flat ground at lsast thirty f€€t (t0 ml from any obstacles

or people.

1. Confirm that the special tool is tunctioning properly

by following the check procedure on this page or on

the tool label.

2. Follow steps 5, 6, 7, and I of the in-vehicle deploy-

menl Drocequre.

Damaged Airbag Spacial Procedure

!@ r an airb.g cannot be deployed, it should

iiiTi-treatcd as normal scrap; il should still be consid-

srsd a potontially oxplosive device that can cau3o ssti-

ous iniury.

1. lf installed in a vehicle, lollow the removal proce-

dure on page 24-67.

2. In all cases. make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new replacement part came in.

4. Mark the outside of the box "DAMAGED AIRBAG

NOT DEPLOYED" so it does not get confused with

your Parts stock.

5. Contact your Honda District Service Manager for

how and where to return it for disposal.

Deployment Tool: Check Procedur€

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK: red means the tool is faulty

3. Disconnect the battery and the yellow clips.