Exhaust HONDA CIVIC 1997 6.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 530 of 2189

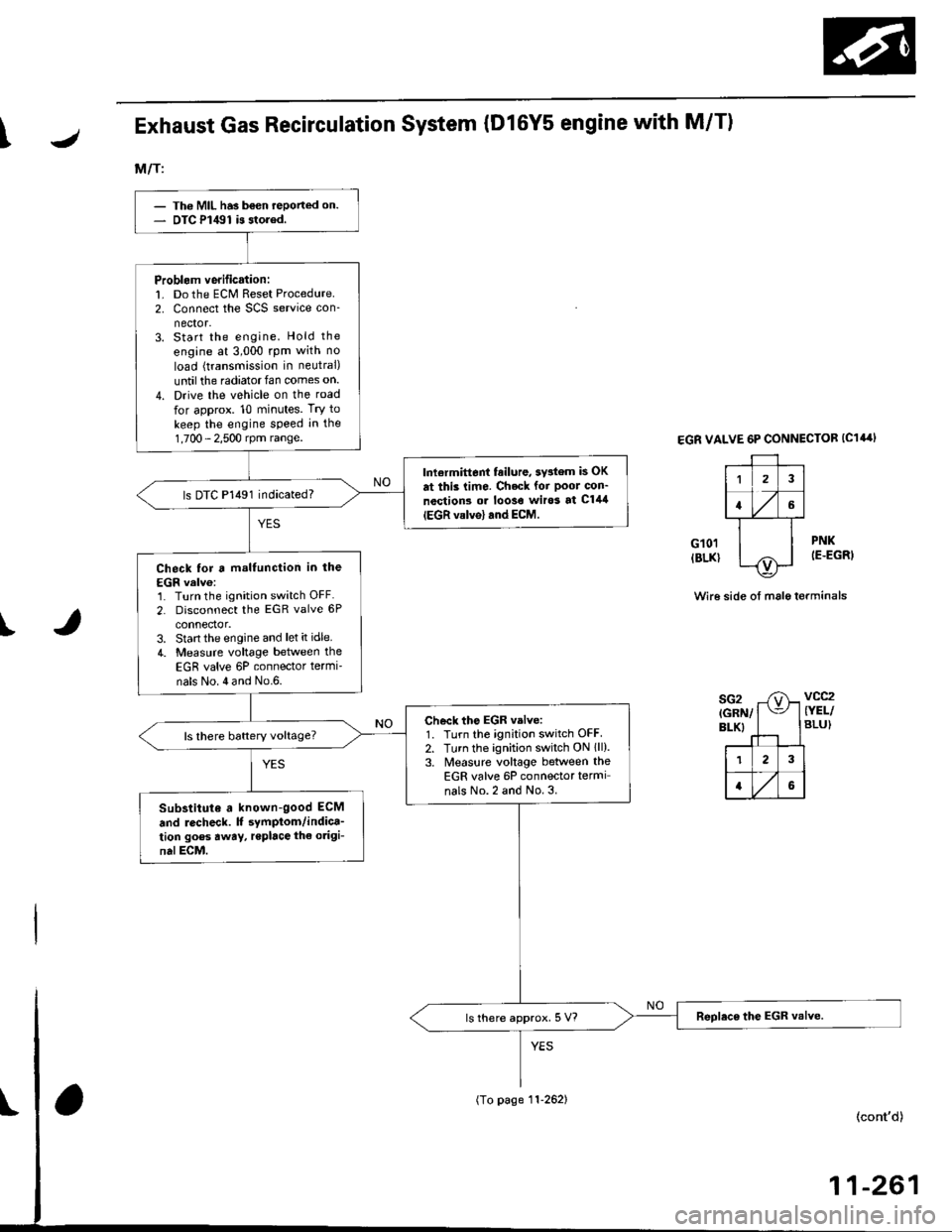

\JExhaust Gas Recirculation System (D16Y5 engine with M/T)

M/T:

EGR VALVE 6P CONNECTOB (C14'rl

G10lIBLK}

1

a

PNK

IE.EGRI

Wi16 side of male terminals

I

sG2{GRN/BLK}

vcc2{YEL/BLU)

- Th6 MIL ha3 b€on reponed on.- DTC Pl,{tl is 3tored.

Prcblem verification:1. Do the ECM Reset Procedure.

2. Connect the SCS service con_nector.3. Start the engine. Hold the

engine at 3,000 rpm with no

load (transmission in neutral)

untilthe radiator fan comes on.

4. Drive the vehicle on the road

for approx. 10 minutes. Try to

keep the engine speed in the

1,700 - 2,500 rpm range.

lnlermittont tailure, svalem is OK

at thi3 tim6. Check foi Poor con'

nections or looso wiro3 at Cl/K

IEGR valvsl and ECM.

ls DTC P1491 indicated?

Check tor a malfunction in the

EGR valv6:1. Turn the ignition switch OFF.

2. Disconnect the EGR valve 6P

connector.3. Stanthe engine and let it idle

4. Measure voltage between the

EGR valve 6P connector termi'

nals No.4and No.6.

Check the EGR valve:1. Turn the ignition switch OFF2. Turn the ignition switch ON lll).3. Measure voltage between theEGR valve 6P connector termi

nals No.2 and No.3.

ls there battery voltage?

Substitute a known-good ECM

and recheck. It symptom/indica_tion goes away, replace th€ origi-

nal ECM.

ls there approx.5V?

(To page 11-262)

Page 531 of 2189

Emission Control System

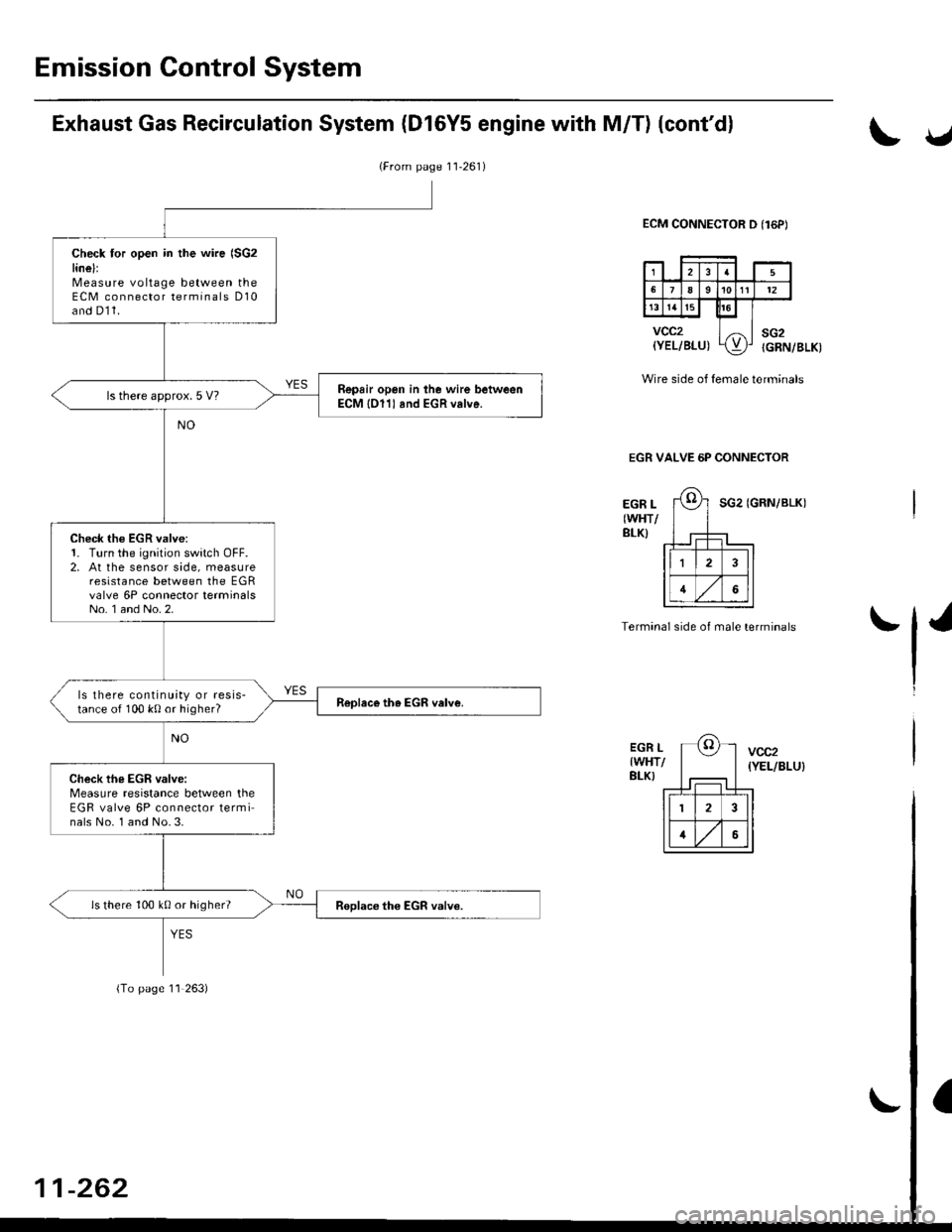

(From page 11-261)

Check tor open in the wire (SG2

linel:Measure voltage between theECM connector terminals D10and D11.

Repsir open in lhe wire beiweenECM lOllland EGR valve.ls there approx. 5 V?

Check the EGR valve:1. Turn the ignition switch OFF.2, At the sensor side, measureresistance between the EGRvalve 6P connector terminalsNo. 1 and No. 2.

ls there continuity or resis-tance of 100 k0 or higher?

Check the EGR valve:Measure resistance between theEGR valve 6P connector terminals No. 1 and No.3.

ls there 100 k0 or higher?

Exhaust Gas Recirculation System (D16Y5 engine with M/T) (cont'dl

ECM CONNECTOR D {16P)

vcc2(YEL/BLU)

\v

sG2IGRN/BLK)

Wire side of female term;nals

EGR VALVE 6P CONNECTOR

EGR L(WHT/

BLK}

SG2 (GRN/BLK)

Termanal side of male terminals'l'

EGR L{WHT/BLK}

vcc2

{YEL/BLU}

(To pase 11 263)

1-262

Page 533 of 2189

Emission Gontrol System

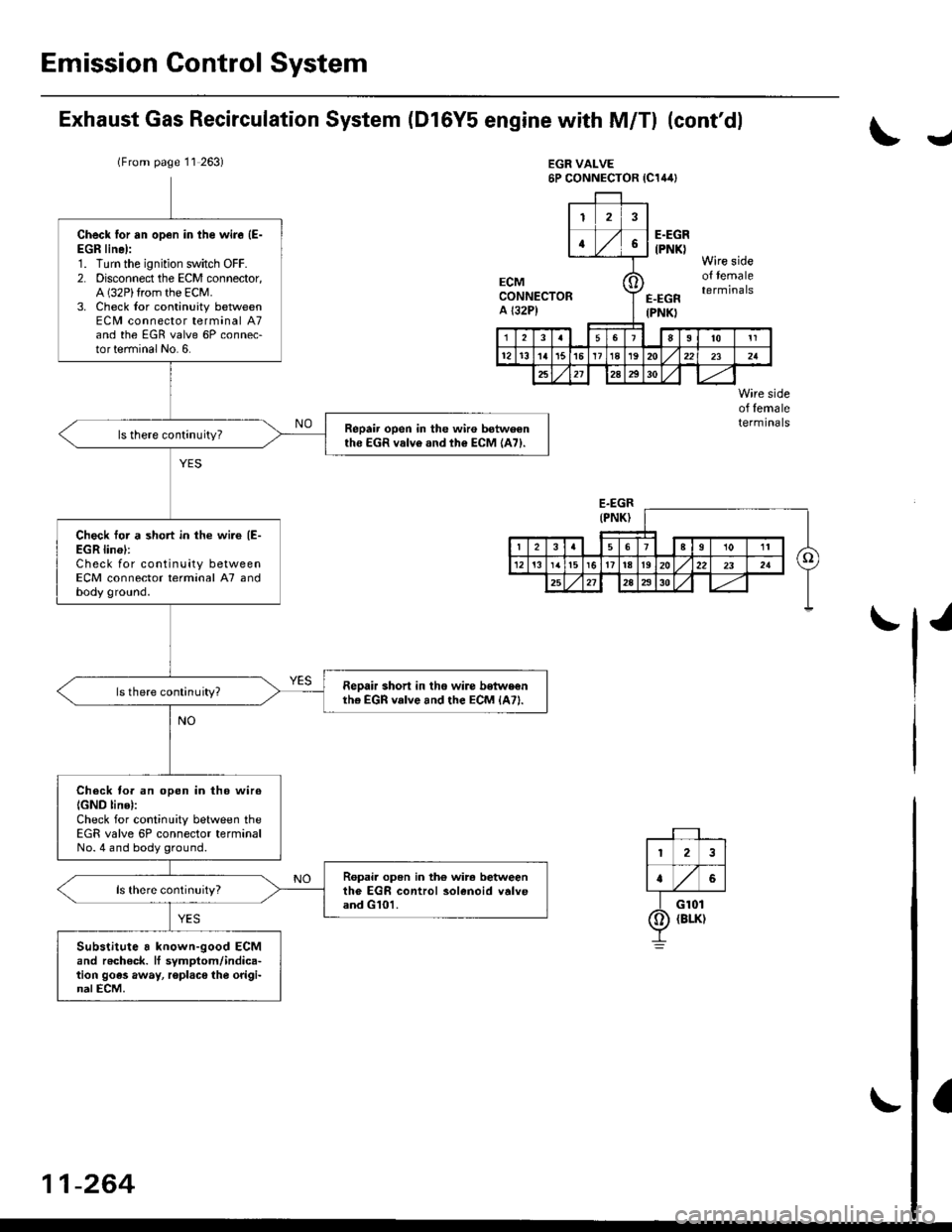

Exhaust Gas Recirculation System (Dl6Y5 engine with M/Tl (cont'dl

lFrom page 11 263)EGR VALVE6P CONNECTOR {C144}

J

Wire sideof femaletermtnals

J

Check lor an op€n in the wire (E-

EGR line):1. Turn the ignition switch OFF.2. Disconnect the ECM connector,A (32P)trom the ECM.3. Check lor continuity betweenECM connector terminal A7and the EGR valve 6P connec-torterminal No. 6.

Repair open in the wiro botweenthe EGR valv6.nd th€ ECM {A71.

Check tor a short in the wire {E-EGR lin6l:Check for continuity betweenECM connector terminal A7 andbody ground.

Reoair shorl in tho wiro belwe€nthe EGn vake rnd the ECM lA7l.ls there continuity?

Check fo. an open in tho wiro

IGND line):Check for continuity between theEGR valve 6P connector terminalNo.4 and body ground.

R6pai. open in th€ wir. betweenth6 EGF control solenoid v6lveand G101.

Substitute 8 known-good ECMand recheck. It symptom/indica-tion goes away, roplace the origi-nalECM.

CONNECTORA l32P)

2

a

I G101

Q) raur

-264

Page 534 of 2189

J\

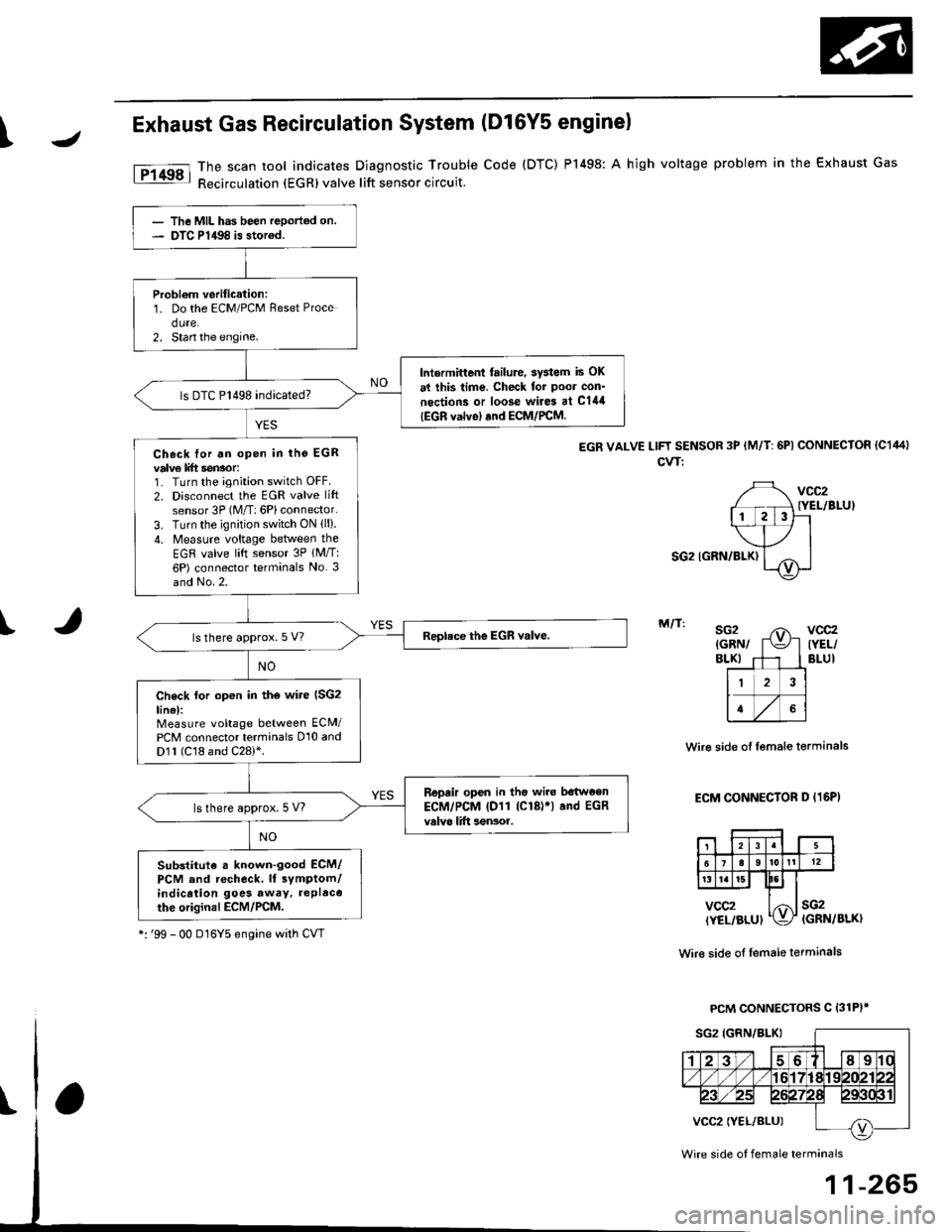

Exhaust Gas Recirculation System

The scan tool indicates Diagnostic Trouble

Recirculation (EGRlvalve lift sensor circuit.

(D16Y5 enginel

Code {DTC) P1498: A high voltage problem in the Exhaust Gas

EGR VALVE LlFf SENSOR 3P {M/T: 6Pl CONNECTOR (C1441

cvT:

vcc2{YEL/BLUI

SG2 IGRN/BLK)

IM/T:sG2{GRN/BLKI

Wir€ side ol lemale terminals

ECM CONNECTOR D (16P)

vcc2(YEL/BLUIsG2(GRN/BLK)

Wir€ side of female terminals

PCM CONNECTORS C 131P)'

Wire side oI female terminals

11-265

- The MIL has been reportod on.- DTC P1498 is storod.

Probl€m verification:1. Do the ECM/PCM Reset Proce

dure.2. Stan the engine.

Intermittent tailure, sy3lem is OK

at lhis time. Check tor poor con'

nections or loose wire3 at C144

|EGR valvel and ECM/PCM.

ls DTC P1498 indicated?

Check for an open in tho EGRvalv6 lift sen3or:1. Turn the ignition switch OFF.

2. Disconnect the EGR valve lift

sensor 3P (M/T: 6Pl connector.

3. Turn the ignition switch ON (ll).

4. Measure voltage between the

EGR valve litt sensor 3P lM/T:6P) connector terminals No. 3and No.2.

ls there approx.5 V?

Check lor op€n in th€ wire (SG2

line):Measure voltage between ECM/PCM connector terminals 010 andD1l (C18 and C28)*.

Repair open in tho wiro betwoen

ECM/PCM lDl1 (Cl8)r) and EGR

valvo lift sensor.ls there approx. 5 V?

Substitute . known-good ECM/PCM and recheck. ll symptom/indicrtion goes away, replacothe original ECM/rcM.

*:'99 - 00 D16Y5 engine with CVT

Page 586 of 2189

Transmission Assembly

Removal (cont'dl

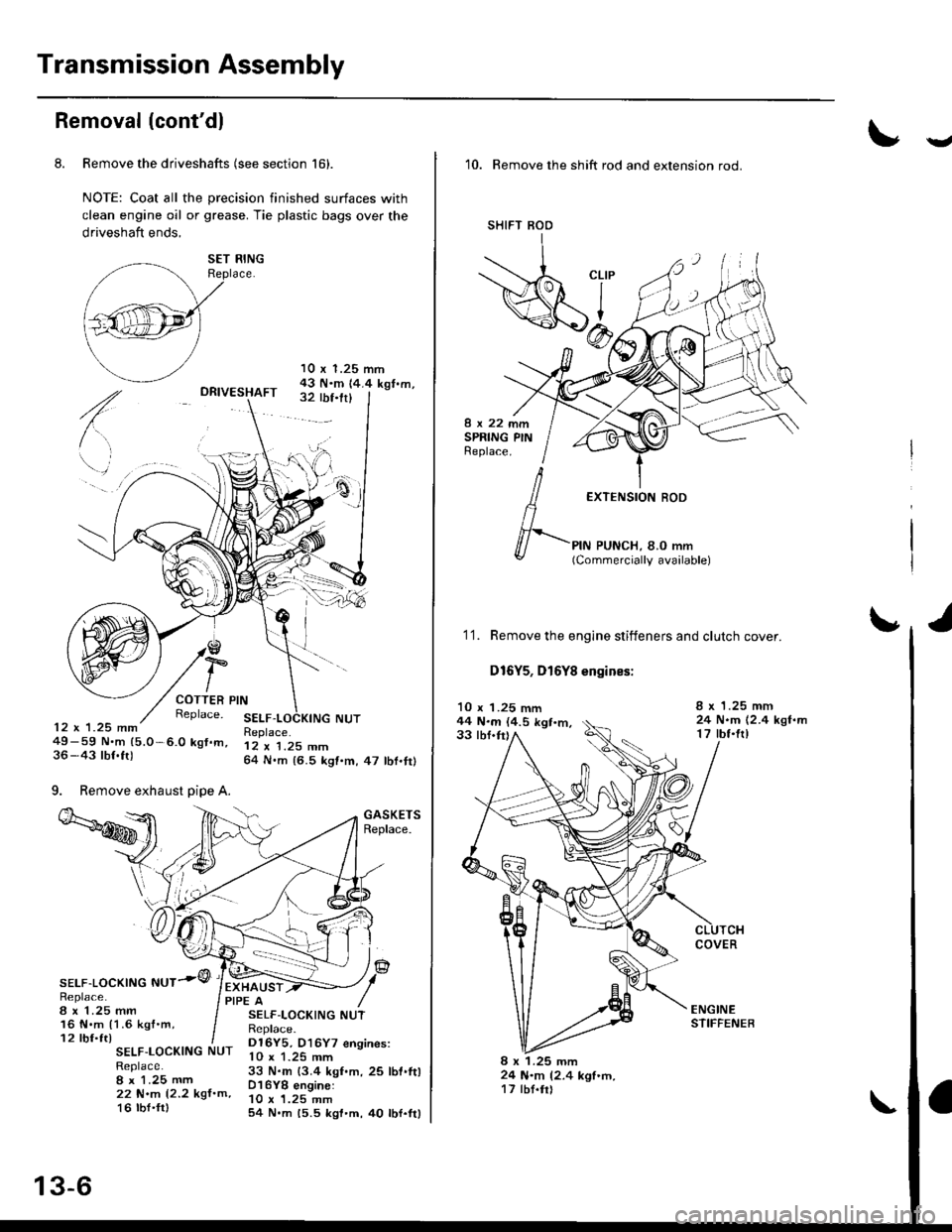

8. Remove the driveshafts (see section 161.

NOTE: Coat all the precision finished surfaces with

clean engine oil or grease. Tie plastic bags over the

driveshaft ends,

DRIVESHAFT

10 x 1.25 mrn43 N.m 14.4 kgt.m,32 rbf.frl

COTTER PINReplace. SELF12 x 1.25 mm49-59 N.m (5.0 -6.0 kgt.m,36-43 lbf.ft)

9. Remove exhaust pipe A.

Replace.12 x 1.25 mm64 N.m {6.5 kgt.m,47 lbf.tr)

GASKETSReplace.

IF\sELF-LocKtNG NUT.''1/Replace.8 x 1.25 mm16 N.m {1.6 kgf'm,12 tbf.ft)

EXHAUSTPIPE A

SELF-LOCKING NUTReplace.I x 1.25 mm22 N.m (2.2 kgf.m,16 tbt'fr)

SELF-LOCKING NUTReplace.D16Y5, D16Y7 engines:

33 N.m {3.4 kgf.m,25 lbt.ft)D16YB engine:10 x 1.25 mm54 N.m 15.5 kgl'm,40 lbf.ttl

SET RING

13-6

v'10. Remove the shift rod and extension rod.

SI'IIFT BOD

8x22mmSPRING PINReplace.

EXTENSION ROD

PIN PUNCH, 8.O mm(Commercially available)f-

'1'1. Remove the engine stiffeners and clutch cover.

D16Y5, D16Y8 engines:

10 x 1.25 mm44 N.m (4.5 kgt.m,33 tbf.tr)

I x 1.25 mm24 N.m (2.4 kgf.m17 lbt.frl

COVER

8 x 1.25 mm24 N.m 12.4 kgf'tn,17 tbt.tr)

Page 629 of 2189

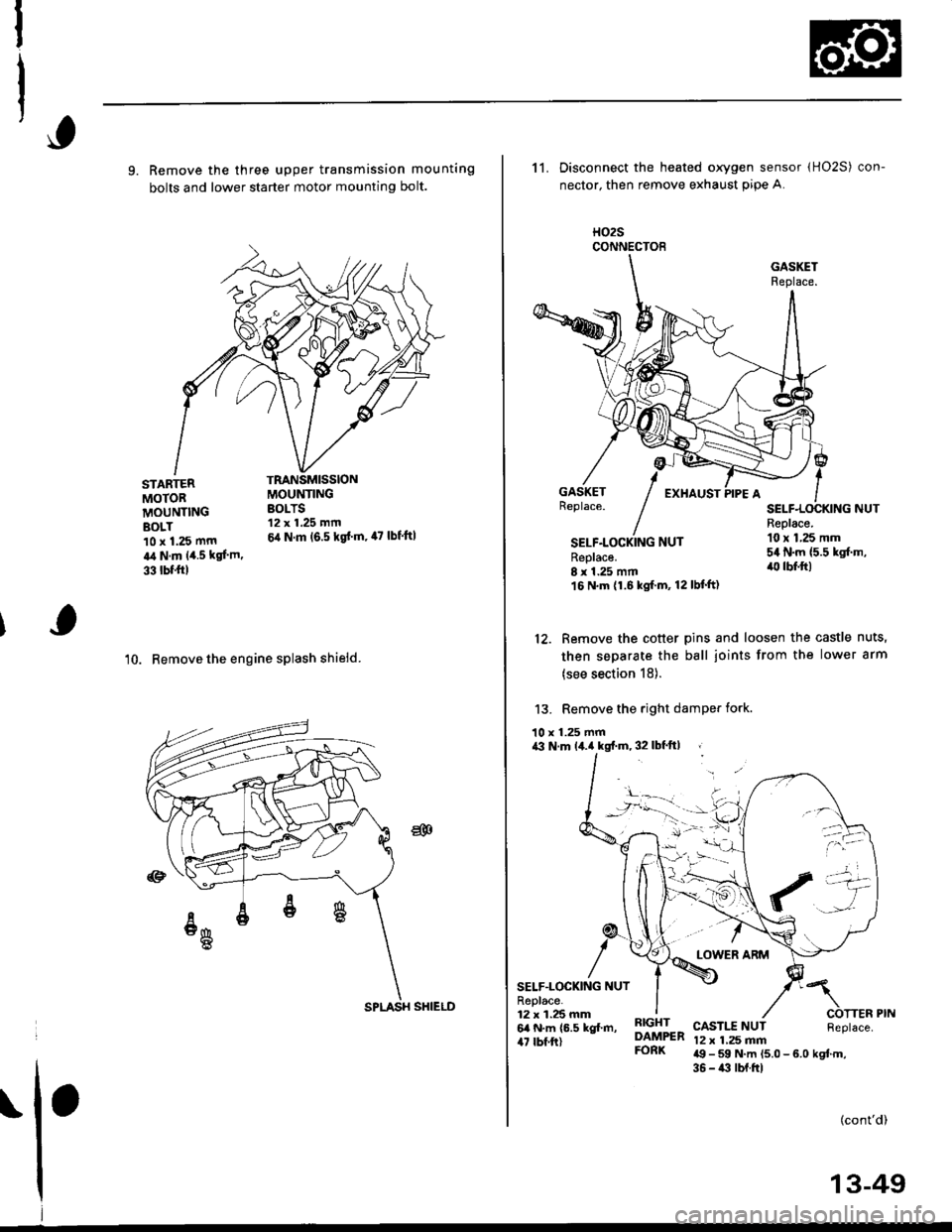

9. Remove the three upper transmission mounting

bolts and lower starter motor mounting bolt.

'10. Remove the engine splash shieid.

TRANSMISSIONMOUNTINGBOLTS12 x 1.25 mm

6,1 N.m (6.5 kgd m, 47 lbf'ft|

STARTERMOTORMOUNTINGBOLT10 x 1.25 mm

a,t N.m 14.5 kgl.m.

33 tbf.trl

CONNECTOE

11. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove exhaust pip€ A.

H02S

SELF.LOCKING NUTReplace.8 r 1.25 mm16 N.m (1.6 kgf.m, 12lbf'ft)

Replace.10 x 1,25 mm54 N.m {5.5 kgf.m,'lll lbf.ft)

12. Remove the cotter pins and loosen the castle nuts,

then separate the ball joints from the lower arm

(see section 18).

13. Remove the right damPer fork.

10 x 1.25 mma3 N.m lil.a kgf.m, 32 lbf'ft| ,

SELF.LOCKING NUTR6place.12 x 1.25 mm6a N.m (6.5 kgl.m,47 rbf ft)

RIGHTDAMPERFORK

CASTI.T NUT12 x 1,25 mma9 - 59 N.m (5.0 - 6.0 kgtm,36 - i(t lbf.ftl

(cont'd)

!-

ria -11: \/-/

't'''-a

SPLASH SHIELD

13-49

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3

Page 698 of 2189

Description

Hydraulic Control (cont'dl

Msin Valve Body

The main valve body houses the manual valve, the 1-2 shift valve, the 2nd orifice control valve, the cpB valve, the modu-lator valve' the servo control valve, and the relief valve. The primary functions of the main valve body are to swatch fluidpressure on and off and to control the hydraulic pressure going to the hydraulic control svstem.

2ND ORIFICE CONTROTVALVE

1-2 SHIFT VALVE

RELIEF VALVE

CPC VAL

3-4 SHTFT V

VALVE

Socondary Valve Body

The secondary valve body is located on the main valve body. The secondary valve body houses the 2-3 shift vatve, the 3-4shift valve, the 3-4 orifice control valve, the 4th exhaust valve, and the CpC valve.

CONTROL

2.3 SHIFT VALVE

4TH EXHAUST VALV€

VALVE

14-20

VALVE

Page 802 of 2189

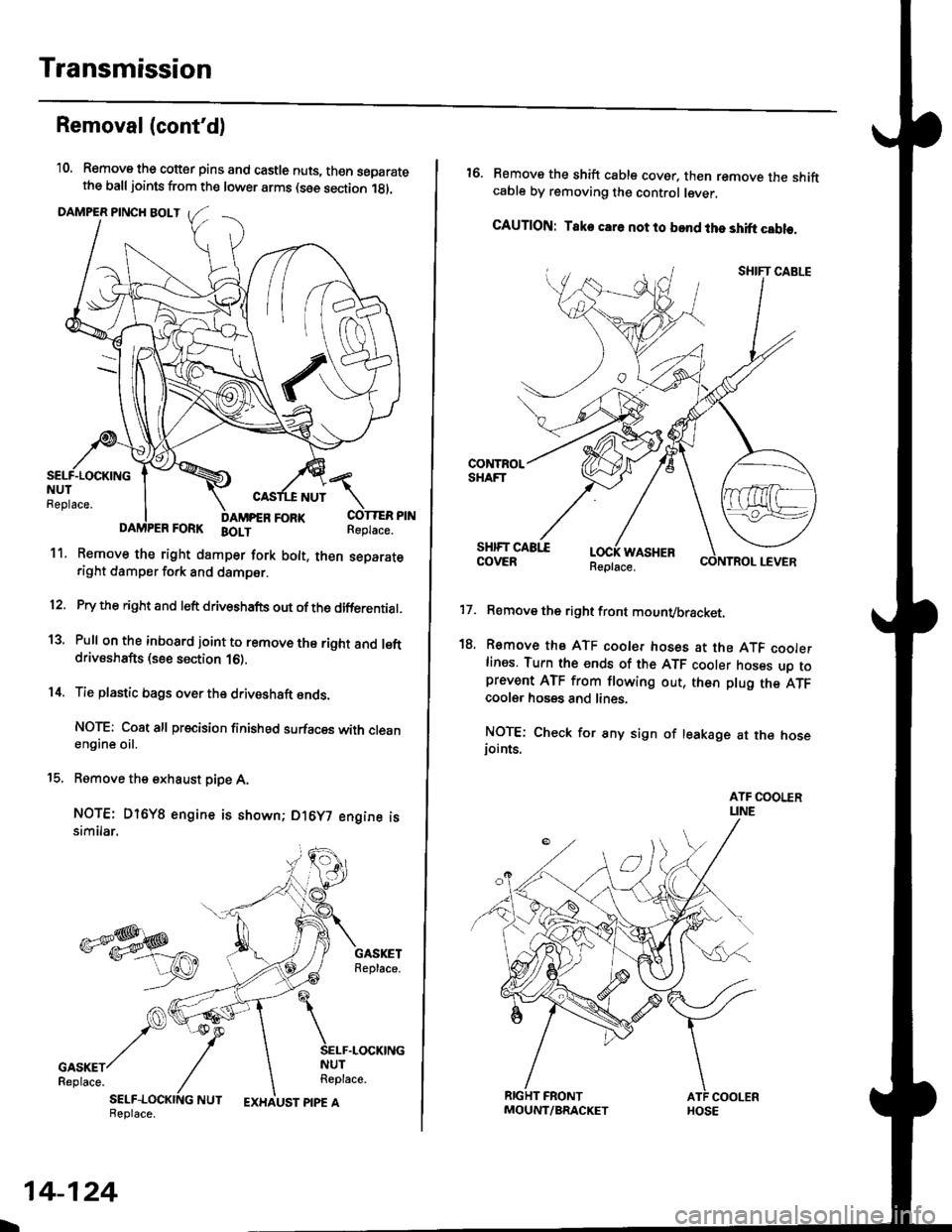

Transmission

Removal(cont'd)

'10. Remove the cotter pins and castle nuts, th€n separatethe balljoints from the lower arms (see section 1gl.

DAMPER PINCH BOLT

NUT

FORI(FORK BOLT

11. Remove the right damper fork bolt. th€nright damper fork and dampor.

COTTER PINReplace.

separate

12.

1a

14.

Pry the right and left driveshafts out ofthe differential.

Pull on the inboard joint to remove the right and leftdrivsshafts (see section 16).

Tie plastic bags over the driveshaft onds.

NOTE: Coat all precision finished surfaces with cleanengine oil.

Remove the exhaust pipe A,

NOTE: Dl6YB engine is shown; D16y7 engine issimilar.

t9.

SELF-LOCKING NUTReplace.

L

14-124

EXHAUST PIPE AMOUNT/BRACKET

17.

18.

16. Remove the shift cable cover. then remove the shiftcable by removing the control lever,

CAUTION: Take car6 not to bond the shift cable.

Remove the right front mounvbracket.

Remove the ATF cooler hoses at the ATF coolerlines. Tufn the ends of the ATF cooler hoses uo toprevent ATF from flowing out, then plug the ATFcooler hosgs and lines.

NOTE: Check for any sign of leakage at the hoseioints.

WASHER

Page 822 of 2189

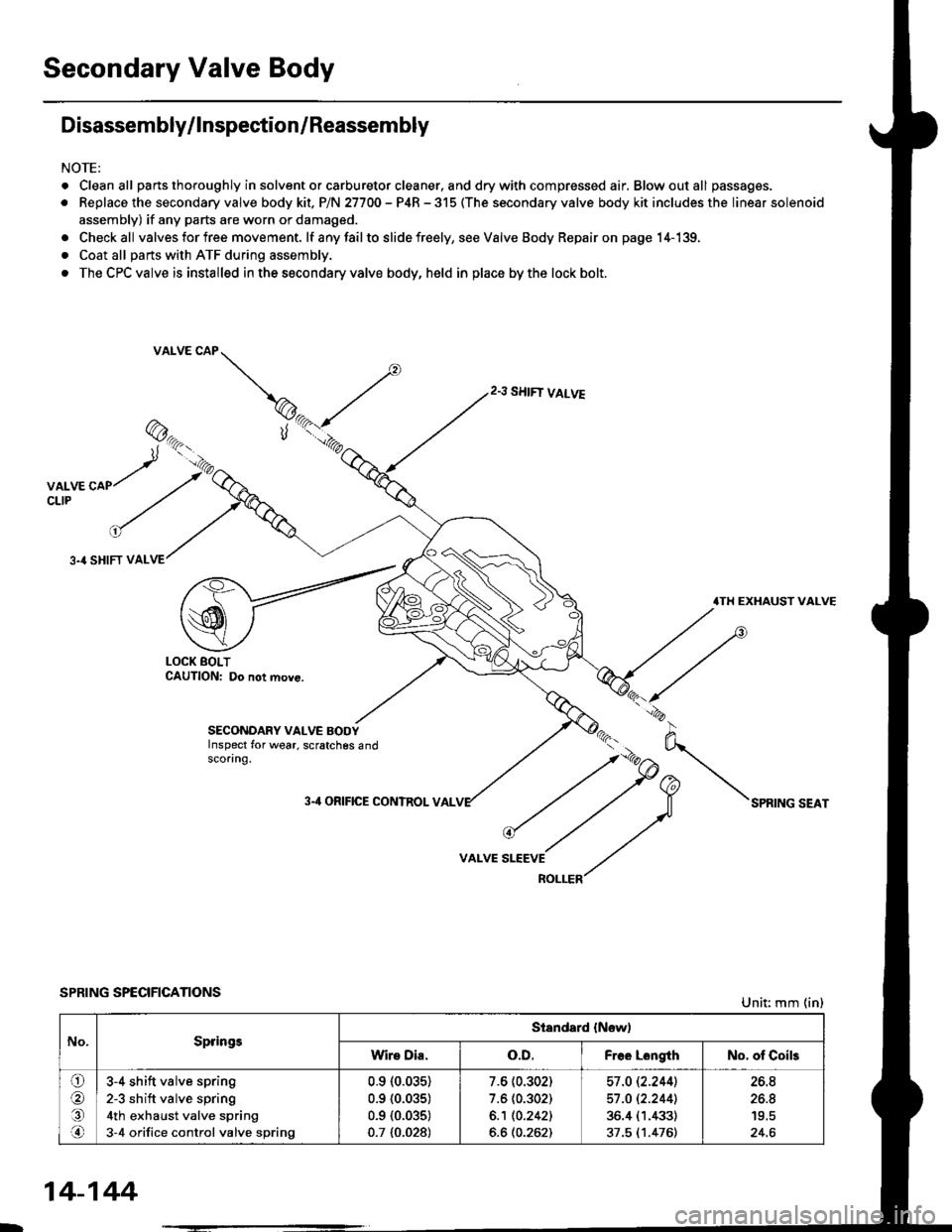

Secondary Valve Body

Disassembly/lnspection/Reassembly

NOTE:

. Cleanall parts thoroughly in solvent or carburetor cleaner. and drywith compressed air, Blowoutall passages.

. Replace the secondary valve body kit. P/N 27700 - P4R - 315 (The secondary valve body kit includes the linear solenoid

assembly) if any parts are worn or damaged.

. Checkall valves for free movement. lf anyfailto slide freely, seeValveBody Repairon page 14-139,

. Coat all parts with ATF during assembly.

. The CPC valve is installed in the secondary valve body, held in place by the lock bolt.

2.3 SHIFT VALVE

3.4 SHIFT VAL

.TH EXHAUST VALVE

LOCK BOLTCAUTION: Do not move.

SECONDARY VALVE BODYInspect for wear, scratches 6ndscoring.

3-'l ORIFICE CONTROL VAL

VALVE

SPRING SPECIFICATIONSUnit: mm (in)

No.SpringsStandard {New)

Wire Dia.o.D.Free LongthNo. of Coils

ora,.n

3-4 shift valve spring

2-3 sh ift valve spring

4th exhaust valve spring

3-4 orifice control valve spring

0.910.035)

0.9 {0.035)

0.9 {0.035)

0.7 {0.028)

7.6 (0.302)

7.6 (0.302)

6.1 10.2421

6.6 (0.262)

57 .O 12.2441

57 .O 12.2441

36.4 (1.433)

37.5 (1.476)

26.8

26.8

24.6

14-144