Gear HONDA CIVIC 1997 6.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CIVIC, Model: HONDA CIVIC 1997 6.GPages: 2189, PDF Size: 69.39 MB

Page 659 of 2189

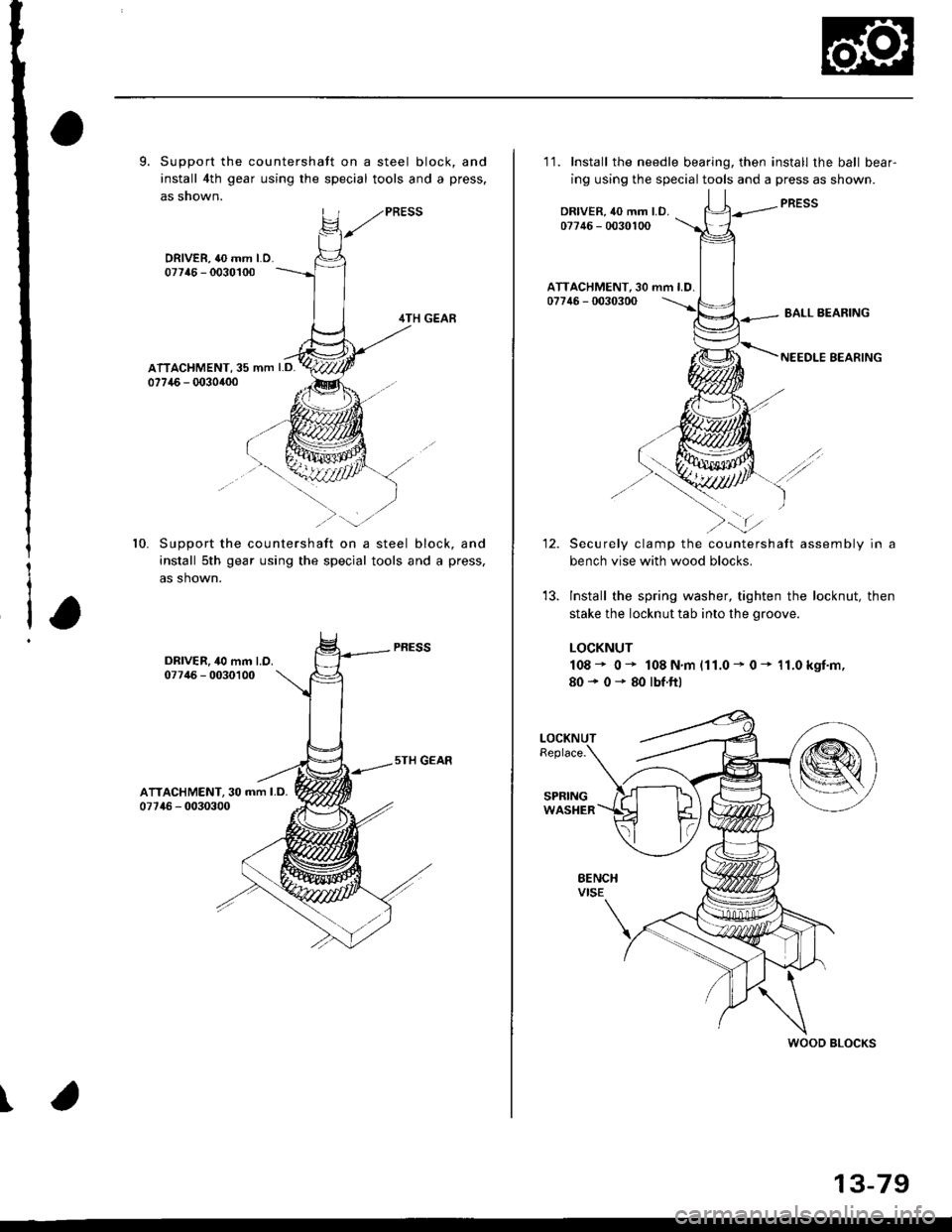

9. Support the countershaft on a steel block, and

install 4th gear using the special tools and a press.

as 5nown.

ATTACHMENT,35 mm LD.07746 - 0030400

Support the countershaft on a steel block, and

install 5th gear using the special tools and a press,

as shown.

ATTACHMENT, 30 mm I,D,07746 - 0030300

10.

\

'1'1. Install the needle bearing, then install the ball bear-

ing using the special tools and a press as shown.

PRESSDRIVER,40 mm LD.07746 - 0030100

ATTACHMENT,30 mm LD.07746 - 0030300

J.-12.Securely clamp the countershaft assembly in a

bench vise with wood blocks.

lnstall the spring washer, tighten the locknut, then

stake the locknut tab into the groove.

LOCKNUT

108- 0- 108N.m 111.0- 0- 11.0kgt.m,

80+ 0* 80 lbf'ftl

WOOD BLOCKS

13-79

Page 660 of 2189

Synchro Sleeve, Synchro Hub

Inspection

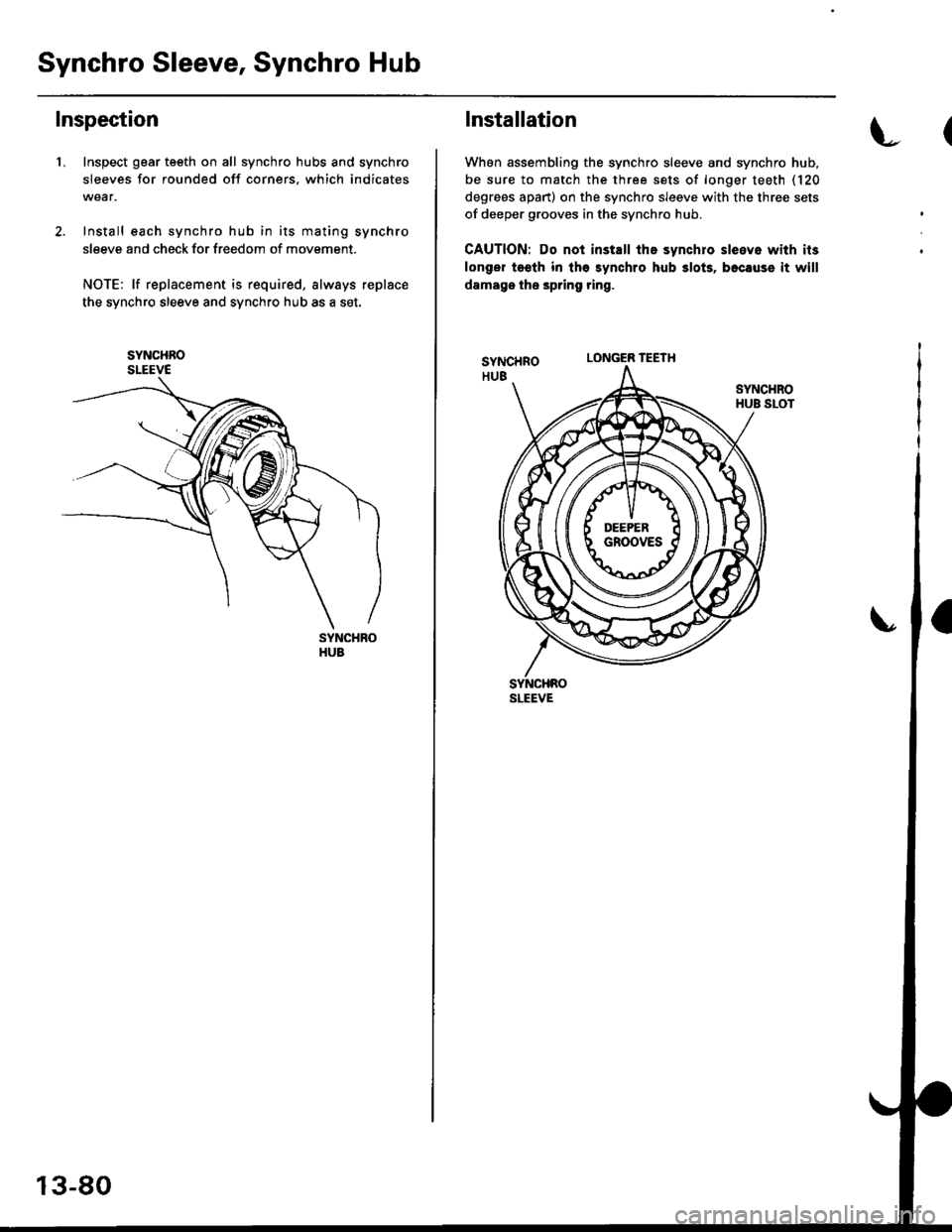

1,Inspect gear teeth on all synchro hubs and synchro

sleeves for rounded off corners. which indicates

Install each synchro hub in its mating synchro

sleeve and check for freedom of movement.

NOTE: lf replacement is required, always replace

the synchro sleeve and synchro hub as a set.

Installation

When assembling the synchro sleeve and synchro hub,

be sure to match the three sets of longer teeth (120

degrees apart) on the synchro sleeve with the three sets

of deeper grooves in the synchro hub.

CAUTION: Do noi install tho synchro sleeve with its

longer toeth in the synchro hub slots, because it will

damage the spring ring.

SYNCItROSLEEVCLONGER TEETH

13-80

Page 661 of 2189

Synchro Ring, Gear

Inspection

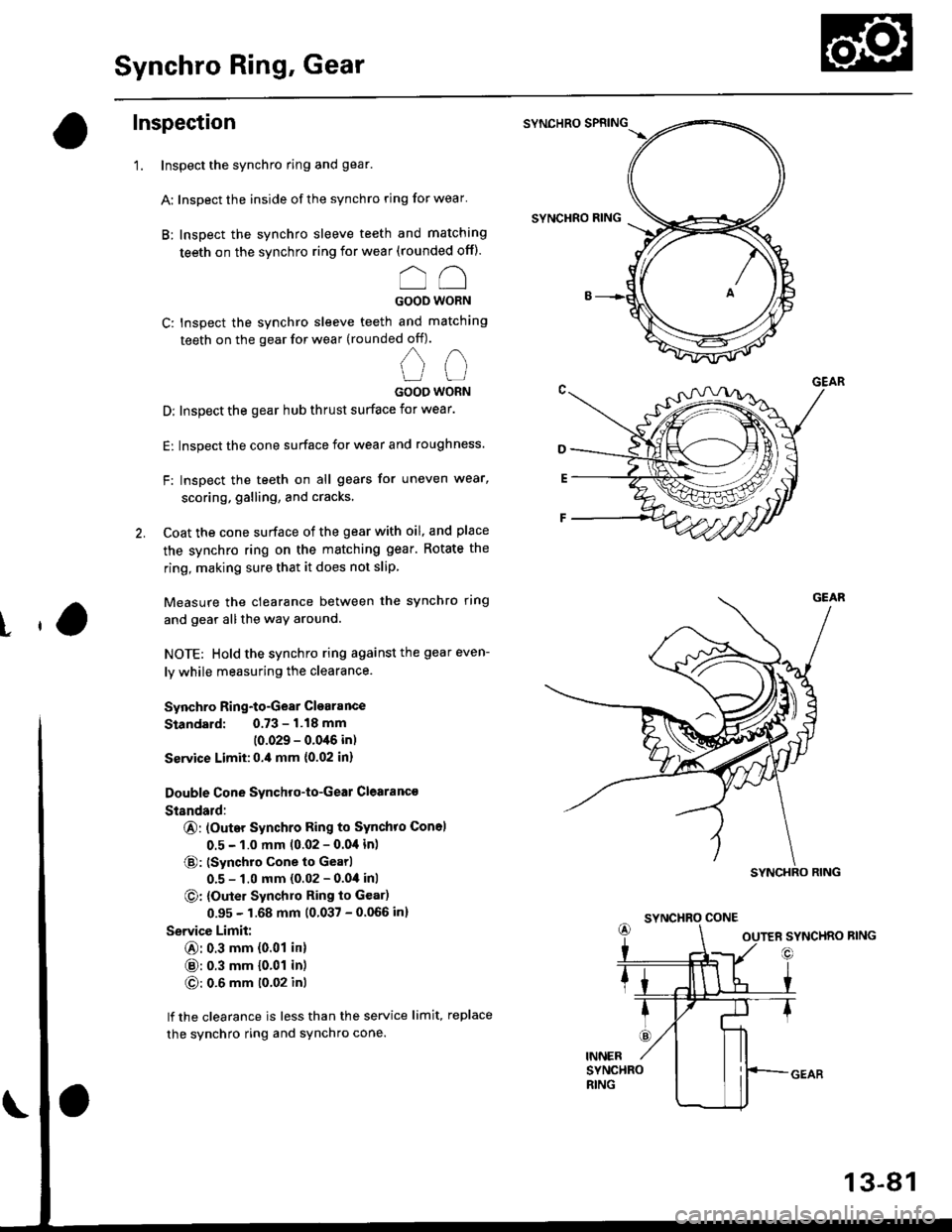

'1. Inspect the synchro ring and gear.

A: Inspect the inside of the synchro ring for wear'

B: Inspect the synchro sleeve teeth and matching

teeth on the synchro ring for wear (rounded off).

oo

GOOD WORN

C: Inspect the synchro sleeve teeth and matching

teeth on the gear for wear (rounded off).

nn

UUGOOO WORN

D: Inspect the gear hub thrust surface for wear.

E: Inspect the cone surface for wear and roughness.

F: Inspect the teeth on all gears for uneven wear,

scoring, galling, and cracks'

2. Coat the cone surface of the gear with oil, and place

the synchro ring on the matching gear. Rotate the

ring, making sure that it does not slip

Measure the clearance between the synchro ring

and gear allthe way around.

NOTE: Hold the synchro ring against the gear even-

ly while measuring the clearance.

Synchro Ring-to-Gear Clearance

Standard: 0.73 - 1.18 mm

(0.029 - 0.0'16 in)

Ssrvice Limit:0.,0 mm {0.02 in}

Double Cone Synchro-to-Geal Clearanc€

Standald:

@: (Outer Synchro Ring to Synchro Con6l

0.5 - 1.0 mm 10.02 - 0.04 in)

@: (Synchro cone to Gearl

0.5 - 1.0 mm (0.02 - 0.04 inl

O: {Outer Synchlo Ring to Gear)

0.95 - 1.68 mm (0.037 - 0.066 in)

Service Limit:

@: 0.3 mm {0.01 in}

@: 0.3 mm {0.01 in)

O: 0.6 mm t0'02 inl

lf the clearance is less than the service limit, replace

the synchro ring and sYnchro cone.

SYNCHRO SPRING

SYNCHRO RING

t

SYNCHRO CONE

13-81

Page 662 of 2189

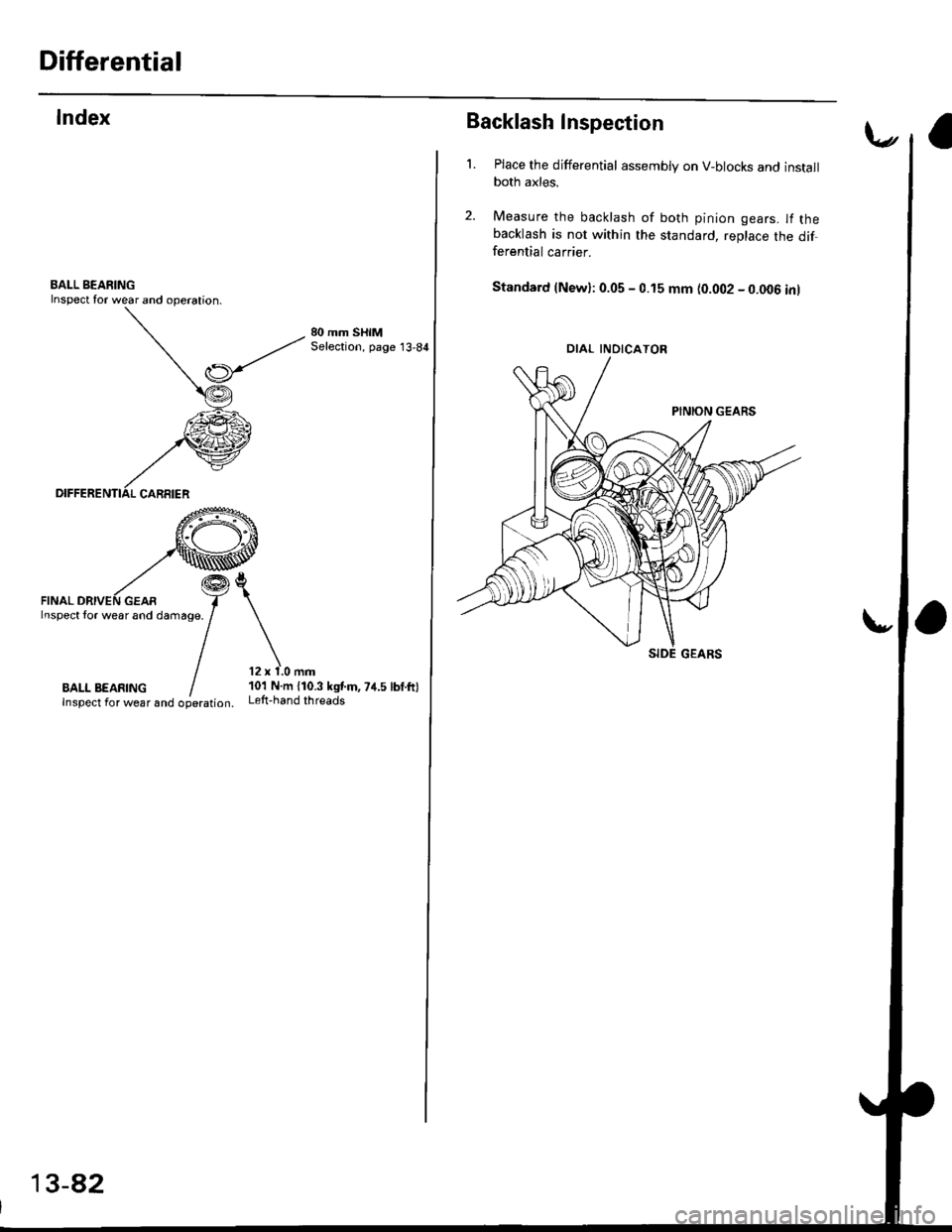

Differential

Index

FINAL DRIVEN GEARInspect tor wear and damage.

80 mm SHIMSelection, page'13,84

101 N.m {10.3 kgtm,74.5 lbf.ft)Left-hand threadsBALL BEAFINGInspect foa wear and ooeration.

13-82

Backlash Inspection

1. Place the differential assembly on V-blocks and installboth axles.

Measure the backlash of both pinion gears. lf thebacklash is not within the standard, replace the dif,ferential carrier.

Standard (New): 0.05 - 0.15 mm (0.002 - 0.006 inl

DIAL INDICATOR

Page 663 of 2189

rla

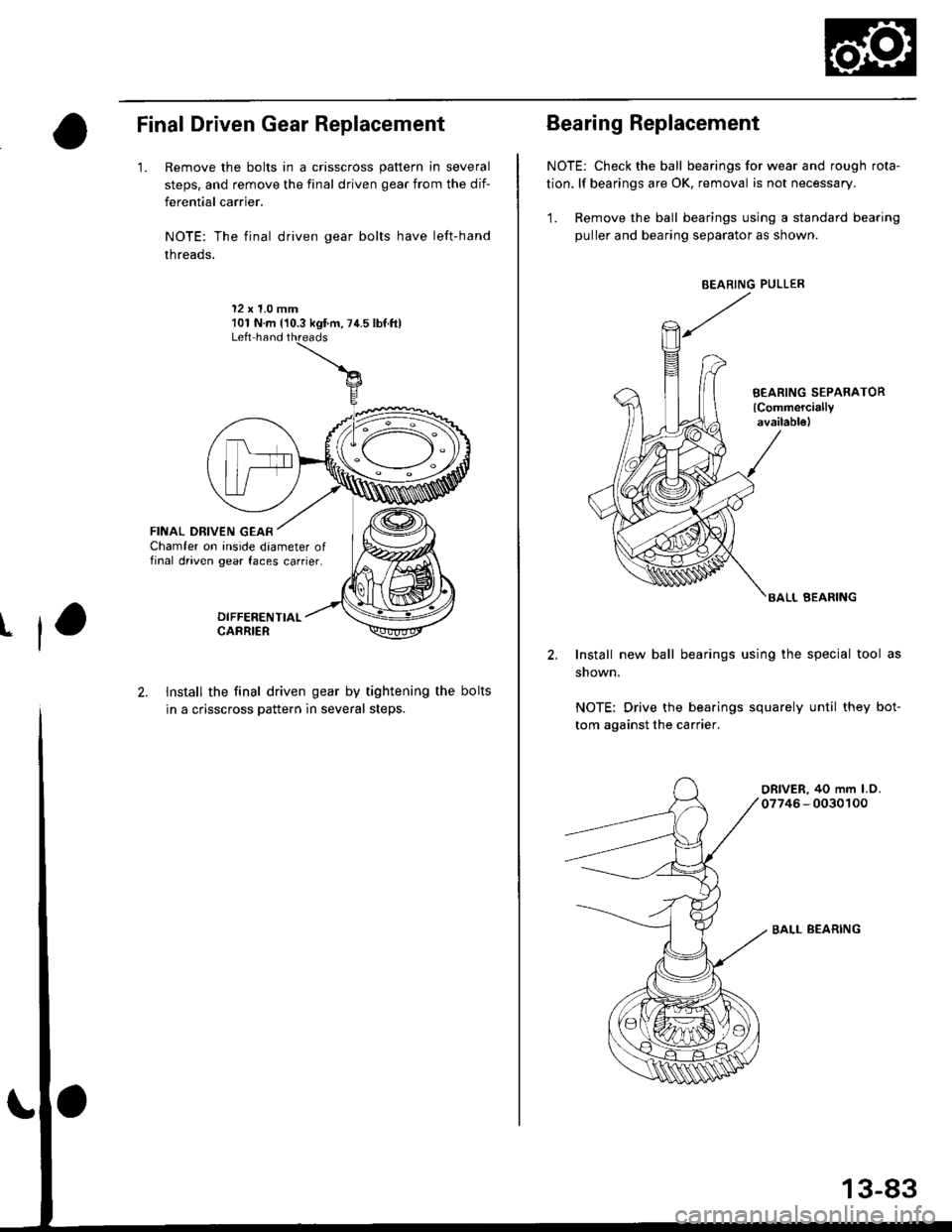

Final Driven Gear Replacement

'1. Remove the bolts in a crisscross pattern in several

steps, and remove the final driven gear from the dif-

ferential carrier.

NOTE: The final driven gear bolts have left-hand

threads,

12 x 1.0 mm101 N.m {'10.3 kgf.m,74.5 lbf.ftlLeft hand

FINAL DRIVEN GEARChamfer on inside daameter offinal driven gear faces carrier.

2. Install the final driven gear by tightening the bolts

in a crisscross pattern in several steps.NOTE: Drive the bearings squarely until they bot-

tom against the carrier.

BALL BEARING

13-83

Bearing Replacement

NOTE: Check the ball bearings for wear and rough rota-

tion. lf bearings are OK, removal is not necessary.

1. Remove the ball bearings using a standard bearing

puller and bearing separator as shown.

BEARING PULLER

BEARING SEPARATOR

lCommerciallyavailab16)

BALL BEARING

2. Install new ball bearings using the special tool as

shown.

Page 672 of 2189

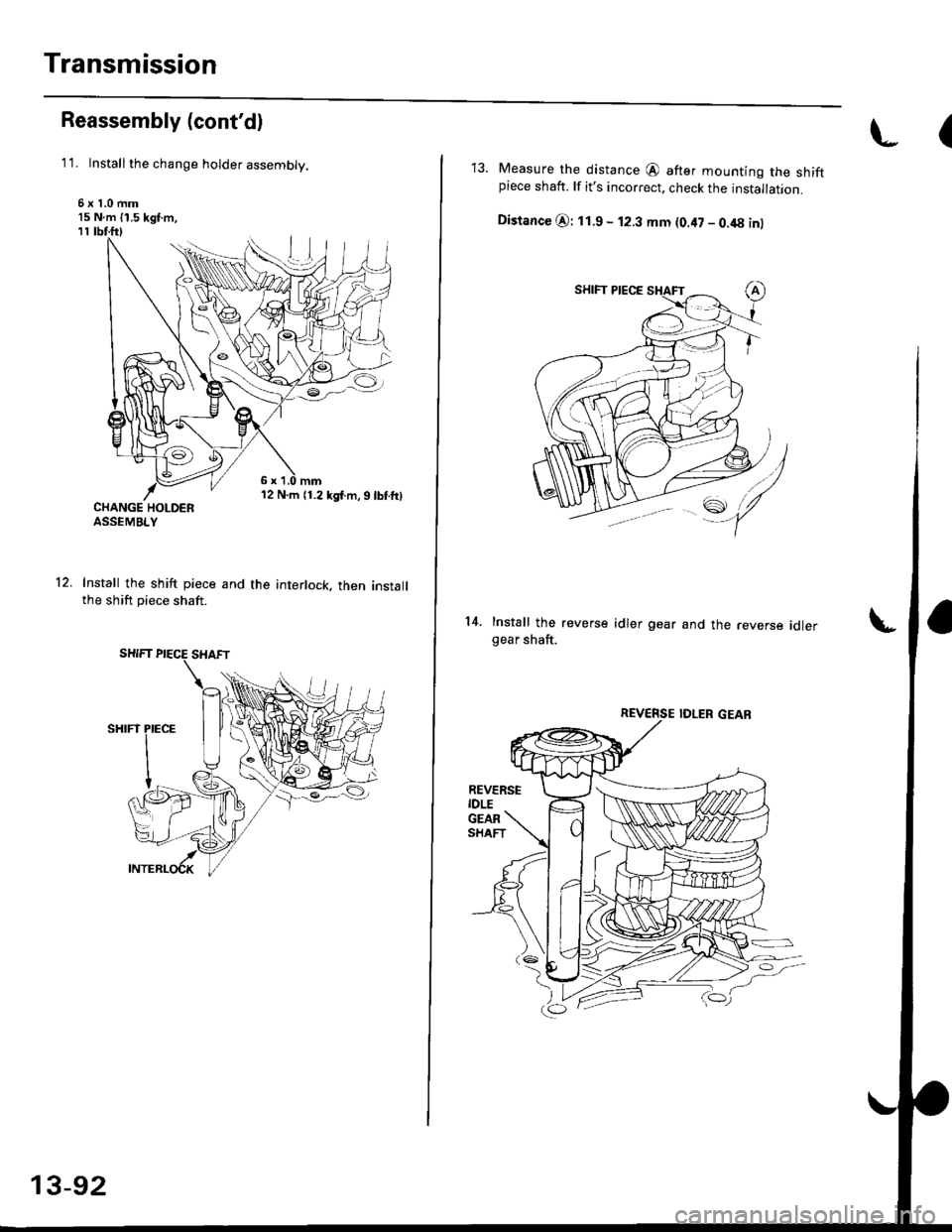

Transmission

Reassembly (cont'd)

11. Installthe change holder assembly.

6x1.0mm15 N.m {1.5 kgf.m,

12 N.m {1.2 kgf.m,9lbtftlCHANGE HOLDERASSEMBLY

Install the shift piece and the interlock. then installthe shift piece shaft.

12.

13-92

(

13. Measure the distance @ after mounting the shiftpiece shaft. lf it's incorrect. check the installation.

Distance @: 11.9 - 12.3 mm {0./t7 - 0.48 inl

14. Install the .everse idler gear and the reverse idlergear shaft.

REVERSE IDLER GEAR

REVERSEIDLE

Page 675 of 2189

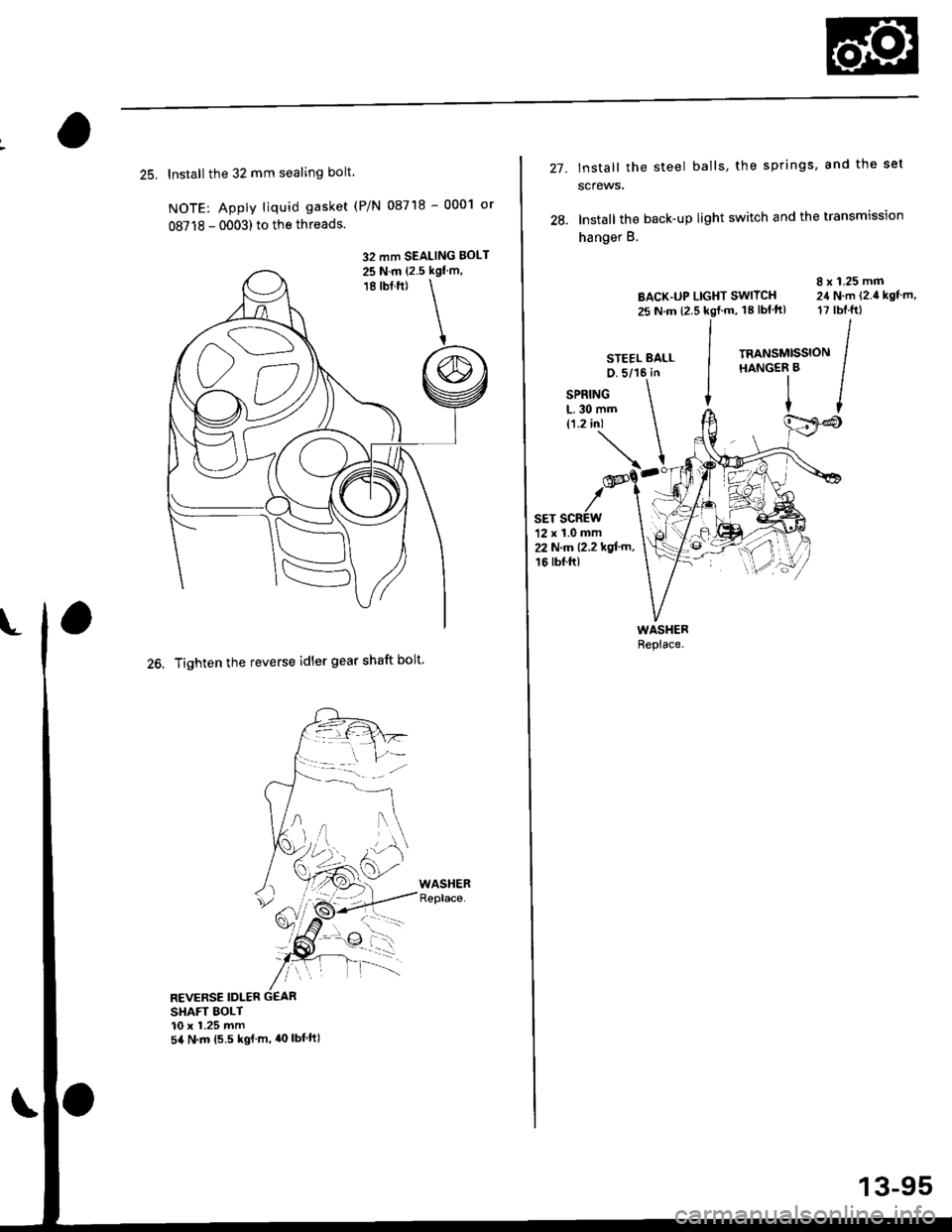

25. Install the 32 mm sealing bolt

NOTE: Apply liquid gasket (P/N 08718 - 0001 or

08718 - 0003) to the threads.

26. Tighten the reverse idler gear shaft bolt'

REVERSE IDLER G€AR

SHAFT BOLT10 x 1.25 mm5a N.rn t5.5 kgl m, {0 lbtftl

32 mm SEALING BOLT

25 N.m {2.5 kgl'm,

lnstall the steel balls, the springs, and the set

screws.

Install the back-up light switch and the transmission

hanger B.

BACK.UP LIGHT SWITCH

25 N.m 12.5 kgt m, 18 lblttl

TRANSMISSIONHANGER B

8x2117

1.25 mmN.m (2.4 kgf m,lbf.ftt

II

I

I

EALL

\\

\

\

SET SCREW'12 x 1.0 mm

22 N.m (2.2 kgf'm,16 tbt.trl

13-95

Page 677 of 2189

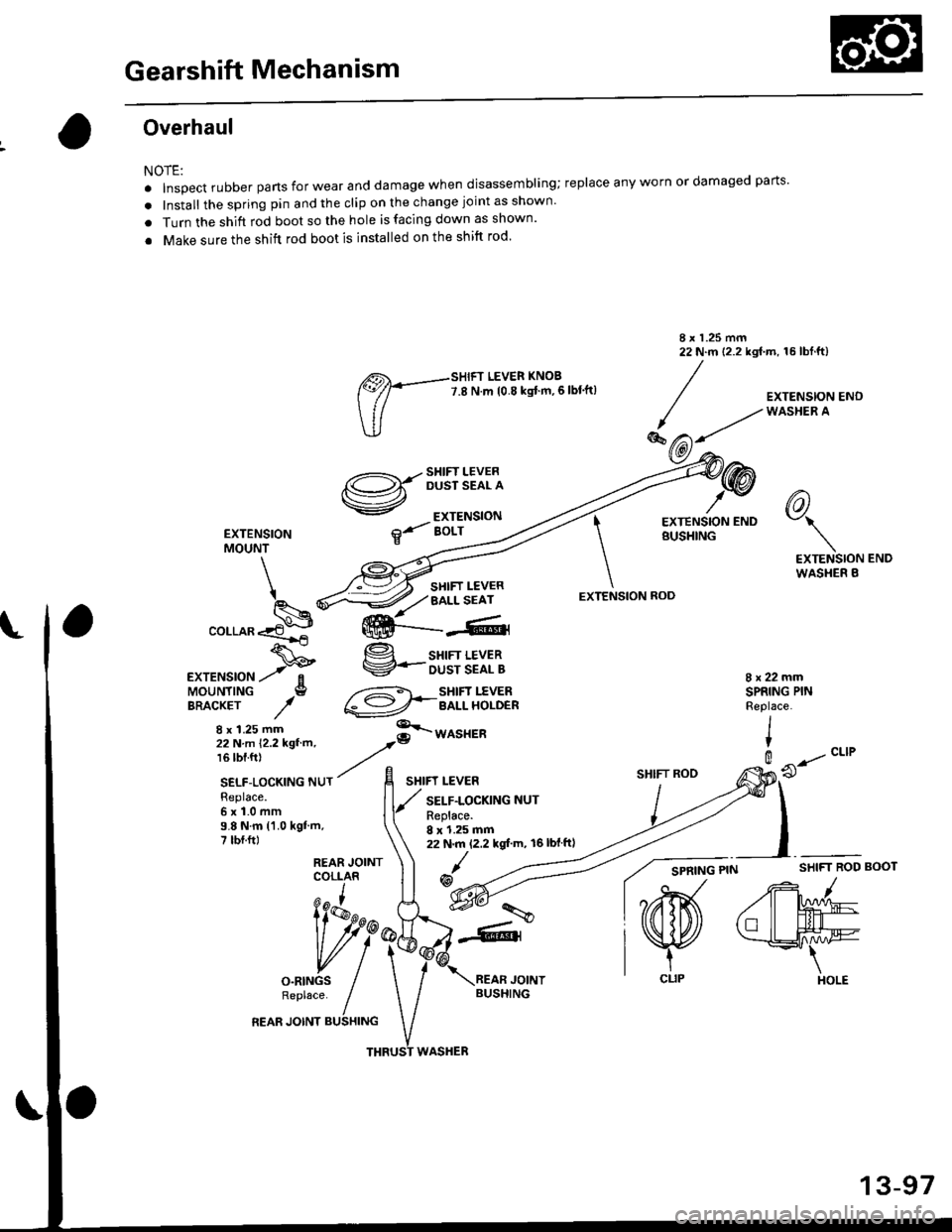

Gearshift Mechanism

Overhaul

NOTE:

. Inspect rubber parts for wear and damage when disassembling;

. Install the spring pin and the clip on the change joint as shown'

. Turn the shift rod boot so the hole is facing down as shown'

. Make sure the shift rod boot is installed on the shift rod'

reDlace any worn or damaged Parts.

I x 1.25 mm22 N.m 12.2 kgf.m, 16 lbf.ft)

ffi-:t't:il1ii51i?"'*,

TU

/g3i'51!Exii

V ExrENsroN

EXTENSfON ilr'eol.T

EXTENSION ENDBUSHING

hV\

EXTENSIONWASI{ER B

MOUNT -_.--_-_---

@2'

--1'>=2 -:liT.i'ff"

.o,-.o*&--ffi{---*,

v/,,/ BALL SEAT

8 x 1.25 mm22 N.m 12.2 kgf'm, 16lblftl

,@

EXTENSION ROD

SHIFT ROD

SPRING

END

BOOT

N: g sHrFr LEvER

.*rr"r,o"-tf V-oiliiSi[a

MOUNTING I --::=t SHIFT I"EVERBRAcxEr / €9-l--enr xoloen

8 x 1.2s mm :-,rro""a,ii-ri- ri.z rsr.-, -.Q u

16 tbf.ft) ,,,.

,rar-aoa*,"o "u, / E ,",t.ruaa

Replace.6x1.0mm9.8 N.m ('1.0 kgt'm,7 tbr.ftt

8x22mmSPRING PINReplace.

IIt

@CLIP

9.a-"t't

PIN SHIFT ROD/

ZW

€lt#-,\

HOLE

13-97

Page 679 of 2189

Automatic Transmission

Special Tools ......... .....'."".'-.-.' 14'2

Description .,....................-...... 14-3

power Flow ......,................. 14"6

Elestronic Control System .... . ................'..'.'.. 14-13

Hvdraulic Control .....'......" 1'l-19

Hydraulic F|ow...... .'.'.".'....11-21

Lock-up System '............ ... t/t'33

Electrical System

Component Locations....,.............'......'.............'.,. 14'39

PCM Circuit Diagram

lA/T Control Syst€m: '96 - 98 Models) .........'.. 1/t-40

PCM Tarminal Volt8ge/Measuring Condhions

{'96 - 98 ModeblA/T Control System ............

PCM Circuit Disgram(A/T Conlrol System: '99 - 00 Modsls) '..........' 14-44

PCM Terminal Voltage/Measuring Conditions('99 - 00 Models)A/T Control System ...

Troubleshooting Proceduros ....

Symptom-to-ComPonent Chari

Efectricaf SFiem - '96 - 98 Models '..-.-..."'.'..11-52

Eloqtrical System -'99 - 00 Modols ... .........". 1+54

EleclricatTroubl$hooting ('96 - 98 Models)

Valve Body

Repair .................... ........'.... 14-139

Valve

Assembly

ATF Pump

1,1-1i10

Inspection ...........'.......... 14-141

Main Valvs Body

Disass€mbf y/lnspoction/R.sssembly .'.'.'.'.. -. -. 1 1-1 12

Secondsry Valve BodY

Disa$embfy/lnspoction/Rsassembly ......'.'.'.'. 11-111

Regulator Valve Body

Disa$embly/lnspoction/Rea3sembly ..........'... 14-1{5

Servo Body

Disassombly/lnsp€ction/Reassembly .".'........ 14-146

Lock-up Valv6 Body

Dis$s.mbf y/ln3poction/Rea$embly .'.. -. -..'.'.' 1 1-1 17

Mainsh!ft

Dkassembly/lnep€ction Reassembly ..'...'........ 14'148

Inspoction .............'..........'. l it-149

Countsrshaft

Disa$embly/lnspeqtion/Rea3sembly .......'...'.. 1a-l51

Dba$ombly/Re$s.mblY11-152

til-46

I rl-48

Troubleshooting Flowcharts

Electrical Troubleshooting ('9!t - 00 Models)

Troublsshooting Flowchart3

Lock-up Control Solenoid vslvo A/B AssemblY

RePlacoment

Shift Cont.ol Solenoid Valve A/B A3sembly

Inspestion

Ona-way Clutch

Disassembh/lrupoction/Rca$embly .. "'........ l4-155

Clutch

lllustlttcd Ind.x {A48A, B4RA Transmlssion) ..' 14-156

tustr.tod Index (MrnA Transmi$ionl ............ til-158

...................... 14-153

L

14-56

1+81'

14-105

1+105

Replacoment ......

Mainshaft/Countorshaft Spo€d Sonsors

Replacemsnt ......'."'........... lit'108

Hydraulic System

Symptom-to-Componeni Chart

Hydraulic Sydemr+109

t4-113

1+116

11-117

Rea$emblY

14-106 Difforrr ial

llhdraied Index........ t4-156

B.ckhrh ln3poction. 14-167

Boaring Roplacemont..-..........11-167

..... 14-108 Diftrrsniial Carrior Repl8cemeni .'.-.............'...' lil-168

Oil Sall Romovalt4-t 59

Oil Soal ln3tallstion/Sidc Clearance'......'.....'... 1'l'169

Torqua Convertcr Housing Boarings

Mlin3haft Besring/Oil Scal Roplac.ment ."..'.. lil-172

Counio6hatt Betring R.plscem.nt ..'...... ....... 14-173

Test.....,......14-106

14-107

14-160

11-162

11-171

11-175

Replacement

Test .....,.,..........

Road Te3t

Linear Solenoid AsssmblY

Stall Speed

lllustrated Indax

Transmission/End Cover'. ....

Transmission Hou3ing,.............'.'......'....""..-.-.. 11-128

Torque Conve.ter Housing/Valvo Body ........... 14-130

End Cover

14-itB Park Stop

1+119 In3pection/Adiustmsnt...'......'.'............'...."""'14-175

Transmbgion

Reassombly

11-122 Torquo Convertet/Drivr Plsie ............'.'............'.. . l4-182

Transmission

11.726 Inrtallation

Tranlmission Housing Boarings

Msinsh.ft /CounteEhaft Bearings

B!pltcomgnt

Rcvo.3s ldlor Gear

lnrtallation

Cooler Flushing ..

Shift Cabls

Test

Fluid Level

Checkin9 .........."..'.'.....

Changing

Pressure Testing

Transmission

Transmission

Rgmoval ..

lil-176

.'..........'.'.'..... 1'l-183

.... lil-187

11-132Adiustmont

RemovaUlnttallation1,1-190

lit-191Transmisgion Housing

Removal ... '.'...... ......'..... 14-l3il

Tolque Convgrter Housing/valvs Body

Rsmoval .........,...... ............. 14-136

Valve CaDs

Description .......'................. t 4'138

Shift lndicator Panel

Adiu3tmant ..'.................. 14-192

ATF Coolor Hoses

Connection ..,............,.,....... l'l-192

Shift Lever .,........

Page 681 of 2189

Description

The automatic transmission is a 3-element torque converter and a dual-shaft electronically controlled unit which provides

4 soeeds forward and 1 reverse.

Torque Convertel, Geats, and Clutches

The torque converter consists of a pump, turbine and stator, assembled in a single unit. They are connected to the engine

crankshaft so they turn together as a unit as the engine turns. Around the outside of the torque converter is a ring gear

which meshes with the starter pinion when the engine is being started. The entire torque converter assembly seryes as a

flywheel while transmiuing power to the transmission mainshaft.

The transmission has two parallel shafts: the mainshaft and the countershaft. The mainshaft is in Iine with the engine

crankshaft. The mainshaft includes the 1st, 2nd and 4th clutches, gears tor 2nd, 4th, reverse and lst (3rd gear is integral

with the mainshaft, while the reverse gear is integral with the 4th gear). The countershaft includes the 3rd clutch, and

gears for 3rd,2nd, 4th, reverse. 1st and park. The gears on the mainshaft are in constant mesh with those on the counter-

shaft. When certain combinations of gears in transmission are engaged by clutches. power is transmitted from the main-

shaft to the countershaft to provide E, ld, E, and E positions.

Electronic Control

The electronic control svstem consists of the Powertrain Control Module {PCM), sensors, a linear solenoid and four

solenojd valves. Shifting and lock-up are electronically controlled for comtonable driving under all conditions. The PCM is

located below the dashboard, under the front lower panel on the passenger's side

Hydraulic Control

The valve bodies include the main vatve body, the secondary valve body, the regulator valve body, the servo body and the

lock-up valve body through the respective separator plates, They are bolted on the torque converter housang

The main valve body contains the manual valve, the 1-2 shift valve. the 2nd orifice control valve, the CPB {Clutch Pressure

Back-up) valve, the modulator valve. the servo control valve, the relief valve, and ATF pump gears The secondary valve

body contains the 2-3 shift valve. the 3-4 shift valve, the 3-4 orifice control valve, the 4th exhaust valve and the CPC (Clutch

pressure Control) valve. The regulator valve body contains the pressure regulator valve, the torque converter check valve,

the cooler relief valve, and the lock-up control valve. The servo body contains the servo valve which is integrated with the

reverse shift fork, and the accumulators. The lock-up valve body contains the lock-up shift valve and the lock-up timing

valve. The linear solenoid and the shift control solenoid valve Ay'B are bolted on the outside of the transmission housing,

and the lock-up control solenoid valve Ay'B is bolted on the outside of the torque converter housing. Fluid from regulator

passes through the manual valve to the various control valves. The clutches receive fluid from their respective teed pipes

or internal hydraulic circuit.

Shift Control Mechanism

Input from various sensors located throughout the car determines which shift control solenoid valve the PCM will activate

Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes a line

to one of the clutches, engaging that clutch and its corresponding gear, The shift control solenoid valves A and B are con-

trolled by the PCM.

Lock-up Mechanism

In ,Dt1 position, in 3rd and 4th. and in E position in 3rd, pressurized fluid is drained from the back of the torque converter

through a fluid passage, causing the lock-up piston to be held against the torque converter cover. As this takes place, the

mainshaft rotates at the same as the engine crankshaft. Together with hydraulic control, the PCM optimizes the timing of

the lock-up mechanism. The lock-up valves control the range of lock-up according to lock-up control solenoid valves A and

B, and linear solenoid. When lock-up control solenoid valves A and B activate, the modulator pressure changes The lock-

up control solenoid valves A and B and the linear solenoid are controlled by the PCM.

(cont'd)

14-3