pedal HONDA CIVIC 1997 6.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 975 of 2189

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not test stall sp€€d for mole than 10 seconds at a time.

. Do not shift the lsver whils raising the engine speod.

. Be sure lo remove the pressure gauge before tosting stall speed.

. Stall speed tssts should be used tor diagnostic purposes only,

1. Engage the parking brake, and block the tront wheels.

2. Connect a tachometer to the engine, and stan the engine.

3. Make sure the A/C switch is OFF.

4. After the engine has warmed up to normal operating temperature (the radiator fan comes on), shift into E position.

5. Fully depress the brake pedal and accelerator for 6 to 8 seconds, and note engine speed,

6. Allow two minutes for cooling, then repeat the test in E, E, and E positions.

Stall Speed BPM in E poshion:

Specification: 2,500 rpm

Servic€ Limit: 2,350 - 2.650 rpm

Stall Speed RPM in E, E and E positions:

Specitication: 3,000 rpm

Service Limit: 2,800 - 3,100 rpm

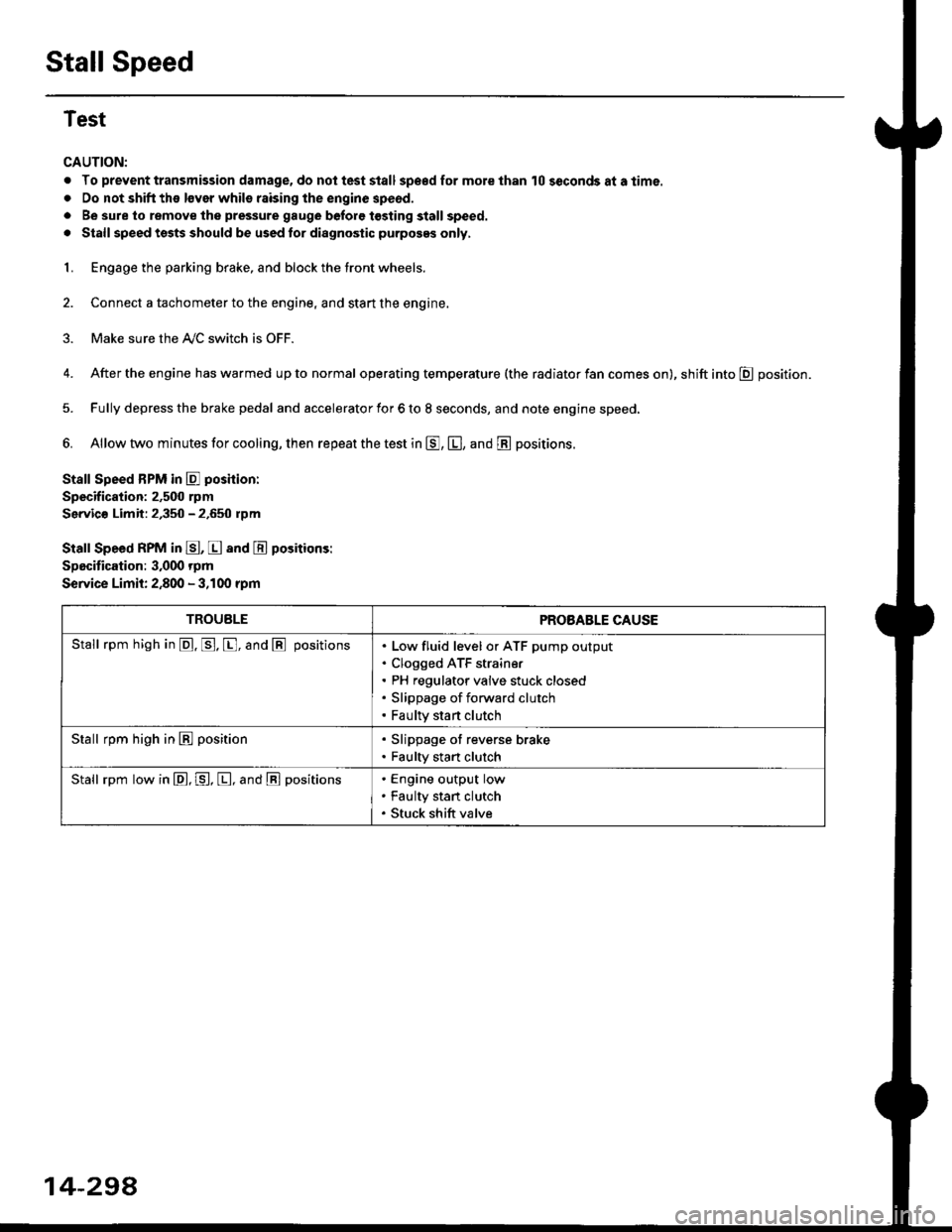

TROUBLEPROBABLE CAUSE

Stall rpm high in @. p. [, and @ positionsLow fluid level or ATF pump output

Clogged ATF strain€r

PH regulator valve stuck closed

Slippage of forward clutch

Faulty start clutch

Stall rpm high in E position. Slippage of reverse brake. Faulty start clutch

Stall rpm low in E, P, [, and @ positionsEngine output low

Faulty stan clutch

Stuck shift valve

14-294

Page 1155 of 2189

t

Conventional Brake

Speciaf Tools .............19'2

Component Locations

lndex ................ ...... 19-3

Inspection and Adiustment

Brake System Rubber Parts

and Brake Booster ...........,.,............. 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19-7

Front Brake Pads

Inspection and Replacement .......... 19-8

Front Erake Disc

Disc Runout Inspection ................... 19-12

Disc Thickness and Parallelism

Inspection .......... 19-12

Front Brake Caliper

Disassembly .......... 19'13

Reassembly ........... 19-16

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-21

Pushrod Clearance Adiustment ...... 19-22

Brake Booster Inspection ................ 19-23

Rear Brake Pads

Inspection and Replacement ,,........ 19-24

Rear Brake Disc

Disc Runout lnspection ................... 19-26

Disc Thickness and Parallelism

Inspection .......... 19-26

Rear Brake Caliper

Disassembly ...........19-27

Reassembly ........." 19-31

Rear Drum Brake

Index/lnspection .............................. 19-35

Inspection ....,.,....... 19-36

Brake Shoe Disassembly ..............." 19-37

Brake Shoe Reassembly ...............'.. 19-37

Brake Hoses/Lines

Inspection/Torque Specifications ..... 19-39

Hose Replacement ........................... 19-40

Parking Brake Cable

lnspection and Replacement ........,. 19-41

l-l

Page 1157 of 2189

Component Locations

I

lndex

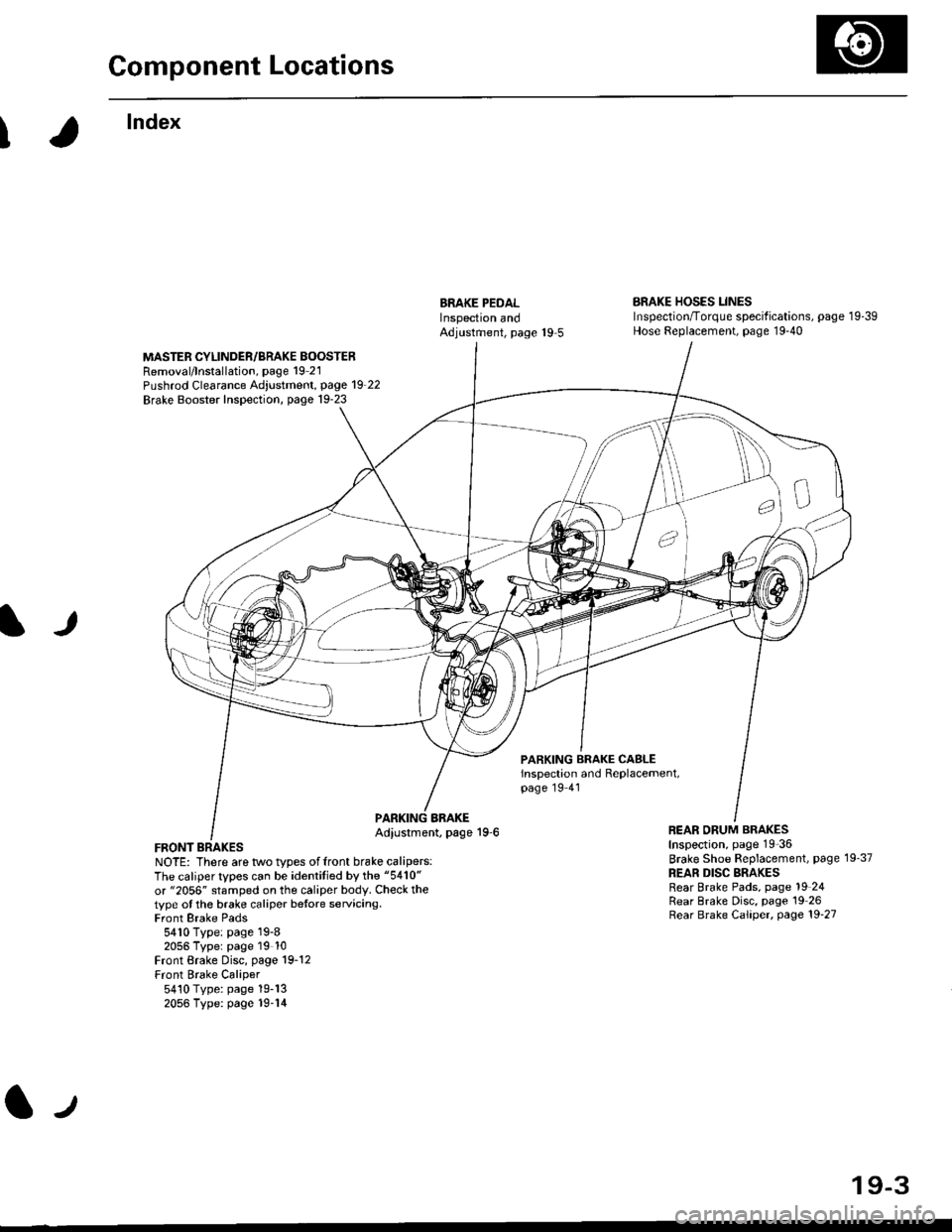

ERAKE PEDALInspectron andAdjustment, page 19 5

BRAKE HOSES LINESInspection/Torque specif ications, page 1 9-39Hose Replacement, page 19-40

MASTER CYLINDER/BRAKE BOOSTERRemoval/lnstallation, page 19 21Pushrod Clearance Adjustment, page 19_22

Brake Booster Inspection, page 19-23

lJ

PARKING BRAKE CASLEinspection and Replacement,page 19 41

FRONT BRAKESNOTE: There are two types offront brake calipers:The caliper types can be identitied by the "5410"

or "2056" stamped on the caliper body. Check thetype ot the brake caliper betore servicing.Front Brake Pads5410 Type: page 19-82056 Typer page 19 10Front Brake Disc, page 19-12Front Brake Caliper5410 Type: page 19-132056 Type: page 19-14

BBAKEAdiustment, page 19-6REAR ORUM BRAKESInspection, page 19-36

Brake Shoe Beplacement, page 19'37

REAR DISC BRAKESRear Brake Pads, page 19 24Rear Brake Disc, page 19 26Rear Brake Caliper, page 19'27

lJ

19-3

Page 1158 of 2189

Inspection and Adjustment

€)

@

@

@

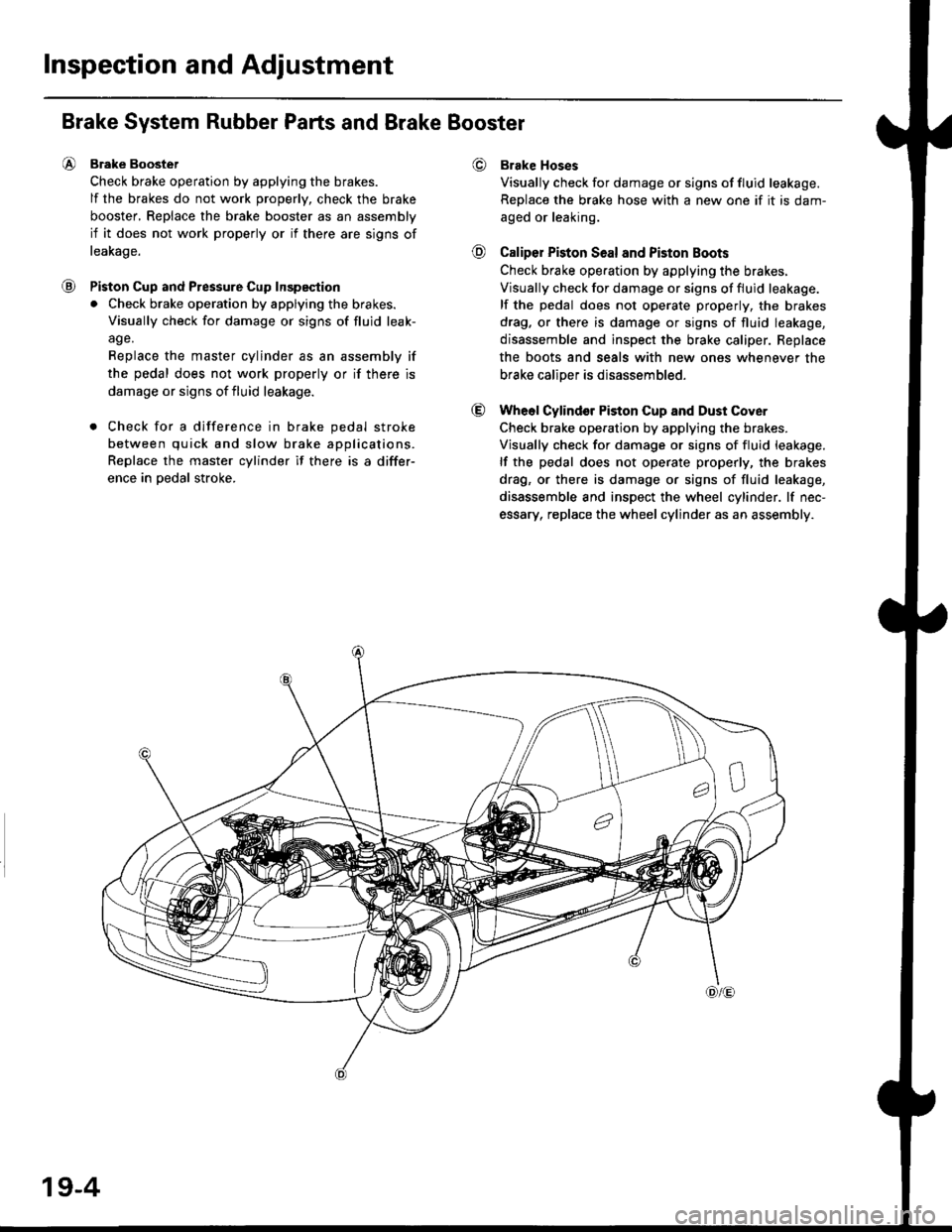

Brake System Rubber Parts and Brake Booster

Brake Boostet

Check brake operation by applying the brakes.

lf the brakes do not work properly, check the brake

booster, Replace the brake booster as an assembly

if it does not work properly or if there are signs of

leakage.

Piston Cup and Pressure Cup Inspeqtion

. Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leak-

age.

Replace the master cylinder as an assembly if

the pedal does not work properly or if there is

damage or signs of fluid leakage.

. Check for a difference in brake pedal stroke

between quick and slow brake applications.

Replace the master cylinder if there is a differ-

ence in oedal stroke.

Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is dam-

aged or leaking.

Caliper Piston Seal and Piston Boots

Check brake ope.ation by applying the brakes.

Visually check for damage or signs of fluid leakage.

lf the pedal does not operate properly, the brakes

drag. or there is damage or signs of fluid leakage,

disassemble and inspect the brake caliper. Replace

the boots and seals with new ones whenever the

brake caliDer is disassembled.

Wheol Cylindor Piston Cup and Dust Cover

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage.

lf the pedal does not operate properly, the brakes

drag, or there is damage or signs of fluid leakage,

disassemble and inspect the wheel cylinder. lf nec-

essary, replace the wheel cylinder as an assembly.

19-4

Page 1159 of 2189

)

Brake Pedal

Pedal Height

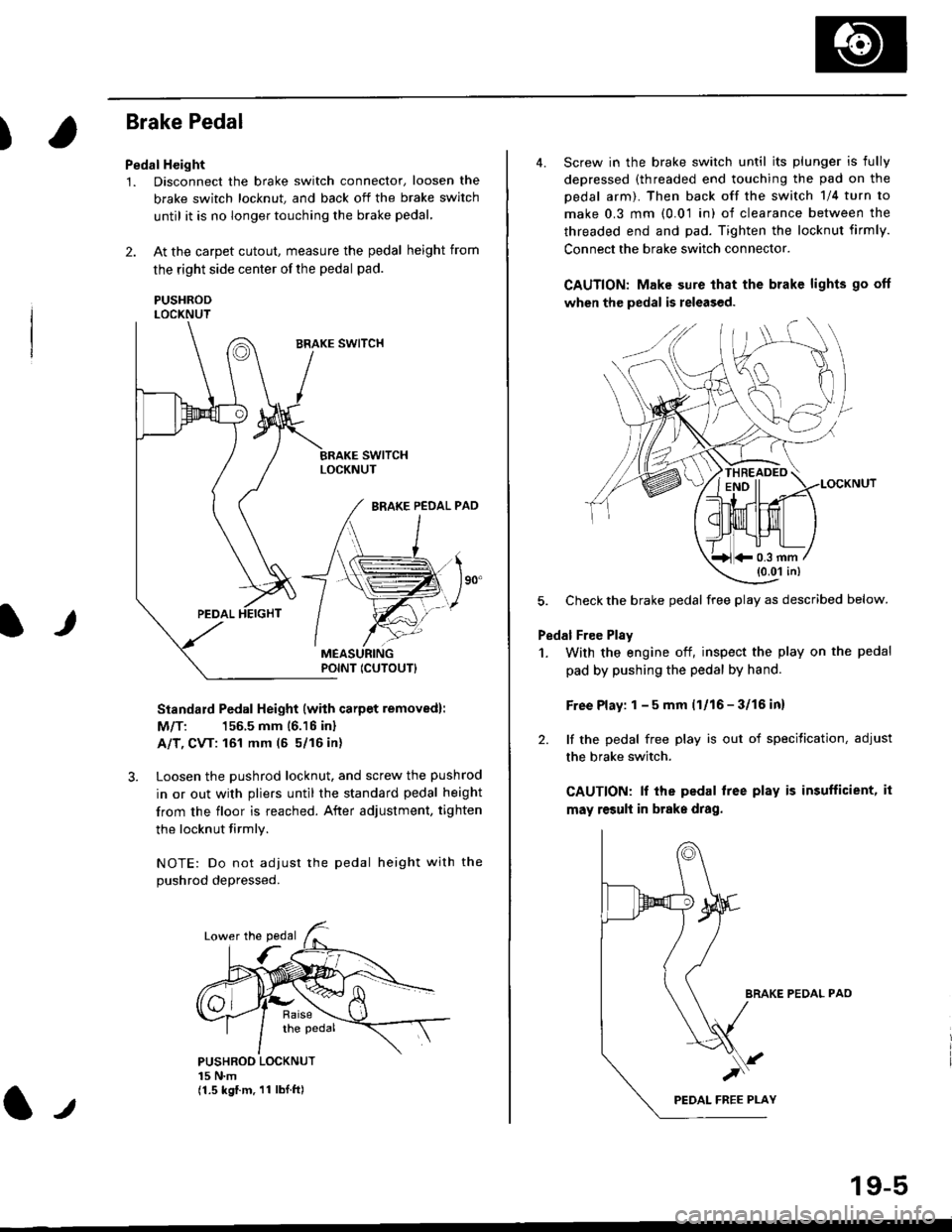

1. Disconnect the brake switch connector, loosen the

brake switch locknut, and back off the brake switch

until it is no longer touching the brake pedal,

2. At the carpet cutout, measure the pedal height from

the right side center of the pedal pad.

PUSHRODLOCKNUT

Standard Pedal Height (with carpet removed):

M/T: 156.5 mm 16.16 inl

A/T, CVT: 161 mm (5 5/16 in)

3. Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. After adjustment, tighten

the locknut firmly.

NOTE: Do not adiust the pedal height with the

Dushrod depressed.

It

PUSHROO LOCKNUT15 N.m(1.5 kgf.m. 11 lbI.ft)

POINT ICUTOUTI

4. Screw in the brake switch until its plunger is fully

depressed (threaded end touching the pad on the

pedal arm). Then back off the switch 1/4 turn to

make 0.3 mm (0.01 in) of clearance between the

threaded end and pad. Tighten the locknut firmly.

Connect the brake switch connector.

CAUTION: Make sure that the brake lights go off

when the pedal is released.

LOCKNUT

5. Check the brake pedal free play as described below.

Pedal Free Plsy

1. With the engine off, inspect the play on the pedal

pad by pushing the pedal by hand.

Free Play: 1 - 5 mm (1/16 - 3/16 inl

2. lf the pedal free play is out of specitication, adjust

the brake switch.

CAUTION: lf the pedal free play is insufficient, it

may result in brake drag.

BRAKE PEDAL PAO

)

19-5

*0.3 mm(0.01 in)

Page 1160 of 2189

Inspection and Adjustment

Parking Brake

Inspection

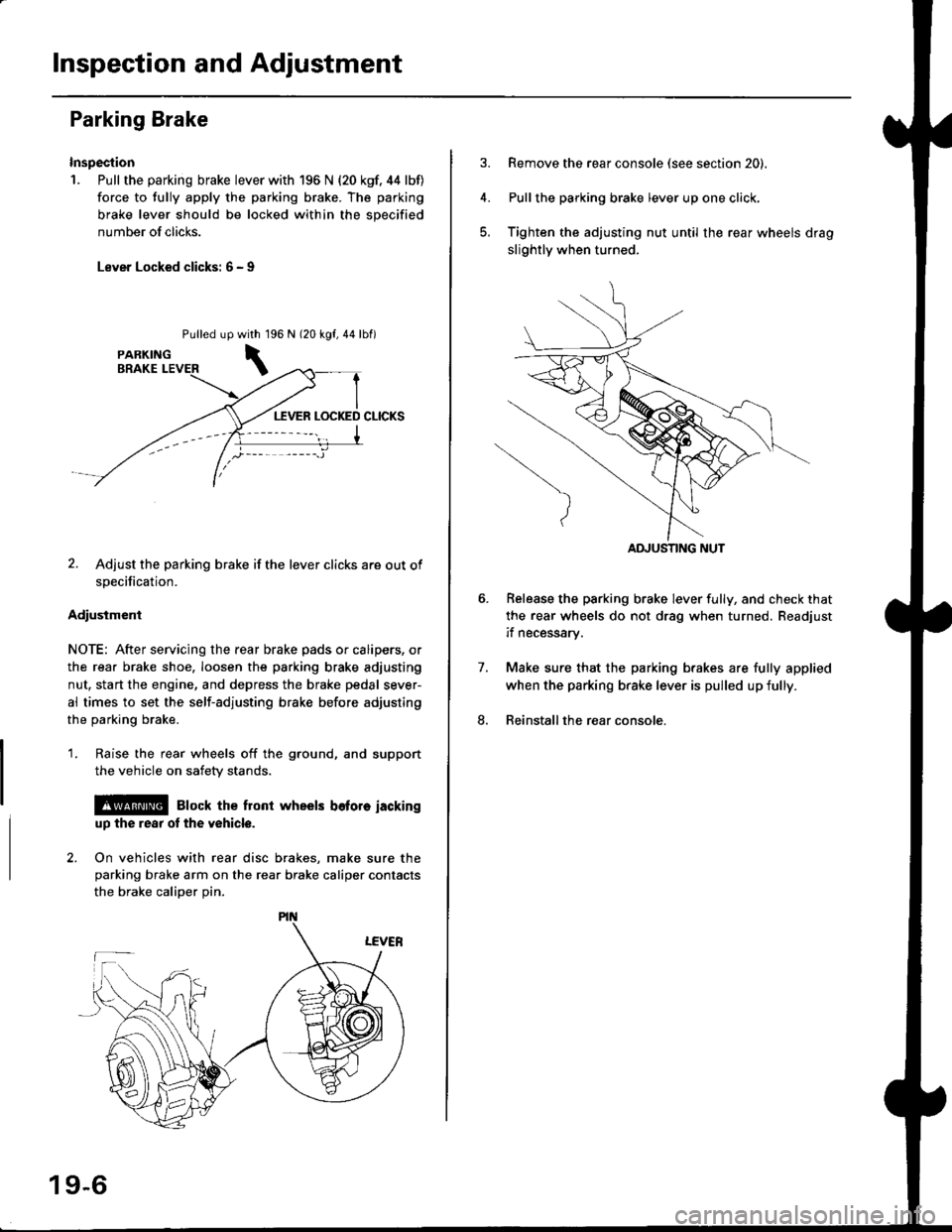

1. Pull the parking brake lever with 196 N {20 kgf. 44 lbf)

force to fully apply the parking brake. The parking

brake lever should be locked within the sDecified

number of clicks.

Lever Locked clicks: 6 - I

Pulled up96 N 120 kgf,44lbf)

2. Adjust the parking brake if the lever clicks are out of

specification.

Adiusiment

NOTE: After servicing the rear brake pads or calipers, or

the rear brake shoe, loosen the parking brake adjusting

nut, start the engine, and depress the brake pedal sever-

al times to set the self-adjusting brake before adjusting

the parking brake.

1. Raise the rear wheels off the ground, and support

the vehicle on safety stands.

l@ Elock the front wheels bofore iackinguD the rear ot the v6hicle.

2. On vehicles with rear disc brakes, make sure theparking brake arm on the rear brake caliper contacts

the brake calioer Din.

with 1

\

19-6

Remove the rear console (see section 20).

Pullthe parking brake lever up one click,

Tighten the adjusting nut until the rear wheels drag

slightly when turned.

Belease the parking brake lever fully, and check that

the rear wheels do not drag when turned. Readjust

if necessarv.

Make sure that the parking brakes are fully applied

when the parking brake lever is pulled up fully.

Reinstall the rear console.

7.

8.

ADJUSTING NUT

Page 1163 of 2189

)

It

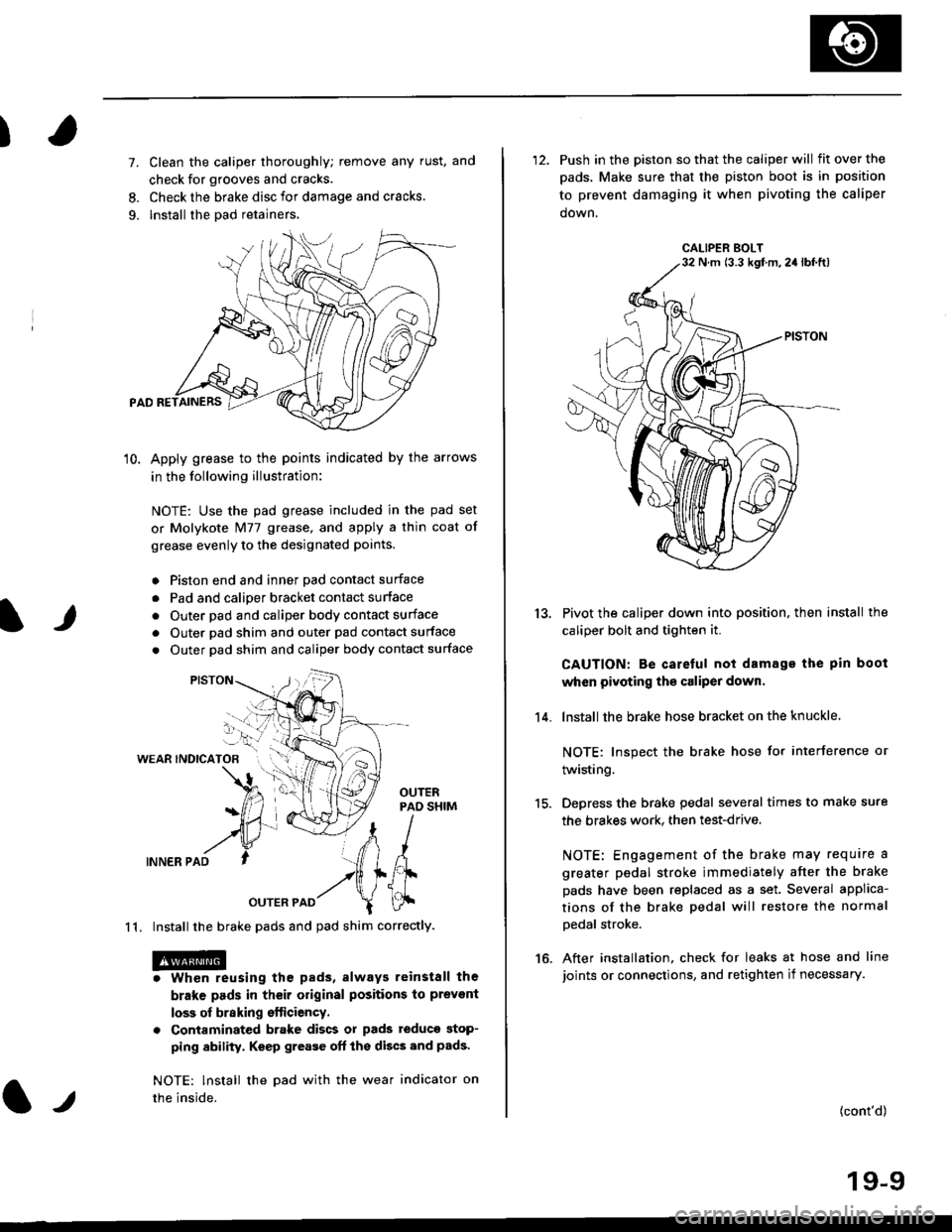

7. Clean the caliper thoroughly; remove any rust, and

check for grooves and cracks.

8. Check the brake disc for damage and cracks.

9. lnstall the pad retainers,

10. Apply grease to the points indicated by the arrows

in the following illustration:

NOTE: Use the pad grease included in the pad set

or Molykote Nl77 grease, and apply a thin coat of

grease evenly to the designated points.

o Piston end and inner Dad contact surface

. Pad and calioer bracket contact surface

. Outer pad and caliper body contact surface

. Outer pad shim and outer pad contact surface

. Outer pad shim and caliper body contact surface

WEAR INDICATOB

INNER PAD

OUTER PAD

1 1. Install the brake pads and pad shim correctly.

. Whon reusing the pads, always reinstall the

brake pads in their original positions to prevont

loss of braking efticiency.

. Contaminated brake discs or pads teduce stop-

ping ability. Keep grease oft the discs and pads'

NOTE: lnstall the Dad with the wear indicator on

the inside.l.t

'12. Push in the piston so that the caliper will fitoverthe

pads, Make sure that the piston boot is in position

to prevent damaging it when pivoting the caliper

down.

Pivot the caliper down into position, then install the

caliper bolt and tighten it.

CAUTION: Be caretul not damage the pin boot

when pivoting the caliper dowr.

lnstall the brake hose bracket on the knuckle

NOTE: Inspect the brake hose for interference or

twisting.

Depress the brake pedal several times to make sure

the brakes work. then test-drive.

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions of the brake pedal will restore the normal

Dedal stroke.

After installation. check for leaks at hose and line

joints or connections, and retighten if necessary.

13.

14.

15.

16.

(cont'd)

19-9

CALIPER BOLTN m (3.3 kgf m,2a lbf.ft)

Page 1165 of 2189

)

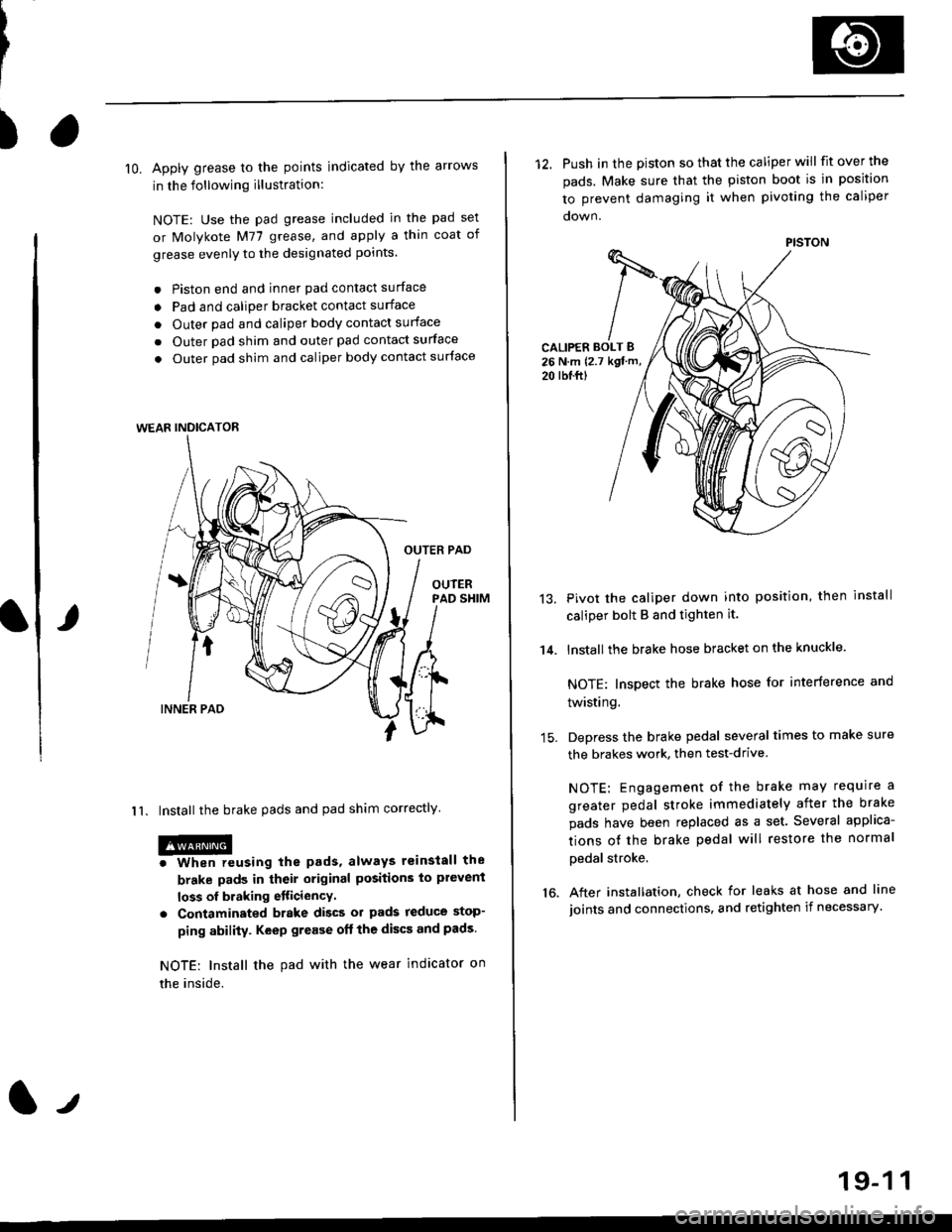

lO. Apply grease to the points indicated by the arrows

in the following illustration:

NOTE: Use the pad grease included in the pad set

or Molykote M77 grease, and apply a thin coat of

grease evenly to the designated points.

. Piston end and inner pad contact surface

o Pad and caliper bracket contact surface

. Outer pad and caliper body contact surface

. Outer pad shim and outer pad contact surface

. Outer pad shim and caliper body contact surface

OUTER PAD

OUIERPAD SHIM

I 1. Install the brake pads and pad shim correctly

@o When reusing the pads, always reinstall the

brake pads in their original positions to plevent

loss of braking etticiencY.

. Contaminated brake discs ol pads reduce stop-

ping ability. Keep grease oft the discs and pads.

NOTE: Install the pad with the wear indicator on

the inside.

WEAR INDICATOR

12. Push in the piston so that the caliper will fit over the

pads. Make sure that the piston boot is in position

to prevent damaging it when pivoting the caliper

CALIPER BOLT B26 N.m {2.7 kgt m,

20 rbl.ftl

14.

13.Pivot the caliper down into position, then install

caliper bolt B and tighten it.

lnstallthe brake hose bracket on the knuckle.

NOTE: Inspect the brake hose for interference and

twisting.

Depress the brake pedal several times to make sure

the brakes work, then test-drive

NOTE: Engagement of the brake may require a

greater pedal stroke immediately after the brake

pads have been replaced as a set. Several applica-

tions ot the brake pedal will restore the normal

pedal stroke.

After installation, check for leaks at hose and line

joints and connections, and retighten if necessary.16.

PISTON

19-1 1

Page 1175 of 2189

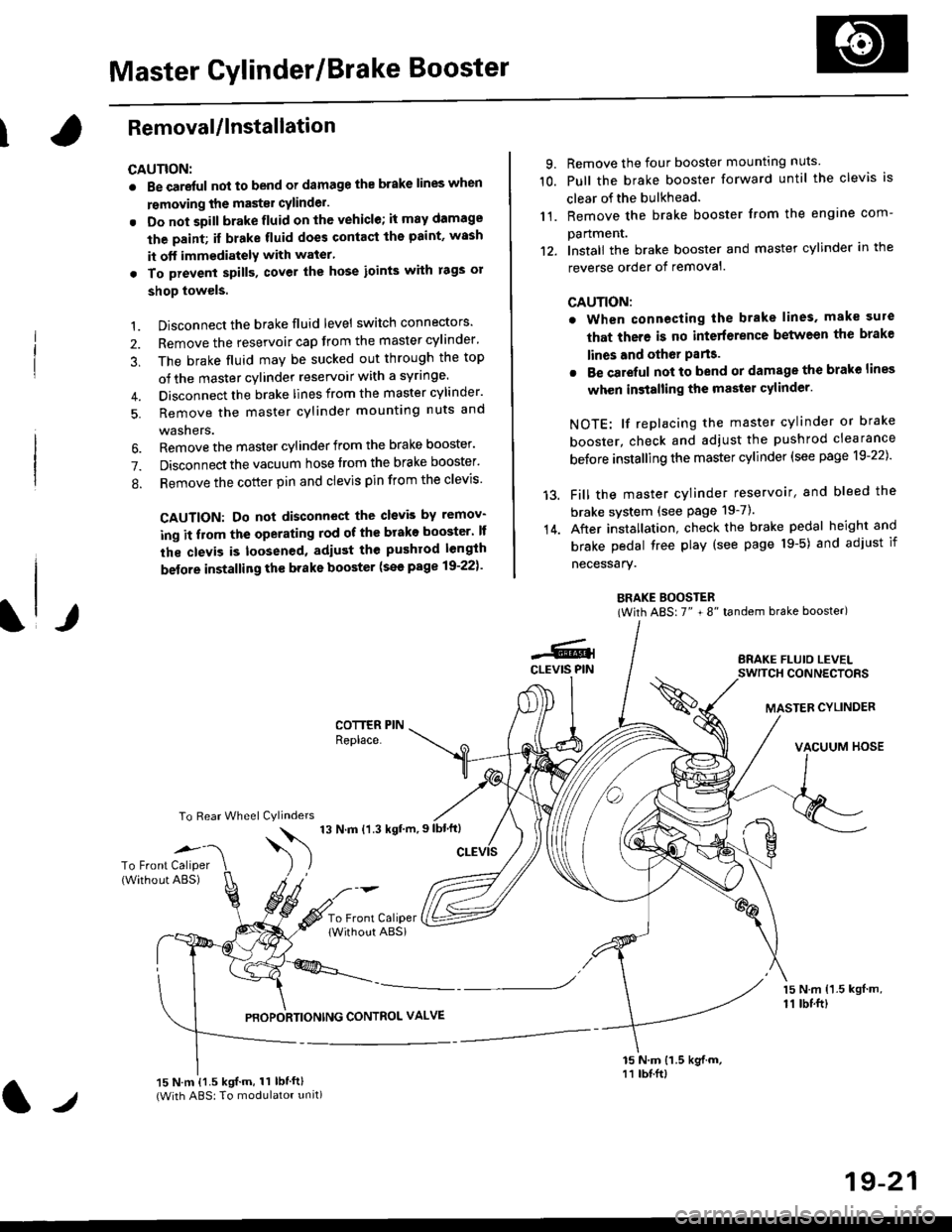

Master Cylinder/Brake Booster

IRemovaUlnstallation

CAUTION:

. Be care{ul nol to bend or damage the brake lines when

rsmoving the mastsr cYlinder.

. Do not soill brakefluid on the vehicle; it may damage

the paint; if brake fluid does contact the paint, wssh

it off immediatelY with water'

. To prevent spill3, cover the hose ioints with rags or

shop towels.

9. Remove the four booster mountlng nuts

10. Pull the brake booster forward until the clevis is

clear of the bulkhead.

11. Remove the brake booster from the engine com-

panmenr.'12. Install the brake booster and master cylinder in the

reverse order of removal.

CAUTION:

. When connecting the brake lines. make sure

that there is no inte erence between the brake

lines and oth6r Parts.

r Be careful not to bend or damage the brake lines

when installing the master cylinder.

NOTE: lf replacing the master cylinder or brake

booster, check and adiust the pushrod clearance

be{ore installing the master cylinder (see page 19-221'

Fill the master cylinder reservoir, and bleed the

brake svstem (see Page 19-7).

After installation. check the brake pedal height and

brake pedal tree play (see page l9-5) and adjust if

necessary.

BRAKE BOOSTER(With ABS: 7" + 8" tandem brake booster)

BRAKE FLUIO LEVELSWITCH CONNECTORS

MASTER CYLINDER

VACUUM HOSE

1.

2.

3,

5.

Disconnect the brake fluid level switch connectors'

Remove the reservoir cap from the master cylinder'

The brake fluid may be sucked out through the top

of the master cylinder reservoir with a syrlnge.

Disconnect the brake lines from the master cylinder'

Remove the master cylinder mounting nuts and

washers.

\l/

6. Remove the master cylinder from the brake booster'

7. Disconnect the vacuum hose trom the brake booster'

8. Remove the cotter pin and clevis pin from the clevis'

CAUTION: Do not disconnect the clevb by remov-

ing it from the operating rod of the brako booster' lf

the clevis is loosened, adiust the pushrod length

before installing th€ brake booster (see page 19-221'

COTTER PINReplace.

To Rear Wheel Cylinders

14.

-6.4CLEVIS PIN

To Front Caliper(Without ABS)$

t'N't'ttrnt'-''

To Front CaliperlWithout ABSi

PBOPORTIONING CONTROL VALVE

15 N.m {1.5 kgl m,11 tbtft)

15 N.m {1.5 kgif.m, 11 lbtft}(With ABS: To modulator unit)lr

19-21

Page 1177 of 2189

Brake Booster InsPection

FunctionalTest

1. With the engine stopped, depress the brake pedal

several times to deplete the vacuum reservoir, then

depress the pedal hard and hold it for 15 seconds lf

the pedal sinks' either the master cYlinder is

bypassing internally, or the brake system (master

cylinder. lines. modulator, proportioning control

valve, or caliPer) is ieaking.

2. Start the engine with the pedal depressed lf the

pedal sinks slightly, the vacuum booster is operating

normally. lf the pedal height does not vary, the

booster or check valve is faultY.

3. With the engine running. depress the brake pedal

lightly. Apply just enough pressure to hold back

automatic transmission creep. lf the brake pedal

sinks more than 25 mm (1.0 in.) in three minutes,

the master cvlinder is faulty. A slight change in

pedal height when the A'lC compressor cycles on

and off if normal. (The A/C compressor load

changes the vacuum available to the booster')

Leak Test

1. Depress the brake pedal with the engine running.

then stop the engine. lf the pedal height does not

vary while depressed for 30 seconds, the vacuum

booster is OK. lf the pedal rises. the booster is

faulty.

2, With the engine stopped, depress the brake pedal

several times using normal pressure When the

Dedal is first depressed, it should be low On con-

secutive applications, the pedal height should grad-

uallv rise. lf the pedal position does not vary, checK

the booster check valve.

l./

19-23

Booster Check Valve Test

1. Disconnect the brake booster vacuum hose at the

booster.

2. Stan the engine and let it idle. There should be vac-

uum. lf no vacuum is available, the check valve is

not working properly. Replace the brake booster

vacuum hose and check valve, and retest.

BRAKE BOOSTERVACUUM HOSE(Check valve

built-in)