locks HONDA CIVIC 1997 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1341 of 2189

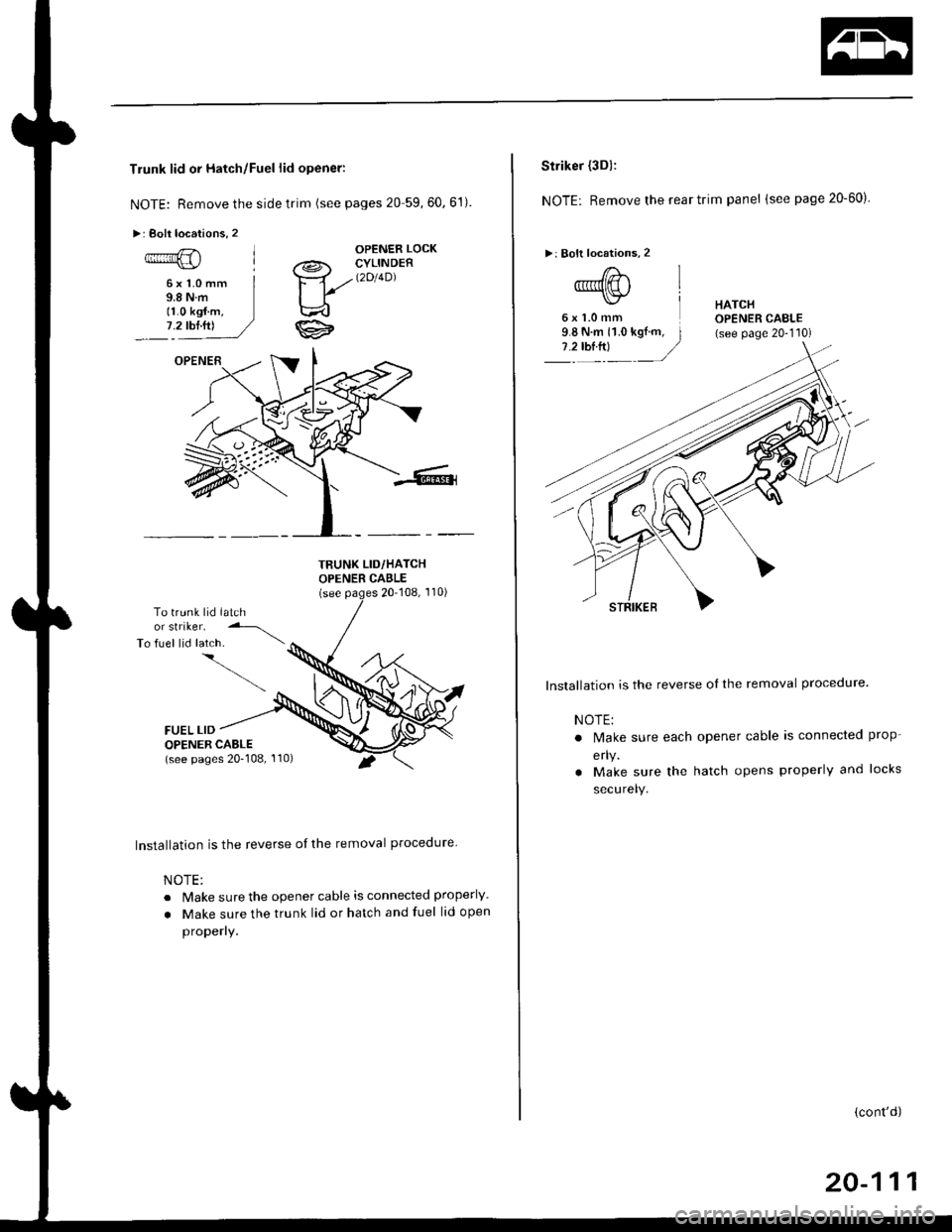

Trunk lid or Hatch/Fuel lid opener:

NOTE: Remove the side trim (see pages 20 59,60.61)

>: Boll locations, 2

OPENER LOCK

6xl.0mm9.8Nm11.0 kgf.m,7.2 tbl.ttl

a@- CYLINDER

Ya//t2't4Dl

ti

TBUNK LID/HATCHOPENER CABLE(see20-108, 110)

To trunk lid latchor striker.

To fuel lid latch. \

FUEL LIDOPENER CABLE(see pages 20-108, '110)

Installation is the reverse of the removal procedure

NOTE:

. lvake sure the opener cable is connected properly.

. Make sure the trunk lid or hatch and fuel lid open

properly.

l:'.j

Striker (3Dl:

NOTE: Remove the rear trim panel (see page 20-60)

>: Bolt locations, 2

6xl.0mmHATCHOPENER CAELE(see page 20-110)

lnstallation is the reverse of the removal procedure.

NOTE:

. N4ake sure each

erlY.

. Make sure the

securelY.

opener cable is connected ProP-

hatch opens properly and locks

(cont'd)

20-111

Page 1342 of 2189

Opener and Latch

Replacement (cont'd)

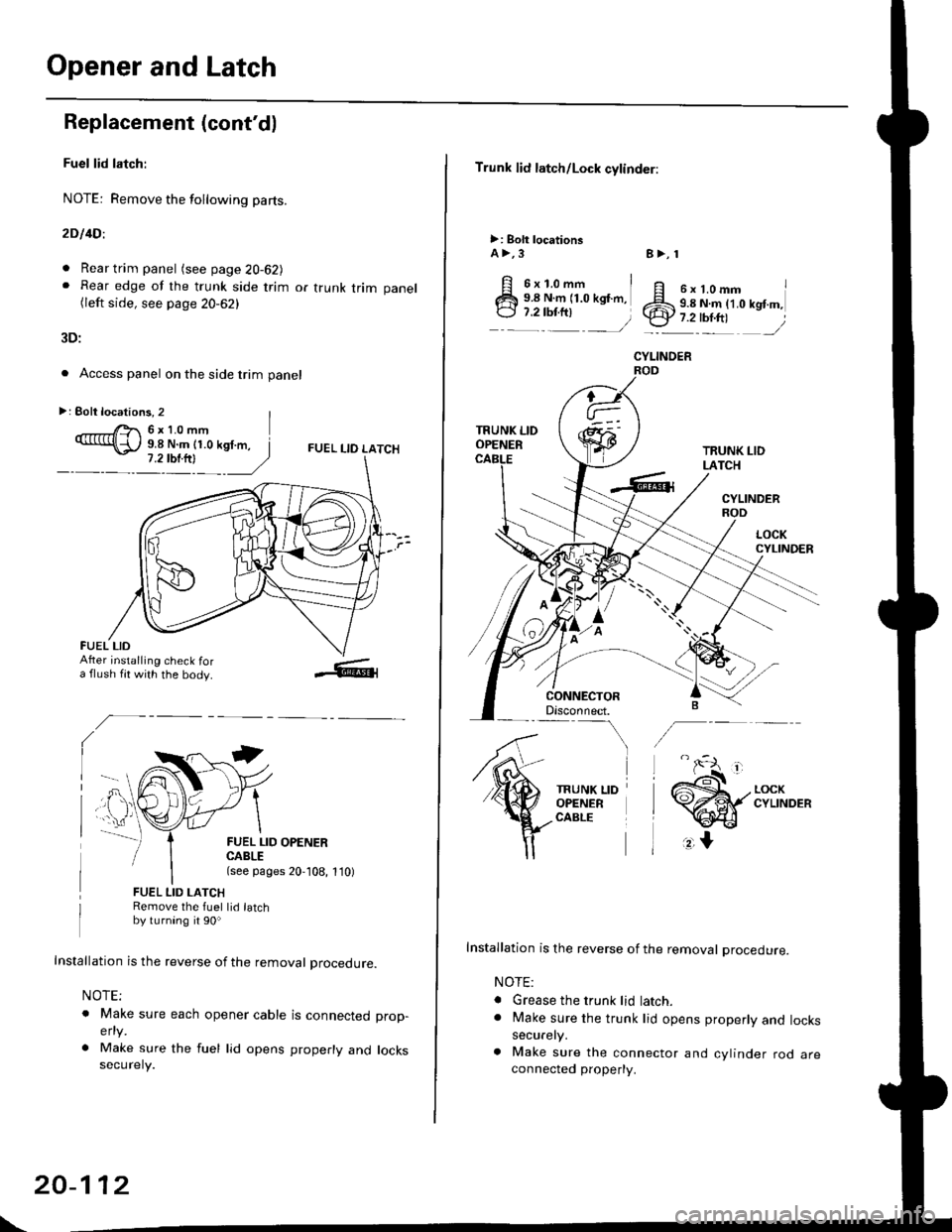

Fuel lid latch:

NOTE: Remove the following pa(s.

2D l4Dl

. Rear trim panel (see page 20-62J. Rear edge of the trunk side trim or trunk trim panel(left side, see page 20-62)

3D:

. Access panel on the side trim panel

FUEL I-IO LATCH

II

FUEL LID OPENERCABLE(see pages 20,108, 1'10)

FUEL LID LATCHRemove the fuel lid latchby turning it 90o

Installation is the reverse of the removal procedure.

NOTE;

o Make sure each opener cable is connectedelty

. Make sure the fuel lid opens properly andsecurely.

prop-

locks

>: Eolt locations, 2 |r'- 6x10mm9.8 N.m (1.0 kgf.m, I

FUEL LIDAfter installing check fora flush fit with the body.

\

20-112

Trunk lid latch/Lock cylinder:

>: Bolt locationsA >,3

6x1.omm i9.8 N.m (1.0 kgf.m,

:::^ _=)

TRUNK LIDOPENER

CONNECTORDisconnect.-\

TRUNK LIDOPENERCABLE

8>, 1

ff e rt.omm IZS 9.8 N.ln (1.0 kgt m,.ty 7.2-tbr.ftt ,/

CYLINOER

TRUNK LIDLATCH

CYLINDERROD

Installation is the reverse of the removal procedure.

NOTE:

. Grease the trunk lid latch.. Make sure the trunk lid opens properly and lockssecurely.

a Make sure the connector and cylinder rod areconnected property.

Page 1343 of 2189

Windshield Wiper Arms

and Linkage

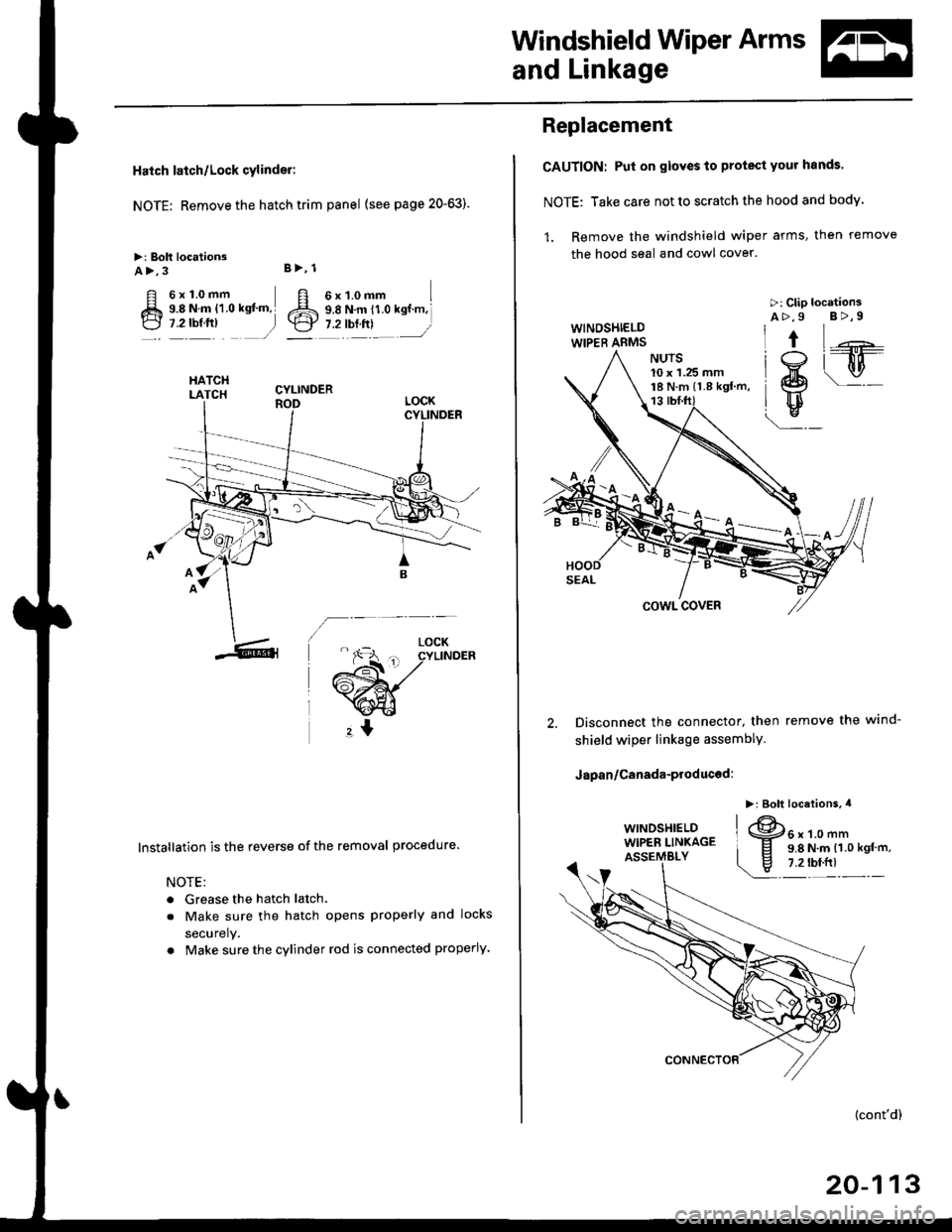

Hatch latch/Lock cylinder:

NOTE: Remove the hatch trim panel (see page 20-63).

>: Bolt locationsA>,3

6x1.0mm I9.8 N.m i1.0 ksf m,l

1.2lbl.trl /

B>, 1

E6'cr

CYLINDER

6;:il;l,lr'.",

.r\

LOCK- r€ cYLTNDERL^ ! ./

rAs<.L ,/

\faa"El

rl

lnstallation is the reverse of the removal procedure.

NOTE:

. Grease the hatch latch.

. Make sure the hatch opens properly and locks

securely.

. Make sure the cylinder rod is connected properly.

Replacement

CAUTION: Pul on gloves to protect your hands

NOTE: Take care not to scratch the hood and body.

1. Remove the windshield wiper arms, then remove

the hood seal and cowl cover.

>: Clip locationsA>,9 B>,9WINOSHIELDWIPER ABMS

\j:_

Hw

u

cowl covER

Disconnect the connector, then

shield wiper linkage assemblY.

Japan/Canada-produced:

remove the wind-

10 x 1.25 mm18 N.m ll.8 kgf m,

(cont'd)

20-113

Page 1355 of 2189

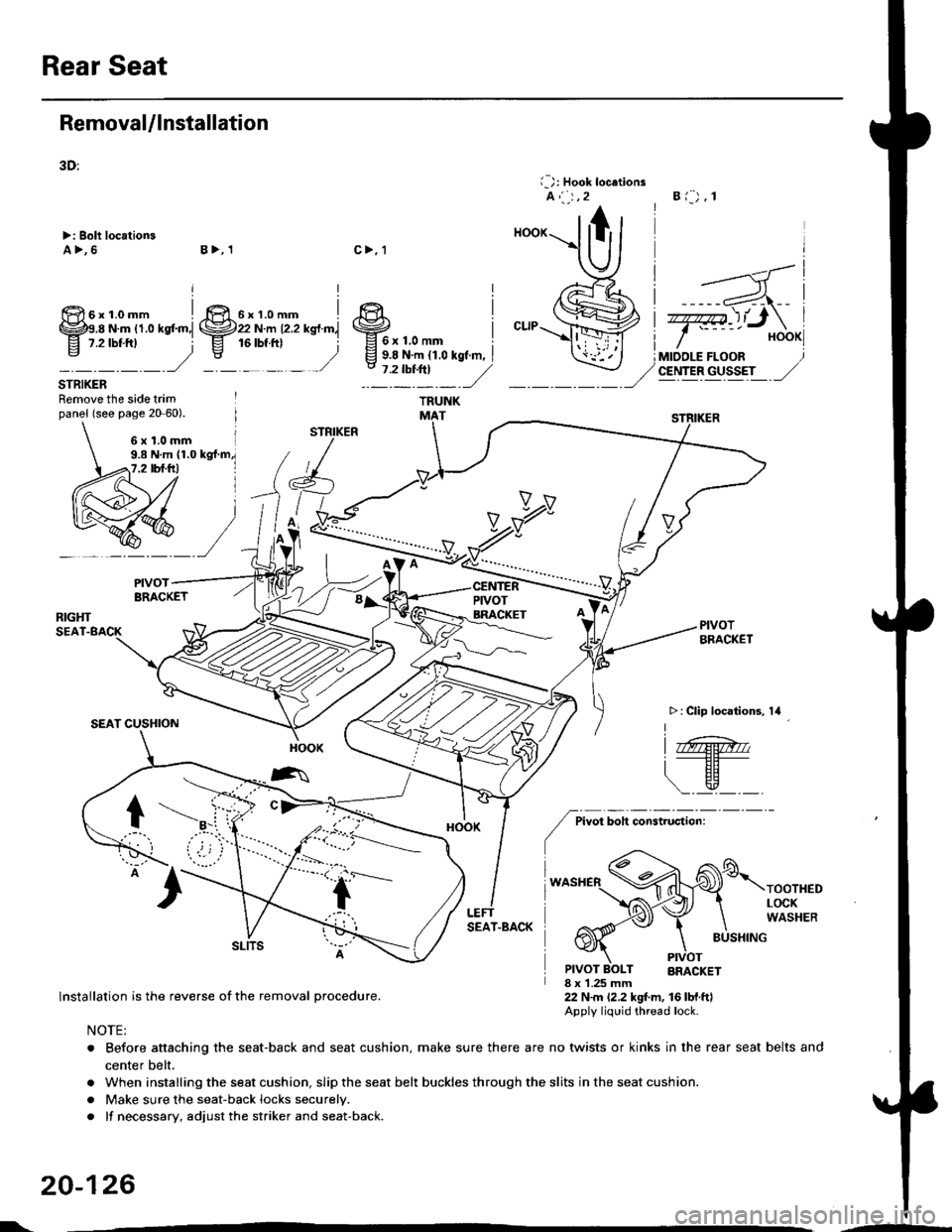

Rear Seat

RemovaUlnstallation

3D:

>: Bolt locationsa>,6

i_): Hook locations4i.,,2

c>, 1

Bt-;,1

T=ttJX,.)MIOOLE FLOORCENTER GUSSET

6x1.Omm9.8 N.m {1.07.2 tbt.trl

STRIKERRemove the side trimpanel (see page 20 60).

.2 tb,f.ft)

--::.........VV

STNIKER

>: Clip locations, 14

l@nIFF(EE

\qt

;*... 1PIVOTBRACKET

SEAT CUSHION

HOOK

A

c

Pivot boft con3truction:

TOOTXEDLOCKWASHERSEAT.BACK

A

Instailation is the reverse of the removal procedure.

NOTE:

. Before attaching the seat-back and seat cushion, make sure there are

center belt.

. When installing the seat cushion, slip the seat belt buckles through the

. Make sure the seat-back locks securely.

. lf necessary, adjust the striker and seat-back.

20-126

PIVOT BOLT BRACKET8 x 1.25 mm22 N.m 12,2 kgf,m, 16 lbl.ftlApply liquid thread lock.

no twists or kinks in the rear seat belts and

slits in the seat cushion.

iI

*nt.]

j

6x1.0mm9.8 N.m {1.0

B>,'t

I

-@e ' t.o.- |S=222 N.m 12.2 kg{.m,Ig 16 tbf.ft) j

:,/

I

I

Ifgf..,i

l

)

l---

Page 1356 of 2189

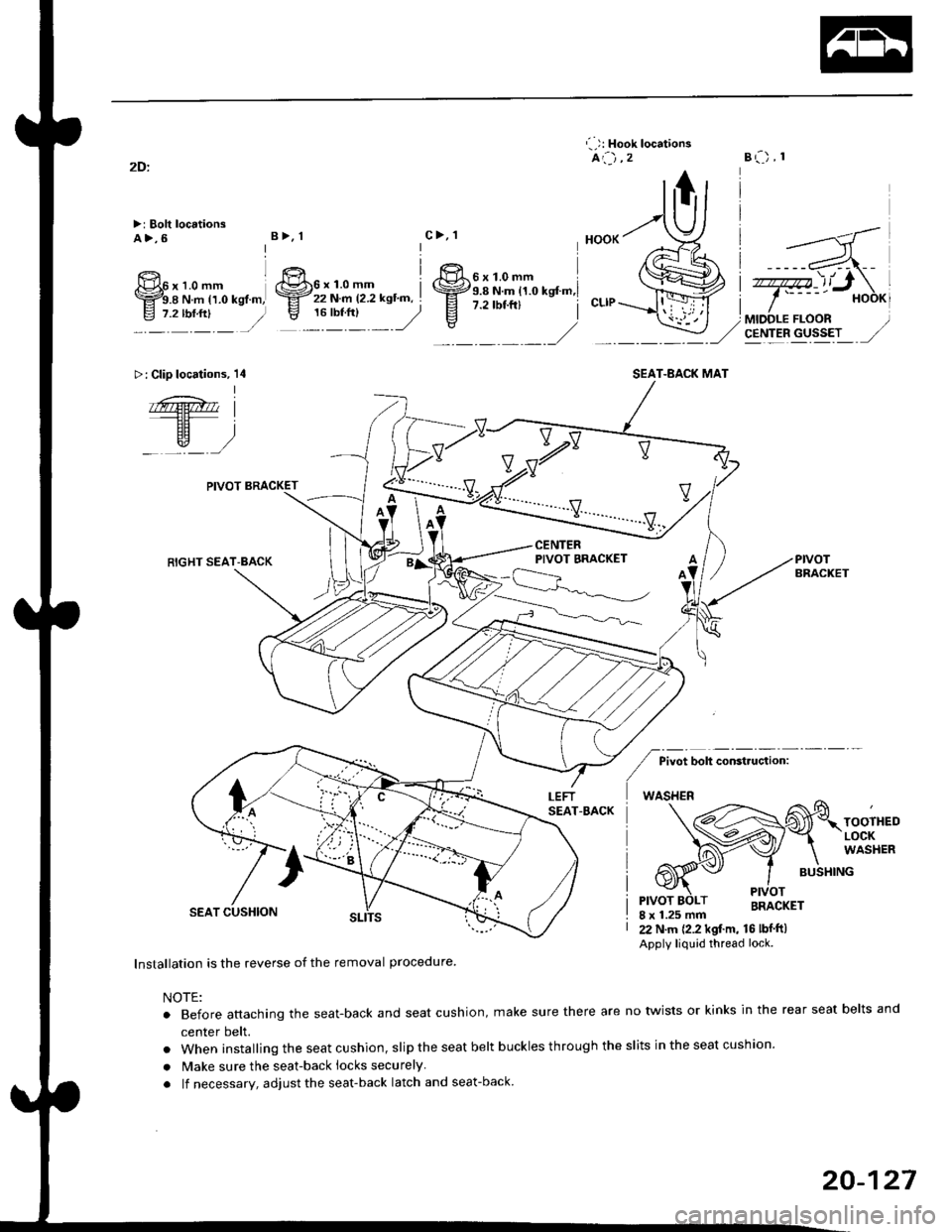

,-. ): Hook locations^(:).zB() ' t2D:

>: Bolt locationsA>,6c>,1B>. 1

6le

9rJ*'Ll-",-, i VH 16 rbr'frl ) g

,/v

6x1.omm i9.8 N.m 11.0 ksf.m,l7.2 rbf.ft) i

>: Clio locations, 14

PIVOT BRACKET

V

CENTER

RIGHT SEAT-BACK

LEFTSEAT-BACK

SEAT CUSHION

lnstallation is the reverse of the removal procedure.

NOTE:

. Before attaching the seat-back and seat cushion, make sure there are

center belt.

. When installing the seat cushion, slip the seat belt buckles through the

. Make sure the seat-back locks securely

. lf necessary, adjust the seat-back latch and seat-back

BUSHING

PIVOT BOLTBRACKET8 x 1.25 mm22 N.m {2.2 kgf.m, 16 lbIft)Apply liquid thread lock.

no twists or kinks in the rear seat belts and

slits in the seat cushion.

SEAT-AACK MAT

VV

TOOIHEDLOCKWASHER

PIVOT BRACKET

20-127

Page 1363 of 2189

Opener and Latch

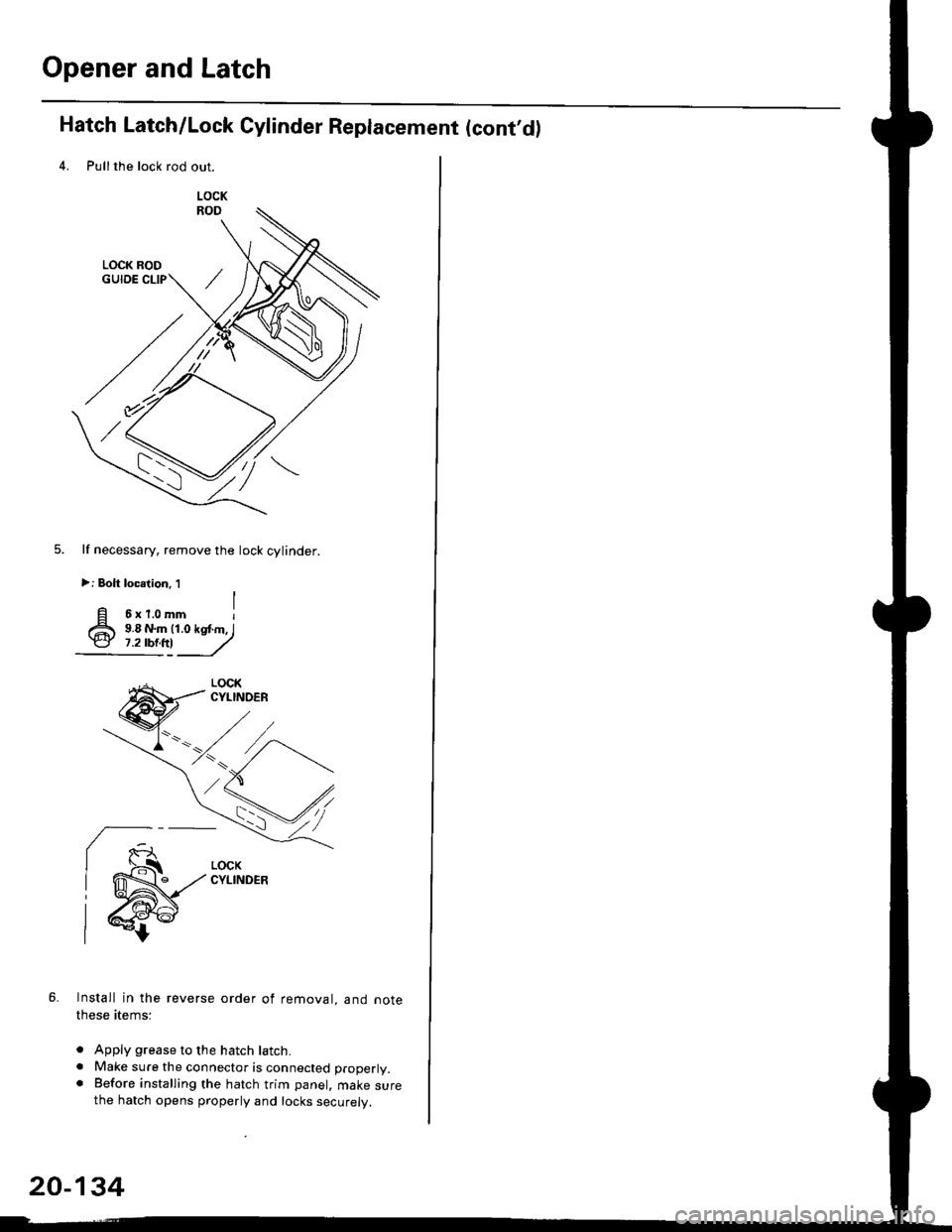

Hatch Latch/Lock Cylinder Replacement (cont'd)

4. Pullthe lock rod out.

lf necessary, remove the lock cylinder.

>: Bolt locelion. 1

6xr.omm I9.8 N.m (1.0 kq .m, I9.8 N.m (1.0 kq .m, I,:!!_J

6. Install in the reverse order of removal, and note

these atems:

. Apply grease to the hatch latch.. Make sure the connector is connected properly.. Before installing the hatch trim panel, make surethe hatch opens properly and locks securely.

ry*)*,,

\""<,/

.z ,/\

20-134

Page 1417 of 2189

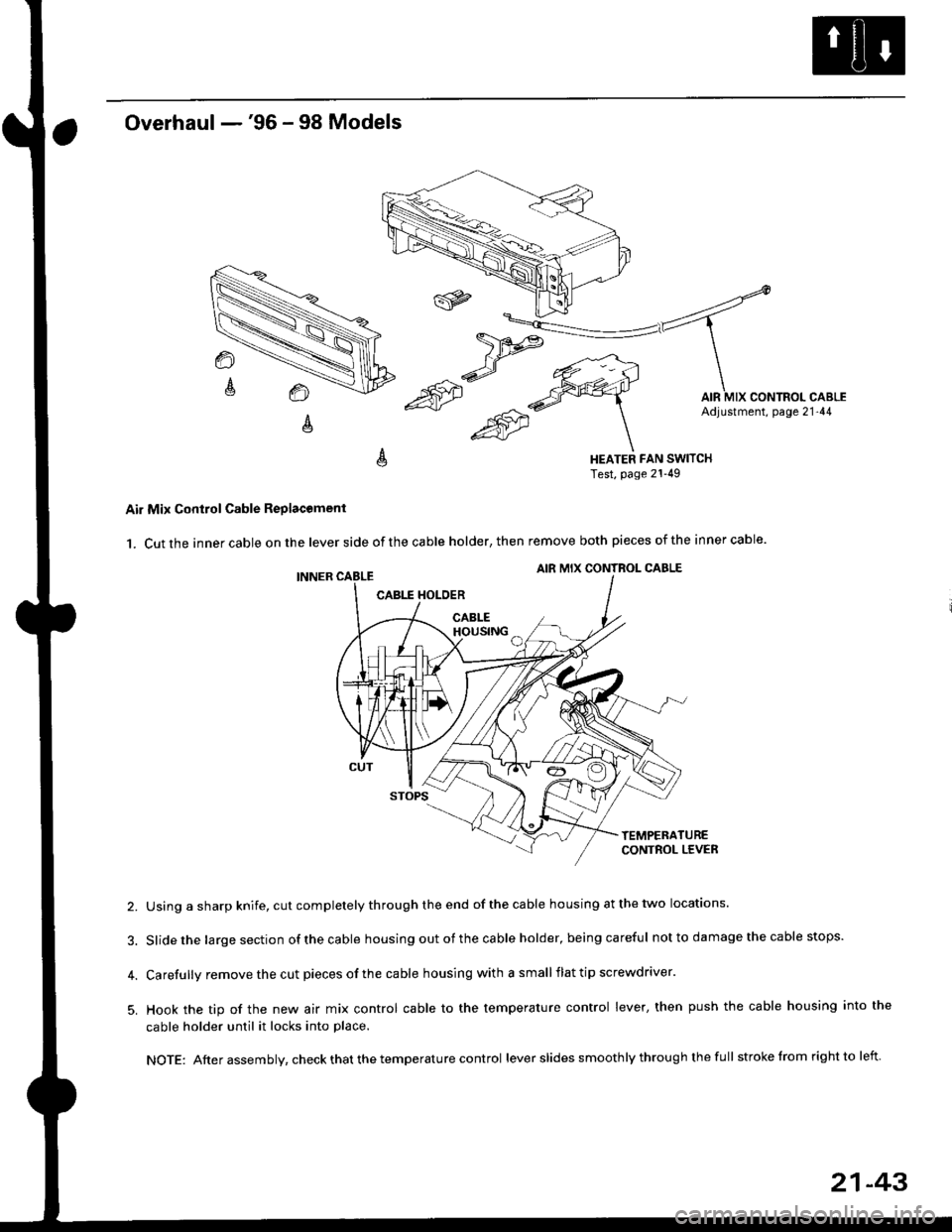

Overhaul -'96 - 98 Models

HEATER FAN SWITCHTest, page 21-49

Air Mix Control Cable Replacomenl

1. Cut the inner cable on the lever side of the cable holder, then remove both pieces of the inner cable.

2. Using a sharp knife, cut completely through the end of the cable housing at the two locations.

3. Slidethe largesection ofthecable housing outofthe cable holder, being careful not to da mage the cable stops.

4. Carefully remove the cut pieces of the cable housing with a small flat tip screwdriver.

5. Hook the tip of the new air mix control cable to the temperature control lever, then push the cable housing into the

cable holder until it locks into place.

NOTE: After assembly, check that the temperature control lever slides smoothly through the full stroke lrom right to left.

21-43

Page 1471 of 2189

l'f .

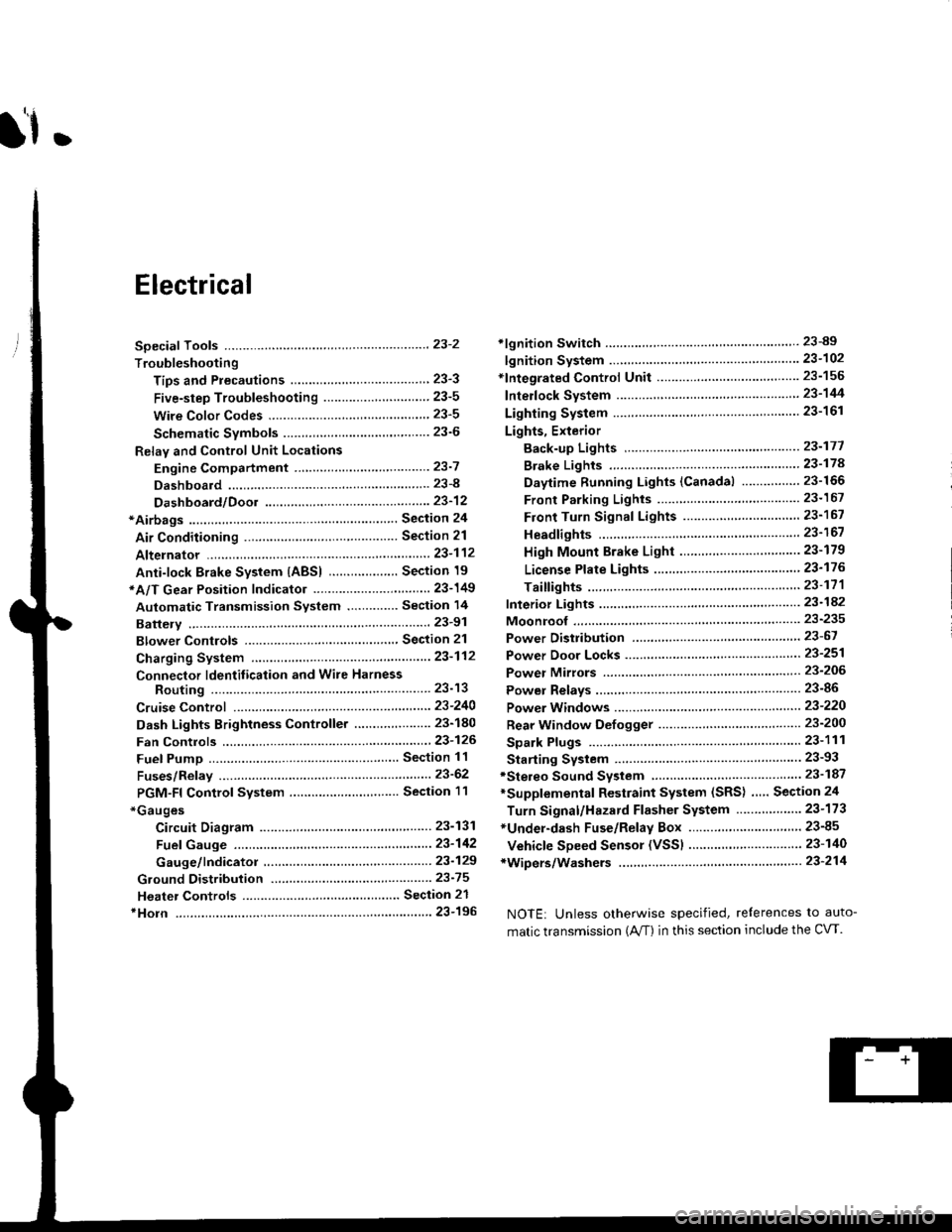

Electrical

Special Toofs .,....................,23-2

Troubleshooting

Tips and Precautions ..............,.................... . 23-3

Five-step Troubleshooting .............. ......... . . 23-5

wire color codes ..........,23-5

Schematic Symbols ........,................... . . .. .... 23-6

Relay and Control Unit Locations

Engine Compartment ...,..................... ... .. . 23'7

Dashboard ......................23-8

Dashboard/Door ......... 23-12*Airbags ................. ....... Section 24

Air Conditioning ......... Section 21

Aftelnator ..........."""" """ 23-112

Anti-lock Brake System {ABS) Section 19*A/T Gear Position Indicator .....................,. .... ... 23-149

Automatic Transmission Svstem .... . ....... Section 14

Batterv ......... . . . ... ...... .......23-91

Blower controls .. . ... Section 2l

Charging System ....'...........23'112

Connector ldentilication and Wire Harness

Routing .................. ......23'13

Cruise Control ............,........23-240

Dash Lights Brightness Controller ............. ....... 23-180

Fan controfs "" 23'126

Fuel PumD ........ . ........ section 11

Fuses/Refay ...............,..,,.. 23'62

PGM-FI Control System ......................,....... Section 1 1

*Gauges

Circuit Diagram ....,.,.......23-131

Fuef Gauge ...........'.'.......23-142

Gauge/lndicator .. . .. 23-129

Ground Distribution .. . 23-75

Heatei controls .. . ..... Section 21*Horn................. ...............23-196

*tgnition Switch ....................23-89

lgnition System .......,.... 23-102

*lntegrated Control Unit ....................................... 23-156

fnterlock System ,........ . . , ,23-144

Lighting System . . . .. ......... 23-161

Lights, Exterior

Back-up Lights ..'............23'171

Brake Lights .................. 23'174

Daytime Bunning Lights (Canadal ............... 23'166

Front Parking Lights ......,................ .'. .......... 23-167

Front Turn Signal Lights .......... . . ............ ..,.23-167

Headtights ....".'....-... ..... 23'167

High Mount Brake Light ...................... ... .23'179

License Plate Lights ...... 23'176

Taitfights ................ .......23'171

lnterior Lights ..-.......,, . 23-142

Moonroof ..,.................,........ 23-235

Power Distribution ....... . . .23-61

Power Door Locks .......,,,. .23'251

Power Mirrors ,..............,.,...23'206

Power Relays ....... . ...... . . .. 23-86

Power Windows ............,,....23-220

Rear Window Defogger .......................... . . ... . . 23-2OO

Spark Plugs . ..... . ........ .....23-111

Slarting System ................23-93*stereo Sound Svstem ,................. ..... ... . ... ,.,.,,23'147'Supplemental Restraint System (SRS) ... . Section 24

Turn Signal/Hazard Flasher System .......'.'....-... 23-173

*Undel-dash Fuse/Relay Box ............,.................. 23-85

vehicfe soeed sensor (VSSI """" ""' 23-140+Wipers/Washers .........,.,.,...23-214

NOTE: Unless otherwise specified, references to auto-

matic transmission (Mf) in this section include the CVT.

Page 1473 of 2189

Troubleshooting

ll.

Tips and Precautions

Bef ore Troubleshooting

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconneqted, otherwise you

will damage the alternator diodes.

. Do not attempt to crank the engine with the battery

ground cable loosely connecled or you will severely

damage the wiling,

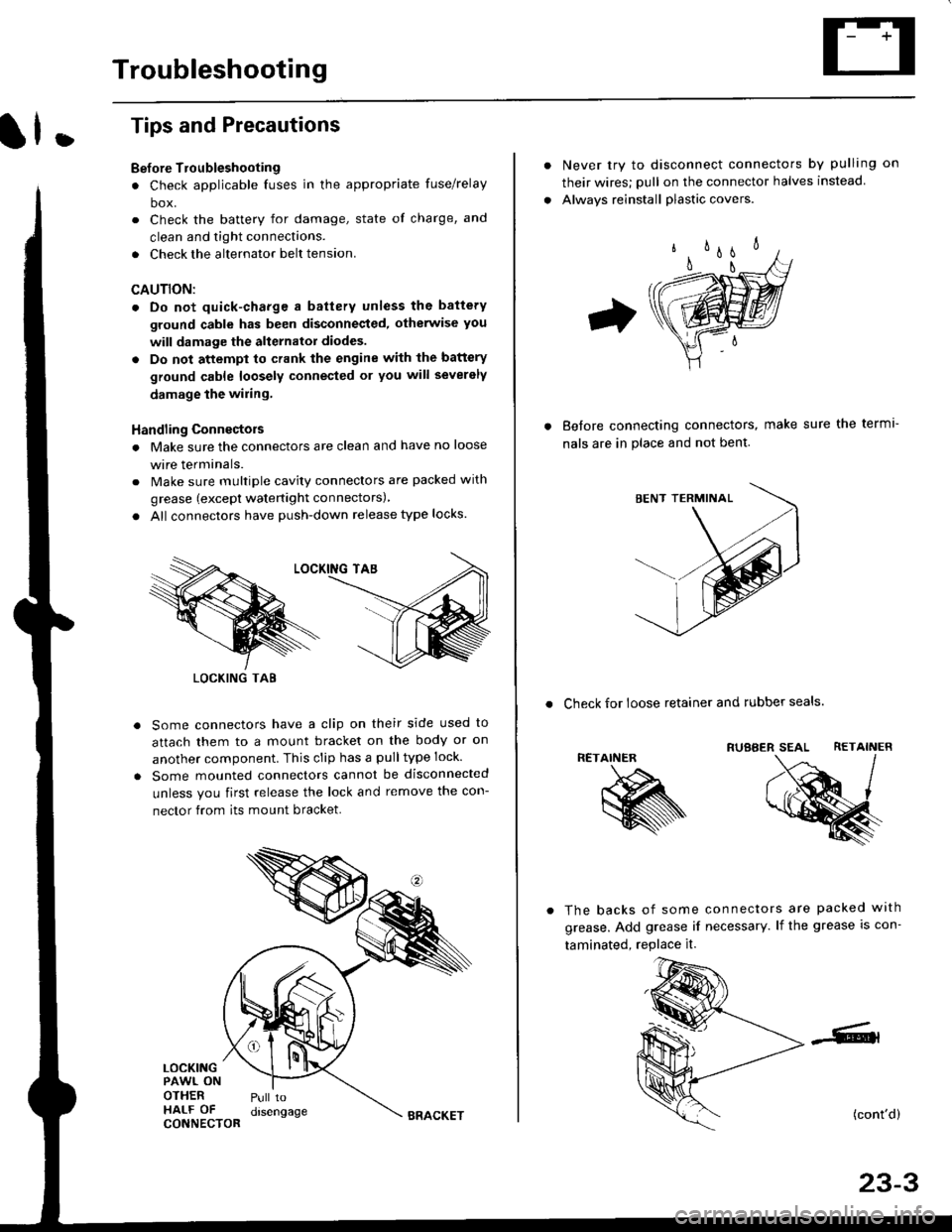

Handling Connectois

. Make sure the connectors are clean and have no loose

wire terminals.

. Make sure multiple cavity connectors are packed with

grease (except watertight connectors)

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pulltype lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFCONNECTOR

Pull todrsengage

LOCKING TAB

BRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead

Alwavs reinstall plastic covers.

Before connectang connectors,

nals are in place and not bent.

make sure the terml-

. Check for loose retainer and rubber seals.

RETAINER

The backs of some connectors are packed with

grease. Add grease if necessary. lf the grease is con-

taminated, replace it.

(cont'd)

23-3

Page 1474 of 2189

Troubleshooting

Tips and Precautions (cont'dl

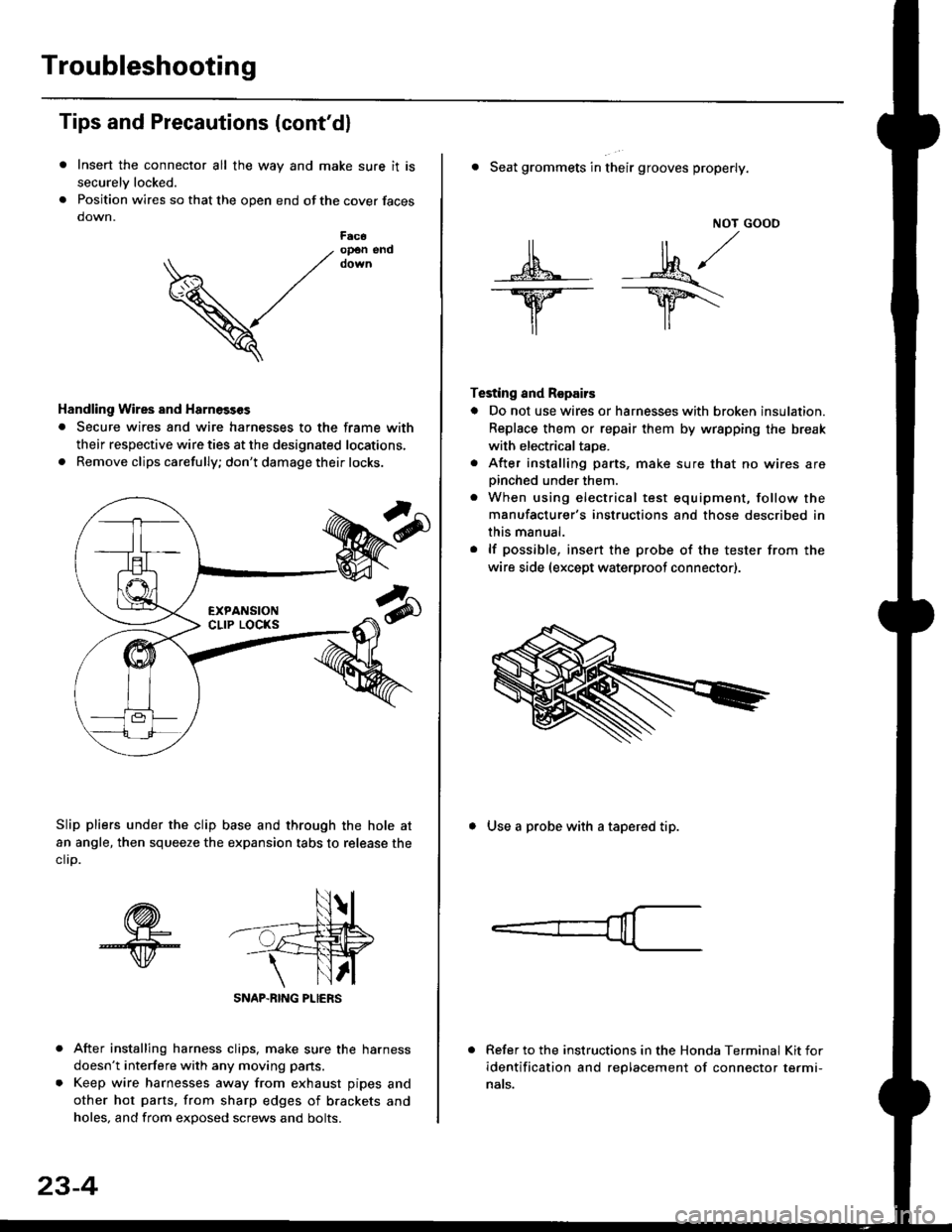

Insert the connector all the way and make sure it is

securelv locked.

Position wires so that the open end of the cover faces

down.

After installing harness clips, make sure the harness

doesn't interfere with any moving pans.

Keep wire harnesses away from exhaust pipes and

other hot parts. from sharp edges of brackets and

holes, and from exDosed screws and bolts.

V

F6c6op€n end

Handling Wires and Harnosscs

. Secure wires and wire harnesses to the frame with

their respective wire ties at the designated locations,

. Remove clips carefully; don't damage their locks.

Slip pliers under the clip base and through the hole at

an angle, then squeeze the expansion tabs to release the

clrp.

SNAP-BING PLIERS

23-4

NOT GOOO

ll il,/

s*' -.1}8."/_Y--_Y5\

il ,,

Testing and Repairs

o Do not use wires or harnesses with broken insulation.

Replace them or repair them by wrspping the break

with electricaltaoe.

. After installing parts, make sure that no wires arepinched under them.. When using electrical test equipment, follow the

manufacturer's instructions and those described in

this manual.

. lf possible, insert the probe of the tester from the

wire side (except waterproof connector).

. Seat grommets in their grooves properly.

. Use a probe with a tapered tip.

Refer to the instructions in the Honda Terminal Kit for

identification and replacement of connector termi-

nats.