Disc HONDA CIVIC 1997 6.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 1805 of 2189

Airbag

)Replacement

After a collision in which the airbags were deployed' the

airbag assemblies and the SRS unit must be replaced'

!!!@ Store a removed airbag with the pad sur'

iFup. rr trt" airbag is improperly stored face down'

accidental deployment could propel the unit with

enough force to cause serious iniury'

CAUTION:

. Always disconnsct lhe airbag conn€ctor(s) when the

harness is disconnected.

. Do not disassemble or tamper with the ailbag'

NOTE:

. Do not install used SRS parts from another vehicle'

When repairing, use only new SRS parts'

o Carefully inspect the airbag before you install it Do

not insiall an airbag that shows signs oI being

dropped or improperly handled, such as dents' cracks

or deformation.

1. Disconnect the battery negative cable' then discon-

nect the positive cable from the battery' and wait at

least three minutes

2. Disconnect the airbag connector(s):

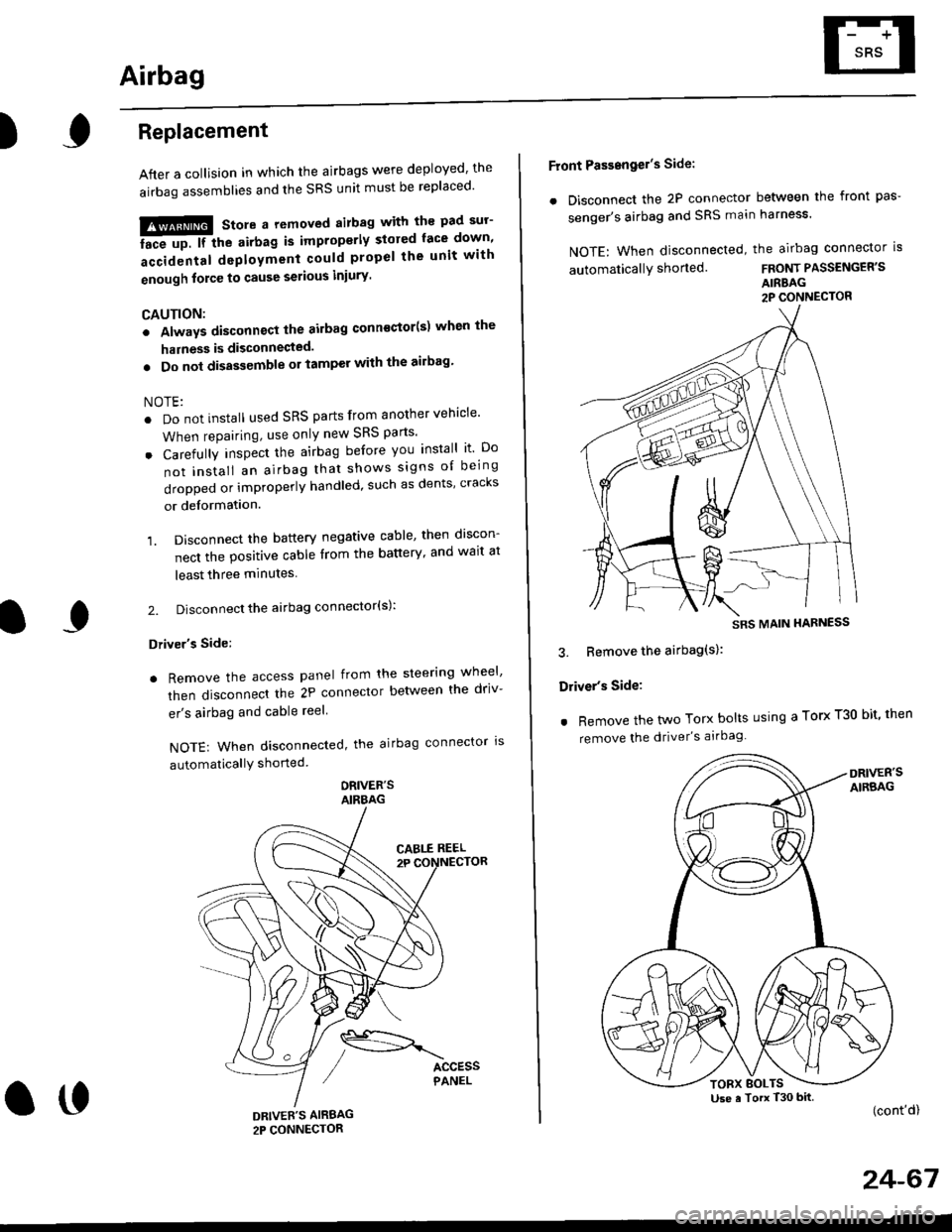

Driver's Side:

. Remove the access panel from the steering wheel'

then disconnecl the 2P connector betlveen the driv-

er's airbag and cable reel

NOTE: When disconnected, the airbag connector ls

automaticallY shorted

ORIVER'SAIRBAG

DRIVEE'S AIRBAG2P CONNECTOR

oo

Front Passengel's Side:

. Disconnect the 2P connector between the front pas-

senger's airbag and SRS main harness'

NOTE: When disconnected, the airbag connector is

automaticallY shorted.FRONT PASSENGER'S

AIRBAG2P CONNECTOR

3. Bemove the airbag(s):

Driver's Side:

. Remove the two Torx bolts using a Torx T30 bit' then

remove the driver's airbag

(cont'd)

24-67

SRS MAIN HARNESS

Use a Torx T30 bitTORX BOLTS

Page 1808 of 2189

Airbag

Disposal

Before scrapping any airbags (including those in a wholevehicle to be scrapped), the airbags must be deployed. lfthe vehicle is still within the warranty period, before youdeploy the airbags, the Honda District Service Managermust give approval and/or special instructions. Onlv afterthe airbags have been deployed (as the result of vehiclecollision, for example), can they be scrapped.lf the airbags appear intact (not deployed). treat themwith extreme caution.

Follow this p.ocedure:

Deploying the Airbags: In.vehiclo

NOTE: lf an SRS vehicle is to be entirely scrapped, itsairbags should be deployed while still in the vehicle. Theairbags should not be considered as salvageable partsand should never be installed in another veh;cle.

!@ confirm thst oach airbag assembty issecurely mounted; otharwiso. sev€re personal iniurycould result lrom deployment.

1. Disconnect the baftery negative cable, then discon_nect the positive cable.

2. Confirm that the special tool is functioning properlyby following the check procedure on the tool labelor on page 24-'l'l .

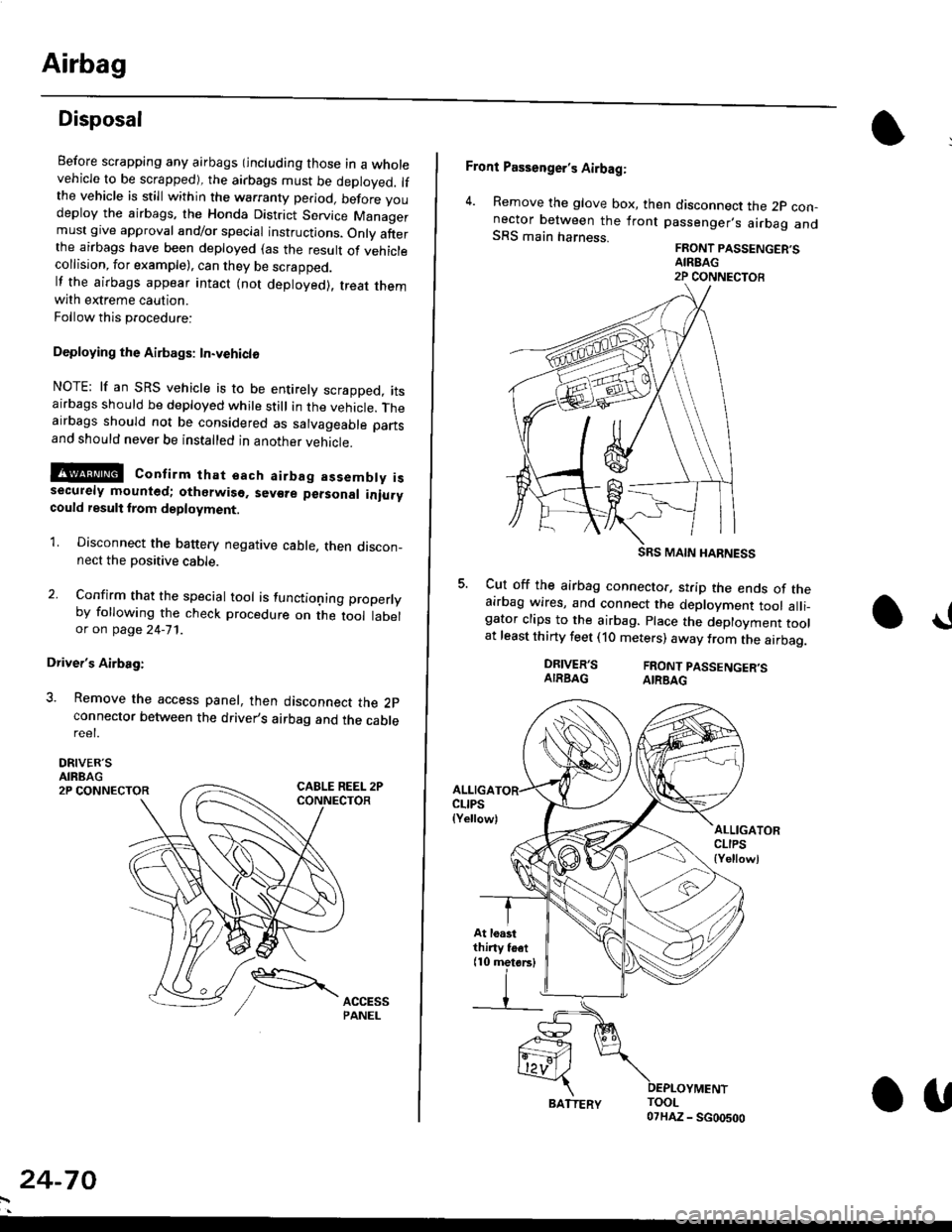

Driver's Airbag:

3. Remove the access panel, then disconnect the 2pconnector between the driver,s airbag and the cablereet.

DRIVER'SAIRBAG2P CONNECTOR

24-70

BATTERY.U

Front Passenger's Airbag:

4. Remove the glove box, then disconnect the 2p con-nector between the lront passenger,s airbag andSRS main harness.FRONT PASSENGER'SAIREAG2P CONNECTOB

SRS MAIN HARNESS

Cut off the airbag connector, strip the ends of theairbag wires, and connect the deployment tool alli_gator clips to the airbag. place the deployment toolat least thirty feet (10 meters) away from the airbag.

a!

DRIVER'SAIRBAGFRONT PASSENGER'SAIRBAG

ALLIGACLIPS(Yellow)ALLIGATORCLIPS{Yellowl

At loastthiny toet(10 metorsl

Page 1809 of 2189

E-

)I

Connect a 12 volt battery to the tool:

. lf the green light on the tool comes on, the aar-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

. lf the red light on the tool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploY (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on. continue with this procedure.

. l{ an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

!!@ During doployment, the airbag sssom'

bly can become hot enough to buln you. Wait thir'

ty minutes aftsr deployment belore touching tho

assembly.

Dispose of the complete airbag assembly. No part

of it can be reused. Place it in a sturdy plastic bag,

and seal it securelY,

CAUTION:

. Wear a fsce shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

wat6r after handling. deployed airbag.

t('

24-71

7.

AIRAAG

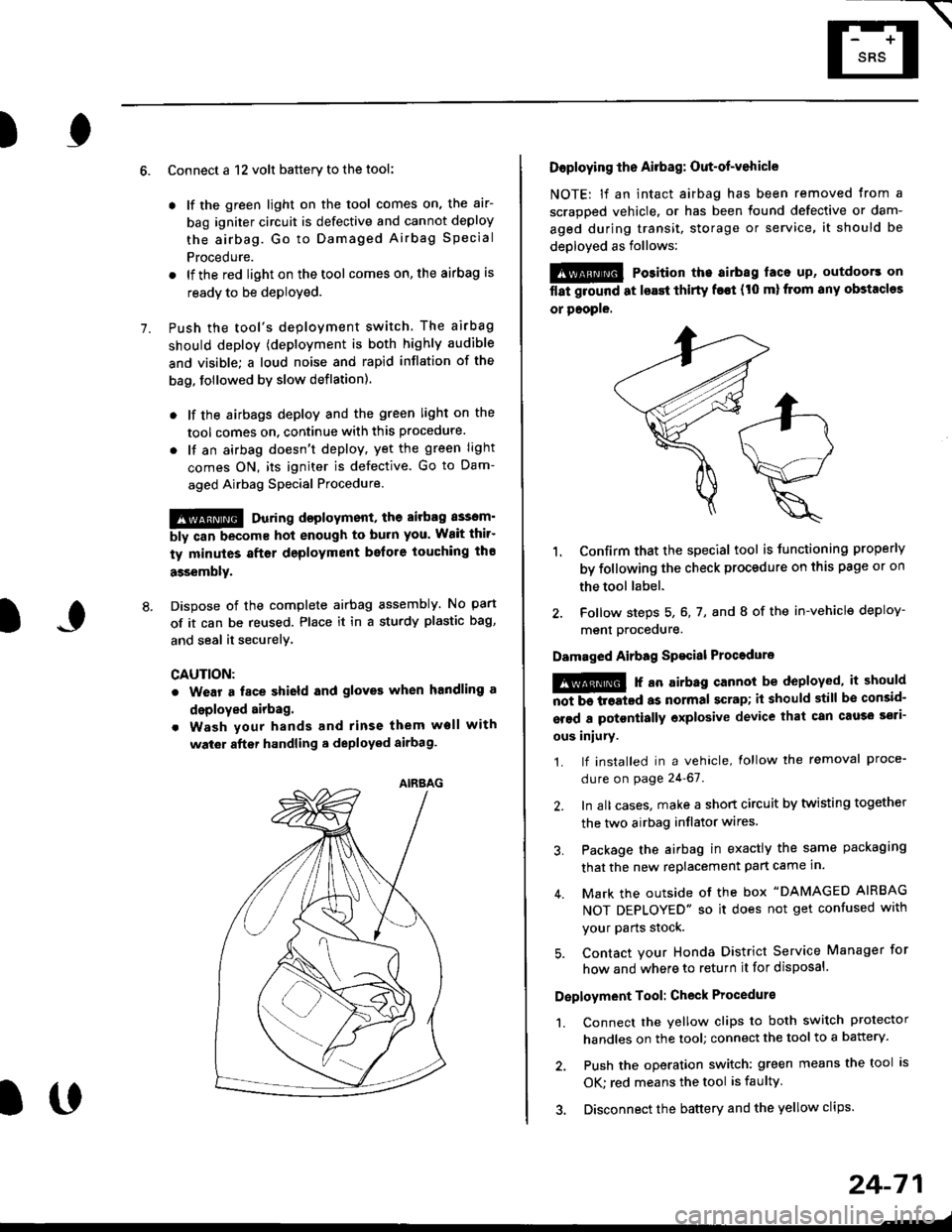

Doploying th6 Airbag: Out-of-vehicle

NOTE: lf an intact airbag has been removed from a

scrapped vehicle. or has been found defective or dam-

aged during transit, storage or service, it should be

deployed as follows:

@ Po3ition the airbag laca up, outdoors on

flat ground at lsast thirty f€€t (t0 ml from any obstacles

or people.

1. Confirm that the special tool is tunctioning properly

by following the check procedure on this page or on

the tool label.

2. Follow steps 5, 6, 7, and I of the in-vehicle deploy-

menl Drocequre.

Damaged Airbag Spacial Procedure

!@ r an airb.g cannot be deployed, it should

iiiTi-treatcd as normal scrap; il should still be consid-

srsd a potontially oxplosive device that can cau3o ssti-

ous iniury.

1. lf installed in a vehicle, lollow the removal proce-

dure on page 24-67.

2. In all cases. make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new replacement part came in.

4. Mark the outside of the box "DAMAGED AIRBAG

NOT DEPLOYED" so it does not get confused with

your Parts stock.

5. Contact your Honda District Service Manager for

how and where to return it for disposal.

Deployment Tool: Check Procedur€

1. Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

2. Push the operation switch: green means the tool is

OK: red means the tool is faulty

3. Disconnect the battery and the yellow clips.

Page 1810 of 2189

Gable Reel

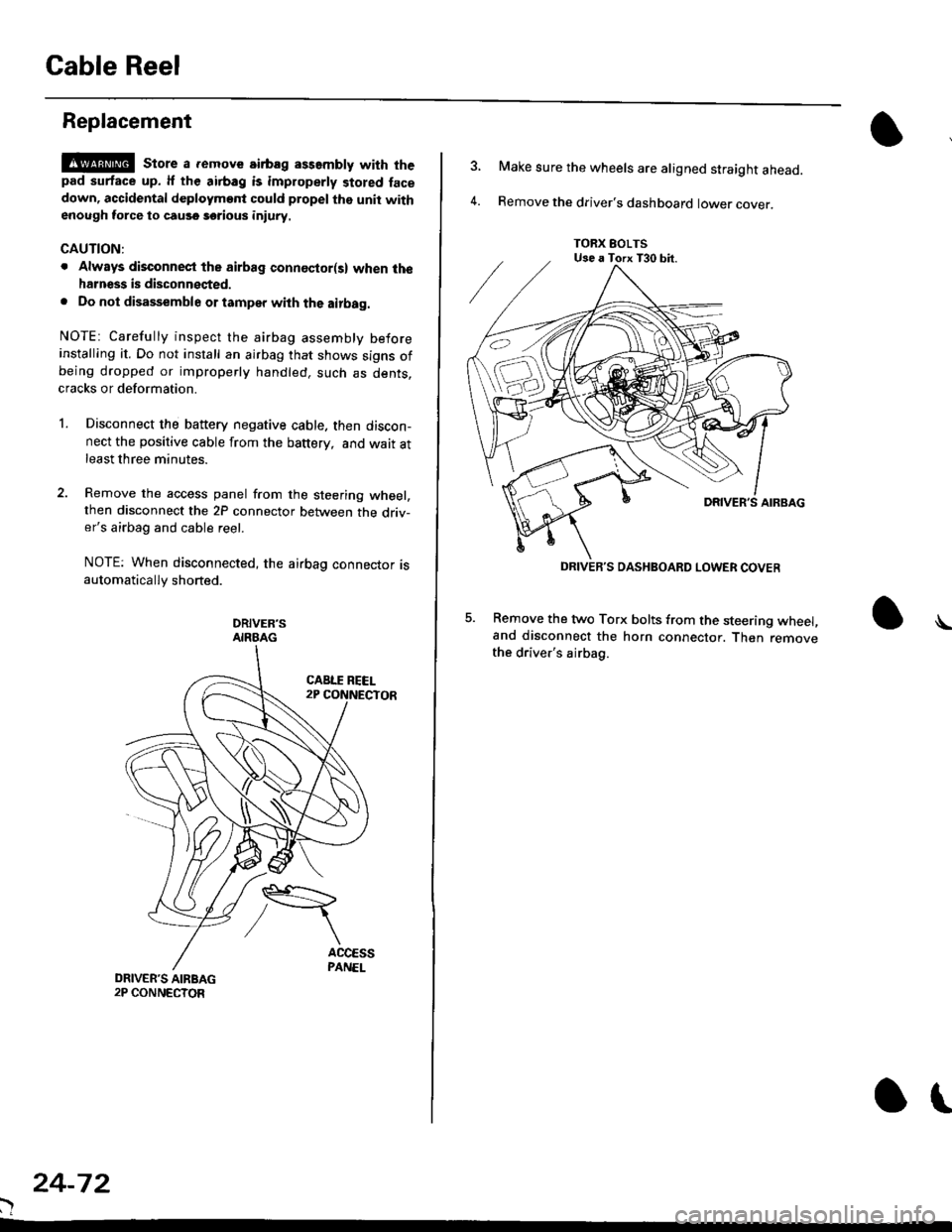

Replacement

!@@ store a .emove airbag assambly with thepad surtace up. lf the airbag is improperly stored face

down, accidental deploymont could propel the unit withenough force to cause sorious iniury.

CAUTION:

. Alwsys disconnect the airbag connoctor(s) when ih€harness is disconngcted.

. Do not disassemble or tamper with the airbag.

NOTE: Carefully inspect the airbag assembly beforeinstalling it. Do not install an airbag that shows signs ofbeing dropped or improperly handled. such as dents,cracks or deformation.

l.Disconnect the battery negative cable. then discon-nect the positive cable from the battery, and wait atleast three minutes.

Remove the access panel from the steering wheel,then disconnect the 2P connector between the driv-er's airbag and cable reel.

NOTE: When disconnected, the airbag connector isautomatically shorted.

DRIVER'SAIRBAG

)

24-72

or

TORX EOLTSUse a Torx T30 bit.

DRIVEB'S DASHBOARD LOWER COVER

4.

Make sure the wheels are aligned straight ahead.

Remove the driver's dashboard lower cover.

5. Remove the two Torx bolts from the steering wheel,and disconnect the horn connector. Then removethe driver's airbag.

\

Page 1811 of 2189

\

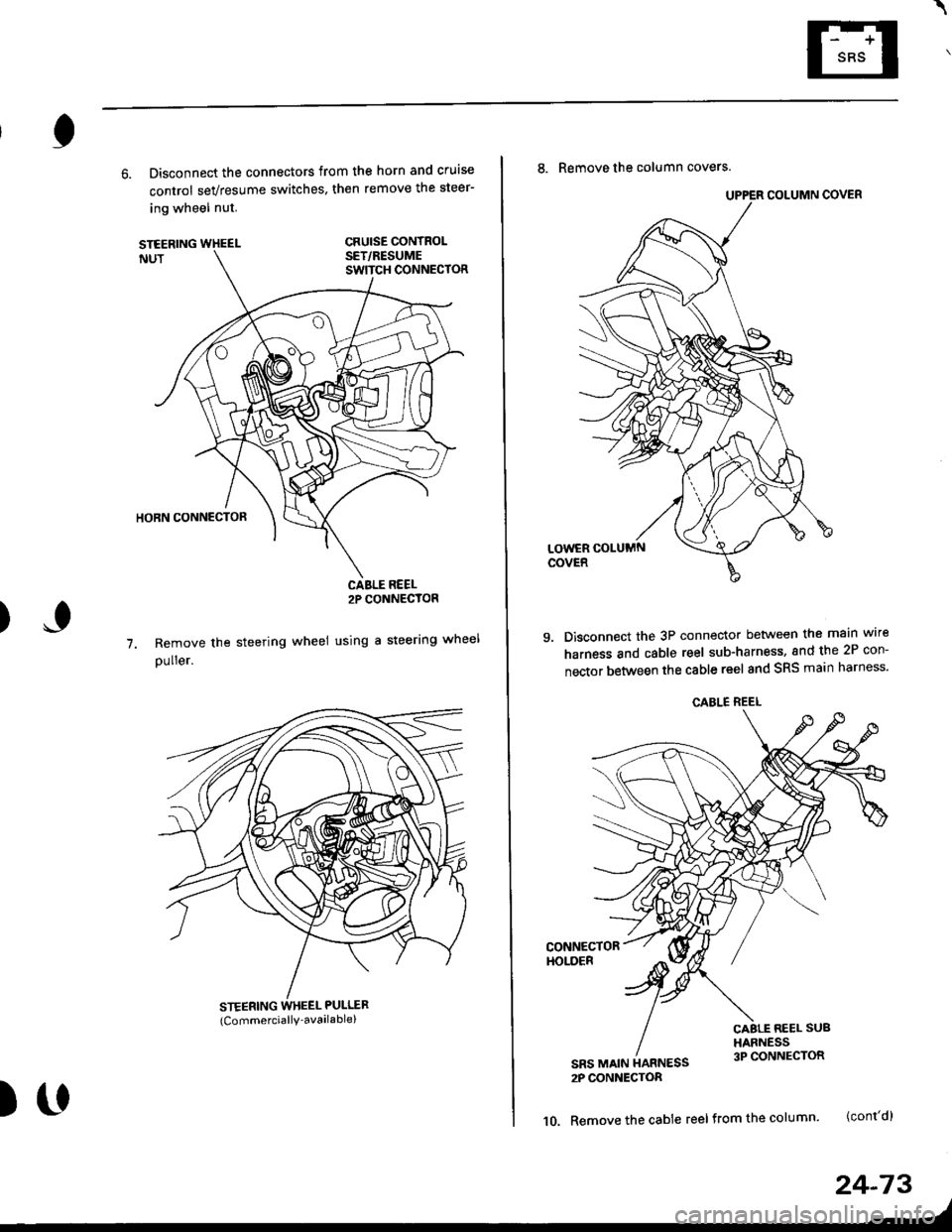

6. Disconnect the connectors from the horn and cruise

control sevresume switches, then remove the steer-

ing wheel nut.

STEERINGNUT

CRUISE CONTROLSET/RESUMESWITCH CONNECTOR

)

HORN CONNECTOR

Remove the steerlng

pulrer.

CABLE REEL2P CONNECYOR

wheel using a steering wheel7.

STEERING WHEEL PULLEF

{Commerciallv_available)

)U

8. Remove the column covers.

Disconnect the 3P connector between the main wire

harness and cable reel sub-harness, 8nd the 2P con-

nector between the cable reel and SRS main harness'

CONNECTORHOLOER

SRS MAIN HARNESS2P CONNECTON

CABLE REEL SUBHARNESS3P CONNECTOR

10. Remove the cable reel from the column {cont'd}

24,73

--/

CABLE REEL

Page 1814 of 2189

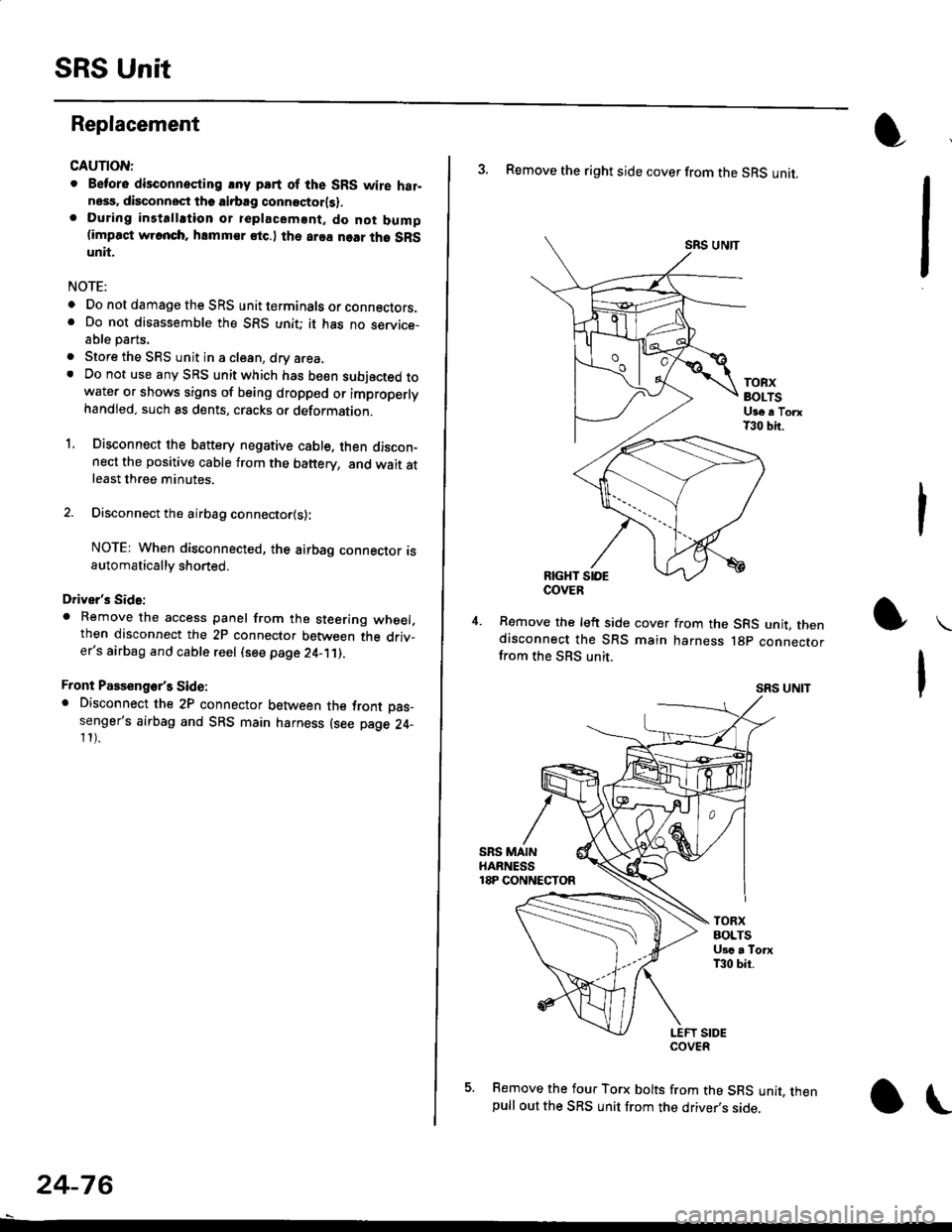

SRS Unit

Replacement

CAUTION:

. Betore disconnoqting lny pErt of the SRS wire hal-ness, disconnect th9 airbag conn"ctorlsl.. During installltion or teplacemsnt. do not bump(impact w.cnch, hamm€r stc.l the area noar tho SRSunit.

NOTE:

o Do not damage the SRS unit terminals or connectors.. Do not disassemble the SRS unit; it has no service-able parts,

. Store the SRS unit in a clean, dry a.ea,. Do not use any SRS unit which has be€n subjected towater or shows signs of being dropped or improperlyhandled. such 8s dents, cracks or deformation.

1. Disconnect the bsttery negative cable. then discon-nect the positive cable from the battery, and wait atleast three minutes.

2. Disconnect the airbag connector{s}:

NOTE: When disconnected, the airbag connector isautomatically shorted,

Driver's Side:

. Remove the access panel from the steering wheel.then disconnect the 2P connector between the driv_er's airbag and cable reel (see page 24-11).

Front Passenge/s Side:. Disconnect the 2P connector between the tront oas_senger's airbag and SRS main harness (see page 24-11).

24-76

o\

3. Remove the right side cover from the SRS unit.

SRS UNTT

TOBXBOLTSUge a TorxT30 bit.

RIGHT SIOE

Remove the left side cover from the SRS unit, thendisconnect the SRS main harness lgp connectorfrom the SBS unit.

SRS UNIT

5. Remove the four Torx bolts from the SRS unit, thenpull out the SRS unit from the driver,s side,

COVER

Page 1828 of 2189

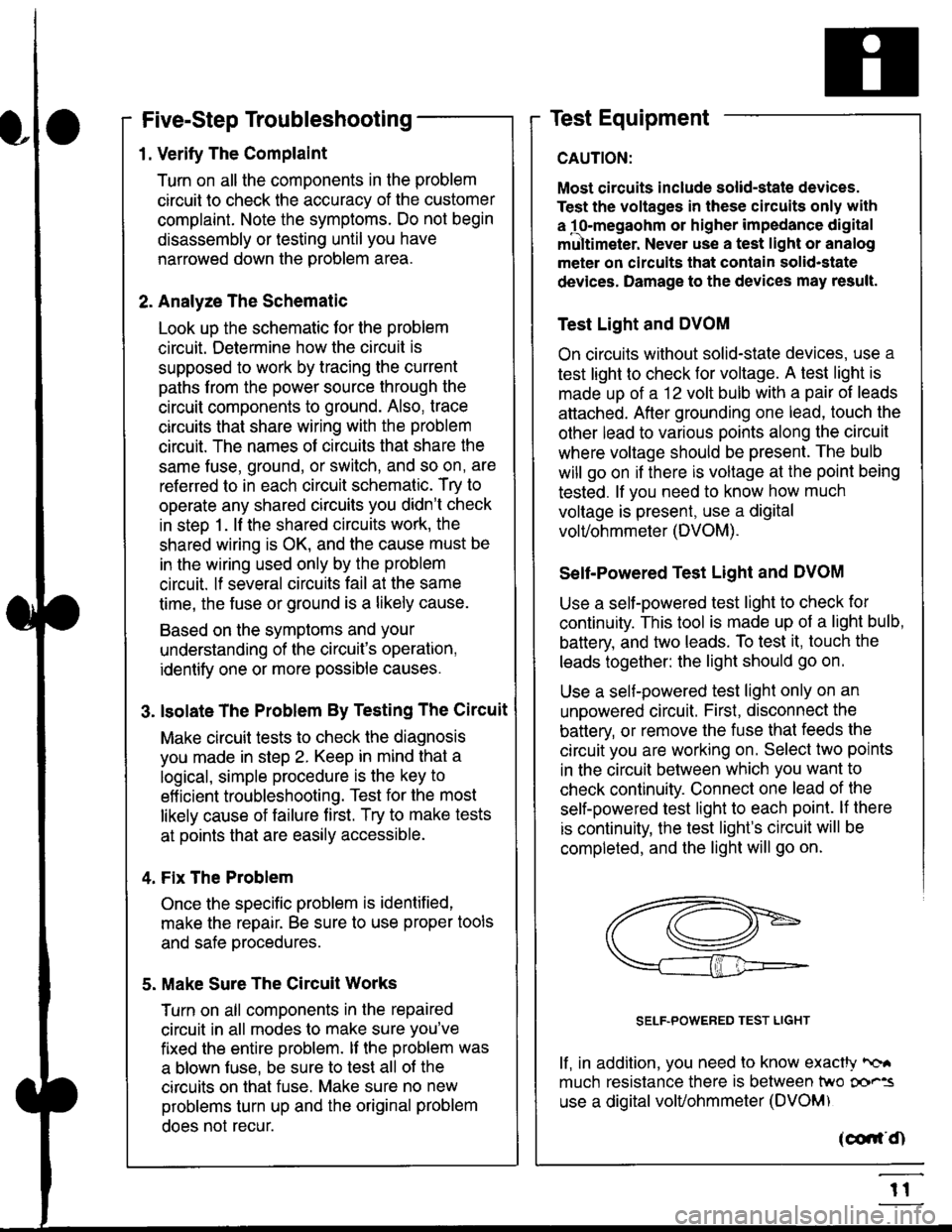

Five-Step Troubleshooting

L Verify The Complaint

Turn on all the components in the problem

circuil lo check the accuracy of the customer

complaint. Note the symptoms. Do not begin

disassembly or testing until you have

narrowed down the problem area.

2. Analyze The Schematic

Look up the schematic for the problem

circuit. Determine how the circuit is

supposed to work by tracing the current

paths lrom the power source through the

circuit components to ground. Also, trace

circuits that share wiring with the problem

circuit. The names of circuits that share the

same fuse, ground, or switch, and so on, are

referred to in each circuit schematic. Try to

operate any shared circuits you didn't check

in step 1 . lt the shared circuits work, the

shared wiring is OK, and the cause must be

in the wiring used only by the problem

circuit. lf several circuits fail at the same

time, the fuse or ground is a likely cause.

Based on the symptoms and your

understanding of the circuit's operation,

identify one or more possible causes.

3. lsolate The Problem By Testing The Circuit

Make circuit tests to check the diagnosis

you made in step 2. Keep in mind that a

logical, simple procedure is the key to

efficient troubleshooting. Test for the most

likely cause of failure first. Try to make tests

at points that are easily accessible.

4. Fix The Problem

Once the specific problem is identified,

make the repair. Be sure to use proper tools

and safe procedures.

5. Make Sure The Circuit Works

Turn on all components in the repaired

circuit in all modes to make sure you've

fixed the entire problem. ll the problem was

a blown fuse, be sure to test all of the

circuits on that fuse. Make sure no new

problems turn up and the original problem

does not recur.

Test Equipment

Most circuits include solid-state devices.

Test the voltages in these circuits only with

a 1o-megaohm or higher impedance digital

mUltimeter. Never use a test light or analog

meter on circuits that contain solid-state

devices. Damage to the devices may result.

Test Light and DVOM

On circuits without solid-state devices, use a

test light to check for voltage. A test light is

made up of a 12 volt bulb with a pair of leads

attached. After grounding one lead, touch the

other lead to various points along the circuit

where voltage should be present. The bulb

will go on if there is voltage at the point being

tested. lf you need to know how much

voltage is present, use a digital

volVohmmeter (DVOM).

Self-Powered Test Light and DVOM

Use a self-powered test light to check for

continuity. This tool is made up of a light bulb,

battery, and tlvo leads. To test it, touch the

leads together: the light should go on.

Use a self-powered test light only on an

unoowered circuit. First, disconnect the

battery, or remove the fuse that feeds the

circuit you are working on. Select two points

in the circuit belween which you want to

check continuity. Connecl one lead of the

self-powered test light to each point. lf there

is continuity, the test light's circuit will be

completed, and the light will go on.

SELF-POWERED TEST LIGHT

lf, in addition, you need lo know exacW hc'.

much resistance there is between two oo'^=

use a digital volUohmmeter (DVOM)

acdrt'Cn

t1

Page 1829 of 2189

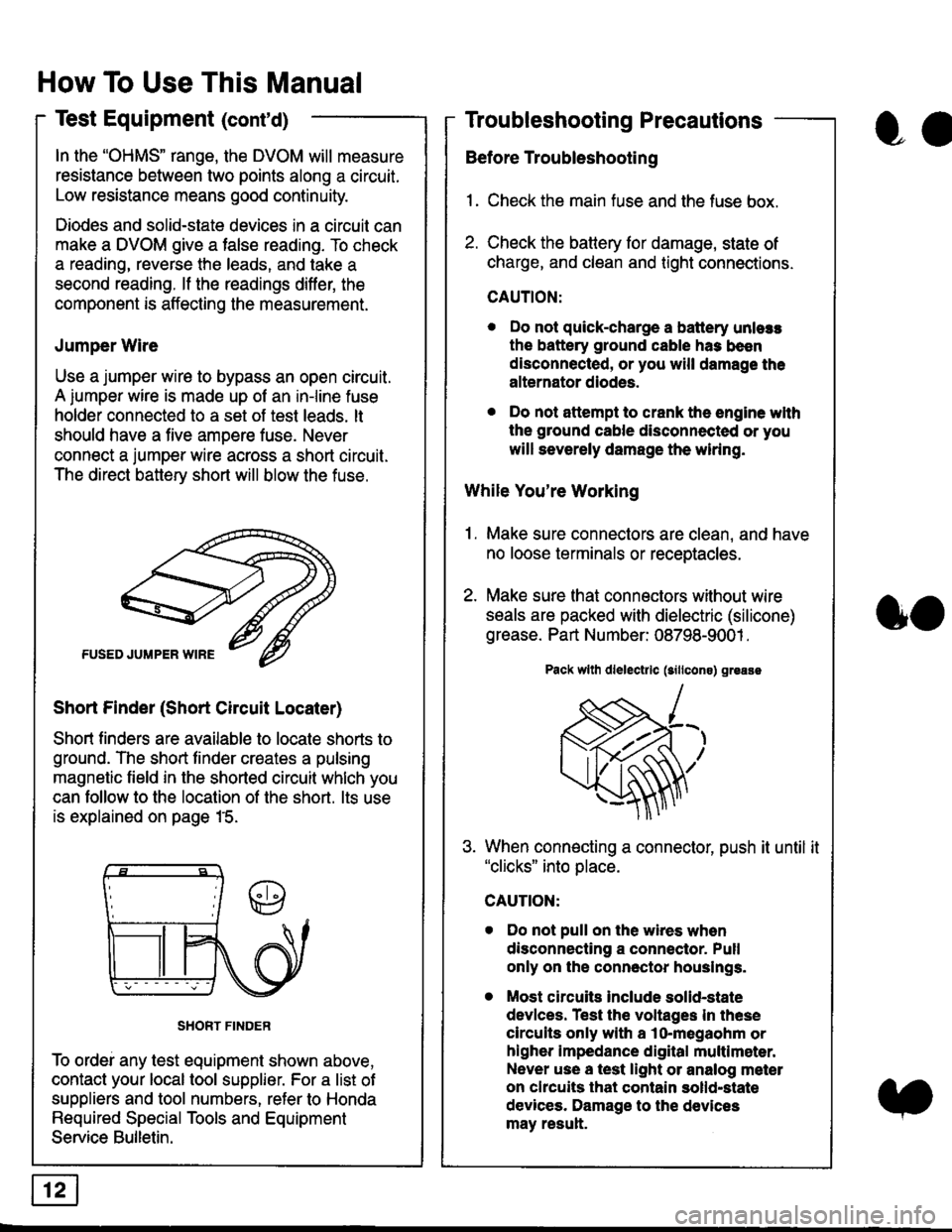

In the "OHMS" range, the DVOM will measure

resistance between two points along a circuit.

Low resistance means good continuity.

Diodes and solid-state devices in a circuit can

make a DVOM give a false reading. To check

a reading, reverse the leads, and take a

second reading. lf the readings differ, the

component is affecting lhe measurement.

Jumper Wire

Use a jumper wire to bypass an open circuit.

A iumper wire is made up ot an in-line fuse

holder connected to a set of test leads. lt

should have a five amoere fuse. Never

connect a jumper wire across a short circuit.

The direct battery short will blow the fuse.

Short Finder (Short Circuit Locater)

Short finders are available to locale shorts to

ground. The short tinder creates a pulsing

magnetic field in the shorted circuit whlch you

can follow to the location of the short. lts use

is explained on page 15.

SHORT FINDER

To ordei any test equipment shown above,

contact your local tool supplier. For a list of

suppliers and tool numbers, refer to Honda

Required Special Tools and Equipment

Service Bulletin.

How To Use This Manual

Test Equipment (cont'd)

oa

Troubleshooting Precautions

Before Troubleshooting

1. Check the main fuse and the fuse box.

2. Check the battery for damage, state of

charge, and clean and tight connections.

CAUTION:

. Do not quick-charge a battery unlers

the battery ground cable has been

disconnected, or you will damage the

alternator diodes.

. Do not attempt to crank the engine wlth

the ground cable disconnected or you

will severely damage the wiring.

While You're Working

1. Make sure connectors are clean, and have

no loose terminals or receptacles.

2. Make sure lhat connectors without wire

seals are packed with dielectric (silicone)

grease. Part Number: 08798-9001 .

Pack wllh dlelectrlc (sillcons) greass

When connecting a connector, push it until it"clicks" into place.

Do not pull on the wires when

disconnecting a connector. Pull

only on the connector houslngs.

Most circuits Include solid-state

devlces. Test the voltages In these

circuits only with a lo-megaohm or

higher impedance digital multlm6ter.

Never use a test light or analog meter

on chcuits that contain solld-state

devices. Damage to the devices

may result.

oo

Page 1830 of 2189

Troubleshooting Tests

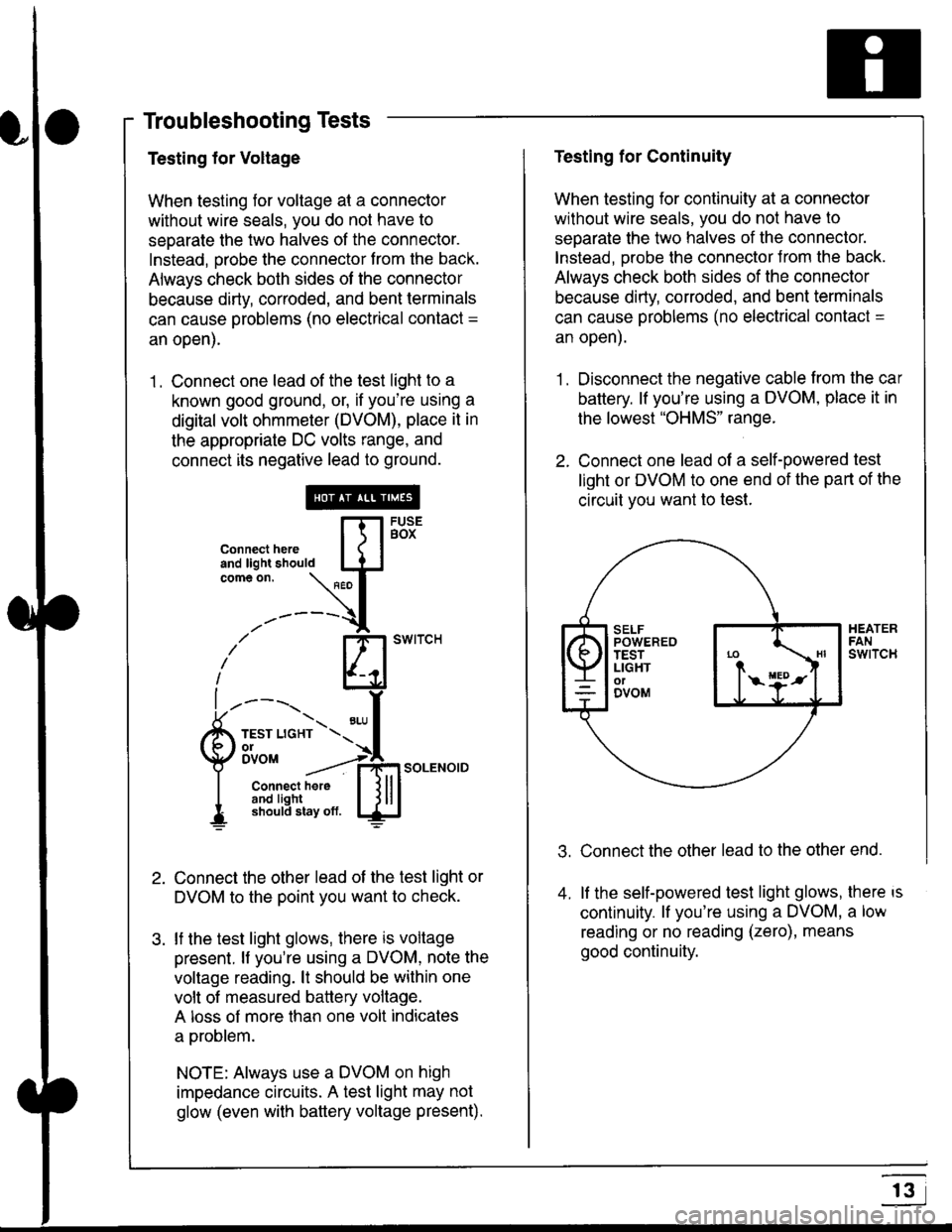

Testing for Voltage

When testing for voltage at a connector

without wire seals, you do not have to

seoarate the two halves of the connector.

Instead, probe the connector from the back.

Always check both sides of the connector

because dirty, corroded, and bent terminals

can cause problems (no electrical contact =

an open).

1 . Connect one lead of the test light to a

known good ground, or, if you're using a

digital volt ohmmeter (DVOM), place it in

the appropriate DC volts range, and

connect its negative lead to ground.

Connect the other lead of the test light or

DVOM to the point you want to check.

lf the test light glows, there is voltage

present. lf you're using a DVOM, note the

voltage reading. lt should be within one

volt of measured battery voltage.

A loss of more than one volt indicates

a problem.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with baftery voltage present).

connecthere [fl5tst-tand light should IJJcomeon.

\" I

------{

/' BT swrrcH

lhl

l ----., I

6m""*soLENo,DI connect here I { lll

I 3#Ji8iL,* lj!!J

Testing for Continuity

When testing for continuity at a connector

without wire seals, you do not have to

separate the two halves of the connector.

lnstead. Drobe the connector Jrom the back.

Always check both sides of the connector

because dirty, conoded, and bent terminals

can cause problems (no electrical contacl =

an open).

1. Disconnect the negative cable from the car

battery. lf you're using a DVOM, place it in

the lowest "OHMS" range.

2. Connect one lead of a self-powered test

light or DVOM to one end of the part of the

circuit vou want lo test.

Connect the other lead to the other end.

lf the self-powered test light glows, there is

continuity. lf you're using a DVOM, a low

reading or no reading (zero), means

good continuity.

.t.

A

r3

Page 1831 of 2189

How To Use This Manual

Troubleshooting Tests

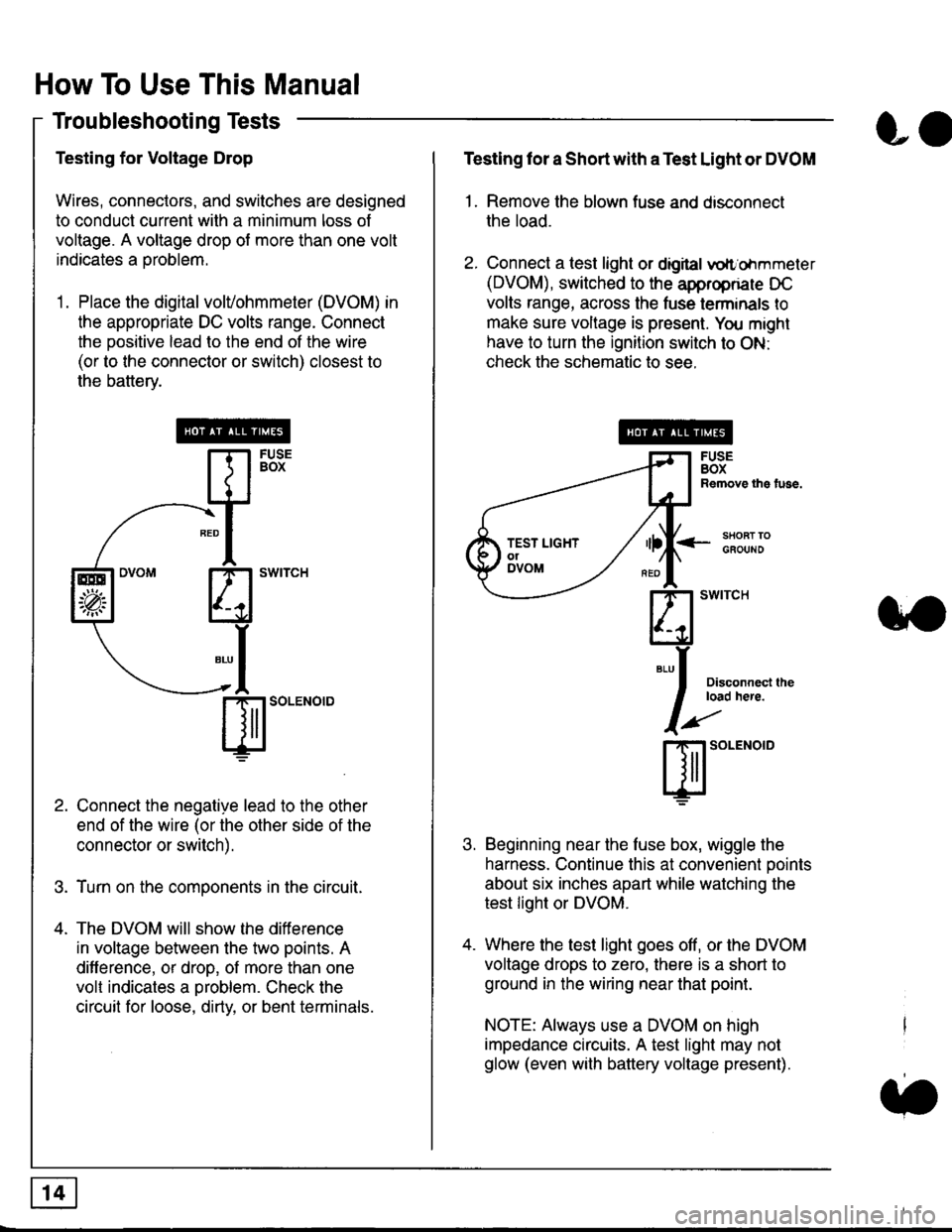

Testing for Voltage Drop

Wires, connectors, and switches are designed

to conduct current wilh a minimum loss of

voltage. A voltage drop of more than one volt

indicates a Droblem.

'1. Place the digital volVohmmeter (DVOM) in

the appropriate DC volts range. Connect

the positive lead to the end of the wire

(or to the connector or switch) closest to

the bafterv.

Connect the negative lead to the other

end of the wire (or the other side of the

connector or switch).

Turn on the components in the circuit.

The DVOM will show the difference

in voltage between the two points. A

difference, or drop, of more than one

volt indicates a oroblem. Check the

circuit for loose, dirty, or bent terminals.

co

Testing lor a Short with a Test Light or DVOM

1. Remove the blown fuse and disconnect

the load.

2. Connect a test light or digital

oltr'ohmmeter

(DVOM), switched to the appropnare DC

volts range, across the tuse lerminals to

make sure voltage is present. You might

have to turn the ignition switch to ON:

check the schematic to see.

<-s80RT TOGFOUNO

Disconnecl lheload here.

Beginning near the luse box, wiggle the

harness. Continue this at convenient ooints

about six inches apart while watching the

test light or DVOM.

Where the test light goes off, or the DVOM

voltage drops to zero, there is a short to

ground in the wiring near that point.

NOTE: Always use a DVOM on high

impedance circuits. A test light may not

glow (even with battery voltage present).

3'�'

ffito.'"o'o

.t.

TEST LIGHTolDVOM